Safety Risk Assessment of Deep Excavation for Metro Stations Using the Second Improved CRITIC Cloud Model

Abstract

1. Introduction

2. Engineering Case and Methodology

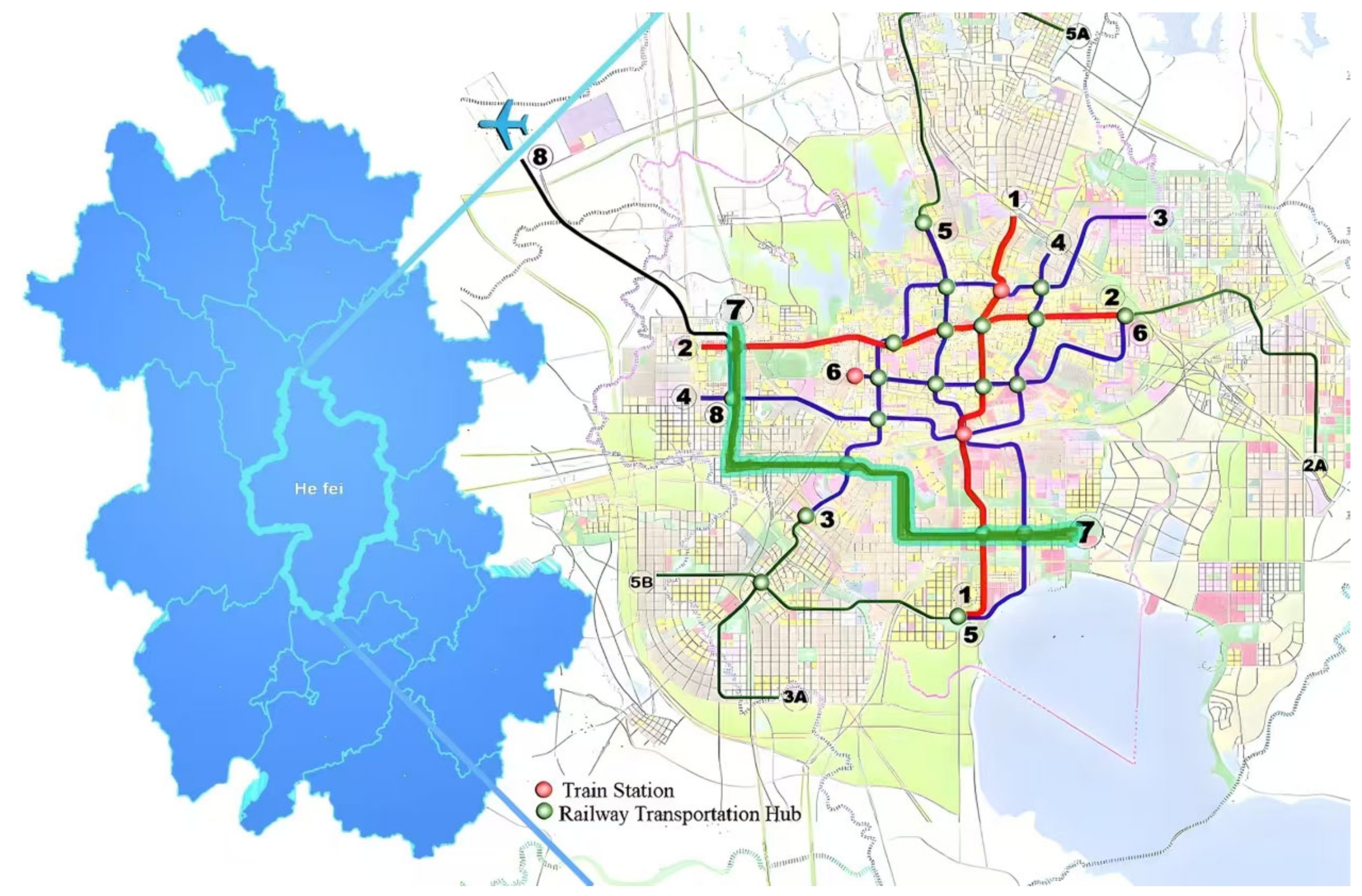

2.1. Engineering Case

2.2. Cloud Model

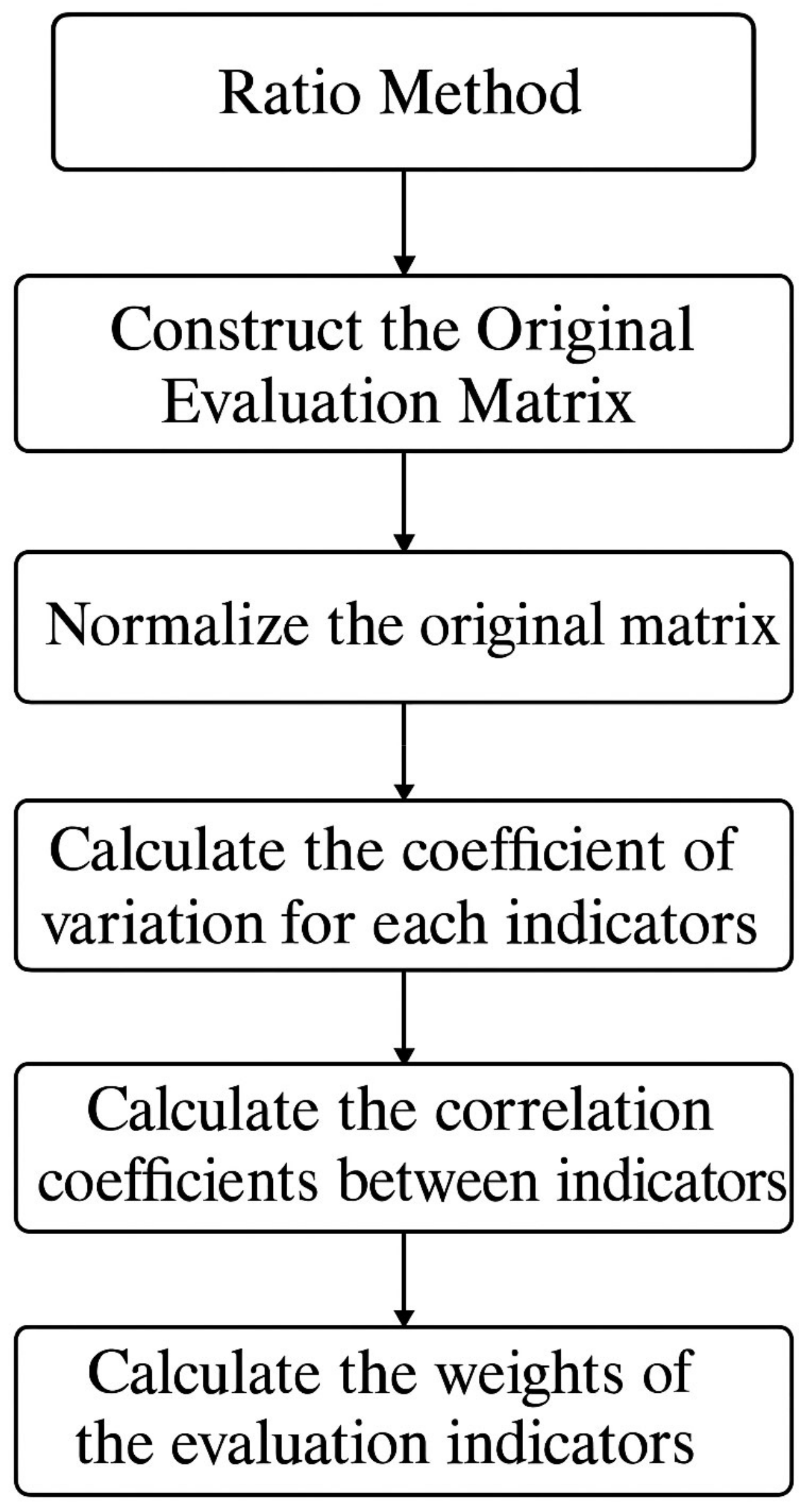

2.3. The Second Improved CRITIC Methods

2.4. Determination of Evaluation Indicator Weights

- Ratio method

- 2.

