1. Introduction

The latest official data from the International Energy Agency show that building operations are responsible for 30% of the final energy consumption and 26% of energy-related emissions at the global level [

1]. Regardless of the extended energy-saving strategies and measures implemented in several countries over the past two decades, the buildings’ operational energy demand continues to rise [

1,

2]. Specifically, from 2021 to 2022, the buildings’ total energy consumption further increased by 1% [

1], while the energy use, particularly for space cooling, increased by over 5%, which is expected to double by 2050, along with the corresponding Greenhouse Gas (GHG) emissions [

3,

4]. In contrast, downward trends have been observed for space heating energy use [

4,

5]; nevertheless, around 45% of the total building energy consumption may be attributed to space heating [

6], with fossil fuels still accounting for 63% of the global energy demand for building heating, along with relevant heating emissions over 80% of the direct CO

2 emissions in the building sector [

7]. In addition to energy consumption and its related emissions, building space heating and cooling drag further attention for improvement, as they are the main drivers of indoor thermal comfort.

Therefore, research and development on building sustainability have focused on energy-efficient building solutions, such as thermal energy storage (TES) systems, for the mitigation of heating and cooling loads. TES allows the reservation of thermal energy in a storage medium for later use. The heat captured at the medium may then be utilised to cover building energy loads or peaks, thereby avoiding energy generation and consequently reducing the total energy demands of the building along with the respective GHG emissions and energy generation costs [

8,

9,

10,

11,

12,

13,

14]. TES systems are divided into three implementation types: (a) sensible heat storage, which is based on the storage of thermal energy by heating or cooling a medium, like water, molten salts, sand, and nanofluids; (b) latent heat storage, achieved by Phase Change Materials (PCMs); and (c) thermochemical heat storage, which stores energy in reversible chemical reactions [

15,

16].

PCMs are materials that are able to capture or release heat during their phase transition, that is, their change of physical state, e.g., from gas to liquid or from liquid to solid, and vice versa [

8,

9]. As indicated by literature research, PCMs receive continuous attention for TES applications [

17,

18], due to their upgraded properties, such as constant temperature during the heat storage process, which offer system stability, higher storage capacity, and storage efficiency (from 75% to 90% [

16]), as well as lower weight and volume per storage capacity unit, when compared with sensible heat storage materials [

18]. Their costs are considered moderate when compared with those of thermochemical storage [

14,

16]. Moreover, PCMs have a significant storage capacity per volume unit, particularly for low- and medium-temperature applications [

19]; thus, they are ideal TES candidates for building environments.

However, when aiming to build sustainability solutions, not only the operational energy demands and emissions are to be considered, but also the embodied ones. In fact, embodied emissions related to materials and processes throughout the entire building life cycle are estimated to account for 50% of the total carbon footprint of a new building [

20], where the basic source of embodied carbon lies in the production stage of building materials [

21]. Consequently, as PCMs gain ground in commercial building applications for the mitigation of operational energy demands, it is crucial to investigate their embodied energy and emissions at the product stage, in order to fulfil their purpose as a sustainable solution from a building life cycle perspective. In this regard, Life Cycle Assessment (LCA), a standardised method at the international level [

22,

23], may be utilised to evaluate the potential environmental impacts of these materials and their building applications. However, the extended literature on PCMs is mainly oriented toward technical issues and does not consider environmental aspects [

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19], while literature dedicated to the LCA of PCMs for building applications seems limited, revealing a knowledge gap [

24,

25]. In addition, since the relevant literature is mainly dedicated to commercial PCMs like paraffin, recommendations indicate further research on other PCMs, such as salt hydrates and synthesised PCMs, for building applications [

8].

In this context, this research work performs LCA for the production stage of a PCM module for building applications to quantify its potential environmental impacts, with the intention to mitigate its embodied emissions. Specifically, the object of this study is a Compact Storage Module (CSM) filled with a specific PCM of salt hydrates, supporting various conventional and innovative building applications, like air-handling ceilings, smart ventilated heat-harvesting windows, and sandwich wall panels, aiming to achieve operational energy savings and indoor thermal comfort [

26,

27,

28]. This research is based on up-to-date real data provided by the PCM manufacturer RUBITHERM. It also illustrates a detailed Life Cycle Inventory (LCI) for the product stage of the assessed PCM module. Such data, as well as further data produced by this study, are currently missing from both the literature and available databases; therefore, this research constitutes a reference for future studies, facilitating follow-up research in this field through methodological transparency and communication of the assumptions and proxies considered. Finally, this assessment aims to enhance sustainable decision-making across the product stage of this PCM module by identifying environmental hotspots, thus leading to actions for the mitigation of potential embodied emissions.

2. Materials and Manufacturing

2.1. Materials

2.1.1. Phase Change Materials (PCMs)

Phase Change Materials (PCMs) are key players in latent heat thermal energy storage systems, offering a sustainable solution for thermal management in buildings. These materials absorb and release notable amounts of latent heat during phase transitions, particularly between the solid and liquid states. Most conventional PCMs undergo solid-liquid phase transitions, necessitating encapsulation or containment to prevent leakage [

29]. Phase changes involving liquid-gas or solid-gas transitions are less practical for building applications due to substantial volume variations and the high pressures required in such systems [

30].

Classification of PCMs

PCMs, widely utilised in TES systems as they are able to capture and release significant amounts of latent heat, are categorised into three main types: organic, inorganic, and eutectic-based PCMs, each exhibiting unique thermophysical properties that determine their suitability for various applications, including buildings, electronics, cooling, textiles, and industrial waste heat recovery. The choice of a PCM depends on several factors, like melting temperature range, latent heat capacity, thermal stability, thermal conductivity, and compatibility with the surrounding environment [

31,

32,

33].

Examples of organic PCM include paraffins, alcohols, fatty acid esters, and alcohols. They are recognised for their chemical stability, non-corrosiveness, and long-term phase transition reliability, making them suitable for applications requiring multiple thermal cycles. In addition, they have been widely explored for TES due to their tunable melting ranges, making them suitable for various building applications [

34]. Inorganic PCMs, such as salt hydrates and metallic alloys [

35,

36], have attracted research attention due to their superior thermal properties compared to organic PCMs. These materials exhibit high thermal conductivity, density, and latent heat storage capacity; therefore, they are a high-efficiency solution for TES applications in industrial waste heat recovery and high-temperature energy systems. Additionally, inorganic PCMs are generally not toxic or flammable, which enhances their sustainability and safety and broadens their applicability in high-temperature environments where organic PCMs may pose fire hazards [

37]. Finally, eutectic-based PCMs encompass organic, inorganic, and organic-inorganic mixtures engineered to achieve precise melting temperatures and enhanced latent heat storage capacity; therefore, are highly suitable for TES systems.

The selection of an appropriate PCM also strongly depends on the target application, thermal requirements, and economic and environmental considerations. Ongoing research focuses on material modifications, encapsulation techniques, and hybrid PCM composites to address existing limitations and expand the applicability of these materials in thermal energy storage and building efficiency systems.

PCMs in Building Applications

PCMs in the building sector can be applied using two main approaches: passive and active [

38]. Passive applications exploit the thermal storage capacity of building materials to reduce indoor temperature fluctuations without the need for additional mechanical systems [

18]. Heat is absorbed and released primarily through natural heat convection [

39], with PCMs embedded in walls, floors, roofs, or ceilings to enhance thermal inertia and shift peak heat loads to later hours [

40]. In contrast, active applications, integrate PCMs with mechanical systems, such as HVAC equipment, thereby improving energy efficiency by expanding the operational performance ranges. These systems rely on enhanced heat transfer mechanisms that involve forced convection and controlled mass transfer [

39]. The latest applications of PCMs in building HVAC systems include shell-and-coil ice storage for air conditioning by the enclosure of PCMs, while research continues to investigate such systems in terms of optimal design, geometries, configurations, and forms of PCM enclosures [

41].

The method of PCM integration into building structures varies depending on the material properties and application. A common approach is the impregnation of porous building materials with liquid PCMs, which allows for direct thermal energy exchange [

42]. However, encapsulated PCMs require durable containment solutions that can withstand repeated thermal cycling over their service life without degradation [

42]. Stability is a critical factor, as supercooling and phase segregation in some PCMs can lead to undesirable interactions with container materials, such as metal corrosion, potentially compromising the performance of the entire TES system [

43]. Research continues to enhance the stability of PCMs in building applications, as well as their thermal conductivity and safety, expanding their role in sustainable energy solutions [

44].

A notable example of high-performance PCMs is the RUBITHERM product series, which was designed for TES applications and has already been commercialised. RUBITHERM produces different types of PCMs (organic (RT) and inorganic (SP)), depending on the desired properties and applications [

27], while inorganic (SP) PCMs are primarily used in the building sector [

45]. In particular, RUBITHERM has developed over 20 types of SP products, each with a different melting temperature area and heat storage capacity [

46]. The RUBITHERM SP materials are based on salt hydrates and other additives. Theirchange of phase from liquid to solid and vice versa is used to absorb and release high heat quantities, respectively. To ensure the cycling stability of the SP products, which is the main challenge when it comes to inorganic PCMs, RUBITHERM cycles the SPs at their laboratories up to 10,000 cycles, thus ruling out ageing effects. The SP materials of RUBITHERM are filled into Compact Storage Modules (CSMs) and may be used for active and passive applications, both in heating and cooling systems, e.g., air conditioning, ventilation, and wall elements [

46]. In this study, the PCM examined is the inorganic salt hydrate SP21EK produced by RUBITHERM (

Figure 1a), with a heat storage capacity of 170 kJ/kg [

47].

