1. Introduction

Energy is considered a backbone to human activity; while the global population increasing the demand for energy also increases [

1] Due to the increase on energy demand globally and the increasing levels of greenhouse gases, researchers are continuously looking for greener alternatives for energy storage and supply [

2,

3]. One such area of research is the Phase Change Materials (PCMs). PCMs have the unique ability to absorb (store) and release enormous quantities of heat without a substantial temperature change taking place [

4]. Therefore, there is a need to conduct research into the potential that PCMs have in the development of greener energy systems, particularly in residential buildings.

The aim of the current work is to highlight the major disadvantages that dominate the use of PCMs in residential buildings, along with identifying any gaps in previous research and proposing ideas for future research into this field.

The study begins with a review into residential energy usage with data provided by the government of the United Kingdom. This is followed by a detailed look at the design stages of PCM systems, along with three current applications for PCMs in residential buildings.

Section 4 is a review of five major disadvantages facing PCM systems in this application and the impact they have. Following on from this section is a detailed breakdown of emerging technologies for residential PCM applications. The concluding section discusses areas for further research into PCM technology based around gaps in current research for residential applications.

2. Residential Energy Usage

According to several studies [

5] it was clear that buildings account for 41% of worldwide energy consumption, which in turn equates to 30% of annual greenhouse gas emissions. The United Nations Environmental Program [

6] report into buildings and climate change goes into more detail about the contribution that buildings have on energy use and greenhouse gas emissions. It states that carbon dioxide emissions from residential buildings are rising at a rate of 1.7% each year. However, the report is optimistic that by utilizing current technologies, the total energy consumption of buildings can be cut down drastically (30–80%, depending on the building and investment). The report by the UNEP provides an unbiased outlook on the impact of the building sector has on energy use, and outlines the issues facing the sector, as well as potential solutions to the problem.

The United Kingdom’s Government Department for Business, Energy & Industrial Strategy released a report in 2016 that documents the energy usage in the United Kingdom (UK) from 1970 to 2015. This report is broken down by industry, domestic, services, and transport sectors. From the data provided, it was discovered that roughly 30% of energy consumed in the UK is by residential users [

7].

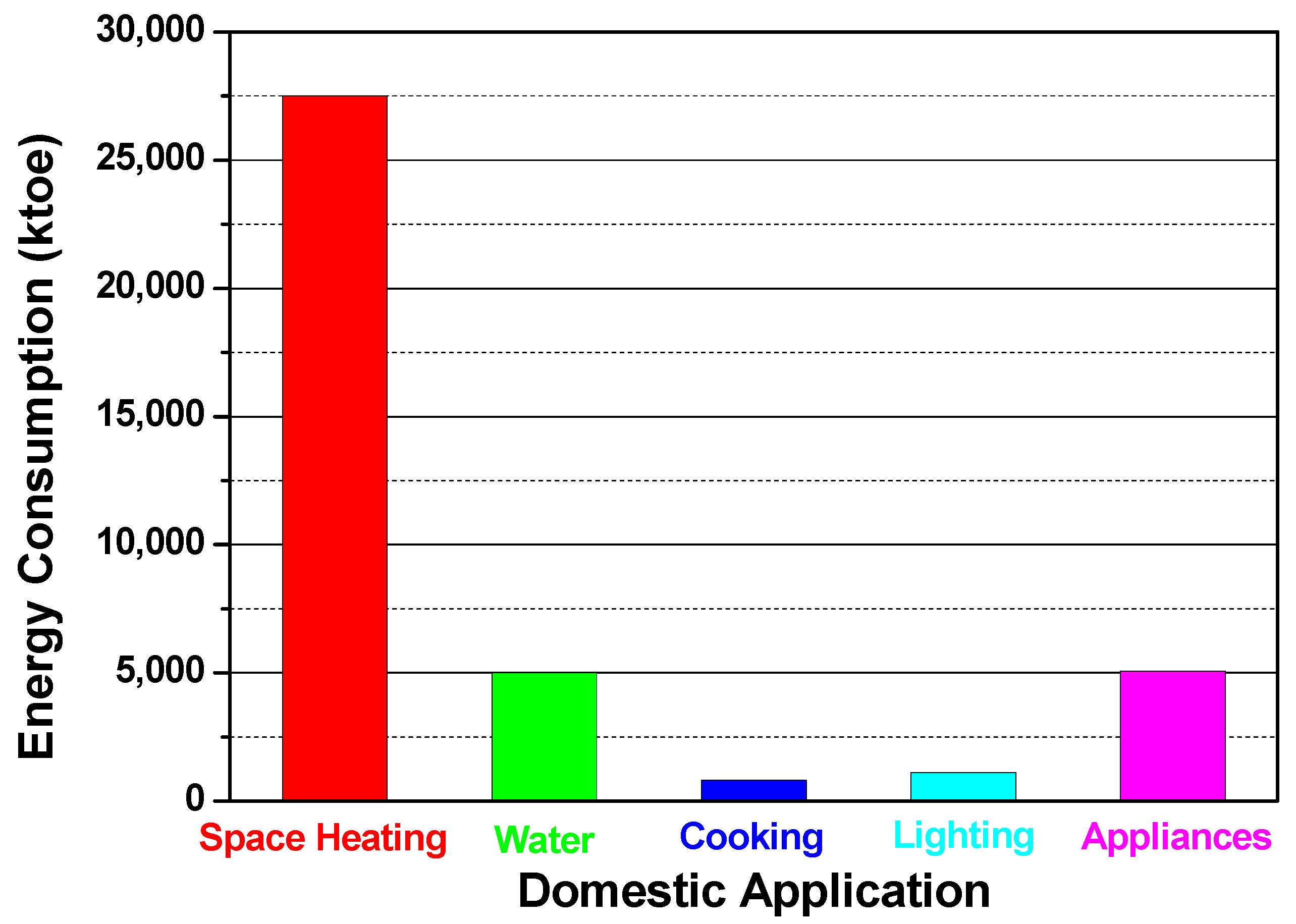

Figure 1 illustrates the energy used in residential applications in the UK by application.

