Mechanical and Durability Properties of Green Star Concretes

Abstract

1. Introduction

2. Materials and Methods

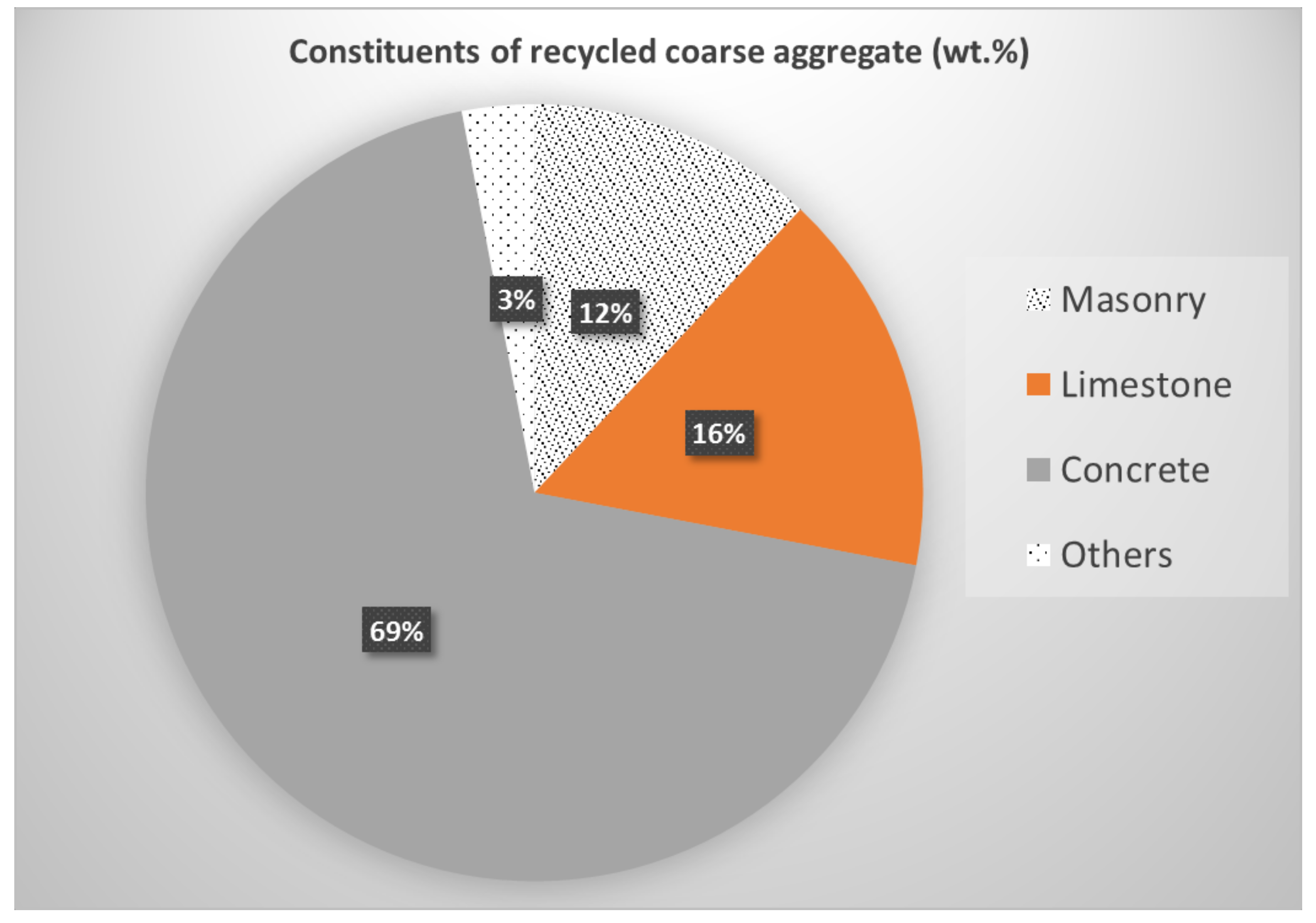

2.1. Materials

2.2. Methods

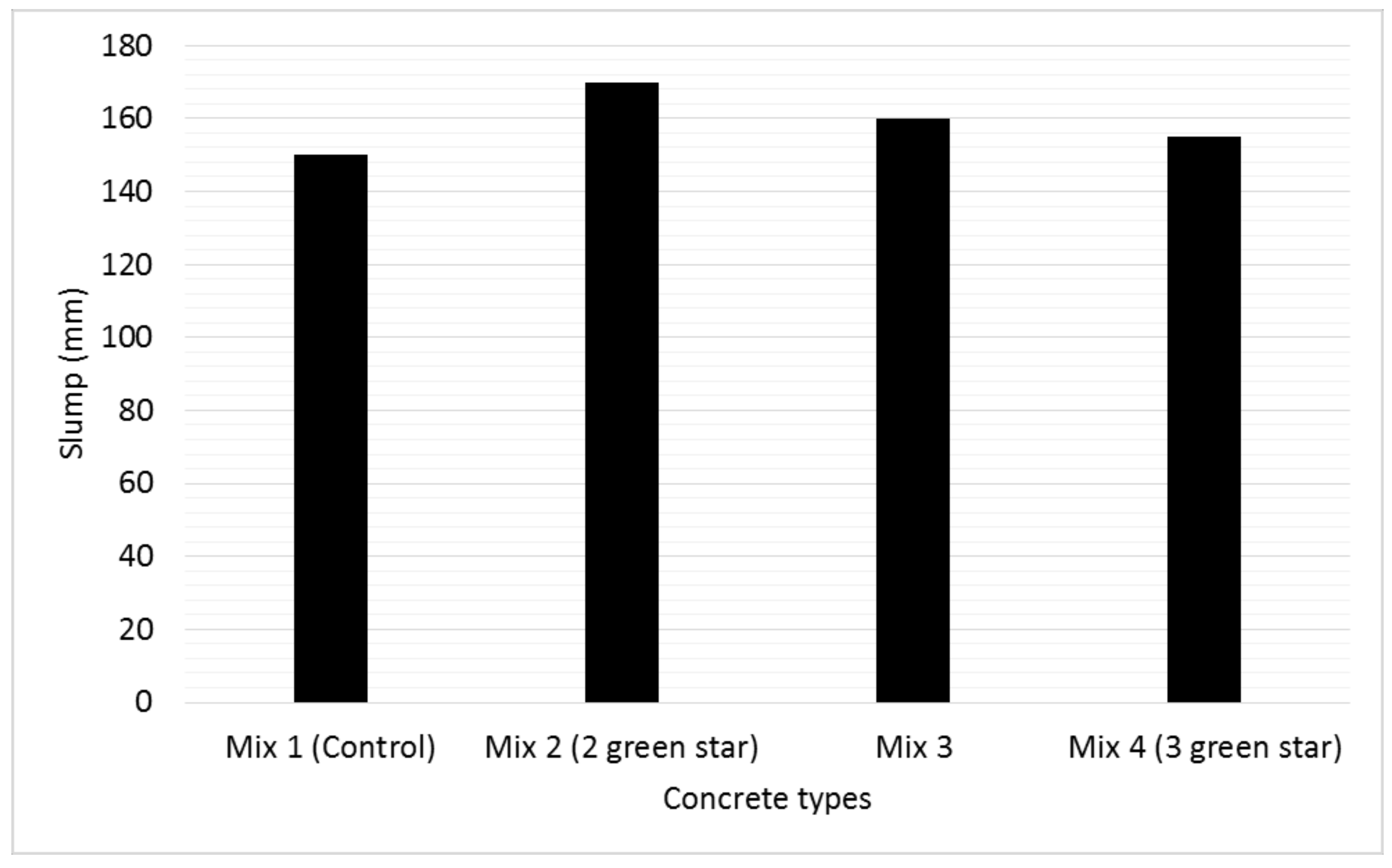

3. Results and Discussion

4. Conclusions