- Construct the original evaluation matrix

- 3.

- Normalize the original matrix

- 4.

- Calculate the coefficient of variation for each indicator

- 5.

- Calculate the correlation coefficients between indicators

- 6.

- Calculate the weights of the evaluation indicators

2.5. Determination of Safety Risk Levels for Excavation Process

- When one level’s comprehensive certainty in the sample is significantly larger than the others’ (the maximum value is at least twice the second largest), the level is determined using the Maximum Comprehensive Certainty Method.

- 2.

- When the difference between the maximum and second-largest comprehensive certainty values is small (relatively close), the Kp Method is used. The Kp value is defined as 0–1 for Level I, 1–2 for Level II, and so on for the iii-th level [55].

- 3.

- When the comprehensive certainty values for each level fall between the two cases mentioned above—some values are close, while others differ significantly—the excavation is considered a high-risk project. In this situation, both the Maximum Comprehensive Certainty Method and the Kp Method are used, and the smaller value is taken to indicate a more dangerous state Kp.

2.6. Multidimensional Connection Cloud Model

- When xi∈ [ − , + ], it is considered as belonging to be in the identity or difference relationship:

- 2.

- When other intervals:

3. Results

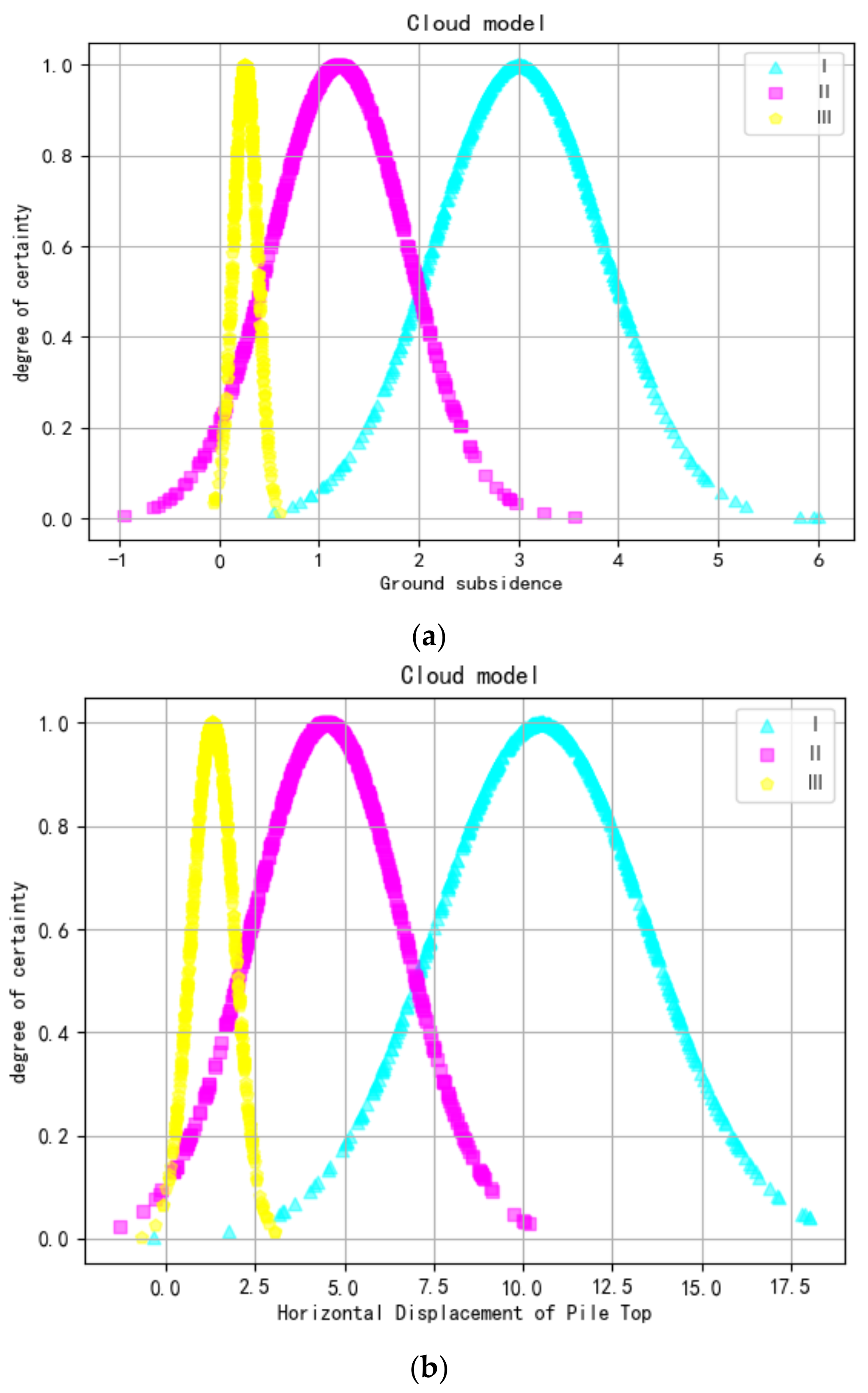

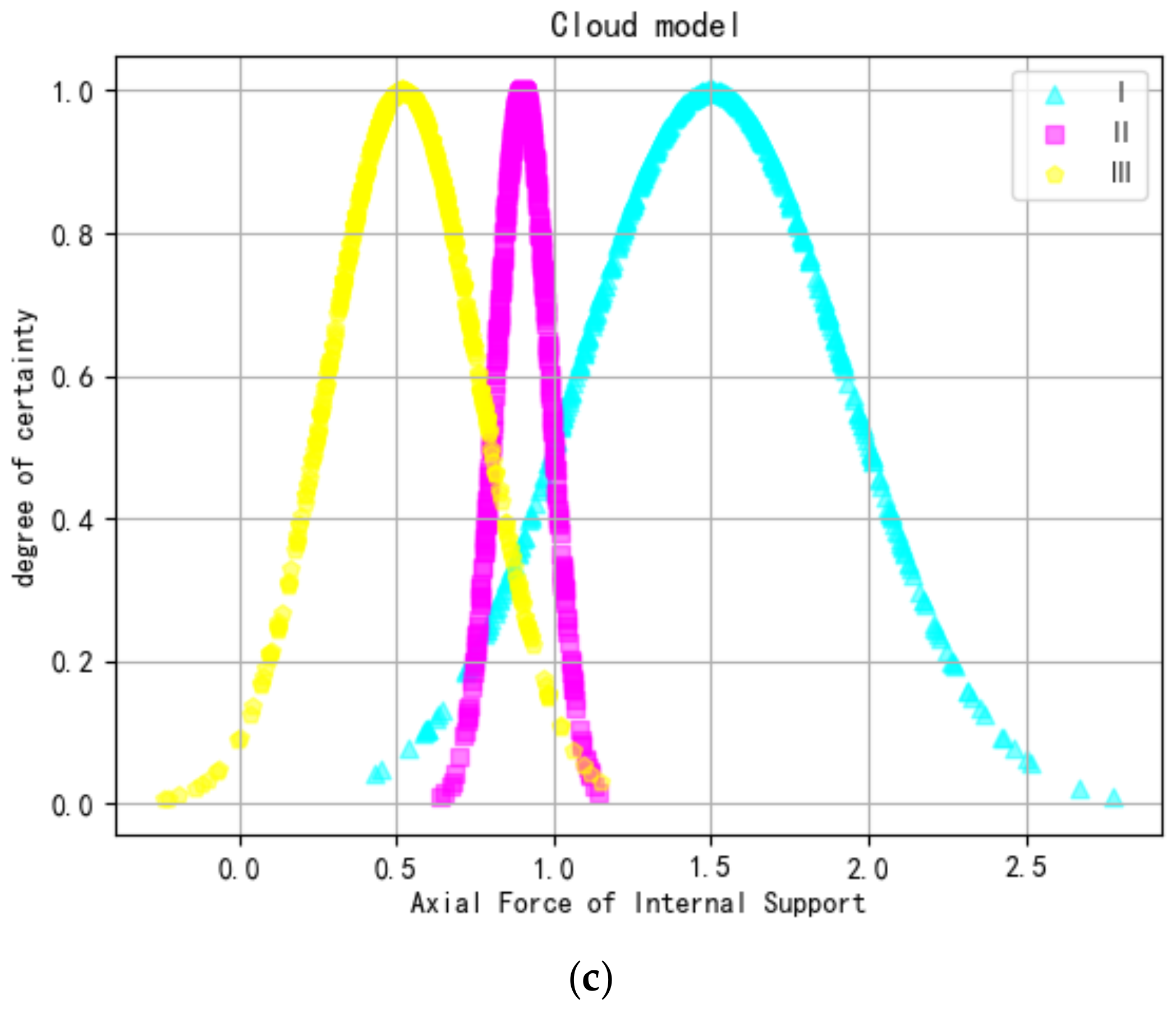

3.1. Generating Evaluation Factor Cloud Model

3.2. Calculating Evaluation Index Weights

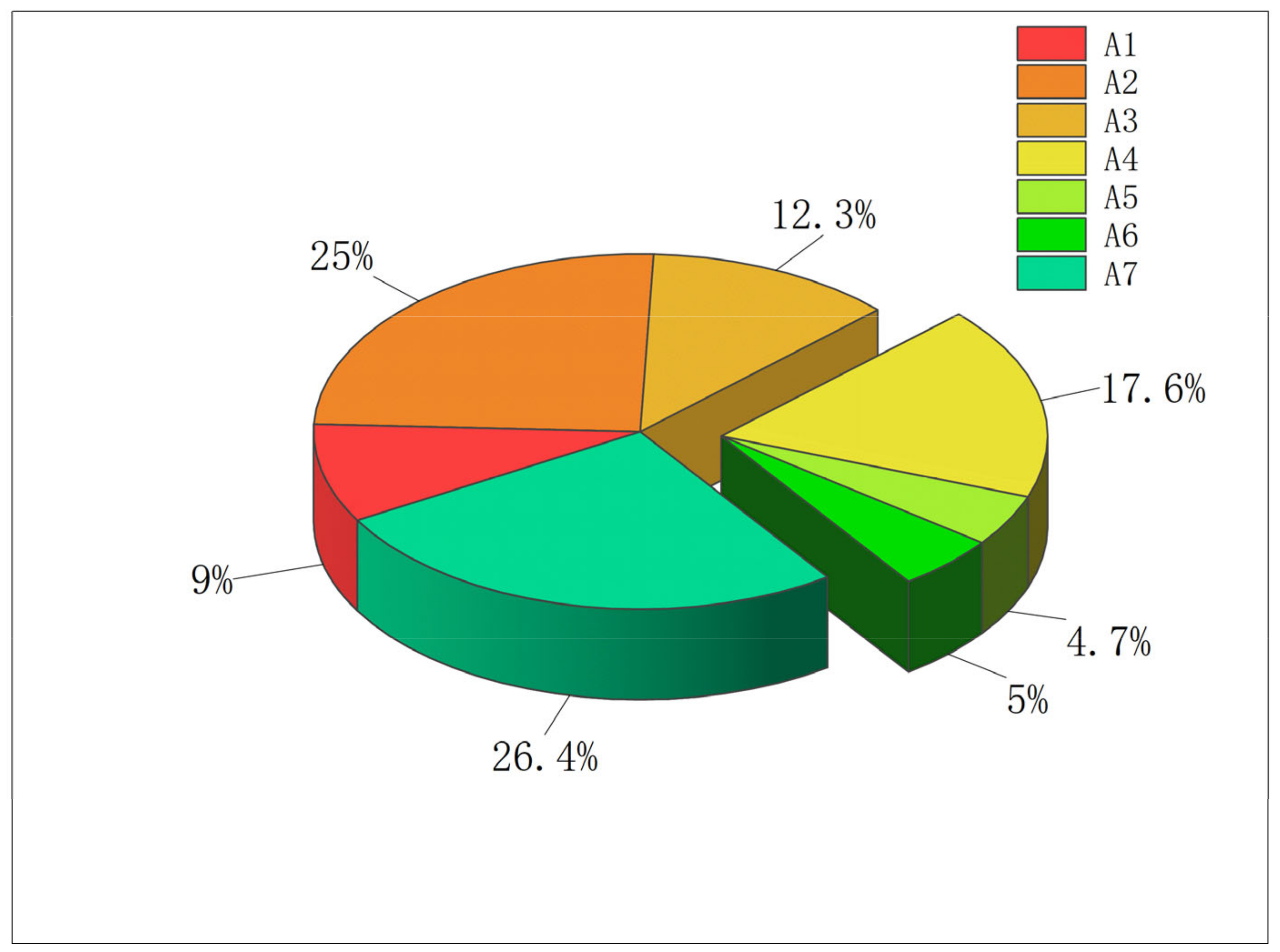

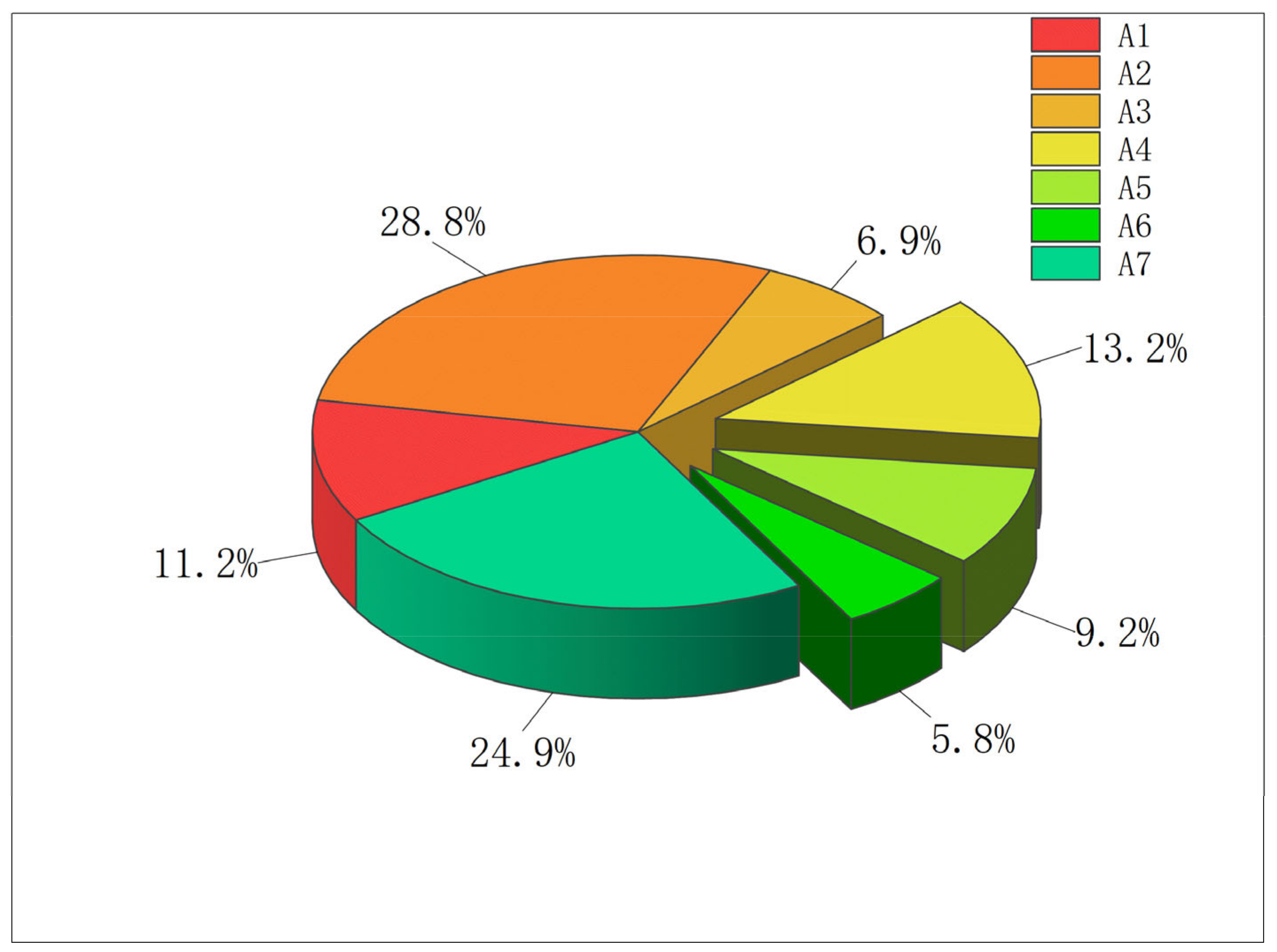

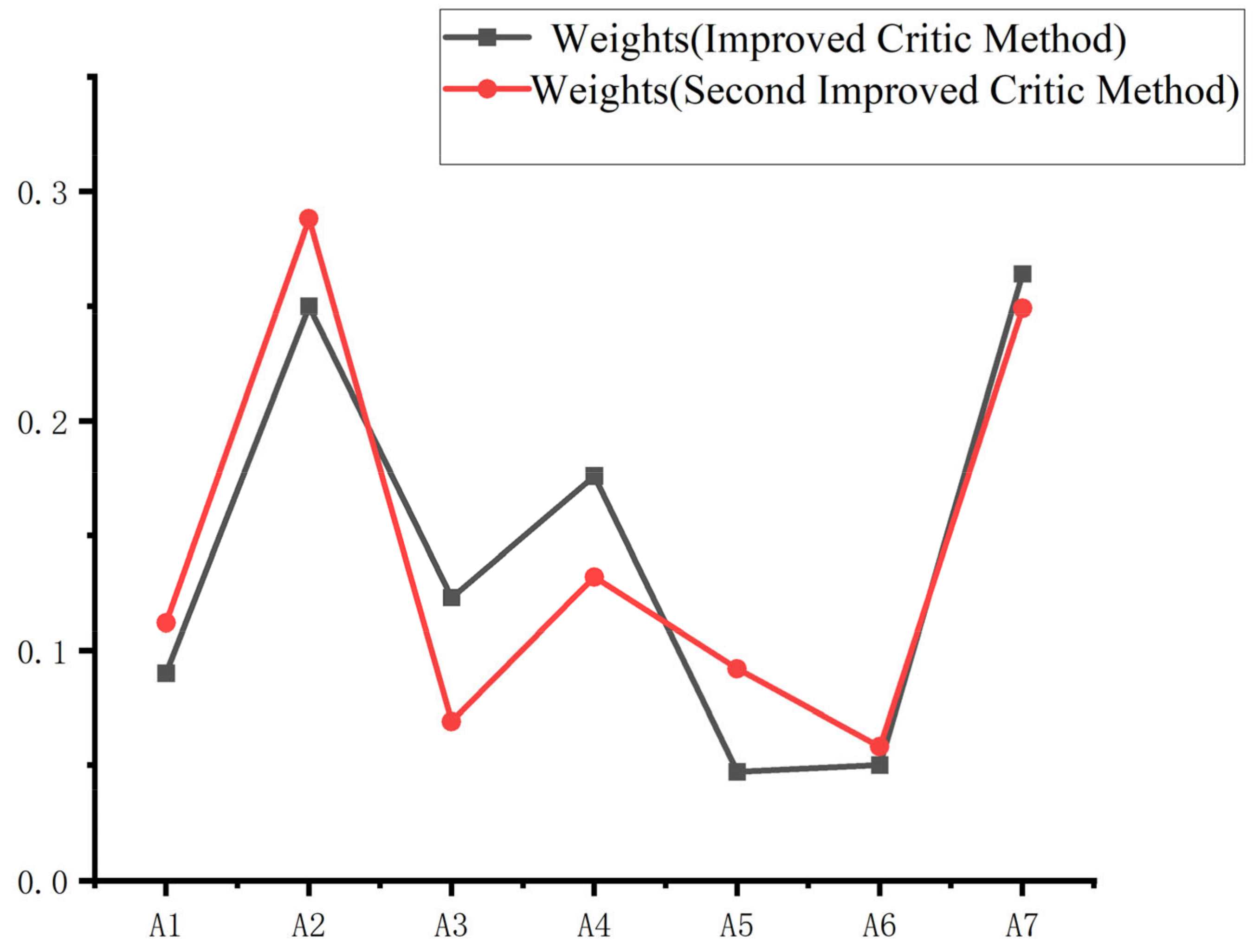

3.3. Foundation Pit Safety Risk Evaluation

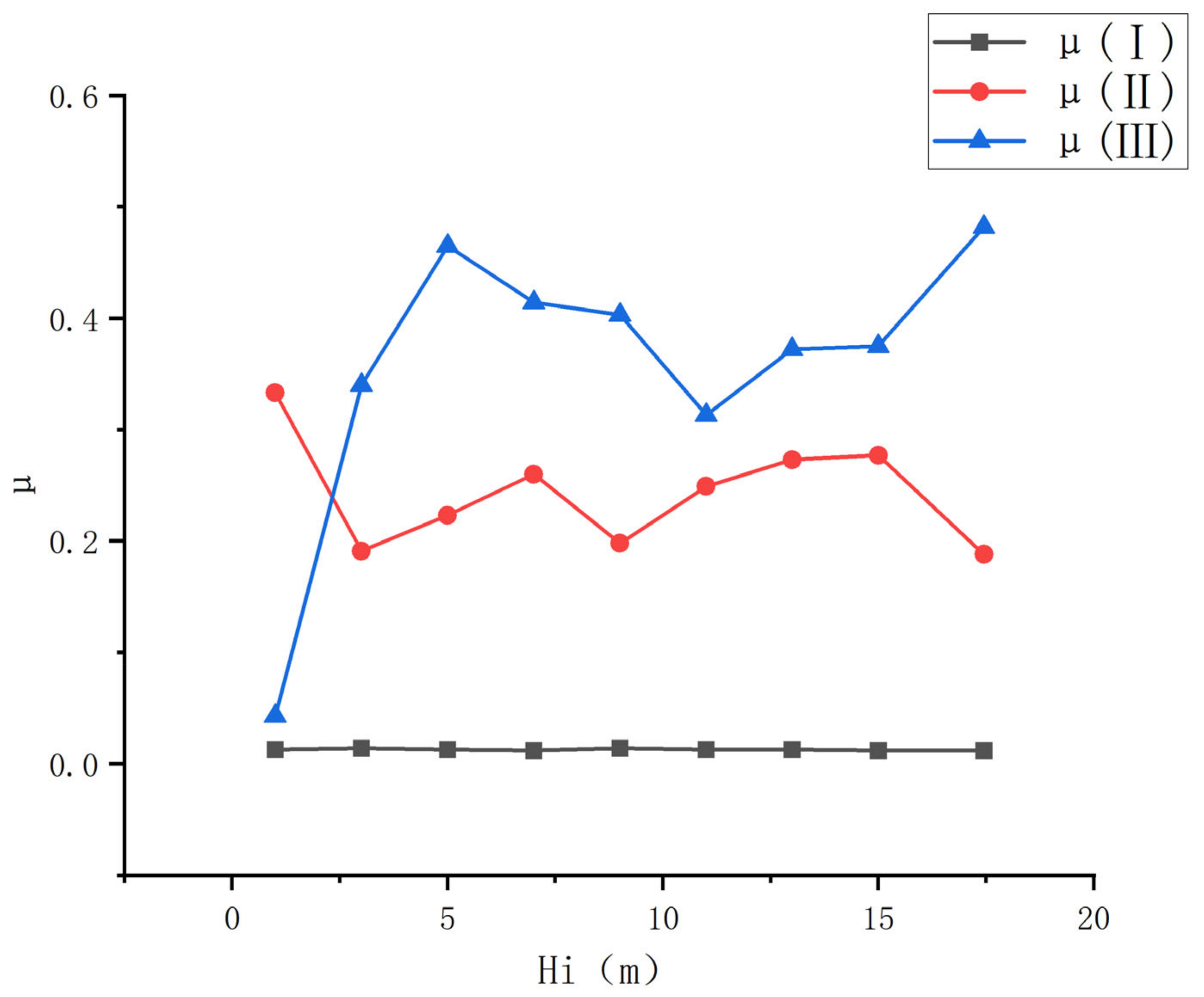

4. Discussion

5. Conclusions

