Abstract

This paper presents work undertaken as part of the European H2020 project OptEEmAL (Optimized Energy Efficient Design Platform for Refurbishment at District Level), toward development of a decision-support platform for building and district refurbishment interventions. We describe a methodology for generation and evaluation of refurbishment scenarios for building and districts with particular emphasis on “active” energy conservation measures (i.e., installation or replacement of heating, ventilation, air conditioning (HVAC) systems) and related controls. The impact of HVAC and controls on energy and economic key performance indicators are usually neglected or very simplified in existing energy simulation tools. We apply a model-based approach to evaluate key-performance indicators related to energy consumption and energy costs in buildings and districts, such that possible refurbishment alternatives can be easily evaluated, thereby showing how a smart decision support tool will allow stakeholders to compare multiple alternatives quickly. By considering relevant case studies at building and district level, including refurbishment of heating and cooling plants, we highlight, in a simulation-based study, how the deployment of efficiency-based controls enable significant energy savings thanks to the exploitation of the model-based approach. This way, additional motivations for energy savings and ultimately for new investments in energy-related technologies are provided.

1. Introduction

Buildings account for 40% of the European Union’s (EU) energy consumption, 36% of its CO2 emissions, and 55% of its electricity consumption. The EU building stock is relatively old, with more than 40% of it comprising buildings built before 1960 and 90% before 1990; because of different regulatory requirements and performance degradation over time, older buildings typically use more energy than newer buildings. Renovation of the existing building stock for upgrading energy performance is key to achieving EU’s climate and energy targets. However, it remains challenging to estimate using existing methodologies the potential energy savings and concomitant return on investment. Despite EU’s policy efforts to increase the renovation rate, the actual rates are below target, and this is attributed to both technical and non-technical barriers. There is a clear need (and lack, at present) for holistic decision support tools that take into account the building or district as an integrated system and provide reliable retrofitting decision support.

Recent papers have reported research related to design and development of a platform or tools for energy efficiency refurbishment of buildings and districts [1,2,3,4]. In these contributions, the use of standardized calculation methodologies and multi-objective optimization algorithms to determine the benefit of different retrofit interventions and compute energy performance indicators are the key ideas to achieve results, which can greatly facilitate the work of engineers and designers.

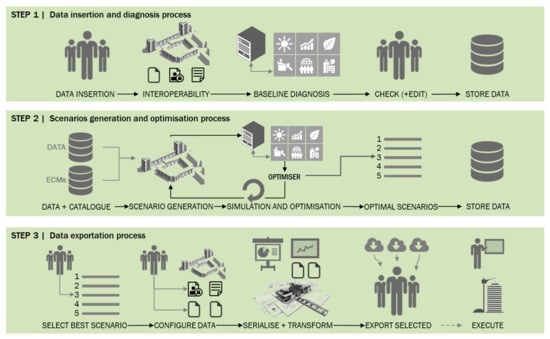

OptEEmAL, a project funded under the EU’s Horizon 2020 programme, is developing an optimization and decision support platform for energetic refurbishment at building and district level. As depicted in Figure 1, the OptEEmAL platform supports the implementation of a three-step process: (1) data-insertion and diagnosis—here, users add prerequisite information through user-friendly Graphical User Interfaces (e.g., IFC data files for each building of interest and CityGML file for the district), information that is processed to generate and evaluate the baseline scenario (current situation of the district) by invoking external tools to perform simulations and obtain a series of district performance indicators (DPIs); (2) scenarios generation and optimization—an optimization algorithm generates candidate retrofit scenarios (combinations of energy conversion measures) that are applied to the baseline and evaluated in the same way as the baseline scenario (external tools invocation and DPIs retrieve), once the optimization termination criteria have been met, the best performing scenarios are stored to the platform; (3) data exportation process—the user selects the preferred scenario from the set generated in step 2, information of which is serialized and transformed to generate the outcomes to be provided to the platform users. The output is adequate information for the stakeholders to implement the subsequent phases of the retrofitting project.

Figure 1.

Steps enabling the deployment of OptEEmAL methodology. ECM—energy conservation measures.

The decision support platform integrates interoperable modules and tools while involving all relevant stakeholders to deliver an optimized design that meets end-user specified objectives and targets. Within OptEEmAL an energy conservation measures (ECMs) catalogue is developed. The catalogue contains measures for building and district retrofitting including passive and active ECMs, renewables, and control strategies for post-retrofit efficient operation. Different retrofit scenarios are automatically generated by possible combination of entries from the ECM catalogue and evaluated using simulation tools for the calculation of district performance indicators (DPIs). The list of DPIs supported goes beyond energetic ones, to lifecycle cost, social, and environmental; as such, a multi-faceted view of the impact of retrofitting options to DPIs can be realized.

This paper presents the developments in the area of modelling and simulation of retrofit scenarios to meet the OptEEmAL objectives.

The methodology for the generation and analysis of retrofit scenarios is discussed focusing on tools and process followed in the selection and evaluation using a comprehensive set of DPIs. The approach is to generate multiple configurations for building and district retrofit designs based on a combination of passive, active, renewables, and control measures and their comparative assessment. Passive ECMs include upgrades to building envelope including internal and external insulation measures on the façade. Active ECMs include installation of new heating, ventilation, air conditioning systems (HVACs) or replacement of existing units. Associated with active ECMs are some control ECMs that enable one to determine the way the overall system is controlled to ensure efficient operation. This includes the effects of changes to pre-defined (baseline) set-points and energy consumption (load) sharing between different supply units, as well as environmental condition variations. In this way, multi-domain DPIs (e.g., energy-based and economic-based aspects) can be jointly analyzed and optimized with the objective of maximizing the impact of the retrofit interventions. A customized stochastic optimization algorithm will enable multi-objective optimization and Pareto-Front analysis. This algorithm uses some of the concepts and ideas from Geem et al. [5].

Beside the development of a customized design platform for selecting most appropriate retrofitting options, we aim at developing a methodology, a set of applicable models, and a process to automate the generation and execution of simulation models. For this reason, the paper will elaborate on existing tools and simulation flow before discussing in more detail an approach for model-based refurbishment scenarios assessment and simulation of optimized controls for efficient operation of building and district level HVACs. The inclusion of control strategies that can be implemented in modern energy management systems (EMS) is one major element of novelty of the proposed methodology and tool. These controls can be seen as a particular class of ECMs enabling the improvement of energy efficiency and the reduction of energy costs compared with the pre-retrofit system operation. The importance of such a class of controls is highlighted in a recent literature review [6], which reports energy savings potential in the order of 15% for optimized operation of HVAC systems. Modelling aspects also need to be investigated to generate a comprehensive set of models that can evaluate in automatic fashion refurbishment scenarios. In particular, we will consider the individual modelling of household consumption and their subsequent aggregation at district level scale [7].