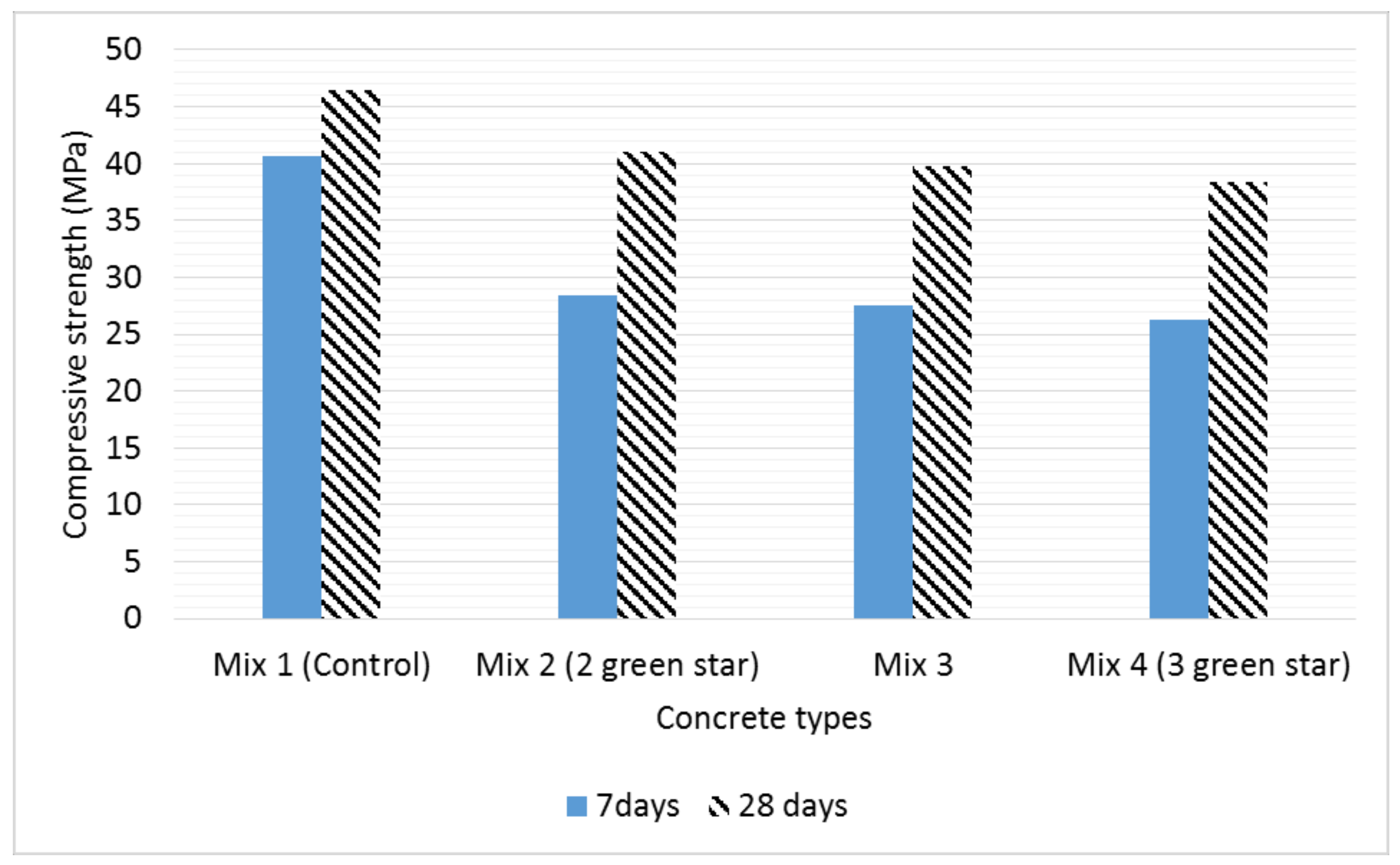

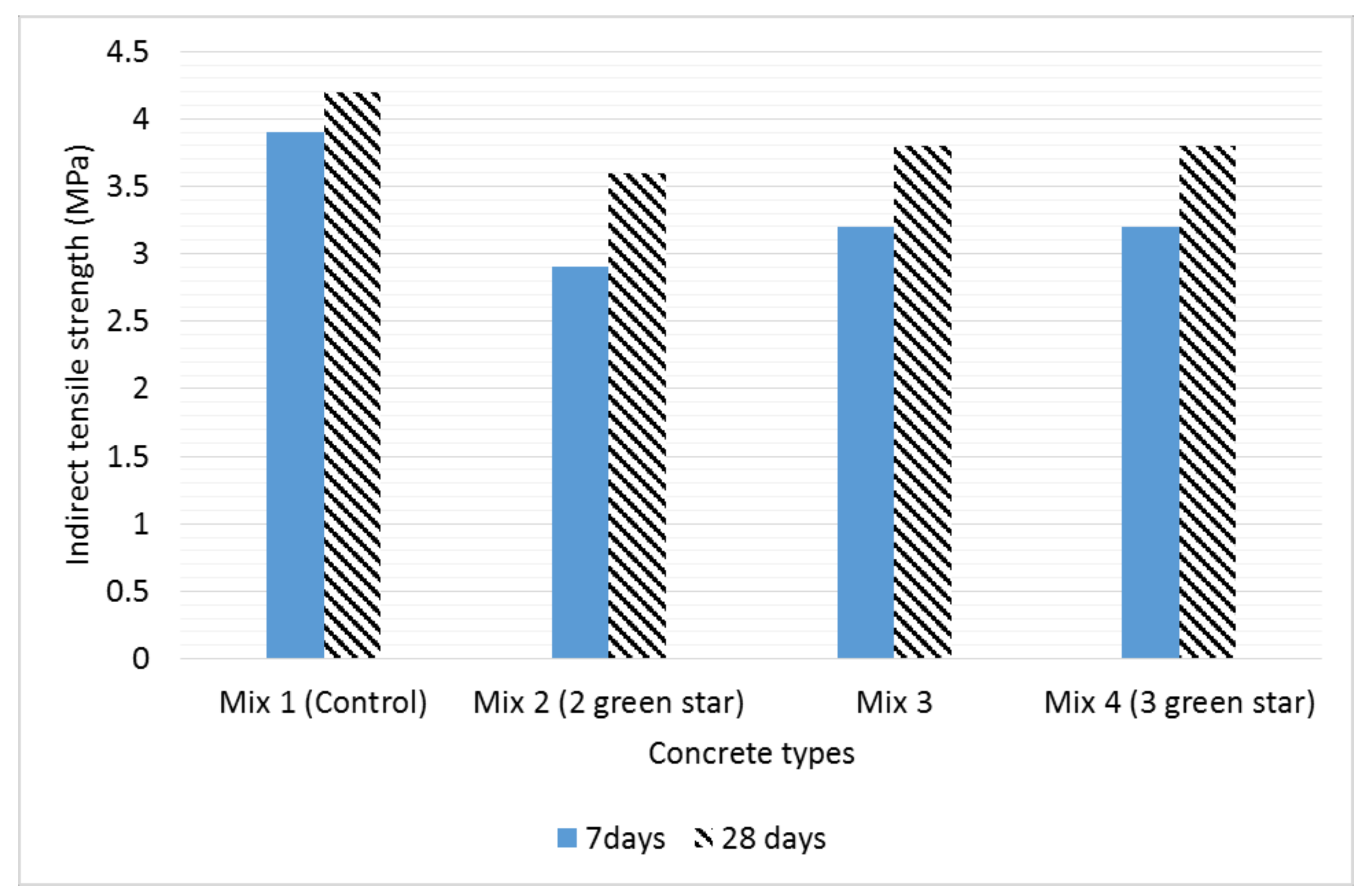

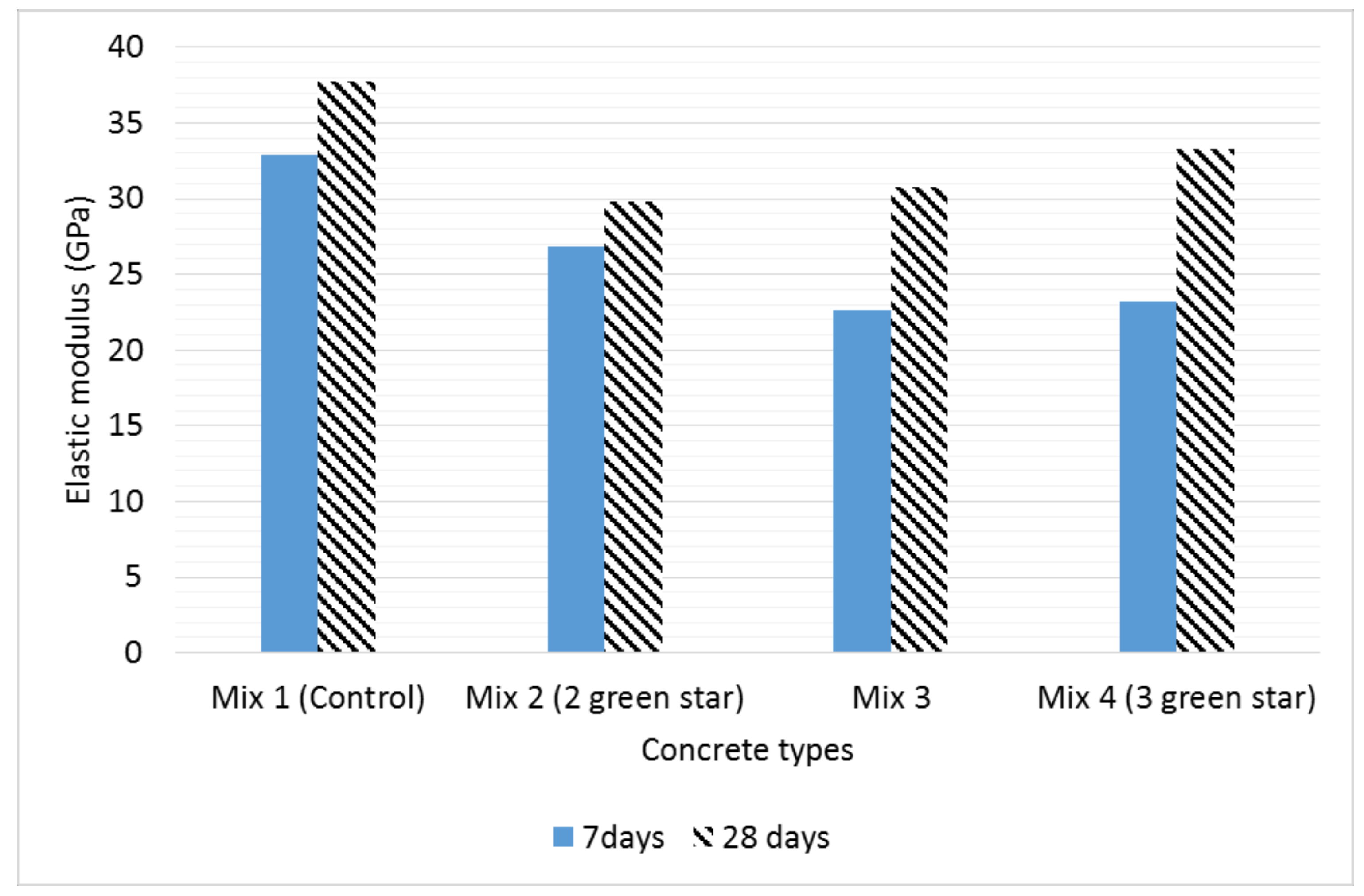

- Green star concretes exhibited reduction in compressive strength, indirect tensile strength and elastic modulus at both 7 and 28 days compared to control concrete. However, the reduction at 7 days of green star concrete is much higher than at 28 days. Formation of additional hydration products and particle packing due to pozzolianic reaction and small particle size of slag are contributed to the increase in above mechanical properties at 28 days. Three green star concrete exhibited about 18%, 10% and 12% reduction in compressive strength, indirect tensile strength and elastic modulus, respectively at 28 days compared to control concrete while containing 40% less OPC, 40% less NCA and 50% less fresh water.