- This study employs the Second Improved CRITIC method, which comprehensively measures the objective weights of indicators based on their comparative intensity and conflict. The weights of the evaluation indicators A1, A2, A3, A4, A5, A6, A7, were calculated as w = [0.09, 0.25, 0.123, 0.176, 0.047,0.050, 0.264]. It was found that building settlement (A2) and horizontal displacement of the support structure (A7) have the greatest impact on excavation safety risk, with weights exceeding 0.2. Pile top settlement (A4), pile top horizontal displacement (A3), and ground settlement (A1) follow, with weights between 0.1 and 0.2 or close to 0.1. In contrast, internal support axial force (A5) and pipeline settlement (A6) have weights below 0.05, making this method more reasonable and suitable for foundation pit evaluation.

- Based on the Second Improved CRITIC-Cloud Model, a multidimensional connection cloud model was constructed that reflects the actual distribution and interaction of each evaluation indicator during the excavation process. For the eastern end well section of Hefei Metro Line 7 Phase 1, the evaluation results at all excavation depths are found to be classified as Grade III, except for a depth of 1m, which is Grade II, respectively. This outcome is more reasonable when compared to other methods, confirming the model’s effectiveness and feasibility in evaluating excavation safety risks.

- The proposed evaluation method quantitatively characterizes the randomness and fuzziness of evaluation indicators and reflects the interconnection and combined effect among indicators. It overcomes the limitations of traditional multidimensional connection models, providing a scientific basis for the accurate risk assessment of dynamic deep excavations and playing a crucial role in preventing risk events.