In this paper, we propose a methodology and tool to generate multiple HVAC configurations out of a catalogue of commercial products, which can supply a given district or building load and simulate them to determine key performance indicators [8,9,10]. HVAC units included in the catalogue are part of an ECM catalogue [11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27] and are characterized by their size and variable efficiencies or coefficient of performances. In addition, optimized controls are included among the ECMs to be automatically evaluated when applicable to particular system configurations.

Several papers have appeared describing the application of multi-objective optimization algorithms to the problem of building/district retrofitting; high-fidelity simulation models are usually not included in the decision support tool (see e.g., [1] or [2,4]), both for building/district energy demand (EnergyPlus in this work) and for HVAC units and related controls (Matlab models in this work). Compared with Carli et al. [1], we can assess the actual costs and energy performances of commercial HVAC units; whereas in Carli et al. [1], costs are taken into account only as costs per kW. Compared with Carli et al. [1] and Dall’O et al. [4], we use detailed simulation tools and models to calculate key performance indicators instead of simplified or standardized equations.

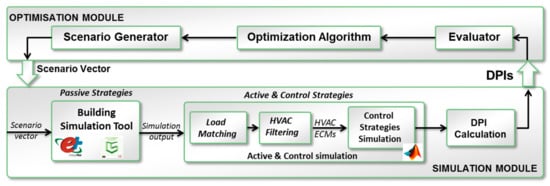

The above-described contributions fit into a decision support platform including an optimization module and a simulation module, shown in Figure 2. In particular, the optimization module generates a number of different refurbishment scenarios, each of them including a combination of passive, active, and control ECMs out of the catalogue, which will be introduced in Section 3. Note that the platform is developed to be used by engineers, architects, designers, facility managers, and building owners, who are involved in the decision-making process of district/building refurbishment. A general knowledge of the sites to be refurbished is helpful to apply the presented methodology and tool more effectively, given the large number of scenarios that can be generated using the built-in ECM catalogues.

Figure 2.

Decision-support platform based on simulation and optimization modules. DPI—district performance indicator; HVAC—heating, ventilation, air conditioning.

Accurate modelling of system components along with their controls, as well as the optimization algorithms, are the key ingredients to be incorporated in a decision support platform for refurbishment design [28,29,30,31,32,33,34,35,36,37,38,39,40,41,42]. We focus on the simulation procedure and ascertaining the impact HVAC and controls to have pertinent performance indicators. The impact of these elements on energy and economic key performance indicators is usually neglected or very simplified in existing building retrofitting tools.

The paper has the following structure: in Section 2, relevant district performance indicators (DPIs) are introduced and those used in this paper are selected. In Section 3, the proposed energy conservation measures (ECMs) catalogue is introduced, thereby highlighting the information that the proposed methodology and tool is using to determine possible refurbishment scenarios. Section 4 discusses the proposed approach for the generation and evaluation of refurbishment scenarios. Section 5 discusses how simulation of active and control ECMs is used to calculate DPIs for the different scenarios configurations. The final section summarizes conclusions of the paper and points to further work. Section 6 introduces the model-based approach and provides examples of how simulation models are used by control ECMs. Section 7 includes results of application of the proposed methodology to selected test cases, providing an extensive analysis of refurbishment scenarios in the case of both cooling and heating. In particular, for the case of cooling, an improved algorithm for chiller plant optimized sequencing is validated, accounting for multiple possible configurations of chillers highlighting the energy savings with respect to the standard predetermined sequencing control.

2. District Performance Indicators

Evaluation of specific key energy performance indicators at building and district level has been the subject of recent research efforts [8,9,10]. Assessment of building and district energy performances using relevant key performance indicators is traditionally performed through energy audits and demand and savings calculations [8]. More recently, building energy performance has been assessed considering different heating systems, as well as renewables [9]. At district level, mathematical models for predicting the heat demand based only on average daily temperature and historical data of natural gas consumption have been developed [10].

In OptEEmAL, with the aim of further expanding the work found in the published literature, we defined a comprehensive set of DPIs, which are grouped in the following categories: Energy, Comfort, Environmental, Economic, Social, Urban and Global. For each of the categories, the list of DPIs of interest is listed in Table 1.

Table 1.

District Performance Indicators defined in the OptEEmAL project.

In this paper, because of space limitations, we focus on the Energy Consumption and the Energy Cost. These are two of the most important DPIs, affected by the choice of the Active and Control ECMs. Starting from the Energy Demand, the total energy required to maintain predefined conditions to all of the conditioned building spaces in the building or district, and more in particular, considering the peak thermal load and the thermal power profile (in Watts) for every building space in the district, we determine the Final Energy Consumption as the total energy consumption of the real heating/cooling systems installed in the building spaces of the district, taking into account system control rules, efficiencies, and coefficients of performances. Other Energy related DPIs will be taken into account in evaluating other case studies in the future, such as the degree of energetic self-supply, the Net fossil energy consumed, the Total energy use per capita, the Energy demand covered by renewable sources, the Total residential natural gas energy use per capita, and so on.

Relevant cost-related DPIs include the Operational energy cost, the Investments, the Life cycle cost, the Return on investment, and the Total energy cost. In this paper, the Operational energy cost is selected; the number of monetary units required to operate a particular district refurbishment solution (for example, in one-year period), because it is affected by system control strategies and is also required to calculate secondary DPIs, such as the return on investment and the total energy cost.

Finally, we highlight that the decision-support tool aggregates the key performance indicators of single buildings to calculate the corresponding district performance indicators related to the whole district. Furthermore, the energy supply systems considered can be building-level (each building has its supply plant) or district-level (there is at least one district plant shared between buildings).

3. Energy Conservation Measures

The published literature reports several studies concerning the application of various ECMs to improve the energy performance of buildings and districts. Traditionally, available ECMs have included upgrades to building insulation, as well as installation or replacement of HVAC units [11,12,13,14,15]. In Iqbal and Al-Homoud [11], different types of HVAC systems were evaluated using simulation software in five office buildings located in Saudi Arabia. In Lam et al. [12], the influence of indoor design temperature, electric lighting, and chiller coefficients of performance (COP) were considered to evaluate the corresponding energy savings. In Difs et al. [13], three ECMs were considered: heat load control, attic insulation, and electricity savings. Additional room for energy savings was identified in Shimoda et al. [14] by taking into account not only appliances, but also changes in occupants’ activities. Finally, a concept to automatically generate combinations of ECMs using an automated tool so that energy savings can be achieved was described in Siddharth et al. [15].

The refurbishment process considered in OptEEmAL takes into account an ECM catalogue—a database containing most of the energy efficiency improvement strategies currently used. In this catalogue, the Energy Conservation Measures have been divided in three general groups: (1) Passive ECMs; (2) Renewable ECMs; and (3) Active and Control ECMs.

