Effect of Low-Grade Calcined Clay on the Durability Performance of Blended Cement Mortar

Abstract

1. Introduction

2. Experimental Plan

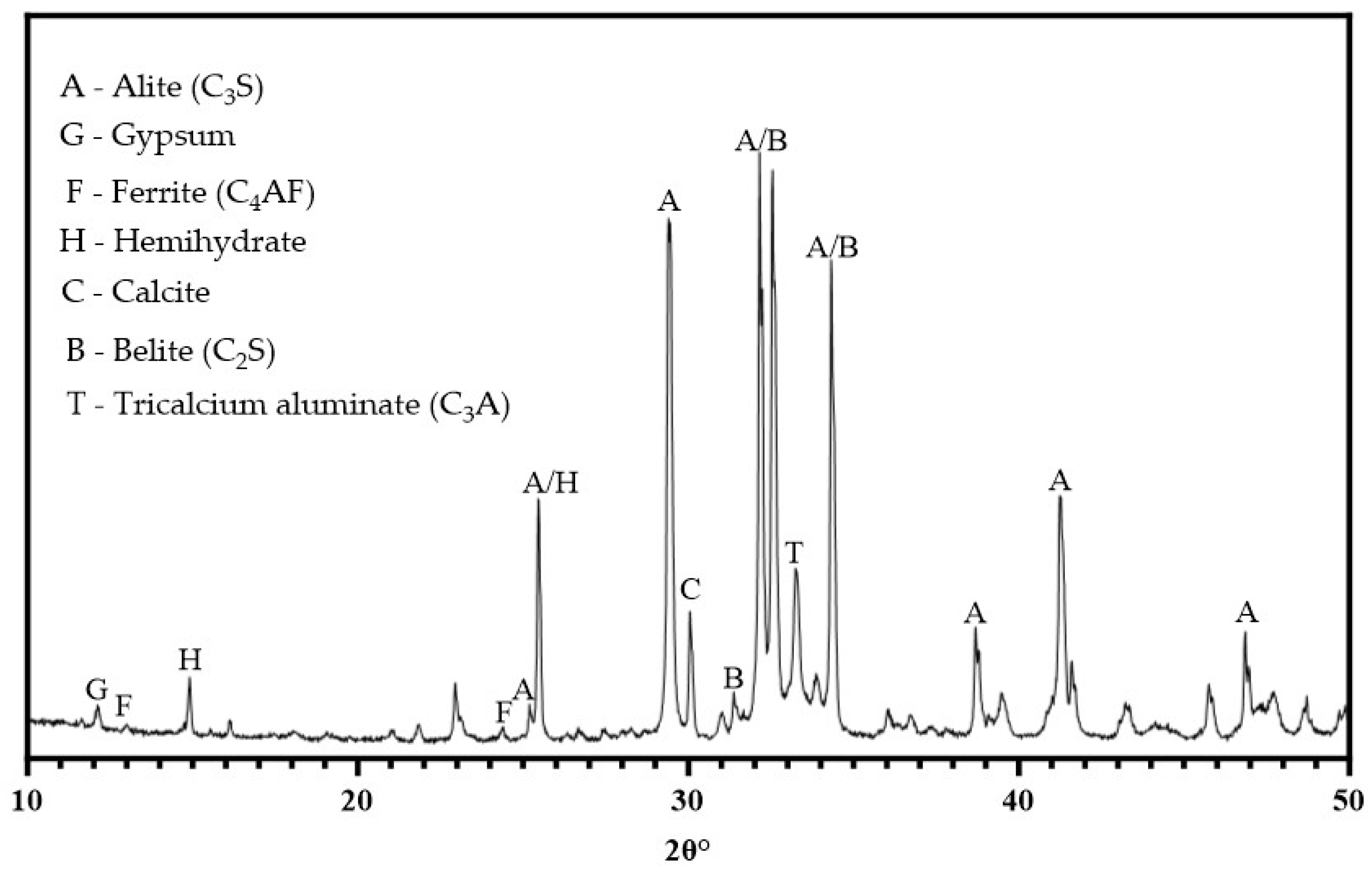

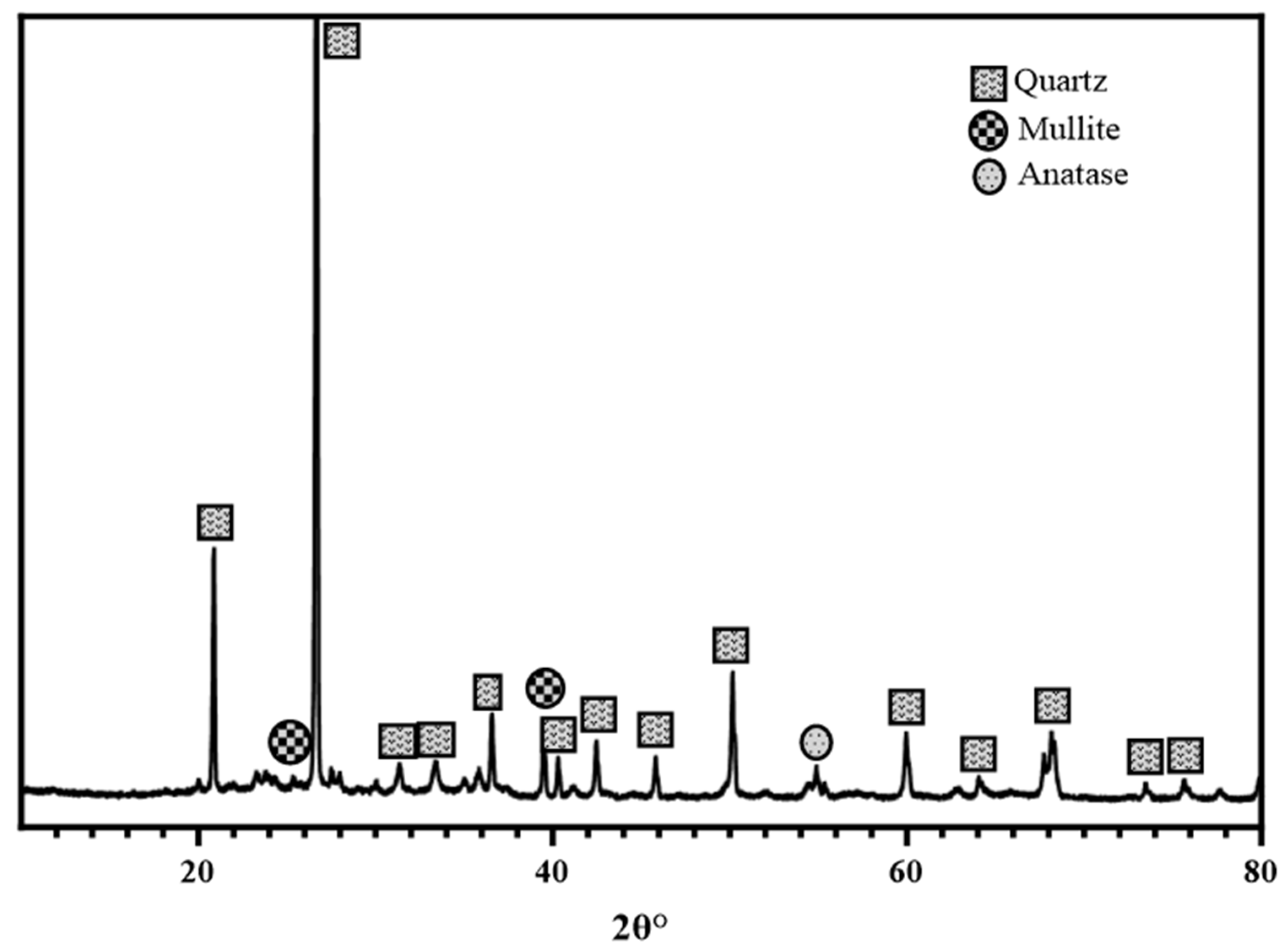

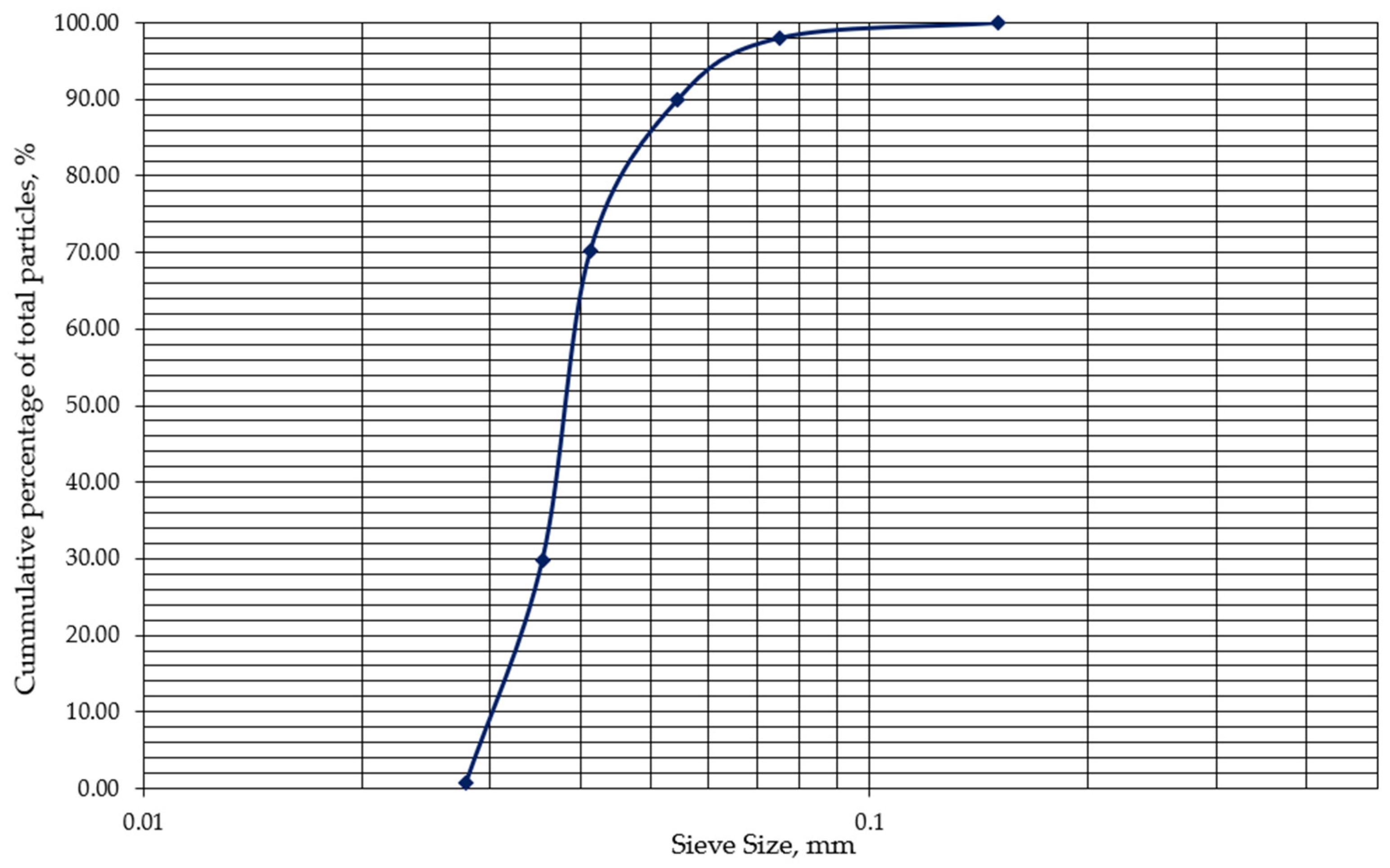

2.1. Materials

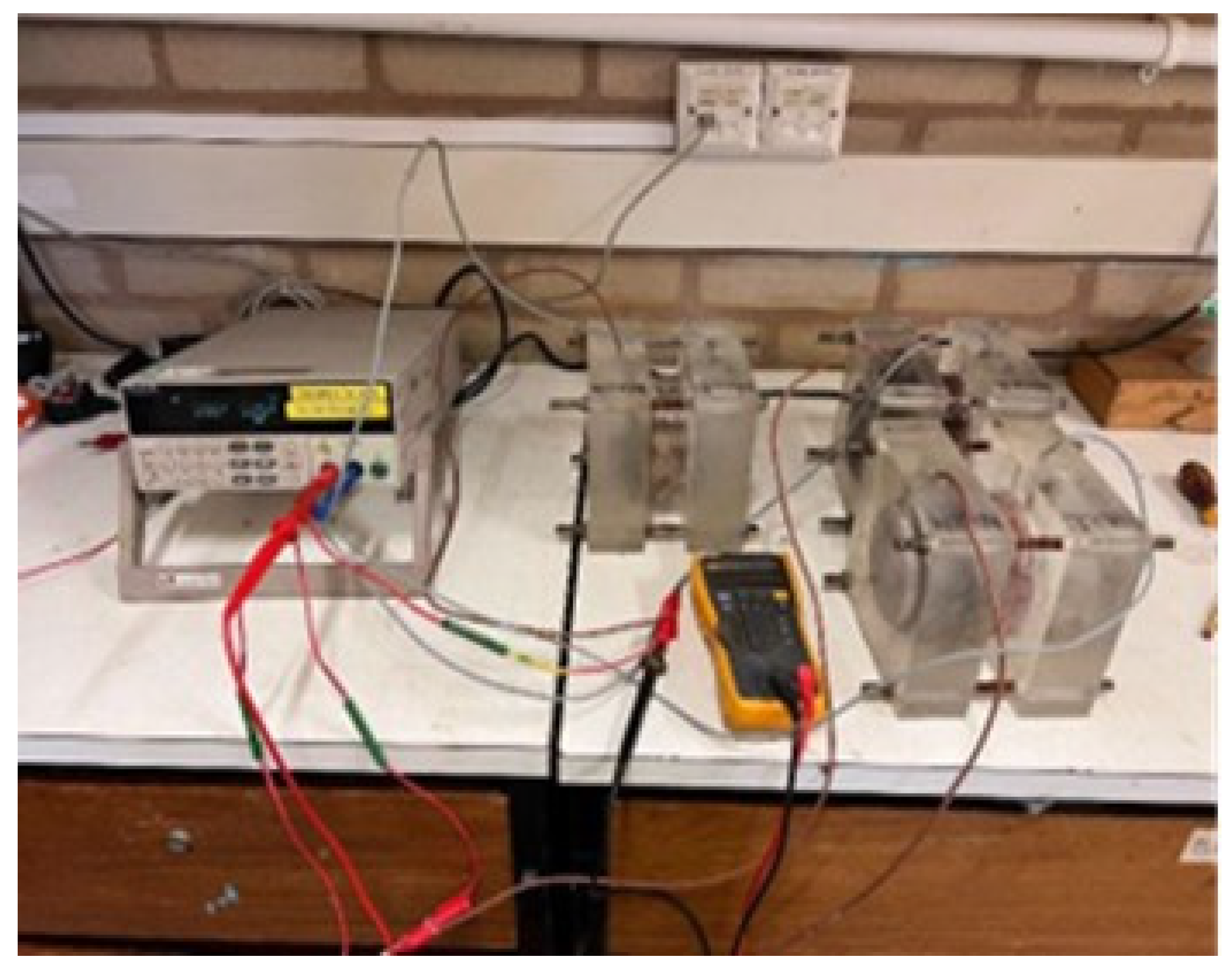

2.2. Methods

2.2.1. Rapid Chloride Penetration Test

2.2.2. Freeze and Thaw Test