- Although a real-time early warning system was not directly developed in this study, the proposed methodology incorporates several design considerations aimed at improving real-time applicability. Firstly, the Second Improved CRITIC method enhances computational efficiency by streamlining weight calculation through refined difference and conflict measures, thereby eliminating the need for complex matrix operations and allowing for incremental updates as new data become available. Secondly, the use of a numerical feature-based cloud model enables rapid and training-free risk classification, relying solely on simple numerical matching rather than computationally intensive models such as neural networks or Bayesian classifiers. Lastly, while validation was conducted using static monitoring data, the proposed framework is algorithmically compatible with real-time data environments, providing a foundation for integration into future engineering monitoring platforms such as those based on IoT technologies.

- Although the Second Improved CRITIC-Cloud Model demonstrates strong comprehensive evaluation capabilities in terms of objective weight assignment and uncertainty representation, it still presents certain limitations. On the one hand, the method heavily relies on the quality of raw data and is susceptible to the influence of outliers; on the other hand, its computational complexity and model stability may be challenged in high-dimensional and complex systems. Future research may consider integrating dimensionality reduction techniques and intelligent fusion mechanisms to enhance the robustness and generalization ability of the model, thereby improving its adaptability to dynamic and evolving evaluation scenarios.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, D.; Bai, J.; Chen, X.; Li, H.; He, Y.; Zhang, Q.; Liu, R. Shallow-buried subway station construction period: Comparison of intelligent early warning and optimization strategies for surface deformation risk. Tunn. Undergr. Space Technol. 2024, 153, 105978. [Google Scholar] [CrossRef]