According to the results, it seems that the biggest potential for energy savings in residential applications is in space heating. This is because there is such a large usage in this area when compared to the rest, that there must be some reductions in space heating first before any substantial energy savings can be made. During the winter months, buildings can lose heat to the environment, which means that the occupants rely on space heating techniques (radiators, gas heat pumps, etc.). Kut [

8] described how heat inside residential houses is lost through building construction (such as walls and roofs). Before heat transmission can take place, there must be a temperature gradient between the internal and external conditions of the room. For a room to lose heat, the air must be warmer inside the room than it is outside. Air inside a room transfers heat via convection to the surface of the wall. It then passes through the material of the wall by conduction and finally transfers from the outer surface of the wall by radiation and convention. Another similar study [

9] is optimistic when it comes to the potential of saving energy currently used for space heating. The study focused on energy savings in Danish residential buildings, an area where 75% of residential buildings were built before important demands for energy performance were introduced in 1979. Due to this, many buildings are due comprehensive renovations which could implement energy saving techniques. A case study is introduced into a renovation project on a multi-residency building. With improved insulation and new heat distribution systems, it was possible to reduce the amount of energy used for space heating by almost 50%. However, the analysis does not contain any information about the materials used for the insulation and whether or not they were PCMs. It does show that older properties can be renovated to become more energy efficient, meaning that PCMs have the potential to make a big impact in this sector.

3. PCMs for Residential Buildings

Residential buildings have been identified as one of the few sectors that have the potential to see large energy savings through the utilization of renewable energy and green building concepts [

10]. This argument is further supported by Kosny [

11], as he states that incorporating building materials with active thermal components will be an ‘ultimate’ step towards achieving significant savings in energy for heating and cooling applications. This is also supported by [

12] where they stated that the use of adequate thermal energy storage systems in buildings will lead to an increase in efficiency and reliability along with a reduction in energy costs and less polluting emissions. Mazzeo et al. [

13] research identifies the use of high thermal performance PCMs in building envelopes as a valuable method for achieving net zero energy buildings in the near future.

Many researchers agree that one of the greatest potentials for PCMs in residential building applications is that of thermal energy storage, specifically solar thermal energy. Kosny [

11] outlines that latent heat storage materials are commonly used to stabilize the building’s interior temperature. Lin et al. [

14] furthers this argument by stating that buildings’ HVAC systems can be integrated with PCMs so that they may act as thermal energy storage units and enhance the systems efficiency. The research conducted by [

14] was based on simulating a variety of house model setups using different PCM materials and thicknesses installed into the building’s walls and measuring the thermal performance of each setup. The simulations showed that by installing PCMs into building walls, the fluctuation of interior temperature is reduced, and increasing the thickness of the PCM improves the efficiency of these systems. Because the research is all simulation based, it makes it difficult to validate the results for their reliability.

An experiment that does use a full-scale model has been performed by Kuznik and Virgone [

15]. Their experiment involved two full-scale assessments, which set out to test the thermal performance of a wallboard made from a PCM copolymer composite, and compare the results with one that does not incorporate a PCM. The experiment was controlled using a thermal guard and climate chamber, which allowed for the temperature to be set so that the tests could be repeated for greater accuracy of results. According to the results extracted from the above research, it was discovered that the PCM filled walls greatly reduced the overheating effects of the room and led to the surface temperature of the wall becoming lower. The results show that PCMs could also be used to increase occupant comfort in buildings as well as store energy.

Zhou et al. [

16] have conducted extensive research into appropriate PCMs and uses for thermal energy storage in building applications. Their research identified many suitable materials, both commercial and non-commercial, that have properties suitable for residential use. They also evaluate several different applications and demonstrate how numerical analysis can evaluate the thermal performance of these buildings with thermal resistance, thermal inertia (decrement factor), and heat storage coefficients being three of the most commonly used parameters. The report, however, does not cover ways that long-term stability of PCM systems can be improved, and states that further research is required in this field. It also concludes that PCMs have a great potential in reducing fluctuations of indoor temperatures in buildings, as well as offer thermal storage and ventilation/cooling solutions.

3.1. PCM Design Criteria

When designing a latent heat energy storage system, there are three main components that need to be considered [

17]:

A suitable phase change material for the operational temperature range.

A container that encapsulates the PCM.

Surface heat exchangers for transferring the heat from source to PCM and then from the PCM to the heat sink.

Material Selection: The first property to consider when deciding on a suitable material for any given application is that of melting temperature. PCMs with melting temperatures below 15 °C are used in air conditioners to store cool air, whereas materials with high melting temperatures (around 90 °C) can be used as absorbers in refrigerators [

18]. Materials with melting temperatures in between these points are generally used for load levelling and solar heating applications. Along with melting temperature, there are a wide range of physical, chemical, economic, and thermal properties that will determine the correct PCM to use (as seen in

Table 1). It is important that a chosen PCM have as many as these properties as possible.

PCM Encapsulation: There must be a suitable way of containing a PCM before it can be a viable option in energy storage and distribution [

17]. There are at least three main container types for PCM applications: bulk storage, macroencapsulation, and microencapsulation. Any container used for PCM encapsulation should meet the following requirements:

Be a barrier to the environment to protect from harmful interaction.

Offer an adequate heat transfer surface.

Ensure structural stability and offer easy handling.

For its given application, it must offer corrosion resistance, thermal stability, required strength, and flexibility.

