Adaptation of Connection Systems for Integration with Engineered Wood Products in Buildings: A Systematic Review

Abstract

1. Introduction

1.1. Background

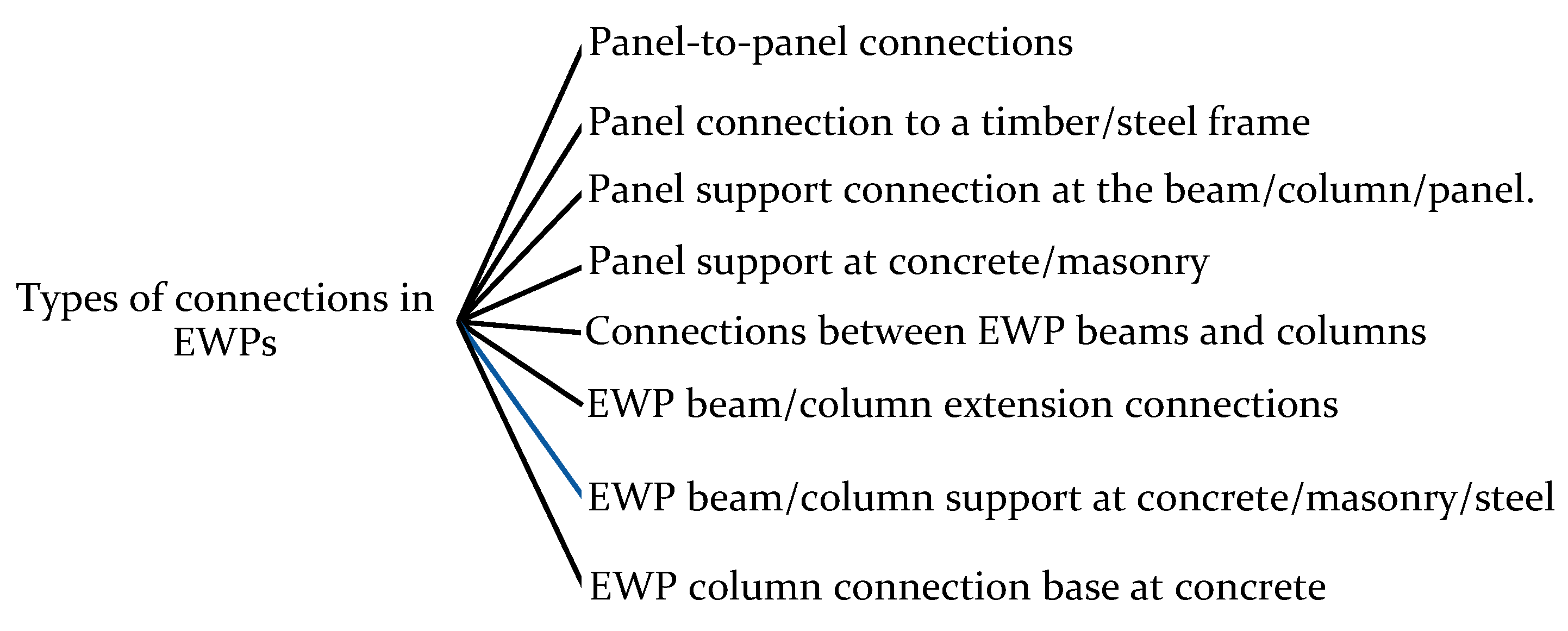

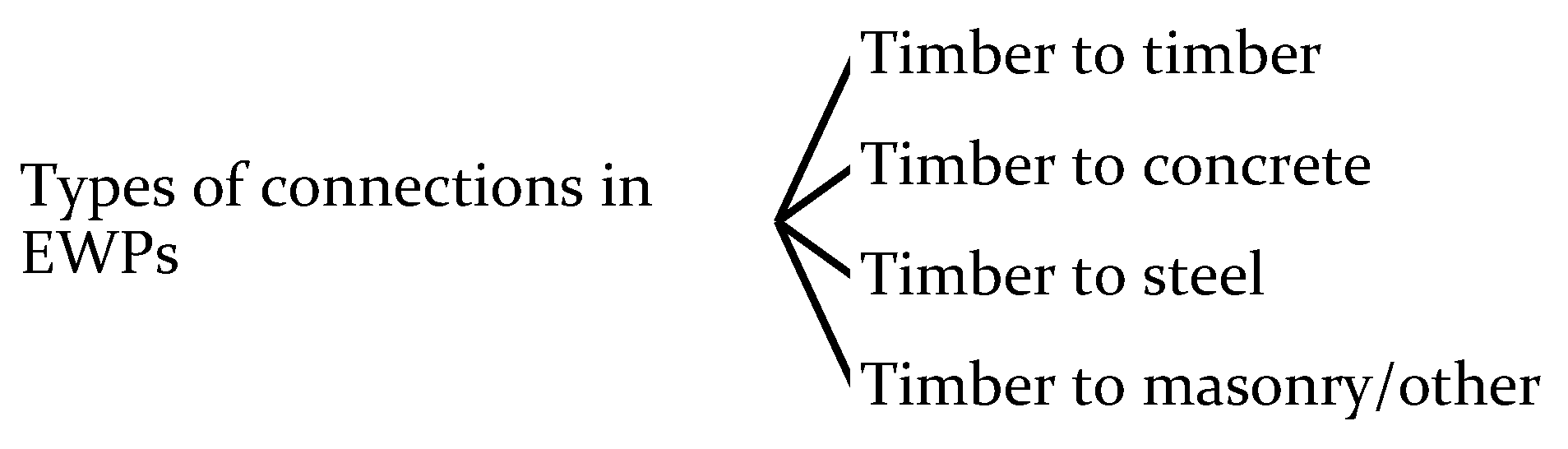

1.2. Classification of Connections in Buildings with EWPs

- Panel-to-panel: connects adjacent panels through techniques such as tongue-and-groove, overlap joints, concealed fixings, and compressed seals, often forming self-supporting structures.

- Panel-to-structure: panels are fixed directly onto the primary structure to ensure load transfer and stability.

- Panel-to-subframe: uses intermediate elements such as mullions or transoms to support the panel.

- Panel-to-cladding: involves mounting cladding walls onto a carrier system or substrate wall often incorporating an air cavity.

