An Introduction to the Methodology of Earthquake Resistant Structures of Uniform Response

Abstract

:Notation

| f | magnification factor | H | total building height | T | period of vibration |

| i, j | integer coordinates | I | beam moment of inertia | U | internal energy |

| h | story height | J | column moment of inertia | V | shear force |

| height from base | K | sub frame stiffness | W | sub frame weight |

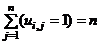

| m | number of stories | L | span length | Q | total weight |

| n | number of bays | M | beam moment |  | local displacement |

| s | order of occurrence | N | column moment |  | total displacement |

| C | numerical constant | P | joint load |  | drift ratio |

| E | modulus of elasticity |  | beam plastic moment |  | joint rotation |

| F | external force |  | column plastic moment |

1. Introduction

- • A prescribed drift ratio at any given loading or performance stage.

- • A prescribed carrying capacity corresponding to any drift ratio or performance stage, including maximum allowable lateral displacement at incipient collapse.

- • Predetermined sequences of formations of plastic hinges before collapse.

- • Damage control in terms of the number of plastic hinges at any loading or response stage compared with number of plastic hinges at zero loading, at first yield or at incipient collapse.

- • Reduction of the total weight of the structure to a theoretical minimum.

- • The possibility to further enhance or the performance of the structure using moment control technologies such as brackets, haunches, end flange plates and/or proprietary devices.

1.1. Basic Design Objectives

- 1. The ideal inter-story drift ratio remains constant along the height of the structure, and that lateral displacements remain a linear function of the height during all phases of loading.

- 2. The plastic hinges are prevented from forming within columns, except at base line. Whenever possible, base line plastic hinges should form within the grade beams. Global mechanism is reached if the concept of strong-column weak-beam is considered.

- 3. For minimum weight MFUR, the demand-capacity ratios of all members are as close to unity as possible.

1.2. Basic Design Assumptions

- 1. Axial, shear and panel zone deformations are not coupled with flexural displacements and can be temporarily ignored for the purposes of this study.

- 2. Groups of similar members simultaneously resist similar types of loading or combinations of loading, e.g., flexural, axial, torsional, etc.

- 3. The shape of code specified distribution of earthquake forces remains constant during all loading phases. The shape could be triangular or determined by any rational analysis.

- 4. Initial design is based on the fundamental period of vibration of the un-degraded structure.

- 5. The effects of plastic hinge offsets from column center lines can be ignored.

- 6. The possible benefits of strain hardening and yield over-strength can be ignored.

- 7. Code level gravity loads have little or no effect on the ultimate carrying capacity of moment frames designed for moderate to severe earthquakes. However the columns should be designed in such a way as to resist gravity forces together with effects induced by plastic hinging of the beams.

- 8. The design earthquake loads act monotonically throughout the history of loading of the structure.

- 9. The frames are two dimensional and are constructed out of ductile materials and connection failure is prevented under all loading conditions.

- 10. The columns remain effectively elastic during all phases of loading.

2. Methodology

.

.  is the maximum roof or

is the maximum roof or  level lateral displacement at

level lateral displacement at  response stage. Symbol

response stage. Symbol  signifies increment at

signifies increment at  consecutive iteration.

consecutive iteration.

. However,

. However,  or

or  offer more practical options for design purposes. Rotation

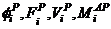

offer more practical options for design purposes. Rotation  may be construed as the initial target drift corresponding to initial target displacement