Passive ECMs are designed to provide a significant reduction of the energy demand for heating and cooling, independently of the equipment that will be installed. These strategies rely on the increment of the thermal resistance of the envelope or the replacement of the current windows, and the reduction of infiltration. Passive strategies include upgrades on façade, roof, ground floor, and openings. Renewable refurbishment strategies are based on the installation of sustainable sources of energy such as: wind, sun, water, and geothermal, to generate energy. Active ECMs include the replacement of current energy generation systems by new systems with increased efficiency and/or other energy sources with a lower environmental impact or lower fuel cost. In particular, we consider the replacement of existing HVAC systems with the following units: natural gas boiler, condensing natural gas boiler, biomass boiler, diesel boiler, natural gas Combined Heat Power CHP unit, and heat pumps. Each of the listed types includes commercial units of different sizes.

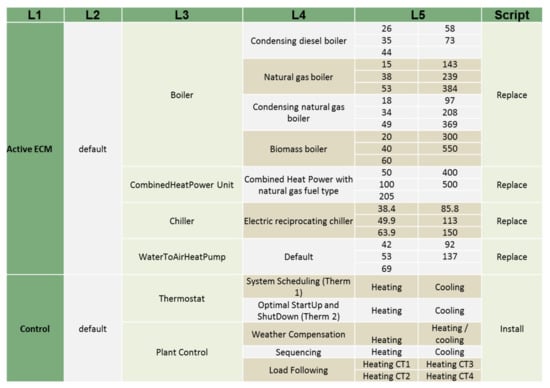

The Control ECMs are the control methods applicable to the selected set of active ECMs and enable the expected and/or optimized system operation. Five control-related ECMs were selected for implementation in the optimization platform: system scheduling [16,17]; optimal start-up and shut-down [18,19]; weather compensation [20,21]; load following [22,23]; and sequencing control [24,25,26,27]. The first two ECMs modify the heating or cooling system scheduling with respect to the initial situation. The weather compensation accounts for the hot and chilled water loop control; in particular, they vary the water temperature set point depending on the outdoor conditions. Load-following and sequencing control are used to coordinate two or more supply equipment such that the energy demand profile is met. Classic examples of load-following and sequencing control are the heat lead operation of CHP [23] and the chiller plant staging [24], respectively. In this paper, we show examples of the latter two, aiming at calculating energy consumption and energy cost for different supply system configurations. An example of implemented Active and Control ECM catalogue is shown in Figure 2. The five levels L1–L5 (Figure 2) were defined for implementation in the OptEEmAL tool, namely Group (L1), Location (L2), Category (L3), Measure Type (L4), and Attributes (L5). Note that L5 includes the actual boiler and HVAC units’ sizes included in the ECM catalogue. Furthermore, the ECM can be a replacement of existing equipment or new installation, see last column in Figure 3. Note that multiple instances of control can be present within the same category to account for different combinations of HVAC (for example CT1, CT2, CT3 and CT4 in the load following entry).

Figure 3.

Example of Active and Control ECM catalogue.

4. Methodology for Refurbishment Scenarios Generation and Model-Based Evaluation

In the literature a number of approaches are reported for the simulation of building/district energy systems and related controls that exploit physics-based and/or reduced-order models. Relevant model parameters need to be properly determined and calibrated to match those of the considered case study [28,29,30,31].

The simulation module included in the block diagram of Figure 2 includes open-source tools such as EnergyPlus, as well as additional components, namely, (1) a combinatorial algorithm for determining the exact list of commercial HVACs of specified type(s) out of the implemented catalogue, which can supply the simulated building/district thermal load; and (2) a set of simulation models implementing the control ECMs mentioned in Section 3, which eventually enable the computation of the DPIs introduced in Section 2. These models take into account variability of efficiencies and coefficients of performance as functions of the actual building/district energy demand, as well as outdoor conditions.

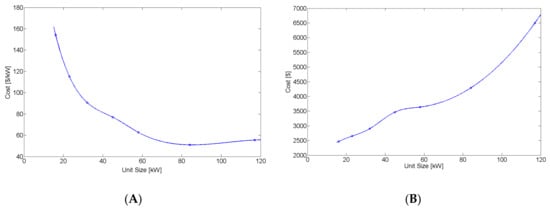

We remark that the novel approach described in this paper relies on actual commercial sizes and associated purchase costs. In fact, the common assumption of constant cost per kW (see e.g., [1]) is dramatically inaccurate; a typical variation of cost functions (cost per kW and cost per unit as function of the unit size) is illustrated in Figure 4, where the dots represent the actual units in the catalogue and the solid line represents the interpolation. As can be seen, the cost per kW significantly decreases with the unit size. This effect needs to be taken into account when calculating important economic key performance indicators, such as payback time, to provide accurate results to the user of the decision-support platform. In fact, a simple definition of the payback time can be the cost of the refurbishment scenario divided by the annual energy savings that can be achieved thanks to the installed ECMs. In addition, efficiency and performance models of units of different size are variable; therefore, adequate simulation models need to be included in the decision-support tool.

Figure 4.

Costs of a gas-fired boiler as a function of its size. (A) cost per kW; (B) cost per unit.

In the most general case, the refurbishment scenarios will include a mix of Passive, Renewable, Active, and Control ECMs. The top-level scenario generator will determine the type of ECMs that will be evaluated (passive, active, and associated controls). In the bottom part of the block diagram, the simulation module performs the following steps to simulate and evaluate a convenient number of applicable refurbishment scenarios.

- Determine one or more building thermal load profiles accounting for the passive ECMs selected. This involves running one or more EnergyPlus simulations where some physical parameters depending on the passive ECMs selected are varied (for example, the U-values of the walls and the roof).

- Determine the sizes of the desired Active ECMs (HVACs) such that the peak load associated with the profiles determined in step 1 can be supplied. The sizing algorithm is a combinatorial algorithm generating all possible combinations of the desired HVAC units of different sizes (different types of boilers, heat pumps, and combined heat power generators), while configurations that do not meet the load (this is the load matching block in Figure 2) or that are too oversized with respect to the maximum load (HVAC filtering block in Figure 2) are filtered out. In addition, constraints related to installation costs or expected payback time can be used to filter out applicable configurations (also included in the HVAC filtering block in Figure 2).

- All refurbishment scenarios characterized by a given building load profile and associated configurations of Active ECMs are simulated, taking into account applicable controls.

- DPIs of interest (for example, energy, comfort, and environmental) are calculated and used to rank accordingly the scenarios. The pre-refurbishment performance of the building or district is estimated by means of the calculation of the selected set of DPIs for the baseline building/district configuration before applying any ECMs. Knowledge of baseline DPIs will enable us to determine the relative improvements that are consequences of the refurbishment actions.

