Investigation of the Optical Performance of a Novel Planar Static PV Concentrator with Lambertian Rear Reflectors

Abstract

:1. Introduction

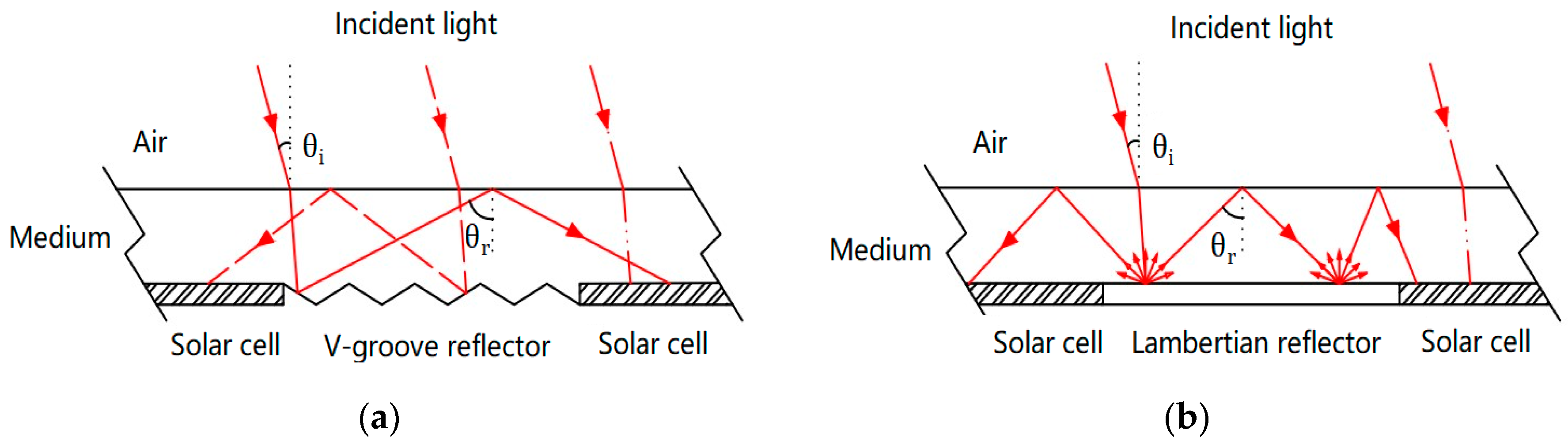

2. Methodology