1.3. Design Methods and Standards

1.4. Modelling Approaches

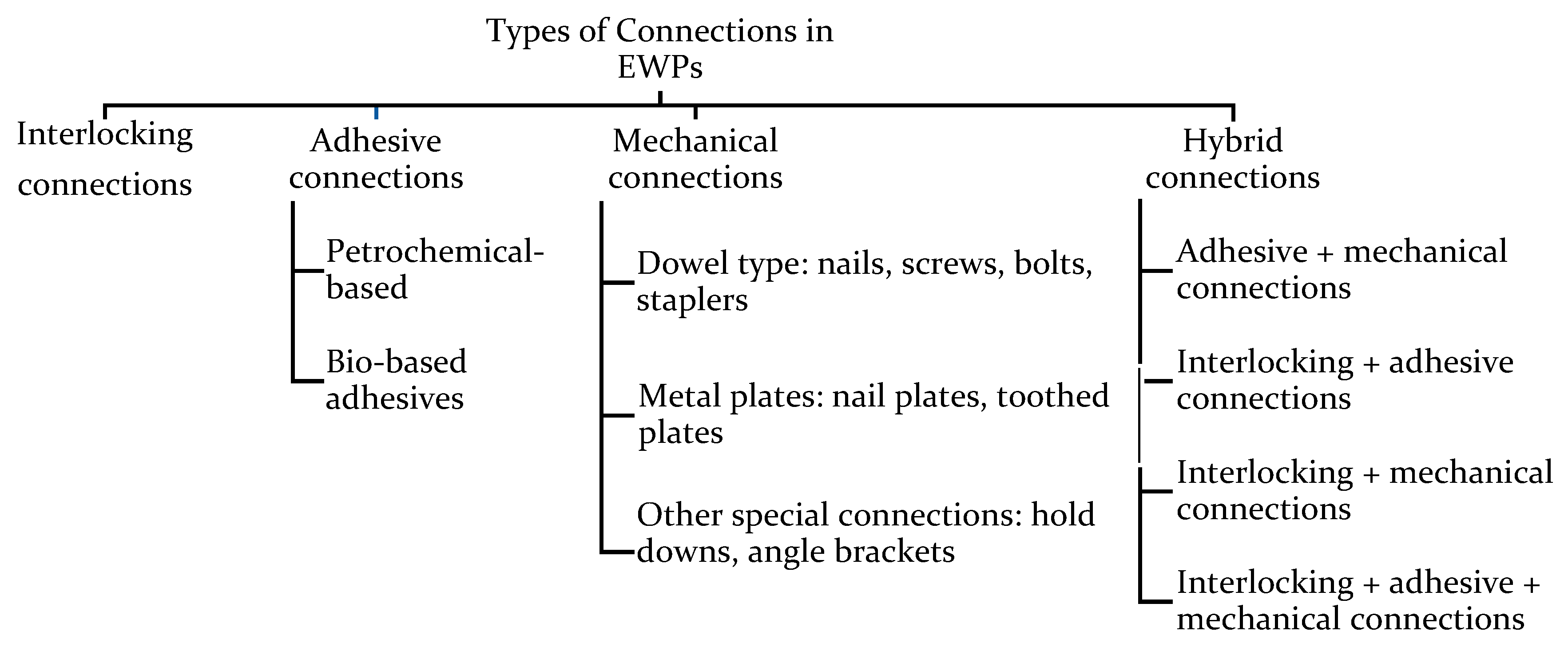

2. Types of Connections and Their Performance

2.1. Mechanical Connections

2.2. Adhesive Connections

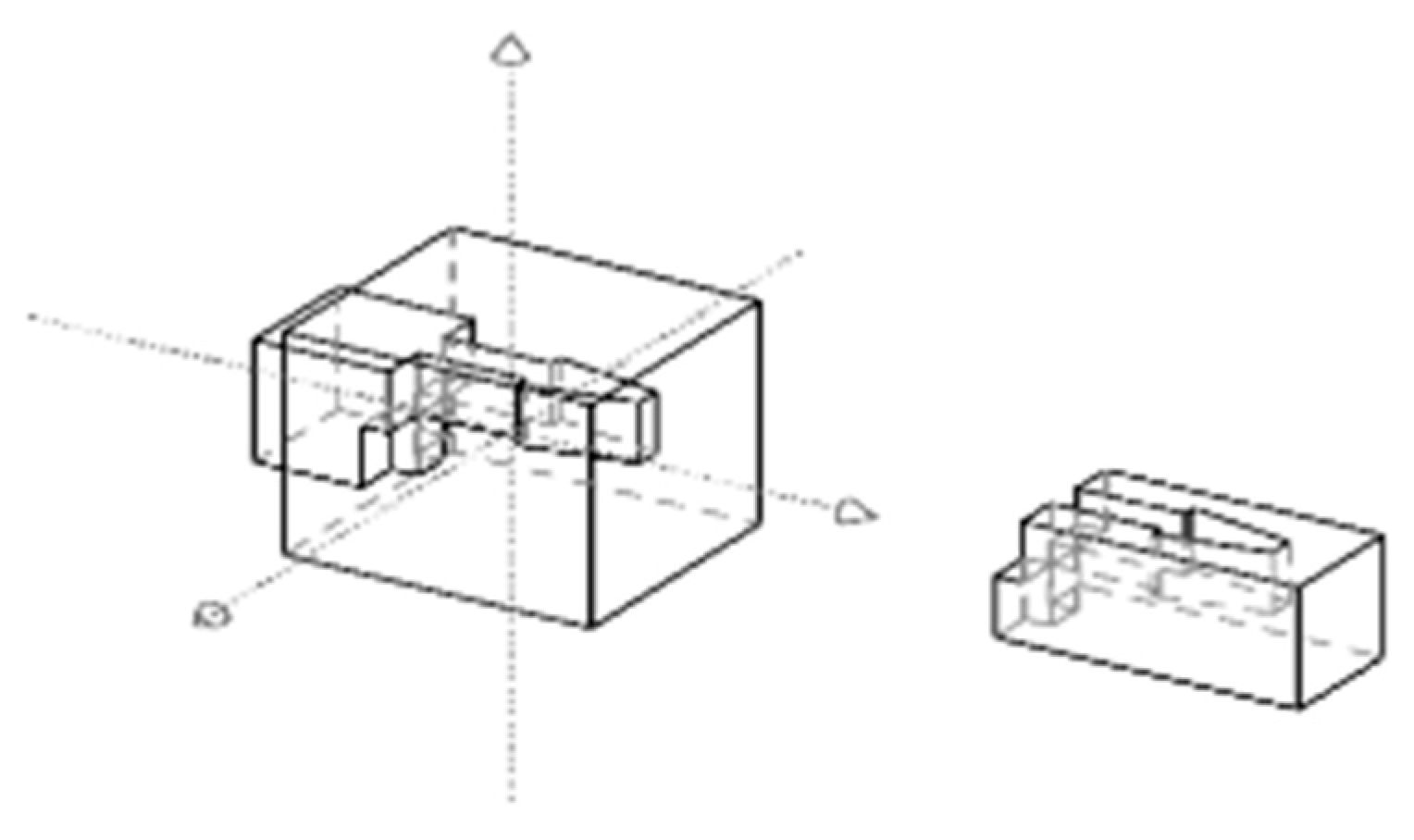

2.3. Interlocking Connections

3. Methodology

3.1. Data Collection and Search Strategy

3.2. Screening Process and Analysis

- Duplicate removal: studies appearing in both queries were identified and removed.

- Title and abstract screening: each paper was assessed for its relevance to EWP connections in prefabricated buildings.

- Exclusion criteria: review articles, editorials, and conference abstracts without full-text access, non-English articles, and studies unrelated to the review topic.