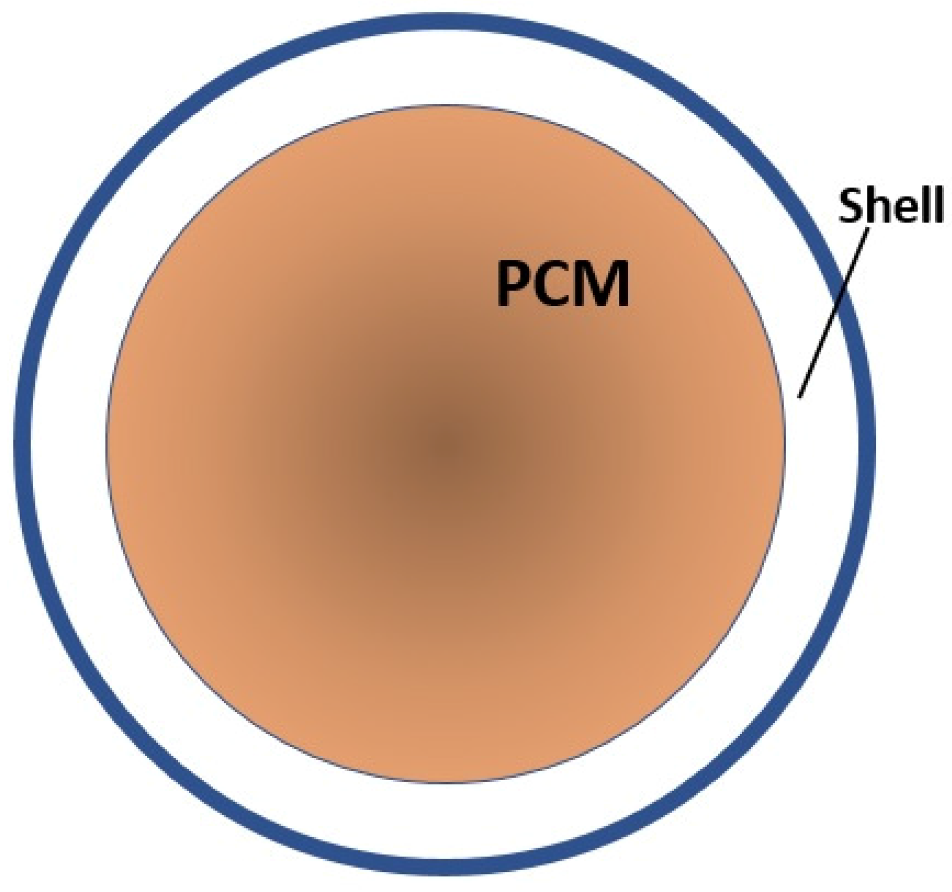

The technique of Microencapsulation involves containing a high amount of micron sized PCM particles in rod-shaped, or spherical containers made of high molecular weight polymeric films [

20] as presented in

Figure 2. Microencapsulated systems usually suffer from low heat transfer rates, which is usually caused by the matrix encapsulating the PCM having a low thermal conductivity [

17]. Due to the nature of microencapsulation, it tends to be high in cost when compared to other storage methods. However, the use of microencapsulation can be optimized by combining the PCM modules with the heat transfer fluid to form a phase change slurry (PCS) [

20]. This method means the heat storage (PCM) and heat transfer (continuous liquid) mediums become one fluid with a high energy density [

21].

The most widely used type of PCM containment, macroencapsulation, involves encapsulating a selected quantity of a PCM inside of a distinct unit [

23]. The use of macroencapsulation makes it easier for the air to be used as a heat transfer fluid [

17], allowing for better use in residential applications. PCMs are stored inside of a module (which come in a variety of forms), and the heat transfer fluid flows over the modules. Macroencapsulation provides a large flexibility for design, and tends to be easy to manufacture for commercial use [

20]. They are also better at avoiding phase separations, can increase the rate of heat transfer, and provide a structure to hold the PCM in place that can be disguised into its environment [

17].

Bulk storage is commonly referred to as the ‘tank heat exchanger’ for PCMs due to their similarity in design to existing tanks used for energy storage [

24]. The issue with bulk storage encapsulation is that there is a need for a large heat transfer area due to lowered PCM thermal conductivity when compared to micro and macro encapsulation [

17]. This issue can be overcome in a variety of ways, including the addition of fins, direct contact with heat exchanger surface, and by adding particles to the PCM with high conductivity properties [

25]. The use of bulk storage encapsulation may be limiting for residential applications due to the size of the storage technique. However, one such technique related is that of storing and heating water using a solar heated tank lined with a PCM.

Heat Transfer Solution: Any latent heat thermal energy storage system must contain a heat exchanger, with the function of transferring heat from a source to the heat storage phase change material and then to the heat sink [

26]. The heat exchanger surface can have a massive influence on the temperature gradient for the warming and cooling of the PCM. This makes it an imperative to have quantitative information available regarding the heat transfer application and phase change process of the PCM before designing a LHTES system. An issue with most PCMs, especially when they are in a solid phase, is that they start to show insulating characteristics. This can create a problem for the heat recovery cycle and cause an increase in their melting temperature, affecting the efficiency of the system. Hasnain [

26] states that this issue can be solved by using extended surfaces to connect the storage unit to the wall.

3.2. PCM Applications

Solar Water Heating: One of the most common applications of solar thermal technology [

27], solar water heating, involves using sunlight to heat water in solar collectors which then, via a heat exchanger, can heat up the fluid in a storage tank where it is then supplied to the building. Research shows that PCMs would likely be integrated into the systems storage tank. One idea proposed was that of using a built-in storage tank containing a layer of capsules containing PCMs at the bottom [

28]. Currently, it is estimated that the cost of installing a standard solar water heating system into a 4–5-bedroom house in the UK would be around £4000–£7000 [

29].

Space Heating/Cooling: Phase change materials can be incorporated into both passive and active space heating and cooling systems [

30]. Passive systems work by capturing thermal energy through natural convection, or directly through solar energy. Potential passive system uses for PCMs include encapsulating the PCM into the buildings materials such as the floor, ceiling, concrete, or gypsum wallboard [

31]. One benefit of this is that adding PCMs increase the thermal storage capacity of a residential building. Research has shown that this can directly increase the occupant comfort level by up to 32%, as it decreases the magnitude of temperature fluctuations, leading to the indoor air temperature being at the desired value for a greater period [

32].

In active space heating and cooling systems, separate collectors are used to capture solar energy during the day and store the energy using latent heat storage materials (PCMs) [

33]. This stored heat is then used during peak electrical load times to decrease the amount of electricity used by the household. Specific components and operations are required in active PCM systems in order to charge and discharge storage vessels before they can be used in conventional heating/cooling systems [

34]. Electrical units such as pumps and fans are used to distribute the energy released by the PCMs around the residential building. The benefits of active systems include improving the thermal efficiency of a building, and reducing the electrical load required to operate a buildings heating/cooling system [

30].

Waste Heat Recovery: A waste heat recovery system is commonly defined as a system which reclaims or recycles heat generated from another process [

35]. These systems store thermal energy by making use of extensive internal waste heat from electrical appliances, lighting, and human bodies [

36]. Heat storage systems using low temperature PCMs were investigated by Kabbara and Abdallah [

37]. Their system used a salt hydrate PCM encapsulated in cylindrical capsules and collected energy from exhaust hot air, and was designed to investigate the effects of air mass flow rate on stored energy. The results showed that higher mass flow rates lead to the system absorbing more energy. These results show that PCM waste heat recovery systems work more efficiently when there is more waste heat to be absorbed, and would hence be of more use in high heat loss areas such as kitchens.

4. Disadvantages of the Use of PCMs

Most buildings are built with the intention of them having a service life of between 50–100 years [

38]. Peippo et al. [

39] found that a house built with PCMs impregnated into the wallboards can save around 4 GJ of energy every year which equates to around 15% reduction in energy costs annually.

