Fracture Toughness and Fracture Surface Morphology of Concretes Modified with Selected Additives of Pozzolanic Properties

Abstract

1. Introduction

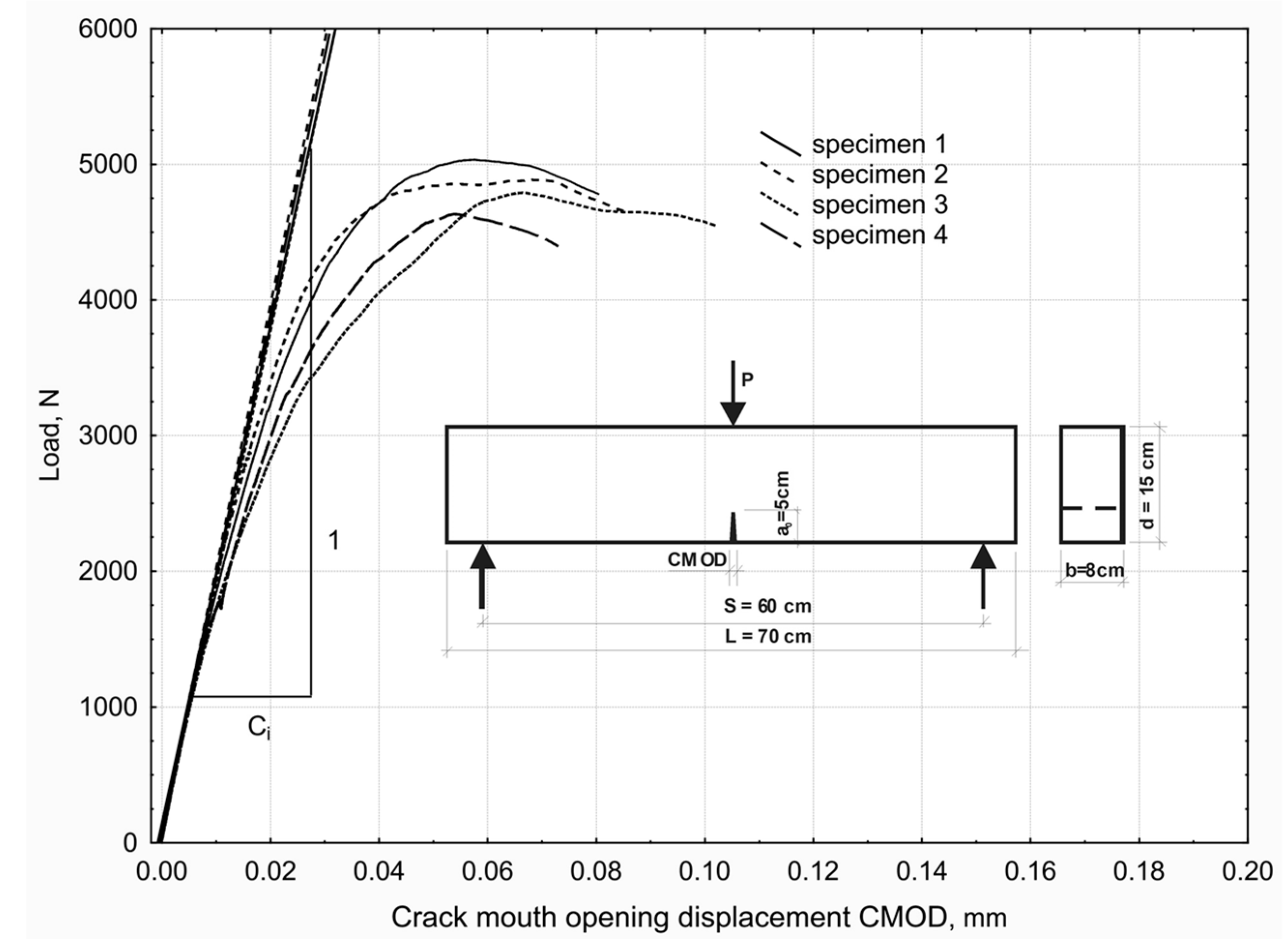

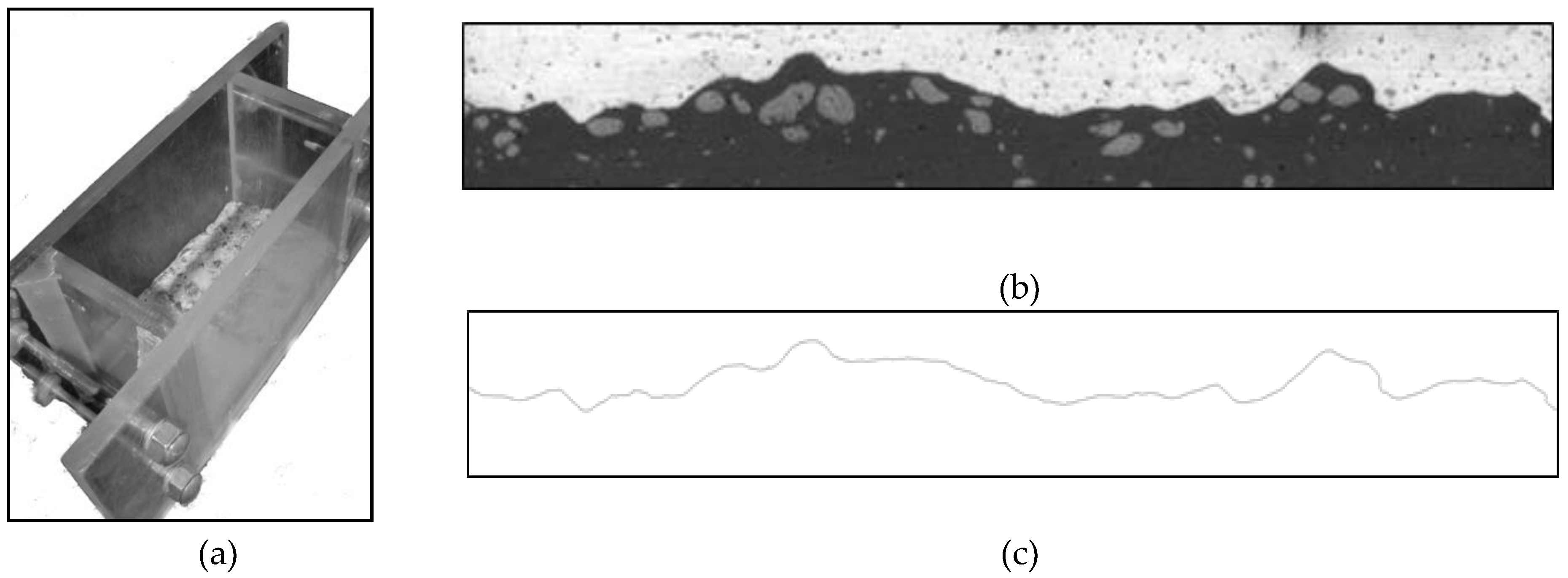

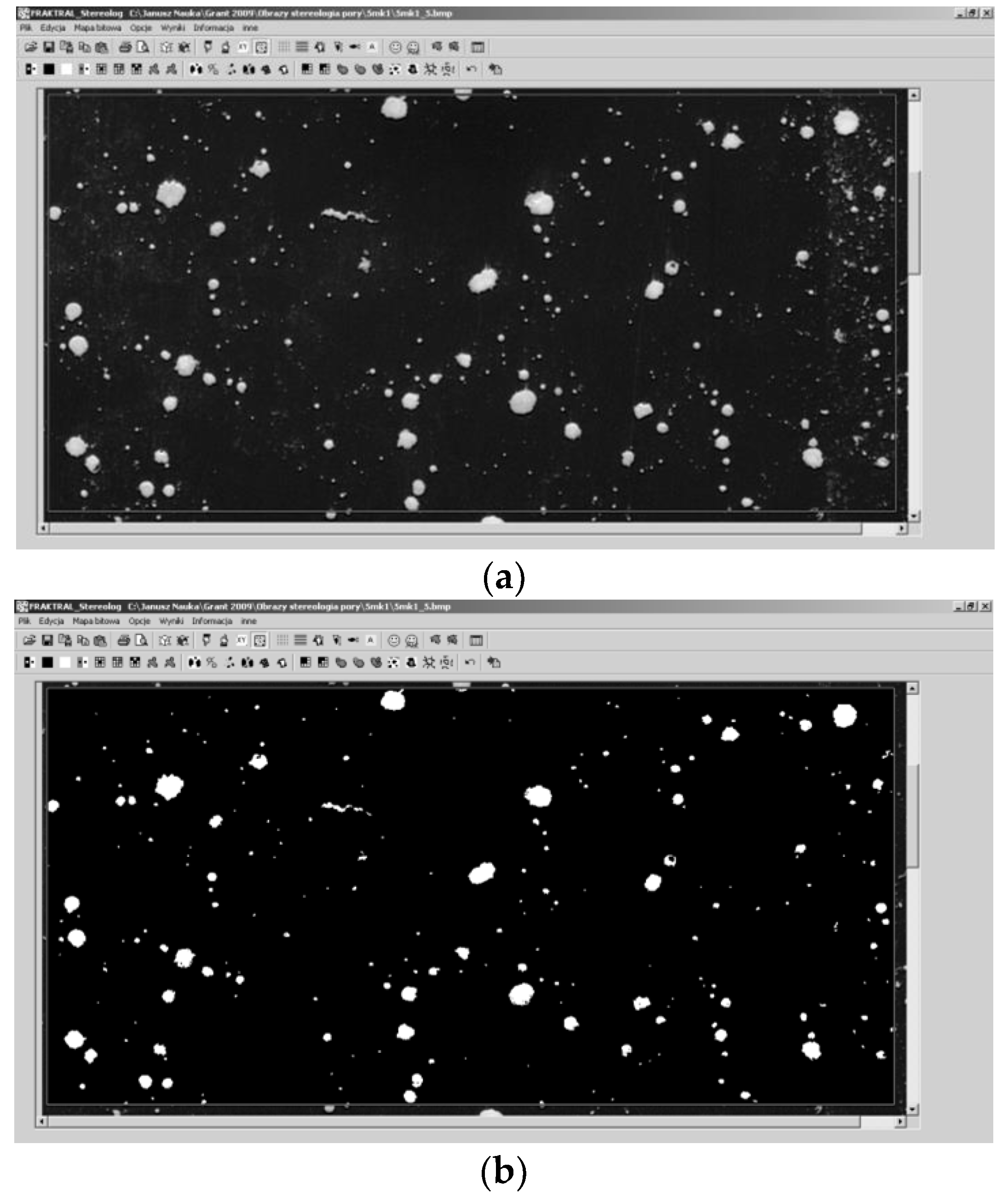

2. Materials and Methods