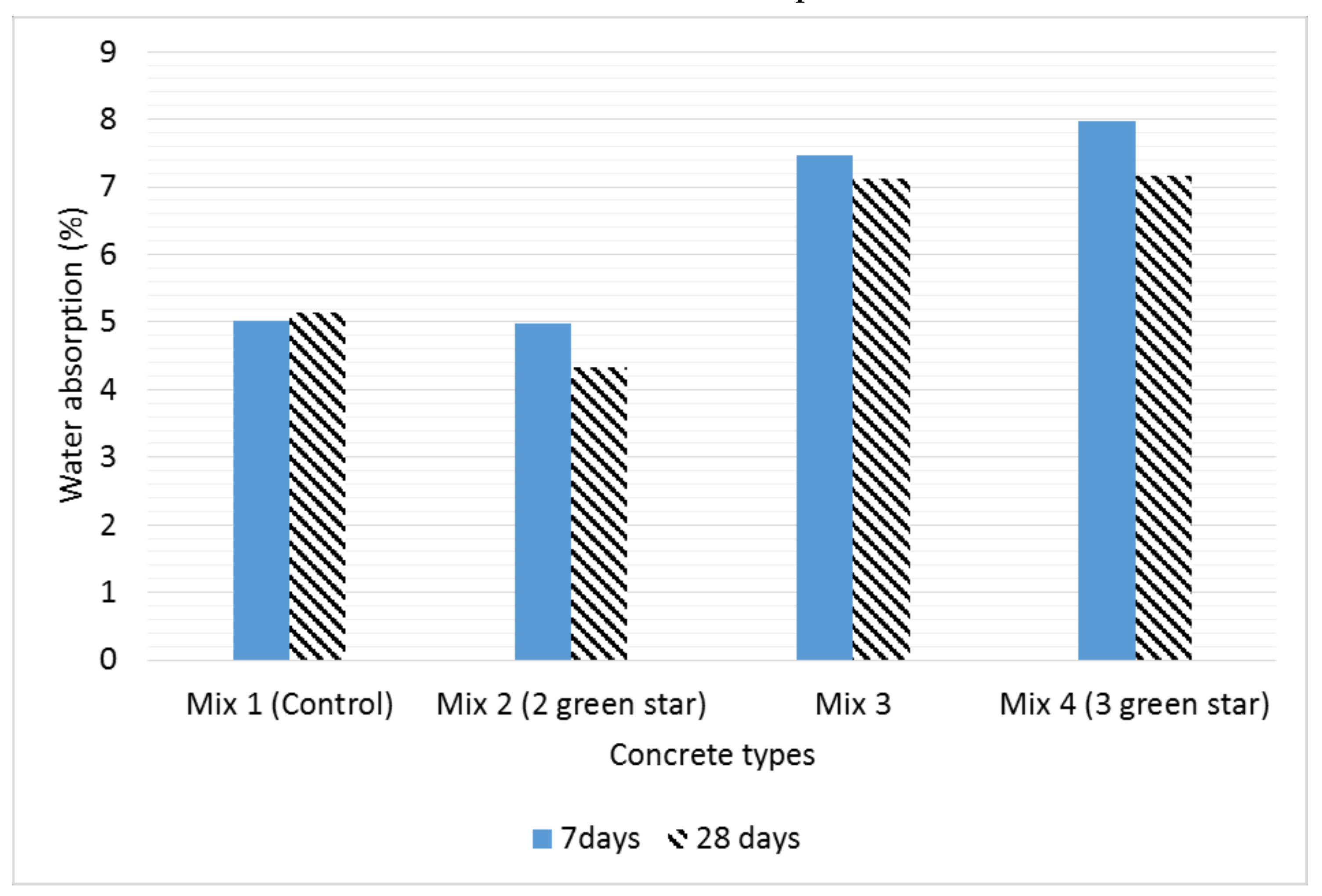

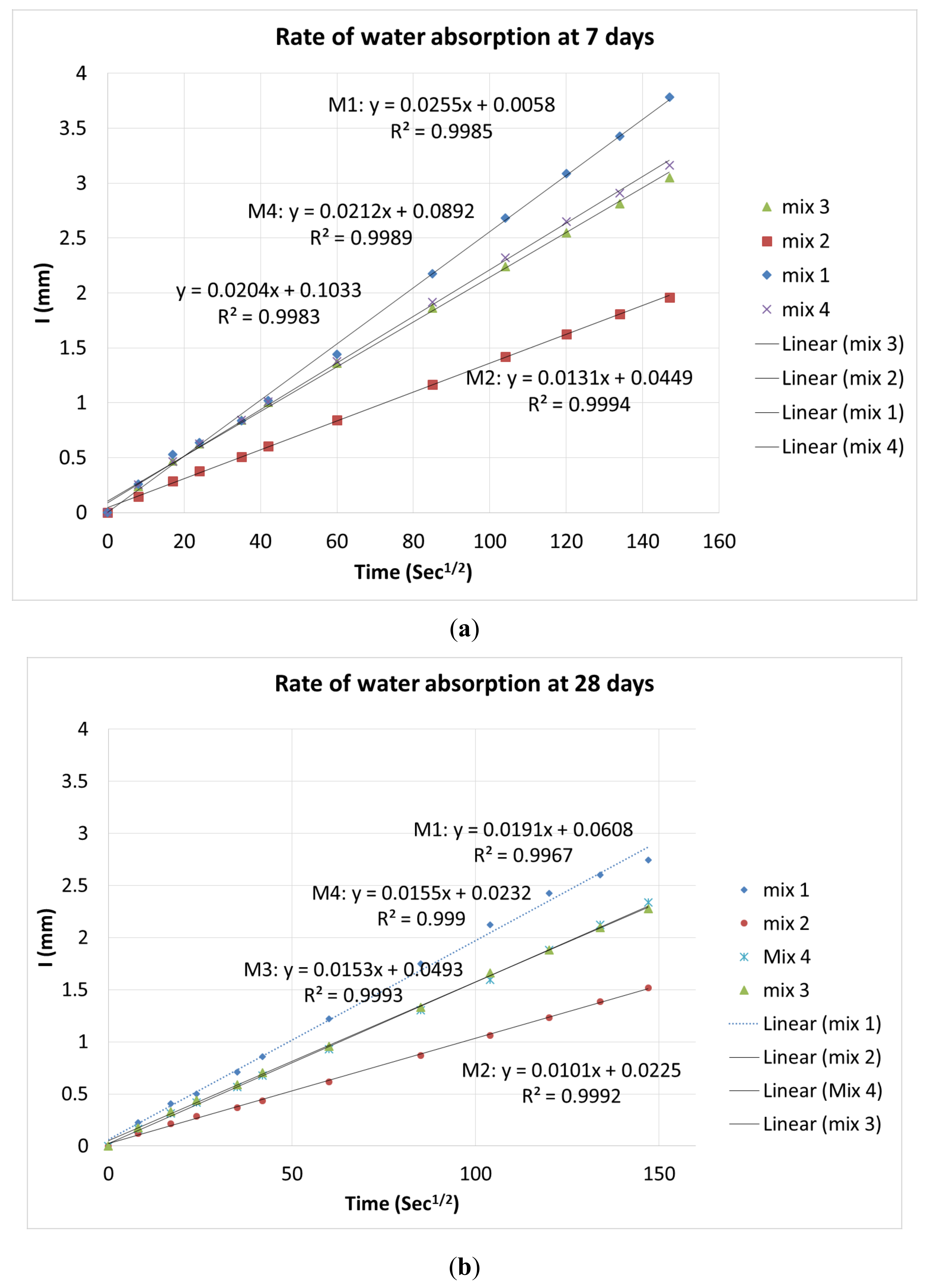

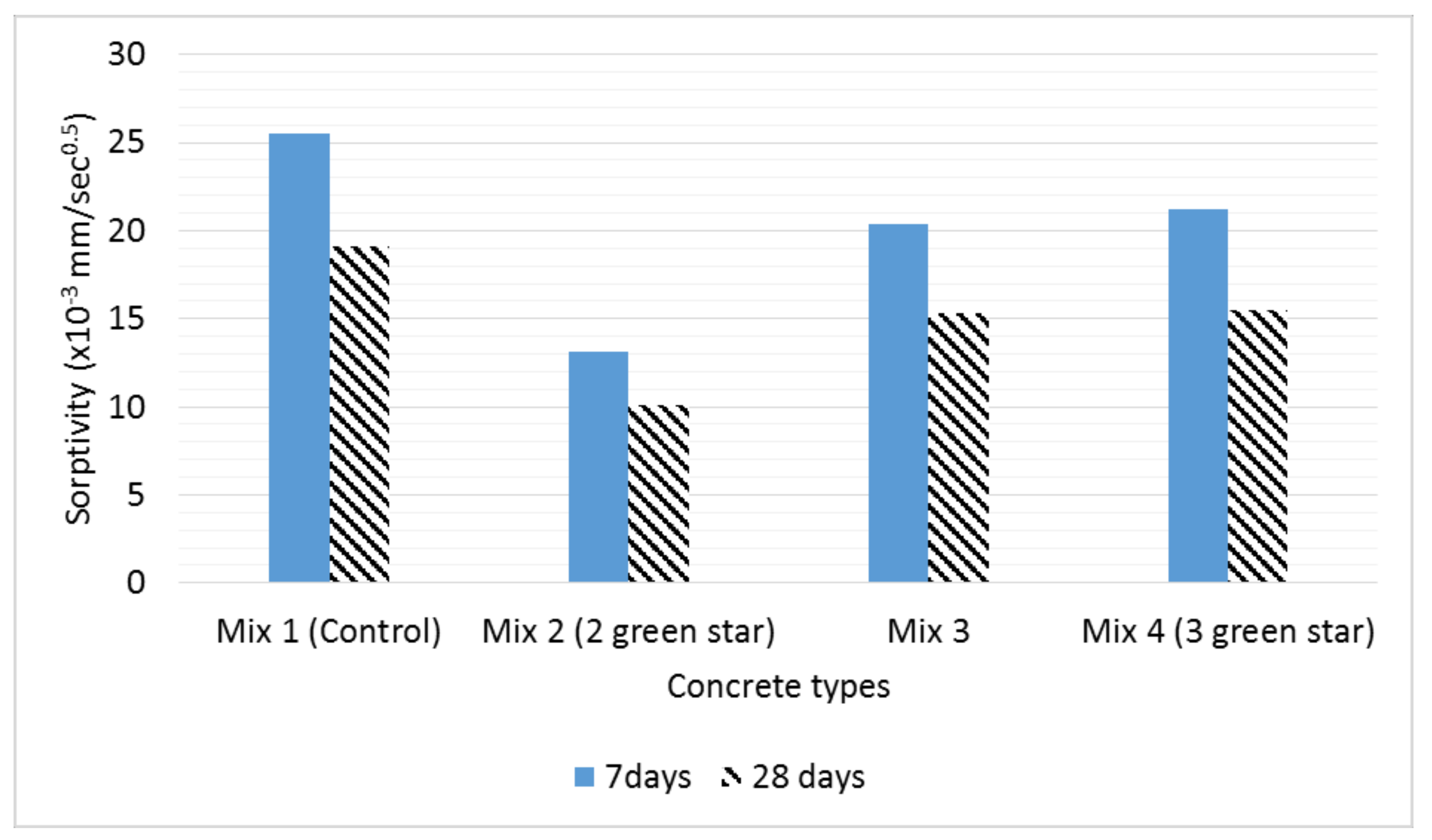

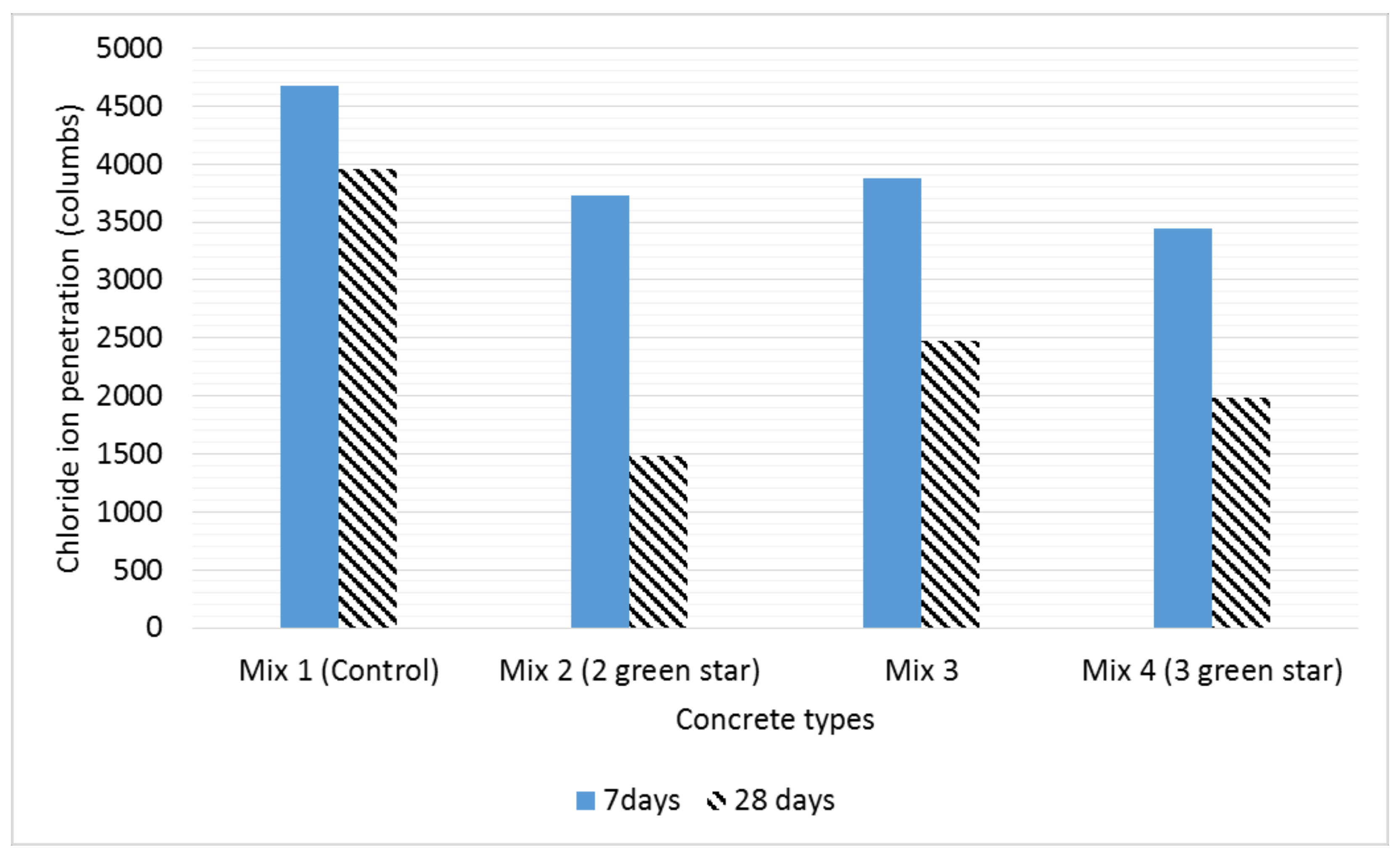

- The two green star concrete containing 40% slag exhibited lower water absorption, sorptivity and chloride permeability than control concrete at both ages, while three green star concrete containing 40% slag, 40% RCA and 50% concrete wash water exhibited better durability properties at both ages except the water absorption which is about 25% higher than two green star concrete at 28 days. The presence of 40% RCA, whose water absorption capacity is much higher than the NCA, is the reason for such increase in water absorption.

- Both two and three green star concretes exhibited 28 days compressive strength of about 40 MPa and much lower chloride permeability than control concrete. Therefore, these green concretes can be used in structural application with good resistance against reinforcement corrosion.