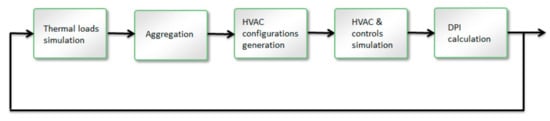

The steps described above are illustrated in the block diagram of Figure 5 and are applicable to any building or district, provided that suitable EnergyPlus models are available; the building or district retrofit will exploit the energy conservation measures previously described, as well as the proposed model-based approach to determine the set of relevant DPIs by simulating the HVAC systems and related controls. Zone level thermal loads or building level thermal loads are aggregated to determine the load supplied by the HVAC plant under study (district level or building level). The process can be repeated such that building level contributions to district level performance indicators are aggregated. Relevant case studies are illustrated in Section 7.1 and Section 7.2.

Figure 5.

Scenario generation and simulation process followed by the decision-support tool.

As a contribution towards an effective and computationally efficient optimization process, we highlighted the fact that the problem of HVAC sizing and filtering of selected configurations can be solved separately thanks to the knowledge of building/district load determined in the simulation module.

Relevant examples are shown in the following sections, whereas additional models and control approaches can be included in the methodology and tool, shown in Figure 3, to automatically generate and evaluate refurbishment scenarios. We emphasize how the evaluation of different types of HVACs characterized by different efficiencies, as well as novel optimization-based controls [32], can be pursued in an automatic manner using the methodology described above.

5. Simulation of Active and Control Energy Conservation Measures

In Caccavelli and Gugerli [33], a decision-support tool for building retrofitting was designed. However, the tool did not include detailed models for the simulation of energy conservation measures and evaluation of related key performance indicators. In Wang et al. [34], a multi-objective optimization formulation was developed to address the retrofitting problem. In this case as well, the assessment of ECMs by means of detailed simulation models did not form part of the study, and the optimized controls available nowadays were not taken into account. In this work, emphasis is placed on the methodology to integrate accurate simulation models in a simulation toolchain, whereas in the next section, some examples will be presented. The study reported in this paper is entirely based on simulation models (building/district thermal loads) and HVAC models; boilers, heat pumps, and chillers. With the proposed framework, real data can be used to better calibrate simulation models.

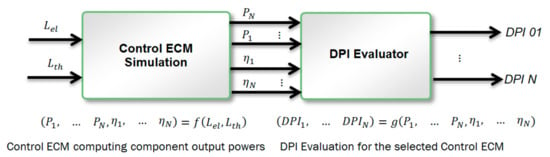

Any Control ECM is computed in two phases as depicted in Figure 6. The first step, control ECM simulation, receives one or more profiles of electrical () and thermal () loads and returns electrical/thermal powers supplied by each active ECM () along with their efficiencies (). Based on the computed power supply and efficiencies, in a second step, the desired set of DPIs is computed by means of relevant equations.

Figure 6.

Control ECMs simulation and DPI evaluation.

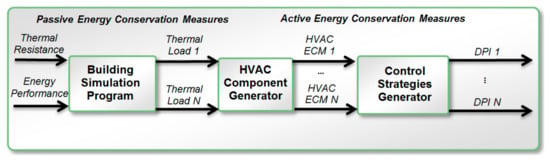

The simulation scheme illustrated in Figure 6 can be applied to both the pre-retrofit (before application of ECMs) and post-retrofit (after application of ECMs) configuration. Configurations of the building/district before and after the refurbishment can be analyzed, and DPIs can be calculated and compared to quantify the improvements. The DPIs analyzed in this paper are annual energy consumption and energy cost. The detailed process of the Control ECM computation and scenario generation specific to HVAC systems is depicted in Figure 7. This process is implemented as an automatic toolchain; it is also important to highlight that thermal loads are estimated using a building simulation program such as EnergyPlus—either using pre-retrofit building data or data corresponding to the application of passive ECMs (which come from the passive ECM catalogue). On the other hand, active and control ECMs are generated by the HVAC component generator and control strategies generator taking information from the HVAC and controls catalogue.

Figure 7.

Scenario Generation Module.

6. Simulation Settings of Refurbishment Scenarios and Case Studies

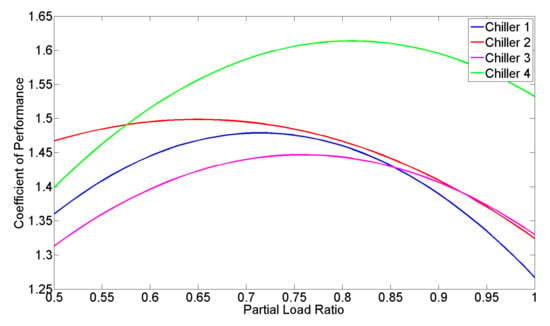

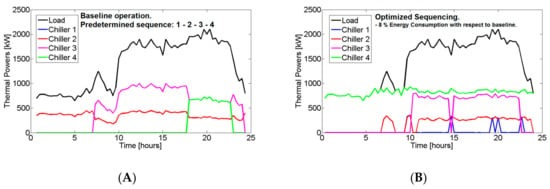

The first case study refers to the optimized operation of a chiller plant. In this case the “optimized sequencing” control ECM is selected to evaluate the energy savings with respect to the baseline. The baseline is the standard sequencing, where the number of running chillers is determined based on the cooling load demand and a predetermined sequence is used, without accounting for the chillers’ part load efficiency curves—see Figure 8 for the example of performance models used in this paper.

Figure 8.

Chillers’ coefficients of performance (COPs) as a function of partial load ratio.

Note that in this section, we develop a control strategy that takes advantage of the COP variations with partial load ratio. However, the COP models included in the tool can take into account the effect of the outdoor temperature as well, and this is shown later in this section.

The method used takes thermal demand as feedback to maximize chiller plant total efficiency. The approach chosen minimizes the energy consumption, taking into account the coefficients of performance (COPs) and its variations with the chiller’s partial load ratio, . We assume that the COP curves can be fitted to quadratic functions. In particular, it can be observed that the COP curves cross each other at some specific values of the partial load ratio. That means that it is not optimal to pre-define a specific sequencing, because the most efficient chiller depends on the actual partial load ratio. The theoretical framework applied for the control of the chiller plant aims at calculating the energy consumption on an annual basis, using EnergyPlus simulations to determine the building cooling load . The timestep considered here is one hour (the default time-step used by EnergyPlus); however, the control algorithm has been tested with 15 min time steps, which is a standard choice for this type of supervisory control. In particular, we seek to minimize the energy consumption (1), accounting for the constraints including the variations of the coefficient of performance with each chiller’s output power , the cooling load balance (3), and the output power constraints (4).

subject to the following:

The controlled variables are the chiller’s state (ON/OFF), as well as its power set point. The set of active chillers includes the list of chillers’ indexes, which are ON, for example, = {1, 3, 4} means that only the chillers 1, 3, and 4 are running at time step 3. It is worth noting that the set of chillers active at each time step is varied such that the energy consumption (1) is minimized. The optimization problem (1–4) simultaneously calculates the chiller’s state variables (ON/OFF), which determines the set of active chillers , as well as the chillers’ output powers, while taking into account the nonlinear terms describing the COPs. The proposed solution method is based on a numerically robust formulation of the branch and bound algorithm, which selects out of all possible combinations of running chillers those that can meet the cooling load at the considered time step. Minimum and maximum output power constraints are applied to discard the possible combinations of running chillers that are infeasible and determine a set of operating scenarios that are feasible. The sorting of all the possible combinations enables a faster selection of the candidate combinations of running chillers for the subsequent set point optimization step. For those combinations, the optimization becomes a nonlinear programming problem, which can be efficiently solved with several existing solvers. We used the interior-point method implemented in Matlab as opposed to the basic Lagrangian method used in Chang et al. [24]. In particular, the energy consumption in each time interval spanned by the discrete time variable is minimized for all the feasible combinations of running chillers, and the scenario corresponding to the lowest energy consumption is selected. Finally, the objective function (1) is minimized by taking the sum over of the inner terms.

Note that only the possible combinations that have sufficient capacity to meet the load are optimized (power set-point optimization) to minimize the energy consumption. Eventually the combination that requires the least energy is selected by our custom optimization algorithm to supply the load at that time step. In Figure 9, a comparison is made between a predetermined sequence, not accounting for energy efficiency and the optimized sequencing. Data about chillers and cooling loads were taken from Chang et al. [24]. It can be seen that the optimized sequencing would preferably use the Chiller number 4, which, in most cases, is the most efficient one. When the scenario including the optimized control ECM is selected by the OptEEmAL tool, the reduction of Energy Consumption is about 8% with respect to the baseline. With the proposed approach, focusing on essential elements of the chiller’s model (COP curves), we combine the optimal load distribution and the optimal number of operating chillers into a single optimization problem, which is often described as a distinct approach [25]. It should be mentioned that recent approaches use data-driven models of chiller plants and minimize the energy cost sometimes with questionable generalization capabilities [26]. Finally, our method is endorsed by recent studies that validate quadratic chiller’s models performing uncertainty and robustness analysis [27].

Figure 9.

Optimized sequencing control ECM for district chiller plant. (A) Baseline system operation; (B) Optimized sequencing control.

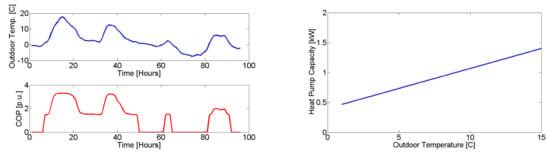

The second case study refers to a scenario where part of thermal demand is supplied by a packaged air-to-air heat pump [35,36], whereas a boiler is used as auxiliary thermal load supply [37]. It is remarked that the types of heat pump and boiler models used for the study included in this paper are those described in the works of [35,37], respectively.

As a reference building, we use a simple shoebox model which is BESTEST Case 195 [38] in EnergyPlus to establish a baseline scenario for determining the building thermal load power profile.

After that, the data were used to determine boiler and heat pump output powers by applying all relevant operating constraints, which include the minimum and maximum values for these powers. In particular, the air-to-air heat pump shows a maximum capacity, which is dependent on the outdoor temperature [35]. Efficiency models considered include variability of efficiency with load fraction for the boiler; the heat pump COP depends on the outdoor temperature, which makes it more efficient to use the heat pump when the outdoor temperature is not too low. Furthermore, additional operating constraints on the minimum outdoor temperature have been applied [35]. In Figure 10, we show the simulated power profiles of heat pump and boiler (top-left panel). The heat pump model is depicted in the two plots on the right-hand side, which represent the variation of the COP as a function of the outdoor temperature (top-right panel) and the variations of the heat pump capacity as a function of the outdoor temperature (bottom-right panel), respectively; the figure shows the COP from four degrees Celsius, however, the pump can be also used at lower temperatures. The application of the heat pump model on the outdoor temperature profile (middle-left panel) provides the COP profile for the simulation period considered (bottom-left panel), which is used to evaluate the energy cost.

Figure 10.

Load following with heat pump and boiler control ECM.

The assumption of linearity of the heat pump COP versus the outdoor temperature is usually a very good approximation. Curve-fitted models from manufacturers often reveal that the coefficient modelling the first-order dependence on the outdoor dry-bulb temperature is much higher than those accounting for return water temperature and other nonlinear terms [39]. In particular, typical refurbishment scenarios analyzed are the following: (i) the load is entirely supplied by a high efficiency boiler (baseline scenario); and (ii) the load is jointly supplied by a boiler and heat pump. After illustrating the concept and the model used, we will determine relevant cost and energy key performance indicators (KPIs) for significant test cases in the next sections. The proposed framework enables us to quickly evaluate the convenience of adopting a certain technology for different levels of gas and electricity costs.

7. Results and Discussion

In this section, we discuss more extensively results obtained using the model-based approach introduced in the previous section. In particular, we consider up to one-year long datasets for the simulation of heating and cooling systems and energy consumption and cost calculations. The test cases considered refer to district-level refurbishment scenarios; building-level cases can be treated analogously. In terms of district size, six case studies and three demonstration sites of mixed use across Europe, with sizes ranging from 18,000–21,000 m2 are considered in OptEEmAL. However, the methodology and tools developed can be applied to any district.

The test case illustrated in Section 7.1 refers to a large office building. Here, the goal is to evaluate the energy consumption of multiple design configurations, taking into account novel optimization-based controls. The methodology is applicable to district level supply in the same way. The test cases illustrated in Section 7.2 refer instead to a district case, which is a district including twenty buildings supplied by a single district level heating plant. Also, in this case, the goal is to evaluate multiple energy supply configurations to provide recommendations to the user of the platform about the associated operating costs. It can be noticed that the proposed test cases are complex case studies developed using high-fidelity models of buildings, HVAC systems, and associated controls, which are not to be found in recent papers [1,2,3,4].