2.1. Ray-Tracing Approach

2.2. Method Validation

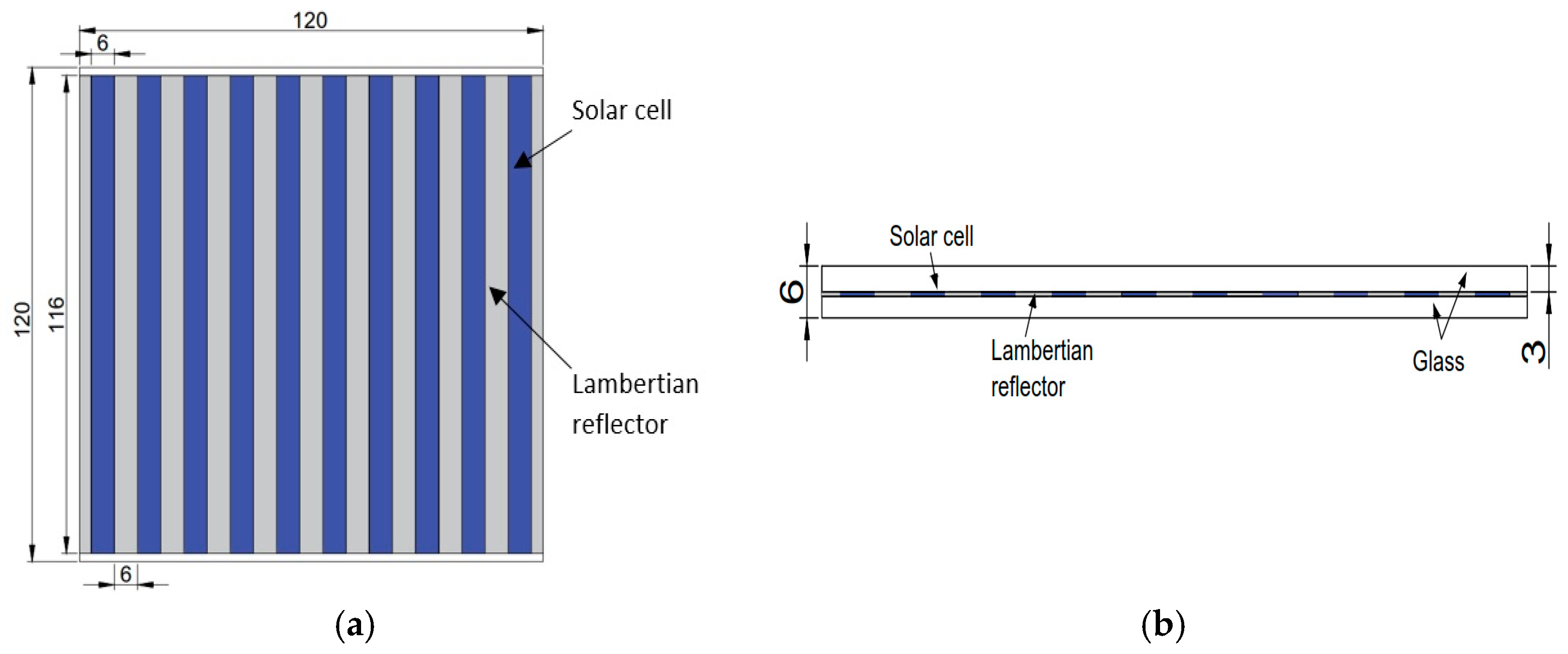

2.3. Model Description

3. Results and Discussion

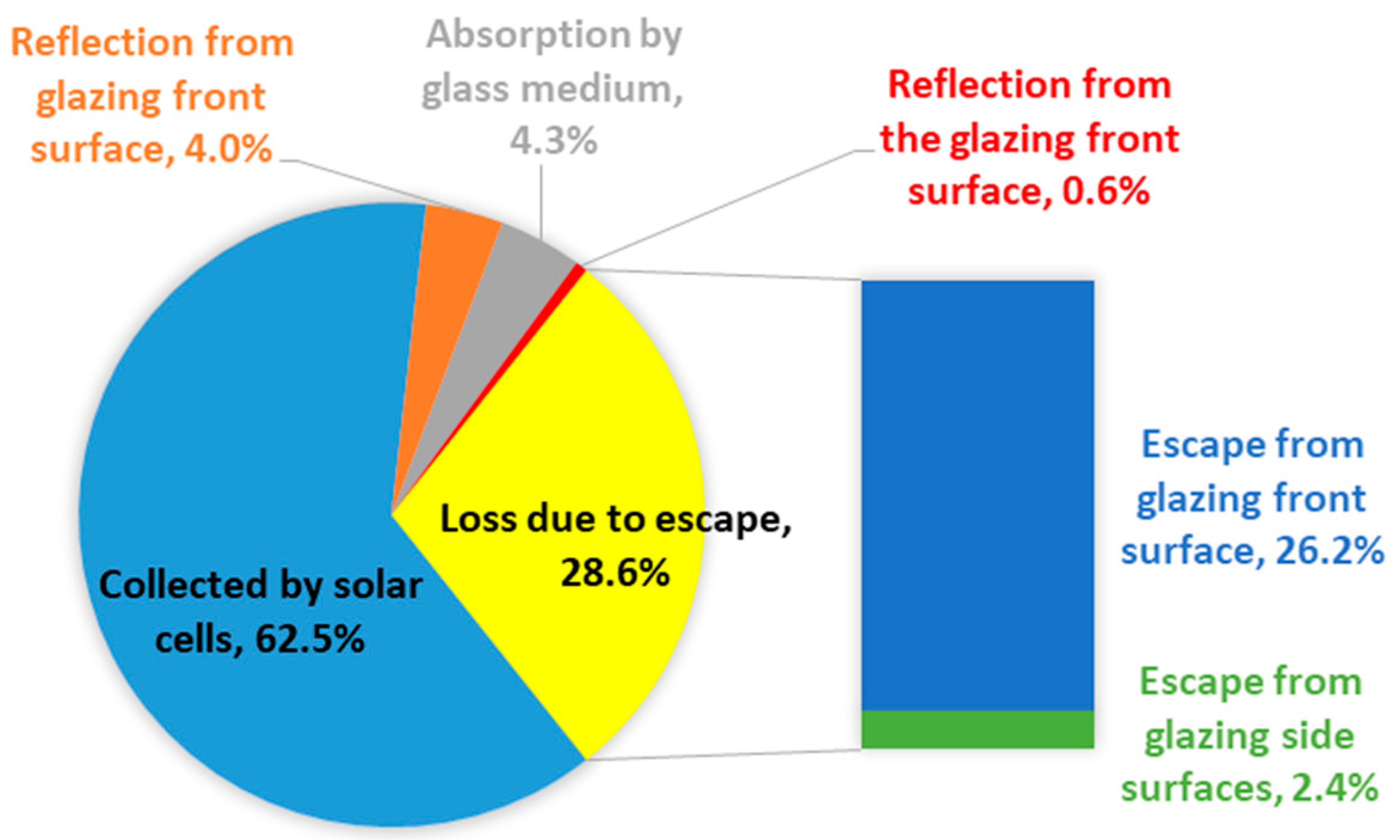

