Understanding the Relationship Between Safety Satisfaction and Total Recordable Incident Rate (TRIR), and Their Relevant Processes Through Self-Determination Theory

Abstract

1. Introduction

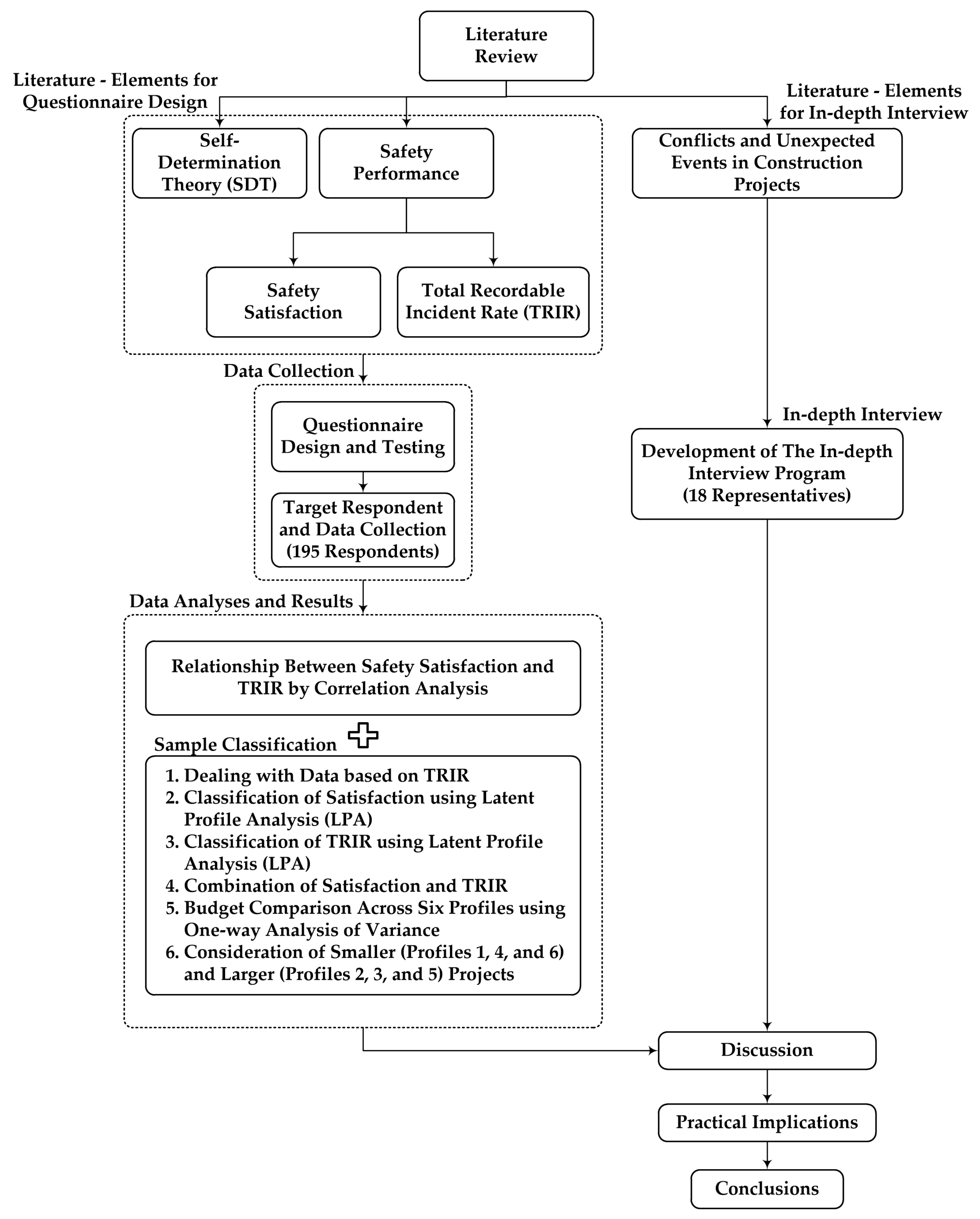

2. Research Methodology

- An analysis of the correlation between safety satisfaction and the TRIR by applying correlation analysis, which indicates that there is a low correlation between two safety performance indicators.

- Classification of project samples into subpopulations, which includes the following steps:

- ➢

- Dealing with project samples based on the TRIR, for which the initial dataset is 195 project samples.

- ➢

- Classification of satisfaction by using latent profile analysis (LPA).

- ➢

- Classification of the TRIR by using latent profile analysis (LPA).

- ➢

- Combination of satisfaction and the TRIR to identify each group of subpopulations.

- ➢

- Comparison of the budget across subpopulations by applying one-way analysis of variance (one-way ANOVA), in which the outliers in terms of project budget were removed so that the final dataset is 133 project samples.

- ➢

- Consideration of the small-scale profiles and large-scale profiles by applying one-way ANOVA to compare the level of autonomy-oriented support from project managers, the motivation of safety officers, and the engagement of safety officers across all small- and large-scale profiles.