2.2.3. Sorptivity and Permeable Porosity Test

2.2.4. Ultrasonic Pulse Velocity

2.2.5. Autogenous Shrinkage

3. Results and Discussion

3.1. Sorptivity and Permeable Porosity

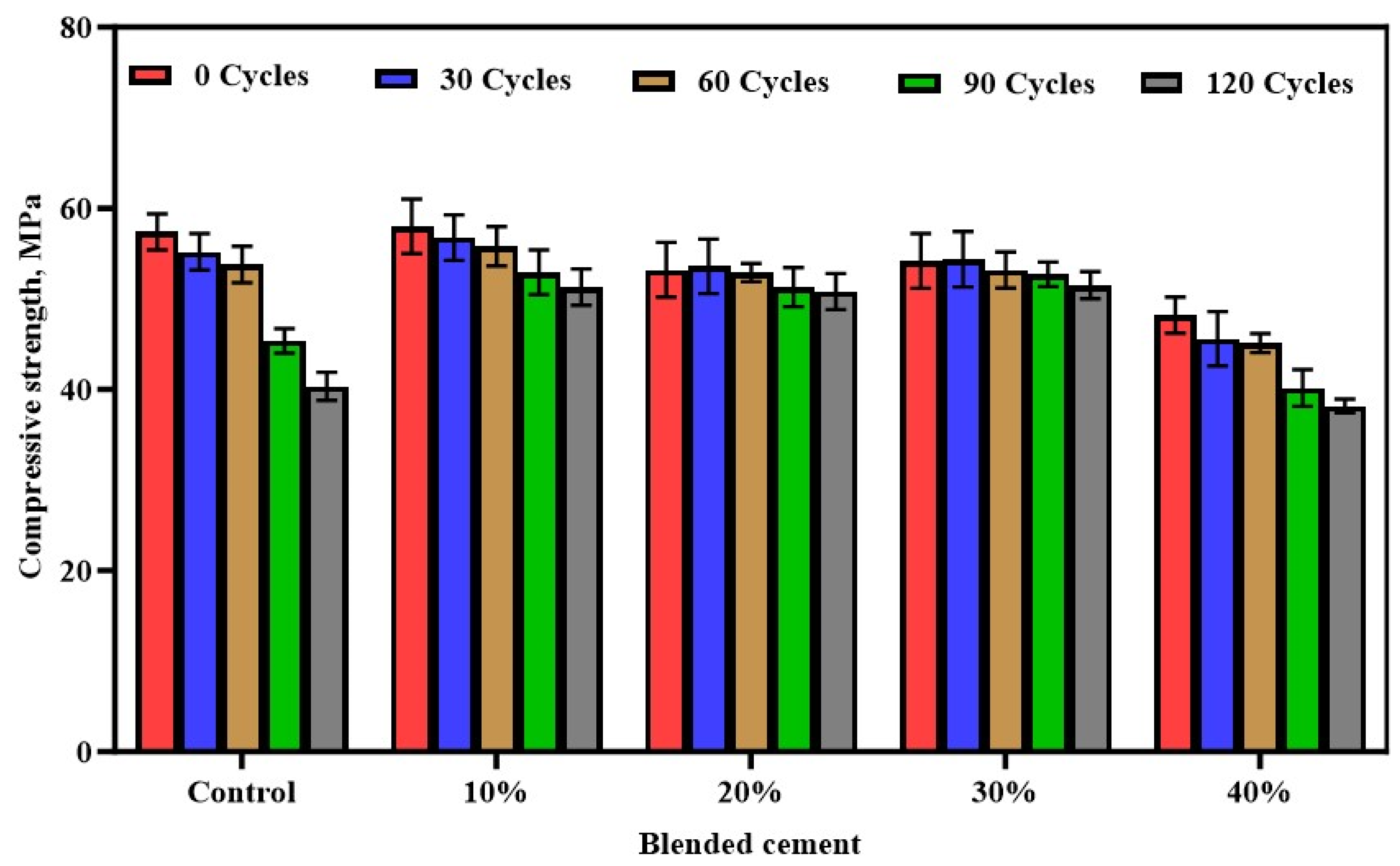

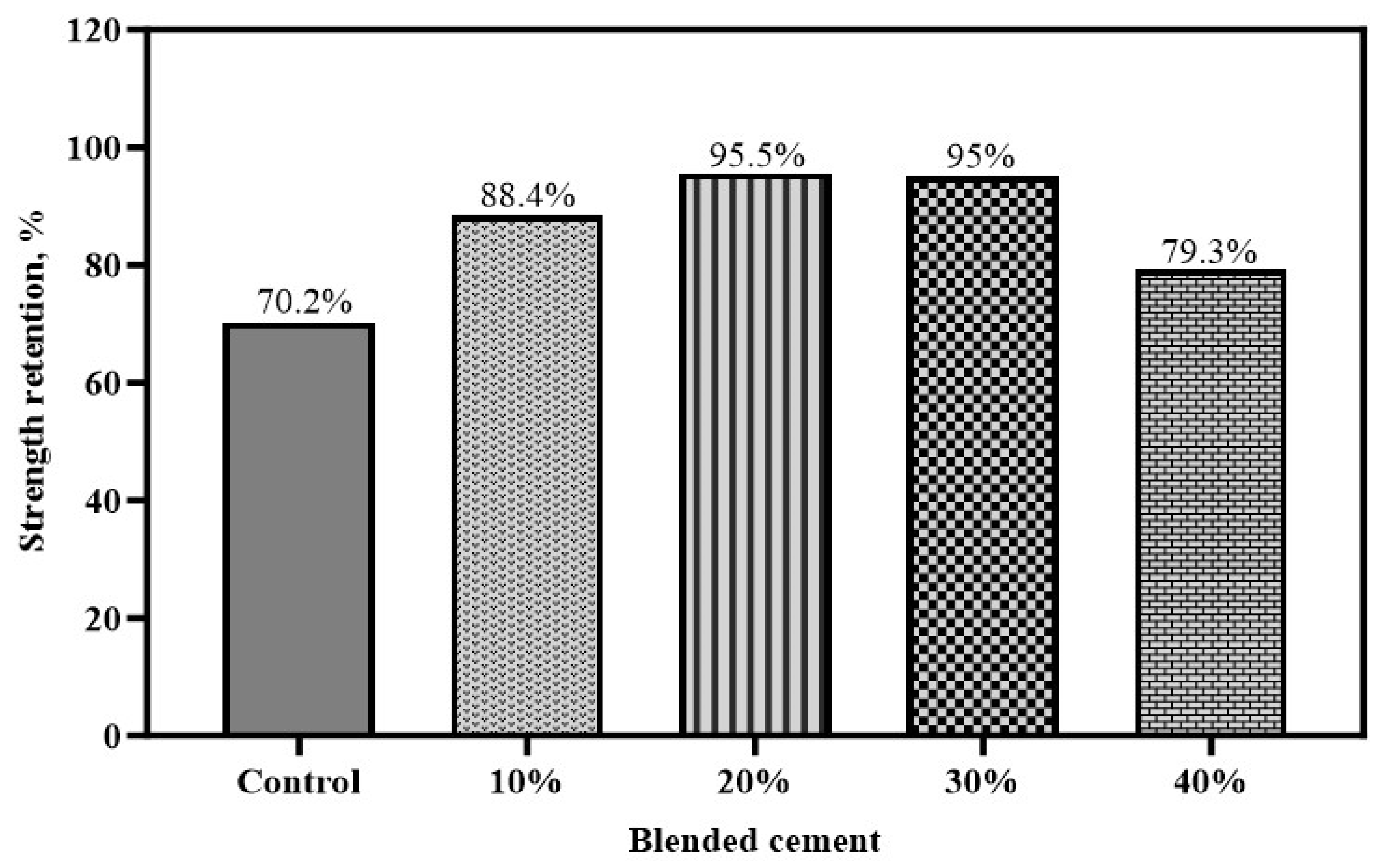

3.2. Resistance to Freeze and Thaw

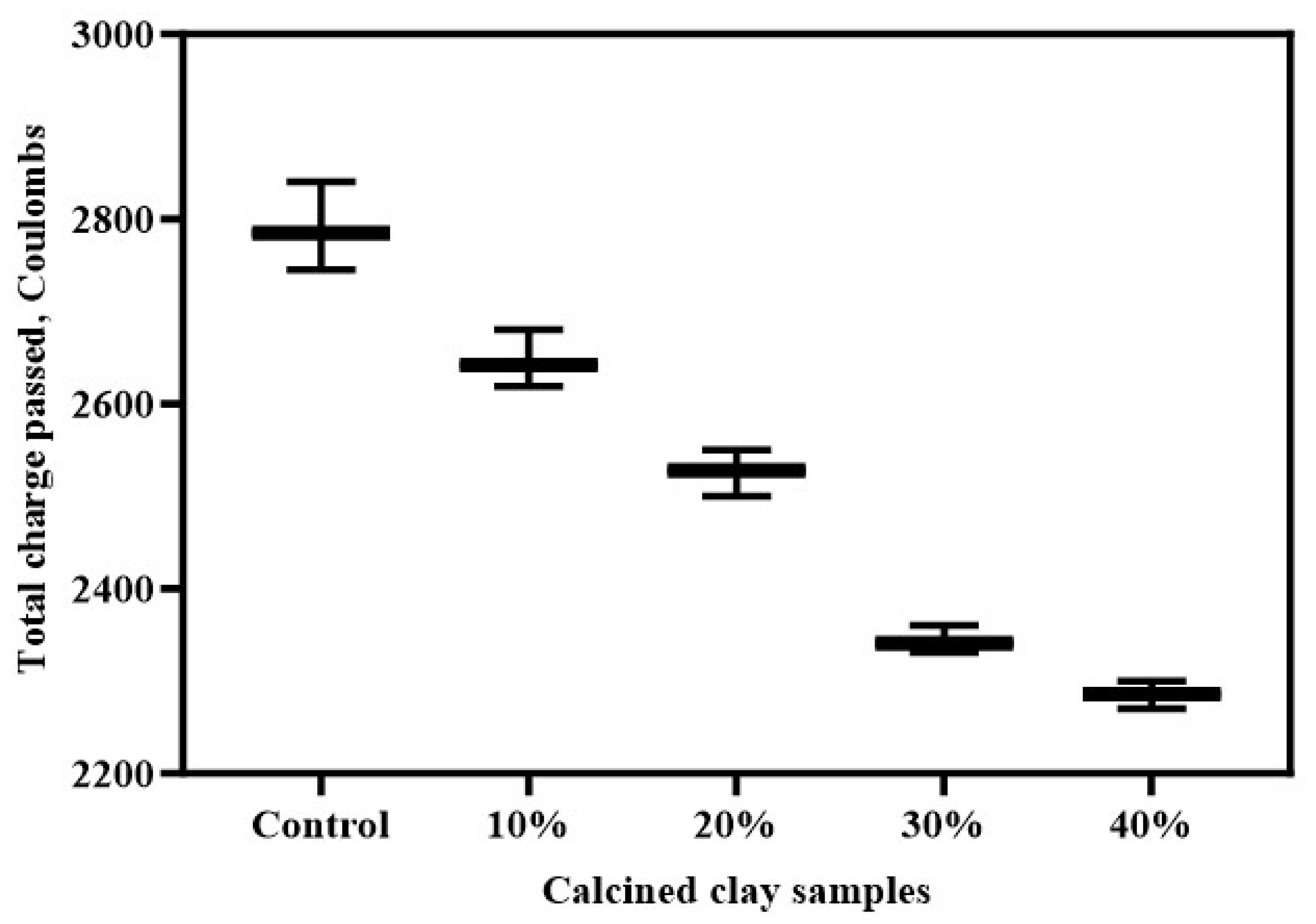

3.3. Chloride Permeability

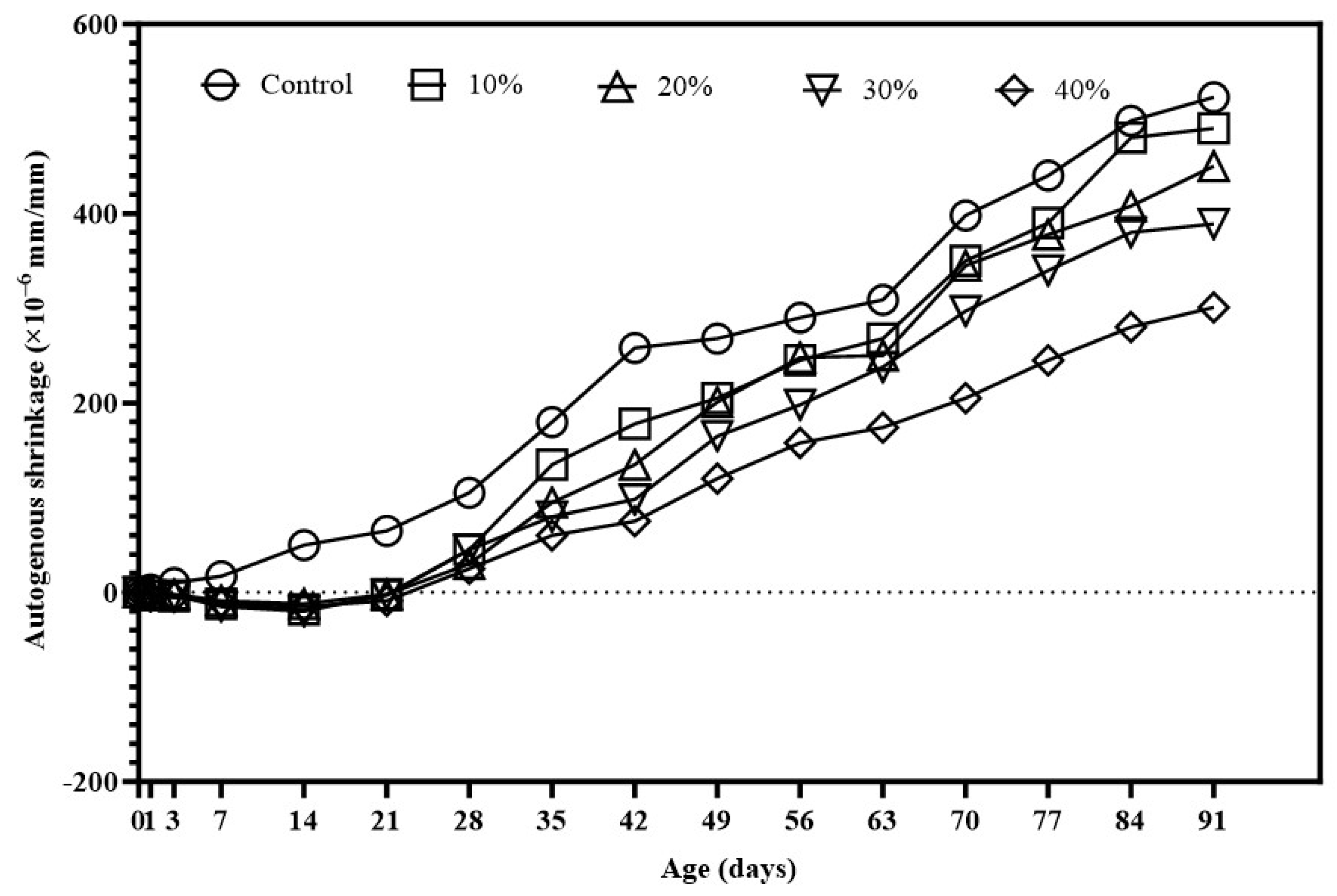