2.1.2. Compact Storage Modules (CSMs)

Compact Storage Modules (CSMs) are widely established aluminium cases filled with PCMs operating as latent heat media; this type of PCM packaging is also called macroencapsulation and enables a variety of applications. The CSMs are two aluminium plates attached to each other, creating an aluminium case. They are joined at two centred points and stuck together at their frames. The phase changes from liquid to solid and vice versa occur inside the CSM, facilitating heat/cold storage. Aluminium assures high heat transfer, due to its thermal conductivity, thus allowing heat absorbance or release by the inner PCM, while it is inherently corrosive only to a very small extent. Resistance to corrosion is further facilitated by applying an additional layer of anticorrosive material inside and outside the CSM. The PCM can then be filled from a small opening in the aluminium case, which is closed afterwards. The PCM selection depends on the CSM application and customer’s needs and requirements. The PCM-filled CSM can be integrated directly into existing and innovative systems. The aluminium cases are supplied to RUBITHERM by a sister company and are available at dimensions of 45 cm × 30 cm, with different thickness levels, while the thickness depends on the PCM filling volume and therefore, it affects the heat storage capacity [

27]. This study examines a specific CSM used by RUBITHERM (

Figure 1b), the CSM 10/5 with a thickness of 15 mm and 2 kg of SP21EK PCM filling.

2.2. Manufacturing

Concerning the manufacturing process, coated aluminium is delivered to the RUBITHERM sister company, which turns it into aluminium plates by cutting it into adequate squares and pressing it into shape using hydraulic presses. Two aluminium plates are connected by adhesive and crimping to develop an aluminium case. Additional layers of epoxy are applied inside and outside the aluminium case to enhance the aluminium anti-corrosion properties and its compatibility with inorganic salt hydrates. Then, the aluminium cases are provided by a sister company to RUBITHERM, ready to be filled with PCMs, through a small opening at each aluminium case. The PCM SP21EK is manufactured by RUBITHERM in a vessel. Water with various salts is heated to 80 °C and stirred until a homogenous liquid is obtained. The aluminium cases are filled with PCM, and the openings are closed using a specific glue adhesive. The aluminium cases with the PCM were then cooled to room temperature. The next day, the PCM in the cases must be initialised. For this purpose, the CSMs are brought into a cold room and cooled to 5 °C. The next day, the CSMs were removed from the cold room and allowed to sit overnight to reach room temperature. The modules are washed by hand with water and are ready for packaging.

Finally, SP21EK was fully encapsulated into the CSM, with validated containment specifically tested with this encapsulation for long-term integrity, further reducing the leakage risk. Encapsulation ensures physical and chemical isolation, meeting typical building safety/environmental standards. Hence, the risk of leakage in well-installed building systems is extremely low. Even in the case of leakage of a single CSM panel, the leaked salt hydrate is not a hazard to the surroundings. In addition, the anti-corrosion-coated aluminium plates are chemically validated to avoid corrosion or degradation during the PCM’s lifetime. In addition, long-term corrosion tests with SP21EK were validated by RUBITHERM. The current production capacity of the RUBITHERM manufacturing line is 300 pcs per day. Nevertheless, as the production process is upscaled, the mass values and energy demands required for final product manufacturing will be updated accordingly.

2.3. Experimental Testing

The thermal testing of SP21EK was conducted under the RAL Quality Association PCM guidelines [

48] at an external laboratory [

49], leading to RUBITHERM’s certification. In particular, the testing was performed using a three layer calorimeter (3LC) that enables the use of large samples of around 100 mL (80–150 g), resulting in accurate and representative data for PCMs. The large sample quantity reduces the impact of potential weighing tolerance deviations and allows for a correct measurement, especially in the case of salt hydrate PCMs, because the sample contains sufficient quantities of all required components, nucleating agents, and crystals to be representative of the PCM as a whole. The required temperature curves are programmed into a standard climatic test cabinet, inside which the 3LC with the sample is placed with temperature set points of ±20 K above and below the melting point, ensuring the full melting and solidification of the PCM. The outer shell of the calorimeter is designed to guarantee that a single temperature is applied evenly to all sides of the device and thus a representative hull temperature can be measured. The next layer attenuates and limits the heat flow into the interior while avoiding unwanted convection effects in the samples. The sample itself is again enclosed in another layer that evens out the temperature distribution on the sample surface. This setup of 3LC enables an average cooling/heating rate of approximately 0.03 K/min to be applied to the test sample. Therefore, the temperature measured at the centre of the sample is representative of the whole sample. The capacity is determined according to the fundamental principles of thermodynamics. The calorimeter is calibrated using materials with known enthalpy distributions. Thus, the sample enthalpy and temperature curves can be directly deduced with ΔT of 15 K (+7.5 K above the melting point and −7.5 K below the crystallisation temperature). The same sample can be subjected to other tests after capacity measurement, such as cycling stability validation. After the cycling test, the same sample is tested again in the 3LC for exact enthalpy and temperature curve determination. The heat storage capacity is given with a ±7.5% uncertainty margin.

2.4. Cycling Stability

To ensure cycling stability, the PCM SP21EK of RUBITHERM was certified for 10,000 cycles (Category A according to the RAL Quality Association PCM [

48]), indicating that it was very stable under thermal cycling, with minimal degradation of thermal storage capacity. In the cycling test, the PCM sample was heated and cooled using Peltier elements. The recorded temperatures are measured (Tmeas) on the sample side opposite the Peltier element. Cycling is controlled by Tmeas. If Tmeas reaches the heating set point, the Peltier element is set to the cooling mode. When Tmeas reaches the cooling setpoints, the Peltier element is set for heating. The set points are adjusted to ~8 K above the melting point for heating and ~13 K below the crystallisation temperature. The procedure ensures that the sample is completely molten and frozen at the turning points for heating/cooling of the Peltier element. For building lifespans of about 20 to 30 years, such stability minimises the need for replacement, thus reducing environmental impacts related to material production, transport and waste. RUBITHERM has also conducted long-term tests for the SP21EK encapsulated in the CSMs and confirmed that SP21EK retains its enthalpy and phase behaviour over cycling (tested > 100 cycles). Therefore, the degradation effects of SP21EK and replacement impacts may be considered negligible for a product lifespan of 20 years or less. However, in the case of longer lifespans, any degradation effects of the PCM application, along with its respective replacement impacts to meet the targeted performance, should be considered in LCA studies that assess the operational stage of buildings and their applications.

3. LCA Methodology

Life Cycle Assessment (LCA) is a powerful analysis that evaluates the environmental impacts of processes, products, or services across their life cycle. It provides a holistic approach to decision-making towards sustainability in a comprehensive way and enables companies to better understand and mitigate their environmental impacts [

50]. LCA is standardised by ISO 14040:2006 [

22] and ISO 14044:2006 [

23], consisting of the following four LCA phases: (1) Goal and Scope definition, (2) Inventory Analysis, (3) Impact Assessment, and (4) Interpretation of results. In this study, the LCA methodology was applied to a specific PCM-filled CSM developed by RUBITHERM.

3.1. Goal and Scope Definition

The goal of the LCA in this study was to quantify and assess the potential environmental impacts of a specific PCM-filled CSM developed by RUBITHERM and to identify any environmental hotspots across materials and processes participating in PCM-filled CSM manufacturing, aiming to mitigate climate change. The CSM 10/5 examined consists of an aluminium case with dimensions of 30 cm × 45 cm × 1.5 cm (area of 0.135 m2) and a volume of ~1300 mL, filled with 2 kg of SP21EK with a heat storage capacity of 170 kJ/kg or 47 Wh/kg. The empty aluminium case weight 0.341 kg, and if the adhesive and epoxy layer applied are considered, the aluminium case mass is 0.347 kg. The total mass of one PCM-filled CSM examined is 2.347 kg.