3. Literature Review

3.1. Self-Determination Theory

3.2. Safety Performance

4. Data Collection for Quantitative Analysis

4.1. Questionnaire Design and Testing

4.2. Target Respondent and Data Collection

5. Data Analyses and Results

5.1. Relationship Between Satisfaction with the Safety Program and TRIR

5.2. Classification of Project Samples into Subpopulation

5.2.1. Dealing with Data Based on TRIR

5.2.2. Classification of Satisfaction

5.2.3. Classification of TRIR

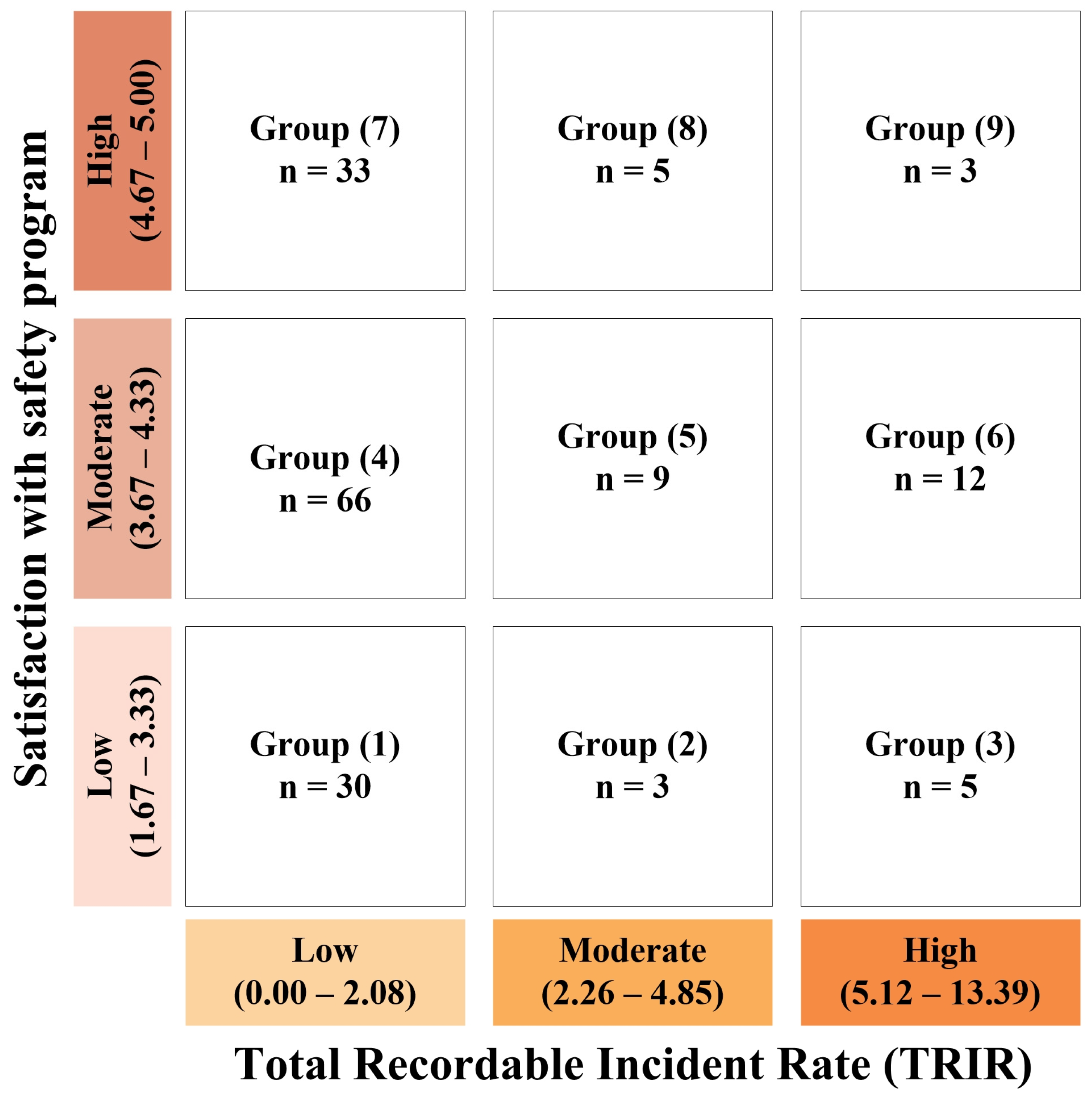

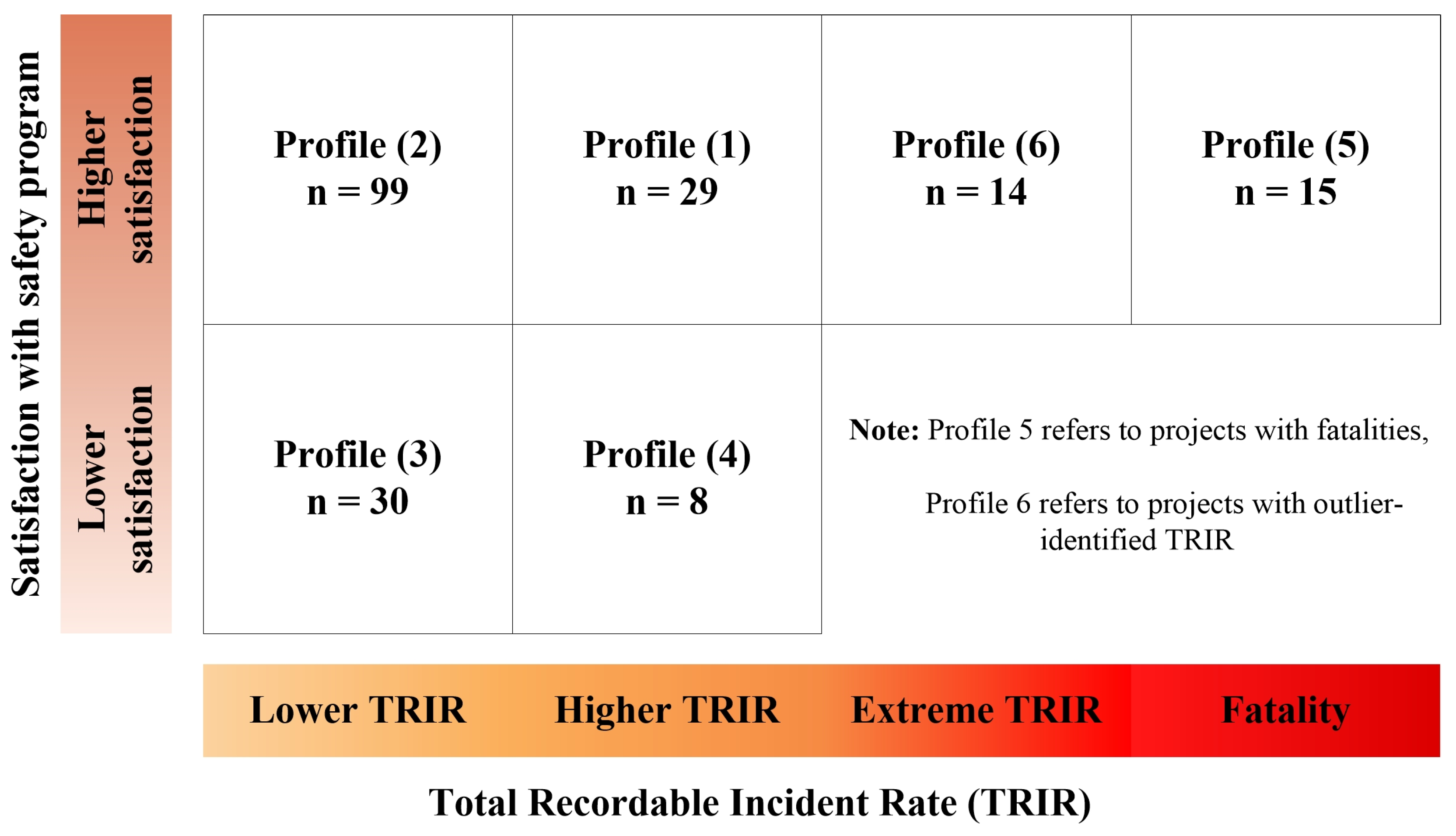

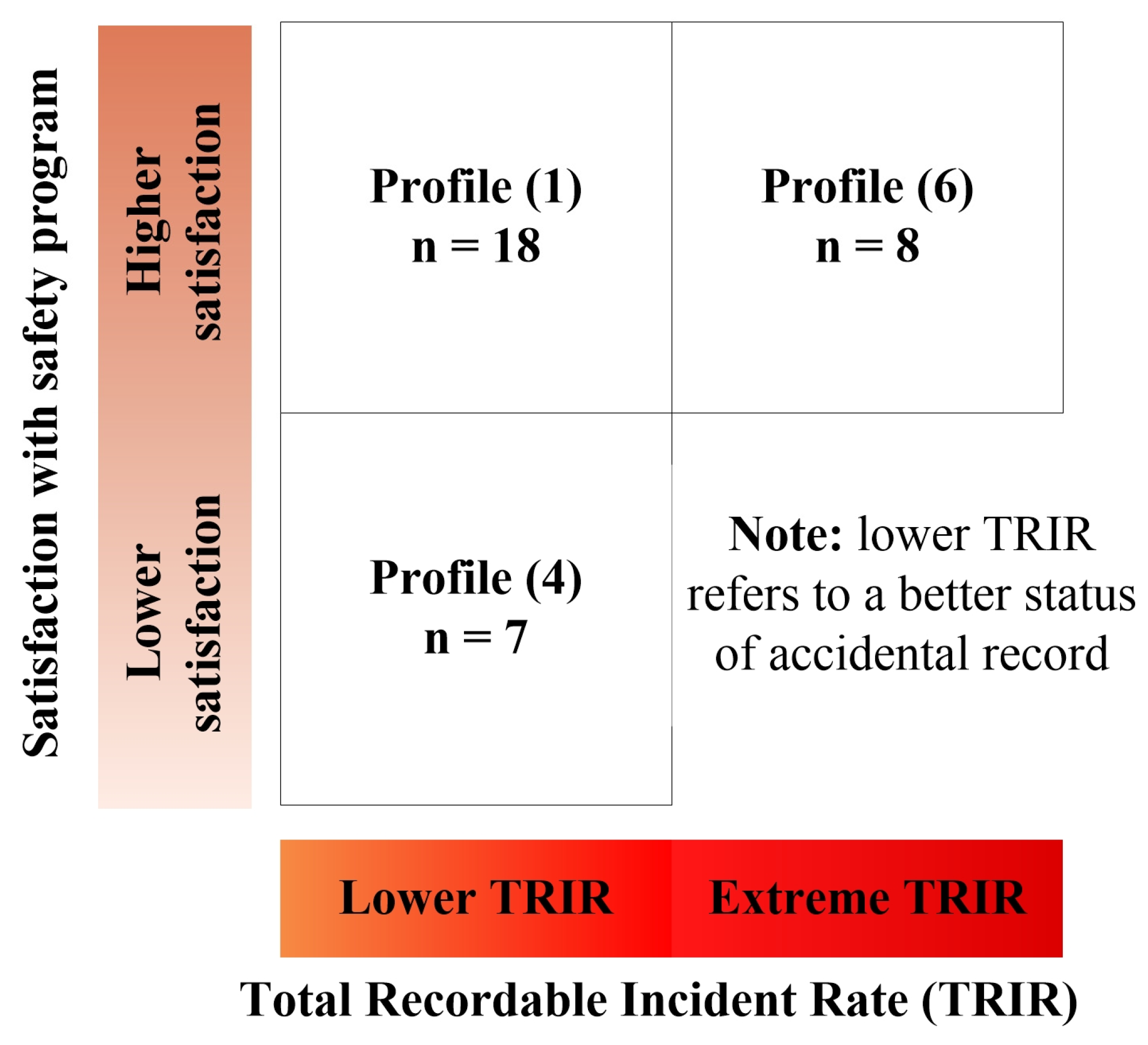

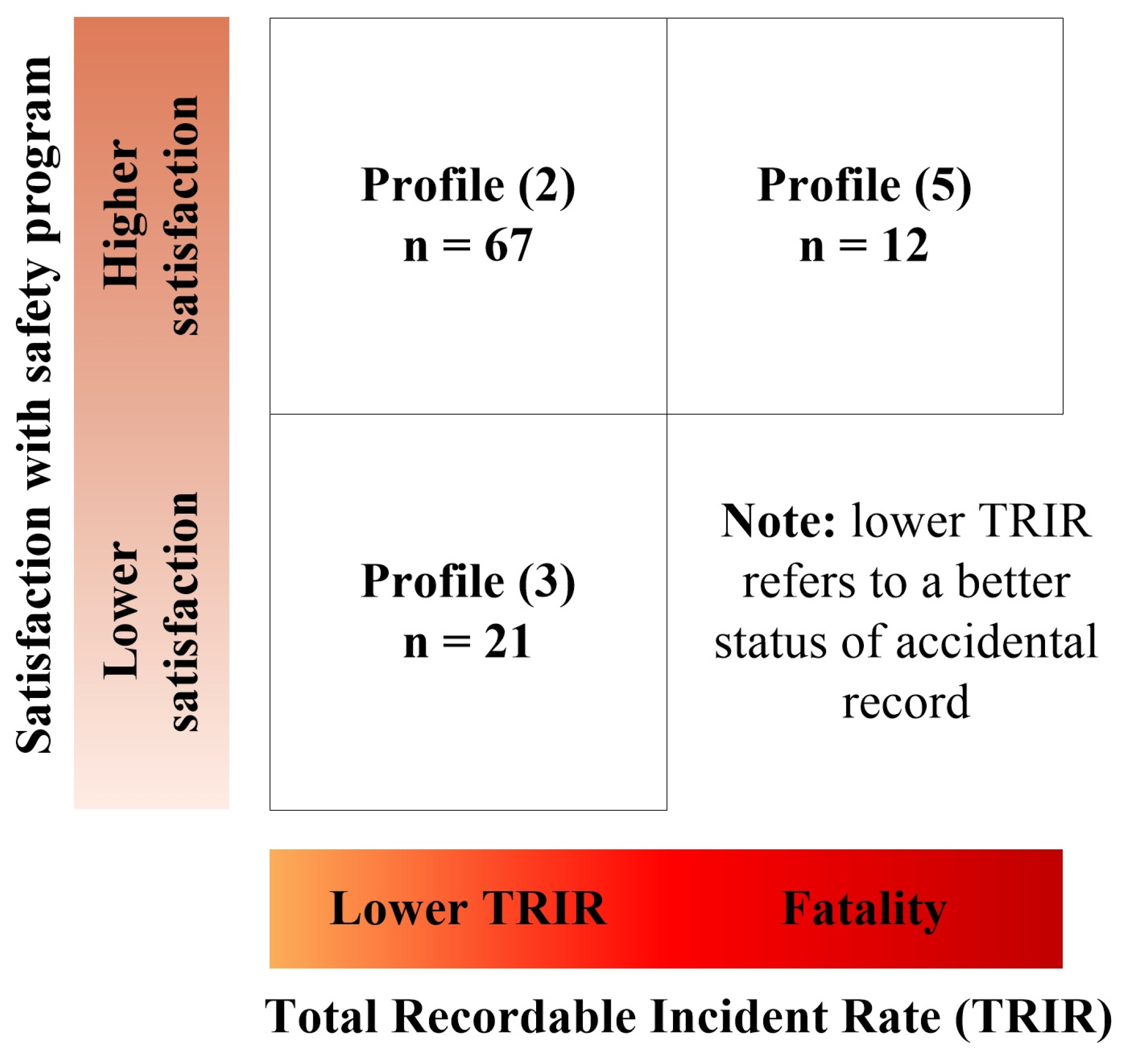

5.2.4. Combination of Satisfaction and TRIR

5.2.5. Budget Comparison Across Six Profiles

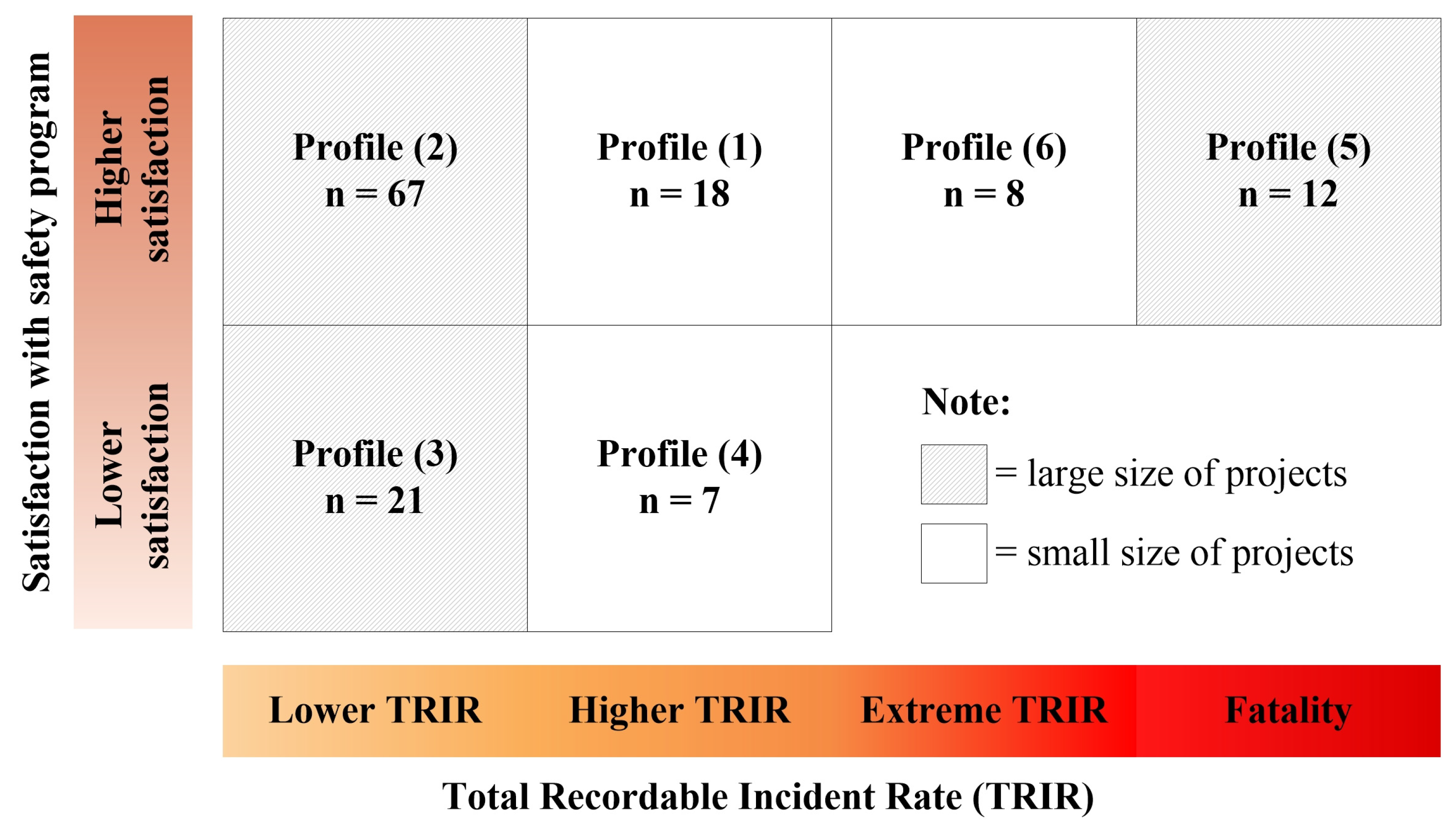

5.2.6. Consideration of Smaller (Profiles 1, 4, and 6) and Larger (Profiles 2, 3, and 5) Projects

6. Framework for In-Depth Interview

6.1. Conflicts and Unexpected Events in Construction Projects

6.2. Development of the In-Depth Interview Program

- 1.

