Optimization of the Supplier Selection Process in Prefabrication Using BIM

Abstract

1. Introduction

2. Literature Review

2.1. BIM in Prefabrication

2.2. Methods in Multiple-Criteria Decision-Making for Supplier Selection

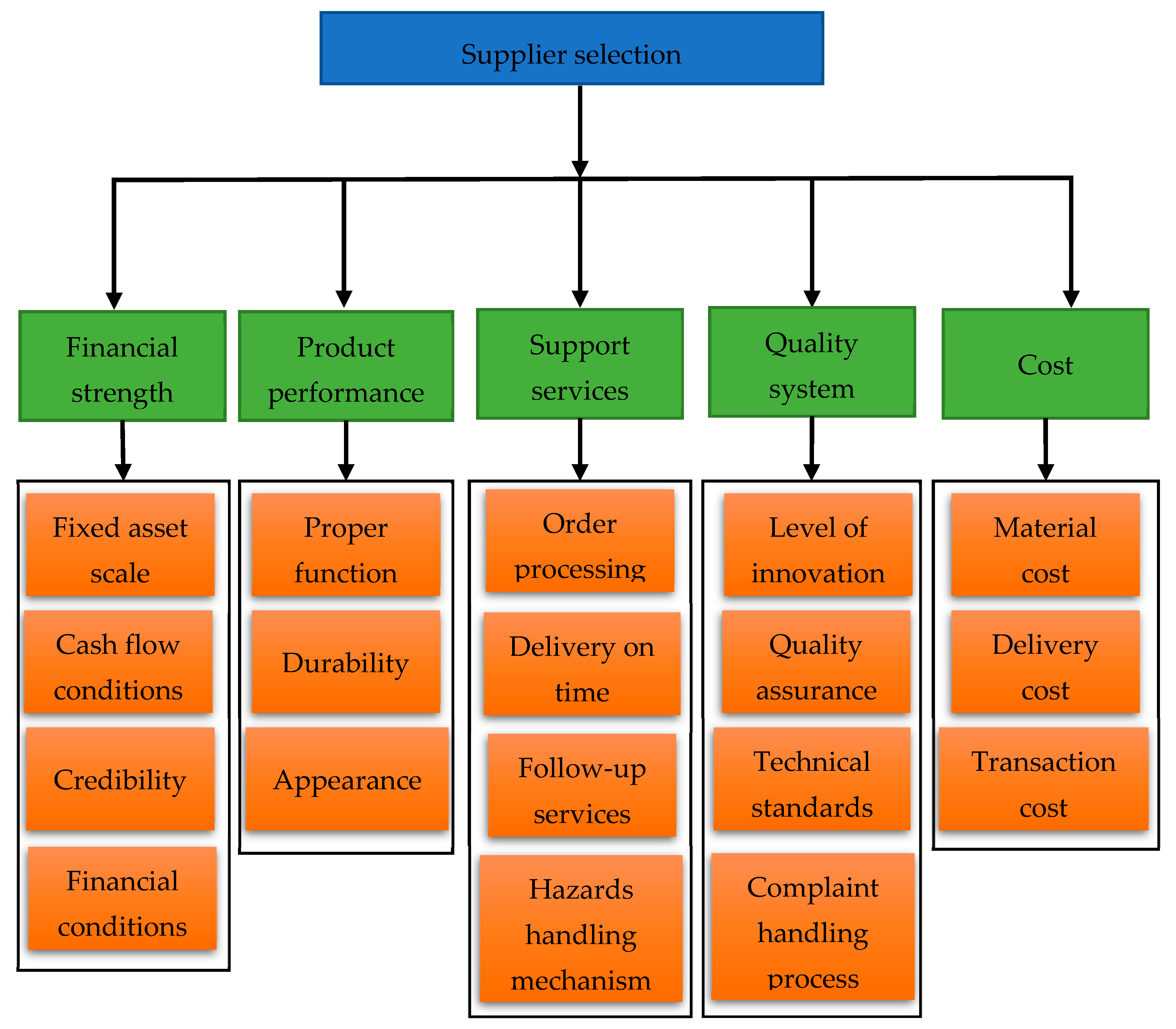

2.3. Supplier Selection Criteria