Table 2 shows a breakdown of the financial viability of installing a PCM system into a UK home.

With an average installation cost, around £5000 [

29]), and an annual energy saving of £202.65 [

7], this means that an ideal PCM system installed into a residential building will need a service life of at least 25 years to make it viable.

One overwhelming issue with the use of PCMs integrated with building materials is that there is little to no way to perform intrusive maintenance on the PCM system. This means that once the PCM has stopped being effective, it is difficult to replace the PCM without performing any destructive methods to access it. Many of the issues associated with PCMs lead to the material degrading over time, rendering it useless after 1000’s of freeze/melt cycles. The following section looks into a number of detrimental effects and ways that current research has improved the issues.

4.1. Super Cooling Effects

Supercooling is defined as the state where a liquid solidifies below its normal freezing point [

40], and hence experiences a delay in starting its solidification process [

41]. After prolonged use, most of salt hydrates tend to supercool before freezing during the extraction of stored heat [

42]. This causes a drop in the efficiency of the material, and will eventually lead to heat recovery not taking place at all in the PCM. It is more common for inorganic PCMs to suffer from this disadvantage, however research has identified that organic PCMs encapsulated in microcapsules tend to severely supercool due to the absence of nuclei in small spaces [

43].

Research has shown that the effect of supercooling can be reduced by adding a nucleating agent [

44]. Fan et al. [

45] has found that supercooling can be prevented by adding around 9 wt % of 1-octadecanol directly in the PCM, or 6 wt % of sodium chloride to the emulsion. However, the results from the research show that the thermal performance of the PCM is affected due to a drop in latent heat of fusion caused by the addition of relatively large amounts of additive.

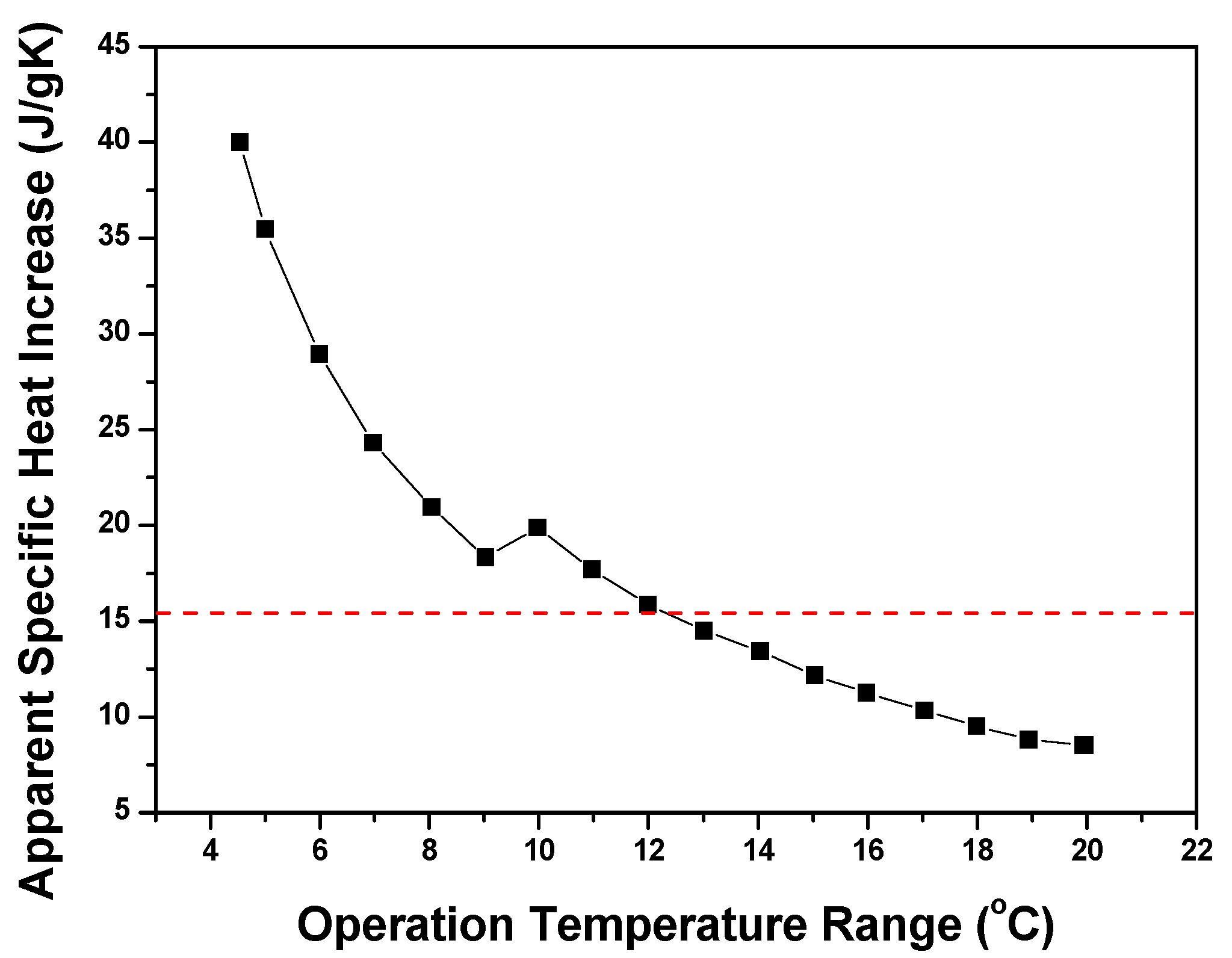

Recent research has been conducted by Cao and Yang [

46] to attempt to suppress the effects of supercooling without effecting the heat capacity of the material in microencapsulated PCM systems by optimising the structure and composition of the microcapsule shell. For their experiment, they selected n-octadecane as the PCM and melamine-formaldehyde resin as the shell of the microcapsule. The results from the research showed that supercooling was significantly suppressed using this technique. It also found that the latent heat of fusion for the PCM is much higher using this technique as well. At the transition temperature of 10 °C, the latent heat increase was around 21.3 kJ/kg, as shown in

Figure 3.

Overcoming supercooling effects in PCM systems has been shown to be a very difficult process. Adding a nucleating agent to the PCM mixture has been proven to work but leads to a decrease in thermal performance. Techniques that look to improve thermal performance whilst limiting supercooling appear to be very expensive and require further development. Based on the review it is advisable that residential PCM systems avoid using microencapsulated PCMs and any hydrated salts where supercooling is very predominant. Macroencapsulation is considered to be very common and viable for residential use, which means that microencapsulation is not essential.

