Optimizing Evaluation Methods for the Embodied Energy and Carbon Management of Existing Buildings in Egypt

Abstract

1. Introduction

2. Literature Review

2.1. A General Overview

2.2. Classification of the Literature

2.2.1. Standardization of Methods

2.2.2. Tool Development for More Accurate and Streamlined Embodied Energy Calculation

2.2.3. Application of Methods

2.2.4. Optimization of Materials

2.2.5. Scalability of Methods

2.3. Data and Research Needed Locally

3. Methods

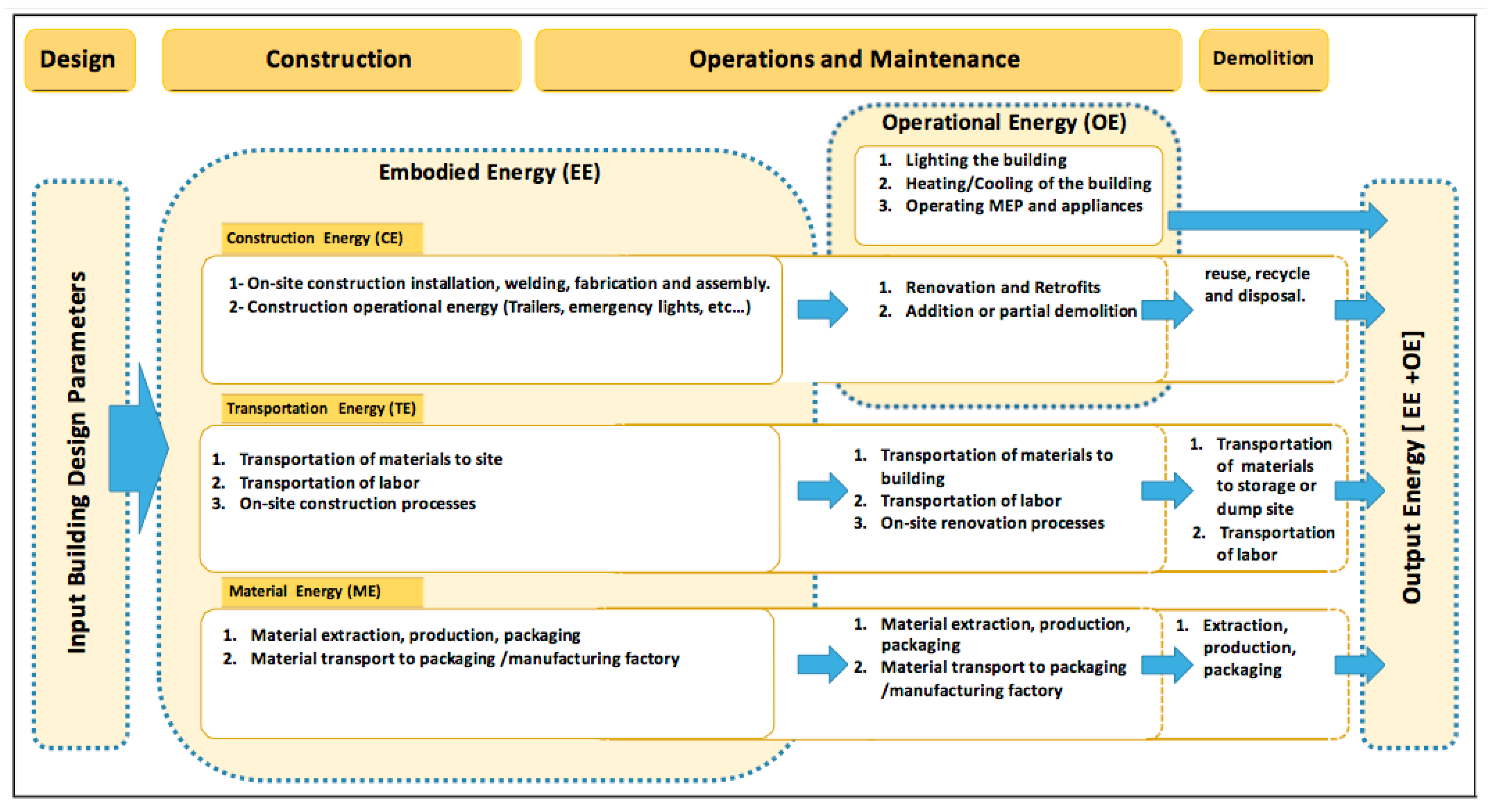

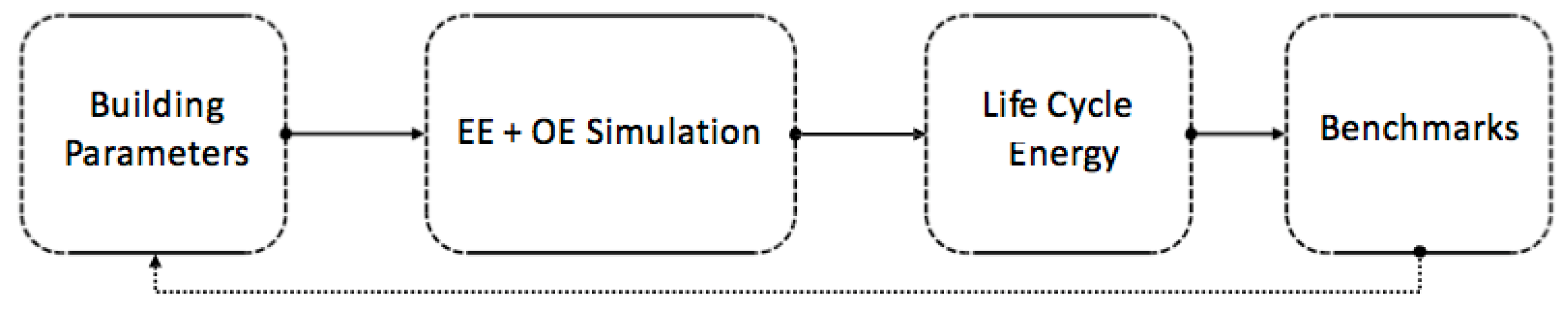

3.1. Proposed Framework

3.2. Methodology and Reasoning for Tool Selection

3.3. Performance-Based Evaluation (PBE)

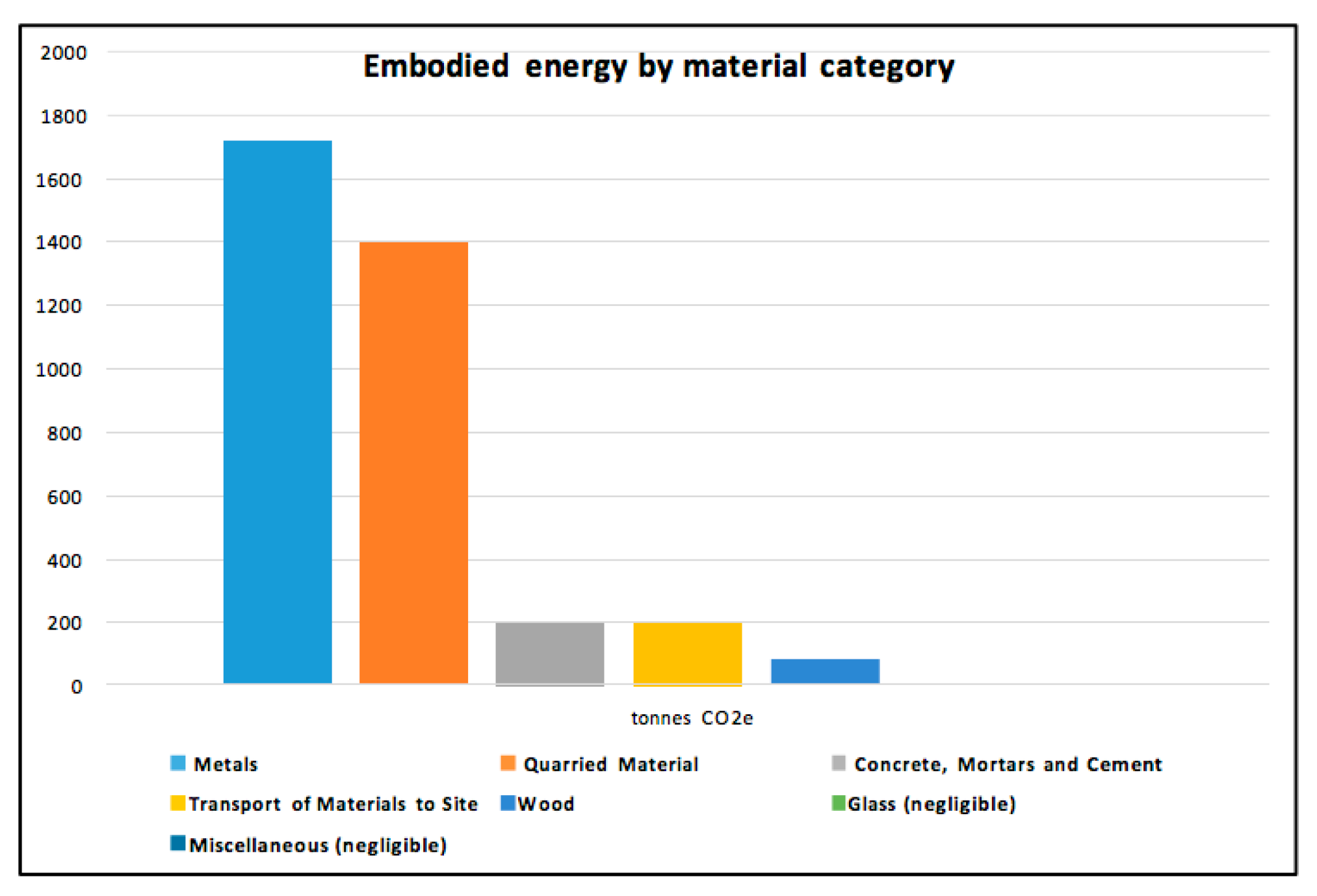

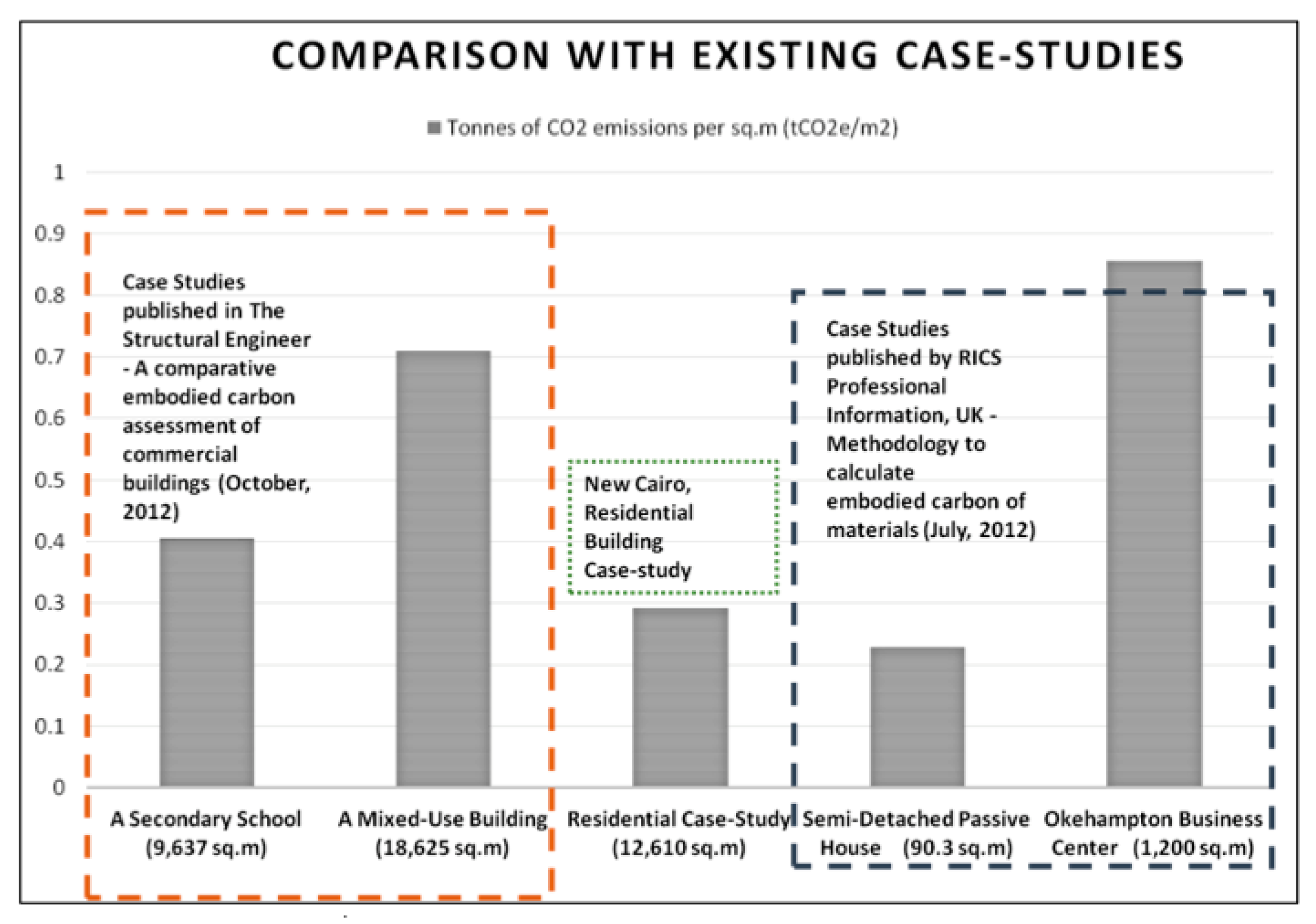

4. Results

4.1. Building Information

4.2. Limitations Faced and Assumptions Made

5. Discussion and Further Research