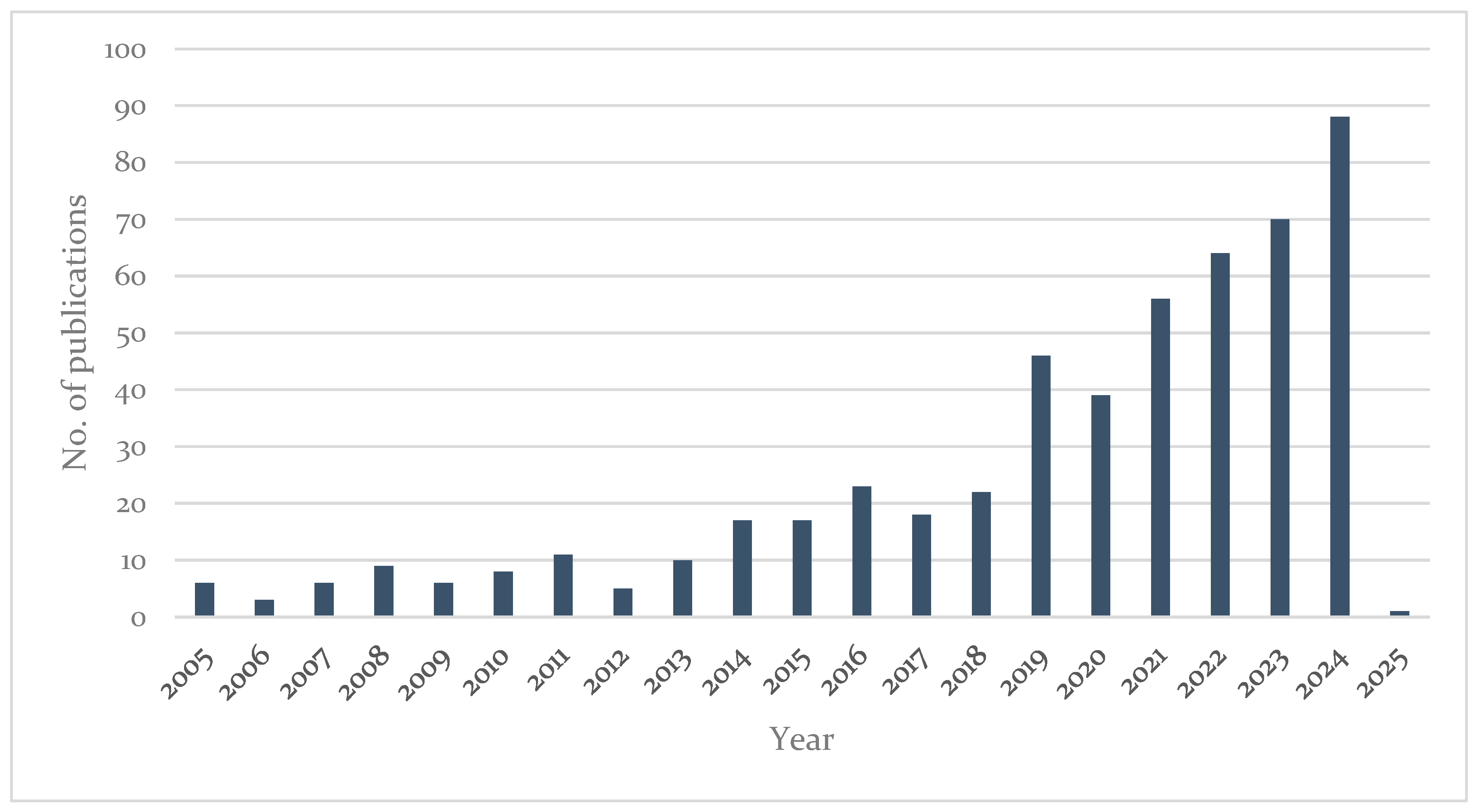

- Bibliometric analysis: carried out based on 525 publications using the VOSviewer version 1.6.19 software.

- Abstract, results, and conclusion review for trend analysis: a subset of 125 full-text papers were selected for in-depth trend analysis based on their contribution to the field.

4. Results

4.1. Bibliometric Analysis

4.2. Recent Trends in Literature

4.2.1. Prefabrication Adaptability

4.2.2. Sustainability and Circular Economy

4.2.3. Hygrothermal Issues

4.2.4. Extreme Conditions

5. Discussion

- Proper design ensures long-term structural reliability by preventing weak points that could lead to premature failure under applied loads.

- Consideration of effective stress distribution and optimised load path design is critical. Precise timber section sizing prevents failure under structural loads.

- Connection designs must comply with regional standards and building codes.

- Seismic and wind load performance is essential for buildings in high-risk regions. Connections must be ductile, capable of dissipating energy, and have optimised section geometry.

- Fire resistance of connections ensures stability under fire exposure through fire-resistant adhesives, coatings for fasteners, and embedded connection designs to minimise weakening.

- Moisture-induced swelling, shrinkage, and decay can be mitigated through tight-fitting dry connections, interlocking systems, or hybrid solutions.

- Connection design should prioritise fast, simple, and precise connection systems to optimise on-site assembly.

- Connection types must align with timber geometry to ensure load transfer without excessive cutting, weakening, or material wastage.

- The design should enable easy, damage-free assembly and disassembly using reversible fasteners, interlocking joints, and prefabricated slots.

- Efficient connections facilitate on-site installation and maintenance with easy accessibility and adjustability.

- Errors can be reduced and on-site modifications minimised through precision manufacturing and digital fabrication, ensuring tight tolerances.

- Facilitate deconstruction and repurposing of timber elements through reversible connection systems.