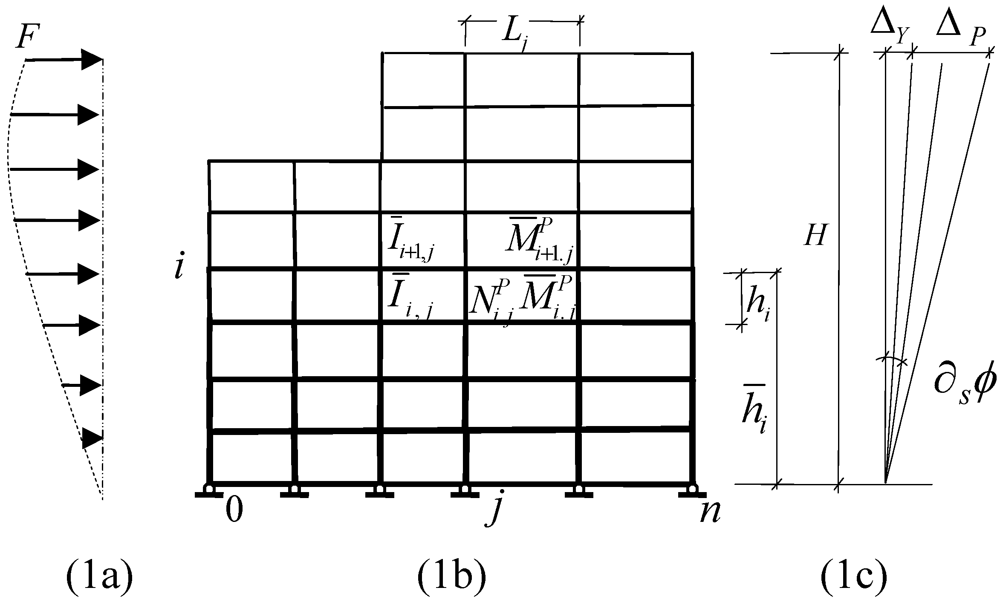

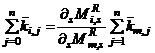

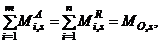

may be construed as the initial target drift corresponding to initial target displacement  at first yield. The line diagram of a regular MFUR together with its idealized design displacement profiles, subjected to a generalized distribution of lateral forces, is presented in Figure 1. The design conditions (1a) and (1b) imply equal incremental joint rotations for all members of the frame i.e.,

at first yield. The line diagram of a regular MFUR together with its idealized design displacement profiles, subjected to a generalized distribution of lateral forces, is presented in Figure 1. The design conditions (1a) and (1b) imply equal incremental joint rotations for all members of the frame i.e.,

at any stage “s” can be expressed as:

at any stage “s” can be expressed as:

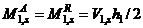

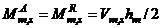

,

,  ,

,  and

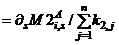

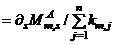

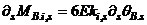

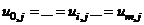

and  are the story level shear force, relative stiffness, end moments and moment of inertia of beam “i,j” respectively. Equation (2a) directly yields the global rotation of the structure as;

are the story level shear force, relative stiffness, end moments and moment of inertia of beam “i,j” respectively. Equation (2a) directly yields the global rotation of the structure as;

and

and  are defined as the average and total racking moment acting on

are defined as the average and total racking moment acting on  level beams at

level beams at  response stage respectively.

response stage respectively.  , and

, and  correspond to average racking moments of grade and roof level beams respectively.

correspond to average racking moments of grade and roof level beams respectively.  is defined as the

is defined as the  story raking moment at

story raking moment at  response stage. Equation (2c) in turn directly yields the floor level rotations as:

response stage. Equation (2c) in turn directly yields the floor level rotations as:

, then equating the global rotation Equation (2b), and floor level rotation, Equation (2d), gives:

, then equating the global rotation Equation (2b), and floor level rotation, Equation (2d), gives:

(3a)

(3a) and expanding the right hand side of Equation (3a), it gives:

and expanding the right hand side of Equation (3a), it gives:

…

…  …

…  (3c)

(3c) ….