3.1. Optical Characteristics of the Base Model

3.2. Influence of the Geometric Concentration Ratio

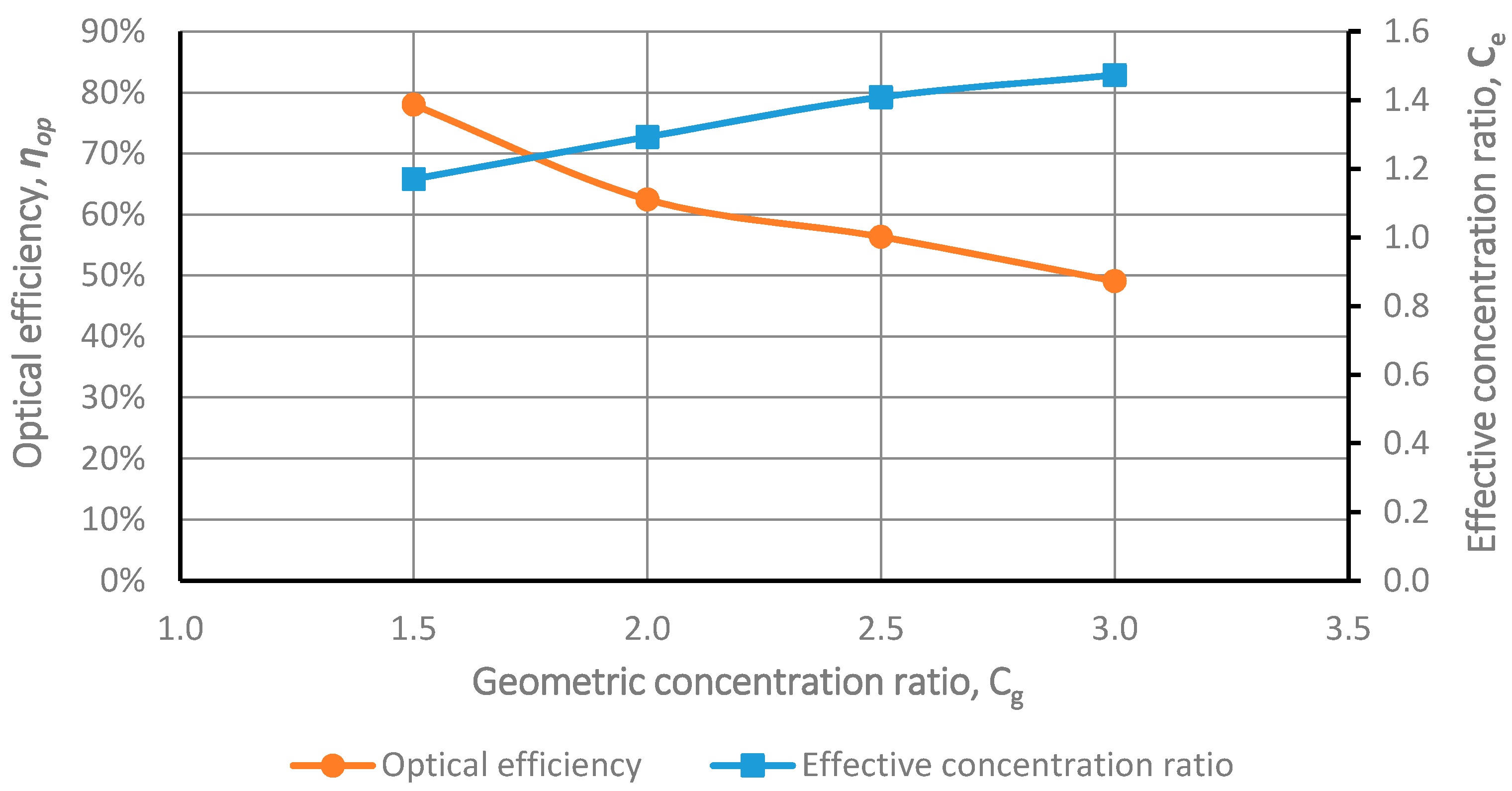

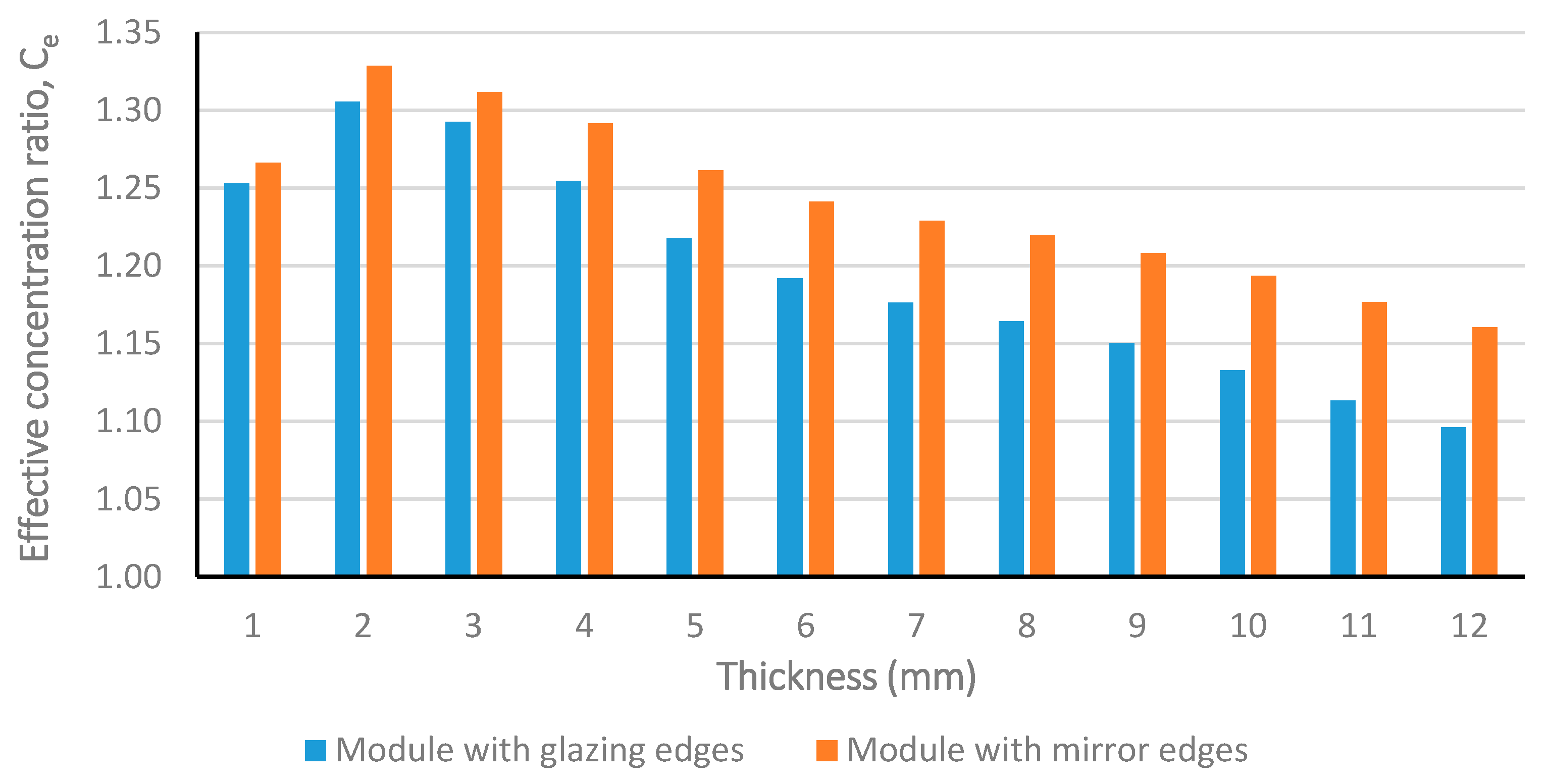

3.3. Influence of the Glass Thickness and Edge Mirror