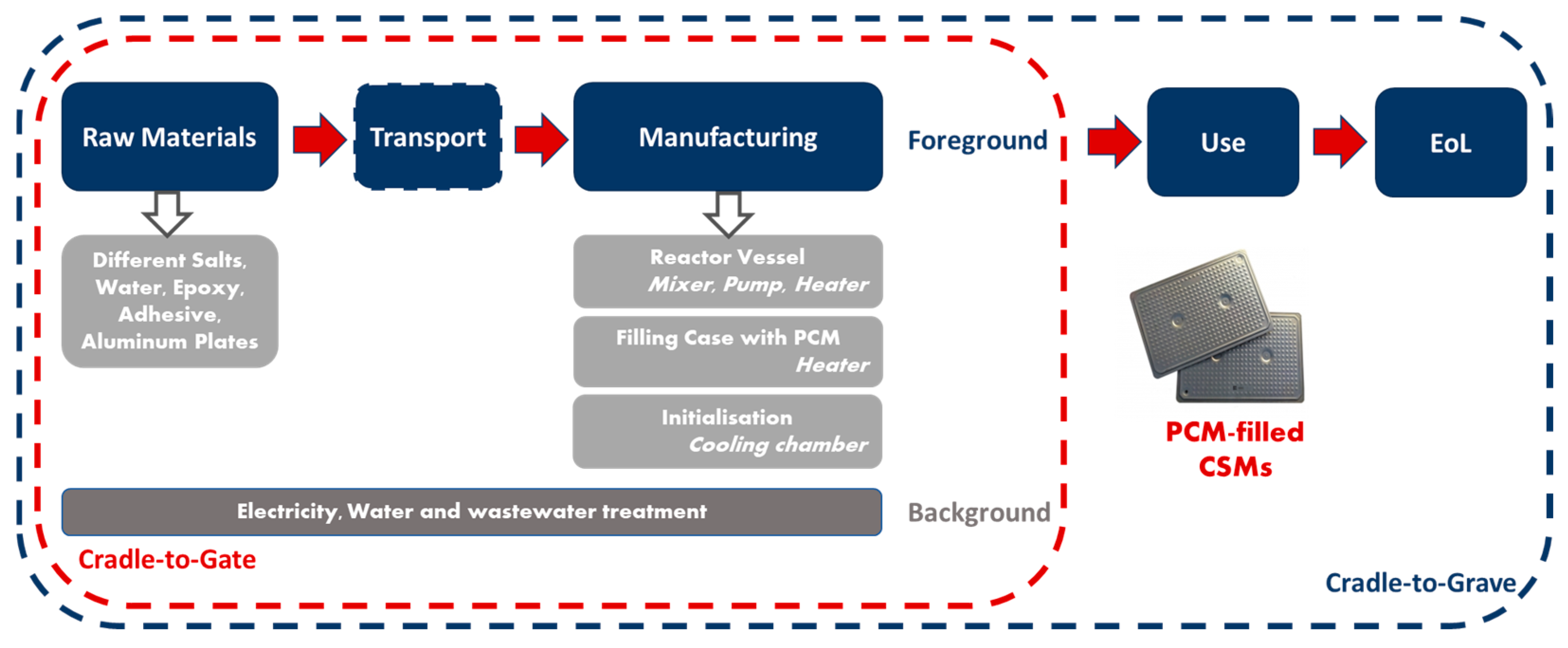

The LCA in this work applies the “cradle to gate” system boundary approach, which by definition includes the following stages: raw material extraction, transport, and manufacturing, and is performed for the product stage (A1–A3) of the PCM-filled CSM, according to the life cycle stages of materials for buildings, according to EN 15978:2011 [

51] and EN 15804:2012 + A2:2019 [

52] European Standards for the Sustainability of Construction Works. Therefore, the life cycle stage considered is A1. Raw material extraction and processing, processing of secondary material input, A2. Transport to the manufacturer, A3. Manufacturing. However, life cycle stage A2 was not considered in the boundaries of the system examined, since the study focused on the materials and manufacturing process of the examined module. Thus, the system boundaries considered in this study are presented in

Figure 2 by a red dashed outline.

As the function of interest in this study is thermal energy storage, the Functional Unit (FU) selected is one piece of CSM, filled with 2 kg of SP21EK, with a targeted performance of 94 Wh heat storage capacity, given for a temperature difference (ΔΤ) of 15 K (+/−7.5 K above and below the melting point), considering a timeframe of 4–8 h for panel charging/discharging, and with a lifetime of 15 years. It should be mentioned that this timeframe depends on different parameters, like the volume flow of the heat transfer medium and the ΔT run.

3.2. Inventory Analysis

The Life Cycle Inventory (LCI) of the PCM-filled CSM under examination presents the inputs and outputs of materials and energy for the manufacturing process. The LCI was developed through iterative data collection in communication with RUBITHERM, with a reference unit of 300 pieces (pcs) of PCM-filled CSM, which reflects the RUBITHERM current daily production capacity (

Table 1). For the background LCI data, information was retrieved from the Ecoinvent professional database version 3.6. Water input flows were considered for European conditions, while electricity input flows were considered for country-specific conditions (Germany, manufacturing location), taking into account medium voltage grid. Proxy values were used when necessary.

The LCA modelling of the PCM-filled CSM was performed using the following assumptions and proxies:

SP21EK is an inorganic salt hydrate PCM that contains a stoichiometric addition of water to form a stable hydrate structure and uniform crystallisation. Water used for this purpose accounted for around 30% of the total mass of the PCM.

Water was also used to wash the vessel and the filled CSMs (

Table 1) at an amount of 30 L per 300 filled CSMs manufactured. Regarding the aluminium processing stages, no water was used from the coil to the aluminium plate.

Magnesium chloride was approximated by calcium chloride, as it was the most relevant material dataset available in Ecoinvent.

The amounts of salts used were provided in ranges, and the assumptions of concentration per salt were based on the average amount used.

An aluminium wrought alloy was chosen as the raw material (not cast) to be formed as a solid, while no production losses were considered due to massive production.

Aluminium plate manufacturing was approximated by aluminium coil manufacturing, which was approximated by aluminium sheet rolling. In addition, aluminium plate manufacturing includes cutting the aluminium coil into adequate squares and then pressing it into shape using hydraulic presses, which is performed by the sister company of RUBITHERM. However, the electricity demand for processing the aluminium coil to manufacture aluminium plates is unknown; as it is estimated to be low in comparison to other manufacturing processes, like initialisation, it is considered negligible.

The connection of two aluminium plates to develop the aluminium case by adhesive and crimping, the additional layers of epoxy applied, as well as the closing of the aluminium case openings was assumed to take place manually, since no energy data were provided for these process steps.

No losses were considered for the PCM and CSM manufacturing, while the wastewater of 30 L, from washing the vessel and CSM was considered.

Packaging is estimated to require about 25 carton board boxes and 1 wooden pallet for 300 pcs; however, it was not considered in the boundaries of the system examined for this LCA study.

Finally, any PCM leakage or degradation effects were assumed to be negligible in the considered lifespan of SP21EK, as analytically explained in

Section 2.2 and

Section 2.4.

3.3. Impact Assessment

Life Cycle Impact Assessment (LCIA) was performed using the commercial LCA software SimaPro version 9.6.0.1 by the ILCD 2011 Midpoint+ method. This method, released by the Joint Research Centre of the European Commission, includes 16 midpoint environmental impact categories [

53], which are addressed in this study. Nevertheless, the focus of this t LCIA is on the climate change impact category: Global Warming Potential (GWP), defining the greenhouse effect over a 100-year time horizon. The 16 environmental impact categories are illustrated with their abbreviations and units of measurement, along with the raw LCA results, in

Appendix A,

Table A1, for one piece of the PCM-filled CSM under investigation.