….  (3d)

(3d)

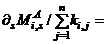

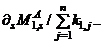

,

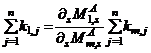

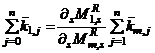

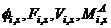

,  , and

, and  are the relative stiffness, end moments and moment of inertia of column “i,j” respectively. Equation (4b) yields the floor level rotations as:

are the relative stiffness, end moments and moment of inertia of column “i,j” respectively. Equation (4b) yields the floor level rotations as:

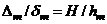

is the drift component of the

is the drift component of the  level floor, due to deformations of the columns of the same level. Comparing the two sides of Equations (4a) and (4c) yields the conditions of uniform response or demand-capacity for the columns of the subject frame as:

level floor, due to deformations of the columns of the same level. Comparing the two sides of Equations (4a) and (4c) yields the conditions of uniform response or demand-capacity for the columns of the subject frame as: ……

……  (4d)

(4d)3. Story Level Elastic-Plastic Displacement Response

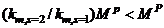

(5b)

(5b)

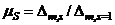

to their sequence of formation of plastic hinges or response stage “s”, by means of subscript ”r”, rather than their location “j”. This is achieved by replacing

to their sequence of formation of plastic hinges or response stage “s”, by means of subscript ”r”, rather than their location “j”. This is achieved by replacing  with

with  and

and  with

with  and incorporating the symbol

and incorporating the symbol  and

and  in Equation (5c) in order to include the effects of formation or prevention of formation of plastic hinges at the ends of beams “

in Equation (5c) in order to include the effects of formation or prevention of formation of plastic hinges at the ends of beams “  ”.i.e.,

”.i.e.,

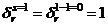

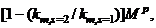

for

for  and implies structural damage and/or loss of stiffness with respect to beam

and implies structural damage and/or loss of stiffness with respect to beam

for

for  . In mathematical terms,

. In mathematical terms,  for

for  and

and  for

for  Similarly the symbol

Similarly the symbol  has

has  been introduced to relate column stifnesses

been introduced to relate column stifnesses  to effects of formation of plastic hinges in the adjoining beams “i,j” and “i,j-1.

to effects of formation of plastic hinges in the adjoining beams “i,j” and “i,j-1.  for

for  and

and  , otherwise

, otherwise

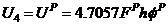

is the force magnification function.

is the force magnification function.  and

and  are the total axial load and the critical axial load of level “i” at

are the total axial load and the critical axial load of level “i” at  response stage respectively. In reality, since the drift ratio is constant, it would be sufficient to compute

response stage respectively. In reality, since the drift ratio is constant, it would be sufficient to compute  for the simplest representative level, i.e., the roof, where,

for the simplest representative level, i.e., the roof, where,  . Equation (5d) reduces to:

. Equation (5d) reduces to:

is the stiffness of the

is the stiffness of the  level framework at

level framework at  response stage.

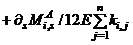

response stage.3.1. Demonstrative Example I

and axial joint forces

and axial joint forces  for all “i” and

for all “i” and  for all other“i,j”.

for all other“i,j”.

and

and  for all “j”.

for all “j”.  and

and  for all other “j”. The primary purpose of this exercise is to generate a MFUR by computing the quantities

for all other “j”. The primary purpose of this exercise is to generate a MFUR by computing the quantities

and

and  in terms of their corresponding values

in terms of their corresponding values  and

and  (at roof level) respectively. The distribution of story level racking moments

(at roof level) respectively. The distribution of story level racking moments  is shown in Figure 2b. The total racking moments

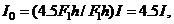

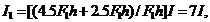

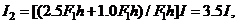

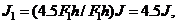

is shown in Figure 2b. The total racking moments  can now be computed as 4.5

can now be computed as 4.5  , 7.0

, 7.0  , 3.5

, 3.5  and 1.0

and 1.0  for the grade, 1st, 2nd and roof level beams respectively. Since

for the grade, 1st, 2nd and roof level beams respectively. Since  is uniform for each level and the quantity

is uniform for each level and the quantity  is constant for the entire frame, then for

is constant for the entire frame, then for

and

and  . And, as a result, Equation (3d) reduces to

. And, as a result, Equation (3d) reduces to  i.e.,

i.e.,

and

and  By the same token, since

By the same token, since  simplifies Equation (4d) to

simplifies Equation (4d) to  then:

then:

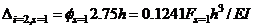

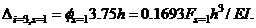

The third level (roof) drift of the newly generated MFUR at s = 1 can now be expressed as:

