1. Introduction

Granulated slag is a by-product of iron manufacturing in blast furnaces, which is produced by rapidly quenching molten slag with water. Composed mainly of calcium silicates and aluminosilicates, this glassy, granular material is finely ground for use as a cementitious additive, improving the strength and sustainability of concrete [

1,

2].

Utilizing slag as a partial substitute for cement can lower concrete’s CO

2 emissions and support the sustainable advancement of the concrete industry [

3,

4]. To date, a multitude of studies have explored the sustainability assessment of slag concrete. Singh and Parad [

5] developed a material design of concrete which reached a strength of 30 MPa at 28 days and found that, compared to Portland cement, using high-volume slag and fly ash concrete could reduce carbon emissions by 54% and energy consumption by 59%. Schack and Haist [

6] produced eco-efficient concrete using slag and limestone powder, discovering that finely ground slag improved the cement’s performance. Nojoukambari et al. [

7] developed ternary concrete using slag and feldspar, revealing that a mixture containing 30% slag and 10% feldspar reduced carbon emissions by approximately 33%. Fakhri and Dawood [

8] manufactured green concrete with slag and other supplementary materials, reporting a 36% reduction in COCO

2 emissions when the cement replacement level reached 50%. Chen et al. [

9] found that substituting cement with slag and recycled brick powder significantly reduced energy consumption, COCO

2 emissions, and material costs as the replacement rate increased. Shamass et al. [

10] demonstrated that using 25% slag and 5% silica fume could improve the global warming potential of concrete. Yang et al. [

11] analyzed the carbon emissions of concrete with varying slag contents and concluded that slag reduces concrete’s carbon footprint. Additionally, as the strength of concrete increases, the carbon emissions per 1 MPa increase in strength decrease. Kim et al. [

12] found that replacing 70% of early-strength cement with slag led to a COCO

2 emissions reduction of approximately 68%.

Compared to the abundant research on COCO

2 emissions, research on the material formulation of low-carbon slag concrete remains relatively limited. Yeh [

13] designed concrete containing slag and fly ash using neural networks and the flattened simplex–centroid method, considering five strength levels and five flowability levels. The optimal mix proportion with the lowest cost was obtained through the use of a genetic algorithm. Kim et al. [

14] developed an optimal design of slag and fly ash concrete to reduce cost and carbon emissions. Shobeiri et al. [

15] developed slag-and-fly-ash-enhanced concrete, employing an artificial neural network to predict strength and slump and employing a genetic algorithm to optimize COCO

2 emissions and cost. The designed strength levels included 30 MPa, 40 MPa, and 50 MPa. Knight et al. [

16] proposed a design method for binary cement–mineral admixture concrete, considering seven types of mineral admixtures and eleven environmental impact categories to calculate the optimal mass ratios between cement and mineral admixtures. Yang et al. [

17] derived the relationship between strength and the water-to-(cement+slag) mass ratio through regression analysis, designing concrete with different mineral admixtures while considering strength and COCO

2 reduction goals. Tapali et al. [

18] designed blended concrete, which was optimized in terms of strength and durability, adjusting the mineral admixture replacement rates to achieve an environmentally friendly concrete that meets both performance requirements.

However, considering the existing low-carbon slag concrete design principles, the following issues arise: First, when the 28-day strength of low-carbon slag concrete is the same as that of Portland concrete, the carbonation depth of low-carbon slag concrete is higher [

19,

20]. Existing concrete mix design methods only consider strength and do not account for carbonation durability, which leads to insufficient carbonation resistance in low-carbon slag concrete and the potential risk of steel reinforcement corrosion. Second, the majority of existing studies on low-carbon concrete design have been focused on the material level, without considering the factor of concrete construction. Notably, the carbonation durability of low-carbon slag concrete is not only related to the mix proportions of the concrete materials, but it is also closely tied to the curing age before carbonation begins (i.e., the time of formwork removal) [

19]. Finally, previous studies focused on predicting the strength of slag concrete have mostly relied on machine learning models. Although these predictions are relatively accurate, the mechanisms of strength development are not sufficiently clear, which limits the application of machine learning models in design specifications [

13].

To address the shortcomings of previous studies, this study proposes a new design method for low-carbon slag concrete that takes into account compressive strength at different ages, the time of formwork removal, and the impact of carbonation durability. For the strength prediction model, this study adopts a prediction formula based on reaction mechanisms, distinguishing the contributions of cement hydration and slag reaction to the resulting strength. For the carbonation depth prediction model, the effects of concrete mix proportions, the curing age before carbonation begins (i.e., the time of formwork removal), and environmental conditions affecting carbonation durability are considered. For the mix proportion design cases, four design examples are used to differentiate the dominant factors in concrete mix design under different scenarios (i.e., strength-dominated, carbonation durability-dominated, and formwork removal time-dominated). In summary, the design method proposed in this study comprehensively considers both material and construction factors, providing significant engineering guidance for the material design of low-carbon slag concrete.

2. Strength Prediction Model

Oner and Akyuz [

1] carried out comprehensive studies on the compressive strength of slag-incorporated concrete. Their tests covered a wide range of curing ages, from early age (7 days) to long-term (365 days), and included multiple slag replacement levels ranging from 0% to 60%. Given the comprehensiveness of Oner and Akyuz’s compressive strength test results [

1], this study adopted their experimental data to develop regression-based predictive equations for the compressive strength of slag concrete across various curing periods.

Based on the concept of the equivalent strength coefficient proposed by Papadakis and Tsimas [

2], the compressive strength of slag-incorporated concrete across various curing periods can be predicted employing the following equation:

In Equation (1), Fc denotes compressive strength (MPa); t represents age (days); A is the strength coefficient of cement (dimensionless number); B is the strength coefficient of slag (dimensionless number); C is an empirical strength coefficient (MPa); and MCE, MSG, and MW represent the mass of cement (kg/m3), mass of slag (kg/m3), and mass of water (kg/m3) in the mix proportion, respectively.