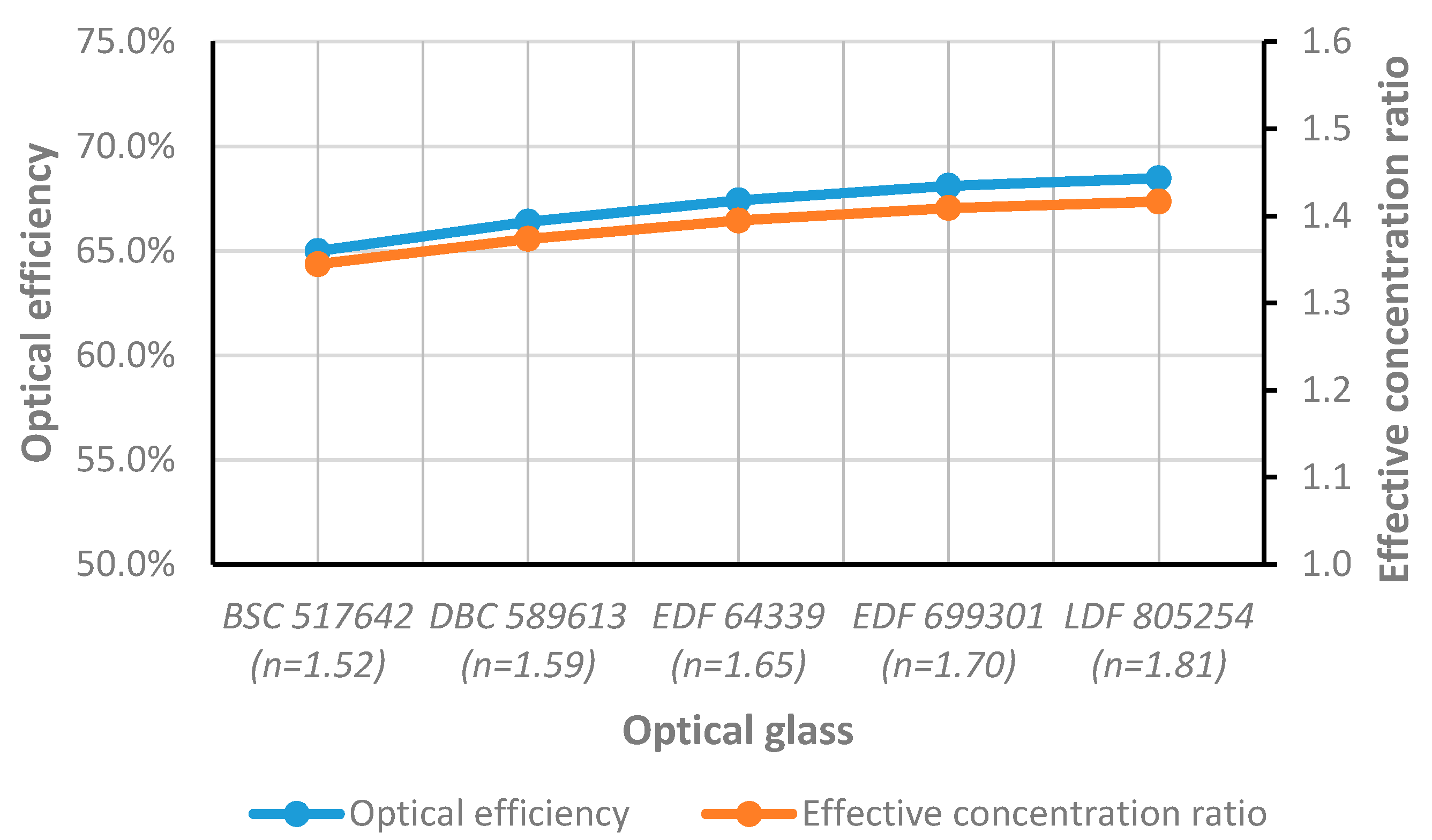

3.4. Influence of the Glazing Optical Properties

3.5. Influence of the Reflectivity of the Lambertian Reflector

3.6. Influence of the Solar Incident Angle

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- The European Commission. Available online: https://ec.europa.eu/energy/en/topics/energy-efficiency/buildings (accessed on 10 March 2017).