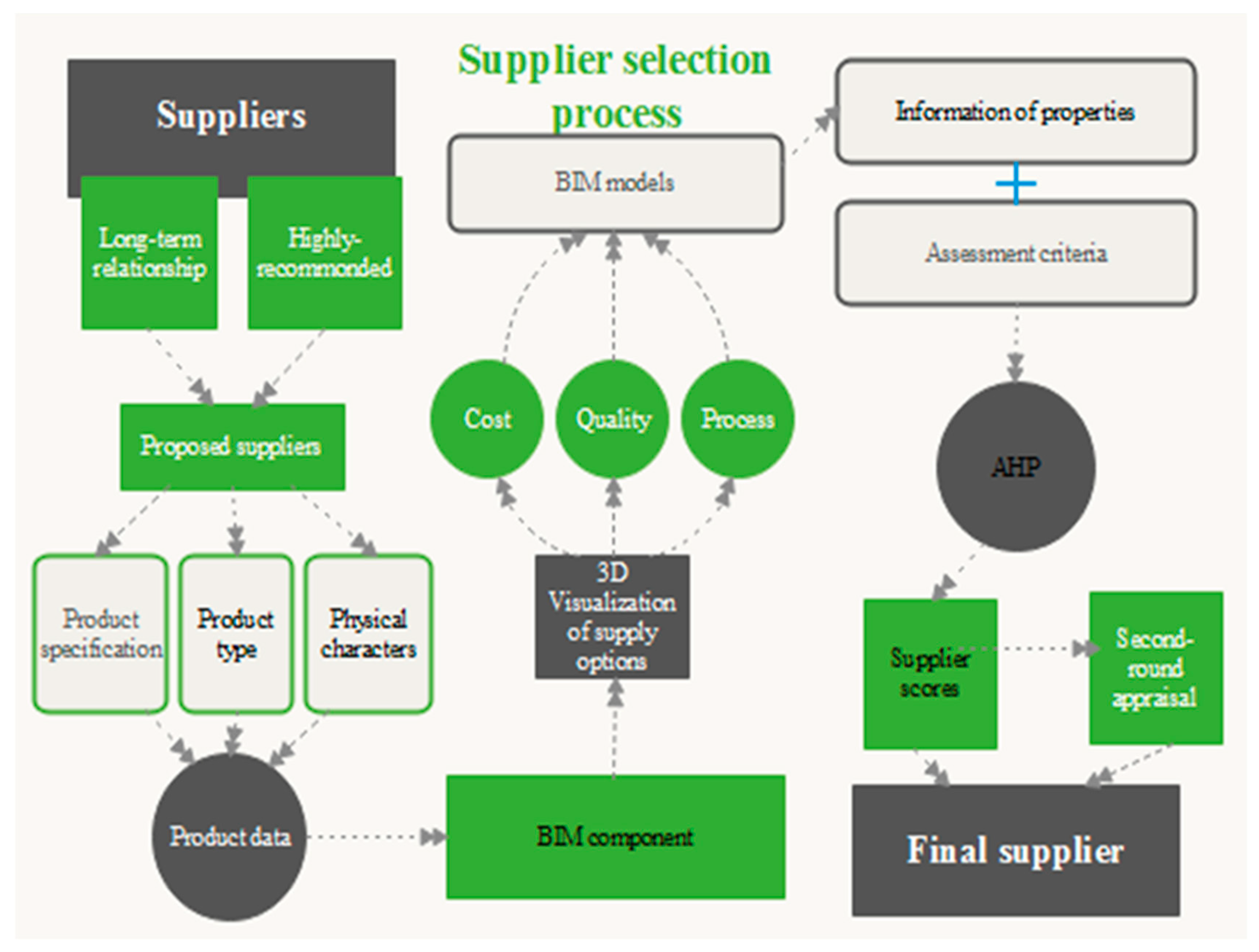

3. The Proposed Method

3.1. Assessment Criteria

3.2. BIM Model

3.3. Analytic Hierarchy Process (AHP)

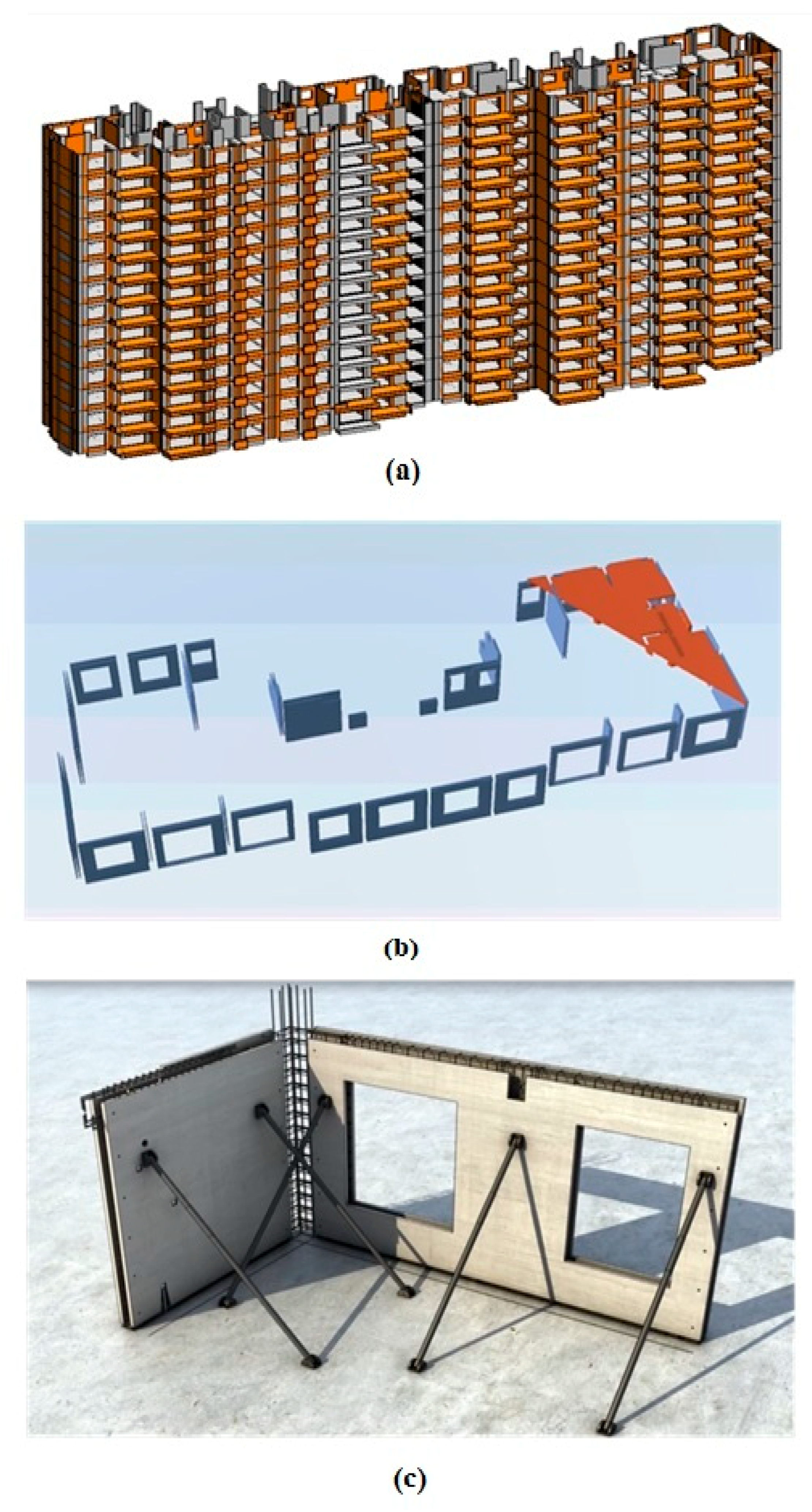

4. Case Study

4.1. Prefabrication Project Information

4.2. Assessment Process

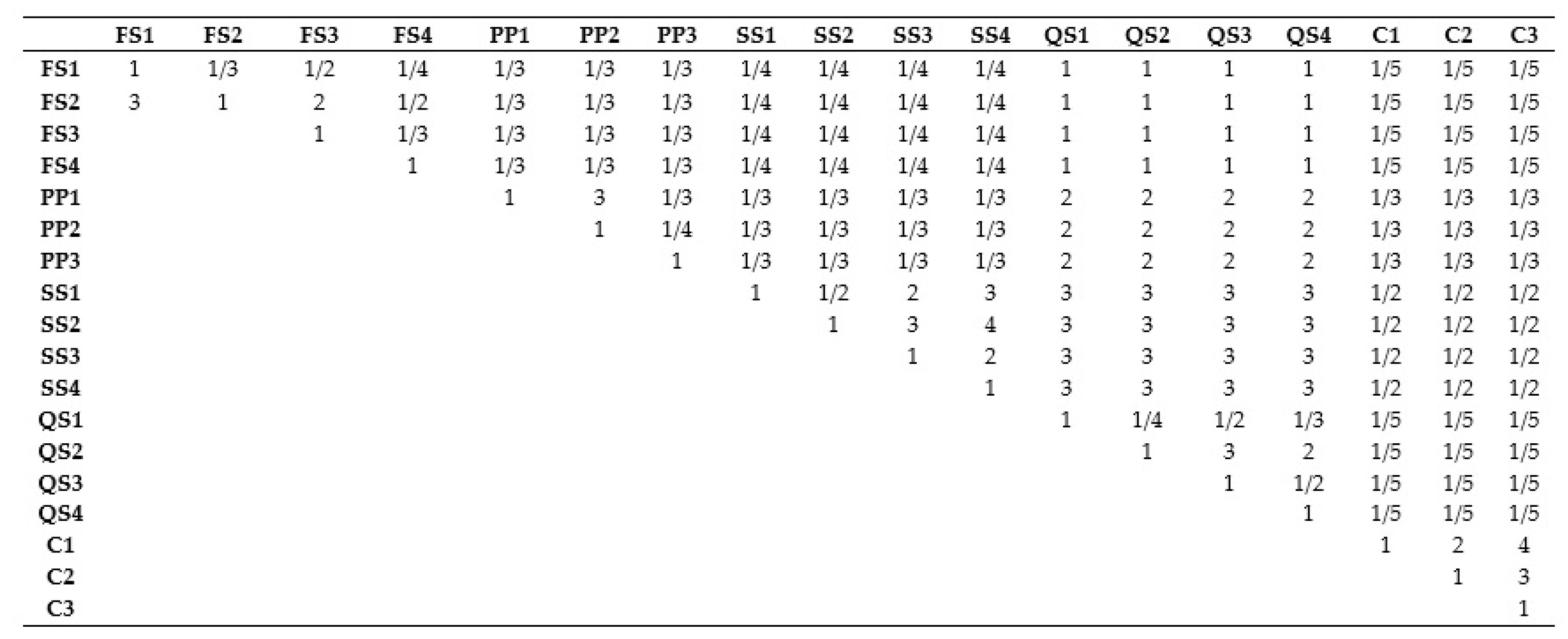

4.2.1. Important Weights of the Criteria

4.2.2. Cost Analysis

4.2.3. Financial Ability Evaluation

4.2.4. Product Performance Evaluation

4.2.5. Support Service Assessment

4.2.6. Quality System Assessment

4.2.7. Final Assessment Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AEC | Architecture, Engineering and Construction |