- The establishment of a parallel carbon emission coefficient inventory, such as that of the University of Bath (ICE—Inventory of Carbon and Energy), that is specific to the local region [33];

- Alternatives to high embodied energy construction materials that are currently extensively used in the Egyptian construction market such as reinforced concrete slabs, cement mortars, and burnt clay bricks;

- The search for alternative, renewable resources to substitute current high carbon content energy sources (high embodied energy does not necessarily mean high embodied carbon);

- The creation of a set of guidelines for designing low embodied energy buildings;

- Advancement of the capabilities of simulation tools to cover a wider scope of the building life cycle.

6. Conclusions

6.1. Decarbonizing Existing Buildings

6.1.1. Decarbonization of Operational Energy Processes

6.1.2. Decarbonization of Material Energy and Construction Processes

- Materials in need of replacement can be exchanged with similar materials of lower embodied energy and carbon emissions. These materials could be sourced locally to reduce transport energy, could have low extraction energies, and may have low processing energies. In addition, they would preferably have an expected lifetime as long as the expected lifetime of the building or longer and/or would be capable of being reused or recycled at the end of the building’s lifetime.

- Construction processes during all maintenance works should be kept as minimal as possible without endangering the safety of the building (which would then require more intervention).

- All minor and major works should employ minimal energy expenditures.

6.1.3. Decarbonization of Demolition Processes

Author Contributions

Funding

Conflicts of Interest

References

- Dixit, M.K.; Culp, C.H.; Fernández-Solís, J.L. System boundary for embodied energy in buildings: A conceptual model for definition. Renew. Sustain. Energy Rev. 2013, 21, 153–164. [Google Scholar] [CrossRef]

- Royal Institution of Chartered Surveyors. Methodology to Calculate Embodied Carbon of Materials; RICS Books (Royal Institution of Chartered Surveyors): Edinburgh, UK, 2012. [Google Scholar]

- Dixit, M.K.; Fernández-Solís, J.L.; Lavy, S.; Culp, H.C. Need for an embodied energy measurement protocol for buildings: A Review paper. Renew. Sustain. Energy Rev. 2012, 16, 3730–3743. [Google Scholar] [CrossRef]

- Nebel, B.; Alcorn, A.; Wittstock, B. Life Cycle Assessment: Adopting and Adapting Overseas LCA Data and Methodologies for Building Materials in New Zealand; Ministry of Agriculture and Forestry: Wellington, New Zeland, 2011.

- Haynes, R. Embodied Energy Calculations within Life Cycle Analysis of Residential Buildings. Etet1812. Staging-Cloud. Netregistry 2010, 1–16. [Google Scholar]

- Energy Information Agency (EIA) Egypt—Country Analysis Briefs. 2018. Available online: https://www.eia.gov/beta/international/analysis_includes/countries_long/Egypt/egypt.pdf (accessed on 17 April 2019).