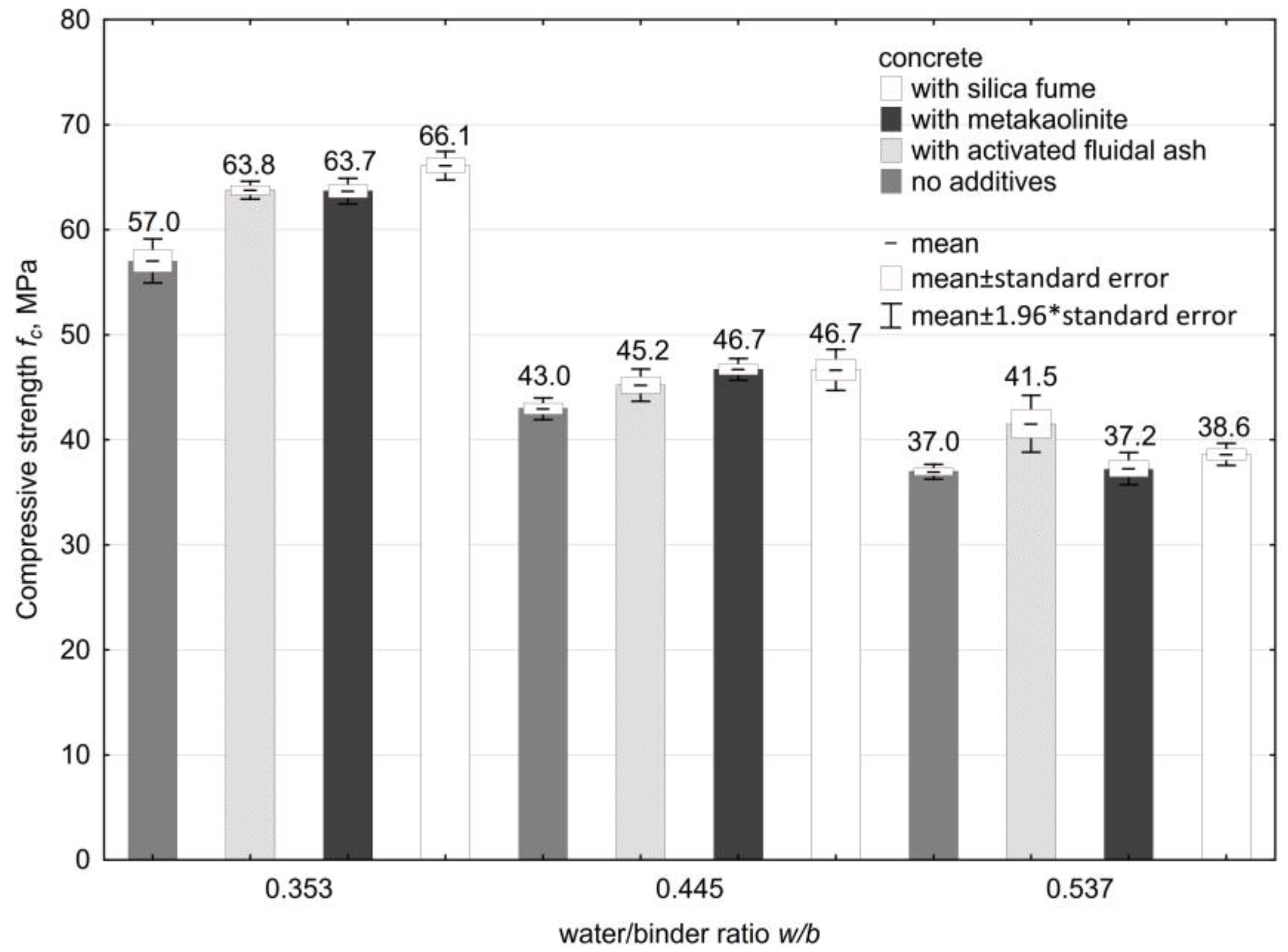

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dantu, P. Etude des Containtes dans les Milieux Hétérogénes, Application au Béton; Annales de L’Institut Technique du Batiment et des Travaux Publics: Paris, France, 1958. [Google Scholar]