- Cao, J.; Gong, H.; Chen, B.; Shi, M.; Zhou, C.; Lei, K.; Yu, H.; Sun, Y. Land Subsidence in Beijing’s Sub-Administrative Center and Its Relationship with Urban Expansion Inferred from Sentinel-1/2 Observations. Can. J. Remote Sens. 2021, 47, 802–817. [Google Scholar] [CrossRef]

- Yao, X.; Feng, W.; Zhang, X.; Wang, W.; Zhang, C.; You, S. Measurement and decomposition of industrial green total factor water efficiency in China. J. Clean. Prod. 2018, 198, 1144–1156. [Google Scholar] [CrossRef]

- Torkayesh, A.E.; Malmir, B.; Rajabi Asadabadi, M. Sustainable waste disposal technology selection: The stratified best-worst multi-criteria decision-making method. Waste Manag. 2021, 122, 100–112. [Google Scholar] [CrossRef]

- Wu, X.; Hu, F. Analysis of ecological carrying capacity using a fuzzy comprehensive evaluation method. Ecol. Indic. 2020, 113, 106243. [Google Scholar] [CrossRef]

- Lai, C.; Chen, X.; Chen, X.; Wang, Z.; Wu, X.; Zhao, S. A fuzzy comprehensive evaluation model for flood risk based on the combination weight of game theory. Nat. Hazards 2015, 77, 1243–1259. [Google Scholar] [CrossRef]

- Kuo, Y.; Yang, T.; Huang, G.-W. The use of grey relational analysis in solving multiple attribute decision-making problems. Comput. Ind. Eng. 2008, 55, 80–93. [Google Scholar] [CrossRef]

- Li, C.; Sun, L.; Jia, J.; Cai, Y.; Wang, X. Risk assessment of water pollution sources based on an integrated k-means clustering and set pair analysis method in the region of Shiyan, China. Sci. Total Environ. 2016, 557–558, 307–316. [Google Scholar] [CrossRef]