- Zeng, R.; Chini, A. A review of research on embodied energy of buildings using biblio-metric analysis. Energy Build. 2017, 155, 172–184. [Google Scholar] [CrossRef]

- Chastas, P.; Theodosiou, T.; Bikas, D. Embodied energy in residential buildings-towards the nearly zero energy building: A literature review. Build. Environ. 2016, 105, 267–282. [Google Scholar] [CrossRef]

- LEED Green Building Certification|USGBC. Available online: https://new.usgbc.org/leed (accessed on 26 March 2019).

- BREEAM: Home Page. Available online: https://www.breeam.com/ (accessed on 26 March 2019).

- Dixit, M.K.; Fernández-Solís, J.L.; Lavy, S.; Culp, H.C. Identification of parameters for embodied energy measurement: A Literature review. Energy Build. 2010, 42, 1238–1247. [Google Scholar] [CrossRef]

- Dixit, M.K. Life cycle embodied energy analysis of residential buildings: A review of literature to investigate embodied energy parameters. Renew. Sustain. Energy Rev. 2017, 79, 390–413. [Google Scholar] [CrossRef]

- Sharma, A.; Marwaha, B.M. A methodology for energy performance classification of residential building stock of Hamirpur. HBRC J. 2017, 13, 337–352. [Google Scholar] [CrossRef][Green Version]

- Azari, R.; Abbasabadi, N. Embodied energy of buildings: A review of data, methods, challenges, and research trends. Energy Build. 2018, 168, 225–235. [Google Scholar] [CrossRef]

- EDGE. EDGE Buildings. Available online: https://www.edgebuildings.com/marketing/edge/ (accessed on 8 January 2019).

- Nizam, R.S.; Zhang, C.; Tian, L. A BIM based tool for assessing embodied energy for buildings. Energy Build. 2018, 170, 1–14. [Google Scholar] [CrossRef]

- Koezjakov, A.; Urge-Vorsatz, D.; Crijns-Graus, W.; van den Broek, M. The relationship between operational energy demand and embodied energy in Dutch residential buildings. Energy Build. 2018, 165, 233–245. [Google Scholar] [CrossRef]

- Praseeda, K.I.; Reddy, B.V.V.; Mani, M. Embodied and operational energy of urban residential buildings in India. Energy Build. 2016, 110, 211–219. [Google Scholar] [CrossRef]

- Zhu, H.; Hong, J.; Shen, G.Q.; Mao, C.; Zhang, H.; Li, Z. The exploration of the life-cycle energy saving potential for using prefabrication in residential buildings in China. Energy Build. 2018, 166, 561–570. [Google Scholar] [CrossRef]

- Lee, B.; Trcka, M.; Hensen, J.L.M. Embodied energy of building materials and green building rating systems—A case study for industrial halls. Sustain. Cities Soc. 2011, 1, 67–71. [Google Scholar] [CrossRef]

- Yolles, H. Embodied Carbon, Sustainable Office—A Supplementary Report; South West Regional Development Agency: Swindon, UK, 2010.

- Lotteau, M.; Loubet, P.; Sonnemann, G. An analysis to understand how the shape of a concrete residential building influences its embodied energy and embodied carbon. Energy Build. 2017, 154, 1–11. [Google Scholar] [CrossRef]

- Venkatarama, R.B.V.; Jagadish, K.S. Embodied energy of common and alternative building materials and technologies. Energy Build. 2003, 35, 129–137. [Google Scholar] [CrossRef]

- Shukla, A.; Tiwari, G.N.; Sodha, M.S. Embodied energy analysis of adobe house. Renew. Energy 2009, 34, 755–761. [Google Scholar] [CrossRef]

- Ramesh, S. Appraisal of vernacular building materials and alternative technologies for roofing and terracing options of embodied energy in buildings. Energy Procedia 2012, 14, 1843–1848. [Google Scholar] [CrossRef][Green Version]

- Yeo, D.; Gabbai, R.D. Sustainable design of reinforced concrete structures through embodied energy optimization. Energy Build. 2011, 43, 2028–2033. [Google Scholar] [CrossRef]

- Crishna, N.; Banfill, P.F.G.; Goodsir, S. Embodied energy and CO2 in UK Dimension stone. Resour. Conserv. Recycl. 2011, 55, 1265–1273. [Google Scholar] [CrossRef]

- Utama, A.; Gheewala, S.H. Influence of material selection on energy demand in residential houses. Mater. Des. 2009, 30, 2173–2180. [Google Scholar] [CrossRef]