7.1. Cooling Test Cases

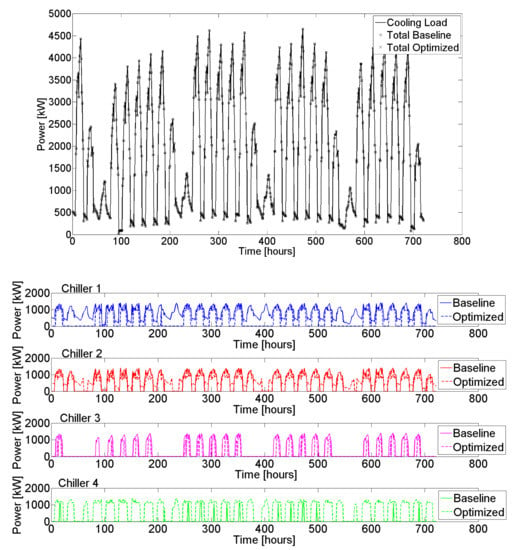

The first set of test cases refers to the optimization of set-points of a chiller plant including from four to five chillers. In Figure 6, we consider four chillers of the same size, namely 1407 kW. The chillers have variable COP curves, which were introduced in Figure 8 [24]. The goal was to determine the amount of cooling power produced by each chiller such that the cooling load is supplied in the most efficient manner. Also, in this case, the cooling load profile was simulated with EnergyPlus and refers to a large office building with surface of 46,320 m2. The building has 12 floors with a floor to floor height of 3.96 m and a glazing factor of 0.38. The building has continuous insulation above the structural roof deck. The roof U-value is . It has mass walls with continuous insulation. The wall U-value is . The building has windows with an overall U-value of and a solar heat gain coefficient of 0.39. The weather file used for all the simulations refers to Denver, Colorado (39.8 degrees latitude and 104.9 degrees west longitude) and is characterized by cold, clear winters and hot, dry summers. Note that a month-long dataset is displayed in Figure 11, whereas annual profiles have been considered in Table 2.

Figure 11.

Optimized sequencing control applied on a cooling load obtained from EnergyPlus simulations.

Table 2.

Comparison of chiller energy consumptions and savings obtained using efficiency-based optimized control.

From Figure 11 (top panel), it can be seen that in both cases, the total power supplied by the chiller plant matches with the profile of the cooling load. On the bottom panel of the same figure, it can be seen that the power supplied has been distributed in a different way among the four chillers after the optimization. In particular, also in this case, it is evident that the fourth chiller (which, in most cases, is the most efficient one) is utilized more than before, whereas in the baseline case, it was set as the last one to be activated. However, as already explained in the previous section, since the COP curves cross each other, it is not possible to predetermine a sequence that is optimal with respect to energy consumption. Therefore, in the general case, any tuning of the basic sequencing control will not be able to achieve the performances of the efficiency-based optimization, which does not rely on a fixed sequence. Simulations showed that assuming COP models, such as those of Figure 8, energy savings in the order of 7–10% should be expected.

Additional simulations were performed to thoroughly validate the proposed method using simulated data from EnergyPlus. The results are summarized in Table 2. The cooling load profile is the one depicted in Figure 11 but extended to one full year length. Furthermore, different scenarios were considered for the retrofitting with modern high efficiency chillers of different sizes. In this case, the COP curves previously used have been rescaled to match with the COPs of modern highly efficient chillers. This way, the maximum COP depends on the chiller size, ranging from 4.80 to 6.00 for small (<350 kW) to large (>1499 kW) units, see Table 3. However, the quadratic variations with the part–load ratio were kept. In this case, baseline is a system with maximum COP of 4.00.

Table 3.

Maximum coefficients of performance (COPs) for chillers of different sizes.

In all the cases, it is possible to achieve energy savings thanks to the efficiency-based chillers’ control. Furthermore, it can be noticed that the configurations including five chillers offered more room for optimization. Despite the fact that the smaller units have a lower maximum COP than the larger units, the variability of COP with the partial load ratio makes the problem of selecting the most efficient units in partial load and determining their optimal set-points not trivial. The complexity of the problem suggests the application of methodologies based on mathematical programming.

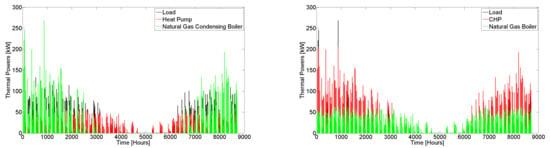

7.2. Heating Test Cases

The second set of tests refers to a heating case study. This is a district case including 20 identical buildings, named case 195. The reference building is a basic test building with a rectangular single zone (), no interior partitions, and no windows. The building is of lightweight construction with characteristics included in tables below. This building is considered a classic example used to study the solid conduction problem for low mass buildings. We chose to follow the settings used in Judkoff and Neymark [38], where infiltration rate and internal gains were set to zero and interior and exterior surface emissivity and absorbance were set to 0.1. The thermostat control is of “20,20 bang–bang” type, where the heating system is switched to ON in case the temperature is lower than 20 °C and switched to OFF in case the temperature is greater than 20 °C. The weather file used refers to Denver, Colorado (39.8 degrees latitude and 104.9 degrees west longitude) and is characterized by cold clear winters and hot dry summers. To obtain the district load profile, the annual heating load of case 195 was rescaled by a factor of 20, to match with that of a small district, and different configurations of HVAC systems were sized to meet the maximum load. The profiles of 20 buildings were randomly shifted to account for the statistical variations associated with different building usages. The analyzed configurations are the following: natural gas boiler, condensing gas boiler, condensing diesel boiler, heat pump, and combined heat power generator. Furthermore, units of different types can be mixed to supply the total load. The following costs of fuel and energy were assumed in the study: gas 0.05 €/kWh, diesel 0.067 €/kWh, biomass 0.06 €/kWh, and electricity 0.08 €/kWh. Nonlinear efficiency curves and coefficients of performance curves of real products obtained by manufacturers’ data sheets were used. In addition, where applicable, we included in the models operating constraints related to the minimum and maximum power. We determined the annual cost of energy for different supply configurations of the heating system, which in turn will enable us to determine energy savings with respect to an existing baseline. In some cases, an old boiler, which needs to be replaced, may have efficiency as low as 50%. We remark that also in this case, EnergyPlus was used to generate heating load profiles. An alternative approach is to use reduced-order models [39,40], which describe the building/zone temperature dynamics accounting for the various thermal masses, thermal resistances, and heat sources. These models are calibrated and can be used to implement predictive control algorithms.

The generation of scenarios included the selection of commercial units out of the Active ECMs catalogue such that the total power available is greater than or equal to the maximum load. We consider the ECM catalogue described in Section 3 and depicted in Figure 3. The results are shown in Table 4; it can be noticed that the configuration enabling us to achieve the highest energy savings is the condensing boiler and heat pump (highlighted in italic in Table 4). However, purchasing and installation costs of these configurations have to be considered in order to determine the actual payback periods. In addition, the results reveal that heat pump and CHP units need to be properly sized in order to balance the annual energy cost savings with purchasing costs, which can be much higher for bigger units. In this way, the payback period can be reduced to a convenient time. Smaller units can be more efficient than bigger units working in partial load conditions. Moreover, operating constraints on the minimum output power may apply and limit the continuous operation of the unit in low load conditions. Examples of simulations are shown in Figure 12.

Table 4.

Comparison of heating systems’ annual energy costs.

Figure 12.

Examples of heating system’s operation obtained using the proposed models.