Using the strength test results at different ages and with different mix proportions reported by Oner and Akyuz [

1], the strength coefficients

A,

B, and

C for Equation (1) at various ages can be obtained. These coefficients correspond to the second to fourth columns of

Table 1. Once the strength prediction equations for different ages are established, their predictions can be compared with the measured results to evaluate the performance of Equation (1). In this study, three indicators were used to assess the prediction accuracy: the root mean square error (RMSE), correlation coefficient (R), and the signal-to-noise ratio (S/N). These values are listed in the fifth to seventh columns of

Table 1.

The onset of the hydration reaction in concrete corresponds to the start of mixing, which is defined as

t = 0. Accordingly, the generation of hydration heat and chemically bound water also begins at

t = 0. However, the development of mechanical properties does not start at

t = 0, as a certain degree of hydration is required before it begins. Strength development only starts when the degree of hydration exceeds a threshold value corresponding to the strength threshold [

21]. A negative value of the coefficient

C indicates that the initiation of compressive strength does not occur at

t = 0 but rather at a later time when

t > 0; in other words, a negative value of the coefficient

C is not a computational coincidence, but a true reflection of the hydration mechanism and strength development process.

In

Table 1, the ages of 63, 119, and 180 days extend the analysis into the intermediate long-term range, capturing the continued strength gain of slag concrete. The reaction of slag progresses more slowly than cement hydration, often contributing significantly to strength beyond 28 days. These points (i.e., 63, 119, and 180 days) help to reveal how slag influences the evolution of strength over an extended curing period.

At all ages, the correlation coefficients between calculated and tested results exceeded 0.91, indicating a strong agreement between the predicted and experimental values. At early curing ages of 7 and 14 days, the root mean square error of the strength equation’s predictions was less than 3 MPa while, at 365 days, it was approximately 5 MPa. The signal-to-noise ratios across all ages ranged between 18.7 and 19.3, suggesting good predictive performance of the equation. The signal-to-noise ratios showed no significant fluctuations across ages, demonstrating the overall stability of the predictive equation.

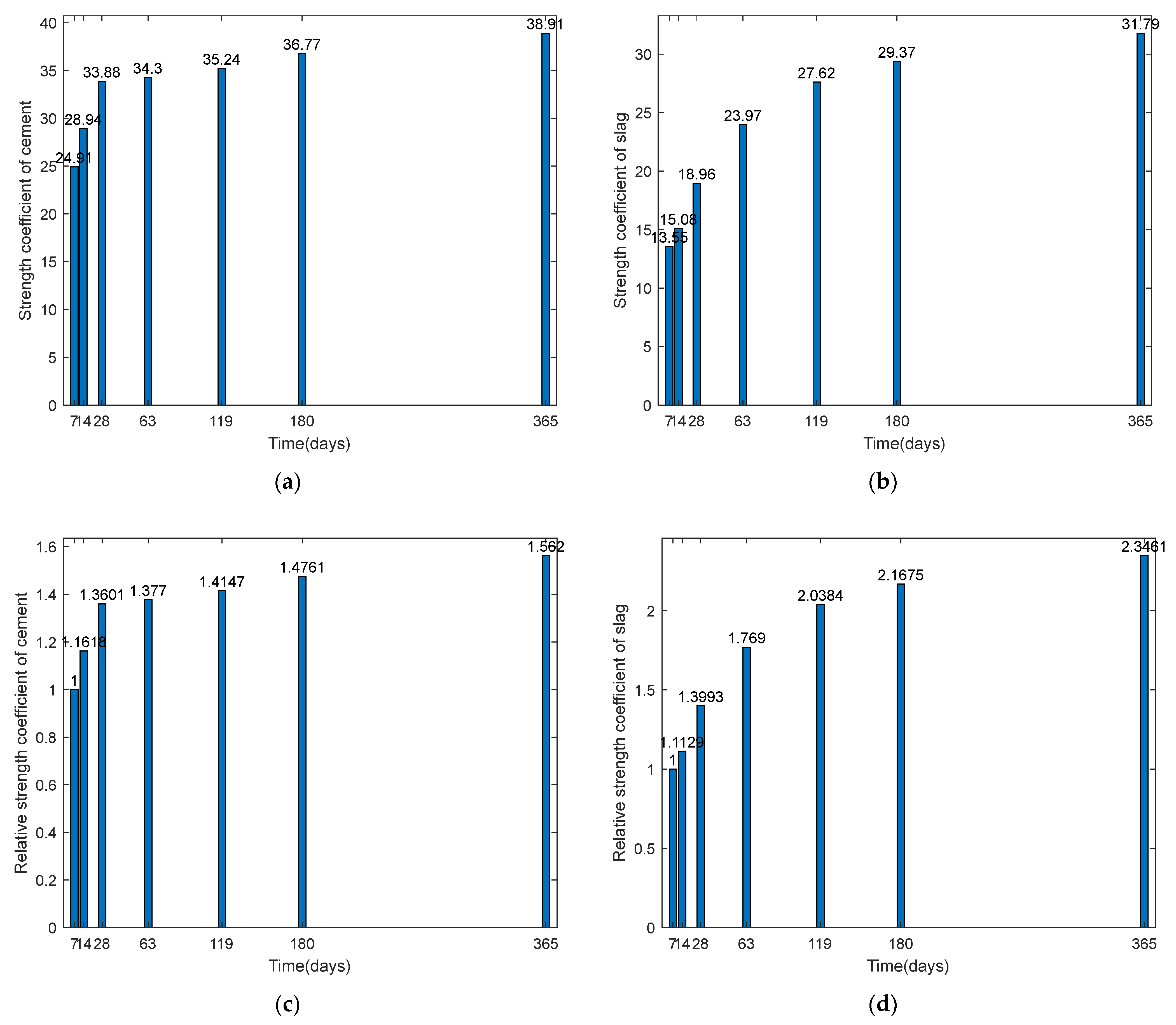

Figure 1 illustrates the relationship between the strength coefficients

A,

B, and age. In particular,

Figure 1a,b depict the relationships between the cement strength coefficient and slag strength coefficient, respectively, with age. As age increases, both coefficients also rise, indicating that the hydration extent of cement and the reaction extent of slag increase with time. Taking the strength coefficients of cement and slag at 7 days as a reference unit (set to 1) and dividing the coefficients at other ages by the 7-day values, the relative strength coefficients for cement and slag at different ages were obtained.