- Radhi, H. On the optimal selection of wall cladding system to reduce direct and indirect CO2 emissions. Energy 2010, 35, 1412–1424. [Google Scholar] [CrossRef]

- Davies, P.; Osmani, M. Low carbon housing refurbishment challenges and incentives: Architect’s perspectives. Build. Environ. 2011, 46, 1691–1698. [Google Scholar] [CrossRef]

- Emmanuel, M.R.; Baker, K. Carbon Management in the Built Environment; Routledge: Abingdon, UK, 2012. [Google Scholar]

- ENERGY STAR Portfolio Manager. Available online: https://portfoliomanager.energystar.gov/pm/login.html (accessed on 26 March 2019).

- Hammond, G.; Jones, C. Inventory of Carbon & Energy: ICE; Sustainable Energy Research Team, Department of Mechanical Engineering, University of Bath: Bath, UK, 2008. [Google Scholar]

- Energy saving Trust (EST). Energy Saving Assumptions. 2013. Available online: http://www.energysavingtrust.org.uk/ (accessed on 1 May 2013).

| Category | Construction Material | Unit Conversion or Density | Embodied tCO2e per Tonne of Material | Quantity (tonnes) | Distance between Source of Supply and Site (km) | Mode of Transport | Footprint (Tonnes Fossil CO2e) | ||

|---|---|---|---|---|---|---|---|---|---|

| Embodied | Transport | Sum | |||||||

| Quarried Material | Quarried aggregate | 2.0 tonnes/m3 | 0.005 | 472 | 70 | Road | 2.360 | 3.526 | 5.886 |

| Recycled aggregate | 2.0 tonnes/m3 | 0.005 | 0.000 | 0.000 | 0.000 | ||||

| Marine aggregate | 2.0 tonnes/m3 | 0.008 | 0.000 | 0.000 | 0.000 | ||||

| Asphalt, 4% (bitumen) binder content (by mass) | 1.7 tonnes/m3 | 0.066 | 0.000 | 0.000 | 0.000 | ||||

| Asphalt, 5% (bitumen) binder content | 1.7 tonnes/m3 | 0.071 | 0.000 | 0.000 | 0.000 | ||||

| Asphalt, 6% (bitumen) binder content | 1.7 tonnes/m3 | 0.076 | 0.000 | 0.000 | 0.000 | ||||

| Asphalt, 7% (bitumen) binder content | 1.7 tonnes/m3 | 0.081 | 0.000 | 0.000 | 0.000 | ||||

| Asphalt, 8% (bitumen) binder content | 1.7 tonnes/m3 | 0.086 | 0.000 | 0.000 | 0.000 | ||||

| Bitumen | 2.4 tonnes/m3 | 0.490 | 26 | 1500 | Road | 12.897 | 4.213 | 17.110 | |

| Bricks | 1.9 tonnes/m3 | 0.240 | 0.000 | 0.000 | 0.000 | ||||

| Clay: general (simple baked products) | 1.9 tonnes/m3 | 0.240 | 5168 | 70 | Road | 1240.320 | 38.607 | 1278.927 | |

| Clay tile | 2.4 tonnes/m3 | 0.480 | 175 | 70 | Road | 84.096 | 1.309 | 85.405 | |

| Vitrified clay pipe DN 100 & DN 150 | 2.4 tonnes/m3 | 0.460 | 0.000 | 0.000 | 0.000 | ||||

| Vitrified clay pipe DN 200 & DN 300 | 2.4 tonnes/m3 | 0.500 | 0.000 | 0.000 | 0.000 | ||||

| Vitrified clay pipe DN 500 | 2.4 tonnes/m3 | 0.550 | 0.000 | 0.000 | 0.000 | ||||

| Ceramics: general | 1.9 tonnes/m3 | 0.700 | 23 | 140 | Road | 15.960 | 0.341 | 16.301 | |

| Ceramics: Tiles and Cladding Panels | 2.2 tonnes/m3 | 0.780 | 35 | 140 | Road | 27.456 | 0.526 | 27.982 | |

| Sand | 1.2 tonnes/m3 | 0.005 | 275 | 70 | Road | 1.401 | 2.053 | 3.454 | |

| Soil - general / rammed soil | 1.7 tonnes/m3 | 0.024 | 0.000 | 0.000 | 0.000 | ||||