The third level (roof) drift of the newly generated MFUR at s = 1 can now be expressed as:

for all other “j” an

for all other “j” an  d satisfy the Strong column-weak beam requirements, then for

d satisfy the Strong column-weak beam requirements, then for  L = h,

L = h,  and

and  , Equation (6a) becomes;

, Equation (6a) becomes;

and

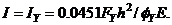

and  Finally, if the target drift

Finally, if the target drift  is not to exceed

is not to exceed  where the subscript Y signifies first yield, i.e.,

where the subscript Y signifies first yield, i.e.,  then, the design representative moment of inertia becomes

then, the design representative moment of inertia becomes

4. Story Level Elastic-Plastic Moment Response

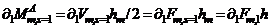

response stage is given by;

response stage is given by;  , then by substituting for

, then by substituting for  from Equation (2d) gives:

from Equation (2d) gives:

and

and  become

become  and

and  respectively.

respectively.  of the system at incipient collapse, e.g., considering the plastic collapse of the moment frame of Figure 3d, through formation of plastic hinges at beam ends only, and conforming to a uniform virtual side sway of inclination θ = 1, it gives:

of the system at incipient collapse, e.g., considering the plastic collapse of the moment frame of Figure 3d, through formation of plastic hinges at beam ends only, and conforming to a uniform virtual side sway of inclination θ = 1, it gives:

= 2[1.0 + 3.5 + 7.0 + 4.5]

= 2[1.0 + 3.5 + 7.0 + 4.5]  or

or  as the ultimate load carrying capacity of the subject moment frame. However in case of MFUR, the racking equilibrium Equation of any story, Equation (2c), can also be used to achieve the same results, i.e.,

as the ultimate load carrying capacity of the subject moment frame. However in case of MFUR, the racking equilibrium Equation of any story, Equation (2c), can also be used to achieve the same results, i.e.,

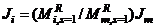

is the plastic moment of resistance of the stiffest beam of the

is the plastic moment of resistance of the stiffest beam of the  level framing. Since the pre-assigned uniformity ratios

level framing. Since the pre-assigned uniformity ratios  are constant for all “i”, then dividing Equations (8a) and (8b) by each other, reaffirms the condition of uniform strength at incipient collapse, i.e.,

are constant for all “i”, then dividing Equations (8a) and (8b) by each other, reaffirms the condition of uniform strength at incipient collapse, i.e.,

and

and  Substituting

Substituting  and

and  in Equation (8c) yields;

in Equation (8c) yields;  or

or  a result already established using Equation (8a) above. This result implies that:

a result already established using Equation (8a) above. This result implies that: MFUR with moment resisting grade beams under lateral loading of apex value

MFUR with moment resisting grade beams under lateral loading of apex value  is

is

,

,  and

and  in Equation (9a) after some rearrangement, it gives the amount of force needed to produce the first set of plastic hinges in the stiffest beam of the

in Equation (9a) after some rearrangement, it gives the amount of force needed to produce the first set of plastic hinges in the stiffest beam of the  level:

level:

beam (x > s) of any level can be expressed in terms of the maximum moments of the stiffest beam of that level i.e.,

beam (x > s) of any level can be expressed in terms of the maximum moments of the stiffest beam of that level i.e.,  and that the sequence of formation of the plastic hinges of any level is the same as the sequence of decreasing values of stiffnesses of the beams of the same floor, then the plastic moment of resistance of the stiffest element s = 1 and moment of resistance of the next stiffest element s = 2 can be computed as

and that the sequence of formation of the plastic hinges of any level is the same as the sequence of decreasing values of stiffnesses of the beams of the same floor, then the plastic moment of resistance of the stiffest element s = 1 and moment of resistance of the next stiffest element s = 2 can be computed as  and

and  respectively. Therefore, the balance of bending moment needed to elevate the moment of resistance of beam s = 2 to

respectively. Therefore, the balance of bending moment needed to elevate the moment of resistance of beam s = 2 to  can be computed as

can be computed as  whence the amount of additional force required to generate plastic hinges at the ends of the next stiffest beam may be generalized as:

whence the amount of additional force required to generate plastic hinges at the ends of the next stiffest beam may be generalized as:

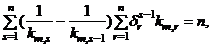

should add up to the ultimate load

should add up to the ultimate load  ,then summing both sides of Equation (9c) over all “n” iterations gives:

,then summing both sides of Equation (9c) over all “n” iterations gives:

and

and  in Equation (9d) leads to the previously established solution;

in Equation (9d) leads to the previously established solution;  .

. 4.1. Demonstrative Example II

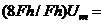

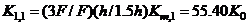

Given;

Given;

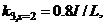

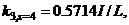

J = 1.2I,

J = 1.2I,  ,

,  , h = L and

, h = L and  Hence from Equation (9c):

Hence from Equation (9c):

, and as expected

, and as expected  , reconfirms the validity of the failure load formula

, reconfirms the validity of the failure load formula

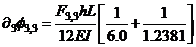

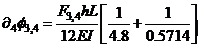

for s = 1 and s = 2. After culmination of stage two, first columns j = 0 and j = 1 together at the beginning of s = 3, next columns j = 2 at the end of s = 3, then columns j = 3 and j = 4 after culmination of s = 4 lose their stiffness, due to formation of plastic hinges at their adjoining beam ends. Equation (5e) for drift increment becomes:

for s = 1 and s = 2. After culmination of stage two, first columns j = 0 and j = 1 together at the beginning of s = 3, next columns j = 2 at the end of s = 3, then columns j = 3 and j = 4 after culmination of s = 4 lose their stiffness, due to formation of plastic hinges at their adjoining beam ends. Equation (5e) for drift increment becomes:

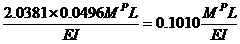

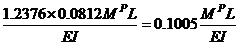

=

=

=

=

=

=  (11b)

(11b) =

=

and

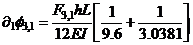

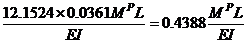

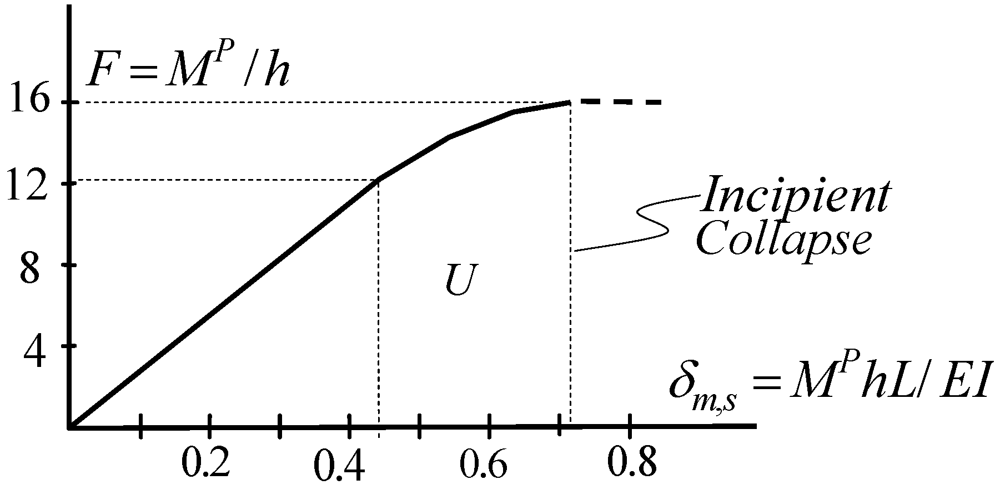

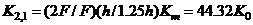

and  The combined numerical results of groups of Equations (10b) and (11b), are presented in Figure 4 as the nonlinear load-displacement relationship of the subject MFUR. Equations (5c) and (9e) together provide useful design information that neither elastic nor plastic methods of analysis can offer on their own, for instance the maximum lateral displacement of the example frame at first yield and incipient collapse can be estimated as:

The combined numerical results of groups of Equations (10b) and (11b), are presented in Figure 4 as the nonlinear load-displacement relationship of the subject MFUR. Equations (5c) and (9e) together provide useful design information that neither elastic nor plastic methods of analysis can offer on their own, for instance the maximum lateral displacement of the example frame at first yield and incipient collapse can be estimated as:

5. Energy Computations For MFUR

is constant, it would suffice to compute the internal energy of any representative level, such as that of the

is constant, it would suffice to compute the internal energy of any representative level, such as that of the  level, and then compute the rest by simple proportioning. The energy Equation corresponding to level “m” may be computed as:

level, and then compute the rest by simple proportioning. The energy Equation corresponding to level “m” may be computed as:

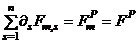

, then the total energy of the system may be expressed as:

, then the total energy of the system may be expressed as:

then Equation (12c) reduces to its most practical form:

then Equation (12c) reduces to its most practical form:

for the preceding example can be worked out via Equation (12b) or as the total area under the force-displacement (push-over) curve of Figure 4, i.e.,

for the preceding example can be worked out via Equation (12b) or as the total area under the force-displacement (push-over) curve of Figure 4, i.e.,  6.9512

6.9512  . Equation (12d) can then be used to compute the total internal energy of the entire system as;

. Equation (12d) can then be used to compute the total internal energy of the entire system as;

55.6096

55.6096  , or in terms of ultimate values;

, or in terms of ultimate values;  and

and  at incipient collapse as;

at incipient collapse as;

can also be looked upon as an indication of the capacity of the structure to absorb external energy.

can also be looked upon as an indication of the capacity of the structure to absorb external energy. 5.1.1. Stiffness Degradation

, is a priori to estimating the momentary periods,

, is a priori to estimating the momentary periods,  , of vibrations of the system at any response stage “s”. Progressive plasticity tends to degrade the global stiffness and modify the dynamic characteristics of statically indeterminate structures under monotonically increasing lateral forces. The effects of stiffness degradation are more pronounced in MFUR since many members of similar characteristics either, fail, become inactive or develop plastic hinges simultaneously. The natural period of vibration of each stage of global loss of stiffness increases with advancing stages of loading until the structure ceases to resist external forces. As the rate of degradation of global stiffness is a function of increasing number of plastic hinges, Equations (5d) and (5e) may be rearranged to assess the gradual loss of global stiffness in terms of sequential formation of plastic hinges.

, of vibrations of the system at any response stage “s”. Progressive plasticity tends to degrade the global stiffness and modify the dynamic characteristics of statically indeterminate structures under monotonically increasing lateral forces. The effects of stiffness degradation are more pronounced in MFUR since many members of similar characteristics either, fail, become inactive or develop plastic hinges simultaneously. The natural period of vibration of each stage of global loss of stiffness increases with advancing stages of loading until the structure ceases to resist external forces. As the rate of degradation of global stiffness is a function of increasing number of plastic hinges, Equations (5d) and (5e) may be rearranged to assess the gradual loss of global stiffness in terms of sequential formation of plastic hinges.  may be summarized as;

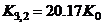

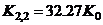

may be summarized as;

,

,

,

,

and

and  , where

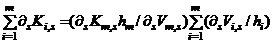

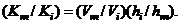

, where  However, since in MFUR the distribution of story level stiffness is also a function of the story level shears, it would be reasonable to seek a simpler method of computing for the story level stiffnesses in terms of shear force ratios at different stages of loading, i.e.,

However, since in MFUR the distribution of story level stiffness is also a function of the story level shears, it would be reasonable to seek a simpler method of computing for the story level stiffnesses in terms of shear force ratios at different stages of loading, i.e.,

,

,  , etc.