| AHP | Analytic Hierarchy Process |

| ANNs | Artificial Neutral Networks |

| ANP | Analytic Network Process |

| BIM | Building Information Modelling |

| CAD | Computer-Aided Design |

| CBR | Case-Based Reasoning |

| C | Cost |

| C1 | Material Cost |

| C2 | Delivery Cost |

| C3 | Transaction Cost |

| DEA | Data Envelopment Analysis |

| GA | Genetic Algorithms |

| IFC | Industry Foundation Classes |

| FS | Financial Strength |

| FS1 | Fixed Asset Scale |

| FS2 | Cash Flow Conditions |

| FS3 | Credibility |

| FS4 | Financial Conditions |

| PC | Prefabrication |

| PP | Product Performance |

| PP1 | Proper Function |

| PP2 | Durability |

| PP3 | Appearance |

| QS | Quality System |

| QS1 | Level of Innovation |

| QS2 | Quality Assurance |

| QS3 | Technical Standards |

| QS4 | Complaint Handling Process |

| SS | Support Services |

| SS1 | Order Processing |

| SS2 | Delivery on Time |

| SS3 | Follow-up Services |

| SS4 | Hazards Handling Mechanism |

| TOPSIS | Technique for Order Preference by Similarity to Ideal Solution |

References

- Wong, J.K.W.; Kuan, K.L. Implementing ‘BEAM Plus’ for BIM-based sustainability analysis. Autom. Constr. 2014, 44, 163–175. [Google Scholar] [CrossRef]

- Dong, Y.H.; Ng, S.T. A life cycle assessment model for evaluating the environmental impacts of building construction in Hong Kong. Build. Environ. 2015, 89, 183–191. [Google Scholar] [CrossRef]

- Wen, T.J.; Siong, H.C.; Noor, Z.Z. Assessment of embodied energy and global warming potential of building construction using life cycle analysis approach: Case studies of residential buildings in Iskandar Malaysia. Energy Build. 2015, 93, 295–302. [Google Scholar] [CrossRef]

- Li, Y.; Chen, X.; Wang, X.; Xu, Y.; Chen, P.H. A review of studies on green building assessment methods by comparative analysis. Energy Build. 2017, 146, 152–159. [Google Scholar] [CrossRef]

- Horta, R.M.C. Sustainable Construction of Nearly Zero-Energy Buildings; Faculdade de Ciências e Tecnologia: Caparica, Portugal, 2012. [Google Scholar]

- Cardoso, L.P.S. Sustainable Refurbishment of Buildings Built before 1951; Universidade do Minho: Braga, Portugal, 2013. [Google Scholar]

- Araújo, C.; Almeida, M.; Bragança, L. Analysis of some Portuguese thermal regulation parameters. Energy Build. 2012, 58, 141–150. [Google Scholar] [CrossRef]

- Motawa, I.; Carter, K. Sustainable BIM-based evaluation of buildings. Proc. Soc. Behav. Sci. 2013, 74, 419–428. [Google Scholar] [CrossRef]

- Solla, M.; Ismail, L.H.; Yunus, R. Investigation on the potential of integrating BIM into green building assessment tools. ARPN J. Eng. Appl. Sci. 2016, 11, 2412–2418. [Google Scholar] [CrossRef]

- Akinade, O.O.; Oyedele, L.O.; Bilal, M.; Ajayi, S.O.; Owolabi, H.A.; Alaka, H.A.; Bello, S.A. Waste minimisation through deconstruction: A BIM based deconstructionability assessment score (BIM-DAS). Resour. Conserv. Recycl. 2015, 105, 167–176. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S.; Chiang, Y.H. Quantifying waste reduction potential of using prefabrication in building construction in Hong Kong. Waste Manag. 2009, 29, 309–320. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Fung, I.W.H.; Sing, M.P.; Ogunlana, S.O. Best practice of prefabrication implementation in the Hong Kong public and private sectors. J. Clean. Prod. 2015, 109, 216–231. [Google Scholar] [CrossRef]

- Cao, X.; Li, X.; Zhu, Y.; Zhang, Z. A comparative study of environmental performance between prefabricated and traditional residential buildings in China. J. Clean. Prod. 2016, 109, 131–143. [Google Scholar] [CrossRef]

- Al-Hussein, M.; Manrique, J.D.; Mah, D. North Ridge CO2 Analysis Report: Comparison Between Modular and Onsite Construction; University of Alberta: Edmontom, AB, Canada, 2009. [Google Scholar]

- Mao, C.; Shen, Q.; Shen, L.; Tang, L. Comparative study of greenhouse gas emissions between off-site prefabrication and conventional construction methods: Two case studies of residential projects. Energy Build. 2013, 66, 165–176. [Google Scholar] [CrossRef]

- Ji, Y.; Li, K.; Liu, G.; Shrestha, A.; Jing, J. Comparing greenhouse gas emissions of precast in-situ and conventional construction methods. J. Clean. Prod. 2016. [Google Scholar] [CrossRef]

- Quale, J.; Eckelman, M.J.; Williams, K.W.; Sloditskie, G.; Zimmerman, J.B. Construction matters: Comparing environmental impacts of building modular and conventional homes in the United States. J. Ind. Ecol. 2012, 16, 243–253. [Google Scholar] [CrossRef]

- Vernikos, V.K.; Goodier, C.I.; Broyd, T.W.; Robery, P.C.; Gibb, A.G.F. Building Information Modelling and Its Effect on Off-Site Construction in UK Civil Engineering; Proceedings—Management, Procurement and Law; ICE: London, UK, 2014; pp. 152–159. [Google Scholar]

- Blismas, N.; Wakefield, R. Drivers, constraints and the future of offsite manufacture in Australia. Constr. Innov. 2009, 9, 72–83. [Google Scholar] [CrossRef]

