Transient Radiator Room Heating—Mathematical Model and Solution Algorithm

Abstract

1. Introduction

- Optimization of heat curve parameters for the weather compensated control,

- Calculation of optimized heat flux for achieving thermal comfort and minimizing energy consumption,

- Determination of the optimal start time of the heating system after night setback in order to reach the desired temperature without excessive energy consumption.

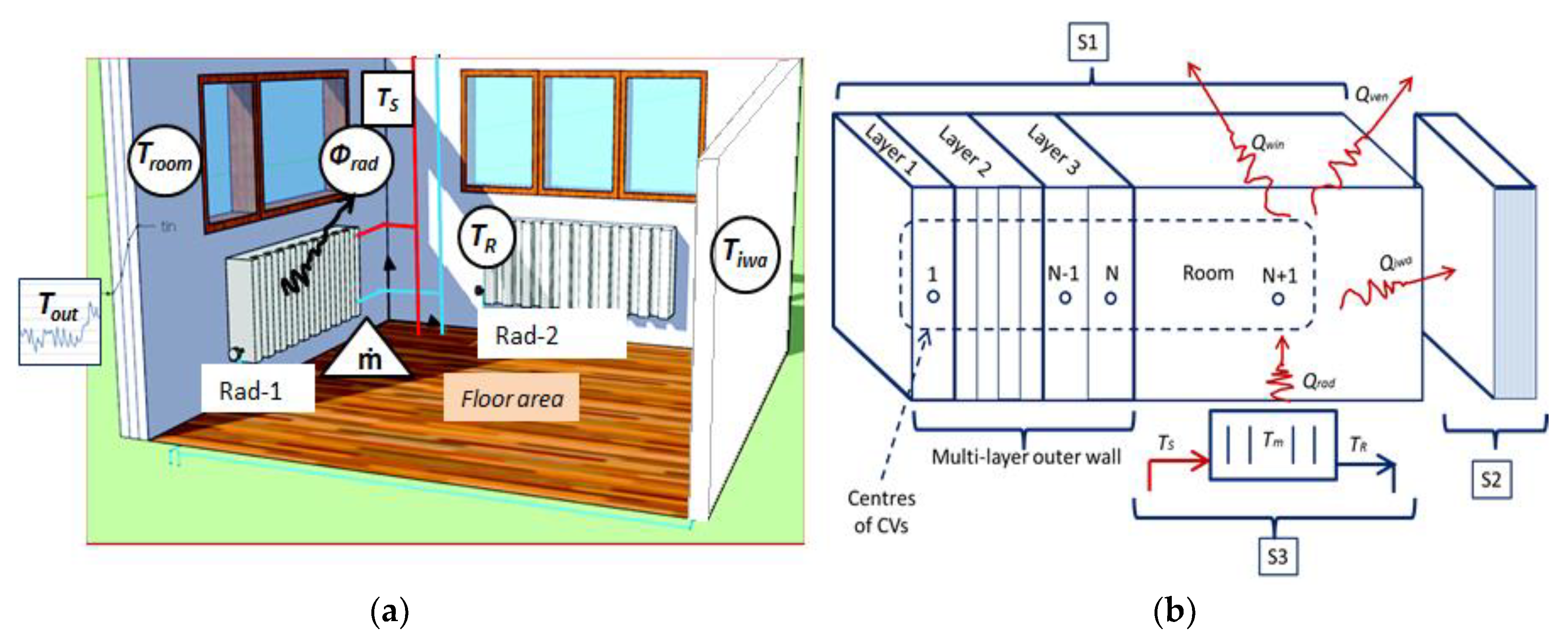

2. Mathematical Model, Numerical Method, and Solution Algorithm

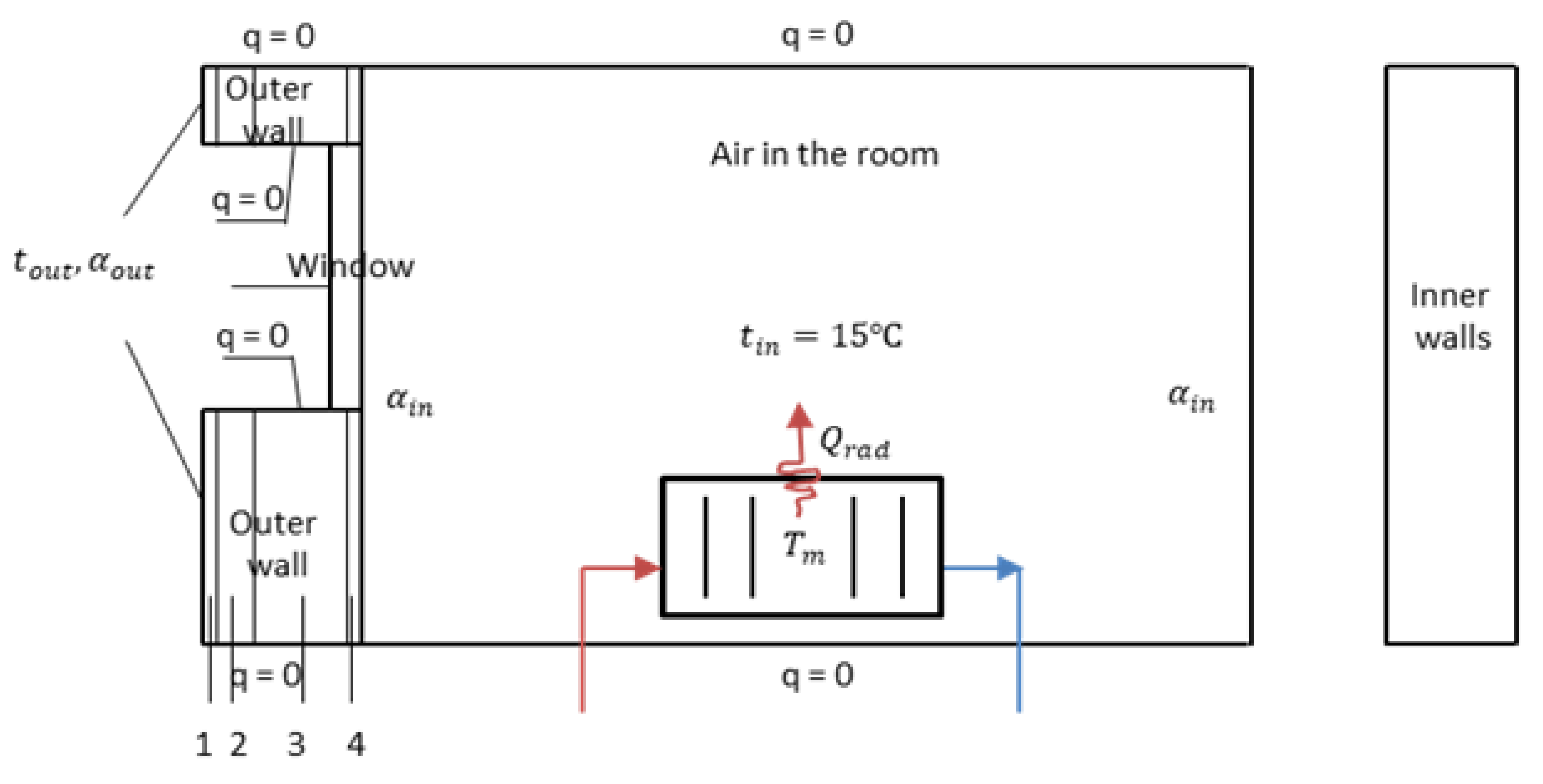

2.1. Modelling Assumptions

2.2. Mathematical Model

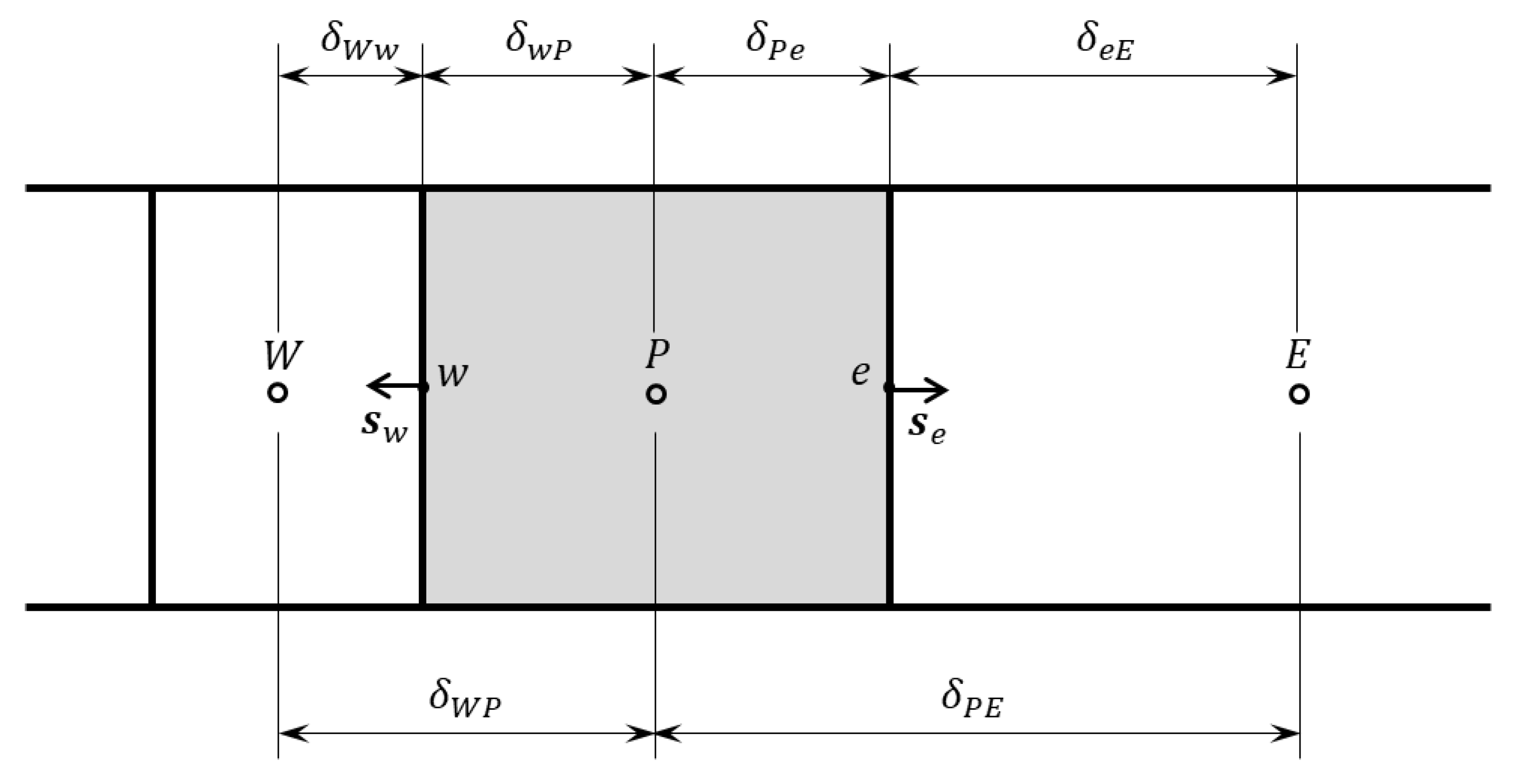

2.3. Numerical Method

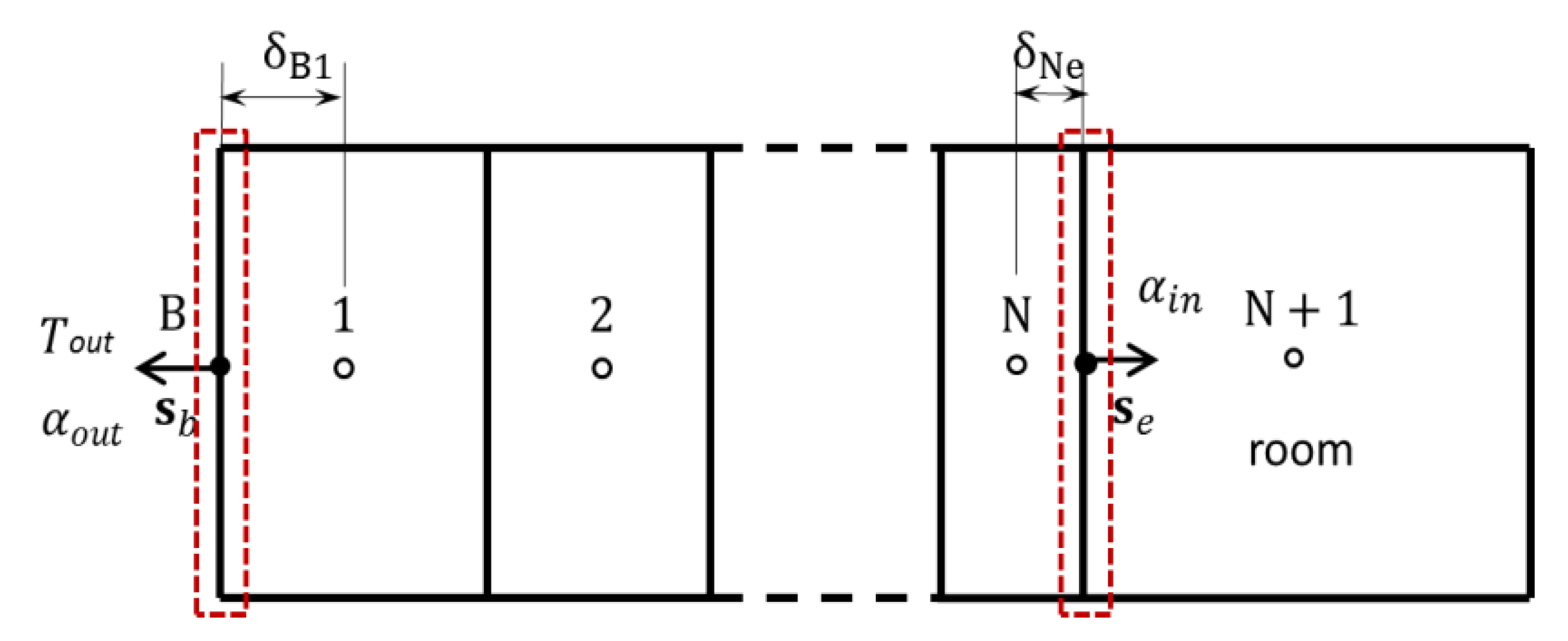