Figure 1c shows that, from 7 to 28 days (a 21-day span), the relative strength coefficient of cement rose by approximately 36%. From 28 to 365 days (a 337-day span), it rose by about (1.562 − 1.360)/1.360 × 100% = 14.9%. This suggests that cement reacts rapidly in the early stage, but its reaction slows significantly after 28 days.

Figure 1d shows that, from 7 to 28 days (21 days), the relative strength coefficient of slag rose by about 40%, while from 28 to 365 days (337 days), it rose by approximately (2.346 − 1.399)/1.399 × 100% = 67.6%.

Comparing

Figure 1c,d, the increase in cement’s relative strength coefficient is less than that of slag [

22]. This is because, at 7 days, cement has already reached a relatively high reaction extent when compared to slag [

3]. Although cement’s reaction extent continues to increase with age, this increase is modest. Additionally, for both cement and slag, the compressive strength growth rate was significantly higher in the early stage (before 28 days) than in the later stage (28 to 365 days).

Figure 1e presents the regression equation for cement’s compressive strength coefficient versus age, showing that the coefficients across ages follow a logarithmic function of time that is consistent with strength prediction equations reported in the scientific literature on concrete materials [

4].

Figure 1f shows the regression equation for slag’s compressive strength coefficient versus age, exhibiting a similar trend to

Figure 1e.

Based on the trends observed in

Figure 1e,f, the strength prediction equation was derived employing the method of undetermined coefficients. According to the experimental results of 224 compressive strength tests under different ages and mix proportions reported by Oner and Akyuz [

1], the strength of cement–slag binary concrete at various ages can be represented by the following equation:

In Equation (2), the units of

Fc and

t are MPa and days, respectively, while

MCE,

MW, and

MSG are measured in kg/m

3. Equation (2) accounts for the effects of mix proportions and curing age on the strength of slag concrete.

MCE/MW represents the mass ratio of cement to water, and the term (22.92 + 2.59·ln(t)) ×

MCE/MW reflects the contribution of cement hydration to strength.

MSG/MW represents the mass ratio of slag to water, and the term (3.68 + 4.81·ln(t)) ×

MSG/MW reflects the contribution of slag’s chemical reaction to strength. The function

ln denotes the natural logarithm, indicating that the strength is a logarithmic function of curing age; this is because both the degree of cement hydration and the reactivity of slag follow a logarithmic relationship with curing time [

23].

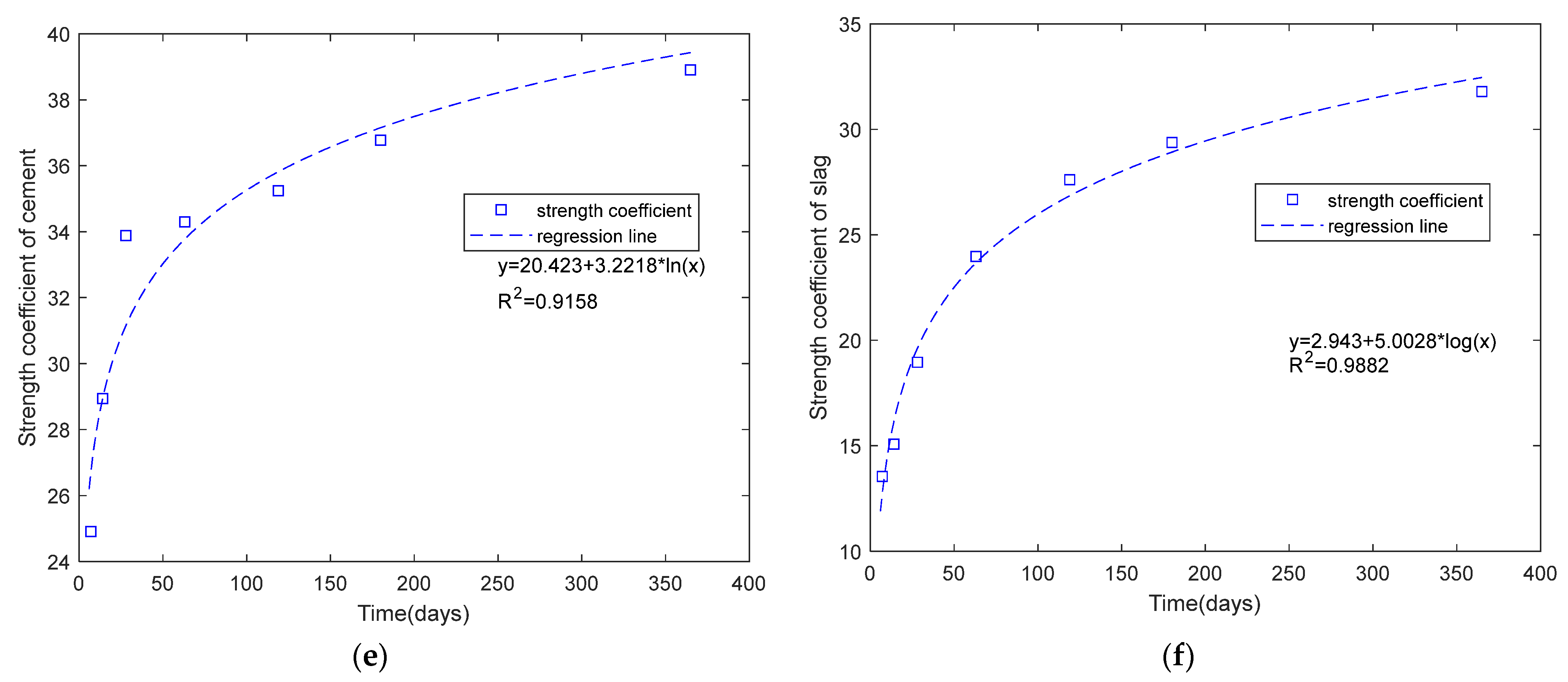

Figure 2 shows a comparison between the calculated and experimental results, with a root mean square error of 4.3175 MPa, a correlation coefficient of 0.9435, and a signal-to-noise ratio of 18.563. Notably, unlike general mechanism-agnostic machine learning regression models [