- Mandelbrot, B.B. Fractals. Form, Chance and Dimension; Freeman: San Francisco, CA, USA, 1977. [Google Scholar]

- Yan, A.; Wu, K.; Zhang, X. A quantitative study on the surface crack pattern of concrete with high content of steel fiber. Cem. Concr. Res. 2002, 32, 1371–1375. [Google Scholar] [CrossRef]

- Prokopski, G.; Konkol, J. The fractal analysis of the fracture surface of concretes made from different coarse aggregates. Comput. Concr. 2005, 2, 239–248. [Google Scholar] [CrossRef]

- Ficker, T. Fractal strength of cement gels and universal dimension of fracture surfaces. Theor. Appl. Fract. Mech. 2008, 50, 167–171. [Google Scholar] [CrossRef]

- Saouma, V.E.; Barton, C.C. Fractals, fractures and size effects in concrete. J. Eng. Mech. 1994, 120, 835–854. [Google Scholar] [CrossRef]

- Issa, M.A.; Hammad, A.M.; Chudnovsky, A. Correlation between crack tortuosity and fracture toughness in cementitious material. Int. J. Fract. 1993, 60, 97–105. [Google Scholar] [CrossRef]

- Prokopski, G.; Langier, B. Effect of water/cement ratio and silica fume addition on the fracture toughness and morphology of fractured surfaces of gravel concretes. Cem. Concr. Res. 2000, 30, 1427–1433. [Google Scholar] [CrossRef]

- Zhou, X.J.; Gao, B.; Guo, J.G. Study on fractal effect of concrete damage induced by corrosion of reinforced bars subjected to externally applied direct current. In Proceedings of the 26th Conference on Our World in Concrete & Structures, Singapore, 27–28 August 2001; pp. 725–732. [Google Scholar]

- Yan, A.; Wu, K.-R.; Zhang, D.; Yao, W. Effect of fracture path on the fracture energy of high-strength concrete. Cem. Concr. Res. 2001, 31, 1601–1606. [Google Scholar] [CrossRef]

- Issa, M.A.; Issa, M.A.; Islam, M.S.; Chudnovsky, A. Fractal dimension—a measure of fracture roughness and toughness of concrete. Eng. Fract. Mech. 2003, 70, 125–137. [Google Scholar] [CrossRef]

- Zhang, H.; Wei, D.M. Fractal effect and anisotropic constitutive model for concrete. Theor. Appl. Fract. Mech. 2009, 51, 167–173. [Google Scholar] [CrossRef]

- Zhang, H.; Wei, D.M. Estimation of fracture toughness, driving force, and fracture energy for fractal cracks using the method of imaginary smooth crack. Eng. Fract. Mech. 2010, 77, 621–630. [Google Scholar] [CrossRef][Green Version]

- Zhang, H.; Wei, D.M. Fracture and damage behaviors of concrete in the fractal space. J. Mod. Phys. 2010, 1, 48–58. [Google Scholar] [CrossRef]

- Erdem, S.; Blankson, M.A. Fractal-fracture analysis and characterization of impact-fractured surface in different types of concrete using digital image analysis and 3D nanomap laser profilometery. Constr. Build. Mater. 2013, 40, 70–76. [Google Scholar] [CrossRef]

- Winslow, D.N. The fractal nature of the surface of cement paste. Cem. Concr. Res. 1985, 15, 817–824. [Google Scholar] [CrossRef]

- Brandt, A.M.; Prokopski, G. On the fractal dimension of fracture surfaces of concrete elements. J. Mater. Sci. 1993, 28, 4762–4766. [Google Scholar] [CrossRef]

- Wang, Y.; Diamond, S. A fractal study of the fracture surfaces of cement pastes and mortars using a stereoscopic SEM method. Cem. Concr. Res. 2001, 31, 1385–1392. [Google Scholar] [CrossRef]

- Konkol, J.; Prokopski, G. The necessary number of profile lines for the analysis of concrete fracture surfaces. Struct. Eng. Mech. 2007, 25, 565–576. [Google Scholar] [CrossRef]

- Carpinteri, A.; Spagnoli, A.; Vantadori, S.; Viappiani, D. Influence of the crack morphology on fatigue crack growth rate: A continuously-kinked crack model based on fractals. Eng. Fract. Mech. 2008, 75, 579–589. [Google Scholar] [CrossRef]

- Carpinteri, A.; Spagnoli, A.; Vantadori, S. A multifractal analysis of fatigue crack growth and its application to concrete. Eng. Fract. Mech. 2010, 77, 974–984. [Google Scholar] [CrossRef]

- Konkol, J.; Prokopski, G. The use of fractal geometry for the assessment of the diversification of macro-pores in concrete. Image Anal. Stereol. 2011, 30, 89–100. [Google Scholar] [CrossRef]

- Ficker, T.; Martisek, D. Digital fracture surface and their roughness analysis: Applications to cement based materials. Cem. Concr. Res. 2012, 42, 827–833. [Google Scholar] [CrossRef]

- Ficker, T. Fracture surfaces and compressive strength of hydrated cement pastes. Constr. Build. Mater. 2012, 27, 197–205. [Google Scholar] [CrossRef]

- Stroeven, P. 2-D and 3-D concepts for roughness and tortuosity in cementitious composites. In Brittle Matrix Composites 6; Brandt, A.M., Li, V.C., Marshall, I.H., Eds.; ZTUREK RSI and Woodhead Publ.: Warsaw, Poland, 2000. [Google Scholar]

- Stroeven, P. A stereological approach to roughness of fracture surfaces and tortuosity of transport paths in concrete. Cem. Concr. Compos. 2000, 22, 331–341. [Google Scholar] [CrossRef]

- Czarnecki, L.; Garbacz, A.; Kurach, J. On the characterization on polymer concrete fracture surface. Cem. Concr. Compos. 2001, 23, 399–409. [Google Scholar] [CrossRef]

- Czarnecki, L.; Chmielewska, B. Fracture and fractography of silane modified resin mortars. Int. J. Restor. Build. Monum. 2003, 9, 603–618. [Google Scholar] [CrossRef]

- Konkol, J.; Prokopski, G. Analysis of the fracture surface morphology of concrete by the method of vertical section. Comput. Concr. 2004, 1, 389–400. [Google Scholar] [CrossRef]

- Siewczyńska, M. Method for determining the parameters of surface roughness by usage of a 3 D scanner. Arch. Civ. Mech. Eng. 2012, 12, 83–89. [Google Scholar] [CrossRef]

