Effect of Drying and Wetting Cycles on Deformation Characteristics of Compacted Loess and Constitutive Model

Abstract

1. Introduction

2. Apparatus and Methodology

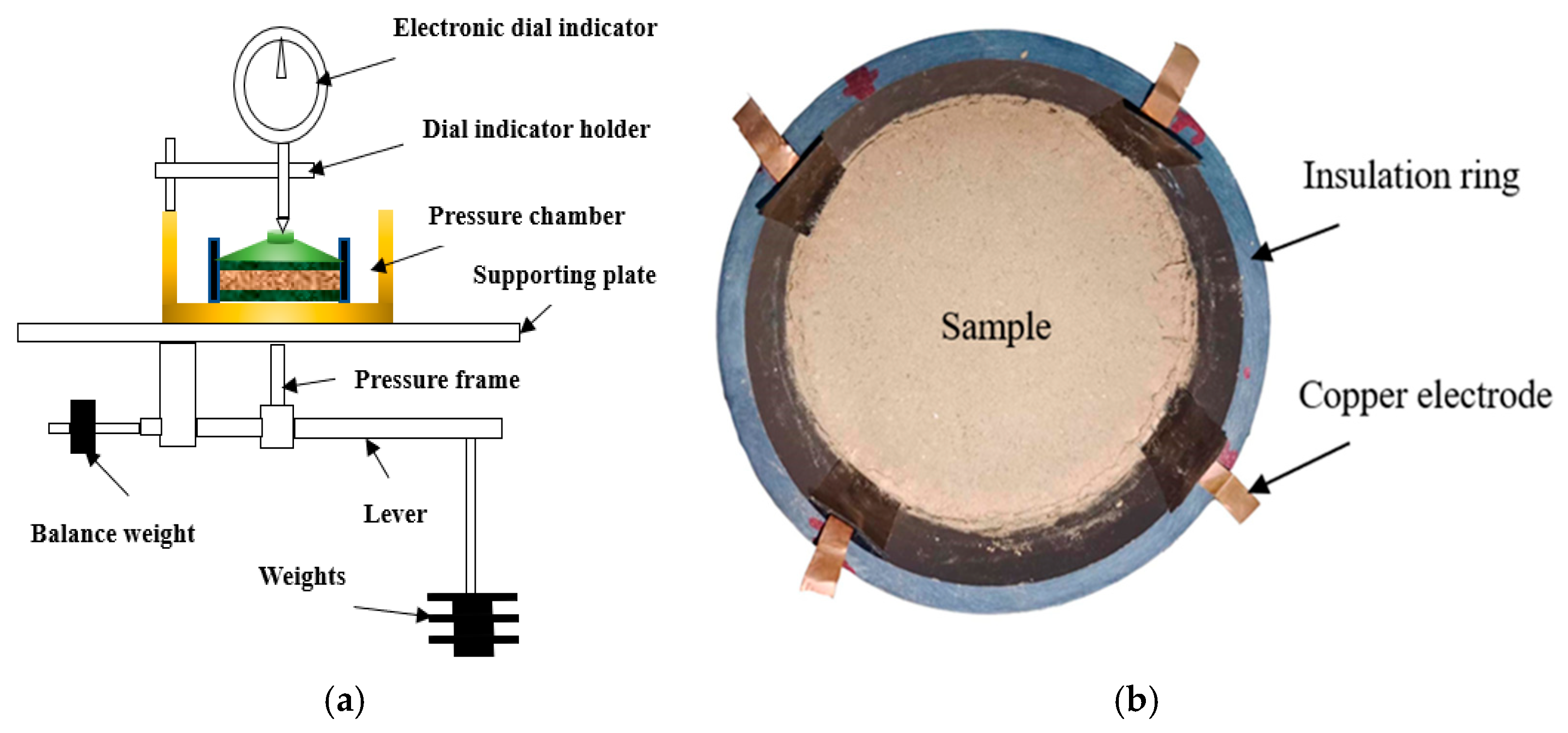

2.1. Test Apparatus

2.2. Sample Preparation