24], the parameters of Equation (2) have clear physical meanings. Equation (2) distinguishes the reactions of cement and slag, accounting for the individual effects of the slag-to-(cement+slag) mass ratio and the water-to-(cement+slag) mass ratio on strength.

3. Carbon Emissions Analysis

For structural concrete, the majority of its carbon emissions come from cementitious materials. The carbon footprint of binder materials derives from the following components: the carbon emissions of the materials themselves, emissions due to transportation, and emissions from the concrete production process. For one cubic meter of concrete, the carbon emissions of cementitious materials can be calculated using the following equation:

In Equation (3),

CO2V represents the total carbon emissions of cementitious materials, while

CO2M,

CO2T, and

CO2P indicate the carbon emissions from the materials themselves, transportation, and the concrete production process, respectively. Equation (4) calculates the material-specific carbon emissions,

CO2M, in which

CO2CE and

CO2SG represent the carbon emissions per kilogram of cement and slag, respectively (

CO2CE = 0.93;

CO2SG = 0.0265) [

11]. Equation (5) computes the transportation-related carbon emissions,

CO2T, in which

CO2TCE and

CO2TSG represent the CO

2 emissions from transporting unit masses of cement and slag over a unit distance, respectively. The values of

CO2TCE and

CO2TSG are closely tied to the transportation mode; for truck transport via highways, both are 0.0000518 [

11].

DCE and

DSG in Equation (5) are the transportation distances for cement and slag, respectively. Equation (6) calculates the carbon emissions from the concrete production process,

CO2P, which primarily stem from electricity consumption; in this equation,

CO2CEP and

CO2SGP represent the CO

2 emissions per kilogram of cement and slag during production, which are both valued at 0.00768 [

11]. Based on Equations (3)–(6), when the transportation distances for cement and slag are 200 km and 300 km, respectively, the carbon emissions of 1 kg cement and 1 kg slag are 0.94804 kg and 0.04972 kg, respectively. Thus, the carbon emissions per unit volume of concrete can be calculated employing the following equation:

In Equation (7), for cement, the total carbon emissions of 0.94804 kg are approximately equal to the material-specific emissions of 0.93 kg. However, for slag, when transportation and production emissions are considered, the carbon emissions rise from 0.0265 kg to 0.04972 kg, constituting an increase of 87.62%. It should be noted that, compared to cement’s carbon emissions, slag’s emissions are minimal. Despite the increase in slag’s carbon emissions, it has a negligible impact on the overall carbon emissions CO2V.

For structural concrete, the water consumption per unit volume is closely associated with the maximum coarse aggregate size. When the maximum coarse aggregate size is 25 mm, the water consumption for structural concrete commonly used in engineering is 179 kg/m

3 [

25,

26], which corresponds to

MW = 179 in the strength prediction equation.

Equation (7) is used to calculate the

CO2V emissions per unit volume of concrete. In engineering, the CO

2 emissions per 1 MPa strength of concrete are also of interest. The CO

2 emissions per 1 MPa strength of concrete,

CO2U, can be calculated employing the following equation:

In particular, the carbon emissions per unit volume of concrete can be calculated through the following steps:

Step 1: Calculate material-related carbon emissions using Equation (4).

Assume the mass of cement and slag per cubic meter of concrete is

MCE = 160 kg/m

3 and

MSG = 240 kg/m

3, respectively, and the carbon emissions per kilogram of cement and slag are

CO2CE = 0.93 kg CO

2/kg and

CO2SG = 0.0265 kg CO

2/kg, respectively [

11].

The material-related carbon emissions can then be calculated as

Step 2: Calculate transportation-related carbon emissions using Equation (5).

Assume the transportation distances for cement and slag are DCE = 200 km and DSG = 300 km, respectively.

The carbon emissions per kilogram per kilometer for transported materials are

CO2TCE =

CO2TSG = 0.0000518 kg CO

2/km [

11].

Thus, the transportation-related carbon emissions are calculated as

Step 3: Calculate production-related carbon emissions using Equation (6).

During the mixing process, the carbon emissions per kilogram of cement and slag are all assumed to be

CO2CEP =

CO2SGP = 0.00768 kg CO

2/kg [

11].

The production-related carbon emissions are calculated as

Step 4: Calculate the total carbon emissions using Equation (3).

The total carbon emissions per cubic meter of concrete are the sum of the material, transportation, and production-related emissions:

Note: The above calculation considers only the carbon emissions from the binder materials (cement and slag) and does not account for emissions relating to the aggregates or mixing water.