- Bio-based adhesives and materials can be used to reduce environmental impact and promote material circularity.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Milner, H.R.; Woodard, A.C. Sustainability of engineered wood products. In Sustainability of Construction Materials, 2nd ed.; Khatib, J.M., Ed.; Woodhead Publishing: Sawston, UK, 2016; Volume 8, pp. 159–180. [Google Scholar] [CrossRef]

- Ilgın, H.E.; Karjalainen, M. Preliminary design proposals for dovetail wood board elements in multi-story building construction. Architecture 2021, 1, 56–68. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Yadav, R.; Kumar, J. Engineered wood products as a sustainable construction material: A review. In Engineered Wood Products for Construction; Gong, M., Ed.; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Loss, C.; Piazza, M.; Zandonini, R. Connections for steel–timber hybrid prefabricated buildings. Part I Exp. Tests. Constr. Build. Mater. 2016, 122, 781–795. [Google Scholar] [CrossRef]

- Hittawe, M.M.; Sidibé, D.; Beya, O.; Mériaudeau, F. Machine vision for timber grading singularities detection and applications. J. Electron. Imaging 2017, 26, 063015. [Google Scholar] [CrossRef]

- Hittawe, M.M.; Sidibé, D.; Mériaudeau, F. A machine vision based approach for timber knots detection. In Twelfth International Conference on Quality Control by Artificial Vision 2015; Meriaudeau, F., Aubreton, O., Eds.; SPIE: Bellingham, WA, USA, 2015; Volume 9534. [Google Scholar] [CrossRef]

- Lopes, G.C.; Vicente, R.; Azenha, M.; Ferreira, T.M. A systematic review of Prefabricated Enclosure Wall Panel Systems: Focus on technology driven for performance requirements. Sustain. Cities Soc. 2018, 40, 688–703. [Google Scholar] [CrossRef]

- Jockwer, R.; Fink, G.; Kohler, J. Assessment of existing safety formats for timber connections: How probabilistic approaches can influence connection design in timber engineering. In Proceedings of the Conference of COST Action FP1402, Graz, Austria, 13 September 2017; Brandner, R., Ringhofer, A., Dietsch, P., Eds.; Verlag der Technischen Universität Graz: Graz, Austria, 2017; pp. 16–31. [Google Scholar] [CrossRef]

- Shirmohammadi, M.; Leggate, W.; Redman, A. Effects of moisture ingress and egress on the performance and service life of mass timber products in buildings: A review. Constr. Build. Mater. 2021, 290, 123176. [Google Scholar] [CrossRef]

- Sandoli, A.; D’Ambra, C.; Ceraldi, C.; Calderoni, B.; Prota, A. Sustainable cross-laminated timber structures in a seismic area: Overview and future trends. Appl. Sci. 2021, 11, 2078. [Google Scholar] [CrossRef]

- Cabrero, J.M.; Stepinac, M.; Ranasinghe, K.; Kleiber, M. Results from a questionnaire for practitioners about the connections chapter of Eurocode 5. In Design of Connections in Timber Structures; Shaker Verlag: Herzogenrath, Germany, 2018; pp. 3–18. [Google Scholar]

- Domínguez, M.; Fueyo, J.G.; Villarino, A.; Anton, N. Structural timber connections with dowel-type fasteners and nut-washer fixings: Mechanical characterization and contribution to the rope effect. Materials 2021, 15, 242. [Google Scholar] [CrossRef]

- Shahin, A.; Cowled, C.J.L.; Bailleres, H.; Fawzia, S. Experimental study on shear performance of nail and screw-laminated timber-steel composite and timber-timber systems using low-grade timber and mechanical fasteners. Constr. Build. Mater. 2024, 418, 135403. [Google Scholar] [CrossRef]

- Liu, L.; Tai, H.-W.; Wang, T.; Qiao, L.; Cheng, K.-T. Analyzing cost impacts across the entire process of prefabricated building components from design to application. Sci. Rep. 2025, 15, 9300. [Google Scholar] [CrossRef]

- Bedon, C.; Fragiacomo, M. Numerical analysis of timber-to-timber joints and composite beams with inclined self-tapping screws. Compos. Struct. 2019, 207, 13–28. [Google Scholar] [CrossRef]

- He, J.; Suwaed AS, H.; Vasdravellis, G.; Wang, S. Standard pushout tests and design rules for a bolted–welded hybrid demountable shear connector. J. Struct. Eng. 2022, 148, 04022097. [Google Scholar] [CrossRef]

- Tzouka, E.; Karavasilis, T.; Kashani, M.M.; Afshan, S. Finite element modelling of push-out tests for novel locking nut shear connectors. Structures 2021, 33, 1020–1032. [Google Scholar] [CrossRef]

- Balduzzi, G.; Bonizzoni, F.; Tamellini, L. Uncertainty quantification in timber-like beams using sparse grids: Theory and examples with off-the-shelf software utilization. Constr. Build. Mater. 2023, 406, 132730. [Google Scholar] [CrossRef]

- Nie, Y.; Valipour Hamid, R.; Ghanbari-Ghazijahani, T. Hygro-mechanical analysis of timber-timber composite (TTC) beams in time-dependent environments: A 3D coupled finite element approach. Structures 2025, 71, 107380. [Google Scholar] [CrossRef]