2.3.1. Discretization of Multi-Layer Outer Walls and Room Assembly

2.3.2. Final Form of the Transport Equation for Inner Walls

2.3.3. Final Form of Transport Equation for Radiators

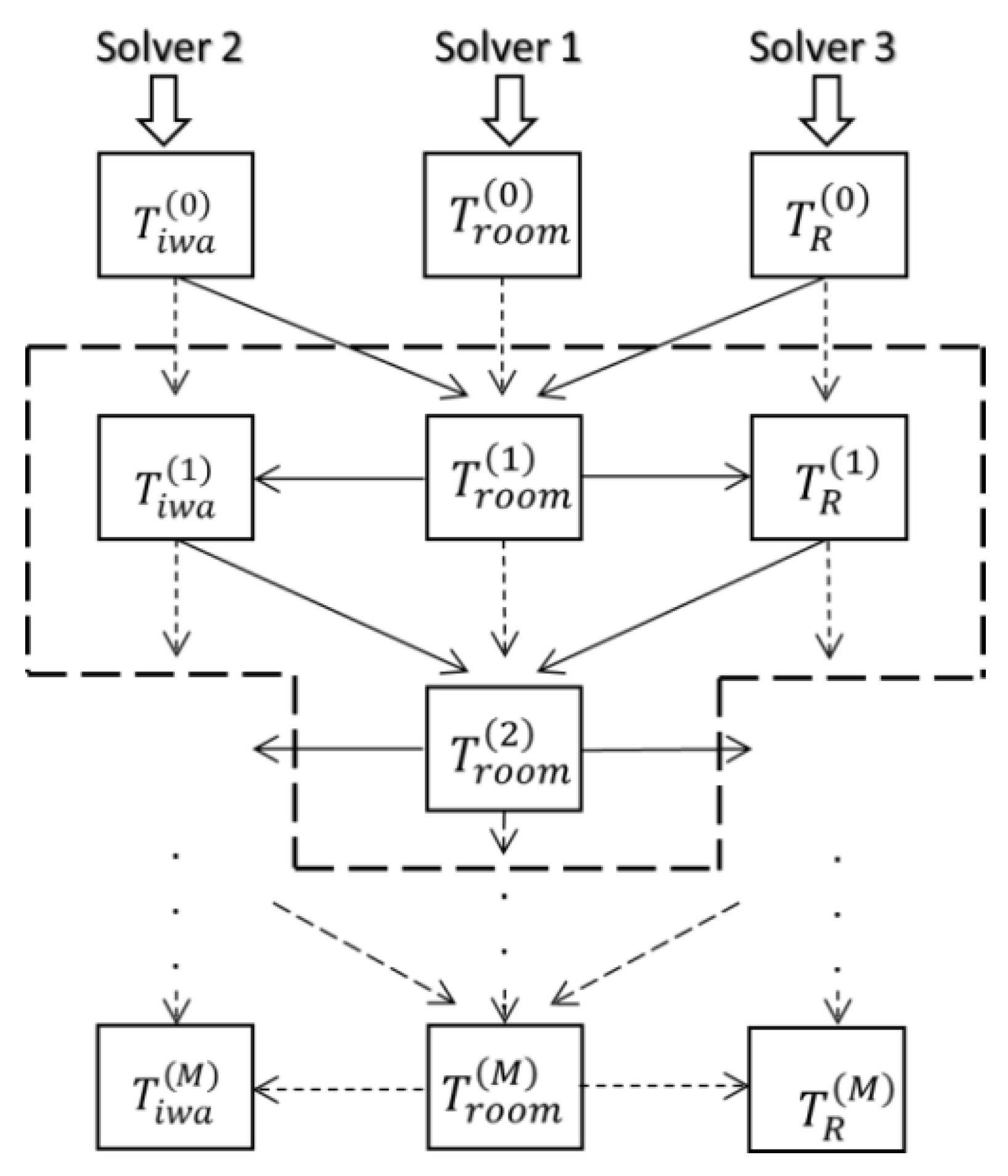

2.4. Solution Algorithm

- Data for domain of multi-layer walls and room assembly are defined

- Dimensions of the room and surface of outer wall are prescribed,

- Dimensions of windows are defined,

- Arbitrary number of layers in the multi-layer wall are prescribed with their physical properties and an arbitrary number of control volumes is assigned for each layer,

- Data for inner walls are defined

- Heat capacity is prescribed with mass of all inner walls and their specific heat,

- Heat transfer coefficient and surface from inner walls to room air is defined,

- Radiator parameters are defined

- Nominal radiator capacity,

- Nominal regime as nominal supply, return, and room temperature,

- Physical properties of mass and specific heat of the radiator body, including the content of the water in the radiator is prescribed,

- Relevant mass flow is defined, either taken from nominal conditions or from the measurements (where available),

- Initial and boundary conditions are given for all equations;

- Initial temperature profile in the outer wall (constant or arbitrary), initial room temperature, initial inner wall temperature, initial hot water supply temperature, and initial lumped temperature of radiators (equal or larger than room temperature) are prescribed,

- Boundary conditions are applied by assuming known, variable, or fixed outside temperature and known hot water supply temperature (note that in weather compensated heating control both values are known),

- The system of Equations (19) is solved by using the TDMA solver and by assuming the known radiator heat flux and the inner wall heat flux from the previous time step, resulting in the new room temperature value,

- Equation (23) for inner walls is solved, resulting in a new inner wall temperature

- Equation (26) for radiators is solved iteratively to get the new return temperature by using the current values of supply temperature and last available room temperature value from the previous time step,

- Steps 5 to 7 are repeated until the final time step is reached.