- Could you explain the conflicts that occurred between you as a safety officer and site supervisors (site engineers and foremen) during the safety programs, and the strategies used to resolve them?

- 2.

- Could you explain the conflicts that arose between you as a safety officer and the workers, and the strategies used to resolve them?

- 3.

- Could you explain unexpected or unplanned events that occurred in your project and the strategies employed to resolve them?

- 4.

- How would you explain the support that you received from the project manager in your project underlying safety program?

- 5.

- Would you like to comment on or share experiences that you encountered during the safety programs in your project?

- ✓

- Three respondents were selected from each profile (Profiles 1–6), thus involving 18 safety officers who were willing to provide further information about their project data.

- ✓

- One face-to-face interview was conducted online with each respondent.

- ✓

- Informed consent was obtained from all 18 respondents.

- ✓

- The purpose of the interview was clearly explained.

- ✓

- Each respondent was interviewed based on the constructed questions.

- ✓

- Each interview lasted for 40 min, of which 5 min was devoted to introducing the interview’s purpose, and the rest of the 35 min was allocated to the respondents to explain their project details.

7. Discussion

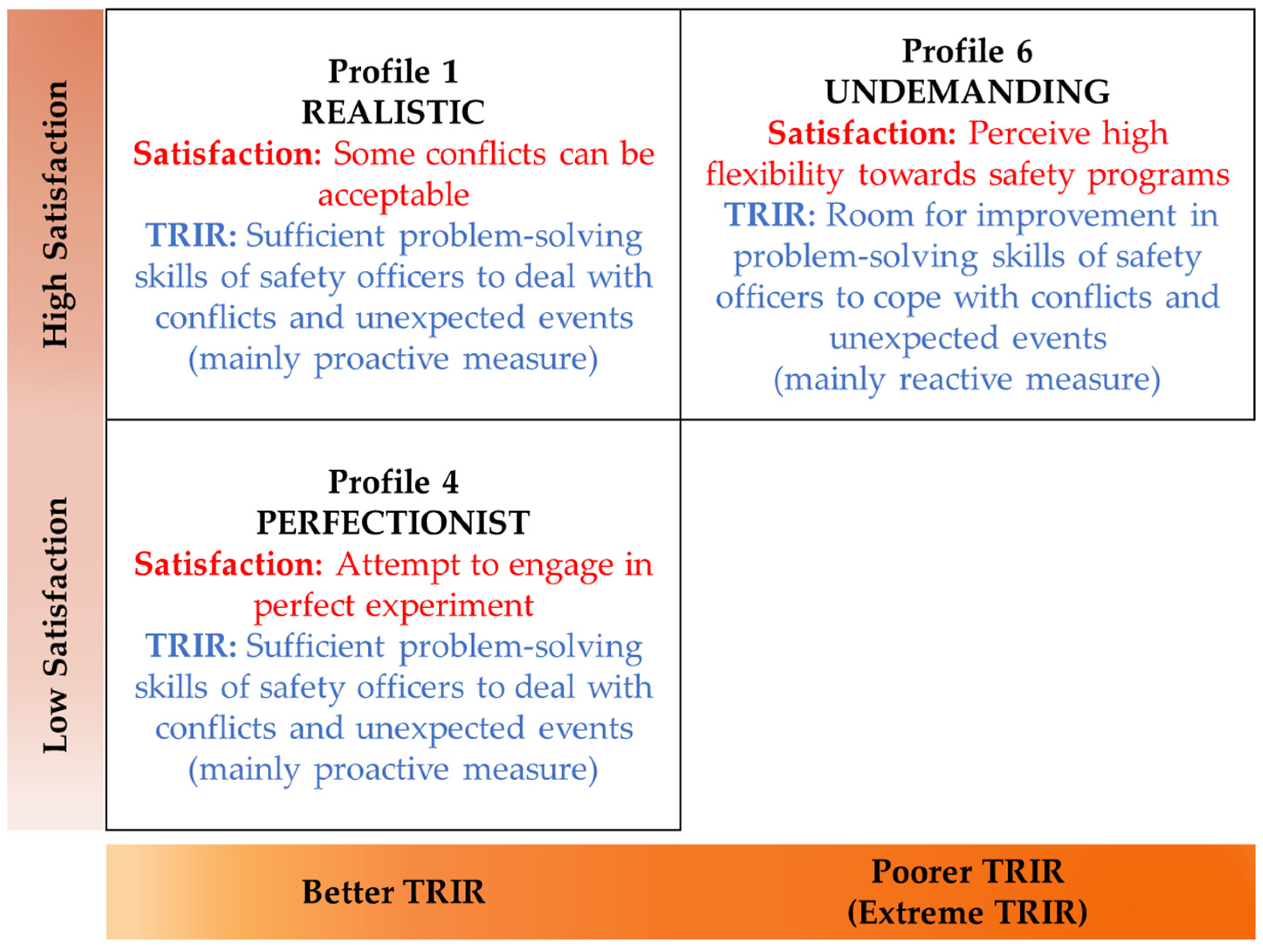

7.1. Discussion About Small-Scale Projects

7.1.1. Safety Officers’ Engagement Levels in Small-Scale Profiles (Profiles 1, 4, and 6)

7.1.2. Autonomy-Oriented Support and Autonomous Motivation (Profiles 1, 4, and 6)

7.1.3. Summary of Specific Characteristics in Small-Scale Projects (Profiles 1, 4, and 6)

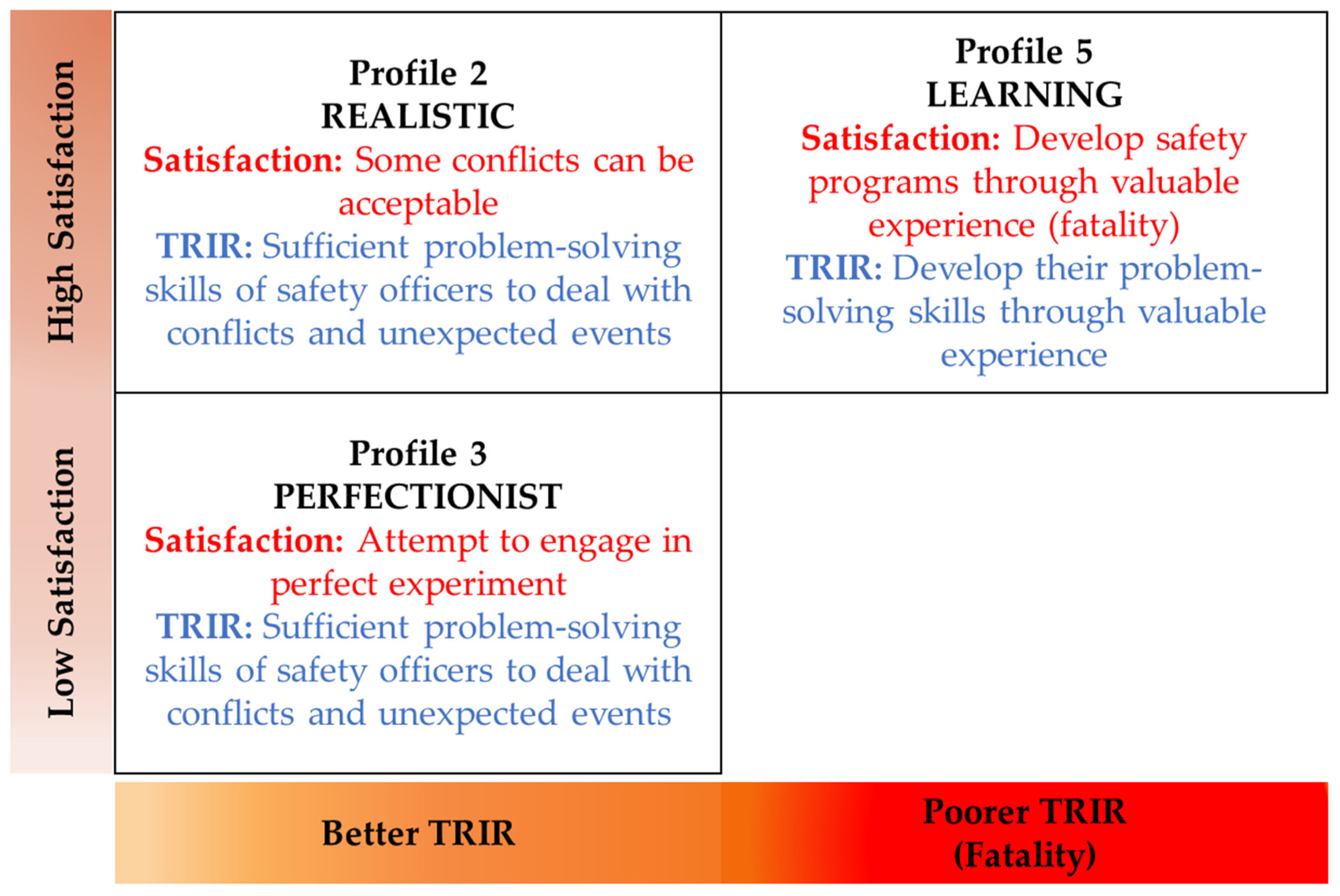

7.2. Discussion for Large-Scale Projects

7.2.1. Engagement of Safety Officers in Large-Scale Profiles (Profiles 2, 3, and 5)

7.2.2. Autonomy-Oriented Support and Autonomous Motivation (Profiles 2, 3, and 5)

7.2.3. Summary of Specific Characteristics in Large-Scale Projects (Profiles 2, 3, and 5)

8. Practical Implications

9. Conclusions

- ➢

- The first characteristic represented realistic safety officers, who can accept minor conflicts and unexpected events through sufficient problem-solving skills and by employing effective strategies to cope with conflicts and unexpected events (proactive strategies), resulting in high satisfaction and a strong accident record (TRIR).

- ➢

- The second characteristic corresponded with perfectionistic safety officers, who attempt to engage in perfect experiments through their adequate problem-solving skills as they seek to eliminate conflicts and cope with unexpected events (proactive strategies), leading to low satisfaction but a strong TRIR record.

- ➢

- The third characteristic involved undemanding safety officers, who often perceive high flexibility on safety programs in terms of attitudes toward conflicts and unexpected events (reactive strategy), resulting in high safety satisfaction but a poor accident record.

- ➢

- The first two characteristics (pertaining to realistic safety officers and perfectionistic safety officers) are similar to those identified in small-scale projects.