2.3. Test Schemes

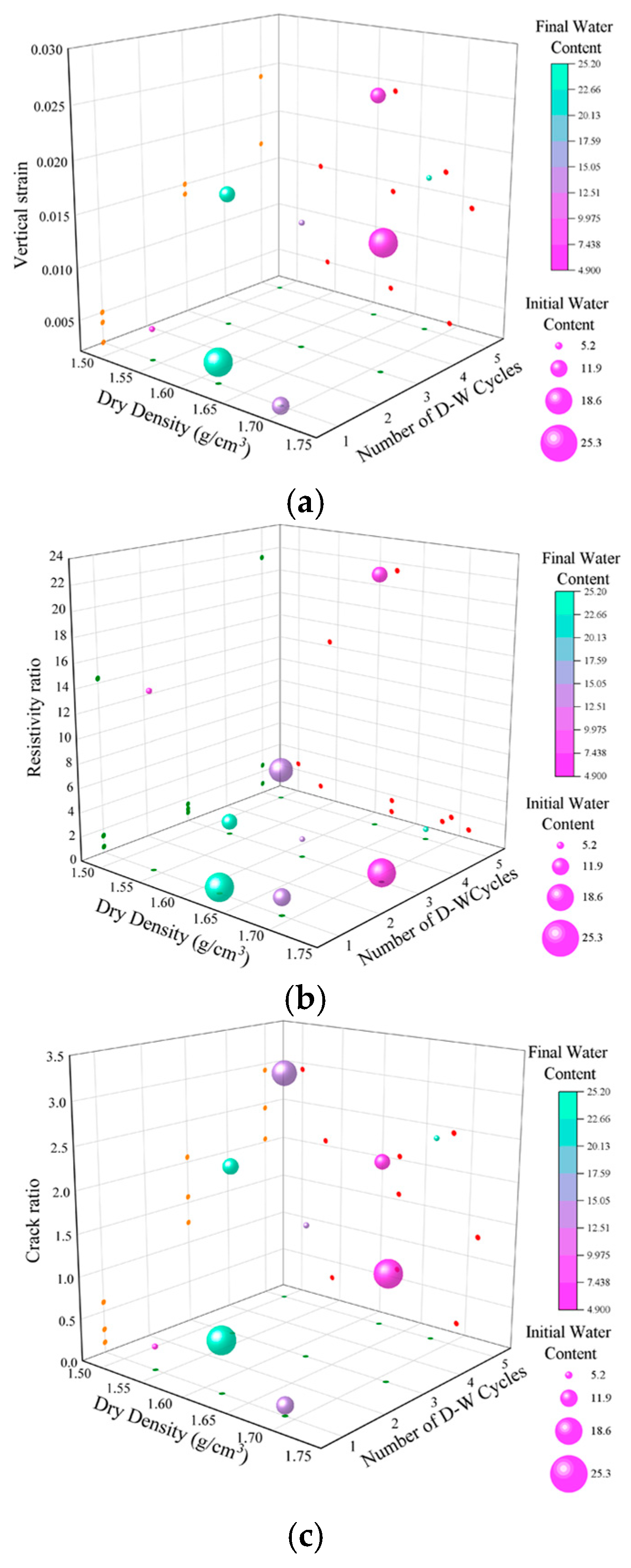

3. Results and Analysis

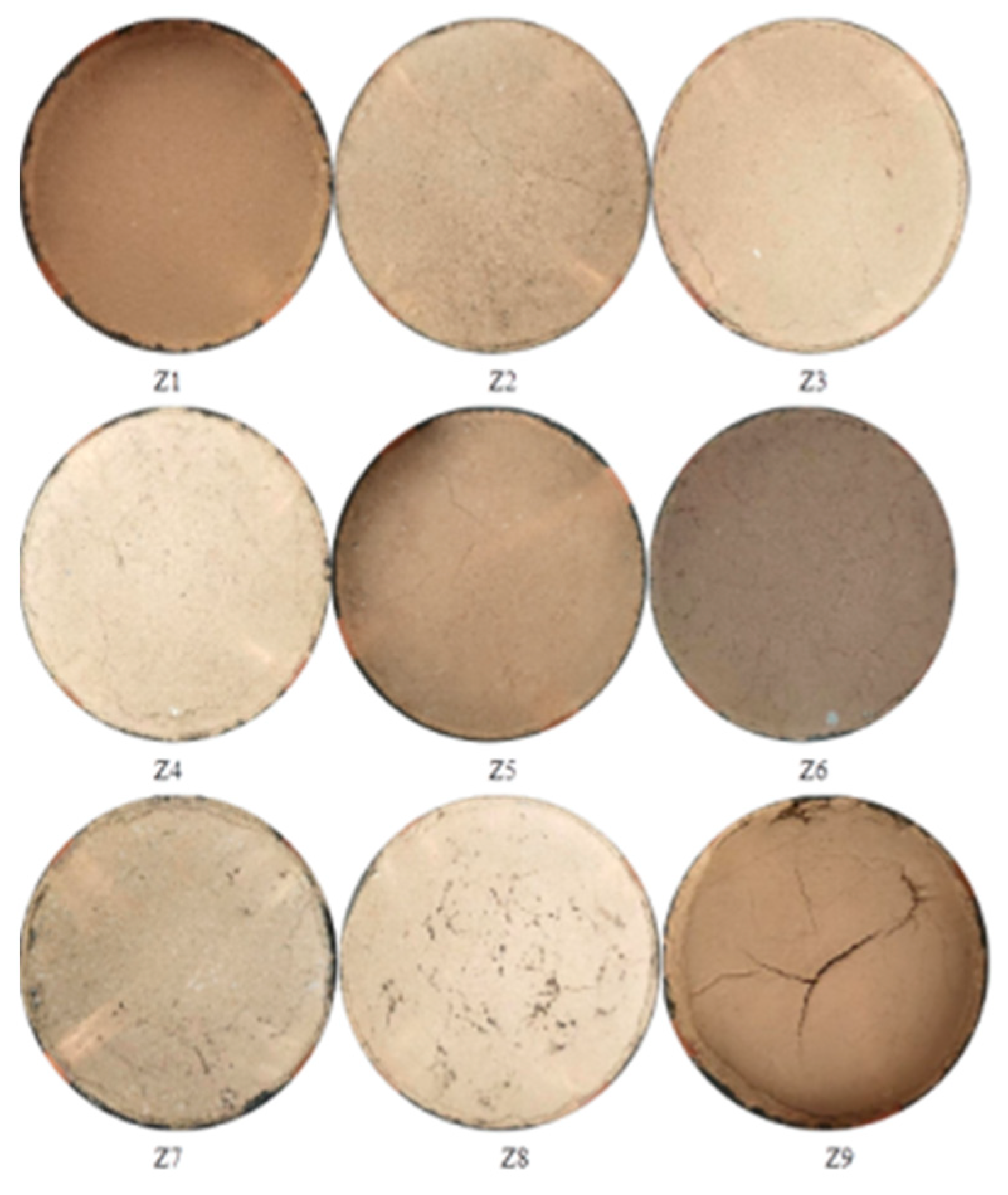