- Zhai, X.; Reed, R.; Mills, A. Factors impeding the offsite production of housing construction in China: An investigation of current practice. Constr. Manag. Econ. 2014, 32, 40–52. [Google Scholar] [CrossRef]

- Patlakas, P.; Livingstone, A.; Hairstans, R. A BIM Platform for Offsite Timber Construction. In Proceedings of the Education and Research in Computer Aided Architectural Design in Europe, Vienna, Austria, 16–18 September 2015; pp. 16–18. [Google Scholar]

- Chen, Y.; Okudan, G.E.; Riley, D.R. Sustainable performance criteria for construction method selection in concrete buildings. Autom. Constr. 2010, 19, 235–244. [Google Scholar] [CrossRef]

- Martinez, S.; Jardon, A.; Navarro, J.M.; Gonzalez, P. Building industrialization: Robotized assembly of modular products. Assem. Autom. 2008, 28, 134–142. [Google Scholar] [CrossRef]

- Li, H.; Guo, H.L.; Skitmore, M.; Huang, T.; Chan, K.Y.N.; Chan, G. Rethinking prefabricated construction management using the VP-based IKEA model in Hong Kong. Constr. Manag. Econ. 2011, 29, 233–245. [Google Scholar] [CrossRef]

- Li, C.Z.; Xue, F.; Li, X.; Hong, J.; Shen, G.Q. An internet of things-enabled BIM platform for on-site assembly services in prefabricated construction. Autom. Constr. 2018, 89, 146–161. [Google Scholar] [CrossRef]

- Said, H. Prefabrication best practices and improvement opportunities for electrical construction. J. Constr. Eng. M 2015, 141. [Google Scholar] [CrossRef]

- Huang, W.K.; Xu, X.X.; Chen, K.; Wu, H.Y.; Li, Z.D. Causal Loop Analysis on the Impact of Schedule Risks in Prefabrication Housing Production in Hong Kong. In 21st International Symposium on Advancement of Construction Management and Real Estate; Chau, K., Chan, I., Lu, W., Webster, C., Eds.; Springer: Singapore, 2018. [Google Scholar]

- Cheng, J.C.P.; Law, K.H.; Bjornsson, H.; Jones, A.; Sriram, R.D. A service-oriented framework for construction supply chain integration. Autom. Constr. 2010, 19, 245–260. [Google Scholar] [CrossRef]

- Briscoe, G.; Dainty, A.R.J.; Millett, S. Construction supply chain partnerships: Skills, knowledge and attitudinal requirements. Eur. J. Purch. Supply Manag. 2001, 7, 243–255. [Google Scholar] [CrossRef]

- Dainty, A.R.J.; Grugulis, I.; Langford, D. Understanding construction employment: The need for a fresh research agenda. J. Pers. Rev. 2007, 36, 501–508. [Google Scholar] [CrossRef]

- Saad, M.; Jones, M.; James, P. A review of the progress towards the adoption of supply chain management(SCM) relationships in construction. Eur. J. Purch. Supply Manag. 2002, 8, 173–183. [Google Scholar] [CrossRef]

- Giunipero, L.C.; Eltantawy, R.A. Securing the upstream supply chain: A risk management approach. Int. J. Phys. Distr. Log. 2004, 34, 698–713. [Google Scholar] [CrossRef]

- Waskett, P. Current Practice and Potential Uses of Prefabrication; Department of Trade and Industry: London, UK, 2001. [Google Scholar]

- Langston, C. The reliability of currency and purchasing power parity conversion for international project cost benchmarking. Benchmarking Int. J. 2016, 23, 61–77. [Google Scholar] [CrossRef]

- Azambuja, M.; O’Brien, W.J. Construction Supply Chain Modelling: Issues and Perspectives. In Construction Supply Chain Management Handbook, 1st ed.; O’Brien, W.J., Formoso, C.T., Vrijhoef, R., London, K.A., Eds.; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Kumar, A.; Pal, A.; Vohra, A.; Gupta, S.; Manchanda, S.; Kumar Dash, M. Construction of capital procurement decision making model to optimize supplier selection using Fuzzy Delphi and AHP-DEMATEL. Benchmark. Int. J. 2018, 25, 1528–1547. [Google Scholar] [CrossRef]

- Merschbrock, C.; Nordahl-Rolfsen, C. BIM technology acceptance among reinforcement workers—The case of Oslo airports terminal 2. J. Inf. Technol. Constr. 2016, 21, 1–12. [Google Scholar]

- Elonen, S.; Artto, K.A. Problems in managing internal development projects in multi-project environments. Int. J. Proj. Manag 2003, 21, 395–402. [Google Scholar] [CrossRef]

- Abanda, F.H.; Tah, J.H.M.; Cheung, F.K.T. BIM in off-site manufacturing for buildings. J. Build. Eng. 2017, 14, 89–102. [Google Scholar] [CrossRef]

- Ezcan, V.; Isikdag, U.; Goulding, J.S. BIM and Off-Site Manufacturing: Recent Research and Opportunities. In Proceedings of the International Council for Research and Innovation in Building and Construction (CIB) World Building Congress, Brisbane, Australia, 5–9 May 2013. [Google Scholar]

- Samarasinghe, T.; Mendis, P.; Ngo, T.; Fernando, W.J.B.S. BIM Software Framework for Prefabricated Construction: Case Study Demonstrating BIM Implementation on a Modular House. In Proceedings of the 6th International Conference on Structural Engineering and Construction Management, Kandy, Sri Lanka, 11–13 December 2015. [Google Scholar]