- ➢

- The third characteristic contemplates learning safety officers, who develop high-quality safety programs after the occurrence of fatalities in two stages: (1) the early stage in which safety programs do not receive substantial attention and (2) the developed stage after the occurrence of fatal cases; this involves close attention to safety programs, resulting in high safety satisfaction but a poor incident record (TRIR).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix A.1. In-Depth Interview Results from Representatives of Small-Scale Projects

| No. | Cause of Conflict with Supervisors | Resolution by Safety Officers |

|---|---|---|

| Profile 1 #25 | Permission to work: “Once a field engineer brought machinery, like a crane, to the site without requesting permission.” | Explain the rationale: “We discussed it in detail since an accident could harm both the project and its reputation.” Negotiate with the owner: “I addressed this by discussing with the project owner the possibility of submitting a later permit application.” |

| Exposure to hazards: “Sometimes, the field engineer works near the electrical system and mentions the urgency of the task.” | Facilitate by overseeing and monitoring the situation: “I can only supervise the field engineer while he works.” | |

| Profile 1 #128 | No conflicts: “I had minor issues with the foreman, but we usually resolved them through compromise.” | NA |

| Profile 1 #154 | Reliance on the safety officer’s expertise: “The field engineer and the foreman have more experience than me. They are quite confident in their experience.” | Encourage learning while closely monitoring: “I let the team try their method while monitoring. When it failed, they adopted mine, reinforcing their trust in me.” |

| Profile 4 #41 | Engineering supervision: “In construction, the field engineer should be on site while workers are active, but sometimes I notice he isn’t present the entire time.” | Discuss and attempt to understand: “I will first speak with the field engineer to understand the issue. If it continues, I’ll involve the project manager to help resolve it.” |

| Permission to work: “Sometimes, the field engineer must rush the work to be on time, which causes the field engineer to bring in various machines, such as forklifts, to use in the project.” | Facilitating by negotiating with project owner: “I try to help negotiate with the project owner whether we can send the permit application later or not.” | |

| Profile 4 #124 | Reliance on the safety officer’s expertise: “Most field engineers and foremen on site had more experience and years of experience than me, so they did not listen to me much at that time.” | Discuss and gently remind: “The professional safety officers discussed and used techniques to remind them of the general reasons why we had to follow safety procedures.” Understand the nature of construction: “Problems like this happen in our work, often due to the rush to meet deadlines in construction, but I can understand.” |

| Compromise of safety with productivity: “Problems like this do occur in our line of work.” | ||

| Profile 4 #222 | Reliance on the safety officer’s expertise: “I faced issues with the supervisor and foreman, as they saw me as a newbie and doubted my safety management skills.” | Discuss with reasons supported by the owner’s statement: “I use the requirements from the project manager and the reasons to discuss and agree with the foreman.” |

| Profile 6 #38 | Engineering supervision: “He lacked leadership, struggled with safety issues, and resisted my advice.” | Fight with supervisors and refer to the law: “We argued at times. To resolve issues, I cited safety laws, warning of legal consequences for noncompliance.” |

| Gender discrimination: “Perhaps because I am a woman, the field engineer doubted my qualifications as a professional safety officer.” | ||

| Profile 6 #96 | No conflicts: “I have a few issues with the field engineer and foreman.” | NA |

| Profile 6 #98 | No conflicts: “A past accident that killed a subordinate deeply affected the foreman, making safety his top priority.” | NA |

| No. | Cause of Conflict with Workers | Resolution by Safety Officers |

|---|---|---|

| Profile 1 #25 | Understanding safety issues: “What I have with workers are minor issues where some workers may not understand why they need to wear safety equipment or PPE.” | Discuss with reasons: “I have to explain the reasons and the possible consequences if they don’t wear safety equipment.” |

| Profile 1 #128 | Understanding safety issues: “For me and my workers, there are times when we don’t understand each other, but not often because I’m quite close to them.” | Warning by using humor: “I warn them by inserting a joke, joking around, so that they don’t feel too opposed to safety regulations.” |

| Profile 1 #154 | Miscommunication: “There were times when I and the workers did not understand or miscommunicate because sometimes these workers do not have a good understanding of safety work.” | Discuss by providing a reason: “I have to try to teach them in addition to training. In the actual work, I have to warn them and explain the reasons for the importance of safety work.” |

| Profile 4 #41 | PPE issue: “There are a few, but not serious problems.” | Warning by using humor: “I will use the method of warning them with jokes to make them feel comfortable.” |

| Profile 4 #124 | PPE issue: “Many workers are unfamiliar with the project’s safety rules. They avoid safety shoes due to discomfort and skip gloves in hot conditions, despite the requirements.” | Warning and attempt to understand: “Most of the time, we use warnings and attitude adjustments with those workers because we can understand that they have never done this type of work before.” |

| Profile 4 #222 | PPE issue: “Sometimes the workers do not wear gloves.” | Warning, informing supervisor, and being flexible: “I typically give a warning and inform the supervisor to address issues. For minor problems with low risk, I let the workers continue.” Creating a good relationship: “I ate lunch with the workers and asked about any issues they encountered.” |

| Profile 6 #38 | No issue: “I have never had any problems with the workers in the construction work. The workers tend to side with me, and often the workers come to inform me about the safety problems of the engineers that the construction work is not careful.” | NA |

| Profile 6 #96 | PPE issue: “There were some problems between me and the workers, which is normal in some construction projects. For example, if the workers did not wear safety equipment, especially the safety helmet.” | Letting site engineer/foreman deal with the conflict: “I thought the workers already knew that wearing safety equipment was something they had to do. I was very picky, and they didn’t want to talk to me, so I solved the problem by leaving it up to the on-site engineer and the foreman to deal with their own subordinates.” |

| Profile 6 #98 | Improper working style: “Workers modify construction equipment to be more suitable for the work because these workers think that they want to help the construction company reduce the cost of work. But in reality, this kind of action tends to be dangerous.” | Discuss with reason, try to be flexible, and retrain: “We solve the problem by calling to talk if it is a small modification of the equipment. But if the foreman modifies the equipment a lot, we will have to train and talk to each other to create a mutual understanding.” |

| No. | Presence of Untrained Workers | Measure | Type of Measure |

|---|---|---|---|

| Profile 1 #25 | No: “For this project, this doesn’t happen very often.” | Proactive measure: “Our project has a measure that most employees who come to work in our project must receive a scan card to enter the project.” | Proactive |

| Profile 1 #128 | No: “In this area, we don’t often have problems with workers not being trained before they start working.” | Proactive measure: “Since our project is quite small, I can remember the faces of every worker.” | Proactive |

| Profile 1 #154 | Yes: “There were some during the rush period.” | Reactive measure: “I tried to talk to the supervisors and field engineers to bring those workers back for training first, because these things could affect indicators, such as the company’s reputation.” | Reactive |

| Profile 4 #41 | No: “In our project, there is no problem of detecting employees who have not been trained before.” | Proactive measure: “We have measures to issue employee ID cards to all employees.” | Proactive |

| Profile 4 #124 | No: “In our project, there is no problem of encountering untrained workers coming to work, because we have employee cards in the project.” | Proactive measure: “We have employee cards in the project.” | Proactive |

| Profile 4 #222 | No: “In our project, there is no problem with this issue at all, and I have never encountered a worker who has not been trained before coming to work.” | Proactive measure: “In our project, every employee who comes to work is always trained beforehand, and we have measures to check this issue by giving cards to employees.” | Proactive |

| Profile 6 #38 | Yes: “At that time, there were some workers from the subcontractors who came to do specific work.” | Reactive measure: “I couldn’t do anything because they had been working for a certain period of time. I later found out that the workers had not been trained. In addition, at the time I was working on this project, I was not brave enough to give a warning.” | Reactive |

| Profile 6 #96 | Yes: “This issue often arises with subcontractors, who sometimes send a list of workers but bring others not listed on the actual workday.” | Reactive measure: “I have warned those subcontractors and, in some cases, provided training at the company. Sometimes, I have to solve the problem by asking the field engineer or project manager first what to do and whether to conduct further training or discussion.” | Reactive |

| Profile 6 #98 | Yes: “During that time, there was a worker who came to work on the project with his face covered. But since I could remember the worker’s appearance, I asked where the worker came from. The conclusion was that he was a worker who had never received any training before.” | Reactive measure: “I called to report and stated my intention that this kind of action was inappropriate, and that this kind of incident should not have happened. In addition, I took the worker back to receive training before coming to work. These things are normal for construction sites.” | Reactive |

| No. | Interview Script | Measure | Type of Measure |

|---|---|---|---|

| Profile 1 #25 | Effect of COVID-19: “During that time, there was a COVID period.” | Provide quarantine area: “If an employee showed symptoms or tested positive for COVID, we isolated them and their close contacts.” Conduct the ATK test: “ATK tests were conducted daily before work each week.” Declare the timeline: “Workers had to report any places they visited while traveling.” | Reactive |

| Profile 1 #128 | No COVID-19: “At that time, there was none yet. COVID-19 had not arrived yet.” | NA | NA |

| Profile 1 #154 | No COVID-19: “There was no issue with COVID at that time, since there was no outbreak.” | NA | NA |

| Profile 4 #41 | Effect of COVID-19: “During that time, there was also some COVID outbreak.” | Stop working: “If a worker tested positive for COVID, we had to suspend work, causing significant delays.” Productivity management: “The project also had to find replacements for workers with COVID.” Human management: “We had measures to confirm with the hospital that the worker was COVID-free.” | Reactive |

| Profile 4 #124 | No COVID-19: “There was no COVID-19 during the project.” | NA | NA |

| Profile 4 #222 | Effect of COVID-19: “At that time, our project had COVID.” | Provide quarantine area: “If someone tested positive for COVID, they were quarantined, treated, and retested. The measures were strict, as it was the start of the pandemic.” Checking temperature: “We implemented measures like checking workers’ temperatures, restricting their movement, and banning outside workers from entering.” | Reactive |

| Profile 6 #38 | No effect of COVID-19: “At the time this project was being done, there was no pandemic or COVID-19 yet.” | NA | NA |

| Profile 6 #96 | No effect of COVID-19: “During the time this project was in progress, there was no pandemic or COVID.” | NA | NA |

| Profile 6 #98 | Effect of COVID-19: “At that time, when our project started to survey.” | Unfamiliar with it at the beginning: “COVID-19 spread quickly, and at the start of the project, we were unsure how to address it due to its newness.” Conflicting information: “The conflicting information from the government and agencies left us unsure how to handle the situation.” Ineffective use of masks: “Masks were ineffective, as workers had to work outdoors in the heat, making them an obstacle.” Impose social distancing measure: “Our project attempted to separate the workers into groups.” | Reactive |

| No. | Interview Script | Type of Measure |

|---|---|---|

| Profile 1 #25 | Yes: “The safety department will check the weather conditions before every time to make sure that the workers can work without danger. If there is a forecast of storm or rain any day, we will inform you in advance.” | Proactive |

| Profile 1 #128 | No: “There aren’t many problems. In this project, there will be some flooding problems, but that is not a big problem because the flooding happened in the area where we did not work.” | NA |

| Profile 1 #154 | Yes: “In terms of weather, we have planned from the beginning by checking the weather forecast to see if it will rain or not.” | Proactive |

| Profile 4 #41 | No: “No, it’s very little. If the wind comes, it will run away on its own.” | NA |

| Profile 4 #124 | Yes: “To solve the problem of rain, we helped each other monitor until the rain stopped and then reassessed the situation. If the situation was good, we would go back to work.” | Proactive |

| Profile 4 #222 | Yes: “We planned for harsh weather, but during the rainy season, continuous rain softened the soil, causing scaffolding to fall. We stopped work and later implemented measures to compact the soil to withstand the weather for scaffolding installation.” | Proactive |

| Profile 6 #38 | Yes: “I remember it occurring once in that project, which happened to be the time when we were setting up scaffolding. So, I asked the workers to stop working so that I could come down and observe the storm situation.” | Reactive |

| Profile 6 #96 | No: “As I mentioned, since it was a small project, there were not many problems, even in terms of weather conditions.” | NA |

| Profile 6 #98 | Yes: “There was one time when it rained but we did not check the weather forecast. At that time, we had to manage the safety of the surrounding environment, which was quite difficult at that time.” | Reactive |

| No. | Autonomy Support | Competency Support | Relatedness Support | |||

|---|---|---|---|---|---|---|

| Profile 1 #25 | “When I have a suggestion, I and the project manager discuss it based on the reason.” | Yes | “The company rewarded good safety performance with awards and a meal, including pizza.” | Yes | “The project manager prioritized safety and recognized its importance in the job.” | Yes |

| Profile 1 #128 | “The project manager prioritizes safety and approves extra measures if my reasons are valid.” | Yes | “The project manager rarely praised me directly but did so indirectly, such as when he commended me before a visiting committee.” | Yes | “She is very determined. She is a person who is serious about everything and every task.” | Yes |

| Profile 1 #154 | “I presented the safety plan to my project manager, who questioned it until satisfied before approving it.” | Yes | “Prizes are rare, but I occasionally receive compliments for good safety performance on the project.” | Yes | “My project manager prioritized safety, work quality, and productivity.” | Yes |

| Profile 4 #41 | “When I noticed safety violations, I urged the project manager to reject the subcontractor’s work. The contractor considered my perspective.” | Yes | “There are no rewards for staff, but if the project earns the owner’s praise, the project manager treats the team to dinner.” | Yes | “The manager is supportive, with a positive attitude toward safety.” | Yes |

| Profile 4 #124 | “Overall, this manager listens, supports, and prioritizes safety on site.” | Yes | “This person excels at these tasks and praises subordinates when they perform well.” | Yes | “My project manager supports safety more than the others I’ve worked with.” | Yes |

| Profile 4 #222 | “The project manager was very open to suggestions and suggestions from the safety professionals.” | Yes | “This project will award certificates to workers who make outstanding safety contributions.” | Yes | “The project manager prioritizes safety, especially since the company values human resources highly.” | Yes |

| Profile 6 #38 | “He listens well to my work issues.” | Yes | “He often treats the team to snacks and food. While my manager does not give many compliments, his actions show trust in me.” | Yes | “My manager addresses safety issues, but at times, I feel a sense of consideration toward him.” | Yes |

| Profile 6 #96 | “The project manager listens to my suggestions, but sometimes it’s not possible to implement them.” | Yes | “Our company rarely gives positive feedback, as this project doesn’t prioritize safety and lacks rewards or incentives.” | No | “The project manager values safety, but not fully. Since the project is small, safety isn’t a major focus.” | No |

| Profile 6 #98 | “The project manager supports safety equipment like signs and cones but views specialized training for workers as a waste of time.” | Yes | “The project manager and I are close, having worked together for seven to eight years.” | Yes | “He has not received training on tool or machinery safety and mostly relies on his understanding of the laws.” | No |