- Erdem, S.; Dawson, A.R.; Thom, N.H. Impact load-induced micro-structural damage and micro-structure associated mechanical response of concrete made with different surface roughness and porosity aggregates. Cem. Concr. Res. 2012, 42, 291–305. [Google Scholar] [CrossRef]

- Konkol, J.; Prokopski, G. Fracture toughness and fracture surfaces morphology of metakaolinite-modified concrete. Constr. Build. Mater. 2016, 123, 638–648. [Google Scholar] [CrossRef]

- Wild, S.; Khabit, J.M.; Jones, A. Relative strength pozzolanic activity and cement hydration in superplasticised metakaolin concrete. Cem. Concr. Res. 1996, 26, 1537–1544. [Google Scholar] [CrossRef]

- Sabir, B.B.; Wild, S.; Bai, J. Metakaolin and cacined clays as Pozzolans for concrete: A review. Cem. Concr. Compos. 2001, 23, 441–454. [Google Scholar] [CrossRef]

- Wong, H.S.; Razak, H.A. Efficiency of calcined kaolin and silica fume as cement replacement material for strength performance. Cem. Concr. Res. 2005, 35, 696–702. [Google Scholar] [CrossRef]

- Ding, J.T.; Li, Z. Effects of metakaolin and silica fume on properties of concrete. ACI Mater. J. 2002, 99, 393–398. [Google Scholar]

- Razak, H.A.; Wong, H.S. Strength estimation model for high-strength concrete incorporating metakaolin and silica fume. Cem. Concr. Res. 2005, 35, 688–695. [Google Scholar] [CrossRef]

- Poon, C.S.; Kou, S.C.; Lam, L. Compressive strength, chloride diffusivity and pore structure of high performance metakaolin and silica fume concrete. Constr. Build. Mater. 2006, 20, 858–865. [Google Scholar] [CrossRef]

- Love, C.A.; Richardson, I.G.; Brough, A.R. Composition and structure of C–S–H in white Portland cement–20% metakaolin pastes hydrated at 25°C. Cem. Concr. Res. 2007, 37, 109–117. [Google Scholar] [CrossRef]

- Siddique, R.; Klaus, J. Influence of metakaolin on the properties of mortar and concrete: A review. Appl. Clay Sci. 2009, 43, 392–400. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Jovein, H.B. Influence of metakaolin as supplementary cementing material on strength and durability of concretes. Constr. Build. Mater. 2012, 30, 470–479. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Karaoğlu, S.; Mermerdas, K. Strength, permeability and shrinkage cracking of silica fume and metakaolin concretes. Constr. Build. Mater. 2012, 34, 120–130. [Google Scholar] [CrossRef]

- Madandoust, R.; Mousavi, S.Y. Fresh and hardened properties of self-compacting concrete containing metakaolin. Constr. Build. Mater. 2012, 35, 752–760. [Google Scholar] [CrossRef]

- Dvorkin, L.; Bezusyak, A.; Lushnikova, N.; Ribakov, Y. Using mathematical modeling for design of self compacting high strength concrete with metakaolin admixture. Constr. Build. Mater. 2012, 37, 851–864. [Google Scholar] [CrossRef]

- Rashad, A.M. Metakaolin as cementitious material: History, scours, production and composition—A comprehensive overview. Constr. Build. Mater. 2013, 41, 303–318. [Google Scholar] [CrossRef]

- Glinicki, M.A.; Zielinski, M. Air void system in concrete containing circulating fluidized bed combustion fly ash. Mater. Struct. 2008, 41, 681–687. [Google Scholar] [CrossRef]

- Łagosz, A.; Małolepszy, J.; Śliwiński, J.; Tracz, T. Utilization of fly-Ash from Fluidized Bed Boilers as a Mineral Additive for Concretes; Concrete Days: Wisła, Poland, 2008; pp. 553–566. (In Polish) [Google Scholar]

- Śliwiński, J.; Tracz, T. Water permeability of cement concrete with addition of fluidized bed combustion fly ash. In Proceedings of the 5th International Conference on Concrete and Concrete Structures, Žilina, Slovakia, 15–16 October 2009; pp. 69–76. [Google Scholar]

- Czarnecki, L.; Woyciechowski, P. Model of concrete. In Brittle Matrix Composites 9; Brandt, A.M., Olek, J., Marshall, I.H., Eds.; Woodhead Publishing Limited: Warsaw, Poland, 2009; pp. 183–194. [Google Scholar]

- Glinicki, M.A.; Zielinski, M. Frost salt scaling resistance of concrete containing CFBC fly ash. Mater. Struct. 2009, 42, 993–1002. [Google Scholar] [CrossRef]

- Brandt, A.M.; Jóźwiak-Niedźwiedzka, D.; Małolepszy, J.; Marks, M.; Śliwiński, J.; Kasperkiewicz, J. Application of CFBC Ely Ash in Structural Concretes. In Studies in Engineering 72; Brandt, A.M., Ed.; Institute of Fundamental Technological Research Polish Academy of Sciences: Warsaw, Poland, 2010. (In Polish) [Google Scholar]

- Małolepszy, J. Utilization of fluidal-bed combustion ash for building materials production. In Proceedings of the VI Scientific and Technical Conference on Material Issues in Civil Engineering—MATBUD’2011, Cracow, Poland, 20–22 June 2011; pp. 17–48. (In Polish). [Google Scholar]

- Garbacz, A.; Sokołowska, J.J. Concrete-like polymer composites with fly ashes—Comparative study. Constr. Build. Mater. 2013, 38, 689–699. [Google Scholar] [CrossRef]

- Shah, S.P. Determination of fracture parameters (KSIc and CTODc) of plain concrete using three-point bend test. RILEM Draft Recommendations, TC 89-FMT Fracture Mechanics of Concrete Test Methods. Mater. Struct. 1990, 23, 457–460. [Google Scholar] [CrossRef]

- Konkol, J.; Prokopski, G. Fracture surface morphology and fracture toughness of fluidal ash or metakaolinite modified concrete. Sci. J. Rzeszow Univ. Tech. Ser. Build. Environ. Eng. 2011, 58, 321–330. (In Polish) [Google Scholar]

| Series no. | Variable | Concrete Mix Composition in kg After the Adopted Plan | ||||||

|---|---|---|---|---|---|---|---|---|

| w/b | FA/b or MK/b (SF/b)1 | Binder | Cement 1 | FA or MK (SF)1 | Water | Sand | Basalt | |

| 1 | 0.380 | 0.04 (0.03) | 454 | 435.8 (440.4) | 18.2 (13.6) | 172.5 | 739.3 | 1212.5 |