- Sebastian, R.; Haak, W.; Vos, E. BIM Application for Integrated Design and Engineering in Small Scale Housing Development: A Pilot Project in the Netherlands. In Proceedings of the Future Trends in Architectural Management, International Symposium CIB-W096 2009 Taiwan, Tainan, Taiwan, 2–4 November 2009. [Google Scholar]

- Cowles, E.; Warner, P. Prefabrication and Modularization in Construction: 2013: Survey Results; FMI Corporation: Raleigh, NC, USA, 2013. [Google Scholar]

- Alaghbari, W.; Kadir, M.R.A.; Salim, A.; Ernawati. The significant factors causing delay of building construction projects in Malaysia. J. Eng. Constr. Arch. Manag. 2007, 14, 192–206. [Google Scholar] [CrossRef]

- Mitchell, C.A.; Keaveney, M. An Examination of the Potential of Building Information Modelling to Increase the Efficiency of Irish Contractors on Design and Build Projects. In Proceedings of the International Virtual Conference, Zilina, Slovakia, 25–29 March 2013. [Google Scholar]

- Taherdoost, H.; Brard, A. Analyzing the process of supplier selection criteria and methods. Proc. Manuf. 2019, 32, 1024–1034. [Google Scholar] [CrossRef]

- Arslan, G.; Kivrak, S.; Birgonul, M.; Dikmen, I. Improving sub-contractor selection process in construction projects: Web-based sub-contractor evaluation system (WEBSES). Autom. Constr. 2008, 17, 480–488. [Google Scholar] [CrossRef]

- Jaskowski, P.; Sobotka, A.; Czarnigowska, A. Decision model for planning material supply channels in construction. Autom. Constr. 2018, 90, 235–242. [Google Scholar] [CrossRef]

- Lam, K.C.; Tao, R.; Lam, C.K. A material supplier selection model for property developers using Fuzzy Principal Component Analysis. Autom. Constr. 2010, 19, 608–618. [Google Scholar] [CrossRef]

- Safa, M.; Shahi, A.; Haas, C.T.; Hipel, K.W. Supplier selection process in an integrated construction materials management model. Autom. Constr 2014, 48, 64–73. [Google Scholar] [CrossRef]

- Deng, X.; Hu, Y.; Deng, Y.; Mahadevan, S. Supplier selection using AHP methodology extended by D numbers. Expert Syst. Appl. 2014, 41, 156–167. [Google Scholar] [CrossRef]

- San, C.J. Contractor selection using multicriteria decision-making methods. J. Constr. Eng. Manag. 2011, 138, 751–758. [Google Scholar] [CrossRef]

- Sonmez, M.; Holt, G.; Yang, J.B.; Graham, G. Applying evidential reasoning to prequalifying construction contractors. ASCE J. Manag. Eng. 2002, 18, 111–119. [Google Scholar] [CrossRef]

- Singh, D.; Tiong, R. A fuzzy decision framework for contractor selection. ASCE J. Constr. Eng. Manag. 2005, 131, 62–70. [Google Scholar] [CrossRef]

- Ho, W.; Xu, X.; Dey, P.K. Multi-criteria decision making approaches for supplier evaluation and selection: A literature review. Eur. J. Oper. Res. 2010, 202, 16–24. [Google Scholar] [CrossRef]

- Faez, F.; Ghodsypour, S.H.; O’Brien, C. Vendor selection and order allocation using an integrated fuzzy case-based reasoning and mathematical programming model. Int. J. Prod. Econ. 2009, 121, 395–408. [Google Scholar] [CrossRef]

- Kuo, R.J.; Wang, Y.C.; Tien, F.C. Integration of artificial neural network and MADA methods for green supplier selection. J. Clean Prod. 2010, 18, 1161–1170. [Google Scholar] [CrossRef]

- Taherdoost, H. Decision Making Using the Analytic Hierarchy Process (AHP); A Step by Step Approach. Int. J. Econ. Manag. Syst. 2017, 2, 244–246. [Google Scholar]

- Saaty, T.L. Theory and Applications of the Analytic Network Process: Decision Making with Benefits, Opportunities, Costs, and Risks; RWS Publications: Pittsburgh, PA, USA, 2005. [Google Scholar]

- Cristea, C.; Cristea, M. A multi-criteria decision making approach for supplier selection in the flexible packaging industry. EDP Sci. 2017, 94, 06002. [Google Scholar] [CrossRef]

- Cengiza, A.E.; Ozdemirb, O.A.I.; Kusanb, H.; Cabuka, A. A Multi-Criteria Decision Model for Construction Material Supplier Selection. Proc. Eng. 2017, 194, 296–301. [Google Scholar] [CrossRef]

- Pal, O.; Gupta, A.K.; Garg, R.K. Supplier Selection Criteria and Methods in Supply Chains: A Review. Int. J. Econ. Manag. Eng. 2013, 7. [Google Scholar]

- Frödell, M. Criteria for achieving efficient contractor-supplier relations. Eng. Constr. Archit. Manag. 2011, 18, 381–393. [Google Scholar] [CrossRef]

- Jabbour, A.B.L.S.; Jabbour, C.J.C. Are supplier selection criteria going green? Case studies of companies in Brazil. Ind. Manag. Data Syst. 2009, 109, 477–495. [Google Scholar] [CrossRef]