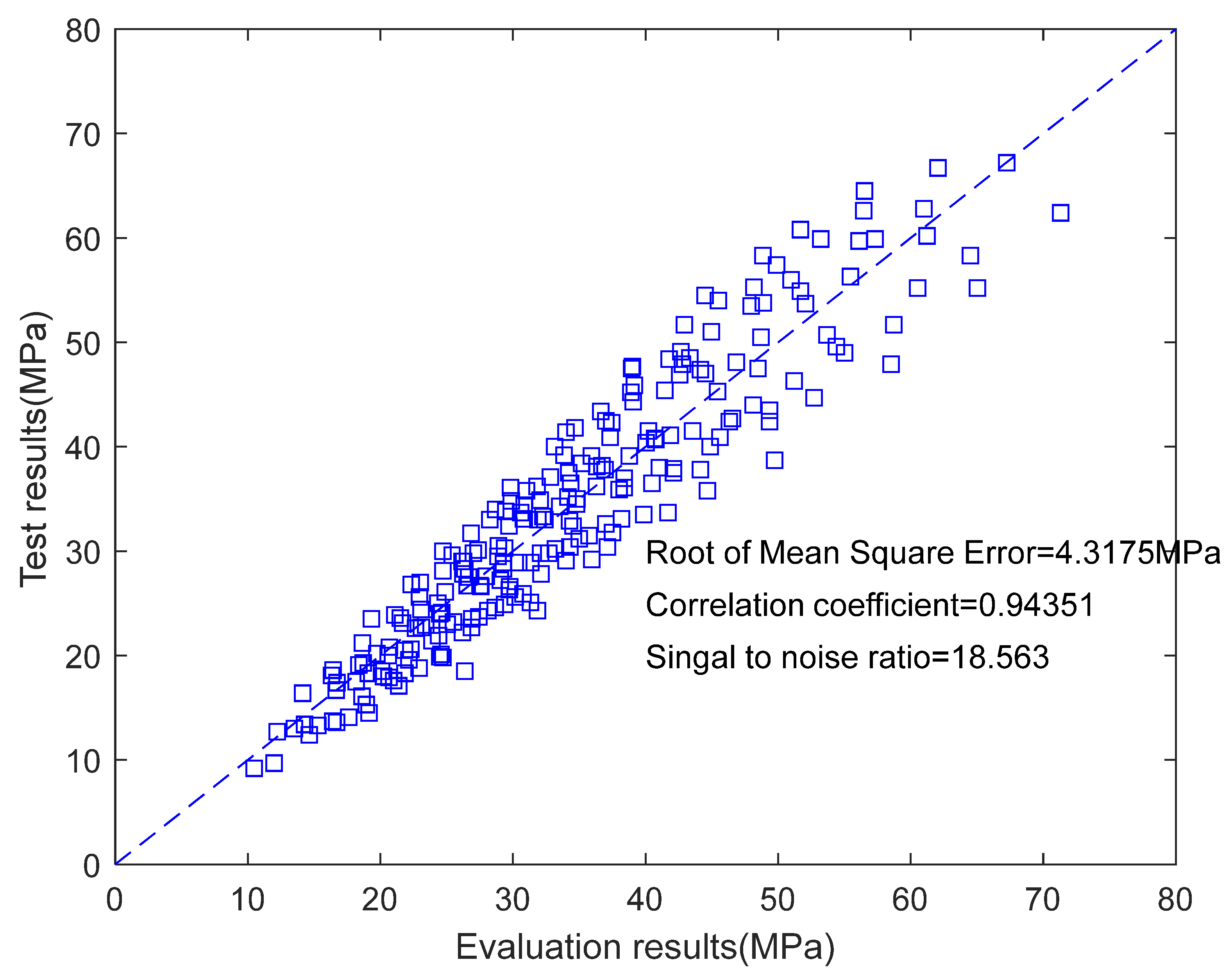

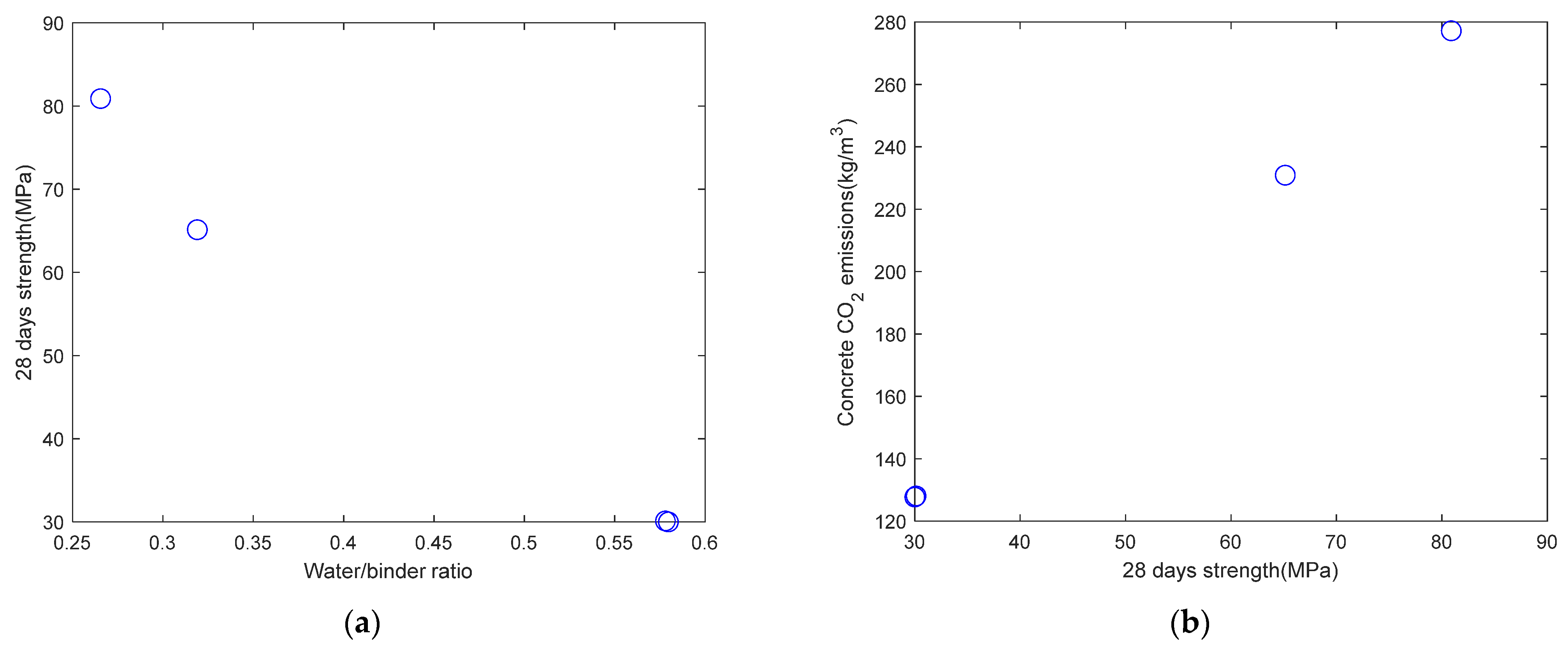

Figure 3a shows the calculated carbon emissions per unit volume of concrete

CO2V. Two factors are considered in

Figure 3a: the water-to-binder ratio and the slag replacement ratio. For a given water-to-binder ratio of 0.5, when the slag replacement ratio increases from 0 to 0.6, the carbon emissions per unit volume of concrete decrease from 341 to 148 kg/m