- Wang, Y.; Jing, H.; Yu, L.; Su, H.; Luo, N. Set pair analysis for risk assessment of water inrush in karst tunnels. Bull. Eng. Geol. Environ. 2017, 76, 1199–1207. [Google Scholar] [CrossRef]

- Wang, D.; Liu, D.; Ding, H.; Singh, V.P.; Wang, Y.; Zeng, X.; Wu, J.; Wang, L. A cloud model-based approach for water quality assessment. Environ. Res. 2016, 148, 24–35. [Google Scholar] [CrossRef]

- Wu, H.-W.; Zhen, J.; Zhang, J. Urban rail transit operation safety evaluation based on an improved CRITIC method and cloud model. J. Rail Transp. Plan. Manag. 2020, 16, 100206. [Google Scholar] [CrossRef]

- Wu, J.; Zhou, Z. Risk assessment of seepage failure in deep excavations based on fuzzy analytic hierarchy process and cloud model. Acta Geotech. 2023, 18, 5635–5658. [Google Scholar] [CrossRef]

- Feng, S.; Lei, H.; Wan, Y.; Jin, H.; Han, J. Influencing factors and control measures of excavation on adjacent bridge foundation based on analytic hierarchy process and finite element method. Front. Struct. Civ. Eng. 2021, 15, 461–477. [Google Scholar] [CrossRef]

- Liu, J.; Shang, W.; Yu, X.; Pi, J.; Xie, J. Risk Assessment on Deep Excavation Construction Based on Fuzzy Evaluation Theory. Chin. J. Undergr. Space Eng. 2016, 12, 825–830. [Google Scholar]

- Zhang, L.; Li, H. Construction Risk Assessment of Deep Foundation Pit Projects Based on the Projection Pursuit Method and Improved Set Pair Analysis. Appl. Sci. 2022, 12, 1922. [Google Scholar] [CrossRef]

- Cheng, W.; Yin, H.; Xie, D.; Dong, F.; Li, Y.; Zhu, T.; Wang, J. Prediction of dominant roof water inrush windows and analysis of control target area based on set pair variable weight—Forward correlation cloud model. J. Clean. Prod. 2024, 483, 144253. [Google Scholar] [CrossRef]

- Ilham, N.I.; Dahlan, N.Y.; Hussin, M.Z. Optimizing solar PV investments: A comprehensive decision-making index using CRITIC and TOPSIS. Renew. Energy Focus 2024, 49, 100551. [Google Scholar] [CrossRef]

- Wu, H.; Liu, S.; Wang, J.; Yang, T. Construction Safety Risk Assessment of Bridges in the Marine Environment Based on CRITIC and TOPSIS Models. J. Coast. Res. 2020, 108, 206–210. [Google Scholar] [CrossRef]

- Xu, M.; Xu, J.; Wan, Y.; Qin, J.; Wu, B.; Xie, Y. Safety evaluation of subway station construction based on CRITIC method and TOPSIS. J. Nat. Disasters 2022, 31, 157–166. [Google Scholar] [CrossRef]

- Bai, Z.; Liu, Q.; Liu, Y. Risk assessment of water inrush from coal seam roof with an AHP–CRITIC algorithm in Liuzhuang Coal Mine, China. Arab. J. Geosci. 2022, 15, 364. [Google Scholar] [CrossRef]

- Wang, H.-L.; Zhao, X.-F.; Chen, H.-J.; Yi, K.; Xie, W.-C.; Xu, W.-Y. Evaluation of toppling rock slopes using a composite cloud model with DEMATEL–CRITIC method. Water Sci. Eng. 2023, 16, 280–288. [Google Scholar] [CrossRef]

- Wu, B.; Zeng, J.; Zhu, R.; Yang, F.; Liu, C.; Xie, Y. A collapse risk assessment method for subway foundation pit based on cloud model and improved Dempster–Shafer evidence theory. Sci. Rep. 2024, 14, 2653. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Li, Y.; Wan, R. Assessment of Water Disaster Resilience in Mountainous Urban Metro Stations by Combination Weighting Method and Extension Cloud Model. Water 2024, 16, 3266. [Google Scholar] [CrossRef]

- Wang, J.; Huang, M.; Guo, J. Rock Burst Evaluation Using the CRITIC Algorithm-Based Cloud Model. Front. Phys. 2021, 8, 593701. [Google Scholar] [CrossRef]

- Li, K.; Liu, X.; Xiao, D.; Zhang, D.; Ye, S. Expressway Tunnel Operation Risk Assessment Model Based on Improved Critic Method and Cloud Model. In Proceedings of the 21st COTA International Conference of Transportation Professionals, CICTP 2021, Xi’an, China, 16–19 December 2021; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2021; pp. 1063–1071. [Google Scholar]

- Wen, X.; Nie, Y.; Du, Z.; Huang, L. Operational safety assessment of straddle-type monorail vehicle system based on cloud model and improved CRITIC method. Eng. Fail. Anal. 2022, 139, 106463. [Google Scholar] [CrossRef]

- Bu, L.; Li, S.-c.; Shi, S.-s.; Xie, X.-k.; Li, L.-p.; Zhou, Z.-q.; Wen, Z.-j. A New Advance Classification Method for Surrounding Rock in Tunnels Based on the Set-Pair Analysis and Tunnel Seismic Prediction System. Geotech. Geol. Eng. 2018, 36, 2403–2413. [Google Scholar] [CrossRef]

- Ha, J.; Yang, L.; Xiao, W.; Li, J.; Kuang, D. Multi-dimensional Dynamic Evaluation on the Safety Risks in the Deep Foundation Pit Excavation of Subway Station Based on Information Entropy. J. Eng. Manag. 2022, 36, 79–84. [Google Scholar] [CrossRef]

- Hsieh, P.-G.; Ou, C.-Y.; Lin, Y.-L. Three-dimensional numerical analysis of deep excavations with cross walls. Acta Geotech. 2013, 8, 33–48. [Google Scholar] [CrossRef]

- Piciullo, L.; Ritter, S.; Lysdahl, A.O.K.; Langford, J.; Nadim, F. Assessment of building damage due to excavation-induced displacements: The GIBV method. Tunn. Undergr. Space Technol. 2021, 108, 103673. [Google Scholar] [CrossRef]

- Tang, C.; He, S.-Y.; Zhou, W.-H. Settlement-based framework for long-term serviceability assessment of immersed tunnels. Reliab. Eng. Syst. Saf. 2022, 228, 108801. [Google Scholar] [CrossRef]

- Tan, Y.; Jiang, W.; Luo, W.; Lu, Y.; Xu, C. Longitudinal Sliding Event during Excavation of Feng-Qi Station of Hangzhou Metro Line 1: Postfailure Investigation. J. Perform. Constr. Facil. 2018, 32, 04018039. [Google Scholar] [CrossRef]

- Pan, Y.; Qin, J.; Hou, Y.; Chen, J.-J. Two-stage support vector machine-enabled deep excavation settlement prediction considering class imbalance and multi-source uncertainties. Reliab. Eng. Syst. Saf. 2024, 241, 109578. [Google Scholar] [CrossRef]

- Wei, X.; Deng, Z.; Wei, G.; Ding, Z. Safety evaluation of foundation pits by extension assessment method combined with entropy law. Chin. J. Geotech. Eng. 2008, 30, 672–676. [Google Scholar]