4.2. Low Thermal Conductivities

PCMs tend to have very low thermal conductivities, which leads to low heat transfer rates in and out of latent heat energy storage systems [

47]. Low thermal conductivities can limit the potential of PCMs in thermal energy storage systems as it causes a decrease in the rate of heat absorbing/releasing during the solid-liquid change of phase [

48]. Much work has been conducted into enhancing thermal conductivities of PCMs by using additives and composites [

49], for example, carbon based additives can be added to stearic acid in a nanocomposite form [

50]. This experiment found that a graphite additive of 5 wt % can increase the thermal conductivity of the PCM by up to 12 times. However, this leads to a weakening of the materials natural convection, and a decrease in the latent heat of fusion. In residential applications, low thermal conductivities could lead to many performance issues with PCM systems. As the rate of phase change is longer with lower thermal conductivities, the occupant comfort benefits provided by PCM systems are not felt to their full potential. Also, energy cannot be quickly distributed/absorbed in times of rapid temperature changes, such as mornings and evenings. These issues make PCM systems less attractive and will limit their potential for deployment into residential buildings.

Experiments which investigate ways of increasing the thermal conductivity of PCMs can generally be split into two categories [

50]; enlarging the heat exchanger area with the addition of fins, or developing new PCM composites with additives to increase the thermal performance. Potential additives to materials include; exfoliated graphite nanoplatelets [

51,

52], metal foams [

53], and carbon fibre insertion [

54]. Research into the enhancement of heat transfer through fins includes Triplex tube heat exchanger [

55] and normal annular fins [

56].

The use of exfoliated graphite nanoplatelets as an enhancement technique for improving the thermal conductivity of paraffin wax PCM systems was investigated by [

52]. Their experiment involved a paraffin wax with a melting point of 75 °C being mixed with xGnP (commercially available graphene nanoplatelets) of a mass fraction ranging between 1–7 wt %. The thermal conductivities of each sample were measured using a UNITHERM 2022 thermal conductivity measuring instrument system, whilst the melting and heat storage behaviours were measured using differential scanning calorimeter (DSC). The experiment showed that there was an almost linear increase in thermal conductivity in the material as the content of xGnP was increased. The material started with a thermal conductivity of around 0.2 W/mK with no xGnP additive, and by the end of the experiment the thermal conductivity was 0.9 W/mK when 7 wt % additive was present. It was also found that the latent heat of fusion value for the material did not decrease with the introduction of the additive. However, the price of xGnP could be a negative contributing factor towards its potential for use in residential applications. Roughly 1kg of the material costs £88 (XG Sciences 2012), whereas paraffin wax costs around 1.60 £/kg [

57]. Even using only 7% xGnP still increases overall material cost by 4 times.

Low thermal conductivities of PCMs can also be improved through enlarging the surface area of the heat exchanger through the use of fins. Al-Abidi et al. [

55] studied the use of a triplex tube heat exchanger, whereby, a PCM was located in the middle tube which worked as a thermal energy storage unit to power a liquid desiccant air conditioning system. Welded onto the middle and inner tubes were four longitudinal fins which enhance the heat transfer process inside the triplex heat exchanger, improving both thermal energy storage capabilities and the thermal performance of the system. The experiment was set up to measure the average temperature of the PCM during the melting process and compare the values for when the fins are attached and for when the system does not have fins attached. The chosen PCM for the experiment was a paraffin wax called RT82, which is commercially supplied by the Rubitherm organization. The experiment found that the inclusion of the fins significantly reduced the amount of time it takes to charge the PCM, hence improving the thermal conductivity if the system. Their data also showed that the thermal energy storage efficiency of the system was quite high at around 71.8%.

It is important that enhancing the thermal conductivity of the PCM system is considered before the system is installed into a building. Enhancements can have a significant effect on the overall efficiency of the system, along with improved performance. The experiment performed by Al-Abidi et al. [

55] demonstrated the potential of adding fins to latent heat thermal energy storage systems as a way to enhance their thermal performance. The cross and longitudinal sections of the heat exchanger are shown in

Figure 4. It can be assumed that this technique is considerably cheaper than creating new PCM composites, and would hence be more appealing to residential applications.

4.3. Phase Segregation

Phase segregation is one of the biggest negative influences on the thermal cyclic stability of PCMs [

58]. Phase segregation can occur when compositions inside of the PCM are at different phases during cyclic loading [

59]. It is most common in multicomponent PCMs where the density of components is different, leading to the eventual separation of components due to gravity, which will alter the melting point of the material [

58]. Incongruent melting of salt hydrate based PCMs is another leading cause of phase segregation in PCM systems [

60]. Oró et al. [

20] stated that many PCMs require the use of nucleating and thickening agents to minimise the effect of phase segregation, especially in low temperature applications (<20 °C). They also advise that the long-term effects of phase segregation be fully researched when it comes to developing a PCM for a new application.

The effect that phase segregation will have on residential applications is that it limits the long-term stability of the phase change material in use. It has already been discussed that a viable thermal energy storage solution needs to be able to work efficiently for many years, hence researchers have investigated techniques to eliminate the detrimental effects of phase segregation from phase change materials.

Ryu et al. [

61] conducted research into the potential of thickening agents as a technique to reduce/eliminate phase segregation from inorganic hydrated salt PCMs. For high hydrated salt compounds, such as sodium sulfate decahydrate (Na

2SO

4·10H

2O), a super-absorbent polymer was found to be an effective thickener to prevent phase segregation. The experiments showed that most high hydrate salts could be stabilised by adding 3 to 5 wt % of the thickener. Phase segregation was prevented in low hydrated salts, such as sodium thiosulfate pentahydrate (Na

2S

2O

3·5H

2O) by adding 2 to 4 wt % of carboxymethyl cellulose. The resulting composites from this experiment all produced PCMs which had melting temperatures in the range of 30–60 °C, which makes it suitable for some residential applications, such as waste heat recovery.

Hadjieva et al. [

62] suggested and investigated using PCMs absorbed into porous concrete as a method of reducing the effects of phase segregation in inorganic PCMs. Their hypothesis predicted that the absorption of sodium thiosulphate pentahydrate (hydrated salt PCM) into a porous concrete containing cavity and a large unfolded surface would avoid a precipitation of incongruent melting of the PCM. The experiment involved impregnating cylindrical samples of porous concrete with the hydrated salt PCM, and then measuring the thermophysical properties of the new composite before, during, and after thermal cycling. The results from the experiment found that the concrete’s large absorption areas served as a good supporting matrix for the PCM and improved its thermal cycling stability. It was also found that the heat capacity of the PCM remains high after it has been incorporated into the porous concrete. However, supercooling effects appeared as the PCM melted completely, which meant that the phase transition followed a random distribution time scale. This means that this solution may not be completely viable without incorporating a nucleating agent to eliminate supercooling.