- Oliveira, D.; Viau, C.; Doudak, G. Predictive capabilities of finite element modelling for timber members subjected to blast loads. In Proceedings of the World Conference on Timber Engineering (WCTE 2023), Oslo, Norway, 19–22 June 2023; pp. 2298–2305. [Google Scholar] [CrossRef]

- Śliwa-Wieczorek, K.; Szeptyński, P.; Kozik, T.; Gubert, M. Creep Behavior of CLT beams with finite thickness layers of flexible adhesives. Materials 2023, 16, 4484. [Google Scholar] [CrossRef]

- Taleshi, M.M.; Tajik, N.; Mahmoudian, A.; Yekrangnia, M. Prediction of pull-out behavior of timber glued-in glass fiber reinforced polymer and steel rods under various environmental conditions based on ANN and GEP models. Case Stud. Constr. Mater. 2024, 20, e02842. [Google Scholar] [CrossRef]

- Wu, Z.; Chen, L.; Xiong, H. Regression algorithms-driven mechanical properties prediction of angle bracket connection on cross-laminated timber structures. J. Wood Sci. 2024, 70, 3. [Google Scholar] [CrossRef]

- Bassier, M.; Hadjidemetriou, G.; Vergauwen, M.; Van Roy, N.; Verstrynge, E. Implementation of scan-to-BIM and FEM for the documentation and analysis of heritage timber roof structures. In Digital Heritage. Progress in Cultural Heritage: Documentation, Preservation, and Protection; Ioannides, M., Fink, E., Moropoulou, A., Hagedorn-Saupe, M., Fresa, A., Liestøl, G., Rajcic, V., Grussenmeyer, P., Eds.; Springer: Cham, Switzerland, 2016; pp. 79–90. [Google Scholar] [CrossRef]

- Yurrita, M.; Cabrero, J.M. On the need of distinguishing ductile and brittle failure modes in timber connections. Eng. Struct. 2021, 242, 112496. [Google Scholar] [CrossRef]

- Schiro, G.; Giongo, I.; Sebastian, W.; Riccadonna, D.; Piazza, M. Testing of timber-to-timber screw-connections in hybrid configurations. Constr. Build. Mater. 2018, 171, 170–186. [Google Scholar] [CrossRef]

- Abdoli, F.; Rashidi, M.; Rostampour-Haftkhani, A.; Layeghi, M.; Ebrahimi, G. Withdrawal performance of nails and screws in Cross-Laminated Timber (CLT) made of poplar (Populus alba) and fir (Abies alba). Polymers 2022, 14, 3129. [Google Scholar] [CrossRef] [PubMed]

- Sotayo, A.; Bradley, D.; Bather, M.; Sareh, P.; Oudjene, M.; El-Houjeyri, I.; Harte, A.M.; Mehra, S.; O’Ceallaigh, C.; Haller, P.; et al. Review of state of the art of dowel laminated timber members and densified wood materials as sustainable engineered wood products for construction and building applications. Dev. Built Environ. 2020, 1, 100004. [Google Scholar] [CrossRef]

- Conway, M.; Mehra, S.; Harte, A.M.; O’Ceallaigh, C. Densified wood dowel reinforcement of timber perpendicular to the grain: A pilot study. J. Struct. Integr. Maint. 2021, 6, 177–186. [Google Scholar] [CrossRef]

- Mehra, S.; O’Ceallaigh, C.; Hamid-Lakzaeian, F.; Guan, Z.; Harte, A.M. Evaluation of the structural behaviour of beam-beam connection systems using compressed wood dowels and plates. In Proceeding of the World Conference on Timber Engineering, Seoul, Republic of Korea, 20 August 2018; pp. 20–23. [Google Scholar]

- Mateusz, K.; Henryk, A.; Grzegorz, G. Stress distribution in a plate with a holes along the diagonal distribution under plane biaxial load. Stroj. íCky Časopis-J. Mech. Eng. 2020, 70, 91–100. [Google Scholar] [CrossRef]

- Li, T.Y.; Chen, J.Q.; Qin, P.C.; Xiao, Y.; Shan, B.; Yang, Y.F.; Qin, S.J.; Fu, X.L. Experimental investigation and evaluation of metal-plate-connected laminated bamboo lumber joints. Constr. Build. Mater. 2024, 411, 134596. [Google Scholar] [CrossRef]

- Dias AM, P.G.; Kuhlmann, U.; Kudla, K.; Mönch, S.; Dias AM, A. Performance of dowel-type fasteners and notches for hybrid timber structures. Eng. Struct. 2018, 171, 40–46. [Google Scholar] [CrossRef]

- Hassanieh, A.; Valipour, H.R.; Bradford, M.A. Experimental and analytical behaviour of steel-timber composite connections. Constr. Build. Mater. 2016, 118, 63–75. [Google Scholar] [CrossRef]

- Dorn, M.; de Borst, K.; Eberhardsteiner, J. Experiments on dowel-type timber connections. Eng. Struct. 2013, 47, 67–80. [Google Scholar] [CrossRef]