3. Results

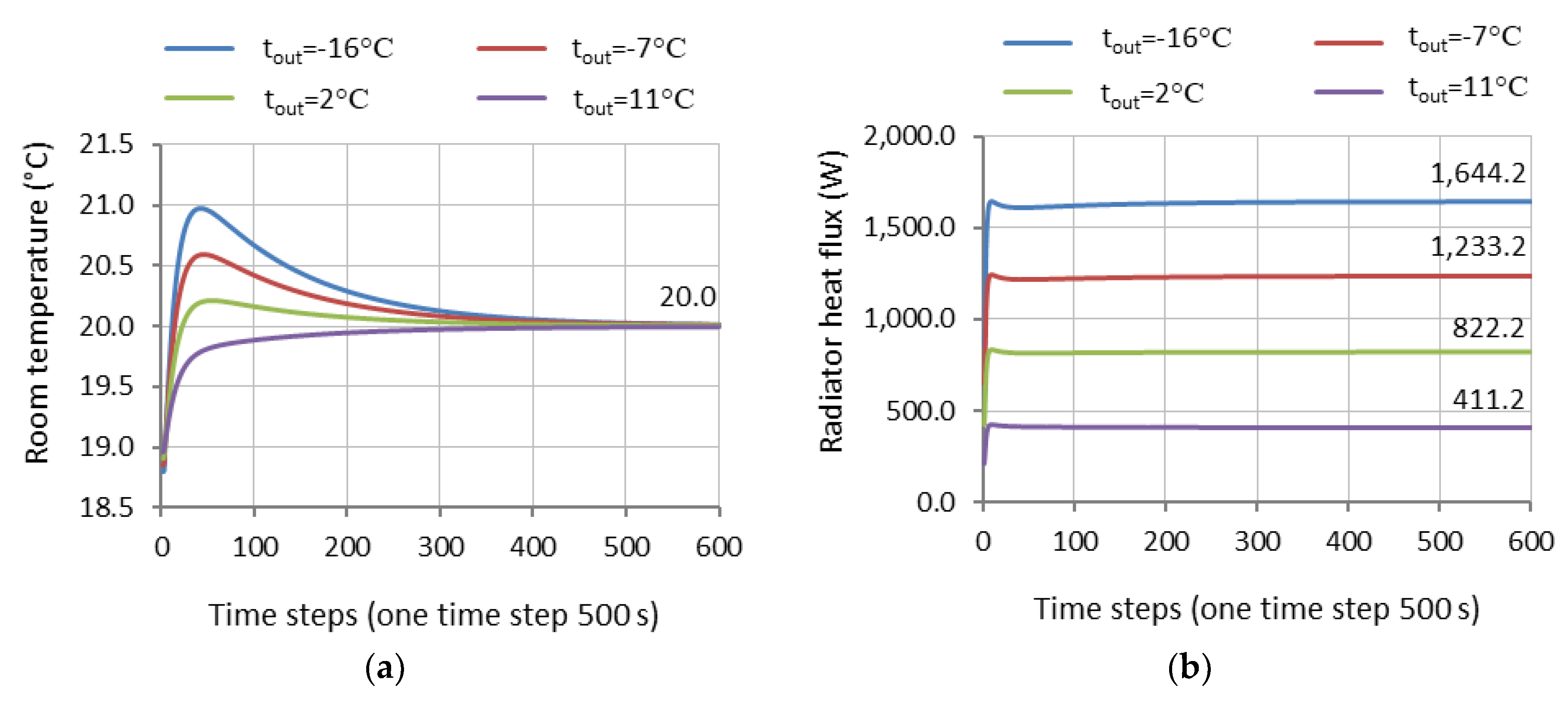

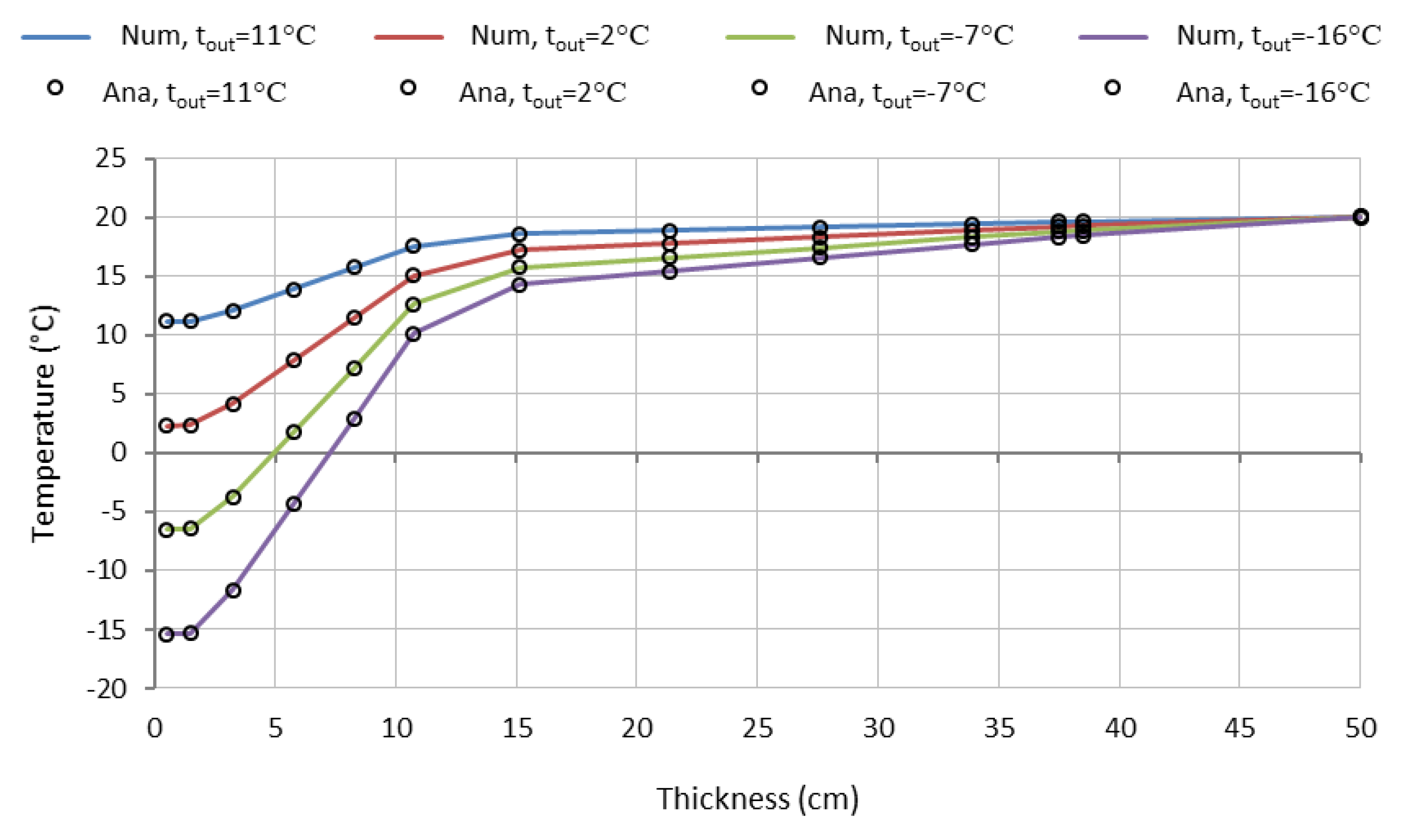

- Case 1 presents the test case in which several features of the tool are tested. Calculations are run transiently with constant outside temperature, leading to the solution of coupled equations to the steady-state result. In this case, the thermal inertia of the inner walls is assumed to be reasonably low. Different initial temperatures are given for the outer wall, room, and inner walls. When the steady-state is reached, the results of calculation are compared to the values of expected room and inner wall temperatures (should be equal) and expected radiator heat flux, which should compensate for heat losses of the room to the