- Kannan, V.R.; Tan, K.C. Supplier selection and assessment: Their impact on business performance. J. Supply Chain Manag 2002, 38, 11–21. [Google Scholar] [CrossRef]

- Katsikeas, C.C.; Paparoidamis, N.G.; Katsikea, E. Supply source selection criteria: The impact of supplier performance on distributor performance. Ind. Mark. Manag. 2004, 33, 755–764. [Google Scholar] [CrossRef]

- Ku, C.; Chang, C.; Ho, H. Global supplier selection using fuzzy analytic hierarchy process and fuzzy goal programming. Qual. Quant. 2010, 44, 623–640. [Google Scholar] [CrossRef]

- Park, J.; Shin, D.; Chang, T.W.; Park, J. An integrative framework for supplier relationship management. Ind. Manag. Data Syst. 2010, 110, 495–515. [Google Scholar] [CrossRef]

- Wang, W.P. A fuzzy linguistic computing approach to supplier evaluation. Appl. Math. Model 2010, 34, 3130–3141. [Google Scholar] [CrossRef]

- Wu, C.; Barnes, D. Formulating partner selection criteria for agile supply chains: A Dempster-Shafer belief acceptability optimization approach. Int. J. Prod. Econ. 2010, 125, 284–293. [Google Scholar] [CrossRef]

- Weele, A.J.; Van, J. Purchasing and Supply Chain Management: Analysis, Strategy, Planning and Practice; Cengage Learning: Andover, UK, 2014. [Google Scholar]

- Thanaraksakul, W.; Phruksaphanrat, B. Supplier Evaluation Framework Based on Balanced Scorecard with Integrated Corporate Social Responsibility Perspective. In Proceedings of the International Multi Conference of Engineers and Computer Scientist, Kowloon, Hong Kong, 18–20 March 2009. [Google Scholar]

- Beil, D. Supplier selection. Stephen M. Ross Sch. Bus. 2009, 6. [Google Scholar] [CrossRef]

- Florez-Lopez, R. Strategic supplier selection in the added-value perspective: A CI approach. Inf. Sci. (Ny) 2007, 177, 1169–1179. [Google Scholar] [CrossRef]

- Yu, J.-R.; Tsai, C.-C. A decision framework for supplier rating and purchase allocation: A case in the semiconductor industry. Comput. Ind. Eng. 2008, 55, 634–646. [Google Scholar] [CrossRef]

- Cakir, O.; Canbolat, M.S. A web-based decision support system for multi-criteria inventory classification using fuzzy AHP methodology. Expert. Syst. Appl. 2008, 35, 1367–1378. [Google Scholar] [CrossRef]

- Ustun, O.; Demirtas, E.A. Multi-period lot-sizing with supplier selection using achievement scalarizing functions. Comput. Ind. Eng. 2008, 54, 918–931. [Google Scholar] [CrossRef]

- Hsu, C.W.; Hu, A.H. Applying hazardous substance management to supplier selection using analytic network process. J. Clean Prod. 2009, 17, 255–264. [Google Scholar] [CrossRef]

- Wadhwa, V.; Ravindran, A.R. Vendor selection in outsourcing. Comput. Oper. Res. 2007, 34, 3725–3737. [Google Scholar] [CrossRef]

- Chan, F.T.S.; Kumar, N. Global supplier develoment considering risk factors using fuzzy extended AHP-based approach. Omega 2007, 35, 417–431. [Google Scholar] [CrossRef]

- Wang, J.W.; Cheng, C.H.; Huang, K.C. Fuzzy hierarchical TOPSIS for supplier selection. Appl. Soft Comput. 2008, 9, 377–386. [Google Scholar] [CrossRef]

- Xia, W.; Wu, Z. Supplier selection with multiple criteria in volume discount environments. Omega Int. J. Manag. Sci. 2007, 35, 494–504. [Google Scholar] [CrossRef]

- Ha, S.H.; Krishnan, R. A hybrid approach to supplier selection for the maintenance of a competitive supply chain. Expert Syst. Appl 2008, 34, 1303–1311. [Google Scholar] [CrossRef]

- Bottani, E.; Rizzi, A. An adapted multi-criteria approach to suppliers and product selection—An application oriented to lead-time reduction. Int. J. Prod. Econ. 2008, 111, 763–781. [Google Scholar] [CrossRef]

- Watt, D.J.; Kayis, B.; Willey, K. The relative importance of tender evaluation and contractor selection criteria. Int. J. Proj. Manag. 2010, 28, 51–60. [Google Scholar] [CrossRef]

- Sarkar, A.; Mohapatra, P.K.J. Evaluation of supplier capability and performance: A method for supply base reduction. J. Purch. Supply Manag. 2006, 12, 148–163. [Google Scholar] [CrossRef]

- NIST. National Building Information Modeling Standard Version 2; US National Institute of Building Science: Washington, DC, USA, 2012.