- Stoeckel, F.; Konnerth, J.; Gindl-Altmutter, W. Mechanical properties of adhesives for bonding wood—A review. Int. J. Adhes. Adhes. 2013, 45, 32–41. [Google Scholar] [CrossRef]

- Ravindran, L.; Sreekala, M.S.; Kumar, S.A.; Thomas, S. A comprehensive review on phenol-formaldehyde resin-based composites and foams. Polym. Compos. 2022, 43, 8602–8621. [Google Scholar] [CrossRef]

- Fang, M.; Tao, J.; Sun, T.; Dong, H. Loading mechanism of timber screw–adhesive composite joint. Low-Carbon Mater. Green Constr. 2024, 2, 17. [Google Scholar] [CrossRef]

- Wang, S.; Wang, F.; Kong, F.; Ma, P.; Chen, Z.; Que, Z. Influence of repeated wetting and drying on withdrawal capacity of wooden nails and metal nails. Constr. Build. Mater. 2023, 409, 133991. [Google Scholar] [CrossRef]

- Ratsch, N.; Böhm, S.; Voß, M.; Vallée, T. Accelerated curing of glued-in rods: Influence of manufacturing defects. Constr. Build. Mater. 2021, 298, 123665. [Google Scholar] [CrossRef]

- Malo, K.A.; Stamatopoulos, H.; Mirko Massaro, F.; Tulebekova, S. Serviceability stiffness of timber connections with dowels and slotted-in steel plates. In Proceedings of the World Conference on Timber Engineering (WCTE 2023), Oslo, Norway, 19–22 June 2023; pp. 1136–1145. [Google Scholar] [CrossRef]

- Xu, Q.; FialhoTeixeira, F.; Shafiei, M. Exploring Rule-Based Discrete Timber Design with Mortise-Tenon Joints. In Proceedings of the 29th Annual Conference for Computer-Aided Architectural Design Research in Asia, Singapore, 20–26 April 2024; pp. 313–322. [Google Scholar] [CrossRef]

- Fang, D.; Mueller, C. Mortise-and-tenon joinery for modern timber construction: Quantifying the embodied carbon of an alternative structural connection. Archit. Struct. Constr. 2023, 3, 11–24. [Google Scholar] [CrossRef]

- Nimwegen, S.E.; van Latteur, P. A state-of-the-art review of carpentry connections: From traditional designs to emerging trends in wood-wood structural joints. J. Build. Eng. 2023, 78, 107089. [Google Scholar] [CrossRef]

- Kanasaki, K.; Tanaka, H. Traditional wood joint system in digital fabrication. In Proceedings of the 31st International Conference on Education and research in Computer Aided Architectural Design in Europe, Delft, The Netherlands, 18–20 September 2013; Stouffs, R., Sariyildiz, S., Eds.; Faculty of Architecture, Delft University of Technology: Delft, The Netherlands, 2013; pp. 711–717. [Google Scholar] [CrossRef]

- Rebstock, F.; Bomark, P.; Sandberg, D. Makerjoint, a new concept for joining members in timber engineering: Strength test and failure analyses. Pro Ligno 2015, 11, 397–404. [Google Scholar]

- Tanadini, D.; Schwartz, J. Analysis and design of timber-to-timber connections based on the lower bound theorem of the theory of plasticity. In Proceedings of the World Conference on Timber Engineering, Santiago, Chile, 9–12 August 2021; pp. 2072–2078. [Google Scholar]

- Ilgın, H.E.; Karjalainen, M.; Koponen, O.P. Review of the current state-of-the-art of dovetail massive wood elements. In Engineered Wood Products for Construction; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Timbolmas, C.; Rescalvo, F.J.; Portela, M.; Bravo, R. Analysis of poplar timber finger joints by means of Digital Image Correlation (DIC) and finite element simulation subjected to tension loading. Eur. J. Wood Wood Prod. 2022, 80, 555–567. [Google Scholar] [CrossRef]

- Gunawardena, T.; Mendis, P. Prefabricated building systems—Design and construction. Encyclopedia 2022, 2, 70–95. [Google Scholar] [CrossRef]

- Xu, F.; Geng, M.; Meng, X.; Diao, Y.; Gao, Y. Out-of-plane shear performance of a novel non-metallic CLT dovetail joint subjected to monotonic and cyclic loading. Ind. Crops Prod. 2024, 208, 117780. [Google Scholar] [CrossRef]

- Larsson, M.; Yoshida, H.; Umetani, N.; Igarashi, T. Tsugite: Interactive design and fabrication of wood joints. In Proceedings of the 33rd Annual ACM Symposium on User Interface Software and Technology, Online, 20 October 2020; ACM: New York, NY, USA, 2020; pp. 317–327. [Google Scholar] [CrossRef]

- Yan, Z.; Ottenhaus, L.M.; Leardini, P.; Jockwer, R. Performance of reversible timber connections in Australian light timber framed panelised construction. J. Build. Eng. 2022, 61, 105244. [Google Scholar] [CrossRef]