Appendix A.2. In-Depth Interview Results from Representatives of Large-Scale Projects

| No. | Cause of Conflict with Supervisors | Resolution by Safety Officers |

|---|---|---|

| Profile 2 #48 | PPE issue: “Most of the time, we can talk and understand each other. One time, it happened to a subcontractor. That day, he did not bring a safety helmet.” | Request to bring PPE, another member helps to mediate the situation: “I didn’t let him enter the site without a helmet. After some arguing, his friend got one, and another safety officer mediated the situation.” |

| Profile 2 #79 | Engineering supervision: “Issues mostly arise with the supervisor, who often works incorrectly and instructs subordinates to follow improper procedures.” | Request to stop and warn in a minor case: “If this happens, we stop them from working. For minor issues, we issue a warning.” |

| Profile 2 #97 | Safety budget: “Some subcontractors said that safety equipment is expensive. Small companies complain that it is too expensive.” | Support some part and help to search for the good one: “The project provides alternative choice for subcontractors, allowing them to select the most affordable and high-quality options.” |

| Profile 3 #24 | Improper working styles: “There are some because sometimes they take easy and convenient work, but sometimes it is not safe like this.” | Discuss and negotiate: “We talked to the team that we asked for 80 percent in terms of safety. If it is not too dangerous, we will close our eyes and get something like that.” |

| Profile 3 #54 | No conflict: “Not very often. There aren’t any at all because I’m the top in the safety department, and I work with a foreman who I’m close to.” | NA |

| Profile 3 #199 | Working style: “There have been some cases, for example, I can mention that it was a concrete pouring job with a basket using a crane to lift it. They said that the height was not that high.” | Discuss by providing reason: “I had to make them understand. At first, they didn’t really understand or were not happy, so I talked to them often and told them about the consequences that would follow.” |

| Profile 5 #17 | Working condition: “There is a matter of accident prevention. I recommend that the engineers on site always install a small railing, but the engineers on site said that they do not have time to do it for me that much. The civil engineering work is urgent.” | Recommended, but no cooperation obtained: No action |

| Profile 5 #26 | Compensate safety with productivity: “Sometimes they have to work according to the time and productivity.” | Taking picture and waiting for the meeting: “We collect pictures and make reports to wait for the meeting that is called to update and collect work data.” |

| Improper working style: “At the early stage, some subcontractors let the construction workers perform the construction activity until the late night.” | Report to PM, and request for termination of contract: “When I found that situation, I reported to the PM and requested for the termination of the contract.” | |

| Profile 5 #32 | Trusting in the ability of safety officer: “Normally the foreman in the construction project will have quite a lot of work experience.” | Try to negotiate: “I used to negotiate with the foreman, but we ended up fighting.” |

| Compensating safety with productivity: “The foreman often negotiates safety measures, believing work should be fast, convenient, and easy.” | Request to terminate contract: “The most serious incident at that time was an accident that caused someone to die. After that, I asked the project manager to fire this foreman.” |

| No. | Cause of Conflict with Workers | Resolution by Safety Officers |

|---|---|---|

| Profile 2 #48 | No issue: “There is no problem with the workers. The workers are obedient and easy to teach.” | NA |

| Profile 2 #79 | Understanding of safety issue: “There were sometimes but not often. When we ask deeper why the workers don’t follow the instructions, the workers will say that our boss ordered them (boss refers to supervisor).” | Warning and reject if necessary: “It is divided into two parts: Unacceptable actions, like climbing scaffolding over 6 m without a belt, are rejected immediately; acceptable behaviors, like not wearing gloves, receive a warning. After three warnings, the worker is asked to leave.” |

| Profile 2 #97 | PPE issue: “It’s normal. Construction work is a rush job with a schedule and time, because the work site is pressed. So, when we find something that they did wrong or a violation.” | Discuss by providing reason: “Most of the time we will go and advise them. Advise them immediately.” |

| Profile 3 #24 | PPE issue: “Sometimes most of the local workers don’t like to wear welding masks and welding gloves while welding.” | Discuss by providing reason: “We explain that wearing protection is necessary because welding dust and metal powder can harm the lungs, potentially causing issues like lung cancer years later.” |

| Profile 3 #54 | PPE issue: “There are some PPE issues.” | Understand the nature: “We didn’t talk to them directly, sometimes the urgent work we understand.” Help and facilitate workers: “If working at night, the most important thing is the reflective vest. Our regular duty is to be on the roadside, helping and facilitating the workers.” |

| Profile 3 #199 | PPE issue: “The Thai workers are skilled craftsmen, but many experienced ones resist wearing PPE, especially during high-rise tasks like steel frame or roof horn installation, despite the necessity for safety.” | Claim the agreement and provide sufficient training: “Before the project starts, we discuss and train everyone to agree on the work and safety measures.” |

| Profile 5 #17 | PPE issue: “The workers are very obedient because we have to train and have meetings. I have encountered this sometimes.” | Warn: “I walked by, and we warned them beforehand.” |

| Profile 5 #26 | Misconception on safety: “Workers can’t differentiate between what they did wrong and what they did as the supervisor told them to do.” | Express a good care: “Our spirit is that we want employees to be safe because they have their own families.” |

| Profile 5 #32 | Communication with foreign workers: “I often argued with my foreign workers, and if we did not argue one day, my food did not taste good.” | Fight back: “I got really angry.” |

| Addiction to drug: “In addition, my project also had some problems with drugs.” | No action: Not mentioned |

| No. | Presence of Untrained Workers | Measure | Type of Measure |

|---|---|---|---|

| Profile 2 #48 | Yes: “There was a worker who had been working for a while and I happened to walk by and saw that the card he was wearing was not the same card that we use on our site. It was another type of card.” | Proactive measure: “The company has the system to provide employee cards for trained workers.” Reactive measure: “We stood and trained him on site to let him know.” | Proactive |

| Profile 2 #79 | No: “My project did not experience that.” | Proactive measure: “Our system uses a two-level scan: scan at the door, then again inside. Without training, workers won’t have cards.” | Proactive |

| Profile 2 #97 | Yes: “There are some.” | Reactive measure: “Mostly I will take the employees to talk and adjust their attitudes. Then, let them get proper training, prepare for the course. Then come back in, but first I will ask the workers to stop working first.” | Reactive |

| Profile 3 #24 | Yes: “Trained workers have a sign indicating completion. This issue mainly occurs with civil engineering subcontractors, who, in their rush, bring in workers without notifying us.” | Proactive plan: “For trained workers, we use a sign to indicate completion. We randomly check names against the system and cards to verify training.” Reactive measure: “If we find any, we stop work and ask them to leave. Subcontractors must follow our initial procedures to bring them in.” | Proactive |

| Profile 3 #54 | Yes: “There are some that are part of the subcontractors. During the additional work, the project has to bring in more people. We don’t know because they didn’t inform us.” | Reactive measure: “When we find workers who haven’t been trained, we will call them back to the office for training.” | Reactive |

| Profile 3 #199 | Yes: “Yes, there is.” | Proactive measure: “We control this by issuing employee cards after training. Security guards check the cards on site, and only those who have completed safety training receive them.” Reactive measure: “We call subcontractors to discuss issues, often involving our project manager or executives talking to their counterparts. It is usually a significant matter.” | Proactive |

| Profile 5 #17 | No: “My part does not have any.” | Proactive measure: “I inform all on-site engineers and subcontractors that new employees must undergo training before starting work, with their names and details announced each time.” | Proactive |

| Profile 5 #26 | No: “My project did not experience that.” | Proactive measure: “There are some measures in place. If the project finds out that workers have not been trained before, they will be asked to leave our worksite.” | Proactive |

| Profile 5 #32 | Yes: “Sometimes the foreman would secretly bring in untrained workers to work, and he would reason that he only brought workers in for a few days.” | Reactive measure: “After that, I solved the problem by having the security guard help screen people before they came in to work. If the workers did not have a card, they would not be able to work.” | Reactive |

| No. | Interview Script | Measure | Type of Measure |

|---|---|---|---|

| Profile 2 #48 | No COVID-19: “At that time, COVID-19 had not yet happened.” | NA | NA |

| Profile 2 #79 | Effect of COVID-19: “Mine is full of COVID-19.” | Provide quarantine area: “We prepare a camp as an isolation zone and take anyone found to the camp.” Provide COVID-19 testing: “We attempt to provide the COVID-19 testing to all employees.” Ensure COVID-19 is not spreading: “If we find the first case, we will have all the workers who are close stop working.” | Reactive |

| Profile 2 #97 | No COVID-19: “When I was on the project, there was no COVID-19.” | NA | NA |

| Profile 3 #24 | Effect of COVID-19: At that time, in the beginning of the project during COVID-19. | Following provincial measures: “We follow provincial measures. Udon Thani province required reporting to health volunteers and testing. The company prioritizes COVID-19 precautions and adheres to these measures.” Second plan to test COVID: “Initially, we used hospital-provided COVID evidence when hospitals were full, then switched to self-testing as measures relaxed.” Require self-quarantine: “Initially, after testing, you had to quarantine for 7–14 days.” Declare timeline: “Everyone must write a timeline. Conduct a COVID test: “There is a check every week.” Provide the necessary kids: “There is a spraying of alcohol.” Provide cleaning: “If I remember correctly, every day after work, there will be a housekeeper to clean.” Ensure everyone does not have COVID: “If one person is found, we will test by having everyone get tested for COVID.” Stricter measure is applied when necessary: “If multiple cases are found, we will close the site for 7 days and clean everything.” | Proactive |

| Profile 3 #54 | Effect during COVID-19 | Provide the test: “There were people infected with COVID-19 at the site. We started to plan to send them for testing and separate people at risk.” Provide quarantine area: “Those who are in close contact will be separated. We will separate them into green, yellow, and red. We have a spare room for quarantine.” Provide necessary kids and food: “The project also has a policy to serve workers, such as giving away free rice 2–3 times a day and various safety equipment such as masks and hand sanitizers.” | Reactive |

| Profile 3 #199 | Effect of COVID-19: “COVID-19 was not an uncertainty when the project started.” | Advanced measure: “COVID-19 was already there, and we knew about it. Oh, so we have some measures to support it.” | Proactive |

| Profile 5 #17 | Effect of COVID-19: “There were a lot of COVID cases at the first project, all 2200 workers.” | Provide COVID-19 testing: “We had a plan to deal with it. When workers entered the project, we checked them before they entered the project, everyone. We checked their body temperature.” Provide a random check: “We checked randomly all the time, going to the victim’s nose.” Provide the necessary kids: “Face masks, hand sanitizers, etc.; the project provided these.” | Reactive |

| Profile 5 #26 | No COVID-19: “When I was working on that project, there was no pandemic or COVID-19.” | NA | NA |

| Profile 5 #32 | Effect of COVID-19: “During that time, there was an outbreak of COVID.” | Project manager support: “During that time, the project manager appointed people to help support my work, and I was able to do my job very well.” Provide the necessary kits: “Our project had measures in place. We provided safety equipment such as hand sanitizers for workers to wash their hands before starting work, and separated areas for eating, which were measured in terms of general health.” Provide a random check: “After that, we randomly tested for COVID once a week.” | Proactive |

| No. | Interview Script | Type of Measure |

|---|---|---|

| Profile 2 #48 | Yes: “When it rains and storms, all work stops.” | Reactive |

| Profile 2 #79 | Yes: “We’ll have a plan to prepare it and let it go in one place so it doesn’t affect the work site we’re working on.” | Proactive |