, etc. by simple, numerical proportioning e.g.,

by simple, numerical proportioning e.g.,

(13b)

(13b)

5.1.2. Period Analysis

- 1. The normalized displacement function

remains unchanged throughout the loading history of the structure. In other words, loss of stiffness changes only the magnitude of lateral displacements, but not the deformed shape

of the system.

- 2. The lateral displacement profile of the frame is a function of the single variable

for all stages of loading, i.e., all displacement profiles

follow the same linear shape function as their normalized displacement function

- 3. Dominant mode shapes remain unchanged during formation of plastic hinges and that the coupling of modes in the inelastic range can be neglected.

- 4. The first mode of the first un-degraded stage is the most dominant mode of all response stages and that the first mode of each stage is the dominant mode of that stage.

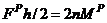

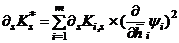

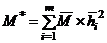

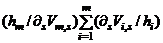

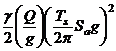

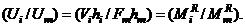

, where, the generalized stiffness and mass of the s

, where, the generalized stiffness and mass of the s  response stage are defined as:

response stage are defined as: and

and  respectively (14a)

respectively (14a) and substituting

and substituting  and

and  in Equation (14a) gives;

in Equation (14a) gives;

and the ratio

and the ratio  are constant for all “s”, then

are constant for all “s”, then  can be expressed in terms of the single variable,

can be expressed in terms of the single variable,  , i.e.,

, i.e.,

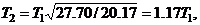

are independent of “s”, once the fundamental period of vibrations of the un-degraded structure,

are independent of “s”, once the fundamental period of vibrations of the un-degraded structure,  , is determined the corresponding values for each degraded stage can be worked out through simple proportioning,

, is determined the corresponding values for each degraded stage can be worked out through simple proportioning,

and

and  as:

as:

5.1.3. Energy Equivalency

), the global stiffness of the structure is in direct proportion with each story level stiffness, and that by definition, Equation (1a), the lateral displacements are a function of the single variable

), the global stiffness of the structure is in direct proportion with each story level stiffness, and that by definition, Equation (1a), the lateral displacements are a function of the single variable  for all “s” then MFUR may be looked upon as SDOF systems for all practical purposes.

for all “s” then MFUR may be looked upon as SDOF systems for all practical purposes.

(15)

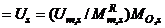

(15) and

and  are the spectral acceleration and the energy equivalency factors respectively [10].

are the spectral acceleration and the energy equivalency factors respectively [10].  and Rμ are defined as the period dependant ductility and ductility reduction factors respectively. If the quantity

and Rμ are defined as the period dependant ductility and ductility reduction factors respectively. If the quantity  is interpreted as the seismic capacity of the structure, then the right hand side of Equation (15), may be looked upon as the seismic demand or equivalent total dynamic input energy of the system.

is interpreted as the seismic capacity of the structure, then the right hand side of Equation (15), may be looked upon as the seismic demand or equivalent total dynamic input energy of the system. 5.2. Demonstrative Example III

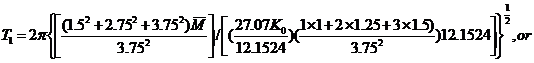

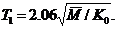

and

and  radians, total structural self weigh Q = 3W and un-medium degraded range fundamental period of vibrations,

radians, total structural self weigh Q = 3W and un-medium degraded range fundamental period of vibrations,  , where,

, where,  is the site specific design spectral response acceleration parameter. Substituting for the corresponding quantities and the total internal energies

is the site specific design spectral response acceleration parameter. Substituting for the corresponding quantities and the total internal energies  at first yield and

at first yield and  at incipient collapse in Equation (15), and bearing in mind that

at incipient collapse in Equation (15), and bearing in mind that  , it gives:

, it gives:

6. Conclusions

- • In MFUR selected groups of beams and columns share the same drift and Demand-capacity ratios.

- • The ultimate load carrying capacity of an (

MFUR with moment resisting grade beams under lateral loading of apex value

is

- • The ratio of total internal energy of MFUR to that of anyone of its levels, such as the roof, is equal to the ratio of the global overturning moment to the overturning moment of that (roof) level.