3.4. Autogenous Shrinkage

3.5. Ultrasonic Pulse Velocity

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterization, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Aghamohammadi, O.; Mostofinejad, D.; Mostafaei, H.; Abtahi, S.M. Mechanical properties and impact resistance of concrete pavement containing crumb rubber. Int. J. Geomech. 2024, 24, 04023242. [Google Scholar] [CrossRef]

- Aprianti, S.E. A huge number of artificial waste material can be supplementary cementitious material (SCM) for concrete production—A review part II. J. Clean. Prod. 2017, 142, 4178–4194. [Google Scholar] [CrossRef]

- Sarfo-Ansah, J.; Atiemo, E.; Bediako, M.; Tagbor, T.A.; Boakye, K.A.; Adjei, D. The influence of calcined clay pozzolan, low-CaO steel slag and granite dust on the alkali-silica reaction in concrete. J. Eng. Res. Appl. 2015, 5, 19–27. [Google Scholar]

- Emmanuel, A.C.; Bishnoi, S. Effect of curing temperature and clinker content on hydration and strength development of calcined clay blends. Adv. Cem. Res. 2023, 35, 12–25. [Google Scholar] [CrossRef]

- Fernandez, R.; Martirena, F.; Scrivener, K.L. The origin of the pozzolanic activity of calcined clay minerals: A comparison between kaolinite, illite and montmorillonite. Cem. Concr. Res. 2011, 41, 113–122. [Google Scholar] [CrossRef]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined clay limestone cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Kijjanon, A.; Sumranwanich, T.; Tangtermsirikul, S. Influences of metakaolin and calcined clay blended cement on chloride resistance and electrical resistivity of concrete. Adv. Cem. Res. 2024, 37, 24–37. [Google Scholar] [CrossRef]