| 2 | 0.380 | 0.13 (0.09) | 395.0 (413.1) | 59.0 (40.9) | 172.5 | |||

| 3 | 0.510 | 0.04 (0.03) | 435.8 (440.4) | 18.2 13.6) | 231.5 | |||

| 4 | 0.510 | 0.13 (0.09) | 395.0 (413.1) | 59.0 (40.9) | 231.5 | |||

| 5 | 0.353 | 0.085 (0.06) | 415.4 (426.8) | 38.6 (27.2) | 160.3 | |||

| 6 | 0.537 | 0.085 (0.06) | 415.4 (426.8) | 38.6 (27.2) | 243.8 | |||

| 7 | 0.445 | 0.02 (0.02) | 444.3 (446.0) | 9.7 (8.0) | 202.0 | |||

| 8 | 0.445 | 0.15 (0.10) | 386.5 (407.5) | 67.5 (46.5) | 202.0 | |||

| 9, 10 | 0.445 | 0.085 (0.06) | 415.4 (426.8) | 38.6 (27.2) | 202.0 | |||

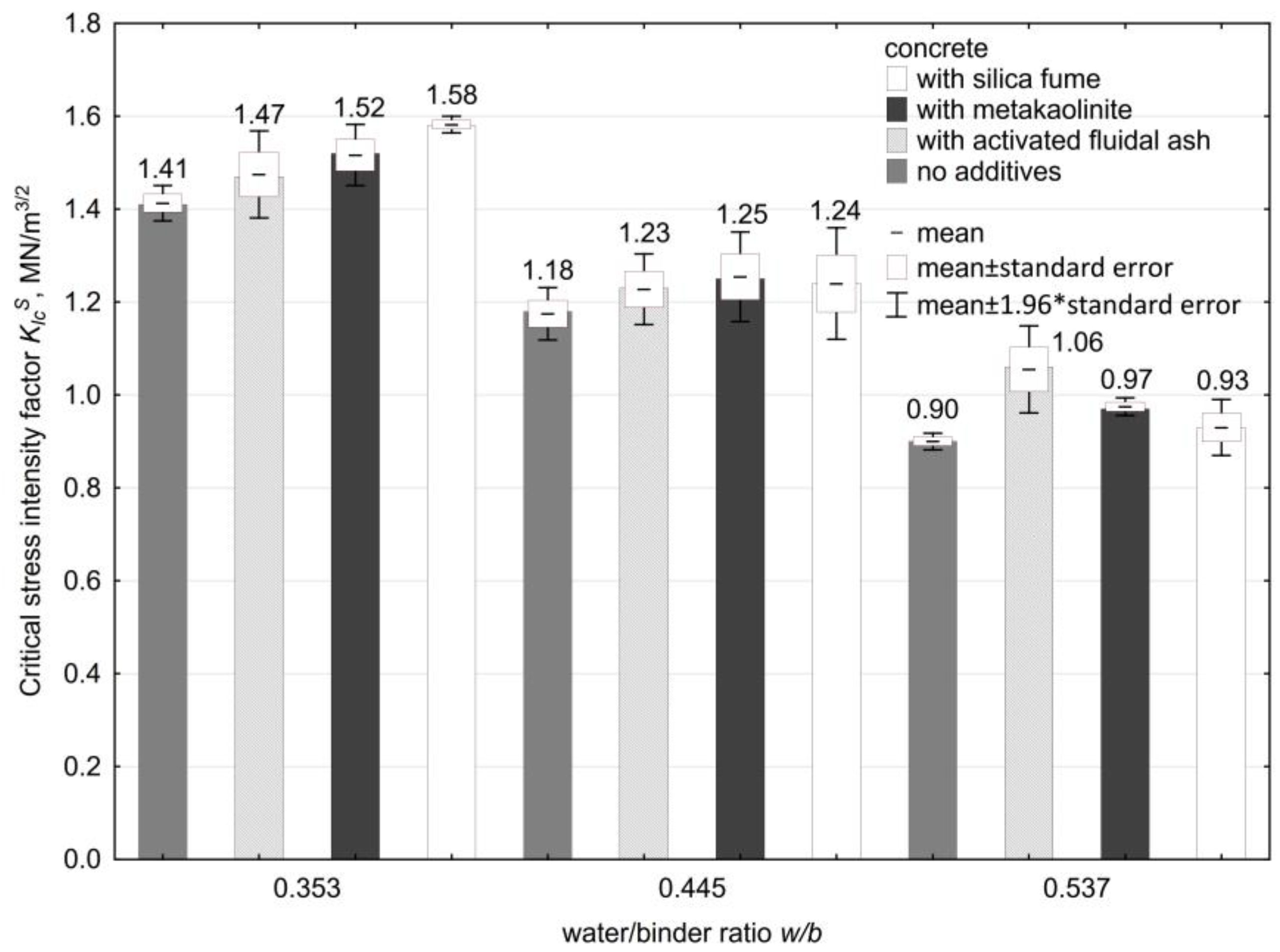

| Series No. | Mechanical Properties of Modified Concrete | |||||

|---|---|---|---|---|---|---|

| Activated Fluidal Ash (FA) | Metakaolinite (MK) | Silica Fume (SF) | ||||

| fc ± Stand. Error MPa | KIcS ± Stand. Error MN/m3/2 | fc ± Stand. Error MPa | KIcS ± Stand. Error MN/m3/2 | fc ± Stand. Error MPa | KIcS ± Stand. Error MN/m3/2 | |

| 1 | 58.3 ± 1.2 | 1.49 ± 0.03 | 53.7 ± 0.5 | 1.44 ± 0.04 | 54.8 ± 1.1 | 1.25 ± 0.04 |

| 2 | 61.0 ± 1.1 | 1.58 ± 0.03 | 61.0 ± 1.2 | 1.57 ± 0.02 | 65.3 ± 1.1 | 1.53 ± 0.05 |

| 3 | 40.0 ± 0.9 | 0.90 ± 0.05 | 40.8 ± 1.2 | 0.94 ± 0.03 | 39.2 ± 0.7 | 0.92 ± 0.02 |

| 4 | 40.9 ± 0.6 | 1.17 ± 0.03 | 41.3 ± 0.4 | 1.02 ± 0.06 | 40.2 ± 1.3 | 0.97 ± 0.03 |

| 5 | 63.8 ± 0.4 | 1.47 ± 0.05 | 63.7 ± 0.6 | 1.52 ± 0.03 | 66.1 ± 0.7 | 1.58 ± 0.01 |

| 6 | 41.5 ± 1.4 | 1.06 ± 0.05 | 37.2 ± 0.8 | 0.97 ± 0.01 | 38.6 ± 0.5 | 0.93 ± 0.03 |

| 7 | 45.2 ± 0.8 | 1.23 ± 0.04 | 46.7 ± 0.5 | 1.25 ± 0.05 | 46.7 ± 1.0 | 1.24 ± 0.06 |

| 8 | 47.3 ± 0.9 | 1.34 ± 0.10 | 51.5 ± 0.9 | 1.32 ± 0.02 | 54.8 ± 1.1 | 1.34 ± 0.04 |

| 9 | 45.5 ± 1.0 | 1.27 ± 0.04 | 47.8 ± 1.0 | 1.25 ± 0.06 | 48.8 ± 0.7 | 1.21 ± 0.03 |

| 10 | 45.9 ± 1.1 | 1.25 ± 0.12 | 48.0 ± 1.0 | 1.20 ± 0.04 | 49.2 ± 0.5 | 1.22 ± 0.01 |