4. Results

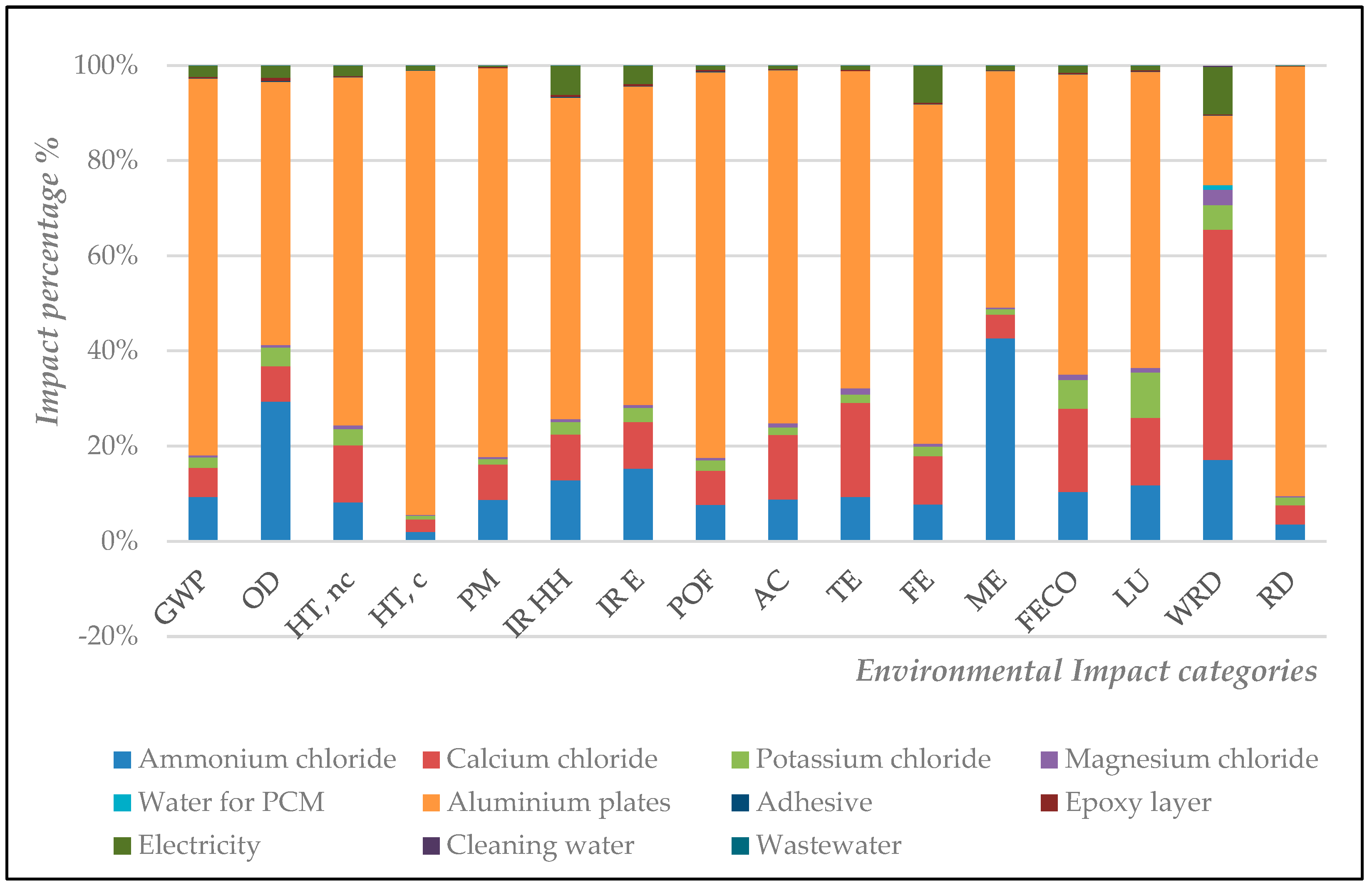

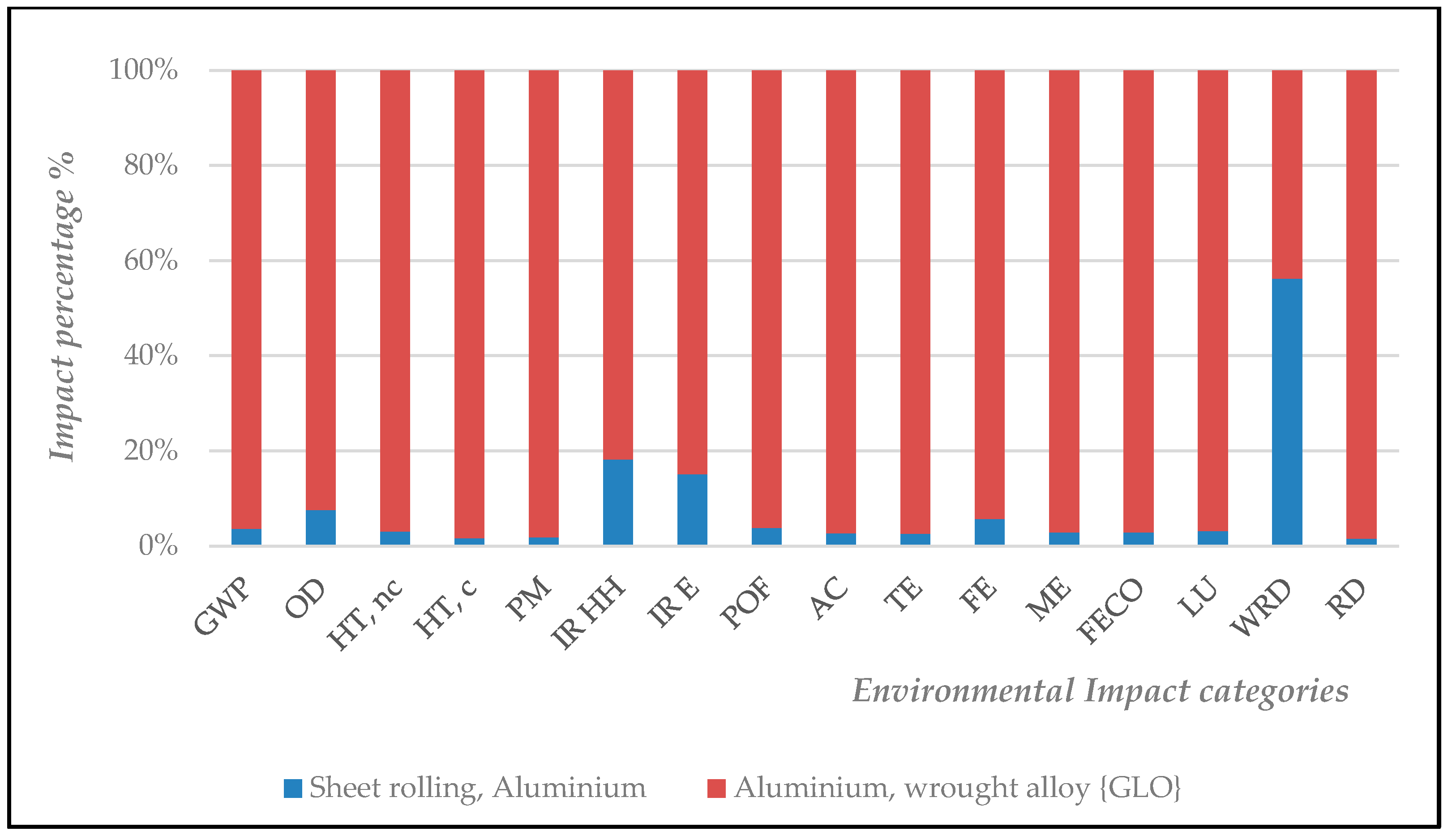

This section presents the LCIA results for the RUBITHERM SP21EK PCM-filled CSM 10/5 under investigation. The characterisation results are illustrated as staked 100% graphs in the following figures for the 16 environmental categories addressed. The input and output flows of materials and energy considered in this analysis are presented in the figure legends. In particular,

Figure 3 shows the LCA results for the production stage of one piece of the PCM-filled CSM examined, with 2 kg of SP21EK and a targeted performance of 94 Wh heat storage capacity, given for a ΔΤ of 15 K. The potential impact of the specific PCM-filled CSM product stage on climate change is 5.81 kg CO

2 eq per piece.

The environmental hotspot analysis indicates that the aluminium plates for CSM manufacturing represent the greatest share of over 50% for all 16 impact categories addressed, except for Water Resource Depletion. Specifically, for climate change, aluminium plates are the predominant contributor, with a share of 79%, resulting in 4.59 kg CO2 eq per piece. Further, the chlorides and water used for the production of the PCM burden climate change by a total share of 18%, while the electricity requirements for manufacturing reach a contribution of 2.3%. The impact category of Water Resource Depletion is mainly affected by calcium chloride, which is predominant in the assumed mass composition of the PCM salts under examination, with a share of 48.5%, followed by ammonium chloride with a share of 17%. Specifically, the dataset selected to approximate calcium chloride considered the Solvay process for the production of calcium chloride, which is water-demanding for both cooling and chemical processing, resulting in water resource depletion. The contributions of the adhesive, epoxy layer, water demand for cleaning the CSM and vessel, and wastewater treatment were considered negligible for any of the 16 environmental impact categories addressed.

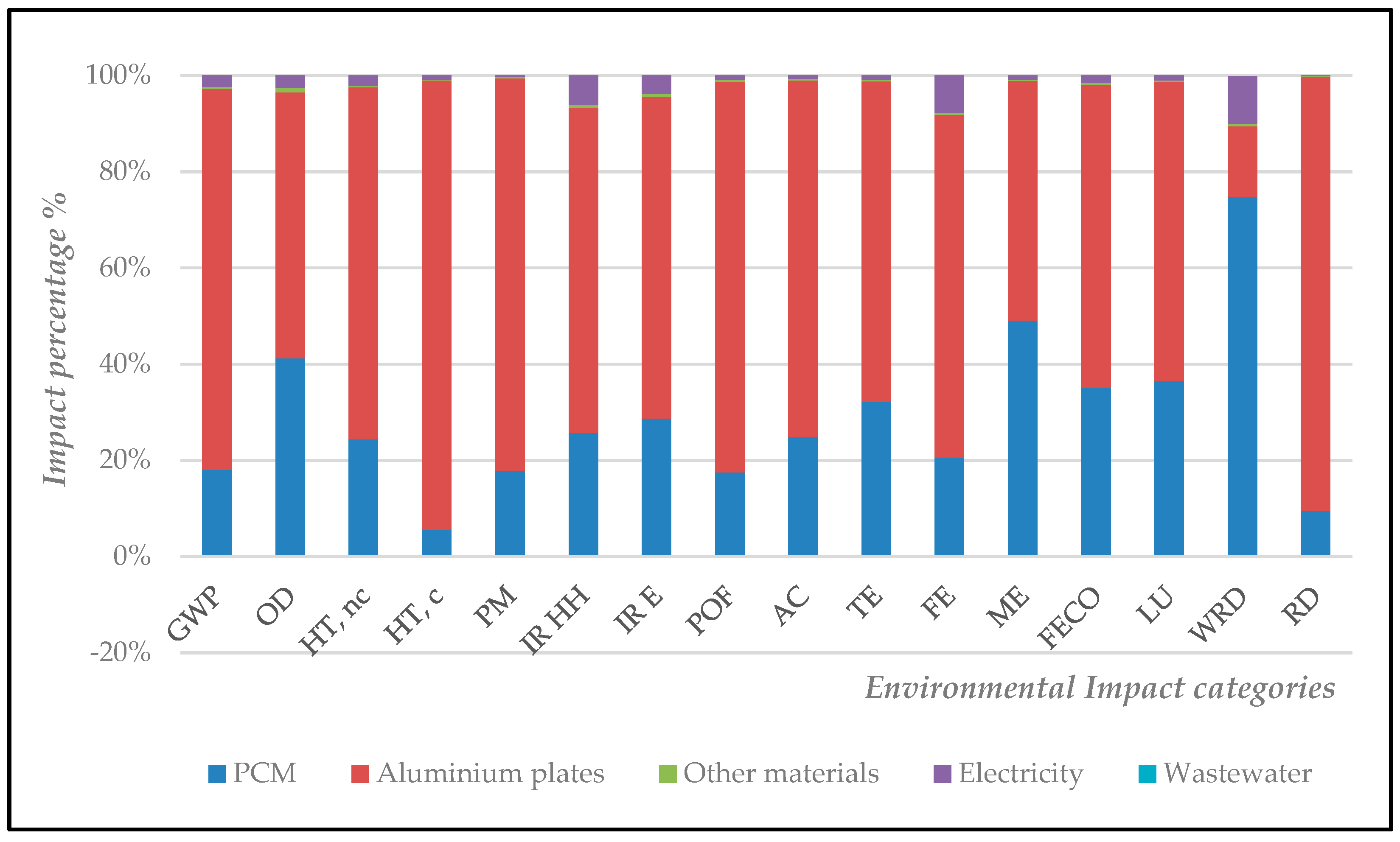

In

Figure 4, the material inputs are classified into specific groups to present the PCM, aluminium plates, and other materials (i.e., adhesive, epoxy layer, and cleaning water) as separate material input categories, and therefore provide aggregated LCIA results for one piece of the PCM-filled CSM under examination.