environment. Also, the temperature profiles in the multi-layer outer wall are compared against the analytical solutions for four characteristic and different values of outside temperatures, each run as separate calculations.

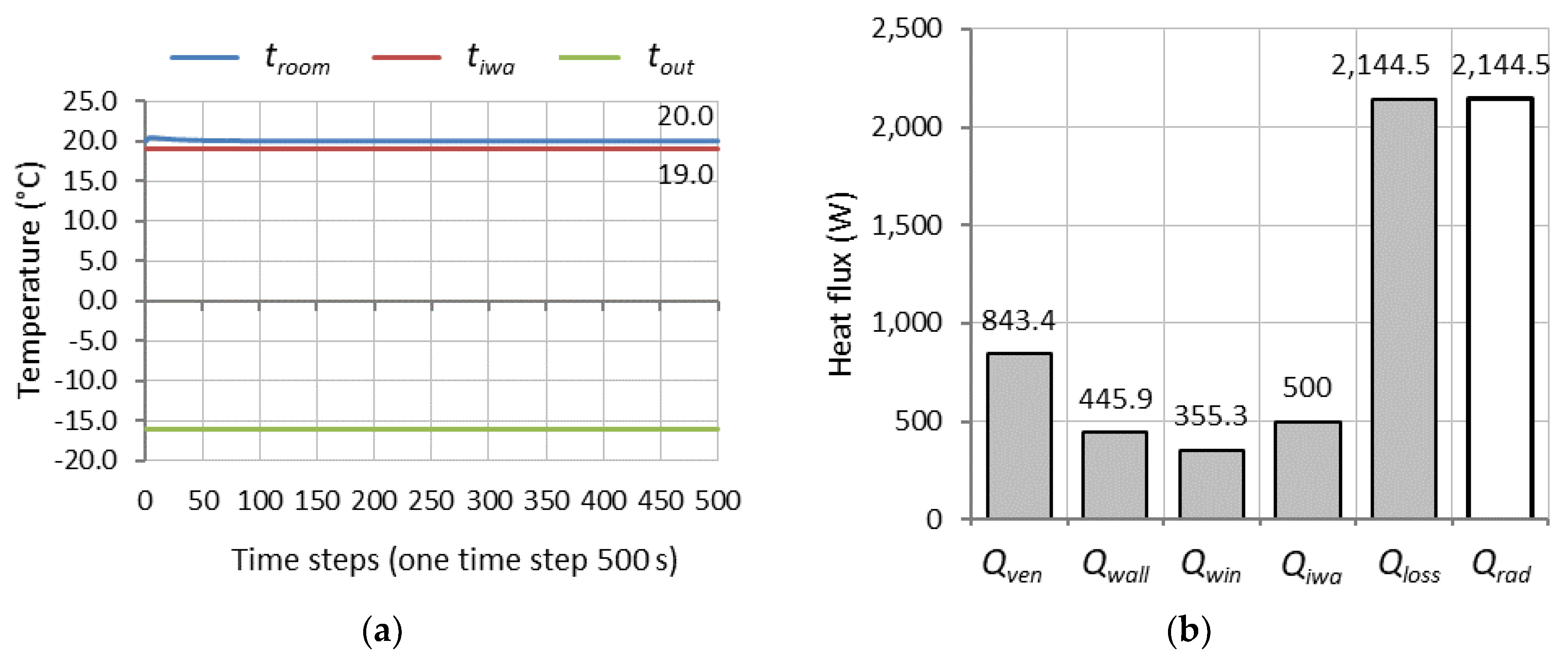

- Case 2 demonstrates a case where the thermal inertia of inner walls is huge, which causes the inner wall temperature to remain constant during the calculations, introducing an additional heat loss to the room. Calculation is run transiently and the expected values—prescribed room temperature and constant inner walls’ temperature—are analyzed when the steady-state is reached. The simulation is run for design conditions in terms of outside and set room temperatures.