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Vaidya, O.; Kumar, S. Analytic hierarchy process: An overview of applications. Eur. J. Oper. Res. 2006, 169, 1–29. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef]

| Please Compare the Level of Relative Importance between Criterion 1 and Criterion 2 | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/5 | 1/4 | 1/3 | 1/2 | 1 | 2 | 3 | 4 | 5 |

| Extremely less important than | Equally important to | Extremely more important than | ||||||

| Please Compare the Level of Relative Performance between Supplier 1 and Supplier 2 | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/5 | 1/4 | 1/3 | 1/2 | 1 | 2 | 3 | 4 | 5 |

| Extremely worse than | Equally good to | Extremely better than | ||||||

| Criteria | Sub-Criteria | Importance Weight | Rank |

|---|---|---|---|

| Cost | Material cost (C1) | 11.80% | 1 |

| Delivery cost (C2) | 11.34% | 2 | |

| Transaction cost (C3) | 10.80% | 3 | |

| Financial strength (FS) | Fixed asset scale (FS1) | 1.63% | 18 |

| Cash flow conditions (FS2) | 2.41% | 14 | |

| Credibility (FS3) | 1.92% | 16 | |

| Financial conditions (FS4) | 3.06% | 12 | |

| Product performance (PP) | Proper function (PP1) | 4.92% | 9 |

| Durability (PP2) | 4.41% | 10 | |

| Appearance (PP3) | 5.59% | 8 | |

| Support services (SS) | Order processing (SS1) | 8.29% | 5 |

| Delivery on time (SS2) | 8.94% | 4 | |

| Follow-up services (SS3) | 7.80% | 6 | |

| Hazards handling mechanism (SS4) | 7.48% | 7 | |

| Quality system (QS) | Level of innovation (QS1) | 1.75% | 17 |

| Quality assurance (QS2) | 3.21% | 11 | |

| Technical standards (QS3) | 2.08% | 15 | |

| Complaint Handling Process (QS4) | 2.57% | 13 |

| Criteria | Weight | Rank |

|---|---|---|

| Cost | 33.93% | 1 |

| Financial strength | 9.03% | 5 |

| Product performance | 14.92% | 3 |

| Support services | 32.51% | 2 |

| Quality system | 9.61% | 4 |

| Supplier 1 | Supplier 2 | Supplier 3 | Supplier 4 | Total | |

|---|---|---|---|---|---|

| Supplier 1 | 1 | 2 | 4 | 5 | 12 |

| Supplier 2 | 1 | 3 | 4 | 8.5 | |

| Supplier 3 | 1 | 1/2 | 2.08 | ||

| Supplier 4 | 1 | 3.45 |

| Supplier 1 | Supplier 2 | Supplier 3 | Supplier 4 | Total | |

|---|---|---|---|---|---|

| Supplier 1 | 1 | 1/2 | 1 | 1 | 3.5 |

| Supplier 2 | 1 | 2 | 2 | 7 | |

| Supplier 3 | 1 | 1 | 3.5 | ||

| Supplier 4 | 1 | 3.5 |

| Supplier 1 | Supplier 2 | Supplier 3 | Supplier 4 | Total | |

|---|---|---|---|---|---|

| Supplier 1 | 1 | 1 | 1/3 | 1/2 | 2.83 |

| Supplier 2 | 1 | 1/2 | 1/2 | 3 | |

| Supplier 3 | 1 | 2 | 8 | ||

| Supplier 4 | 1 | 7 |

| Supplier 1 | Supplier 2 | Supplier 3 | Supplier 4 | Total | |

|---|---|---|---|---|---|

| Supplier 1 | 1 | 1/3 | 1 | 1/2 | 2.83 |

| Supplier 2 | 1 | 3 | 2 | 9 | |

| Supplier 3 | 1 | 2 | 4.3 | ||

| Supplier 4 | 1 | 4 |

| Supplier 1 | Supplier 2 | Supplier 3 | Supplier 4 | Total | |

|---|---|---|---|---|---|

| Supplier 1 | 1 | 1 | 1/2 | 1/2 | 3 |

| Supplier 2 | 1 | 1/2 | 1/2 | 3 | |

| Supplier 3 | 1 | 1 | 6 | ||

| Supplier 4 | 1 | 6 |

| Suppliers | Cost | Financial Strength | Product Performance | Support Services | Quality System | Total | Rank |

|---|---|---|---|---|---|---|---|

| Supplier 1 | 4.072 | 0.316 | 0.422 | 0.920 | 0.288 | 6.018 | 2 |

| Supplier 2 | 2.884 | 0.632 | 0.448 | 2.926 | 0.288 | 7.178 | 1 |

| Supplier 3 | 0.706 | 0.316 | 1.194 | 1.398 | 0.577 | 4.190 | 4 |

| Supplier 4 | 1.171 | 0.316 | 1.044 | 1.300 | 0.577 | 4.408 | 3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, L.; Liu, Z.; Mbachu, J. Optimization of the Supplier Selection Process in Prefabrication Using BIM. Buildings 2019, 9, 222. https://doi.org/10.3390/buildings9100222

Zhao L, Liu Z, Mbachu J. Optimization of the Supplier Selection Process in Prefabrication Using BIM. Buildings. 2019; 9(10):222. https://doi.org/10.3390/buildings9100222

Chicago/Turabian StyleZhao, Linlin, Zhansheng Liu, and Jasper Mbachu. 2019. "Optimization of the Supplier Selection Process in Prefabrication Using BIM" Buildings 9, no. 10: 222. https://doi.org/10.3390/buildings9100222

APA StyleZhao, L., Liu, Z., & Mbachu, J. (2019). Optimization of the Supplier Selection Process in Prefabrication Using BIM. Buildings, 9(10), 222. https://doi.org/10.3390/buildings9100222