Since it is clear that the aluminium plates consist of the main contributor in almost all impact categories addressed, this material input was further investigated in terms of environmental impacts. Specifically, the aluminium plates are developed by a sister company of RUBITHERM and were not accompanied by real production data; therefore, their manufacturing was approximated by aluminium sheet rolling, as the most relevant process available in the Ecoinvent database, while aluminium wrought alloy was chosen as the raw material to be formed as solid (

Section 3.2). The LCIA results for the aluminium plates of one piece of CSM are presented in

Figure 5 and indicate the aluminium wrought alloy as the predominant contributor in all impact categories addressed (except for Water Resource Depletion), including climate change by 96% or 4.41 kg CO

2 eq per piece.

At this point, it is important to highlight that the aluminium wrought alloy dataset, selected from the Ecoinvent database for this assessment, refers to a global level, considered the most inclusive of all possible aluminium wrought alloy production conditions in terms of raw material inputs and geography coverage. Thus, it was selected as the most representative dataset available in the Ecoinvent database in this case of unknown real data. The composition of the aluminium wrought alloy considered in this dataset is available in its inventory at the Ecoinvent database and is illustrated in

Table 2 in terms of the mass composition percentage of each aluminium stream considered for the wrought alloy modelling. The streams used for the aluminium wrought alloy modelling with global geography coverage are as follows: primary aluminium for global geography coverage, new aluminium scrap for European coverage, post-consumer aluminium scrap for European coverage, new aluminium scrap for the rest-of-world coverage, and post-consumer aluminium scrap for the rest-of-world coverage. In this case, the rest-of-world coverage refers to geography coverage outside Europe. Consequently, the aluminium wrought alloy modelled for global coverage is a mix of virgin and recycled aluminium streams from different production locations worldwide.

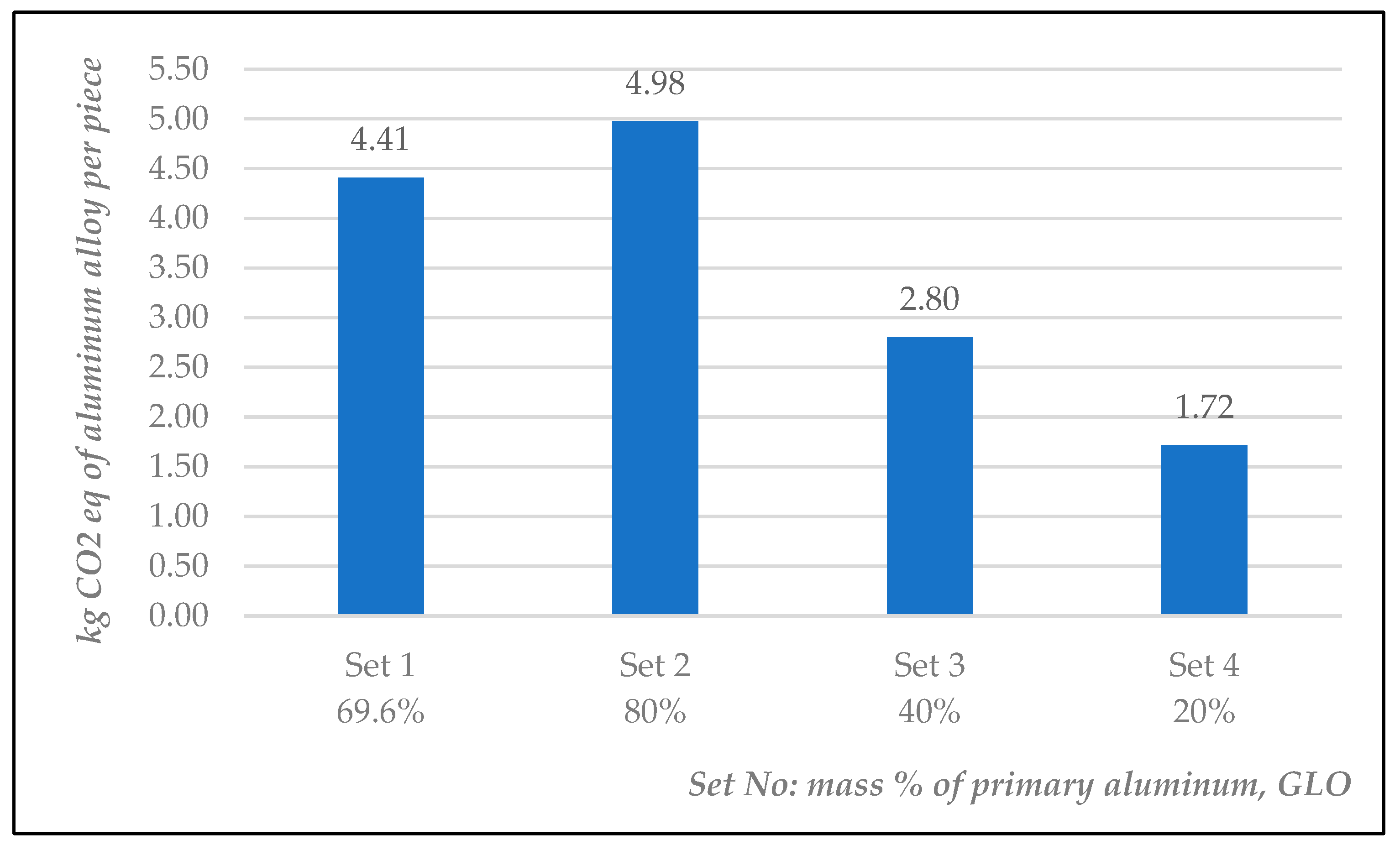

In this context, it is of high interest to perform a sensitivity analysis concerning the parameter of mass percentage for primary, new scrap, and post-consumer scrap of aluminium, and how it influences the environmental impact of climate change. As observed in

Table 2, the mass percentages of new scrap and post-consumer scrap considering European coverage are very low compared with those of the other aluminium streams included. Consequently, the sensitivity analysis examined the mass percentage of primary aluminium with global coverage, as well as new scrap and post-consumer scrap with RoW coverage, in relation to the potential climate change impact. Four different compositions of the aluminium wrought alloy, expressed in mass percentage, were considered in the sensitivity analysis and are presented in four sets, as shown in

Table 3, with Set 1 representing the composition of the aluminium wrought alloy in

Table 2. The mass percentages of the new scrap, RER, and post-consumer scrap, RER, were kept constant across the four sets. In addition, the mass ratio of the post-consumer scrap, RoW, and the new scrap, RoW, at around 25%, was kept constant across the four sets. The sensitivity analysis results (

Figure 6) present the potential climate change impact of the aluminium wrought alloy, expressed in kg CO

2 eq per piece produced, in relation to its mass composition, and particularly the mass percentage of the primary aluminium, GLO.