- Shah, V.; Parashar, A.; Mishra, G.; Medepalli, S.; Krishnan, S.; Bishnoi, S. Influence of cement replacement by limestone calcined clay pozzolan on the engineering properties of mortar and concrete. Adv. Cem. Res. 2020, 32, 101–111. [Google Scholar] [CrossRef]

- Hollanders, S.; Adriaens, R.; Skibsted, J.; Cizer, Ö.; Elsen, J. Pozzolanic reactivity of pure calcined clays. Appl. Clay. Sci. 2016, 132–133, 552–560. [Google Scholar] [CrossRef]

- Tagbor, T.A.; Boakye, K.A.; Sarfo-Ansah, J.; Atiemo, E. A study of the pozzolanic properties of Anfoega Kaolin. Int. J. Eng. Res. Appl. 2015, 5, 28–33. [Google Scholar]

- Avet, F.; Scrivener, K. Investigation of the calcined kaolinite content on the hydration of Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 2018, 107, 124–135. [Google Scholar]

- Boakye, K.; Khorami, M. Hydration, Reactivity and Durability Performance of Low-Grade Calcined Clay-Silica Fume Hybrid Mortar. Appl. Sci. 2023, 13, 11906. [Google Scholar] [CrossRef]

- Beuntner, N.; Thienel, K. Pozzolanic efficiency of calcined clays in blended cements with a focus on early hydration. Adv. Cem. Res. 2022, 34, 341–355. [Google Scholar]

- Zhou, D.; Wang, R.; Tyrer, M.; Wong, H.; Cheeseman, C. Sustainable infrastructure development through use of calcined excavated waste clay as a supplementary cementitious material. J. Clean. Prod. 2017, 168, 1180–1192. [Google Scholar]

- Zheng, D.; Liang, X.; Cui, H.; Tang, W.; Liu, W.; Zhou, D. Study of performances and microstructures of mortar with calcined low-grade clay. Constr. Build. Mater. 2022, 327, 126963. [Google Scholar]

- Dixit, A.; Du, H.; Pang, S.D. Marine clay in ultra-high performance concrete for filler substitution. Constr. Build. Mater. 2020, 263, 120250. [Google Scholar]

- Boakye, K.; Khorami, M.; Saidani, M.; Ganjian, E.; Dunster, A.; Tyrer, M.; Ehsani, A. Influence of Calcining Temperature on the Mineralogical and Mechanical Performance of Calcined Impure Kaolinitic Clays in Portland Cement Mortars. J. Mater. Civ. Eng. 2024, 36, 04024040. [Google Scholar]

- BS EN 197-1; Cement, Composition, Specifications and Conformity Criteria for Common Cements. British Standard Institution: London, UK, 2011.

- Boakye, K.; Khorami, M.; Saidani, M.; Ganjian, E.; Dunster, A.; Ehsani, A.; Tyrer, M. Mechanochemical characterisation of calcined impure kaolinitic clay as a composite binder in cementitious mortars. J. Compos. Sci. 2022, 6, 134. [Google Scholar] [CrossRef]

- BS EN 196-1; Methods of Testing Cement. Determination of Strength. British Standard Institution: London, UK, 2016.

- ASTM C1202; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C1585-13; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2020.

- Ramachandran, V.S.; Beaudoin, J.J. Handbook of Analytical Techniques in Concrete Science and Technology, Principles, Techniques and Applications; Elsevier: Amsterdam, The Netherlands, 2000. [Google Scholar]

- ASTM C642-13; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C490; Standard Practice for Use of Apparatus for the Determination of Length Change of Hardened Cement Paste, Mortar, and Concrete. ASTM International: West Conshohocken, PA, USA, 2010.

- Bamigboye, G.O.; Ademola, D.; Kareem, M.; Orogbade, B.; Odetoyan, A.; Adeniyi, A. 20-Durability assessment of recycled aggregate in concrete production. In The Structural Integrity of Recycled Aggregate Concrete Produced with Fillers and Pozzolans; Awoyera, P.O., Thomas, C., Kirgiz, M.S., Eds.; Woodhead Publishing: Cambridge, UK, 2022; pp. 445–467. [Google Scholar]

- Safiuddin, M.; Hearn, N. Comparison of ASTM saturation techniques for measuring the permeable porosity of concrete. Cem. Concr. Res. 2005, 35, 1008–1013. [Google Scholar]

- Güneyisi, E.; Mermerdaş, K. Comparative study on strength, sorptivity, and chloride ingress characteristics of air-cured and water-cured concretes modified with metakaolin. Mater. Struct. 2007, 40, 1161–1171. [Google Scholar] [CrossRef]

- Tironi, A.; Sposito, R.; Cordoba, G.P.; Zito, S.V.; Rahhal, V.F.; Thienel, K.C.; Irassar, E. Influence of different calcined clays on the water transport performance of concretes. Mag. Concr. Res. 2022, 74, 702–714. [Google Scholar] [CrossRef]

- Dhandapani, Y.; Santhanam, M. Investigation on the microstructure-related characteristics to elucidate performance of composite cement with limestone-calcined clay combination. Cem. Concr. Res. 2020, 129, 105959. [Google Scholar] [CrossRef]

- Shekarchi, M.; Bonakdar, A.; Bakhshi, M.; Mirdamadi, A.; Mobasher, B. Transport properties in metakaolin blended concrete. Constr. Build. Mater. 2010, 24, 2217–2223. [Google Scholar] [CrossRef]

- Chen, J.J.; Ng, P.L.; Chu, S.H.; Guan, G.X.; Kwan, A.K.H. Ternary blending with metakaolin and silica fume to improve packing density and performance of binder paste. Constr. Build. Mater. 2020, 252, 119031. [Google Scholar] [CrossRef]