| Profile 2 #97 | Yes: “All lifting work must stop, no lifting allowed. Then, only the work that can be done will be done. Stop working until the scaffolding is completely dry.” | Reactive |

| Profile 3 #24 | Yes: “Yes, there is. But it’s already a measure. We work with power plants. If it rains, everyone knows that they have to leave the workplace. Everyone knows that. Underground water, we predict that it already exists, because before doing the project, we will have a soil test.” | Proactive |

| Profile 3 #54 | Yes: “During the rainy season, it happens often because it rains and floods. We have to stop working. The workers and supervisors follow the instructions very well.” | Reactive |

| Profile 3 #199 | Yes: “They already have measures in advance, such as flooding. We already know which month the rainy season is in the area we are going to. So we will have a construction plan in place to make it consistent with the weather conditions.” | Proactive |

| Profile 5 #17 | Yes: “When it rains, the upper part cannot work, but the inside of the building can.” | Reactive |

| Profile 5 #26 | Yes: “Every time it rained, the project had to order workers to stop working and strictly forbade them from working at heights. Everyone strictly followed the instructions because they were informed of the consequences that would not be worth what would happen if an accident occurred.” | Reactive |

| Profile 5 #32 | Yes: “…After that, I tried to increase safety measures and tried to inform everyone involved about the weather conditions.” | Reactive |

| No. | Autonomy Support | Competency Support | Relatedness Support | |||

|---|---|---|---|---|---|---|

| Profile 2 #48 | “The project manager listens to opinions and transfers tough decisions to the project director.” | Yes | “There is praise and there is consolation and there is, um, protection of the subordinates.” | Yes | “He considered costs in every decision but always prioritized safety, discussing it in every meeting.” | Yes |

| Profile 2 #79 | “The project manager listened to me when there were critical safety concerns.” | Yes | “In my company, if there is no lost-time work for three months, the project team receives a monetary reward.” | Yes | “The requirements are strict, and the project manager works within the established framework.” | Yes |

| Profile 2 #97 | “I could tell him about project management, PPE equipment, or people management—everything was handled well.” | Yes | “He provided great feedback. We have statistics in place, with a target set: If we reach the target without any accidents, the company rewards us.” | Yes | “My project manager shows strong leadership, making decisions and taking responsibility for the organization—very effective.” | Yes |

| Profile 3 #24 | “If we have additional comments beyond the owner’s requirements, my manager well cooperate with my suggestion more than 50 percent.” | Yes | “The company conducts an annual performance evaluation, including feedback on major projects for each position.” | Yes | “He prioritizes safety at the sufficient level more than 50 percent.” | Yes |

| Profile 3 #54 | “When I suggest choices to the project manager with a clear justification, my manager always approves my choices.” | Yes | “I usually receive compliments when solving problems.” | Yes | “For safety-related work, we receive a certain level of support under the reasonable budget.” | Yes |

| Profile 3 #199 | “The project manager cooperates well and responds positively to requests and suggestions.” | Yes | “We emphasize understanding and ensuring everyone follows basic safety practices.” | Yes | “He gives safety programs equal priority to the productivity in project.” | Yes |

| Profile 5 #17 | “The project manager paid good attention when we made suggestions about safety programs.” | Yes | “The project manager praises us for prioritizing safety and preventing accidents, though compliments are rare due to few incidents.” | Yes | “I have worked with this project manager for many years, and he prioritizes safety.” | Yes |

| Profile 5 #26 | “The project manager listens but considers the project timeline as the main factor.” | Yes | “Feedback is minimal, but if there are no accidents in a quarter, the project rewards employees.” | Yes | “Project managers primarily focus on performance and work quality.” | No |

| Profile 5 #32 | “He listens to my opinions on safety, but sometimes the project manager has to consider other factors, like the project budget.” | Yes | “When inspecting the construction site, he buys snacks, milk, water, and other foods to treat his subordinates.” | Yes | “My manager values safety, but productivity is also important.” | Yes |

References

- Katz, I.; Kaplan, A.; Buzukashvily, T. The role of parents’ motivation in students’ autonomous motivation for doing homework. Learn. Individ. Differ. 2011, 21, 376–386. [Google Scholar] [CrossRef]

- Tam, N.V.; Watanabe, T.; Hai, N.L. Importance of Autonomous Motivation in Construction Labor Productivity Improvement in Vietnam: A Self-Determination Theory Perspective. Buildings 2022, 12, 763. [Google Scholar] [CrossRef]

- Khun-anod, K.; Watanabe, T.; Tsuchiya, S. Roles and Autonomous Motivation of Safety Officers: The Context of Construction Sites. Buildings 2024, 14, 460. [Google Scholar] [CrossRef]

- Ryan, R.M.; Deci, E.L. Intrinsic and extrinsic motivations: Classic definitions and new directions. Contemp. Educ. Psychol. 2000, 25, 54–67. [Google Scholar] [CrossRef]

- Mohammadi, A.; Tavakolan, M.; Khosravi, Y. Factors influencing safety performance on construction projects: A review. Saf. Sci. 2018, 109, 382–397. [Google Scholar] [CrossRef]

- Aksorn, T.; Hadikusumo, B.H. Critical success factors influencing safety program performance in Thai construction projects. Saf. Sci. 2008, 46, 709–727. [Google Scholar] [CrossRef]

- Hwang, B.G.; Shan, M.; Phuah, S.L. Safety in green building construction projects in Singapore: Performance, critical issues, and improvement solutions. KSCE J. Civ. Eng. 2018, 22, 447–458. [Google Scholar] [CrossRef]

- Wachter, J.K.; Yorio, P.L. A system of safety management practices and worker engagement for reducing and preventing accidents: An empirical and theoretical investigation. Accid. Anal. Prev. 2014, 68, 117–130. [Google Scholar] [CrossRef]

- Alruqi, W.M.; Hallowell, M.R.; Techera, U. Safety climate dimensions and their relationship to construction safety performance: A meta-analytic review. Saf. Sci. 2018, 109, 165–173. [Google Scholar] [CrossRef]

- Kim, N.K.; Rahim, N.F.A.; Iranmanesh, M.; Foroughi, B. The role of the safety climate in the successful implementation of safety management systems. Saf. Sci. 2019, 118, 48–56. [Google Scholar] [CrossRef]

- Shaikh, A.Y.; Osei-Kyei, R.; Hardie, M. A critical analysis of safety performance indicators in construction. Int. J. Build. Pathol. Adapt. 2021, 39, 547–580. [Google Scholar] [CrossRef]

- Kim, C.W.; McInerney, M.L.; Alexander, R.P. Job satisfaction as related to safe performance: A case for a manufacturing firm. Coast. Bus. J. 2002, 1, 63–71. [Google Scholar]

- Uusitalo, P.; Peltokorpi, A.; Seppänen, O.; Alhava, O. Towards systemic transformation in the construction industry: A complex adaptive systems perspective. Constr. Innov. 2024, 24, 341–368. [Google Scholar] [CrossRef]

- Alruqi, W.M.; Hallowell, M.R. Critical success factors for construction safety: Review and meta-analysis of safety leading indicators. J. Constr. Eng. Manag. 2019, 145, 04019005. [Google Scholar] [CrossRef]

- Marshall, P.; Robson, R. Preventing and managing conflict: Vital pieces in the patient safety puzzle. Healthc. Q. 2005, 8, 39–44. [Google Scholar] [CrossRef]

- Abudayyeh, O.; Fredericks, T.K.; Butt, S.E.; Shaar, A. An investigation of management’s commitment to construction safety. Int. J. Proj. Manag. 2006, 24, 167–174. [Google Scholar] [CrossRef]

- Al Haadir, S.; Panuwatwanich, K. Critical success factors for safety program implementation among construction companies in Saudi Arabia. Procedia Eng. 2011, 14, 148–155. [Google Scholar] [CrossRef]

- Awolusi, I.G.; Marks, E.D. Safety activity analysis framework to evaluate safety performance in construction. J. Constr. Eng. Manag. 2017, 143, 05016022. [Google Scholar] [CrossRef]

- Department of Labor Protection and Welfare. Statistics on Labor Protection and Welfare Fiscal Year 2013 to 2021; DLPW: Bangkok, Thailand, 2021; Available online: https://www.labour.go.th/index.php/service-statistic/service-statistic-m/category/22-report2 (accessed on 25 December 2021).

- Yamane, T. Elementary Sampling Theory; Prentice-Hall: Englewood Cliffs, NJ, USA, 1967. [Google Scholar]

- VanVoorhis, C.W.; Morgan, B.L. Understanding power and rules of thumb for determining sample sizes. Tutor. Quant. Methods Psychol. 2007, 3, 43–50. [Google Scholar] [CrossRef]

- Guo, B.H.; Yiu, T.W.; González, V.A. Identifying behaviour patterns of construction safety using system archetypes. Anal. Prev. 2015, 80, 125–141. [Google Scholar] [CrossRef]

- Ju, C. Work motivation of safety professionals: A person-centred approach. Saf. Sci. 2020, 127, 104697. [Google Scholar] [CrossRef]

- BLS (Bureau of Labor Statistics). Employer-Reported Workplace Injuries and Illnesses, 2023; BLS (Bureau of Labor Statistics): Washington, DC, USA, 2024. [Google Scholar]

- Collins, W.; Parrish, K.; Gibson, G.E., Jr. Defining and understanding “small projects” in the industrial construction sector. Procedia Eng. 2017, 196, 315–322. [Google Scholar] [CrossRef]

- Yap, J.B.H.; Lee, W.K. Analysing the underlying factors affecting safety performance in building construction. Prod. Plan. Control. 2020, 31, 1061–1076. [Google Scholar] [CrossRef]

- Vinodkumar, M.; Bhasi, M. Safety management practices and safety behaviour: Assessing the mediating role of safety knowledge and motivation. Accid. Anal. Prev. 2010, 42, 2082–2093. [Google Scholar] [CrossRef] [PubMed]

- Choudhry, R.M.; Fang, D.; Ahmed, S.M. Safety management in construction: Best practices in Hong Kong. J. Prof. Iss. Eng. Ed. Pract. 2008, 134, 20–32. [Google Scholar] [CrossRef]

- Vinodkumar, M.; Bhasi, M. Safety climate factors and its relationship with accidents and personal attributes in the chemical industry. Saf. Sci. 2009, 47, 659–667. [Google Scholar] [CrossRef]

- Tam, C.M.; Zeng, S.X.; Deng, Z. Identifying elements of poor construction safety management in China. Saf. Sci. 2004, 42, 569–586. [Google Scholar] [CrossRef]

- Khalid, U.; Sagoo, A.; Benachir, M. Safety Management System (SMS) framework development–Mitigating the critical safety factors affecting Health and Safety performance in construction projects. Saf. Sci. 2021, 143, 105402. [Google Scholar] [CrossRef]

- Tappura, S.; Jääskeläinen, A.; Pirhonen, J. Creation of satisfactory safety culture by developing its key dimensions. Saf. Sci. 2022, 154, 105849. [Google Scholar] [CrossRef]

- Mirchandani, D.A.; Lederer, A.L. The impact of autonomy on information systems planning effectiveness. Omega 2008, 36, 789–807. [Google Scholar] [CrossRef]

- Nguyen, T.; Watanabe, T. Autonomous motivation for the successful implementation of waste management policy: An examination using an adapted institutional analysis and development framework in Thua Thien Hue, Vietnam. Sustainability 2020, 12, 2724. [Google Scholar] [CrossRef]

- Chen, C.F.; Chen, S.C. Measuring the effects of Safety Management System practices, morality leadership and self-efficacy on pilots’ safety behaviors: Safety motivation as a mediator. Saf. Sci. 2014, 62, 376–385. [Google Scholar] [CrossRef]

- Mitkus, S.; Mitkus, T. Causes of conflicts in a construction industry: A communicational approach. Procedia Soc. Behav. Sci. 2014, 110, 777–786. [Google Scholar] [CrossRef]

- Suraji, A.; Duff, A.R.; Peckitt, S.J. Development of causal model of construction accident causation. J. Constr. Eng. Manag. 2001, 127, 337–344. [Google Scholar] [CrossRef]

- Guo, B.H.; Yiu, T.W. Developing leading indicators to monitor the safety conditions of construction projects. J. Manag. Eng. 2016, 32, 04015016. [Google Scholar] [CrossRef]