- Wei, W.; Danna, L.; Di, P. Extension Evaluation on Excavation Safety of Deep Foundation Pit in Sandy Cobble Stratum Based on Entropy Method. J. Southwest Jiaotong Univ. 2021, 56, 785–791+838. [Google Scholar]

- Li, D.; Liu, C.; Gan, W. A new cognitive model: Cloud model. Int. J. Intell. Syst. 2009, 24, 357–375. [Google Scholar] [CrossRef]

- Wang, M.; Wang, Y.; Shen, F.; Jin, J. A novel classification approach based on integrated connection cloud model and game theory. Commun. Nonlinear Sci. Numer. Simul. 2021, 93, 105540. [Google Scholar] [CrossRef]

- Shen, S.-L.; Lin, S.-S.; Zhou, A. A cloud model-based approach for risk analysis of excavation system. Reliab. Eng. Syst. Saf. 2023, 231, 108984. [Google Scholar] [CrossRef]

- Wang, X.; Li, S.; Xu, Z.; Hu, J.; Pan, D.; Xue, Y. Risk assessment of water inrush in karst tunnels excavation based on normal cloud model. Bull. Eng. Geol. Environ. 2019, 78, 3783–3798. [Google Scholar] [CrossRef]

- Wang, M.; Wang, X.; Liu, Q.; Shen, F.; Jin, J. A novel multi-dimensional cloud model coupled with connection numbers theory for evaluation of slope stability. Appl. Math. Model. 2020, 77, 426–438. [Google Scholar] [CrossRef]

- Wu, D.; Yan, J.; Wang, M.; Chen, G.; Jin, J.; Shen, F. Multidimensional Connection Cloud Model Coupled with Improved CRITIC Method for Evaluation of Eutrophic Water. Math. Probl. Eng. 2022, 2022, 4753261. [Google Scholar] [CrossRef]

- Wang, M.; Liu, Q.; Wang, X.; Shen, F.; Jin, J. Prediction of Rockburst Based on Multidimensional Connection Cloud Model and Set Pair Analysis. Int. J. Geomech. 2020, 20, 04019147. [Google Scholar] [CrossRef]

- Wang, M.; Zhu, Q.; Zhu, Y.; Jin, J. Shrinkage-swelling evaluation of untreated and lime-treated expansive clays based on the asymmetric connection cloud model. Yingyong Jichu Yu Gongcheng Kexue Xuebao/J. Basic Sci. Eng. 2017, 25, 162–170. [Google Scholar]

- Chen, H.; Shen, Q.; Feng, Z.; Liu, Y. Vulnerability assessment in urban metro systems based on an improved cloud model and a Bayesian network. Sustain. Cities Soc. 2023, 98, 104823. [Google Scholar] [CrossRef]

- Tu, S.; Zheng, K.; Zhang, Y.; Deng, M. Research on Overall Risk Assessment Model Construction Safety of Freeway High Cutting Slope Engineering Based on Improved CRITIC Method and Cloud Model. Safe Environ. Eng. 2019, 26, 127–132. [Google Scholar]

- Wu, C.; Zhou, L.; Jin, J.; Ning, S.; Zhang, Z.; Bai, L. Regional water resource carrying capacity evaluation based on multi-dimensional precondition cloud and risk matrix coupling model. Sci. Total Environ. 2020, 710, 136324. [Google Scholar] [CrossRef]

- Lang, Q.; Wang, W.; Gao, C. Stability evaluation of deep foundation pit of metro based on grey correlation analysis with combined weights. J. Jilin Univ. (Earth Sci. Ed.) 2020, 50, 1823–1832. [Google Scholar]

- Chai, N.; Zhou, W.; Chen, Z.; Lodewijks, G.; Zhao, Y. Multi-attribute fire safety evaluation of subway stations based on FANP—FGRA—Cloud model. Tunn. Undergr. Space Technol. 2024, 144, 105526. [Google Scholar] [CrossRef]

- Cheng, J.; Yang, X.; Wang, H.; Li, H.; Lin, X.; Guo, Y. Evaluation of the Emergency Capability of Subway Shield Construction Based on Cloud Model. Sustainability 2022, 14, 13309. [Google Scholar] [CrossRef]

- Alinezhad, A.; Khalili, J. (Eds.) CRITIC Method. In New Methods and Applications in Multiple Attribute Decision Making (MADM); Springer International Publishing: Cham, Switzerland, 2019; pp. 199–203. [Google Scholar]

- Liu, P.; Yu, B.; Cao, H. Comprehensive evaluation method of rockburst proneness based on multidimensional normal cloud-CRITIC model. Chin. J. Rock Mech. Eng. 2020, 39, 3432–3439. [Google Scholar]

- Wang, Z.; Hong, J.; Liu, P.; Zhang, L. Voltage fault diagnosis and prognosis of battery systems based on entropy and Z-score for electric vehicles. Appl. Energy 2017, 196, 289–302. [Google Scholar] [CrossRef]

- Bishara, A.J.; Hittner, J.B. Reducing Bias and Error in the Correlation Coefficient Due to Nonnormality. Educ. Psychol. Meas. 2014, 75, 785–804. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Wang, L. Optimization of site investigation program for reliability assessment of undrained slope using Spearman rank correlation coefficient. Comput. Geotech. 2023, 155, 105208. [Google Scholar] [CrossRef]

- Xing, W.; Wang, H.; Fan, J.; Wang, W.; Yu, X. Rockburst risk assessment model based on improved catastrophe progression method and its application. Stoch. Environ. Res. Risk Assess. 2024, 38, 981–992. [Google Scholar] [CrossRef]

- Xing, H.; Xiong, F.; Wu, J. Effects of Pit Excavation on an Existing Subway Station and Preventive Measures. J. Perform. Constr. Facil. 2016, 30, 04016063. [Google Scholar] [CrossRef]

- Zhang, N.; Duan, H.; Sun, P.; Li, J.; Zuo, J.; Mao, R.; Liu, G.; Niu, Y. Characterizing the generation and environmental impacts of subway-related excavated soil and rock in China. J. Clean. Prod. 2020, 248, 119242. [Google Scholar] [CrossRef]

- Li, Y.J.; Zhou, Z.; Alcalá, J.; Yepes, V. Research on spatial deformation monitoring and numerical coupling of deep foundation pit in soft soil. J. Build. Eng. 2025, 99, 111636. [Google Scholar] [CrossRef]

- Lin, S.-S.; Shen, S.-L.; Zhou, A.; Xu, Y.-S. Risk assessment and management of excavation system based on fuzzy set theory and machine learning methods. Autom. Constr. 2021, 122, 103490. [Google Scholar] [CrossRef]

- Sahraei, R.; Kanani-Sadat, Y.; Homayouni, S.; Safari, A.; Oubennaceur, K.; Chokmani, K. A novel hybrid GIS-based multi-criteria decision-making approach for flood susceptibility analysis in large ungauged watersheds. J. Flood Risk Manag. 2023, 16, e12879. [Google Scholar] [CrossRef]

- Lee, P.-C.; Zheng, L.-L.; Lo, T.-P.; Long, D.-B. A Risk Management System for Deep Excavation Based on BIM-3DGIS Framework and Optimized Grey Verhulst Model. KSCE J. Civ. Eng. 2020, 24, 715–726. [Google Scholar] [CrossRef]