| Series No. | Fractal and Stereological Parameters of Modified Concrete | |||||

|---|---|---|---|---|---|---|

| Activated Fluidal Ash (FA) | Metakaolinite (MK) | Silica Fume (SF) | ||||

| DBC ± Stand. Error - | SVP ± Stand. Error cm2/cm3 | DBC ± Stand. Error - | SVP ± Stand. Error cm2/cm3 | DBC ± Stand. Error - | SVP ± Stand. Error cm2/cm3 | |

| 1 | 1.047 ± 0.001 | 2.69 ± 0.09 | 1.051 ± 0.001 | 2.36 ± 0.08 | 1.046 ± 0.001 | 2.75 ± 0.08 |

| 2 | 1.044 ± 0.001 | 2.38 ± 0.11 | 1.045 ± 0.001 | 2.32 ± 0.08 | 1.047 ± 0.001 | 2.56 ± 0.08 |

| 3 | 1.054 ± 0.001 | 2.35 ± 0.20 | 1.053 ± 0.001 | 1.68 ± 0.08 | 1.051 ± 0.001 | 2.73 ± 0.10 |

| 4 | 1.050 ± 0.001 | 2.49 ± 0.17 | 1.047 ± 0.001 | 1.97 ± 0.09 | 1.054 ± 0.001 | 2.64 ± 0.07 |

| 5 | 1.047 ± 0.001 | 2.62 ± 0.12 | 1.045 ± 0.001 | 2.17 ± 0.12 | 1.042 ± 0.001 | 2.49 ± 0.09 |

| 6 | 1.051 ± 0.001 | 2.09 ± 0.08 | 1.050 ± 0.001 | 1.91 ± 0.10 | 1.052 ± 0.001 | 1.65 ± 0.05 |

| 7 | 1.050 ± 0.001 | 2.27 ± 0.09 | 1.051 ± 0.001 | 2.48 ± 0.11 | 1.049 ± 0.001 | 2.46 ± 0.09 |

| 8 | 1.047 ± 0.001 | 2.75 ± 0.10 | 1.047 ± 0.001 | 1.80 ± 0.07 | 1.050 ± 0.001 | 2.46 ± 0.08 |

| 9 | 1.050 ± 0.001 | 2.59 ± 0.14 | 1.049 ± 0.001 | 2.13 ± 0.09 | 1.048 ± 0.001 | 2.42 ± 0.08 |

| 10 | 1.047 ± 0.002 | 2.16 ± 0.12 | 1.050 ± 0.001 | 1.95 ± 0.16 | 1.048 ± 0.001 | 2.46 ± 0.17 |

| Concrete Type | Equality Test for Average Values | |||

|---|---|---|---|---|

| in the Case of Compressive Strength fc | in the Case of the Critical Stress Intensity Factor KIcS | |||

| The Value of the F Test | Limit Level of Significance of the Test | The Value of the F Test | Limit Level of Significance of the Test | |

| no additives | 205.6 | close to 0 | 152.5 | close to 0 |

| with MK | 436.3 | close to 0 | 60.2 | close to 0 |

| with FA | 176.7 | close to 0 | 21.9 | 0.0003 |

| with SF | 388.6 | close to 0 | 66.7 | close to 0 |

| Water/binder ratio w/b | The value of the F test | Limit level of significance of the test | The value of the F test | Limit level of significance of the test |