- Sarıdemir, M.; Çiflikli, M.; Soysat, F. Mechanical and microstructural properties of HFRHSCs containing metakaolin subjected to elevated temperatures and freezing-thawing cycles. Constr. Build. Mater. 2018, 158, 11–23. [Google Scholar] [CrossRef]

- Yan, D.; Xie, L.; Qian, X.; Ruan, S.; Zeng, Q. Compositional dependence of pore structure, strengthand freezing-thawing resistance of metakaolin-based geopolymers. Materials 2020, 13, 2973. [Google Scholar] [CrossRef]

- Nas, M.; Kurbetci, S. Durability properties of concrete containing metakaolin. Adv. Concr. Constr. 2018, 6, 159. [Google Scholar]

- Qin, Z.; Ma, C.; Zheng, Z.; Long, G.; Chen, B. Effects of metakaolin on properties and microstructure of magnesium phosphate cement. Constr. Build. Mater. 2020, 234, 117353. [Google Scholar] [CrossRef]

- Kalkan, E. Effects of silica fume on the geotechnical properties of fine-grained soils exposed to freeze and thaw. Cold Reg. Sci. Technol. 2009, 58, 130–135. [Google Scholar] [CrossRef]

- Sabir, B.B. Mechanical properties and frost resistance of silica fume concrete. Cem. Concr. Compos. 1997, 19, 285–294. [Google Scholar]

- Dhandapani, Y.; Sakthivel, T.; Santhanam, M.; Gettu, R.; Pillai, R.G. Mechanical properties and durability performance of concretes with Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 2018, 107, 136–151. [Google Scholar]

- Ramezanianpour, A.A.; Bahrami Jovein, H. Influence of metakaolin as supplementary cementing material on strength and durability of concretes. Constr. Build. Mater. 2012, 30, 470–479. [Google Scholar] [CrossRef]

- Gill, A.S.; Siddique, R. Durability properties of self-compacting concrete incorporating metakaolin and rice husk ash. Constr. Build. Mater. 2018, 176, 323–332. [Google Scholar]

- Mermerdaş, K.; Arbili, M.M. Explicit formulation of drying and autogenous shrinkage of concretes with binary and ternary blends of silica fume and fly ash. Constr. Build. Mater. 2015, 94, 371–379. [Google Scholar]

- Gao, X.; Kawashima, S.; Liu, X.; Shah, S.P. Influence of clays on the shrinkage and cracking tendency of SCC. Cem. Concr. Compos. 2012, 34, 478–485. [Google Scholar]

- Alujas, A.; Fernández, R.; Quintana, R.; Scrivener, K.L.; Martirena, F. Pozzolanic reactivity of low grade kaolinitic clays, Influence of calcination temperature and impact of calcination products on OPC hydration. Appl. Clay Sci. 2015, 108, 94–101. [Google Scholar] [CrossRef]

- Sui, S.; Wilson, W.; Georget, F.; Maraghechi, H.; Kazemi-Kamyab, H.; Sun, W.; Scrivener, K. Quantification methods for chloride binding in Portland cement and limestone systems. Cem. Concr. Res. 2019, 125, 105864. [Google Scholar]

- Chandak, M.A.; Pawade, P. Compressive Strength and Ultrasonic Pulse Velocity of Concrete with Metakaolin. Civ. Eng. Archit. 2020, 8, 1277–1282. [Google Scholar]

- Kannan, V. Relationship between ultrasonic pulse velocity and compressive strength of self compacting concrete incorporate rice husk ash and metakaolin. Asian J. Civ. Eng. 2015, 16, 1077–1088. [Google Scholar]

- Malagavelli, V.; Angadi, S.; Prasad, J.; Joshi, S. Influence of metakaolin in concrete as partial replacement of cement. Int. J. Civil. Eng. Technol. 2018, 9, 105–111. [Google Scholar]

- Saand, A.; Keerio, M.A.; Khan BANGWAR, D. Effect of metakaolin developed from local natural material soorh on workability, compressive strength, ultrasonic pulse velocity and drying shrinkage of concrete. Archit. Civ. Eng. Environ. 2017, 10, 115–122. [Google Scholar]

| Composition, % | SiO2 | Al2O3 | Fe2O3 | MgO | CaO | Na2O | K2O | MnO | TiO2 | P2O5 | Cl | SO3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Calcined clay | 64.23 | 18.65 | 10.54 | 1.74 | 0.35 | 0.04 | 1.5 | 0.48 | 0.41 | 0.01 | – | 0.16 |

| OPC | 18.75 | 3.68 | 2.58 | 1.85 | 62.18 | 3.14 | 2.1 | 0.11 | 0.18 | 0.21 | 0.01 | 2.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boakye, K.; Khorami, M. Effect of Low-Grade Calcined Clay on the Durability Performance of Blended Cement Mortar. Buildings 2025, 15, 1159. https://doi.org/10.3390/buildings15071159

Boakye K, Khorami M. Effect of Low-Grade Calcined Clay on the Durability Performance of Blended Cement Mortar. Buildings. 2025; 15(7):1159. https://doi.org/10.3390/buildings15071159

Chicago/Turabian StyleBoakye, Kwabena, and Morteza Khorami. 2025. "Effect of Low-Grade Calcined Clay on the Durability Performance of Blended Cement Mortar" Buildings 15, no. 7: 1159. https://doi.org/10.3390/buildings15071159

APA StyleBoakye, K., & Khorami, M. (2025). Effect of Low-Grade Calcined Clay on the Durability Performance of Blended Cement Mortar. Buildings, 15(7), 1159. https://doi.org/10.3390/buildings15071159