- Norton, B.; Eames, P.C.; Mallick, T.K.; Huang, M.J.; McCormack, S.J.; Mondol, J.D.; Yohanis, Y.G. Enhancing the performance of building integrated photovoltaics. Sol. Energy 2011, 85, 1629–1664. [Google Scholar] [CrossRef]

- Chemisana, D. Building integrated concentrating photovoltaics: A review. Renew. Sustain. Energy Rev. 2011, 15, 603–611. [Google Scholar] [CrossRef]

- Sharaf, O.Z.; Orhan, M.F. Concentrated photovoltaic thermal (CPVT) solar collector systems: Part I—Fundamentals, design considerations and current technologies. Renew. Sustain. Energy Rev. 2015, 50, 1500–1565. [Google Scholar] [CrossRef]

- Shanks, K.; Senthilarasu, S.; Mallick, T.K. Optics for concentrating photovoltaics: Trends, limits and opportunities for materials and design. Renew. Sustain. Energy Rev. 2016, 60, 394–407. [Google Scholar] [CrossRef]

- Varieras, R.V.; Wang, J.; King, D.L. System Performance Considerations for Low-Concentration Linear-Focus Silicon-Based Photovoltaic Modules. IEEE J. Photovolt. 2013, 3, 1409–1414. [Google Scholar] [CrossRef]

- Kim, J.M.; Dutta, P.S. Optical efficiency–concentration ratio trade-off for a flat panel photovoltaic system with diffuser type concentrator. Sol. Energy Mater. Sol. Cells 2012, 103, 35–40. [Google Scholar] [CrossRef]

- Baig, H.; Fernández, E.F.; Mallick, T.K. Influence of spectrum and latitude on the annual optical performance of a dielectric based BICPV system. Sol. Energy 2016, 124, 268–277. [Google Scholar] [CrossRef]

- Mallick, T.; Eames, P.; Hyde, T.; Norton, B. The design and experimental characterisation of an asymmetric compound parabolic photovoltaic concentrator for building facade integration in the UK. Sol. Energy 2004, 77, 319–327. [Google Scholar] [CrossRef]

- Zacharopoulos, A.; Eames, P.C.; McLarnon, D.; Norton, B. Linear dielectric non-imaging concentrating covers for PV integrated building facades. Sol. Energy 2000, 68, 439–452. [Google Scholar] [CrossRef]

- Maruyama, T.; Osako, S. Wedge-shaped light concentrator using total internal reflection. Sol. Energy Mater. Sol. Cells 1999, 57, 75–83. [Google Scholar] [CrossRef]

- Kerrouche, A.; Hardy, D.; Ross, D.; Richards, B. Luminescent solar concentrators: From experimental validation of 3D ray-tracing simulations to coloured stained-glass windows for BIPV. Sol. Energy Mater. Sol. Cells 2014, 122, 99–106. [Google Scholar] [CrossRef]

- Leow, S.W.; Corrado, C.; Osborn, M.; Isaacson, M.; Alers, G.; Carter, S.A. Analyzing luminescent solar concentrators with front-facing photovoltaic cells using weighted Monte Carlo ray tracing. J. Appl. Phys. 2013, 113, 214510. [Google Scholar] [CrossRef]

- Klampaftis, E.; Ross, D.; McIntosh, K.R.; Richards, B.S. Enhancing the performance of solar cells via luminescent down-shifting of the incident spectrum: A review. Sol. Energy Mater. Sol. Cells 2009, 93, 1182–1194. [Google Scholar] [CrossRef]

- Smestad, G.; Hamill, P. Concentration of solar radiation by white backed photovoltaic panels. Appl. Opt. 1984, 23, 4394–4402. [Google Scholar] [CrossRef] [PubMed]

- Uematsu, T.; Yazawa, Y.; Tsutsui, K.; Miyamura, Y.; Ohtsuka, H.; Warabisako, T.; Joge, T. Design and characterization of flat-plate static-concentrator photovoltaic modules. Sol. Energy Mater. Sol. Cells 2001, 67, 441–448. [Google Scholar] [CrossRef]