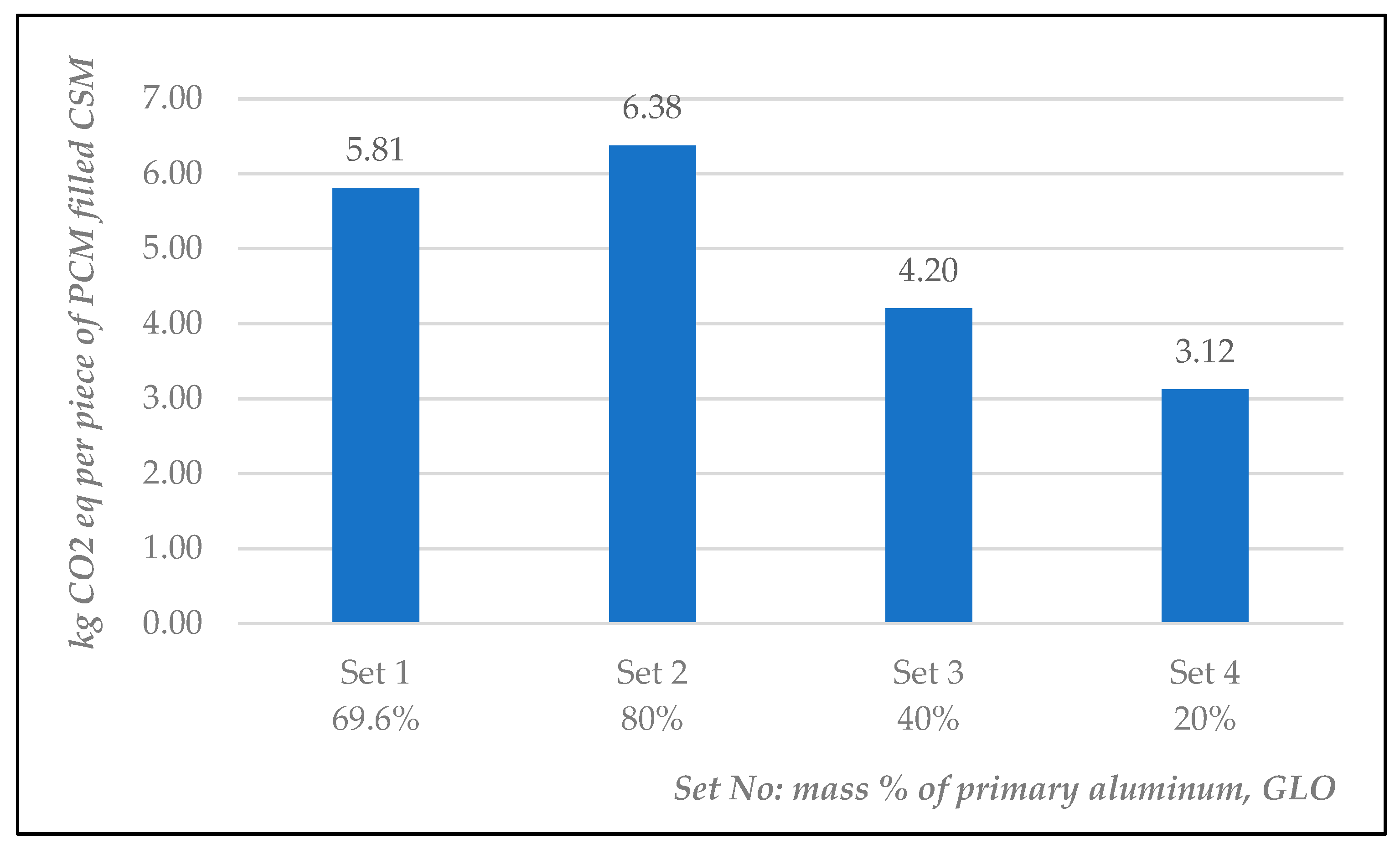

The results of the sensitivity analysis show that the potential impact of climate change is reduced as the primary aluminium mass decreases in relation to the mass of the other two aluminium streams of new scrap and post-consumer scrap, RoW, and vice versa. Specifically, when the primary aluminium mass content was decreased from 69.6% to 40%, by almost 30%, the climate change impact of the aluminium wrought alloy was reduced by 36.5%. A further decrease in the primary aluminium mass content from 69.6% to 20%, by almost 50%, led to a 61% reduction in the climate change impact. Therefore, the increased recycled content of the aluminium wrought alloy may lead to climate change impact mitigation, even by a significant percentage of more than 60% (Set 4) of the initial aluminium wrought alloy composition considered (Set 1). In this case, considering the climate change impact of the aluminium wrought alloy of 1.72 kg CO

2 eq per piece of PCM-filled CSM (Set 4), instead of 4.41 kg CO

2 eq per piece as initially examined (Set 1), the total climate change impact for one piece of PCM-filled CSM drops from 5.81 kg CO

2 eq to 3.12 kg CO

2 eq, achieving a total reduction of climate change impact of the final product by 46%.

Figure 7 illustrates analytically the influence of the different aluminium wrought alloy compositions on the total climate change impact of the final product.

5. Discussion

Materials for TES applications are key players in reducing building operational energy consumption, emissions, and costs, leading to climate change mitigation and green transition. Energy balance, environmental compatibility, and raw material recyclability potential contribute to environmental assessment and potential improvement. LCA offers the opportunity to all interested stakeholders to integrate environmental aspects in the design, manufacturing, and decision-making of building applications, promoting environmental sustainability across the whole building life cycle, considering embodied emissions and trade-offs. However, it is not easy to understand whether a building application is environmentally friendly from a life cycle perspective. Therefore, established LCA insights on innovative materials and their applications may facilitate environmental impact mitigation through the development and improvement of building products and manufacturing techniques. To this end, EC-funded projects, such as Research and Innovation Actions (RIA), promote research studies on innovative materials, components, and applications toenhance building environmental sustainability.

This paper, carried out under the EC-funded RIA project “iclimabuilt”, was dedicated to the LCA of a commercial PCM building application, the RUBITHERM SP21EK PCM-filled CSM 10/5, regarding its production stage, aiming to identify its potential environmental impacts, as well as any environmental hotspots across the manufacturing chain that need further attention. Sixteen environmental impact categories were addressed, with a special focus on the impact of climate change. The LCIA results showed that the potential climate change impact of the specific PCM-filled CSM product stage is 5.81 kg CO2 eq per piece, whereas the aluminium plates are the predominant contributor at 4.59 kg CO2 eq per piece. Further analysis indicated that the aluminium wrought alloy of the plates was the main contributor to climate change at 4.41 kg CO2 eq per piece. In fact, the material input of aluminium, used for the case to be filled in with PCM, was the basic contributor to all impact categories addressed, apart from Water Resource Depletion. This impact category is affected by calcium chloride, which is predominant in the assumed mass composition of the PCM salts under examination, considering the water-demanding Solvay process for its production.

The sensitivity analysis in this study, which investigated the environmental hotspot of aluminium, showed a high dependence of the climate change impact on the aluminium recycled content, revealing significant climate change mitigation levels for the PCM building application when the content of aluminium new scrap and post-consumer scrap was increased in the aluminium wrought alloy for aluminium case manufacturing. In particular, the decrease in the primary aluminium mass content by almost 50% resulted in a reduction in the climate change impact of the aluminium wrought alloy, from 4.41 kg CO2 eq per piece to 1.72 kg CO2 eq per piece, achieving important mitigation of even more than 60%. Additionally, the influence of the primary Al mass content on the total climate change impact of the final product was investigated. In the case of almost 50% primary aluminium content decrease, the total climate change impact of the PCM-filled CSM dropped from 5.81 kg CO2 eq per piece to 3.12 kg CO2 eq per piece, achieving a significant total climate change impact reduction of 46%. Finally, the contribution of the adhesive, epoxy layer, water demand for cleaning the CSM and vessel, and wastewater treatment was considered negligible for any of the 16 environmental impact categories addressed.

6. Conclusions

The results of this study lead to the general conclusion that a PCM building application should be environmentally assessed as a whole component ready for installation since environmental burdens may derive from encapsulation materials or other materials applied and not from the PCMs themselves, especially in the case of the salt hydrates examined herein. Consequently, as this research implies, the recycled content of encapsulation materials, like aluminium, could be further exploited, leading to final PCM building applications with a reduced total climate change impact and thus, to promising candidates for sustainable thermal storage building components. Of course, such climate change mitigation actions require the cooperation of encapsulant material manufacturers and PCM building application producers, both of whom are willing to decrease the primary content of materials to be replaced by new or post-consumer scrap streams.

The main limitation of this research study was the narrow available literature, specifically on the LCA of PCMs and relevant building applications, while presenting a lack of adequate and detailed LCI data necessary for PCM system modelling and environmental assessment. Nevertheless, this limitation, even though critical for the study accomplishment, was addressed by the development of the LCI for the production of the PCM building application under examination, based on real manufacturing data. This was achieved through intensive communication with our manufacturing partner. In the case of specific data gaps, like in the aluminium plate manufacturing, the proxies and assumptions considered, along with the rationale for their selection, were clearly mentioned in the LCI section. Therefore, this study facilitates the ongoing research on PCMs and their applications, by covering existing data gaps in literature, as well as by providing LCA results and detailed real data LCIs for future research.

It should also be mentioned that deficits and ambiguities were noticed in the respective LCA literature on PCMs and their building applications, concerning the system boundaries examined, the definition of the functional unit assessed, and the proxies and assumptions considered, leading to difficulties in the exploitation of information, in follow-up research, and in enabling comparisons of LCA results. Such deficiencies are generally observed in the LCA literature, specifically regarding innovative materials and functionalities. To tackle these issues, this research paper was structured to provide methodology transparency in the field of PCMs and their applications, describing the real manufacturing process, the reasoning for the functional unit selected, the system boundaries considered, and all proxies and assumptions used for the system modelling, enabling a deep understanding of the LCA method and potential consistency in future relevant work and results.

Future work recommendations include the expansion of the system boundaries to assess the end-of-life scenarios of this PCM building application. It is expected that recyclability potential may be revealed in the case of the environmental hotspot of aluminium, resulting in closing the aluminium manufacturing loop and further mitigating the total climate change impact of the PCM-filled CSM. Another suggested system expansion concerns the use phase of this building application, where any degradation effects and/or leakage should be considered during a typical building lifespan of 50 years. Moreover, future research could include the collection of real data specifically for aluminium plates, both for raw materials and the manufacturing process, leading to increased quality and accuracy of results, as well as insights regarding the aluminium wrought alloy itself. Finally, further investigation may be conducted to enable comparisons with relevant PCMs or/and building applications, while sensitivity analysis could also be performed for the synthesis of the current PCM used, to provide insight into optimum compositions of water and salts, always in relation to the PCM performance and environmental impacts.

Author Contributions

Conceptualisation, D.A., F.P. (Foteini Petrakli) and E.P.K.; methodology, D.A., A.G. and A.A.; software, D.A. and F.P. (Foteini Petrakli); validation, F.P. (Felix Pawelz), A.G. and E.K.; formal analysis, D.A.; investigation, F.P. (Foteini Petrakli) and A.G.; resources, F.P. (Felix Pawelz); data curation, E.K.; writing—original draft preparation, D.A., F.P. (Foteini Petrakli) and E.P.K.; writing—review and editing, E.P.K. and A.G.; visualisation, A.A., E.K. and D.A.; supervision, E.P.K.; project administration, E.P.K.; funding acquisition, E.P.K. All authors have read and agreed to the published version of this manuscript.