The most sensitive parameters influencing the energy savings in Table 4 are the following: the supply units’ sizes and efficiencies; and the fuel costs compared with those of natural gas, because the pre-retrofit unit is a gas-fired boiler (diesel/biomasses/electricity prices). Data in Table 4 can be used to perform sensitivity analysis studies such that the marginal cost savings associated with the variation of size of one supply units are evaluated. In addition, the price of the fuel of one supply unit can be varied as well. This kind of analysis is useful to the designer that wants to quickly grasp the effect of varying parameters without executing new simulations. From lines 5 and 6, the sensitivity of annual cost savings to heat pump size, when considering configuration with natural gas boilers and heat pumps, can be derived. In this case, it can be noticed that increasing the size of the heat pump from 42 kW to 137 kW determines additional savings of 6.1 Euros/kW due to the highly efficient supply of the heat pump. Note that the heat pump is the primary unit, which supplies the base load, whereas the boiler supplies the remaining part of the load when the heat pump capacity is not sufficient. It is expected that such marginal savings would decrease when increasing the heat pump size, reducing the exploitability of large units. The heating load is, for most of the time, far below 150 kW; furthermore, the presence of operating constraints in supply units’ models makes the simulation non-trivial. Therefore, sensitivity analysis is only indication and has to be used carefully.

Finally, we remark that refurbishment interventions on the building envelope will enable us, in several cases, to reduce the heating/cooling peak loads and adopt cheaper HVAC units of smaller sizes. Approaches for optimizing the selection of insulation thicknesses [41] are also applicable to our refurbishment design flow automation and are currently under study for their inclusion in the OptEEmAL platform [42]. In addition, stochastic optimization algorithms, such as the harmony search [5], are under evaluation for building and district retrofitting-related optimization problems. A comprehensive set of algorithms and tools for automatic generation and simulation of different refurbishment scenarios is not part of state-of-the-art simulation programs such as EnergyPlus.

8. Conclusions

This paper has presented a model-based framework for the characterization of refurbishment scenarios at building and district level and for the benchmarking of advanced energy conservation measures (ECMs). Beside the classical passive and active energy conservation measures, we have introduced control ECMs and showed the process to determine their impact on relevant energy and cost key performance indicators. A thorough simulation study including the optimized sequencing of a district chiller plant, as well as the configuration of supply systems of building heating load, has been presented. The adoption of the proposed simulation methods and tools will enable system designers to easily generate, evaluate, and compare multiple refurbishment configurations—including existing and future controls. The model-based approach and energy conservation measures catalogues can be integrated into a fully automated optimization platform to generate and analyze refurbishment scenarios that optimize relevant district performance indicators. The work developed proves that it is possible to incorporate the model-based approach in a decision-support tool for building and district retrofitting. Furthermore, it is possible to include in such a tool the support to automatically evaluate the benefits of novel and advanced optimization-based controls. The synergy of detailed equipment models and optimized control algorithms with existing state-of-the-art simulation tools (such as EnergyPlus) enables a very accurate evaluation of key performance indicators.

The HVACs and controls simulation module of the decision-support platform introduced in this paper has been evaluated on significant case studies, including a large building and a district, as well as both the heating and cooling cases. Numerical improvements of the optimized sequencing algorithm have been demonstrated by means of algorithm validation on very long data sets for the energy consumption (multiple years of data) obtained by actual EnergyPlus simulations.

To conclude, we would like to highlight that the decision-support platform, including the simulation models and control algorithms, described in this paper will eventually be deployed with a user-friendly web-interface, and will be usable by any stakeholder interested in the refurbishment process. The only prerequisite is a general knowledge of the building or district site under consideration, given the large number of scenarios that can be automatically generated by the platform.

Author Contributions

L.D.T. has designed and performed the experiments, analyzed results and written the paper. H.R. has contributed to design and analysis of the experiments and writing the paper. G.G., K.K., G.NL. and D.R. contributed to research design and methodologies conceptualization. G.G. also contributed to paper writing. D.R. proofread it.

Funding

The work reported in this paper has received support from the European Commission under grant agreement number 680676.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Carli, R.; Dotoli, M.; Pellegrino, R.; Ranieri, L. A decision making technique to optimize a building stock energy efficiency. IEEE Trans. Syst. Man Cybern. Syst. 2017, 47, 794–807. [Google Scholar] [CrossRef]

- Pacheco-Torres, R.; Heo, Y.; Choudhary, R. Efficient energy modelling of heterogeneous building portfolios. Sustain. Cities Soc. 2016, 27, 49–64. [Google Scholar] [CrossRef]

- Carli, R.; Dotoli, M.; Pellegrino, R. A hierarchical decision making strategy for the energy management of smart cities. IEEE Trans. Autom. Sci. Eng. 2017, 14, 505–523. [Google Scholar] [CrossRef]

- Dall’O, G.; Norese, M.F.; Galante, A.; Novello, C. A multi-Criteria methodology to support public administration decision making concerning sustainable energy action plans. Energies 2013, 6, 4308–4330. [Google Scholar] [CrossRef]

- Geem, Z.W.; Kim, J.H.; Loganathan, G.V. A new heuristic optimization algorithm: Harmony search. Simulation 2001, 76, 60–68. [Google Scholar] [CrossRef]

- Lee, D.; Cheng, C.C. Energy savings by energy management systems: A review. Renew. Sustain. Energy Rev. 2016, 56, 760–777. [Google Scholar] [CrossRef]

- Swan, L.G.; Ugursal, V.I. Modelling of end-Use energy consumption in the residential sector: A review of modelling techniques. Renew. Sustain. Energy Rev. 2009, 13, 1819–1835. [Google Scholar] [CrossRef]

- Poel, B.; Van Cruchten, G.; Balaras, C.A. Energy performance assessment of existing dwellings. Energy Build. 2007, 39, 393–403. [Google Scholar] [CrossRef]

- Thiers, S.; Peuportier, B. Energy and environmental assessment of two high energy performance residential buildings. Build. Environ. 2012, 51, 276–284. [Google Scholar] [CrossRef]

- Spoladore, A.; Borelli, D.; Devia, F.; Mora, F.; Schenone, C. Model for forecasting residential heat demand based on natural gas consumption and energy performance indicators. Appl. Energy 2016, 182, 488–499. [Google Scholar] [CrossRef]

- Iqbal, I.; Al-Homoud, M.S. Parametric analysis of alternative energy conservation measures in an office building in hot and humid climate. Build. Environ. 2007, 42, 2166–2177. [Google Scholar] [CrossRef]

- Lam, J.C.; Wan, K.K.; Yang, L. Sensitivity analysis and energy conservation measures implications. Energy Convers. Manag. 2008, 49, 3170–3177. [Google Scholar] [CrossRef]

- Difs, K.; Bennstam, M.; Trygg, L.; Nordenstam, L. Energy conservation measures in buildings heated by district heating—A local energy system perspective. Energy 2010, 35, 3194–3203. [Google Scholar] [CrossRef]