3.1. Macroscopic Characteristics of Compacted Loess

3.2. Microstructure

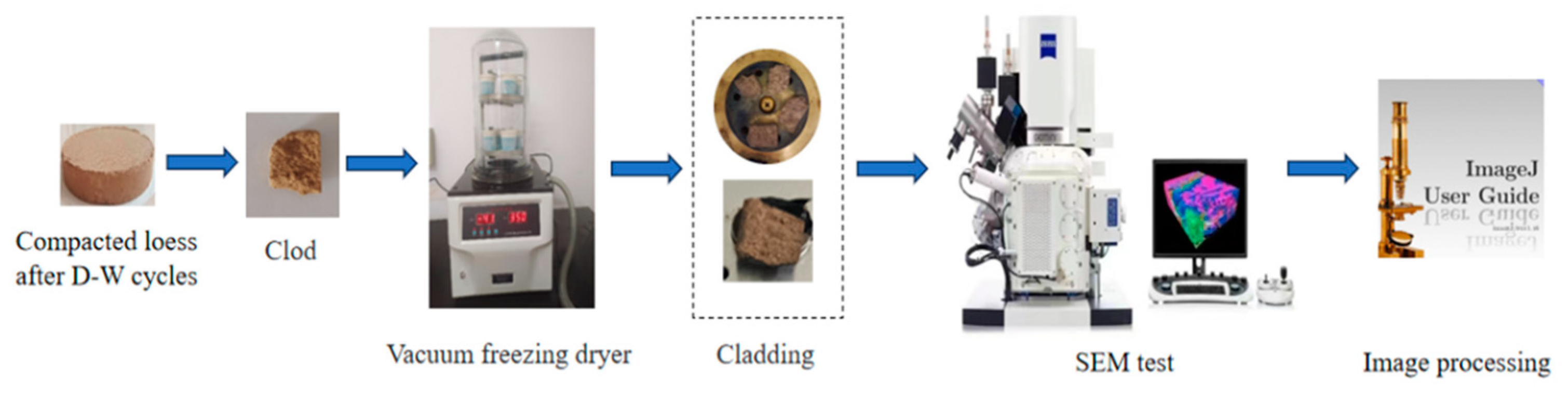