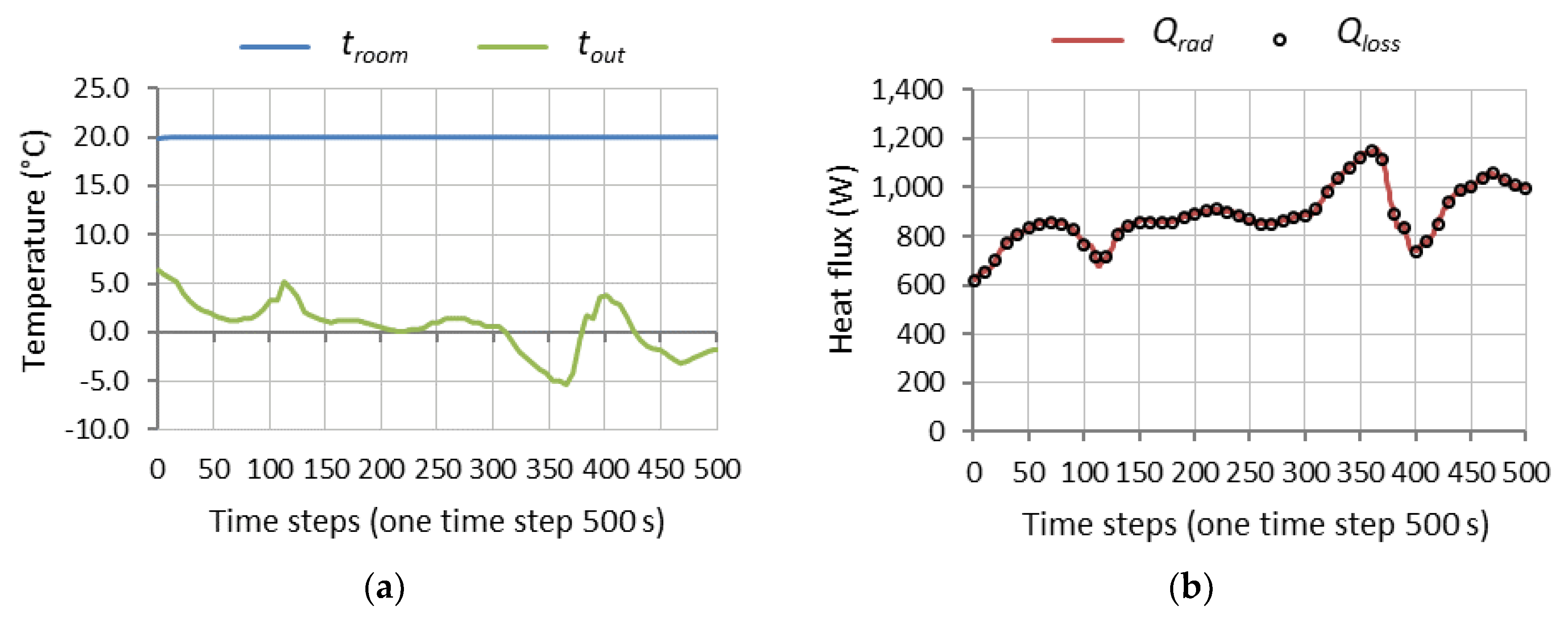

- Case 3 is designed to test the interaction between the heat flux from radiators towards the room and the heat flux between the room and the environment. For this purpose, the thermal inertia of the outer, inner walls, and a radiator is neglected, providing zero influence of the transient terms in Equations (1)–(3). Variable outside temperature is prescribed in time and the calculation is run transiently, formally providing the steady-state solutions for every time step due to the mentioned assumptions.

3.1. Validation Case 1—Low Thermal Inertia of Inner Walls

3.2. Validation Case 2—High Thermal Inertia of Inner Walls

3.3. Validation Case 3—No Thermal Inertia of Inner and Outer Walls

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the energy performance of buildings (EPBD). Off. J. Eur. Union 2010, 153, 13–35.

- Directive 2012/27/EU on energy efficiency (EED) of the European Parliament and of the Council of 25 October 2012. Off. J. Eur. Union 2012, 315, 1–56.

- Blazevic, R. Advanced Modeling and Dynamic Simulation of the Heating System with the Simultaneous Application of Modelica and the Final Volume Method. Ph.D. Thesis, University of Sarajevo, Sarajevo, Bosnia and Herzegovina, 2018. (In Bosnian). [Google Scholar]

- Kensby, J.; Trüschel, A.; Dalenbäck, J.O. Potential of residential buildings as thermal energy storage in district heating systems—Results from a pilot test. Appl. Energy 2015, 137, 773–781. [Google Scholar] [CrossRef]

- Romanchenko, D.; Kensby, J.; Odenberger, M.; Johnsson, F. Thermal energy storage in district heating: Centralized storage vs. storage in thermal inertia of buildings. Energy Convers. Manag. 2018, 162, 26–38. [Google Scholar] [CrossRef]

- Crawley, D.B.; Lawrie, L.K.; Winkelmann, F.C.; Buhl, W.F.; Huang, Y.J.; Pedersen, C.O.; Strand, R.K.; Liesen, R.J.; Fisher, D.E.; Witte, M.J.; et al. EnergyPlus: Creating a new generation building energy simulation program. Energy Build. 2001, 33, 443–457. [Google Scholar] [CrossRef]

- Delcroix, B.; Kummert, M.; Daoud, A.; Hiller, M.D. Conduction Transfer functions in TRNSYS multi-zone building: Current implementation, limitations and possible improvements. In Proceedings of the Fifth National Conference of International Building Performance Simulation Association, Madison, WI, USA, 1–3 August 2012. [Google Scholar]

- Wetter, M. Multizone building model for thermal building simulation in Modelica. In Proceedings of the 5th International Modelica Conference, Vienna, Austria, 4–5 September 2006; Kral, C., Haumer, A., Eds.; Modelica Association and Arsenal Research: Vienna, Austria, 2006; Volume 2, pp. 517–526. [Google Scholar]