- Ottenhaus, L.M.; Yan, Z.; Brandner, R.; Leardini, P.; Fink, G.; Jockwer, R. Design for adaptability, disassembly and reuse—A review of reversible timber connection systems. Constr. Build. Mater. 2023, 400, 132823. [Google Scholar] [CrossRef]

- Yan, Z. Design and Performance Evaluation of Reversible Connections for Modular Adaptable Timber Buildings. Ph.D. Thesis, The University of Queensland, Brisbane, Australia, 2024. [Google Scholar] [CrossRef]

- Yu, C.; Chen, Y.; Li, R.; Jiang, J.; Wang, X. A narrative review: Modification of bio-based wood adhesive for performance improvement. Coatings 2024, 14, 1153. [Google Scholar] [CrossRef]

- Vamza, I.; Krigers, G.; Valters, K. A review of bio-based adhesives from primary and secondary biomass for wood composite applications. Environ. Clim. Technol. 2022, 26, 1350–1360. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.-M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef]

- Toumpanaki, E.; Gawne, A.; Humphreys, R.; Vojnovic, L. Effect of moisture and rate of loading in the withdrawal capacity of screws in Cross Laminated Timber (CLT). Structures 2024, 69, 107530. [Google Scholar] [CrossRef]

- Máchová, E.; Langová, N.; Réh, R.; Joščák, P.; Krišťák, Ľ.; Holouš, Z.; Igaz, R.; Hitka, M. Effect of moisture content on the load carrying capacity and stiffness of corner wood-based and plastic joints. BioResources 2019, 14, 8640–8655. [Google Scholar] [CrossRef]

- Hashemi, A.; Fast, T.; Dickof, C.; Jackson, R.; Fast, P.; Dunbar, A.; Zarnani, P.; Quenneville, P. Seismic Resilient Mass Timber Structures with Damage-Avoidance Connections: Design Methods and Case Studies. In Proceedings of the SESOC Conference, Hamilton, New Zealand, 5–6 July 2021. [Google Scholar]

- Kuai, L. Parametric FE-Modelling of Non-Linear Racking Behaviour of Light-Frame Shear Walls and Modules Used for Multi-storey Timber Buildings. Ph.D. Thesis, Linnaeus University, Växjö, Sweden, 2024. [Google Scholar] [CrossRef]

- La Scala, A.; Śliwa-Wieczorek, K.; Rizzo, F.; Sabbà, M.F.; Zając, B. Flexible polyurethane adhesives: Predictive numerical model calibration through experimental testing at elevated temperature. Appl. Sci. 2024, 14, 1943. [Google Scholar] [CrossRef]

- Maraveas, C.; Miamis, K.; Matthaiou, C.E. Performance of timber connections exposed to fire: A Review. Fire Technol. 2015, 51, 1401–1432. [Google Scholar] [CrossRef]

- Larsson, C.; Abdeljaber, O.; Bolmsvik, Å.; Dorn, M. Long-term analysis of the environmental effects on the global dynamic properties of a hybrid timber-concrete building. Eng. Struct. 2022, 268, 114726. [Google Scholar] [CrossRef]

- Hashemi, A.; Zarnani, P.; Quenneville, P. Development of resilient seismic solutions for timber structures in New Zealand using innovative connections. Struct. Eng. Int. 2020, 30, 242–249. [Google Scholar] [CrossRef]

| Field of Search | Search Term | Records |

|---|---|---|

| Topic | (“Engineered wood” OR “mass timber” OR “Timber”) AND (“connection” OR “joints”) AND (“prefabrication” OR “offsite”) | 55 |

| Title, abstract, author keywords | (“metal plate” OR “dowel type” OR “interlocking” OR “adhesive” OR “Fasteners”) AND (“Engineered wood” OR “mass timber” OR “Cross-laminated Timber” OR “Glulam”) | 575 |

| Country | Number of Publications |

|---|---|

| China | 96 |

| Canada | 76 |

| USA | 62 |

| Germany | 43 |

| Italy | 43 |

| Sweden | 35 |

| Australia | 31 |

| France | 25 |

| England | 24 |

| Switzerland | 24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dissanayake, H.; Gunawardena, T.; Mendis, P. Adaptation of Connection Systems for Integration with Engineered Wood Products in Buildings: A Systematic Review. Buildings 2025, 15, 1131. https://doi.org/10.3390/buildings15071131

Dissanayake H, Gunawardena T, Mendis P. Adaptation of Connection Systems for Integration with Engineered Wood Products in Buildings: A Systematic Review. Buildings. 2025; 15(7):1131. https://doi.org/10.3390/buildings15071131

Chicago/Turabian StyleDissanayake, Harshani, Tharaka Gunawardena, and Priyan Mendis. 2025. "Adaptation of Connection Systems for Integration with Engineered Wood Products in Buildings: A Systematic Review" Buildings 15, no. 7: 1131. https://doi.org/10.3390/buildings15071131

APA StyleDissanayake, H., Gunawardena, T., & Mendis, P. (2025). Adaptation of Connection Systems for Integration with Engineered Wood Products in Buildings: A Systematic Review. Buildings, 15(7), 1131. https://doi.org/10.3390/buildings15071131