Funding

Acknowledgments

Conflicts of Interest

References

- Moretti, L.; Caro, S. Critical analysis of the life cycle assessment of the Italian cement industry. J. Cleaner Prod. 2017, 152, 198–210. [Google Scholar] [CrossRef]

- Limbachiya, M.; Bostanci, S.C.; Kew, H. Suitability of BS EN197 CEM II and CEM V cement for production of low carbon concrete. Constr. Build. Mater. 2014, 71, 397–405. [Google Scholar] [CrossRef]

- Malhotra, V.M. Sustainable development and concrete technology. Concr. Int. 2002, 24, 1–22. [Google Scholar]

- Malhotra, V.M.; Mehta, P.K. High-Performance, High-Volume Fly Ash Concrete: Materials, Mixture Proportioning, Properties, Construction Practice, and Case Histories; HVFA High-Performance-Inc.: Ottawa, ON, Canada, 2002. [Google Scholar]

- Siddique, R. Performance characteristics of high-volume class F fly ash concrete. Cem. Concr. Res. 2004, 34, 487–493. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S.; Chan, D. Influence of fly ash as a cement addition on the hardened properties of recycled aggregate concrete. Mater. Struct. 2007, 41, 1191–1201. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Supit, S.W.M. Compressive strength and durability properties of high volume fly ash concretes containing ultrafine fly ash. Constr. Build. Mater. 2015, 82, 192–205. [Google Scholar] [CrossRef]

- Berndt, M.L. Properties of sustainable concrete containing fly ash, slag and recycled concrete aggregate. Constr. Build Mater. 2009, 23, 2606–2613. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Influence of mineral additions on the performance of 100% recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2869–2876. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Sagoe-Crentsil, K.K.; Brown, T.; Taylor, A.H. Performance of concrete made with commercially produced coarse recycled concrete aggregate. Cement Concr. Res. 2001, 31, 707–712. [Google Scholar] [CrossRef]