| Stone: general | 2.0 tonnes/m3 | 0.079 | 0.000 | 0.000 | 0.000 | ||||

| Granite | 2.9 tonnes/m3 | 0.700 | 73 | 870 | Road | 50.750 | 6.731 | 57.481 | |

| Limestone | 2.2 tonnes/m3 | 0.090 | 0.000 | 0.000 | 0.000 | ||||

| Sandstone | 2.2 tonnes/m3 | 0.060 | 0.000 | 0.000 | 0.000 | ||||

| Shale | 2.7 tonnes/m3 | 0.002 | 0.000 | 0.000 | 0.000 | ||||

| Slate | 2.7 tonnes/m3 | 0.035 | 0.000 | 0.000 | 0.000 | ||||

| Sub-total | 6247 | 1435.2 | 57.3 | 1492.5 | |||||

| Metrics Summary | ||

|---|---|---|

| Metric | Aug 2018 (Energy Baseline) | Aug 2018 (Energy Current) |

| ENERGY STAR Score (1-100) | 83 | 83 |

| Source EUI (GJ/m2) | 1.3 | 1.3 |

| Site EUI (GJ/m2) | 0.47 | 0.47 |

| Energy Cost ($) | Not Available | Not Available |

| Total GHG Emissions Intensity (kgCO2e/m2) | 58.9 | 58.9 |

| Water Use (All Water Sources) (m3) | 6865.90 | 6865.90 |

| Total Waste (Disposed and Diverted) (Metric Tons) | Not Available | Not Available |

| Building Skeleton + Envelope | Total Embodied (per Component) | TOTAL EE/Skeleton + Envelope | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Component | Total | Layers/Elements | Distance from Source | Mode of Trasport | Quantity (per 1) | EE Coefficient | EE (per 1) | |||

| Typical Multi-Storey Residential Building | RC Floor Slabs | 5 | Steel | Road/Rail/Ship | in m3 | coefficient - steel | X | The Skeleton + Envelope’s Total Embodied Energy (XXXX) | ||

| Concrete | Road/Rail/Ship | coefficient | ||||||||

| Insulation | Road/Rail/Ship | |||||||||

| Cement | Road/Rail/Ship | |||||||||

| RC Columns | 30 | Columns | Road/Rail/Ship | Y | ||||||

| Material layer 2 | Road/Rail/Ship | |||||||||

| Material layer 3 | Road/Rail/Ship | |||||||||

| Exterior Walls | (in meters run) | Bricks | Road/Rail/Ship | Z | ||||||

| Mortar | Road/Rail/Ship | |||||||||

| Cladding | Road/Rail/Ship | |||||||||

| Doors | (no. of doors) | Wood | Road/Rail/Ship | X1 | ||||||

| Hinges | Road/Rail/Ship | |||||||||

| Handles | Road/Rail/Ship | |||||||||

| Window Type 1 | (no. of windows) | Alumninum 1 | Road/Rail/Ship | Y1 | ||||||

| Hinges | Road/Rail/Ship | |||||||||

| Handles | Road/Rail/Ship | |||||||||

| Window Type 2 | (no. of windows) | Alumninum 2 | Road/Rail/Ship | Z1 | ||||||

| Hinges | Road/Rail/Ship | |||||||||

| Handles | Road/Rail/Ship | |||||||||

| External Shading | (no. of structures) | Material layer 1 | Road/Rail/Ship | X2 | ||||||

| Material layer 2 | Road/Rail/Ship | |||||||||

| Additional Comp. 1 | (no.) | Material layer 1 | Road/Rail/Ship | Y2 | ||||||

| Material layer 2 | Road/Rail/Ship | |||||||||

| Additional Comp. 2 | (no.) | Material layer 1 | Road/Rail/Ship | Z2 | ||||||

| Material layer 2 | Road/Rail/Ship | |||||||||

| Other | (no.) | Material layer 1 | Road/Rail/Ship | X3 | ||||||

| Building Fixed - Interior Finishing | Total Embodied (per Component) | TOTAL EE/Interior | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Component | Total | Layers/Elements | Distance from Source | Mode of Trasport | Quantity (per 1) | EE Coefficient | EE (per 1) | |||