4.4. Fire Safety of PCMs

The development of a fire inside of a building can be greatly affected by the materials used in the building envelope [

63]. Gypsum plasterboards are a commonly used building material type and have been proven to be very suitable and relatively safe [

64]. However, research conducted by [

65] found that an ordinary gypsum wallboard impregnated with around 24% paraffin-based PCM failed to meet building safety requirements, and was described as being worse in fire safety when compared to standard gypsum wallboard. During a fire, paraffin changes phase into a vapour, which tends to escape its encapsulation and be released into the porous structure of gypsum wallboard [

66]. This paraffin vapour is expected to be ignited by the high temperatures of the fire and hence increases the fire load of a building, decreasing its fire safety characteristics.

Researchers have looked towards the use of fire retardants as a means of reducing the negative effects on fire safety caused by the use of organic PCMs in building envelopes [

67,

68]. Materials used as fire retardants by [

67] in their research include; ammonium polyphosphate (AP), aluminium hydroxide, pentaerythritol, and expanded graphite (EC). The results from their experiment showed that a PCM containing the combination of AP + EC demonstrated the best fire retardancy, as it caused a residue to form during burning, leading the fire to self-extinguish. DSC results also showed that the thermal properties of the PCM were not altered greatly by the addition of fire-retardants.

4.5. Cost

In the previous sectors, it has been analysed how numerous disadvantages of phase change materials can be dealt with, but the common outcome to all the solutions was that an additive must be added to the PCM in order to achieve a certain benefit. This is expected to increase the cost of using a PCM significantly.

Table 3 presents the average cost of commonly used phase change materials. All of the data presented has been obtained from the US Department for Energy’s review into ‘Cost Analysis of Simple Phase Change Material-Enhanced Building Envelopes’ [

57]. The table shows how the basic forms of organic, inorganic, and fatty acid PCMs are relatively cheap. Paraffin wax costs around

$2/kg, and the most common form of salt hydrate, calcium chloride, is only

$0.20/kg. However, the price of a commercially available salt hydrate is roughly 25 times more expensive than the raw material. This is due to the commercially available PCMs including many additives to improve their effectiveness and efficiency.

PCM systems must provide some kind of significant energy savings before they become attractive to commercial buyers. The average annual family spend on gas bills in the United Kingdom is £700 [

7], of which 80% of gas consumption is used in space heating applications. Commercially available residential PCM products do exist, such as the Datum Phase Change FES board, which reportedly costs between £25 and £75/m

2 [

69]. This cost does not include the price of installation, which would require walls being stripped of any wallboard and installation, and replaced with the FES board. On the other hand, the solution is reported to help reduce energy consumption by around 35% [

69].

It’s up to the end user to decide if PCM systems are worth the investment or not. It can be said, however, that public knowledge of PCMs and their advantages is low and hence more companies need to market solutions to the public that highlight their advantages. But with all of the current public financial concerns, the mainstream deployment of PCM systems in residential buildings may still be decades off.

5. Emerging Residential Applications for PCM Technologies

According to a study conducted by [

18], a method for powering satellites under geostationary orbit with the aid of PCMs has been devised. The system works like a conventional solar power system, but with the addition of metal cells containing a high temperature liquid PCM. During hours of darkness, the PCM freezes and releases its stored latent heat, which is used to drive thermoelectric units, generating electricity. The system has been found to produce 3 times the amount of power than a conventional battery of the same size, meaning that the system is a possible alternative to solar power systems that rely on the use of batteries. With enough research focused onto this application, the potential to adapt it into residential use is high. Large multiple occupancy buildings, such as high-rise apartments, could benefit the most from this technology as space on the building’s roof and side could be used to install the necessary components.

A ventilation system that could eliminate the need for air conditioning in buildings has been proposed by Turnpenny et al. [

70]. The LHTES unit consists of heat pipes which are embedded with a PCM of a melting temperature of 21 °C, and tested for application in low energy cooling of buildings. The system works by extracting air from the room and exposing it to the ends of the heat pipes by using low powered fans. During the day, the heat from the room is transferred to the PCM, causing it to absorb the heat energy and melt, which will reduce the internal temperature of the room. Shutters are opened at night to expose the PCM to the cool temperatures from outside, which leads to the PCM freezing and releasing its stored latent heat which can be either extracted to warm the cooling room or released to the external environment, hence making the system reversible. However, the experiment found that the melting period lasted 19 h, but could be reduced to around 10 h (a more desirable time) with the inclusion of fins to the system. The benefits of this system included reducing CO

2 emissions from buildings, as well as saving occupants’ money on energy bills. The heat pipes also avoid the need for complex geometry heat exchangers, which means that the system can be easily retrofitted into existing buildings.

The development of nanoencapsulated PCM technology is another exciting prospect of PCM research. The smaller size of nanocapsules means that a higher heat transfer area is present, which leads to a faster heat transfer speed [

71]. Although not yet commercially available, many researchers including Chen et al. [

72] and Latibari et al. [

73] have looked into ways of creating nanocapsules for latent thermal heat energy storage applications. Chen et al. [

72] created nanocapsules containing a fatty acid PCM by miniemulsion polymerisation, which was found to have a latent heat of fusion value of 98.8 kJ/kg, a value significantly less than most fatty acid based phase change materials [

74]. Latibari et al. [

73] research involved developing nanocapsules containing palmitic acid, which has a typical latent heat of fusion value of 185.4 kJ/kg [

74]. The nanocapsules were made out of an SiO

2 shell and constructed via a sol-gel method. DSC measuring methods found that the latent heat of fusion value for the nanoencapsulated PCM system was around 180 kJ/kg, only a very slight drop in thermal storage capabilities. This suggests that the method proposed by [

73] is better at maintaining the thermal performance of nanoencapsulated PCM systems than the method offered by [

72]. It is expected that the nanoencapuslation technology will be more expensive than microencapsulation, however little evidence is available in research to confirm this hypothesis [

71].