3. For a given water-to-binder ratio of 0.4, when the slag replacement ratio increases from 0 to 0.6, the carbon emissions per unit volume of concrete decrease from 426 to 184 kg/m

3.

Figure 3a indicates that, as both the slag replacement ratio and the water-to-binder ratio increase, the carbon emissions per unit volume of concrete decrease.

Figure 3b shows the calculated results of carbon emissions per 1 MPa strength of concrete, which are denoted as

CO2U. This figure considers three factors: the water-to-binder mass ratio (0.4 and 0.5), the slag-to-binder mass ratio (ranging from 0 to 0.6 in increments of 0.1), and the testing age (28 and 63 days). First, setting a given water-to-binder mass ratio of 0.5 and a testing age of 28 days, as the slag-to-binder mass ratio increases from 0 to 0.6, and the COCO

2 emissions per unit strength decrease from 6.2 to 4 kg/MPa. Similar trends are observed for other water-to-binder ratios and testing ages. Second, under a given slag-to-binder mass ratio of 0.3 and a testing age of 28 days, as the water-to-binder mass ratio decreases from 0.5 to 0.4, the COCO

2 emissions per unit strength drop from 5.3 to 5 kg/MPa. Similar trends are observed for other slag-to-binder ratios and testing ages. Finally, considering a given slag-to-binder mass ratio of 0.3 and a water-to-binder mass ratio of 0.5, as the testing age increases from 28 to 63 days, the COCO

2 emissions per unit strength decrease from 5.3 to 4.9 kg/MPa. Similar trends are observed for other combinations of slag-to-binder and water-to-binder ratios.

Based on the analysis of

Figure 3b, for a given age, adopting a low water-to-(cement + slag) mass ratio and a high slag-to-(cement + slag) mass ratio is an effective approach to reduce carbon emissions per 1 MPa of concrete strength.

4. Calculation of Carbonation Depth

Papadakis [

2,

27] conducted in-depth studies on the hydration reactions and carbonation depth of cement-based materials incorporating slag admixtures. The carbonation depth was measured by spraying a 1% phenolphthalein solution on a freshly broken concrete surface. Areas that remain pink are uncarbonated (alkaline), while colorless areas indicate carbonation. The depth of the colorless zone is measured to determine the carbonation depth [

27].

Through comparing experimental results with actual engineering carbonation depths, the following equations for carbonation depth, accounting for the influence of slag, are proposed:

In Equation (9), xc represents the carbonation depth, tc denotes the carbonation duration, D is the CO2 diffusion coefficient, [CO2]0 represents the CO2 concentration, denotes the extent of hydration of the cementitious materials at the onset of carbonation, and the coefficient 0.7 preceding MSG is the carbonation equivalent coefficient of slag. It can be seen from Equation (9) that carbonation depth is a function of the square root of the carbonation time.

In Equation (10), represents the density of cement, represents the density of water, and RH denotes the relative humidity of the environment.

In Equation (11),

represents the maximum hydration extent of the cementitious materials,

tcur represents the curing age of concrete at the onset of carbonation,

Fc(

tcur) represents the concrete’s strength at the beginning of carbonation, and

Fc(365) corresponds to the concrete’s strength at 365 days. Equation (11) assumes that the cementitious materials reach their maximum hydration extent at 365 days, which aligns with the findings of Oh and Jang [

28]. As shown in Equation (11), with an increase in the curing age at the onset of carbonation

tcur, the hydration extent of the cementitious materials rises, the CO

2 diffusion coefficient decreases, and the carbonation depth consequently decreases [

23]. Equation (12) is the formula for calculation of

, that is, the maximum hydration extent of the cementitious materials.