- Wetter, M.; Zuo, W.; Nouidui, T.S. Modeling of heat transfer in rooms in the Modelica “Buildings” Library. In Proceedings of the Building Simulation 2011: 12th Conference of International Building Performance Simulation Association, Sydney, Australia, 14–16 November 2011. [Google Scholar]

- Nouidui, T.S.; Phalak, K.; Zuo, W.; Wetter, M. Validation and Application of the Room Model of the Modelica Buildings Library. In Proceedings of the 9th International Modelica Conference 2012, Munich, Germany, 3–5 September 2012; Simulation Research Group, Building Technology and Urban Systems Department Environmental Energy Technologies Division, Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2012. [Google Scholar]

- Felgner, F.; Cladera, R.; Merz, R.; Litz, L. Modelling Thermal Building Dynamics with Modelica; Kaiserslautern University of Technology, Institute of Automatic Control: Kaiserslautern, Germany, 2003. [Google Scholar]

- Wetter, M.; Haugstetter, C. Modelica versus TRNSYS—A Comparison between an Equation-Based and a Procedural Modeling Language for Building Energy Simulation; United Technologies Research Center: East Hartford, CT, USA, 2006. [Google Scholar]

- Sodja, A.; Zupančič, B. Modelling thermal processes in buildings using an object-oriented approach and Modelica. Simul. Model. Pract. Theory 2009, 17, 1143–1159. [Google Scholar] [CrossRef]

- Skruch, P. A Thermal Model of the Building for the Design of Temperature Control Algorithms. Automatyka/Automatics 2014, 18, 9–21. [Google Scholar] [CrossRef]

- Verbeke, S.; Verhaert, I.; Audenaert, A. Thermal inertia in dwellings: Adapting thermostat schedules in relation to the building thermal mass. In Proceedings of the REHVA Annual Meeting Conference Low Carbon Technologies in HVAC, Brussels, Belgium, 23 April 2018. [Google Scholar]

- Byrne, A.; Byrne, G.; Davies, A.; Robinson, A.J. Transient and quasi-steady thermal behaviour of a building envelope due to retrofitted cavity wall and ceiling insulation. Energy Build. 2013, 61, 356–365. [Google Scholar] [CrossRef]

- Demirdzic, I.; Muzaferija, S.; Peric, M. Advances in computation of heat, fluid flow and solid body deformation using finite volume approaches. Adv. Numer. Heat Transf. 1997, 2, 59–96. [Google Scholar]

- Teskeredzic, A.; Demirdzic, I.; Muzaferija, S. Numerical method for calculation of complete casting process—Part I, Theory. Numer. Heat Transf. Part B 2015, 68, 295–316. [Google Scholar] [CrossRef]

| Test Case | Room Size (B/H/W) in m | HT Coeff. W/m2K | Design Temp. °C | ||||||

|---|---|---|---|---|---|---|---|---|---|

| αin | αout | ||||||||

| Cases 1, 2, 3 | 5/8/3.5 | 7.05 | 1.4 | 0.5 | 38.45 | 20 | 8 | 20 | −16 |

| Layer | Material | Thickness, m | Thermal Conductivity, W/mK | Specific Heat, J/kgK | Density, kg/m3 |

|---|---|---|---|---|---|

| 1 | Cement mortar | 0.02 | 1.40 | 1000 | 1800 |

| 2 | EPS | 0.10 | 0.04 | 1450 | 20 |

| 3 | Hollow brick | 0.25 | 0.64 | 900 | 1600 |

| 4 | Lime mortar | 0.02 | 0.81 | 1000 | 1500 |

| Test Cases | Inner Wall Properties | Radiator Parameters | ||||||

|---|---|---|---|---|---|---|---|---|

| kg | J/kgK | 90/70/20 | 80/60/20 | kg/s | Supply Temp. | |||

| Case 1 | 100 | 1400 | 100 | 5 | 2084.3 | 1644.5 | 0.019 | Heat curve |

| Case 2 | 2718.1 | 2144.5 | 0.026 | |||||

| Case 3 | 0 | 0 | 0 | 0 | 2084.3 | 1644.5 | 0.019 | |

| Outside Temperature tout (°C) | Water Supply Temp. tS (°C) | Heat Losses Qloss (W) | Qloss/QlossN (%) |

|---|---|---|---|

| −16 | 80.0 | 1644.5 | 100 |

| −7 | 67.6 | 1233.4 | 75 |

| 2 | 54.3 | 822.3 | 50 |

| 11 | 39.7 | 411.1 | 25 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teskeredzic, A.; Blazevic, R. Transient Radiator Room Heating—Mathematical Model and Solution Algorithm. Buildings 2018, 8, 163. https://doi.org/10.3390/buildings8110163

Teskeredzic A, Blazevic R. Transient Radiator Room Heating—Mathematical Model and Solution Algorithm. Buildings. 2018; 8(11):163. https://doi.org/10.3390/buildings8110163

Chicago/Turabian StyleTeskeredzic, Armin, and Rejhana Blazevic. 2018. "Transient Radiator Room Heating—Mathematical Model and Solution Algorithm" Buildings 8, no. 11: 163. https://doi.org/10.3390/buildings8110163

APA StyleTeskeredzic, A., & Blazevic, R. (2018). Transient Radiator Room Heating—Mathematical Model and Solution Algorithm. Buildings, 8(11), 163. https://doi.org/10.3390/buildings8110163