- Ahmed, S.F.U. Properties of concrete containing construction and demolition wastes and fly ash. J. Mater. Civ. Eng. 2013, 25, 1864–1870. [Google Scholar] [CrossRef]

- Ahmed, S.F.U. Properties of concrete containing recycled fine aggregate and fly ash. J. Solid Waste Technol. Manage. 2014, 40, 70–78. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Odoh, H.; Than, A.B. Effect of nano silica on properties of concrete containing recycled coarse aggregates. Constr. Mater. 2014, 168, 68–76. [Google Scholar] [CrossRef]

- Shaikh, F.U.A. Effect of ultrafine fly ash on properties of concretes containing construction and demolition wastes as coarse aggregates. Struct. Concr. 2016, 17, 116–122. [Google Scholar] [CrossRef]

- Zhang, W.; Ingham, J.M. Using recycled concrete aggregates in New Zealand ready-mix concrete production. J. Mater. Civ. Eng. 2010, 22, 443–450. [Google Scholar] [CrossRef]

- Kadir, A.A.; Shahidan, S.; Yee, L.H.; Hassan, M.I.H.; Abdullah, M.A. The effect on slurry water as a fresh water replacement in concrete properties. IOP Conf. Ser. Mater. Sci. Eng. 2016, 133, 012041. [Google Scholar] [CrossRef]

- Al-jabri, K.S.; Al-saidy, A.H.; Taha, R.; Al-kemyani, A.J. Effect of using waste water on the properties of high strength concrete. Procedia Eng. 2011, 14, 370–376. [Google Scholar] [CrossRef]

- Lobo, C.; Mullings, G.M. Recycled water in ready mixed concrete operations. Concr. Focus 2003, 2, 1–10. [Google Scholar]

- Revised green star concrete credit, Green building council Australia. Available online: https://www.gbca.org.au/green-star/materials-category/revised-green-star-concrete-credit/34008.htm (accessed on 30 October 2017).

- Water Research Centre National Secondary Drinking Water Standards. Available online: https://www.water-research.net/index.php/standards/secondary-standards (accessed on 9 July 2018).

- AS 1012.9. Determination of Compressive Strength of Concrete; Australia Standards: Sydney, Australia, 2010. [Google Scholar]

- AS 1012.10. Determination of Indirect Tensile Strength of Concrete; Australia Standards: Sydney, Australia, 2010. [Google Scholar]

- AS 1012.17. Determination of Elastic Modulus of Concrete; Australia Standards: Sydney, Australia, 2010. [Google Scholar]

- ASTM C1585-13. Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic Cement Concretes; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM C1202. Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride ion Penetration; American Society for Testing and Materials: Philadelphia, PA, USA, 2012. [Google Scholar]

- AS 1012.21. Determination of Water Absorption and Apparent Volume of Permeable Voids in Hardened Concrete; Australia Standards: Sydney, Australia, 1999. [Google Scholar]

| Series | Mix Proportions in Kg/m3 | ||||||

|---|---|---|---|---|---|---|---|

| OPC | Slag | Fine Aggregate | Natural Coarse Aggregate | Recycled Coarse Aggregate | Tap Water | Wash Water | |

| Mix 1 (Control) | 413 | - | 512 | 1254 | - | 190 | - |

| Mix 2 (2 Green star) | 248 | 165 | 512 | 1254 | - | 190 | - |

| Mix 3 | 248 | 165 | 512 | 752 | 502 | 190 | - |

| Mix 4 (3 Green star) | 248 | 165 | 512 | 752 | 502 | 95 | 95 |

| Chemical Analysis | OPC (wt %) | Slag (wt %) |

|---|---|---|

| SiO2 | 21.1 | 32.45 |

| Al2O3 | 5.24 | 13.56 |

| Fe2O3 | 3.1 | 0.82 |

| CaO | 64.39 | 41.22 |

| MgO | 1.1 | 5.1 |

| K2O | 0.57 | 0.35 |

| Na2O | 0.23 | 0.27 |

| SO3 | 2.52 | 3.2 |

| LOI | 1.22 | 1.11 |

| Specific gravity | 3.17 | 3.00 |

| Properties | NCA | RCA | NFA |

|---|---|---|---|

| Un-compacted bulk density (kg/m3) | 1547 | 1301 | 1498 |

| Water absorption (%) | 1.6 | 7.1 | 1.16 |

| Chemical Properties | Tap Water | Wash Water |

|---|---|---|

| pH value | 8.95 | 12.26 |

| Chloride content (mg/L) | 60 | 61 |

| Turbidity (NTU) | - | 41 |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shaikh, F. Mechanical and Durability Properties of Green Star Concretes. Buildings 2018, 8, 111. https://doi.org/10.3390/buildings8080111

Shaikh F. Mechanical and Durability Properties of Green Star Concretes. Buildings. 2018; 8(8):111. https://doi.org/10.3390/buildings8080111

Chicago/Turabian StyleShaikh, Faiz. 2018. "Mechanical and Durability Properties of Green Star Concretes" Buildings 8, no. 8: 111. https://doi.org/10.3390/buildings8080111

APA StyleShaikh, F. (2018). Mechanical and Durability Properties of Green Star Concretes. Buildings, 8(8), 111. https://doi.org/10.3390/buildings8080111