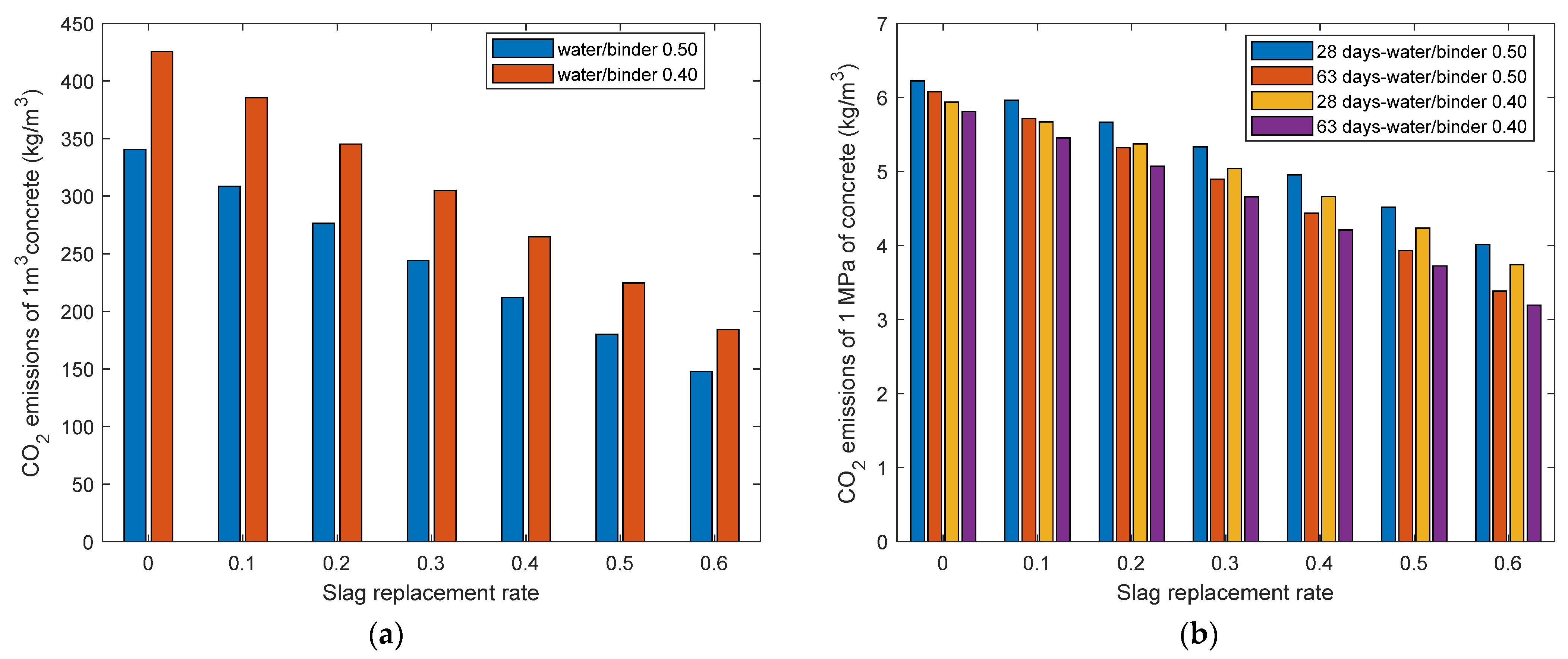

Figure 4 presents the results of the parameter analysis for carbonation depth. During the parameter analysis, the CO

2 concentration in the environment was assumed to be 0.04%, the temperature was set to 20 °C, the relative humidity was 0.6, and the water content per unit volume of concrete was equal to 179 kg per cubic meter. The parameters analyzed included the concrete curing time (reflecting the curing age before the start of carbonation), water-to-(cement+slag) mass ratio, and slag-to-(cement+slag) mass ratio. In the parameter analysis, two parameters were held constant while the third was varied.

As seen in

Figure 4a, the water-to-binder mass ratio was fixed at 0.50 and the slag replacement ratio at 0.30 in order to analyze the effect of curing age before the start of carbonation. The curing age was divided into three levels: 7 days, 28 days, and 63 days. When the curing age before carbonation increased from 7 to 28 days, the carbonation depth of concrete after 50 years decreased from 44.08 mm to 35.98 mm, representing a reduction of (44.08 − 35.98)/44.08 = 18.37%. When the curing age increased from 28 to 63 days, the carbonation depth after 50 years decreased from 35.98 mm to 33.57 mm, representing a reduction of (35.98 − 33.57)/35.98 = 6.61%. Although the time span from 7 to 28 days is 21 days and that from 28 to 63 days is 35 days, the earlier curing period (7–28 days) revealed a more significant improvement in carbonation resistance. This is because the hydration reaction progresses rapidly in the early stages (from 7 to 28 days), whereas the reaction rate slows down in the later stages (from 28 to 63 days).

As seen in

Figure 4b, the curing age before the start of carbonation was fixed at 28 days and the slag replacement ratio at 0.3 in order to analyze the effect of the water-to-binder mass ratio. For the three water-to-binder mass ratios of 0.40, 0.50, and 0.60, the carbonation depths after 50 years were 26.45 mm, 35.98 mm, and 45.74 mm, respectively. The content of carbonatable materials increased as the water-to-binder ratio decreased, leading to a decrease in carbonation depth over the carbonation duration.

As seen in

Figure 4c, the curing age before the start of carbonation was fixed at 28 days and the water-to-binder mass ratio at 0.5 in order to analyze the effect of the slag-to-binder mass ratio. For slag-to-binder mass ratios of 0, 0.30, and 0.60, the carbonation depths after 50 years were 28.70 mm, 35.98 mm, and 45.14 mm, respectively. The increase in the slag-to-binder mass ratio led to an increase in carbonation depth over the carbonation duration.

In summary, the parameter analysis in

Figure 4 indicates that extending the curing time before carbonation begins, reducing the water-to-binder mass ratio, and lowering the slag-to-binder mass ratio are effective strategies for improving the carbonation resistance of slag concrete.

6. Discussion

The contributions and core findings of this study are summarized as follows:

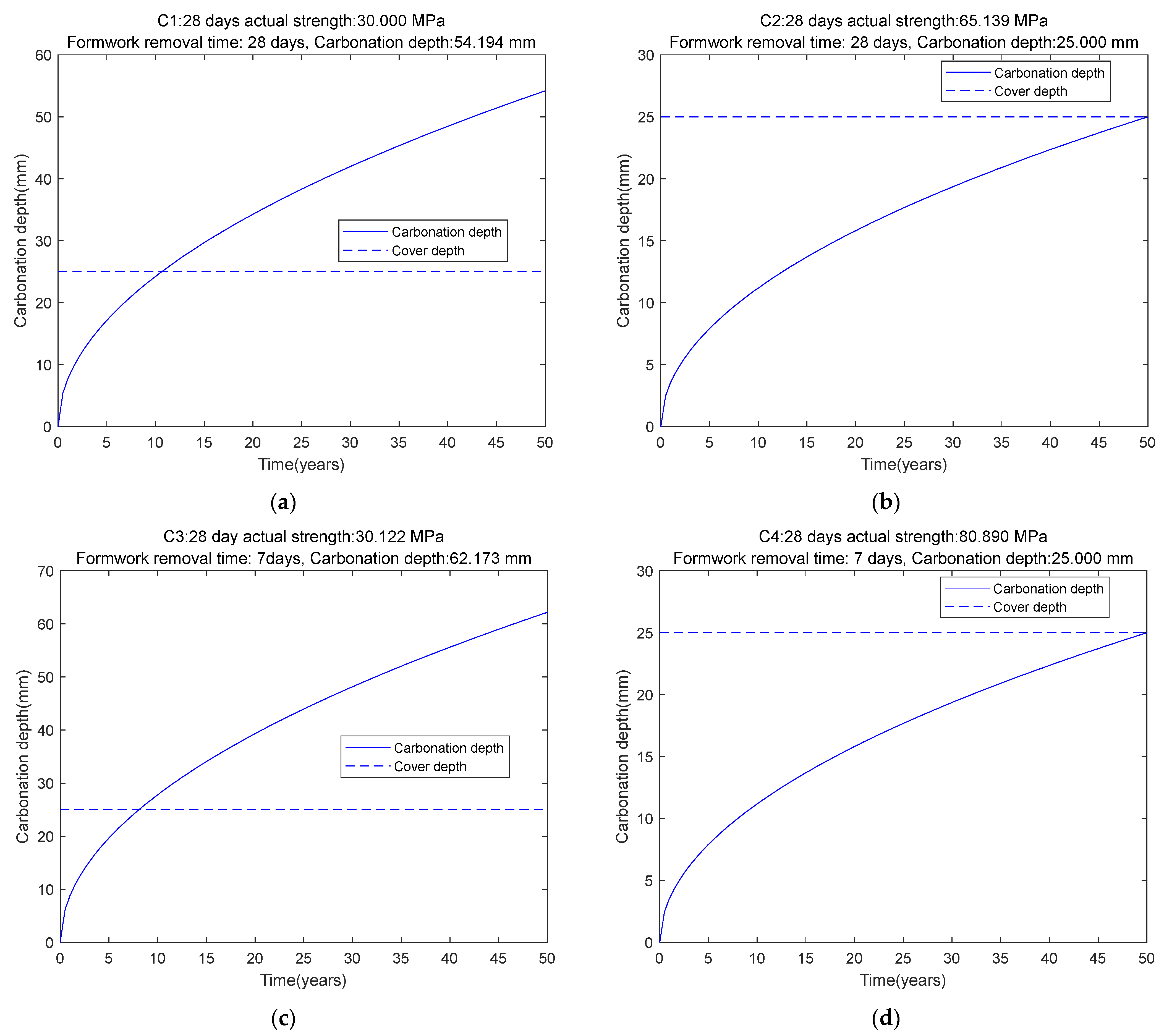

First, in the concrete design methods proposed by the American Concrete Institute (ACI), it is commonly assumed that if the compressive strength requirement is satisfied, the durability requirement will also be met [

25]. However, the results of this study reveal that this assumption is not valid for low-carbon slag concrete. When only the 28-day compressive strength requirement was considered, the carbonation depth after a 50-year service life significantly exceeded the concrete cover thickness (Design Scenario C1); in other words, for low-carbon slag concrete, it is carbonation durability—not compressive strength—that governs the mix design. Through the application of a genetic algorithm, this study successfully developed low-carbon slag concrete mixtures that meet both durability- and strength-related requirements.

Second, the design of low-carbon concrete depends not only on the materials used but also closely on construction practices. Previous studies on low-carbon concrete have mostly focused on materials [

13], often overlooking the impact of construction methods. In slag concrete, early formwork removal can reduce construction costs but also leads to decreased carbonation resistance and poses a risk of steel reinforcement corrosion. The design method proposed in this study takes into account both material and construction aspects. It provides a material-based solution that reduces the risk of corrosion and prevents increased repair costs due to inadequate carbonation resistance.

Finally, although previous researchers have suggested that improving the carbonation resistance of concrete in the cover region is essential for durability, they did not provide specific design methods [

35]. In contrast, the mix proportions listed in

Table 4 of this study offer practical solutions that satisfy both durability and construction requirements. These optimized mixes can be used for the cover region of reinforced concrete structures. Such mix designs offer several advantages: they are associated with low carbon emissions, meet structural strength requirements, fulfill durability demands, and are compatible with general construction constraints.

Currently, the method proposed in this paper is based on the experiments conducted by Oner and Akyuz [

1]. When other users wish to apply the model presented in this study, they can follow these steps: First, collect local compressive strength data and perform regression analysis to determine the coefficients for the strength prediction equation (Equation (1)). Second, calculate the carbon emissions per unit volume of concrete based on local carbon emission data according to Equation (3). Third, determine the local carbonation depth according to regional climatic conditions according to Equation (9). Finally, use a genetic algorithm in conjunction with local durability design standards to obtain the optimal low-carbon concrete mix proportions. Although the results of the calculations may vary across different countries and regions, the overall procedure remains similar. From this perspective, the proposed method can serve as a general approach for designing low-carbon slag concrete.

8. Future Works

Future studies need to further explore the following aspects:

First, this study did not consider the effect of slag fineness on compressive strength and carbonation resistance. Under fixed slag content and water-to-binder ratio conditions, increasing slag fineness has been shown to enhance slag reactivity, resulting in higher compressive strength and improved resistance to carbonation [

36]. Future research should incorporate the influence of slag fineness into both the strength and carbonation depth models.

Second, the present study did not address the effects of slag on shrinkage and cracking. When shrinkage is restrained, tensile stress and cracking can occur which, in turn, accelerate concrete carbonation and affect the mix design of slag concrete. Future optimization design should take into account the effects of shrinkage, cracking, and different levels of tensile stress.

Third, due to differences in raw materials, the strength development and carbonation resistance of slag concrete may vary in different geographical areas. To improve the applicability of the design method, it is necessary to adjust the calculation formulas for compressive strength, carbon emissions, and carbonation depth based on experimental data and industry standards from different countries, allowing for the development of optimization design programs tailored to specific national conditions.