An issue with incorporating phase changing technology into residential applications is that different seasons and weather conditions supply a variety of temperatures throughout the year, it is common for most PCM systems to have an optimal phase change temperature, which will not suit both summer and winter conditions. This issue, however, can be solved with multilayered PCM systems, whereby PCMs of different phase temperatures work together to create a system with two or more optimal temperatures [

75]. Research conducted by [

76] found that double layered PCM systems on building roofs can be adopted to narrow internal air temperature fluctuations all throughout the year. A suggestion for further research into this field would be to develop PCMs with adjustable phase temperatures, which could be controlled as a part of an adaptive system [

71].

6. Further Research Needs for Residential Applications

According to the results presented in the current analysis, it is obvious that there is a lack of evidence to suggest that PCM technology is being widely utilised in large-scale residential projects. It will be difficult to build public awareness of the advantages of PCMs if there aren’t enough major projects utilising the technology. Another outstanding issue is that no reviewed technical paper has suggested ways in which residential PCM systems can be maintained on a regular basis. Issues have been highlighted in which the thermal performance and energy storage capabilities of PCMs degrade after many thermal cycles, and while there are techniques to prolong the lifetime of PCMs or limit the detrimental effects, there are no suggestions on how material in incorporated systems can be replaced once it has degraded. Many residential applications rely on PCMs to be integrated into building construction materials, such as concrete blocks. With this approach, once the PCMs useful life-time is up, it cannot be replaced and simply stops becoming effective. Techniques do exist which place encapsulated PCMs between wall boards, but no design has a system whereby the PCM can be retrieved and replaced once its thermal performance becomes too inefficient. It is therefore proposed that this must become a part of future research into phase change material technology. Below are two original concept ideas that may provide a starting point for researchers.

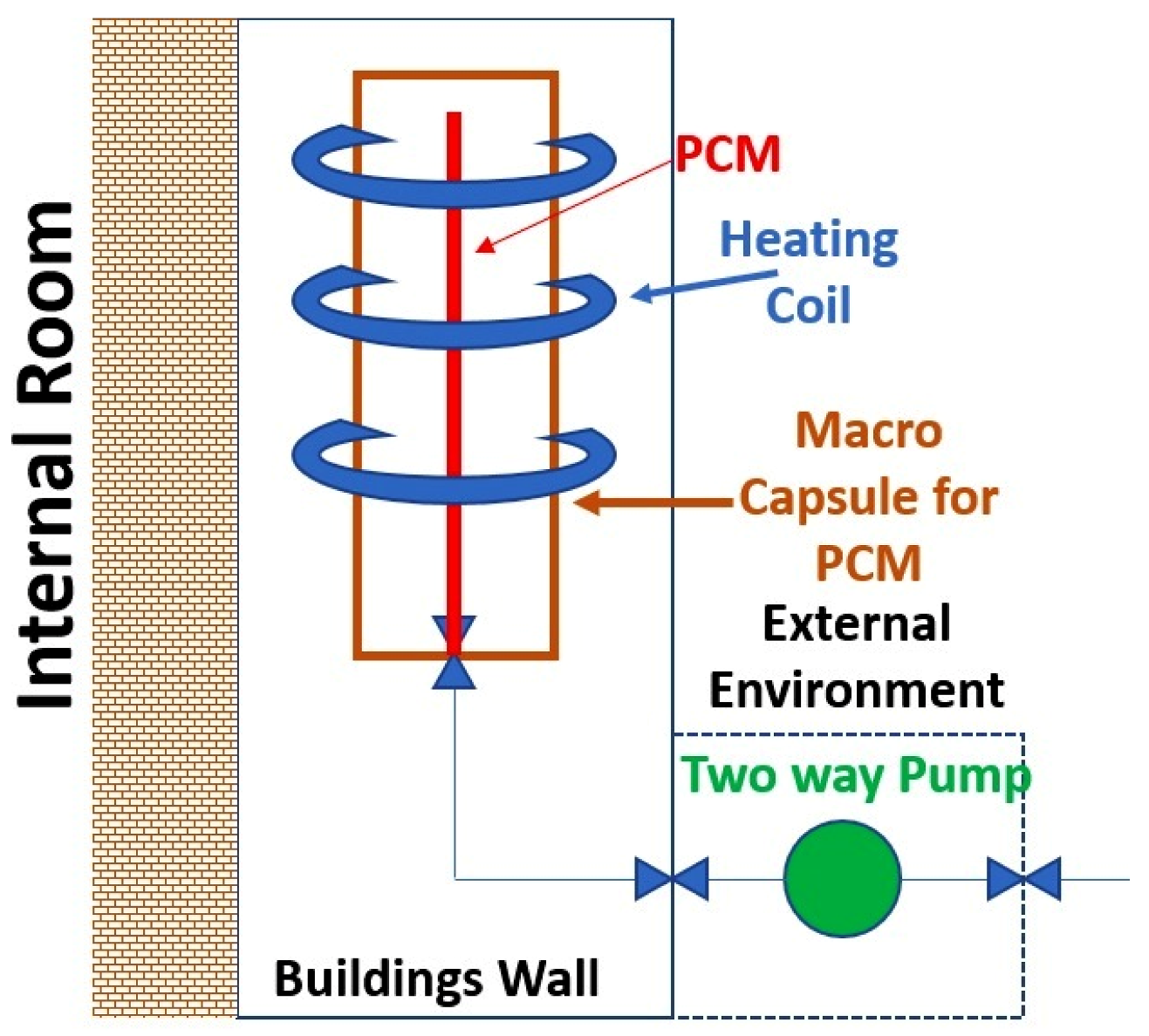

6.1. Pump and Tap System Proposal

Figure 5 shows a schematic of an original proposal for a method of installing and removing a PCM from building materials. This design works by pumping liquid PCM into macro-capsules located on the inside of the wall. As most PCMs are expected to have a lifetime of around 1000 thermal cycles, this system allows for the degraded material to be removed from the walls. The inefficient PCM is then extracted from the capsules by heating the material via heating coils to liquefy it, and then using the two-way pump to pull the material out of the system and empty it via a drain. Fresh phase change material can now be pumped into the system to allow it to run effectively again. Valves stop the material from leaving the system while it is in use, and can be opened to allow the material to be drained. It would be expected that this process would be performed by a trained engineer who would also be responsible for disposing the old material.