Funding

The activities presented in this paper were carried out as part of the European Union’s Horizon 2020 research and innovation programme iclimabuilt: “iclimabuilt—Functional and advanced insulating and energy harvesting/storage materials across climate adaptive building envelopes” (Grant Agreement no. 952886).

Data Availability Statement

Dataset available on request from the authors.

Conflicts of Interest

The authors declare that the research was conducted under the framework of the EU funded project “iclimabuilt”, in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| 3LC | Three Layer Calorimeter |

| AC | Acidification |

| CSM | Compact Storage Module |

| FE | Freshwater eutrophication |

| FECO | Freshwater ecotoxicity |

| FU | Functional Unit |

| GHG | Greenhouse Gas |

| GLO | Global geography coverage |

| GWP | Global Warming Potential |

| HT, c | Human toxicity, cancer effects |

| HT, nc | Human toxicity, non-cancer effects |

| HVAC | Heating, Ventilation, and Air Conditioning |

| ILCD | International Reference Life Cycle Data System |

| IR E | Ionising radiation E (interim) |

| IR HH | Ionising radiation HH |

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| LCIA | Life Cycle Impact Assessment |

| LU | Land use |

| ME | Marine eutrophication |

| OD | Ozone depletion |

| PCM | Phase Change Material |

| PM | Particulate matter |

| POF | Photochemical ozone formation |

| RD | Mineral, fossil & ren resource depletion |

| RER | European geography coverage |

| RoW | Rest-of-world geography coverage |

| RT | Organic |

| SP | Inorganic |

| TE | Terrestrial eutrophication |

| Tmeas | Temperature measured |

| TES | Thermal Energy Storage |

| WRD | Water resource depletion |

Appendix A

Table A1.

The LCA results for one piece of the PCM-filled CSM under investigation, for the 16 environmental impact categories addressed.

Table A1.

The LCA results for one piece of the PCM-filled CSM under investigation, for the 16 environmental impact categories addressed.

| Impact Category | Abbreviation | Unit | Ammonium Chloride | Calcium Chloride | Potassium Chloride | Magnesium Chloride | Water for PCM | Aluminium Plates | Adhesive | Epoxy Layer | Electricity | Cleaning Water | Wastewater | Total |

|---|

| Global warming potential | GWP | kg CO2 eq | 0.542460095 | 0.353103208 | 0.129420147 | 0.023540214 | 0.000210016 | 4.601475 | 0.006425 | 0.018327 | 0.135724205 | 3.5 × 10−5 | 6.89 × 10−5 | 5.810789 |

| Ozone depletion | OD | kg CFC-11 eq | 1.20244 × 10−7 | 3.06402 × 10−8 | 1.6107 × 10−8 | 2.04268 × 10−9 | 2.263 × 10−11 | 2.27 × 10−7 | 9.06 × 10−10 | 2.75 × 10−9 | 1.05446 × 10−8 | 3.77 × 10−12 | 4.35 × 10−12 | 4.1 × 10−7 |

| Human toxicity, non-cancer effects | HT, nc | CTUh | 1.81463 × 10−7 | 2.65474 × 10−7 | 7.71257 × 10−8 | 1.76983 × 10−8 | 1.42463 × 10−10 | 1.62 × 10−6 | 1.72 × 10−9 | 4.55 × 10−9 | 4.82547 × 10−8 | 2.37 × 10−11 | 3.01 × 10−10 | 2.22 × 10−6 |

| Human toxicity, cancer effects | HT, c | CTUh | 2.86143 × 10−8 | 3.79263 × 10−8 | 1.12808 × 10−8 | 2.52842 × 10−9 | 1.00701 × 10−10 | 1.35 × 10−6 | 3.38 × 10−10 | 9.51 × 10−10 | 1.35417 × 10−8 | 1.68 × 10−11 | 1.72 × 10−11 | 1.45 × 10−6 |

| Particulate matter | PM | kg PM2.5 eq | 0.000521383 | 0.000450892 | 6.6143 × 10−5 | 3.00595 × 10−5 | 1.32179 × 10−7 | 0.004917 | 4.06 × 10−6 | 1.21 × 10−5 | 1.75622 × 10−5 | 2.2 × 10−8 | 9.36 × 10−8 | 0.00602 |

| Ionising radiation HH | IR HH | kBq U235 eq | 0.047105941 | 0.035484532 | 0.009439477 | 0.002365635 | 7.24334 × 10−5 | 0.248622 | 0.000522 | 0.001541 | 0.022615971 | 1.21 × 10−5 | 6.8 × 10−6 | 0.367788 |

| Ionising radiation E (interim) | IR E | CTUe | 1.83248 × 10−7 | 1.1783 × 10−7 | 3.50266 × 10−8 | 7.85531 × 10−9 | 1.93303 × 10−10 | 8.03 × 10−7 | 1.71 × 10−9 | 4.96 × 10−9 | 4.60707 × 10−8 | 3.22 × 10−11 | 2.04 × 10−11 | 1.2 × 10−6 |

| Photochemical ozone formation | POF | kg NMVOC eq | 0.001377957 | 0.001290914 | 0.00040249 | 8.6061 × 10−5 | 6.30598 × 10−7 | 0.014622 | 2.25 × 10−5 | 6.71 × 10−5 | 0.000163205 | 1.05 × 10−7 | 2.25 × 10−7 | 0.018033 |

| Acidification | AC | molc H+ eq | 0.003735982 | 0.005779125 | 0.00066654 | 0.000385275 | 1.19195 × 10−6 | 0.031609 | 2.94 × 10−5 | 8.56 × 10−5 | 0.000303255 | 1.99 × 10−7 | 5.67 × 10−7 | 0.042596 |

| Terrestrial eutrophication | TE | molc N eq | 0.007418802 | 0.015853788 | 0.001383254 | 0.001056919 | 2.17057 × 10−6 | 0.053294 | 5.58 × 10−5 | 0.000163 | 0.000718987 | 3.62 × 10−7 | 1.61 × 10−6 | 0.079949 |

| Freshwater eutrophication | FE | kg P eq | 0.000181972 | 0.000239978 | 4.67387 × 10−5 | 1.59985 × 10−5 | 1.51505 × 10−7 | 0.001682 | 2.14 × 10−6 | 6.3 × 10−6 | 0.000183611 | 2.53 × 10−8 | 1.14 × 10−7 | 0.002359 |

| Marine eutrophication | ME | kg N eq | 0.004450436 | 0.000512573 | 0.000123583 | 3.41715 × 10−5 | 2.31508 × 10−7 | 0.005184 | 5.34 × 10−6 | 1.57 × 10−5 | 9.67712 × 10−5 | 3.86 × 10−8 | 2.05 × 10−6 | 0.010425 |

| Freshwater ecotoxicity | FECO | CTUe | 13.48862324 | 22.97723362 | 7.843612713 | 1.531815575 | 0.004353233 | 82.4105 | 0.14093 | 0.35436 | 1.959344409 | 0.000726 | 0.00196 | 130.7135 |

| Land use | LU | kg C deficit | 0.820632864 | 0.990092394 | 0.665682669 | 0.06600616 | 0.00029267 | 4.345212 | 0.00635 | 0.016091 | 0.069863188 | 4.88 × 10−5 | 0.000469 | 6.98074 |

| Water resource depletion | WRD | m3 water eq | 0.001792212 | 0.005063948 | 0.000545376 | 0.000337597 | 9.88801 × 10−5 | 0.001528 | 8.07 × 10−6 | 2.32 × 10−5 | 0.001041774 | 1.65 × 10−5 | −1.4 × 10−5 | 0.010441 |

| Mineral, fossil & ren resource depletion | RD | kg Sb eq | 2.72885 × 10−5 | 3.09046 × 10−5 | 1.26979 × 10−5 | 2.0603 × 10−6 | 6.13824 × 10−9 | 0.000691 | 1.76 × 10−7 | 4.31 × 10−7 | 8.65944 × 10−7 | 1.02 × 10−9 | 2.09 × 10−9 | 0.000766 |

References

- International Energy Agency (IEA). IEA/Energy System/Buildings. 11 July 2023. Available online: https://www.iea.org/energy-system/buildings#tracking (accessed on 12 February 2025).

- Santamouris, M.; Vasilakopoulou, Κ. Present and future energy consumption of buildings: Challenges and opportunities towards decarbonization. E-Prime—Adv. Electr. Eng. Electron. Energy 2021, 1, 100002. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). IEA/Energy System/Buildings/Space Cooling. 12 July 2023. Available online: https://www.iea.org/energy-system/buildings/space-cooling#tracking (accessed on 12 February 2025).

- International Energy Agency (IEA). Net Zero Roadmap: A Global Pathway to Keep the 1.5 °C Goal in Reach; IEA Publications: Paris, France, 2023. [Google Scholar]

- Rousselot, M.; Da Rocha Pinto, F. Policy Brief: Energy efficiency trends in buildings in the EU. ODYSSEE-MURE 2021. Available online: https://www.odyssee-mure.eu/publications/policy-brief/buildings-energy-efficiency-trends.pdf (accessed on 29 April 2025).

- Wei, C.; Huang, Y.; Löschel, A. Recent advances in energy demand for residential space heating. Energy Build. 2022, 261. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). IEA/Energy System/Buildings/Heating. 11 July 2023. Available online: https://www.iea.org/energy-system/buildings/heating#tracking (accessed on 12 February 2025).