| all concretes | ||||

| 0.353 | 27.1 | close to 0 | 5.21 | 0.0156 |

| 0.445 | 6.64 | 0.0018 | 0.56 | 0.6486 |

| 0.537 | 6.57 | 0.0019 | 5.35 | 0.0142 |

| only concretes with additives | ||||

| 0.353 | 5.41 | 0.0127 | 2.51 | 0.1364 |

| 0.445 | 1.28 | 0.3023 | 0.07 | 0.9328 |

| 0.537 | 5.11 | 0.0175 | 3.63 | 0.0698 |

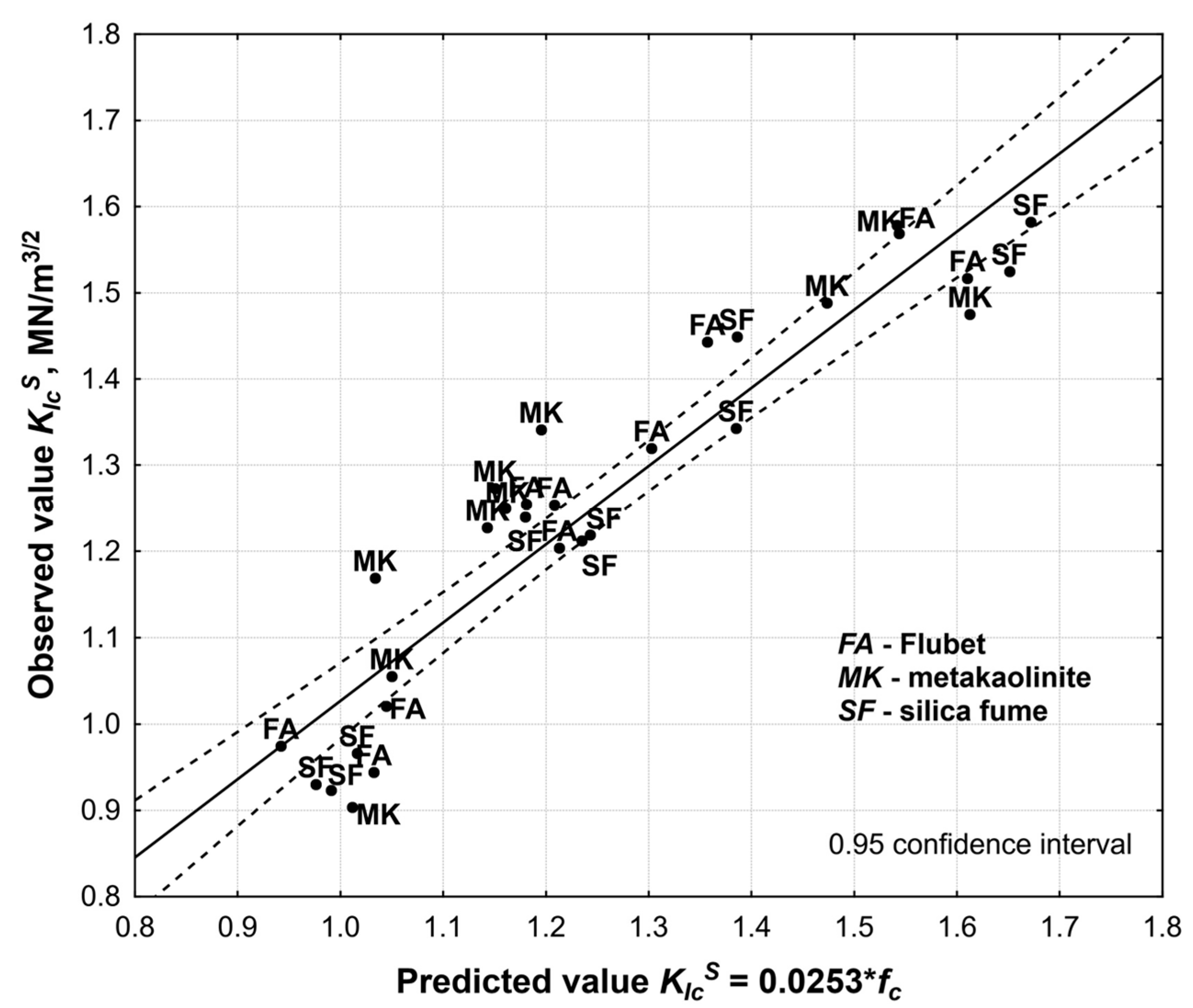

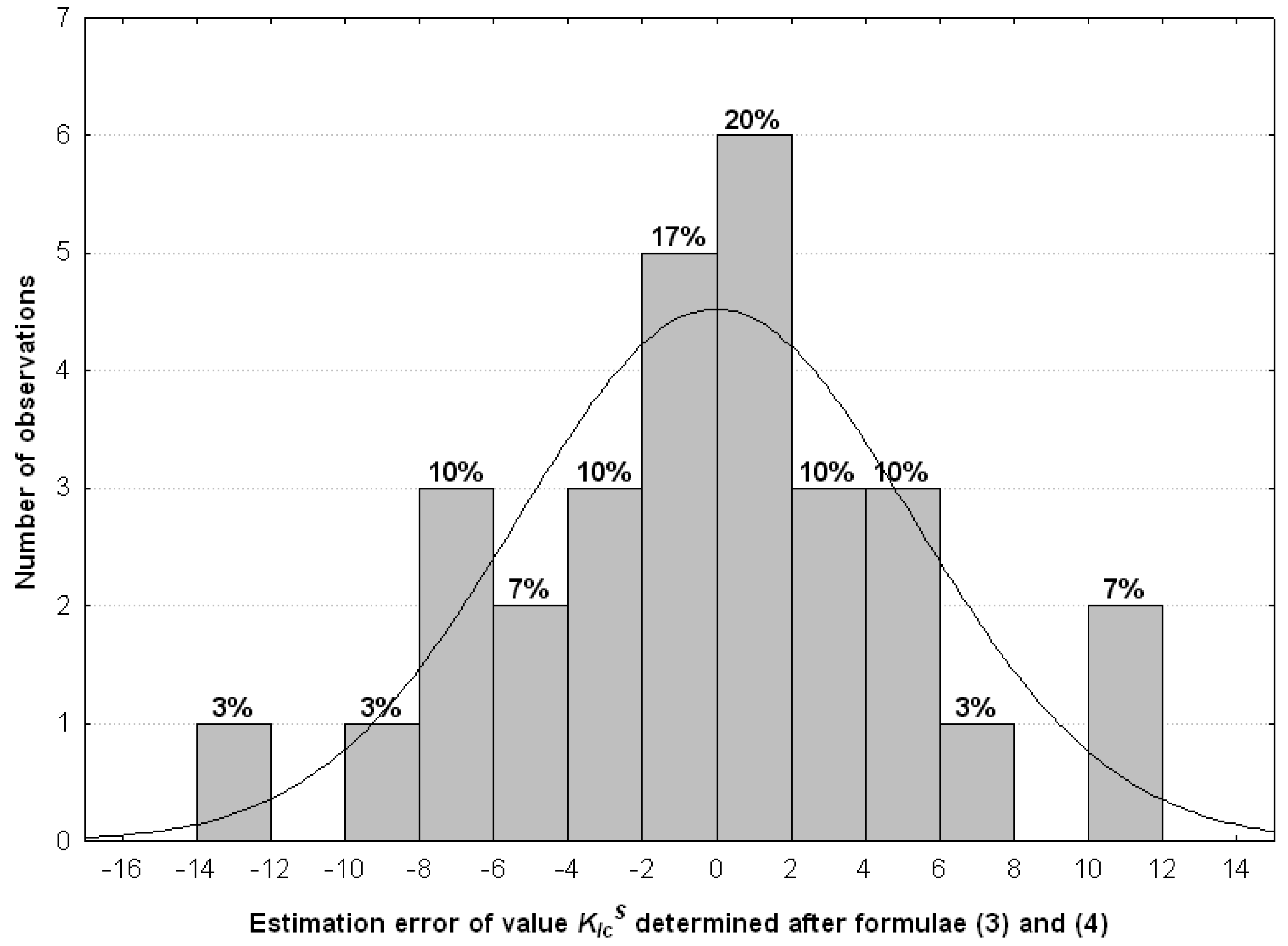

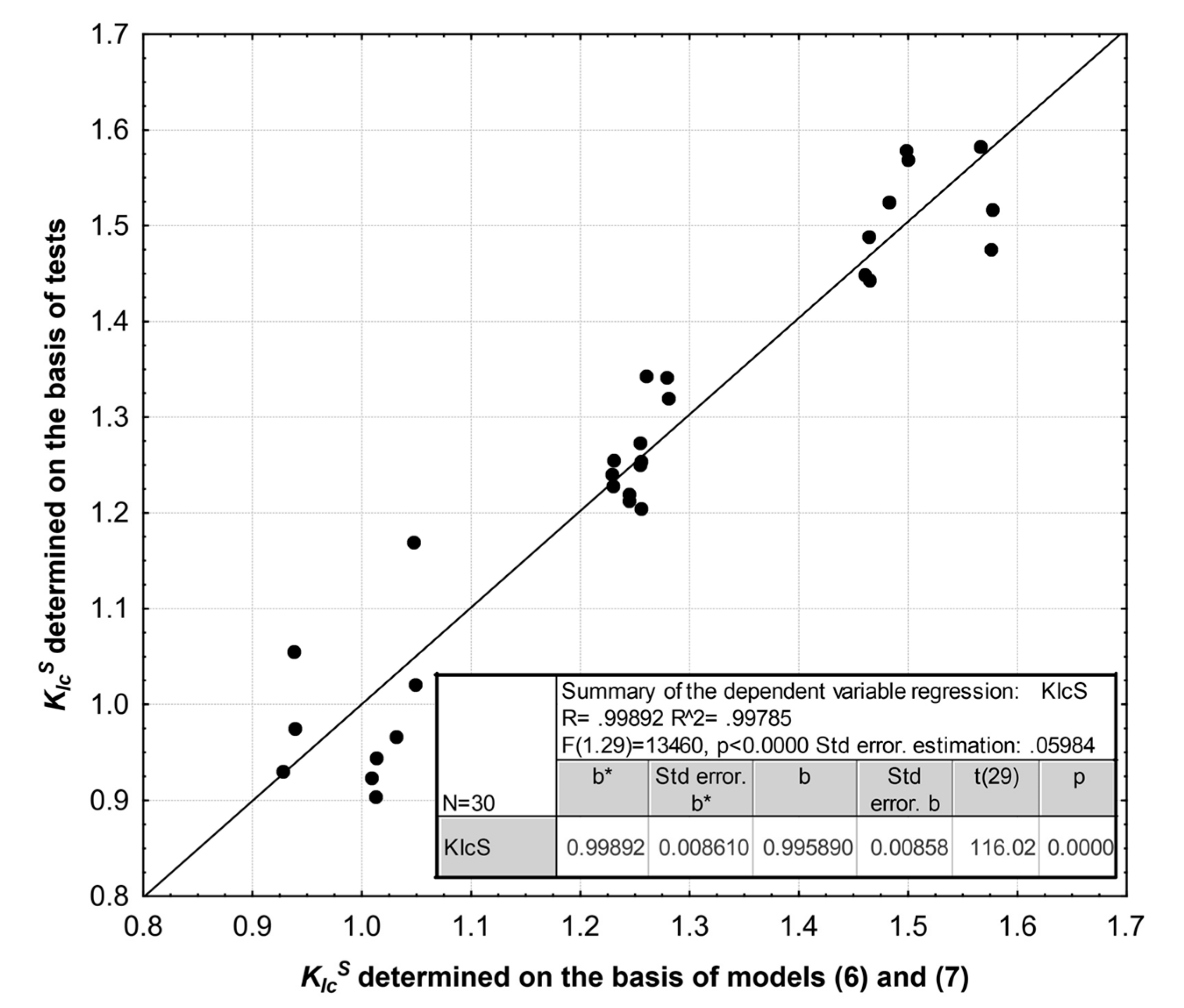

| N = 30 | Summary Regression of the Dependent Variable KIcS R = 0.960, R2 = 0.922 F (2.27) = 159.68, p < 0.00000, Std. Error Estimation: 0.0625 | |||||

|---|---|---|---|---|---|---|

| b* | Stand. Error b* | b | Stand. Error b | t(27) | p | |

| Absolute term | 20.161 | 6.3245 | 3.188 | 0.0036 | ||

| w/b | −0.7854 | 0.0802 | −2.869 | 0.2929 | −9.797 | 0.0000 |

| DBC | −0.2202 | 0.0802 | −16.813 | 6.1224 | −2.746 | 0.0106 |

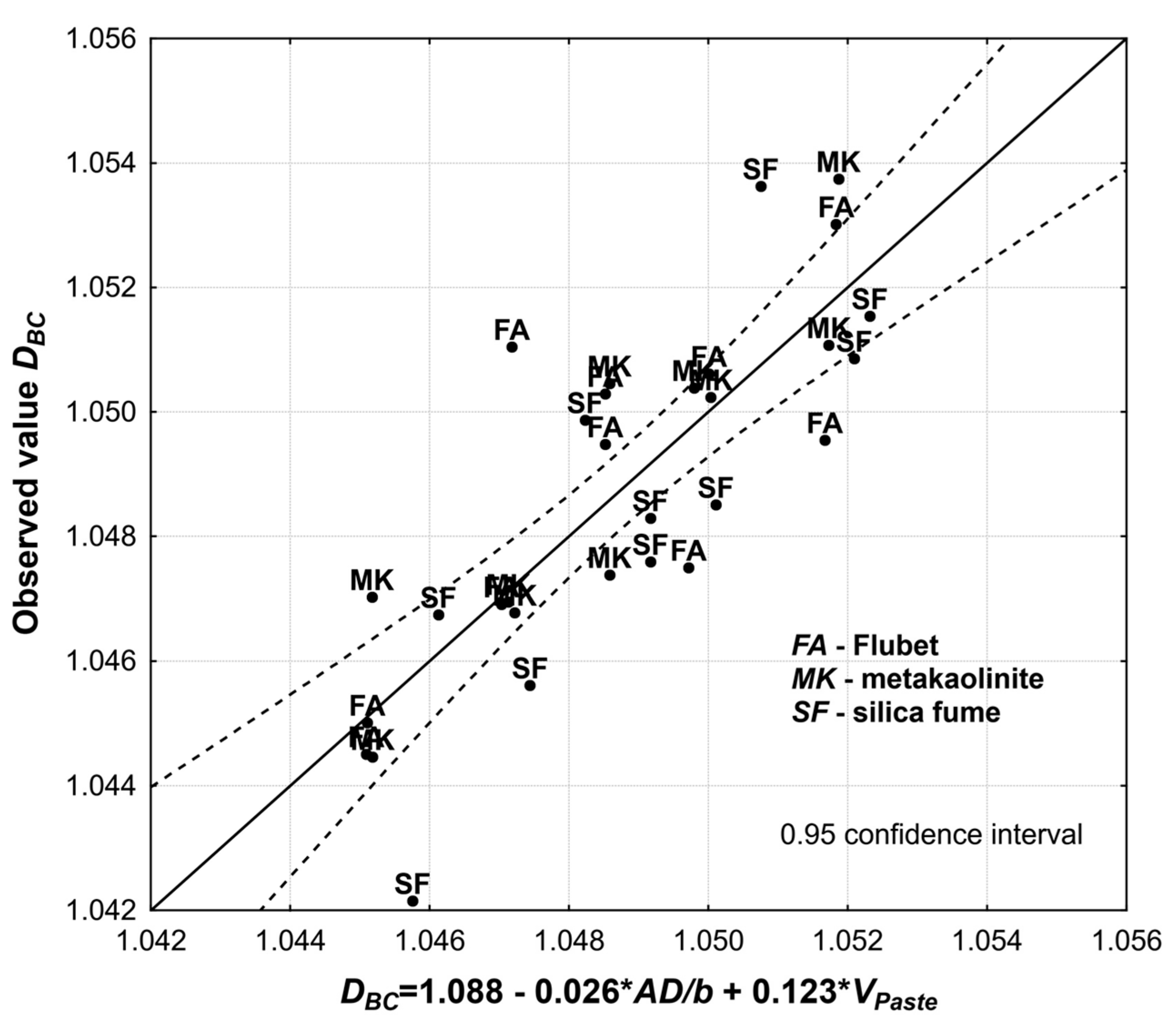

| N = 30 | Summary Regression of the Dependent Variable DBC R = 0.811, R2 = 0.657 F (2.27) = 25.870, p < 0.00000, Std. Error Estimation: 0.0017 | |||||

|---|---|---|---|---|---|---|