- Shimoda, Y.; Asahi, T.; Taniguchi, A.; Mizuno, M. Evaluation of city-scale impact of residential energy conservation measures using the detailed end-use simulation model. Energy 2007, 32, 1617–1633. [Google Scholar] [CrossRef]

- Siddharth, V.; Ramakrishna, P.V.; Geetha, T.; Sivasubramaniam, A. Automatic generation of energy conservation measures in buildings using genetic algorithms. Energy Build. 2011, 43, 2718–2726. [Google Scholar] [CrossRef]

- Radhakrishnan, N.; Su, Y.; Su, R.; Poolla, K. Token based scheduling for energy management in building HVAC systems. Appl. Energy 2016, 173, 67–79. [Google Scholar] [CrossRef]

- Khan, K.H.; Ryan, C.; Abebe, E. Optimizing HVAC energy usage in industrial processes by scheduling based on weather data. IEEE Access 2017, 5, 11228–11235. [Google Scholar] [CrossRef]

- Kohonen, R.; Laitinen, A.; Aho, I.; Madjidi, M.; Stephan, W. Study on optimal start/stop operation of hydronic heating systems. In Proceedings of the International Building Performance Simulation Association (IBPSA), Nice, France, 20–22 August 1991; pp. 175–186. [Google Scholar]

- Marik, K.; Rojicek, J.; Stluks, P.; Vass, J. Advanced HVAC control: Theory vs. reality. In Proceedings of the 18th IFAC World Congress, Milano, Italy, 28 August–2 September 2011; pp. 3108–3113. [Google Scholar]

- Ogonowski, S. Modeling of the heating system in small building for control. Energy Build. 2010, 42, 1510–1516. [Google Scholar] [CrossRef]

- Mustafaraj, G.; Marini, D.; Costa, A.; Keane, M. Model calibration for building energy efficiency simulation. Appl. Energy 2014, 130, 72–85. [Google Scholar] [CrossRef]

- Valdivia, V.; O’Connell, S.; Gonzalez-Espin, F.; Mady, A.E.D.; Kouramas, K.; De Tommasi, L.; Hertig, L. Sustainable building integrated energy test-Bed. In Proceedings of the 2014 IEEE 5th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Galway, Ireland, 24–27 June 2014. [Google Scholar]

- Peacock, A.D.; Newborough, M. Controlling micro-CHP systems to modulate electrical load profiles. Energy 2007, 32, 1093–1103. [Google Scholar] [CrossRef]

- Chang, Y.C.; Lin, F.A.; Lin, C.H. Optimal chiller sequencing by branch and bound method for saving energy. Energy Convers. Manag. 2005, 46, 2158–2172. [Google Scholar] [CrossRef]

- Huang, S.; Zuo, W.; Sohn, M.D. Amelioration of the cooling load based chiller sequencing control. Appl. Energy 2016, 168, 204–215. [Google Scholar] [CrossRef]

- Wei, X.; Xu, G.; Kusiak, A. Modelling and optimization of a chiller plant. Energy 2014, 73, 898–907. [Google Scholar] [CrossRef]

- Liao, Y.; Sun, Y.; Huang, G. Robustness analysis of chiller sequencing control. Energy Convers. Manag. 2015, 103, 180–190. [Google Scholar] [CrossRef]

- Allegrini, J.; Orehounig, K.; Mavromatidis, G.; Ruesch, F.; Dorer, V.; Evins, R. A review of modelling approaches and tools for the simulation of district-Scale energy systems. Renew. Sustain. Energy Rev. 2015, 52, 1391–1404. [Google Scholar] [CrossRef]

- Keirstead, J.; Jennings, M.; Sivakumar, A. A review of urban energy system models: Approaches, challenges and opportunities. Renew. Sustain. Energy Rev. 2012, 16, 3847–3866. [Google Scholar] [CrossRef]

- O’Dwyer, E.; De Tommasi, L.; Kouramas, K.; Cychowski, M.; Lightbody, G. Modelling and disturbance estimation for model predictive control in building heating systems. Energy Build. 2016, 130, 532–545. [Google Scholar] [CrossRef]

- O’Dwyer, E.; De Tommasi, L.; Kouramas, K.; Cychowski, M.; Lightbody, G. Prioritized objectives for model predictive control of building heating systems. Control Eng. Pract. 2017, 63, 57–68. [Google Scholar] [CrossRef]

- Macek, K.; Marik, K. A methodology for quantitative comparison of control solutions and its application to HVAC (heating, ventilation and air conditioning) systems. Energy 2012, 44, 117–125. [Google Scholar] [CrossRef]

- Caccavelli, D.; Gugerli, H. TOBUS—A European diagnosis and decision-making tool for office building upgrading. Energy Build. 2002, 34, 113–119. [Google Scholar] [CrossRef]

- Wang, B.; Xia, X.; Zhang, J. Multi-objective optimization model for the life-cycle cost analysis and retrofitting planning of buildings. Energy Build. 2014, 77, 227–235. [Google Scholar] [CrossRef]

- Kent, E.F. Performance evaluation of a compact air-To-Air heat pump. Energy Convers. Manag. 1997, 38, 341–345. [Google Scholar] [CrossRef]

- Chua, K.J.; Chou, S.K.; Yang, W.M. Advances in heat pump systems: A review. Appl. Energy 2010, 87, 3611–3624. [Google Scholar] [CrossRef]

- Lazzarin, R.M. The importance of the modulation ratio in the boilers installed in refurbished buildings. Energy Build. 2014, 75, 43–50. [Google Scholar] [CrossRef]

- Judkoff, R.D.; Neymark, J.S. Adaptation of the BESTEST intermodel comparison method for proposed ASHRAE standard 140P: Method of test for building energy simulation programs. ASHRAE Trans. 1999, 105, 721–736. [Google Scholar]

- Perera, D.W.U.; Skeie, N.-O. Comparison of Space Heating Energy Consumption of Residential Buildings Based on Traditional and Model-Based Techniques. Build. 2017, 7, 27. [Google Scholar] [CrossRef]

- Fong, J.; Edge, J.; Underwood, C.; Tindale, A.; Potter, S.; Du, H. Application of a New Dynamic Heating System Model Using a Range of Common Control Strategies. Build. 2016, 6, 23. [Google Scholar] [CrossRef]

- Mabe, L.; Garcia, M.A.; Escudero, A.; Giannakis, G.; Aguirre, P.; De Tommasi, L.; Mameli, G.; Manjarres, D.; Hernandez, G.; Pousse, M.; et al. D4.1: Requirements and Design of the Optimization Module, H2020 Optimized Energy Efficient Design Platform for Refurbishment at District Level, Public Deliverable. Available online: https://www.opteemal-project.eu (accessed on 8 June 2017).

- Gelegenis, J.; Axaopoulos, P. A multi-Parametric mathematical approach on the selection of optimal insulation thicknessess in buildings. Build. 2016, 7, 15. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).