The proposed benefits of this system are that it allows for new phase change material to be installed when the previous material has degraded, without the need for removing building materials. The pump and heating coils would not consume a lot of energy, as they would only need to be used every 3–4 years. However, one major disadvantage is that it is unexpected that this system could be retrofitted into many existing builds, and hence would only be useful for new builds. The design is quite complicated, and would likely be only installed on one side of a house due to its expectedly high cost. Also, the process of removal of material could be dangerous to an untrained individual, and it is likely that an engineer would have to carry out the task.

6.2. Wall Panel System Proposal

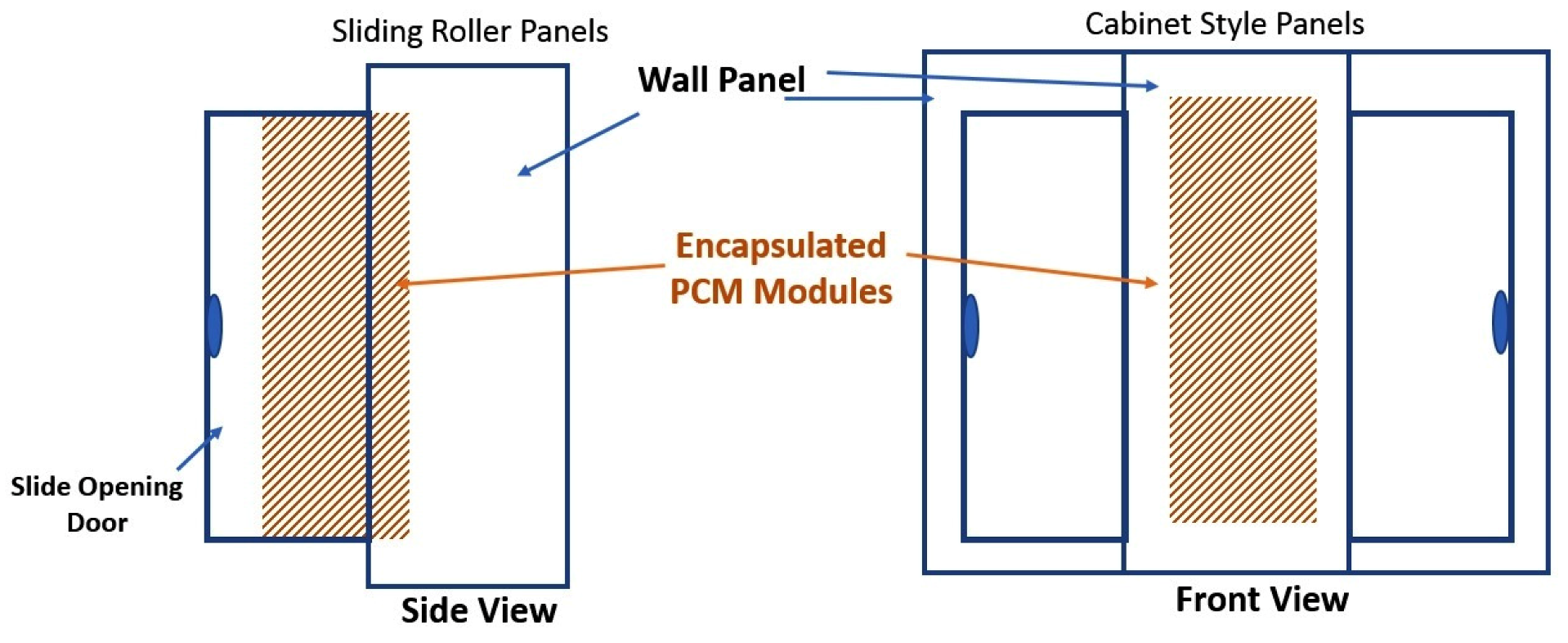

The systems proposed in

Figure 6 demonstrate a simpler approach to removing degraded PCM from building materials. Phase change materials would be macroencapsulated in removable modules position inside of a buildings wall. The idea behind these designs is that the PCM can be removed and replaced by the occupant, with a purpose-built wall allowing the modules to be safely stored inside. These modules will be accessed via either a sliding roller system, which would bring the modules out of the wall, or, by a cabinet system that would expose the modules and allow them to be manually removed from the wall. To protect occupants and keep the system secure, a locking mechanism will be present which would require a special key to open.

An expected benefit of this system is a reduced cost when compared to the pump system as the PCMs will be supplied in modules that can be replaced without any special training. This system is more appealing to retrofitting applications then the pump system. However, as this system is accessed internally, occupants won’t be able to cover up the wall panels with wall-paper or personal effects. This could make the system less attractive due to the unfamiliar nature of having removable wall panels inside of a house. It’s also unclear how such a system would be insulated; an issue that will require further research.

Both systems offer customers the chance to purchase cheaper, lower quality materials. As the materials can be replaced, costly PCMs with additives to prolong their cyclic stability can be avoided, saving occupants money. The replaceable material solutions also offer life-time stability for the LHTES system, something that is not guaranteed with impregnated designs.

7. Conclusions

This work has identified that although using PCMs in buildings can improve the energy efficiency of buildings and lead to improved occupant comfort, the major disadvantages of PCMs could limit their potential. It is well documented that many PCMs suffer from low thermal conductivities, which prolongs the phase transition of the material, an undesired effect for both occupant comfort and the energy efficiency of the system. Other major disadvantages are supercooling, phase segregation, fire safety, and cost. This report has discussed ways that these issues can be limited or completely overcome through the use of additives and improved system design.

The design criteria for PCM systems has been highlighted by this report and broken down into three main considerations; material, encapsulation, and heat transfer solution. It is important that these design steps be taken seriously by designers, as choosing the wrong material could lead to undesirable phase change temperatures, and the wrong encapsulation technique could impact the thermal capabilities of the material. Also, different applications require different design considerations. The report shows how PCMs can be used in heating and cooling rooms, collecting solar energy as a means of heating water, and to recover waste heat from household appliances.

The viability of PCMs for residential applications has been a big focal point of this review. There are many developed applications available, in which PCMs can be used to store latent heat, with the most popular being space and water heating. Although most disadvantages to PCMs can be a negative impact; a low public knowledge of PCMs and a high cost of implementation mean that they are still a long way from becoming mainstream solutions. Along with raising public knowledge of PCMs, several other factors were identified as areas that require further research attention. For example, there is a big gap in research surrounding maintaining PCM systems once they have been installed into buildings. As most PCMs tend to suffer from thermal cyclic degradation, it should be paramount that innovative ways to provide non-intrusive maintenance on residential PCM systems be developed before they become a conventional solution. Potential solutions have been conceptualised by this report but not researched further.