- Hallowell, M.R.; Hinze, J.W.; Baud, K.C.; Wehle, A. Proactive construction safety control: Measuring, monitoring, and responding to safety leading indicators. J. Constr. Eng. Manag. 2013, 139, 04013010. [Google Scholar] [CrossRef]

- Hallowell, M.R.; Gambatese, J.A. Construction safety risk mitigation. J. Constr. Eng. Manag. 2009, 135, 1316–1323. [Google Scholar] [CrossRef]

- Fonseca, E.D.; Lima, F.P.; Duarte, F. From construction site to design: The different accident prevention levels in the building industry. Saf. Sci. 2014, 70, 406–418. [Google Scholar] [CrossRef]

- Wanberg, J.; Harper, C.; Hallowell, M.R.; Rajendran, S. Relationship between construction safety and quality performance. J. Constr. Eng. Manag. 2013, 139, 04013003. [Google Scholar] [CrossRef]

- Jiang, Z.; Fang, D.; Zhang, M. Understanding the causation of construction workers’ unsafe behaviors based on system dynamics modeling. J. Manag. Eng. 2015, 31, 04014099. [Google Scholar] [CrossRef]

- Chen, Q.; Jin, R. Multilevel safety culture and climate survey for assessing new safety program. J. Constr. Eng. Manag. 2013, 139, 805–817. [Google Scholar] [CrossRef]

- Feng, Y. Effect of safety investments on safety performance of building projects. Saf. Sci. 2013, 59, 28–45. [Google Scholar] [CrossRef]

- Feng, Y. Mathematical models for determining the minimum level of voluntary safety investments for building projects. J. Constr. Eng. Manag. 2015, 141, 04015015. [Google Scholar] [CrossRef]

- Han, S.; Saba, F.; Lee, S.; Mohamed, Y.; Peña-Mora, F. Toward an understanding of the impact of production pressure on safety performance in construction operations. Anal. Prev. 2014, 68, 106–116. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, A.; Tavakolan, M. Construction project risk assessment using combined fuzzy and FMEA. In Proceedings of the 2013 Joint IFSA World Congress and NAFIPS Annual Meeting (IFSA/NAFIPS), Edmonton, AB, Canada, 24–28 June 2013. [Google Scholar]

- Khosravi, Y.; Asilian-Mahabadi, H.; Hajizadeh, E.; Hassanzadeh-Rangi, N.; Bastani, H.; Behzadan, A.H. Factors influencing unsafe behaviors and accidents on construction sites: A review. Int. J. Occup. Saf. Ergon. 2014, 20, 111–125. [Google Scholar] [CrossRef]

- Choudhry, R.M. Achieving safety and productivity in construction projects. J. Civ. Eng. Manag. 2017, 23, 311–318. [Google Scholar] [CrossRef]

- Zou, P.X.; Sunindijo, R.Y. Strategic Safety Management in Construction and Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Mitropoulos, P.; Abdelhamid, T.S.; Howell, G.A. Systems model of construction accident causation. J. Constr. Eng. Manag. 2005, 131, 816–825. [Google Scholar] [CrossRef]

- Karthick, S.; Kermanshachi, S.; Pamidimukkala, A. Analysis of the health and safety challenges faced by construction workers in extreme hot weather conditions. J. Leg. Aff. Dispute Resolut. Eng. Constr. 2023, 15, 04522048. [Google Scholar] [CrossRef]

- Ng, S.T.; Cheng, K.P.; Skitmore, R.M. A framework for evaluating the safety performance of construction contractors. Build. Environ. 2005, 40, 1347–1355. [Google Scholar]

- Terwel, K.C.; Jansen, S.J. Critical factors for structural safety in the design and construction phase. J. Perform. Constr. Facil. 2015, 29, 04014068. [Google Scholar] [CrossRef]

- Gariazzo, C.; Taiano, L.; Bonafede, M.; Leva, A.; Morabito, M.; De’Donato, F.; Marinaccio, A. Association between extreme temperature exposure and occupational injuries among construction workers in Italy: An analysis of risk factors. Environ. Int. 2023, 171, 107677. [Google Scholar] [CrossRef] [PubMed]

- Duan, P.; Goh, Y.M.; Zhou, J. The impact of COVID-19 pandemic on construction safety in China and the US: A comparative study. Saf. Sci. 2023, 161, 106076. [Google Scholar] [CrossRef] [PubMed]

- Asanka, W.; Ranasinghe, M. Study on the impact of accidents on construction projects. In Proceedings of the 6th International Conference on Structural Engineering and Construction Management, Kandy, Sri Lanka, 11–13 December 2015; pp. 58–67. [Google Scholar]

| Variables | SD | Safety Officers’ Satisfaction | Project Managers’ Satisfaction | Project Owners’ Satisfaction | |

|---|---|---|---|---|---|

| Safety officers’ satisfaction | 4.036 | 0.770 | 1.000 | ||

| Project managers’ satisfaction | 3.886 | 0.797 | 0.748 ** | 1.000 | |

| Project owners’ satisfaction | 4.120 | 0.761 | 0.717 ** | 0.682 ** | 1.000 |

| Variable | SD | Satisfaction | TRIR | |

|---|---|---|---|---|

| Satisfaction | 3.976 | 0.717 | 1.000 | |

| TRIR | 237.107 | 3247.503 | 0.102 | 1.000 |

| Model | AIC | BIC | Entropy | BLRT |

|---|---|---|---|---|

| 1-class model | 355.000 | 361.220 | 1.000 | |

| 2-class model | 351.830 | 364.280 | 0.670 | 0.030 |

| 3-class model | 330.730 | 349.400 | 0.900 | 0.010 |

| No. | N | Mean | SD | Minimum | Maximum |

|---|---|---|---|---|---|

| Low satisfaction | 38 | 3.000 | 0.347 | 1.667 | 3.333 |

| Moderate satisfaction | 87 | 4.038 | 0.206 | 3.667 | 4.333 |

| High satisfaction | 41 | 4.902 | 0.154 | 4.667 | 5.000 |

| Total | 166 | 4.014 | 0.699 | 1.667 | 5.000 |

| Model | AIC | BIC | Entropy | BLRT |

|---|---|---|---|---|

| 1-class model | 798.192 | 804.416 | 1 | |

| 2-class model | 696.959 | 709.407 | 0.946 | 0.010 |

| 3-class model | 700.958 | 719.630 | 0.457 | 0.010 |

| 4-class model | 704.959 | 729.855 | 0.309 | 1.000 |

| 5-class model | 637.357 | 668.477 | 0.491 | 0.010 |

| 6-class model | 641.356 | 678.700 | 0.422 | 0.010 |

| 7-class model | 617.812 | 661.379 | 0.499 | 0.010 |

| 8-class model | 621.812 | 671.604 | 0.454 | 1.000 |

| 9-class model | 606.084 | 662.100 | 0.533 | 0.010 |

| Model | AIC | BIC | Entropy | BLRT |

|---|---|---|---|---|

| 1-class model | 451.085 | 457.053 | 1 | |

| 2-class model | 377.101 | 389.036 | 0.955 | 0.010 |

| 3-class model | 381.11 | 399.012 | 0.454 | 1.000 |

| 4-class model | 324.692 | 348.561 | 0.677 | 0.010 |

| 5-class model | 328.692 | 358.528 | 0.565 | 0.762 |

| 6-class model | 289.142 | 324.945 | 0.668 | 0.010 |

| 7-class model | 283.988 | 325.758 | 0.694 | 0.020 |

| 8-class model | 287.985 | 335.723 | 0.657 | 0.059 |

| 9-class model | 292.024 | 345.728 | 0.674 | 0.980 |

| TRIR | N | Mean | SD | Minimum | Maximum |

|---|---|---|---|---|---|

| Low TRIR | 129 | 0.398 | 0.567 | 0.000 | 2.080 |

| Moderate TRIR | 17 | 3.332 | 0.879 | 2.260 | 4.630 |

| High TRIR | 20 | 7.712 | 2.563 | 4.840 | 13.390 |

| Total | 166 | 1.580 | 2.654 | 0.000 | 13.390 |

| Variables | Profile 1 (n = 18) | Profile 2 (n = 67) | Profile 3 (n = 21) | Profile 4 (n = 7) | Profile 5 (n = 12) | Profile 6 (n = 8) | ANOVA (sig.) |

|---|---|---|---|---|---|---|---|

| Project budget (Million USD) | 4.187 | 19.265 | 10.608 | 5.984 | 67.357 | 0.937 | 0.000 |

| Point of View | Safety-Related Tasks | Items | Sources |

|---|---|---|---|

| Plan | 1. Planning safety programs |

| [6,17] |

| Do | 2. Execution for workers |

| [6,17,26] |

| [14,27,28] | ||

| [27,28] | ||

| [6,14,17,27] | ||

| [6,16,17] | ||

| [6,16,17,29] | ||

| [27] | ||

| 3. Execution for supervisors |

| [6,17] | |

| [6,17] | ||

| [6,17] | ||

| 4. Execution for all individuals |

| [14,17,30] | |

| [6,17] | ||

| [26,28] | ||

| [6] | ||

| [6,14,17,28] | ||

| [6,17,28] | ||

| See | 5. Safety evaluation |

| [14,31] |

| Rule | 6. Safety act/regulation |

| [6,17,27,31] |

| Variables | Profile 1 (n = 18) | Profile 4 (n = 7) | Profile 6 (n = 8) | ANOVA (sig.) | |

|---|---|---|---|---|---|

| Support | Autonomy support | 4.037 | 3.000 | 3.375 | 0.021 |

| Competency support | 3.907 | 2.857 | 3.500 | 0.056 | |

| Relatedness support | 4.056 | 3.095 | 3.667 | 0.069 | |

| Motivation | Autonomous motivation | 4.403 | 3.714 | 4.141 | 0.017 |

| Controlled motivation | 3.269 | 2.548 | 3.188 | 0.100 | |

| Amotivation | 1.444 | 1.714 | 1.750 | 0.546 | |

| Engagement | Safety plan | 4.407 | 3.524 | 4.042 | 0.004 |

| Implementation for workers | 4.566 | 3.701 | 3.946 | 0.001 | |

| Implementation for site supervisors | 4.611 | 3.413 | 4.056 | 0.001 | |

| Implementation for all individuals | 4.587 | 3.855 | 4.215 | 0.003 | |

| Safety evaluation | 4.574 | 3.381 | 3.875 | 0.000 | |

| Safety regulation | 4.759 | 4.190 | 4.792 | 0.036 |

| Variables | Profile 2 (n = 67) | Profile 3 (n = 21) | Profile 5 (n = 12) | ANOVA (sig.) | |

|---|---|---|---|---|---|

| Support | Autonomy support | 4.264 | 3.444 | 3.667 | 0.000 |

| Competency support | 4.244 | 3.270 | 3.583 | 0.000 | |

| Relatedness support | 4.338 | 3.175 | 3.583 | 0.000 | |

| Motivation | Autonomous motivation | 4.500 | 4.089 | 4.573 | 0.001 |

| Controlled motivation | 3.082 | 2.992 | 2.820 | 0.703 | |

| Amotivation | 1.786 | 1.779 | 1.361 | 0.452 | |

| Engagement | Safety plan | 4.612 | 4.270 | 4.500 | 0.084 |

| Implementation for workers | 4.579 | 4.163 | 4.234 | 0.004 | |

| Implementation for site supervisor | 4.491 | 4.026 | 3.935 | 0.003 | |

| Implementation for all individuals | 4.622 | 4.159 | 4.281 | 0.003 | |

| Safety evaluation | 4.632 | 3.889 | 4.000 | 0.000 | |

| Safety regulation | 4.736 | 4.444 | 4.278 | 0.020 | |

| Variables | Profile 1 (n = 18) | Profile 2 (n = 67) | Profile 3 (n = 21) | Profile 4 (n = 7) | Profile 5 (n = 12) | Profile 6 (n = 8) |

|---|---|---|---|---|---|---|

| Satisfaction | 4.259 | 4.363 | 3.016 | 2.905 | 3.583 | 3.917 |

| TRIR | 5.399 | 0.358 | 0.715 | 6.334 | 5.374 | 51.445 |

| Profile 1 (n = 18) | Profile 4 (n = 7) | Profile 6 (n = 8) | ANOVA (sig.) | |

|---|---|---|---|---|

| Engagement score | 4.562 | 3.709 | 4.106 | 0.001 |

| No. | Cause of Conflict | Resolution by Safety Officers |

|---|---|---|

| Profile 1 #25 | Permission to work | Explain the rationale and negotiate with the owner |