- Sarbu, I.; Sebarchievici, C. A Comprehensive Review of Thermal Energy Storage. Sustainability 2018, 10, 191. [Google Scholar] [CrossRef]

- Podara, C.; Kartsonakis, I.; Charitidis, C. Towards Phase Change Materials for Thermal Energy Storage: Classification, Improvements and Applications in the Building Sector. Appl. Sci. 2021, 11, 1490. [Google Scholar] [CrossRef]

- Lamrani, B.; Johannes, K.; Kuznik, F. Phase change materials integrated into building walls: An updated review. Renew. Sustain. Energy Rev. 2021, 140, 110751. [Google Scholar] [CrossRef]

- Koohi-Fayegh, S.; Rosen, M. A review of energy storage types, applications and recent developments. J. Energy Storage 2020, 27, 101047. [Google Scholar] [CrossRef]

- Junaid, Μ.; Rehman, Z.; Čekon, M.; Čurpek, J.; Farooq, R.; Cui, H.; Khan, I. Inorganic phase change materials in thermal energy storage: A review on perspectives and technological advances in building applications. Energy Build. 2021, 252, 111443. [Google Scholar] [CrossRef]

- Hassan, F.; Jamil, F.; Hussain, A.; Ali, H.; Janjua, M.; Khushnood, S.; Farhan, M.; Altaf, K.; Said, Z.; Li, C. Recent advancements in latent heat phase change materials and their applications for thermal energy storage and buildings: A state of the art review. Sustain. Energy Technol. Assess. 2022, 49, 101646. [Google Scholar] [CrossRef]

- Sadeghi, G. Energy storage on demand: Thermal energy storage development, materials, design, and integration challenges. Energy Storage Mater. 2022, 46, 192–222. [Google Scholar] [CrossRef]

- Venkateswarlu, K.; Ramakrishna, K. Recent advances in phase change materials for thermal energy storage—A review. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 6. [Google Scholar] [CrossRef]

- IEA-ETSAP; IRENA. Thermal Energy Storage Technology Brief. 2013. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2013/IRENA-ETSAP-Tech-Brief-E17-Thermal-Energy-Storage.pdf (accessed on 29 April 2025).

- Wang, X.; Li, W.; Luo, Z.; Wang, K.; Shah, S. A critical review on phase change materials (PCM) for sustainable and energy efficient building: Design, characteristic, performance and application. Energy Build. 2022, 260, 111923. [Google Scholar] [CrossRef]

- Jha, S.; Sankar, A.; Zhou, Y.; Ghosh, A. Incorporation of Phase Change Materials in Buildings. Constr. Mater. 2024, 4, 676–703. [Google Scholar] [CrossRef]

- Fikri, M.; Suraparaju, S.; Samykano, M.; Pandey, A.; Rajamony, R.; Kadirgama, K.; Ghazali, M. Enhanced Thermal Properties of Phase Change Materials through Surfactant-Functionalized Graphene Nanoplatelets for Sustainable Energy Storage. Energies 2023, 16, 7668. [Google Scholar] [CrossRef]

- World Green Building Council. Bringing Embodied Carbon Upfront; Built Environment Economist: London, UK, 2019. [Google Scholar]

- Yan, H.; Shen, Q.; Fan, L.; Wang, Y.; Zhang, Y. Greenhouse gas emissions in building construction: A case study of One Peking in Hong Kong. Build. Environ. 2010, 45, 949–955. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment-Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment-Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Struhala, K.; Ostrý, M. Life-Cycle Assessment of phase-change materials in buildings: A review. J. Clean. Prod. 2022, 336, 130359. [Google Scholar] [CrossRef]

- Vega, M.; Marín, P.; Ushak, S.; Shire, S. Research trends and gaps in experimental applications of phase change materials integrated in buildings. J. Energy Storage 2024, 75, 109746. [Google Scholar] [CrossRef]

- Rubitherm Technologies GmbH. Building Application; Office Building and More. Rubitherm Technologies GmbH. Available online: https://www.rubitherm.eu/en/references/2-ref (accessed on 17 February 2025).

- Rubitherm Technologies GmbH. Macroencapsulation—CSM; PCM in Aluminum Case. Rubitherm Technologies GmbH. Available online: https://www.rubitherm.eu/en/productcategory/makroverkaspelung-csm (accessed on 17 February 2025).

- iclimabuilt. Funding from the European Union’s Horizon 2020 Research and Innovation Programme Under Grand Agreement No: 952886. Available online: https://iclimabuilt.eu/ (accessed on 17 February 2025).

- Khodadadi, J.M.; Vafai, K. Analysis of phase change material-based thermal energy storage systems. Renew. Sustain. Energy Rev. 2011, 15, 5283–5292. [Google Scholar]

- Nazir, H.; Batool, M.; Osorio, F.J.B.; Isaza-Ruiz, M.; Xu, X.; Vignarooban, K.; Phelan, P.; Kannan, A.M. Recent developments in phase change materials for energy storage applications: A review. Int. J. Heat Mass Transf. 2019, 129, 491–523. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.; Chen, C.; Prakash, J. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Solé, C.; Barreneche, C. Phase change materials for thermal energy storage in buildings: A review. Renew. Sustain. Energy Rev. 2015, 43, 74–90. [Google Scholar]

- da Cunha, S.R.L.; de Aguiar, J.L.B. Phase change materials and energy efficiency of buildings: A review of knowledge. J. Energy Storage 2020, 27. [Google Scholar] [CrossRef]

- Palacios, J.M.; González, J.F.; García, L. Phase change materials for thermal energy storage in buildings: A review of methods and applications. Energy Build. 2018, 174, 1–12. [Google Scholar]

- Farid, M.M.; Khudhair, A.M.; Razack, S.A.A.; Al-Hallaj, S. A review on phase change energy storage: Materials and applications. Energy 2004, 29, 513–536. [Google Scholar] [CrossRef]

- Dinker, R.; Sharma, A.; Sagara, K. Recent developments in phase change materials for thermal energy storage applications: A review. Renew. Sustain. Energy Rev. 2017, 71, 381–397. [Google Scholar]

- Faraj, M.H.; Ranjbar, A.; Chena, J. Inorganic phase change materials: A review of their application in thermal energy storage systems. Energy Rep. 2020, 6, 493–505. [Google Scholar]

- Cui, Y.; Xie, J.; Liu, J.; Wang, J.; Chen, S. A review on phase change material application in building. Adv. Mech. Eng. 2017, 9, 6. [Google Scholar] [CrossRef]

- Lizana, J.; Álvarez, S.; López, J. Heat convection. In Encyclopedia of Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Cabezaa, L.F.; Chàfer, M. Technological options and strategies towards zero energy buildings contributing to climate change mitigation: A systematic review. Energy Build. 2020, 219, 110009. [Google Scholar] [CrossRef]

- Izadi, M.; Afsharpanah, F.; Mohadjer, A.; Shobi, M.O.; Ajarostaghi, S.S.M.; Minelli, F. Performance enhancement of a shell-and-coil ice storage enclosure for air conditioning using spiral longitudinal fins: A numerical approach. Heliyon 2025, 11, 4. [Google Scholar] [CrossRef]

- Khosrojerdi, S.; Mortazavi, S.M. A review on the use of phase change materials for thermal energy storage in building applications: Integration methods and containment solutions. J. Energy Storage 2013, 1, 15–27. [Google Scholar]

- Kalnæs, S.E.; Jelle, B.P. Phase change materials for energy storage in buildings: A review of materials, applications, and performance improvements. Energy Build. 2015, 94, 124–135. [Google Scholar] [CrossRef]

- White, M.A.; Kahwaji, S.; Noël, J.A. Recent advances in phase change materials for thermal energy storage. Chem. Commun. 2024, 60, 1690–1706. [Google Scholar] [CrossRef] [PubMed]

- Rubitherm Technologies GmbH. Buildings; Centralized/Decentralized Storage. Rubitherm Technologies GmbH. Available online: https://www.rubitherm.eu/en/applications/building (accessed on 17 February 2025).

- Rubitherm Technologies GmbH. PCM SP-Line. Rubitherm Technologies GmbH. Available online: https://www.rubitherm.eu/en/productcategory/anorganische-pcm-sp (accessed on 17 February 2025).

- Rubitherm Technologies GmbH. SP21EK Data Sheet. Available online: https://www.rubitherm.eu/media/products/datasheets/Techdata_-SP21EK_EN_13112023.PDF (accessed on 18 February 2025).

- RAL Deutsches Institut für Gütesicherung und Kennzeichnung e.V. Phase Change Materials-Quality Assurance—RAL-GZ 896; RAL Deutsches Institut für Gütesicherung und Kennzeichnung e.V.: Bonn, Germany, 2018. [Google Scholar]

- w&a, Wärme-und Anwendungstechnische Prüfungen. External Monitoring Institut der PCM-RAL Gütegemeinschaft. Available online: http://wunda.tech/3-Schicht-Kalorimeter/ (accessed on 16 April 2025).

- Green Business. Life Cycle Assessment: The Scientific Foundation of the Environmental Footprint Methods. Directorate-General for Environment. Available online: https://green-business.ec.europa.eu/environmental-footprint-methods/life-cycle-assessment-ef-methods_en (accessed on 18 March 2025).

- EN 15978:2011; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. European Committee For Standardization: Brussels, Belgium, 2011.

- EN15804:2012+A2; 2019-Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. European Committee For Standardization: Brussels, Belgium, 2019.

- European Commission—Joint Research Centre—Institute for Environment and Sustainability. International Reference Life Cycle Data System (ILCD) Handbook—Recommendations for Life Cycle Impact Assessment in the European Context; Publications Office of the European Union: Luxemburg, 2011. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).