| b* | Stand. Error b* | b | Stand. Error b | t(27) | p | |

| Absolute term | 1.088 | 0.0063 | 159.25 | 0.0000 | ||

| AD/b | −0.3567 | 0.1129 | −0.026 | 0.0082 | −3.161 | 0.0039 |

| VPaste | 0.7470 | 0.1129 | 0.123 | 0.0185 | 6.620 | 0.0000 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Konkol, J. Fracture Toughness and Fracture Surface Morphology of Concretes Modified with Selected Additives of Pozzolanic Properties. Buildings 2019, 9, 174. https://doi.org/10.3390/buildings9080174

Konkol J. Fracture Toughness and Fracture Surface Morphology of Concretes Modified with Selected Additives of Pozzolanic Properties. Buildings. 2019; 9(8):174. https://doi.org/10.3390/buildings9080174

Chicago/Turabian StyleKonkol, Janusz. 2019. "Fracture Toughness and Fracture Surface Morphology of Concretes Modified with Selected Additives of Pozzolanic Properties" Buildings 9, no. 8: 174. https://doi.org/10.3390/buildings9080174

APA StyleKonkol, J. (2019). Fracture Toughness and Fracture Surface Morphology of Concretes Modified with Selected Additives of Pozzolanic Properties. Buildings, 9(8), 174. https://doi.org/10.3390/buildings9080174