- Hezel, R. Novel applications of bifacial solar cells. Prog. Photovolt. Res. Appl. 2003, 11, 549–556. [Google Scholar] [CrossRef]

- Yoshioka, K.; Koizumi, K.; Saitoh, T. Simulation and fabrication of flat-plate concentrator modules. Sol. Energy Mater. Sol. Cells 2003, 75, 373–380. [Google Scholar] [CrossRef]

- Weber, K.; Everett, V.; Deenapanray, P.; Franklin, E.; Blakers, A. Modeling of static concentrator modules incorporating Lambertian or v-groove rear reflectors. Sol. Energy Mater. Sol. Cells 2006, 90, 1741–1749. [Google Scholar] [CrossRef]

- McIntosh, K.R.; Swanson, R.M.; Cotter, J.E. A simple ray tracer to compute the optical concentration of photovoltaic modules. Prog. Photovolt. Res. Appl. 2006, 14, 167–177. [Google Scholar] [CrossRef]

- Moehlecke, A.; Febras, F.; Zanesco, I. Electrical performance analysis of PV modules with bifacial silicon solar cells and white diffuse reflector. Sol. Energy 2013, 96, 253–262. [Google Scholar] [CrossRef]

- Van Dijk, L.; van de Groep, J.; Veldhuizen, L.W.; Di Vece, M.; Schropp, R.E.I. Concepts for external light trapping and its utilization in colored and image displaying photovoltaic modules. Prog. Photovolt. Res. Appl. 2017, 25, 553–568. [Google Scholar] [CrossRef]

- Teijido, J.M. Conception and Design of Illumination Light Pipes; Université de Neuchâtel: Neuchâtel, Switzerland, 1999. [Google Scholar]

- Tracepro 7.8 User’s Manual. Available online: https://www.lambdares.com/wp-content/uploads/TraceProDownload/TracePro_User_Manual.pdf (accessed on 31 July 2017).

- NSG Group. Pilkington North America Architectural Glass Product Guide; Pilkington: Toledo, OH, USA.

- Nicolau, V.D.P.; Maluf, F.P. Determination of radiative properties of commercial glass. In Proceedings of the 18th Conference on Passive and Low Energy Architecture, Florianopolis, Brazil, 7–9 November 2001; PLEA: Florianopolis, Brazil, 2001. [Google Scholar]

- Koizumi, K.; Sugita, K.; Yoshioka, K.; Saitoh, T. Performance improvement of a static concentrator module with an asymmetric v-groove backsheet structure. Sol. Energy Mater. Sol. Cells 2003, 75, 623–627. [Google Scholar] [CrossRef]

| BSC 517642 | DBC 589613 | EDF 648339 | EDF 699301 | LDF 805254 | |

|---|---|---|---|---|---|

| Refractive index | 1.52 | 1.59 | 1.65 | 1.70 | 1.81 |

| Critical angle (°) | 41.5 | 41.1 | 39.0 | 37.3 | 36.0 |

| Reflectivity at the air-glass interface | 4.3% | 5.2% | 6.0% | 6.7% | 8.3% |

| Absorption coefficient (cm−1) | 0.003 | 0.003 | 0.002 | 0.002 | 0.001 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Wu, Y.; Hou, X.; Liu, H. Investigation of the Optical Performance of a Novel Planar Static PV Concentrator with Lambertian Rear Reflectors. Buildings 2017, 7, 88. https://doi.org/10.3390/buildings7040088

Liu X, Wu Y, Hou X, Liu H. Investigation of the Optical Performance of a Novel Planar Static PV Concentrator with Lambertian Rear Reflectors. Buildings. 2017; 7(4):88. https://doi.org/10.3390/buildings7040088

Chicago/Turabian StyleLiu, Xiao, Yupeng Wu, Xianghui Hou, and Hao Liu. 2017. "Investigation of the Optical Performance of a Novel Planar Static PV Concentrator with Lambertian Rear Reflectors" Buildings 7, no. 4: 88. https://doi.org/10.3390/buildings7040088

APA StyleLiu, X., Wu, Y., Hou, X., & Liu, H. (2017). Investigation of the Optical Performance of a Novel Planar Static PV Concentrator with Lambertian Rear Reflectors. Buildings, 7(4), 88. https://doi.org/10.3390/buildings7040088