| Typical Multi-Storey Residential Building | Interior Walls | 15 m (in plan) | Brick | Road/Rail/Ship | in m3 | coefficient - steel | X | Interior Finishing Embodied Energy (XXXX) | ||

| Cement | Road/Rail/Ship | |||||||||

| Paint 1 | Road/Rail/Ship | |||||||||

| Paint 2 | Road/Rail/Ship | |||||||||

| Interior Partitions | 3 m (in plan) | Material layer 1 | Road/Rail/Ship | Y | ||||||

| Material layer 2 | Road/Rail/Ship | |||||||||

| Material layer 3 | Road/Rail/Ship | |||||||||

| Living Room Finishing | in m2 | Sand | Road/Rail/Ship | kg/tonnes (per m2) | coefficient - sand | Z | ||||

| Cement | Road/Rail/Ship | kg/tonnes (per m2) | coeff. - cement | |||||||

| (Select) Final Finish | Road/Rail/Ship | |||||||||

| Bedroom 1 Surface Finishing | Ceiling (Area m2) | Paint type 1 | Road/Rail/Ship | XX | ||||||

| Wall Surface (Area m2) | Paint type 2 | Road/Rail/Ship | ||||||||

| Floor Finish | Sand | Road/Rail/Ship | ||||||||

| Cement | Road/Rail/Ship | |||||||||

| (Select) Final Finish | Road/Rail/Ship | |||||||||

| Bathroom 1 Surface Finishing | Ceiling Paint | Paint type 2 | Road/Rail/Ship | YY | ||||||

| Wall Finish | Cement | Road/Rail/Ship | ||||||||

| Ceramic Tiles | Road/Rail/Ship | |||||||||

| Floor Finish | Sand | Road/Rail/Ship | ||||||||

| Cement | Road/Rail/Ship | |||||||||

| (Select) Final Finish | Road/Rail/Ship | |||||||||

| Bedroom 2 Surface Finishing | Ceiling (Area m2) | Paint type 1 | Road/Rail/Ship | XX | ||||||

| Wall Surface (Area m2) | Paint type 2 | Road/Rail/Ship | ||||||||

| Floor Finish | Sand | Road/Rail/Ship | ||||||||

| Cement | Road/Rail/Ship | |||||||||

| (Select) Final Finish | Road/Rail/Ship | |||||||||

| Bathroom 2 Surface Finishing | Ceiling Paint | Paint type 2 | Road/Rail/Ship | YY | ||||||

| Wall Finish | Cement | Road/Rail/Ship | ||||||||

| Ceramic Tiles | Road/Rail/Ship | |||||||||

| Floor Finish | Sand | Road/Rail/Ship | ||||||||

| Cement | Road/Rail/Ship | |||||||||

| (Select) Final Finish | Road/Rail/Ship | |||||||||

| Kitchen Surface Finishing | Ceiling (Area m2) | Paint type 1 | Road/Rail/Ship | XX | ||||||

| Wall Surface (Area m2) | Paint type 2 | Road/Rail/Ship | ||||||||

| Floor Finish | Sand | Road/Rail/Ship | ||||||||

| Cement | Road/Rail/Ship | |||||||||

| (Select) Final Finish | Road/Rail/Ship | |||||||||

| Other | Material layer 1 | Material layer 1 | Road/Rail/Ship | Z1 | ||||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tarabieh, K.; Khorshed, M. Optimizing Evaluation Methods for the Embodied Energy and Carbon Management of Existing Buildings in Egypt. Buildings 2019, 9, 90. https://doi.org/10.3390/buildings9040090

Tarabieh K, Khorshed M. Optimizing Evaluation Methods for the Embodied Energy and Carbon Management of Existing Buildings in Egypt. Buildings. 2019; 9(4):90. https://doi.org/10.3390/buildings9040090

Chicago/Turabian StyleTarabieh, Khaled, and Mirette Khorshed. 2019. "Optimizing Evaluation Methods for the Embodied Energy and Carbon Management of Existing Buildings in Egypt" Buildings 9, no. 4: 90. https://doi.org/10.3390/buildings9040090

APA StyleTarabieh, K., & Khorshed, M. (2019). Optimizing Evaluation Methods for the Embodied Energy and Carbon Management of Existing Buildings in Egypt. Buildings, 9(4), 90. https://doi.org/10.3390/buildings9040090