- • The ratio of stiffness of any two floors of an MFUR is proportional to the ratio of shear forces of the two levels multiplied by the inverse ratio of their heights.

- • MFUR may be treated as statically determinate, SDOF structures.

References

- Goel, S.C.; Liao, W.; Bayat, M.R.; Chao, S. Performance-based plastic design method for earthquake resistant structures. Struct. Des. Tall Spec. Build. 2010, 19, 115–137. [Google Scholar]

- Mazzolani, F.; Pilosu, V. Theory and Design of Seismic Resisting Moment Frames; Taylor & Francis: Oxford, UK, 1996. [Google Scholar]

- Grigorian, M.; Grigorian, C. Performance control for seismic design of moment frames. J. Construct. Steel Res. 2011, 67, 1106–1114. [Google Scholar] [CrossRef]

- Grigorian, M.; Grigorian, C. Recent developments in plastic design analysis of steel moment frames. J. Construct. Steel Res. 2012, in press. [Google Scholar]

- Grigorian, M. On the lateral response of regular high-rise frames. Struct. Des. Tall Spec. Build. 1993, 2, 233–252. [Google Scholar] [CrossRef]

- Grigorian, M.; Grigorian, C. Preliminary minimum weight design of moment frames under lateral loading. AISC Eng. J. 1988, 25, 129–136. [Google Scholar]

- Beedle, L.S. Plastic Design of Steel Frames; John Wiley & Sons: Hoboken, NJ, USA, 1985. [Google Scholar]

- Neal, B.G. The Plastic Methods of Structural Analysis; Chapman & Hall Ltd.: London, UK, 1963. [Google Scholar]

- Housner, G.W. Limit Design of Structures to Resist Earthquakes. In Proceedings of the 1st World Conference on Earthquake Engineering, Berkeley, CA, USA, 1956; Earthquake Engineering Research Institute (EERI): Berkeley, CA, USA, 1956. [Google Scholar]

- Chopra, A.K.; Goel, R.K. Capacity-demand diagram methods for estimating seismic deformations of inelastic structures. Earthq. Spectra 1999, 15, 637–655. [Google Scholar] [CrossRef]

Appendix I

, consider the ratio of internal energy of any level “i” to that of the roof level “m”, i.e.,

, consider the ratio of internal energy of any level “i” to that of the roof level “m”, i.e.,

, then

, then  Substituting for

Substituting for  in Equation (16a), it gives

in Equation (16a), it gives  The total internal energy of the system may also be computed as the sum of internal energies of the “m” individual levels, i.e.,

The total internal energy of the system may also be computed as the sum of internal energies of the “m” individual levels, i.e.,

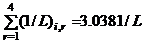

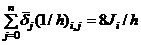

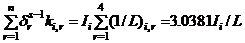

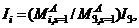

Appendix II

, and for the roof level as

, and for the roof level as  . Observing that by definition,

. Observing that by definition,  , then the division (

, then the division (  gives;

gives;

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Grigorian, M.; Grigorian, C.E. An Introduction to the Methodology of Earthquake Resistant Structures of Uniform Response. Buildings 2012, 2, 107-125. https://doi.org/10.3390/buildings2020107

Grigorian M, Grigorian CE. An Introduction to the Methodology of Earthquake Resistant Structures of Uniform Response. Buildings. 2012; 2(2):107-125. https://doi.org/10.3390/buildings2020107

Chicago/Turabian StyleGrigorian, Mark, and Carl E. Grigorian. 2012. "An Introduction to the Methodology of Earthquake Resistant Structures of Uniform Response" Buildings 2, no. 2: 107-125. https://doi.org/10.3390/buildings2020107

APA StyleGrigorian, M., & Grigorian, C. E. (2012). An Introduction to the Methodology of Earthquake Resistant Structures of Uniform Response. Buildings, 2(2), 107-125. https://doi.org/10.3390/buildings2020107