| Exposure to hazards | Facilitate by overseeing and monitoring the situation | |

| Profile 1 #128 | No conflict | NA |

| Profile 1 #154 | Reliance on safety officer’s expertise | Encourage learning while closely monitoring |

| Profile 4 #41 | Engineering supervision | Discuss and attempt to understand |

| Permission to work | Facilitate by negotiating with the project owner | |

| Profile 4 #124 | Reliance on safety officer’s expertise | Discuss and gently remind, and understand the nature |

| Compromise of safety with productivity | Discuss and gently remind, and understand the nature | |

| Profile 4 #222 | Reliance on safety officer’s expertise | Discuss with reason supported by owner statement |

| Profile 6 #38 | Engineering supervision | Fight with supervisors, and refute a supervisor’s argument by referring to the law |

| Gender discrimination | Fight with supervisors, and refute a supervisor’s argument by referring to the law | |

| Profile 6 #96 | No conflicts | NA |

| Profile 6 #98 | No conflicts | NA |

| No. | Cause of Conflict with Workers | Resolution by Safety Officers |

|---|---|---|

| Profile 1 #25 | Safety issues-related understanding | Discuss by providing reasons |

| Profile 1 #128 | Safety issues-related understanding | Warn by using humor |

| Profile 1 #154 | Miscommunication | Discuss by providing reasons |

| Profile 4 #41 | PPE issue | Warn by using humor |

| Profile 4 #124 | PPE issue | Warn and attempt to understand |

| Profile 4 #222 | PPE issue | Warn, inform supervisors, be flexible, and create strong relationships with workers |

| Profile 6 #38 | No issue | NA |

| Profile 6 #96 | PPE issue | Let the site engineer/foreman deal with the conflict resolution |

| Profile 6 #98 | Improper working style | Discuss by providing reason, try to be flexible, and retrain workers |

| Respondent | Presence of Untrained Workers | COVID-19 | Weather Conditions |

|---|---|---|---|

| Profile 1 #25 | Proactive strategy | Reactive strategy | Proactive strategy |

| Profile 1 #128 | Proactive strategy | NA | NA |

| Profile 1 #154 | Reactive strategy | NA | Proactive strategy |

| Profile 4 #41 | Proactive strategy | Reactive strategy | NA |

| Profile 4 #124 | Proactive strategy | NA | Proactive strategy |

| Profile 4 #222 | Proactive strategy | Reactive strategy | Proactive strategy |

| Profile 6 #38 | Reactive strategy | NA | Reactive strategy |

| Profile 6 #96 | Reactive strategy | NA | NA |

| Profile 6 #98 | Reactive strategy | Reactive strategy | Reactive strategy |

| Respondent | Autonomy | Competency | Relatedness | Counting | Percentage of Support |

|---|---|---|---|---|---|

| Profile 1 #25 | Yes | Yes | Yes | 3/3 | 100% |

| Profile 1 #128 | Yes | Yes | Yes | 3/3 | |

| Profile 1 #154 | Yes | Yes | Yes | 3/3 | |

| Profile 4 #41 | Yes | Yes | Yes | 3/3 | 100% |

| Profile 4 #124 | Yes | Yes | Yes | 3/3 | |

| Profile 4 #222 | Yes | Yes | Yes | 3/3 | |

| Profile 6 #38 | Yes | Yes | Yes | 3/3 | 66.667% (partial support) |

| Profile 6 #96 | Yes | No | No | 1/3 | |

| Profile 6 #98 | Yes | Yes | No | 2/3 |

| Profile 1 (n = 18) | Profile 4 (n = 7) | Profile 6 (n = 8) | ANOVA (sig.) | ||

|---|---|---|---|---|---|

| Engagement score | 4.562 | 3.709 | 4.106 | 0.001 | |

| Strategy to solve conflict | Effective | Effective | Ineffective | – | |

| Management of unexpected events | Appropriate (Proactive) | Appropriate (Proactive) | Inappropriate (Reactive) | – | |

| Support | Autonomy | 4.037 | 3.000 | 3.375 | 0.021 |

| Competency | 3.907 | 2.857 | 3.500 | 0.056 | |

| Relatedness | 4.056 | 3.095 | 3.667 | 0.069 | |

| % of support by interview | 100% | 100% | 66.7% (partial) | – | |

| Rating | Fair | Underrating | Overrating | – | |

| Characteristics | Realistic | High expectation | Perceived flexibility | – | |

| No. | Did Fatalities Occur? | Reaction from Project Managers | Reaction from Project Owners |

|---|---|---|---|

| Profile 2 #48 | No | NA | NA |

| Profile 2 #79 | No | NA | NA |

| Profile 2 #97 | No | NA | NA |

| Profile 3 #24 | No | NA | NA |

| Profile 3 #54 | No | NA | NA |

| Profile 3 #199 | No | NA | NA |

| Profile 5 #17 | Yes | Stricter rules: “After the incident, stricter measures were designed in the project. If we were to move the crane, we would have to have a mechanical engineer on site until the work was completed. The project manager ordered that the project engineer, who is involved in the mechanical side, must be stationed to supervise work, such as the installation of the Tower Crane.” | Frequent inspection: “The owner also came to supervise the work. He came to check how work was all the time. Regarding the training for the card, it was more intensive. He came to check before going up to work every time until the work was finished or until the project was finished.” |

| Profile 5 #26 | Yes | Frequent inspection and reform safety training course: “Action from the project manager action is better; there are more frequent site inspections, and there is also training, better site walking, and more attention. And then the correctness of safety equipment and training, it’s like it’s more intensive.” | Intensive involvement in safety requests from the contractor side: “The project owners became more involved after the death rate on construction sites increased. Requests from contractors are well received.” |

| Profile 5 #32 | Yes | Appointing authority to support safety officers: “Both the owner and my project manager play a role in appointing the authorities to support the safety work I was doing.” | Support statement of safety officers: “I demanded that both the owner and my project manager appoint the authorities to support the safety work that I was doing. I was able to use the owner’s or project manager’s requirements as a reason for the workers and foreman to follow the safety requirements.” Finding the root cause of accidents and soliciting opinions about safety: “The project owner also became more involved and dedicated more attention to the details of the safety aspects, as shown by his attempt to investigate and have more conversations about safety.” |

| Profile 2 (n = 67) | Profile 3 (n = 21) | Profile 5 (n = 12) | ANOVA (sig.) | |

|---|---|---|---|---|

| Engagement score | 4.585 | 4.132 | 4.221 | 0.002 |

| Respondent | Conflict with Supervisors | Solution of Safety Officers |

|---|---|---|

| Profile 2 #48 | PPE issue | Request a supervisor to bring PPE while another member helps mediate the situation |

| Profile 2 #79 | Engineering supervision | Request a supervisor to stop; warnings in minor cases |

| Profile 2 #97 | Safety budget (expensive equipment) | Support some parts while helping in the search for effective equipment |

| Profile 3 #24 | Improper working styles | Discuss and negotiate with a supervisor |

| Profile 3 #54 | No conflict | NA |

| Profile 3 #199 | Improper working style | Discuss a supervisor |

| Profile 5 #17 | Working conditions (extra installation) | Recommend choices to a supervisor but no cooperation |

| Profile 5 #26 | Compromising safety for productivity | Take picture and wait for the meeting |

| Improper working style | Report to PM and request to terminate the contract | |

| Profile 5 #32 | Trust in the ability of safety officers | Negotiate with a supervisor |

| Compromising safety for productivity | Terminate the contract |

| Respondent | Conflict with Workers | Solution by Safety Officers |

|---|---|---|

| Profile 2 #48 | No issue | No action |

| Profile 2 #79 | Issue regarding understanding of safety | Warn workers and reject if necessary |

| Profile 2 #97 | PPE issue | Discuss rationally |

| Profile 3 #24 | PPE issue | Discuss rationally |

| Profile 3 #54 | PPE issue | Understand the nature of the issue and support workers |

| Profile 3 #199 | PPE issue | Claiming the agreement and providing sufficient training |

| Profile 5 #17 | PPE issue | Warning |

| Profile 5 #26 | Misconception on safety | Providing high-quality care |

| Profile 5 #32 | Communication with foreign workers | Fighting back |

| Addiction to drugs | No action |

| Respondent | Presence of Untrained Workers | COVID-19 | Weather Condition |

|---|---|---|---|

| Profile 2 #48 | Proactive strategy | NA | Reactive strategy |

| Profile 2 #79 | Proactive strategy | Reactive strategy | Proactive strategy |

| Profile 2 #97 | Reactive strategy | NA | Reactive strategy |

| Profile 3 #24 | Proactive strategy | Proactive strategy | Proactive strategy |

| Profile 3 #54 | Reactive strategy | Reactive strategy | Reactive strategy |

| Profile 3 #199 | Proactive strategy | Proactive strategy | Proactive strategy |

| Profile 5 #17 | Proactive strategy | Reactive strategy | Reactive strategy |

| Profile 5 #26 | Proactive strategy | NA | Reactive strategy |

| Profile 5 #32 | Reactive strategy | Proactive strategy | Reactive strategy |

| Respondent | Relatedness | Autonomy | Competency | Total Count | Percentage of Support |

|---|---|---|---|---|---|

| Profile 2 #48 | Yes | Yes | Yes | 3/3 | 100% |

| Profile 2 #79 | Yes | Yes | Yes | 3/3 | |

| Profile 2 #97 | Yes | Yes | Yes | 3/3 | |

| Profile 3 #24 | Yes | Yes | Yes | 3/3 | 100% |

| Profile 3 #54 | Yes | Yes | Yes | 3/3 | |

| Profile 3 #199 | Yes | Yes | Yes | 3/3 | |

| Profile 5 #17 | Yes | Yes | Yes | 3/3 | 88.889% (partial support) |

| Profile 5 #26 | Yes | Yes | No | 2/3 | |

| Profile 5 #32 | Yes | Yes | Yes | 3/3 |

| Profile 2 (n = 67) | Profile 3 (n = 21) | Profile 5 (n = 12) | ANOVA (sig.) | ||

|---|---|---|---|---|---|

| Engagement score | 4.585 | 4.132 | 4.221 | 0.002 | |

| Strategy to solve conflicts | Effective | Effective | Develop problem-solving skills through fatality cases | -- | |

| Management of unexpected events | Appropriate (mainly proactive) | Appropriate (mainly proactive) | -- | ||

| Support | Autonomy | 4.264 | 3.444 | 3.667 | 0.000 |

| Competency | 4.244 | 3.270 | 3.583 | 0.000 | |

| Relatedness | 4.338 | 3.175 | 3.583 | 0.000 | |

| % of support by interview | 100% | 100% | 88.889% (partial) | -- | |

| Rating | Fair | Underrated | Dynamic change | -- | |

| Characteristics | Realistic | High expectations | Learning characteristics | -- | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khun-anod, K.; Watanabe, T.; Tsuchiya, S. Understanding the Relationship Between Safety Satisfaction and Total Recordable Incident Rate (TRIR), and Their Relevant Processes Through Self-Determination Theory. Buildings 2025, 15, 1274. https://doi.org/10.3390/buildings15081274

Khun-anod K, Watanabe T, Tsuchiya S. Understanding the Relationship Between Safety Satisfaction and Total Recordable Incident Rate (TRIR), and Their Relevant Processes Through Self-Determination Theory. Buildings. 2025; 15(8):1274. https://doi.org/10.3390/buildings15081274

Chicago/Turabian StyleKhun-anod, Kritsada, Tsunemi Watanabe, and Satoshi Tsuchiya. 2025. "Understanding the Relationship Between Safety Satisfaction and Total Recordable Incident Rate (TRIR), and Their Relevant Processes Through Self-Determination Theory" Buildings 15, no. 8: 1274. https://doi.org/10.3390/buildings15081274

APA StyleKhun-anod, K., Watanabe, T., & Tsuchiya, S. (2025). Understanding the Relationship Between Safety Satisfaction and Total Recordable Incident Rate (TRIR), and Their Relevant Processes Through Self-Determination Theory. Buildings, 15(8), 1274. https://doi.org/10.3390/buildings15081274