- Wang, X.; Pan, Y.; Chen, J. Digital twin with data-mechanism-fused model for smart excavation management. Autom. Constr. 2024, 168, 105749. [Google Scholar] [CrossRef]

| Excavation Depth Hi (m) | a1 (mm) | a2 (mm) | a3 (mm) | a4 (mm) | a5 (kN) | a6 (mm) | a7 (mm) |

|---|---|---|---|---|---|---|---|

| 1 | 1.14 | 0.81 | 0.5 | 0.69 | 1346.59 | 0.62 | 0.2 |

| 3 | 2.42 | 0.96 | 1.6 | 0.95 | 1406.52 | 1.63 | 1.3 |

| 5 | 3.28 | 1.01 | 2.4 | 1.74 | 1612.21 | 2.06 | 3.65 |

| 7 | 4.67 | 1.73 | 3.2 | 2.19 | 1655.23 | 3.38 | 3.99 |

| 9 | 5.83 | 1.89 | 4.1 | 3.12 | 1726.77 | 4.33 | 4.02 |

| 11 | 6.66 | 1.99 | 4.6 | 4.05 | 1772.86 | 5.06 | 4.23 |

| 13 | 7.03 | 2.24 | 4.9 | 5.21 | 1780.54 | 5.88 | 5.88 |

| 15 | 7.65 | 2.56 | 5.3 | 5.62 | 1810.7 | 6.72 | 6.98 |

| 17.45 | 8.56 | 3.59 | 5.9 | 6.07 | 1778.59 | 6.97 | 7.51 |

| Evaluation Index | Discriminate Index | I | II | III |

|---|---|---|---|---|

| a1 | A1 = a1/H1 | >2 | 0.4~2 | <0.4 |

| a2 | A2 = a2/H2 | >2 | 0.4~2 | <0.4 |

| a3 | A3 = a3/H3 | >7 | 2~7 | <2 |

| a4 | A4 = a4/H4 | >2 | 0.4~2 | <0.4 |

| a5 | A5 = a5/N | >1 | 0.8~1 | <0.8 |

| a6 | A6 = a6/H6 | >2 | 0.4~2 | <0.4 |

| a7 | A7 = a7/H7 | >7 | 2~7 | <2 |

| Excavation Depth Hi (m) | A1 | A2 | A3 | A4 | A5 | A6 | A7 |

|---|---|---|---|---|---|---|---|

| 1 | 1.14 | 0.81 | 0.50 | 0.69 | 0.30 | 0.62 | 0.20 |

| 3 | 0.81 | 0.32 | 0.53 | 0.32 | 0.31 | 0.54 | 0.43 |

| 5 | 0.66 | 0.20 | 0.48 | 0.35 | 0.36 | 0.41 | 0.73 |

| 7 | 0.67 | 0.25 | 0.46 | 0.31 | 0.37 | 0.48 | 0.57 |

| 9 | 0.65 | 0.21 | 0.46 | 0.35 | 0.38 | 0.48 | 0.45 |

| 11 | 0.61 | 0.18 | 0.42 | 0.37 | 0.39 | 0.46 | 0.38 |

| 13 | 0.54 | 0.17 | 0.38 | 0.40 | 0.40 | 0.45 | 0.45 |

| 15 | 0.51 | 0.17 | 0.35 | 0.37 | 0.40 | 0.45 | 0.47 |

| 17.45 | 0.49 | 0.21 | 0.34 | 0.35 | 0.40 | 0.40 | 0.43 |

| Grade | Numerical Characteristics | A1 | A2 | A3 | A4 | A5 | A6 | A7 |

|---|---|---|---|---|---|---|---|---|

| I | Ex | 3.000 | 3.000 | 10.500 | 3.000 | 1.500 | 3.000 | 10.500 |

| En | 0.849 | 0.849 | 2.973 | 0.849 | 0.425 | 0.849 | 2.973 | |

| He | 0.085 | 0.085 | 0.297 | 0.085 | 0.042 | 0.085 | 0.297 | |

| II | Ex | 1.200 | 1.200 | 4.500 | 1.200 | 0.900 | 1.200 | 4.500 |

| En | 0.679 | 0.679 | 2.123 | 0.679 | 0.085 | 0.679 | 2.123 | |

| He | 0.068 | 0.068 | 0.212 | 0.068 | 0.008 | 0.068 | 0.212 | |

| III | Ex | 0.260 | 0.260 | 1.300 | 0.260 | 0.520 | 0.260 | 1.300 |

| En | 0.119 | 0.119 | 0.595 | 0.119 | 0.238 | 0.119 | 0.595 | |

| He | 0.012 | 0.012 | 0.059 | 0.012 | 0.024 | 0.012 | 0.059 |

| Evaluation Index | A1 | A2 | A3 | A4 | A5 | A6 | A7 |

|---|---|---|---|---|---|---|---|

| A1 | 1.000 | 0.946 | 0.759 | 0.771 | −0.920 | 0.921 | −0.528 |

| A2 | 0.946 | 1.000 | 0.514 | 0.901 | −0.813 | 0.868 | −0.661 |

| A3 | 0.759 | 0.514 | 1.000 | 0.205 | −0.855 | 0.673 | −0.014 |

| A4 | 0.771 | 0.901 | 0.205 | 1.000 | −0.533 | 0.698 | −0.705 |

| A5 | −0.920 | −0.813 | −0.855 | −0.533 | 1.000 | −0.828 | 0.319 |

| A6 | 0.921 | 0.868 | 0.673 | 0.698 | −0.828 | 1.000 | −0.680 |

| A7 | −0.528 | −0.661 | −0.014 | −0.705 | 0.319 | −0.680 | 1.000 |

| Excavation Depth Hi (m) | Correlation Cloud Association | Maximum Membership Principle | Kp Value | This Paper | Information Entropy Multi-Dimensional Dynamic Evaluation | ||

|---|---|---|---|---|---|---|---|

| μ(I) | μ(II) | μ(III) | |||||

| 1 | 0.013 | 0.333 | 0.043 | 0.333 | / | II | III |

| 3 | 0.014 | 0.191 | 0.340 | 0.340 | 2.599 | III | III |

| 5 | 0.013 | 0.223 | 0.465 | 0.465 | 2.645 | III | III |

| 7 | 0.012 | 0.260 | 0.414 | 0.414 | 2.586 | III | III |

| 9 | 0.014 | 0.198 | 0.403 | 0.403 | 2.633 | III | III |

| 11 | 0.013 | 0.249 | 0.313 | 0.313 | 2.522 | III | III |

| 13 | 0.013 | 0.273 | 0.372 | 0.372 | 2.546 | III | III |

| 15 | 0.012 | 0.277 | 0.375 | 0.375 | 2.547 | III | III |

| 17.45 | 0.012 | 0.188 | 0.482 | 0.482 | 2.690 | III | III |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, W.; Abdullah, A.; Xu, X. Safety Risk Assessment of Deep Excavation for Metro Stations Using the Second Improved CRITIC Cloud Model. Buildings 2025, 15, 1342. https://doi.org/10.3390/buildings15081342

Zhou W, Abdullah A, Xu X. Safety Risk Assessment of Deep Excavation for Metro Stations Using the Second Improved CRITIC Cloud Model. Buildings. 2025; 15(8):1342. https://doi.org/10.3390/buildings15081342

Chicago/Turabian StyleZhou, Wen, Amizatulhani Abdullah, and Xinyu Xu. 2025. "Safety Risk Assessment of Deep Excavation for Metro Stations Using the Second Improved CRITIC Cloud Model" Buildings 15, no. 8: 1342. https://doi.org/10.3390/buildings15081342

APA StyleZhou, W., Abdullah, A., & Xu, X. (2025). Safety Risk Assessment of Deep Excavation for Metro Stations Using the Second Improved CRITIC Cloud Model. Buildings, 15(8), 1342. https://doi.org/10.3390/buildings15081342