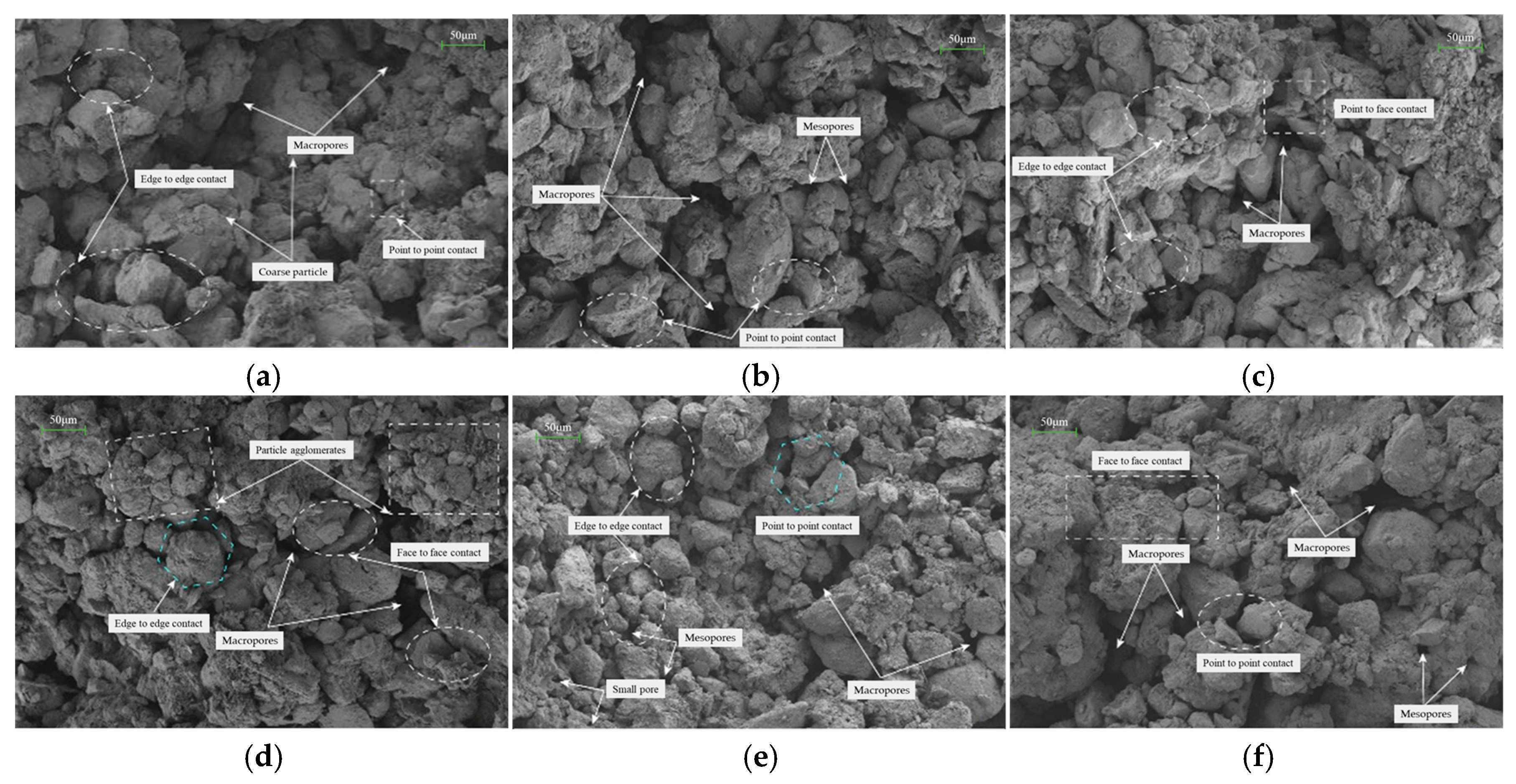

3.2.1. Analysis of SEM Images

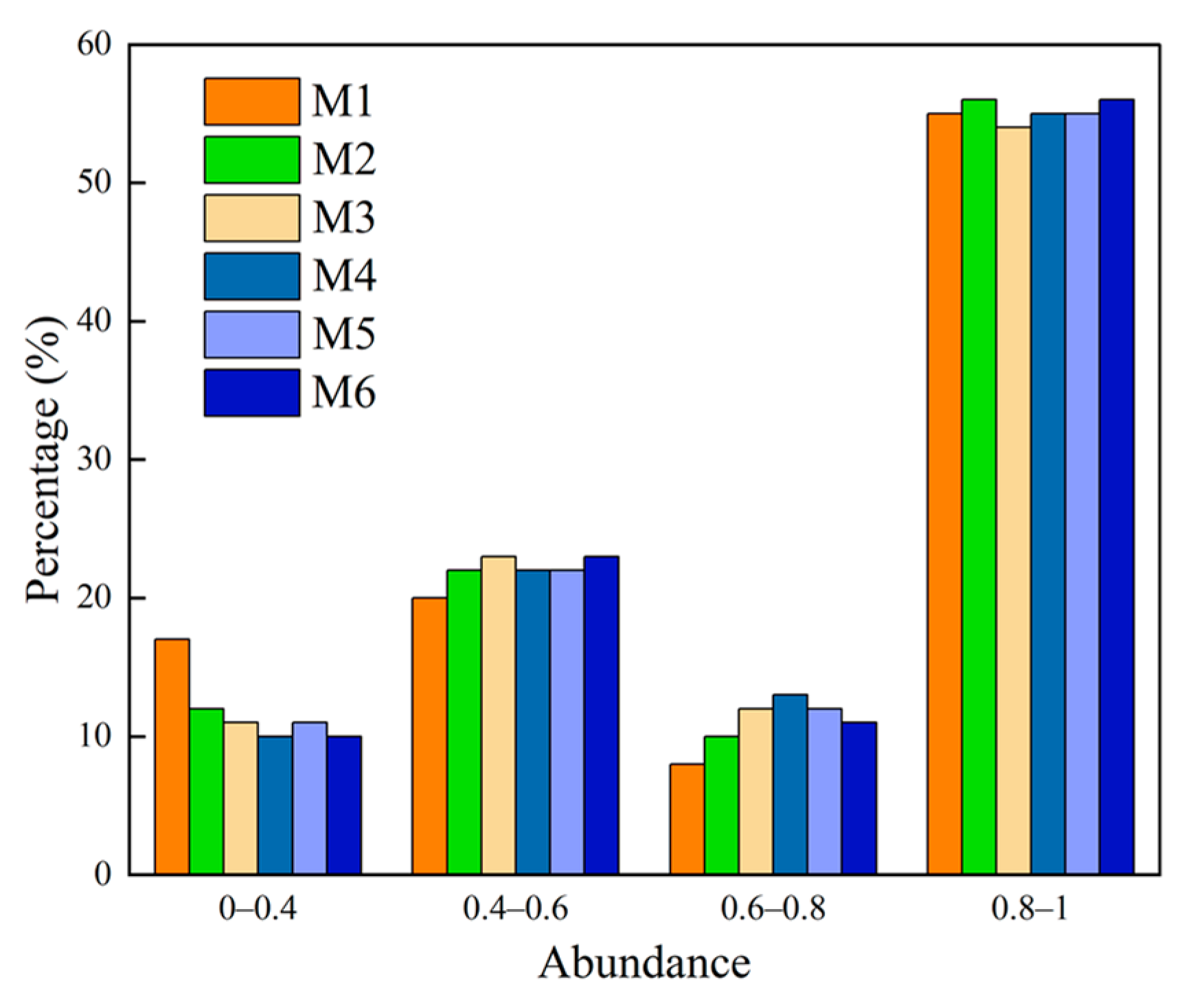

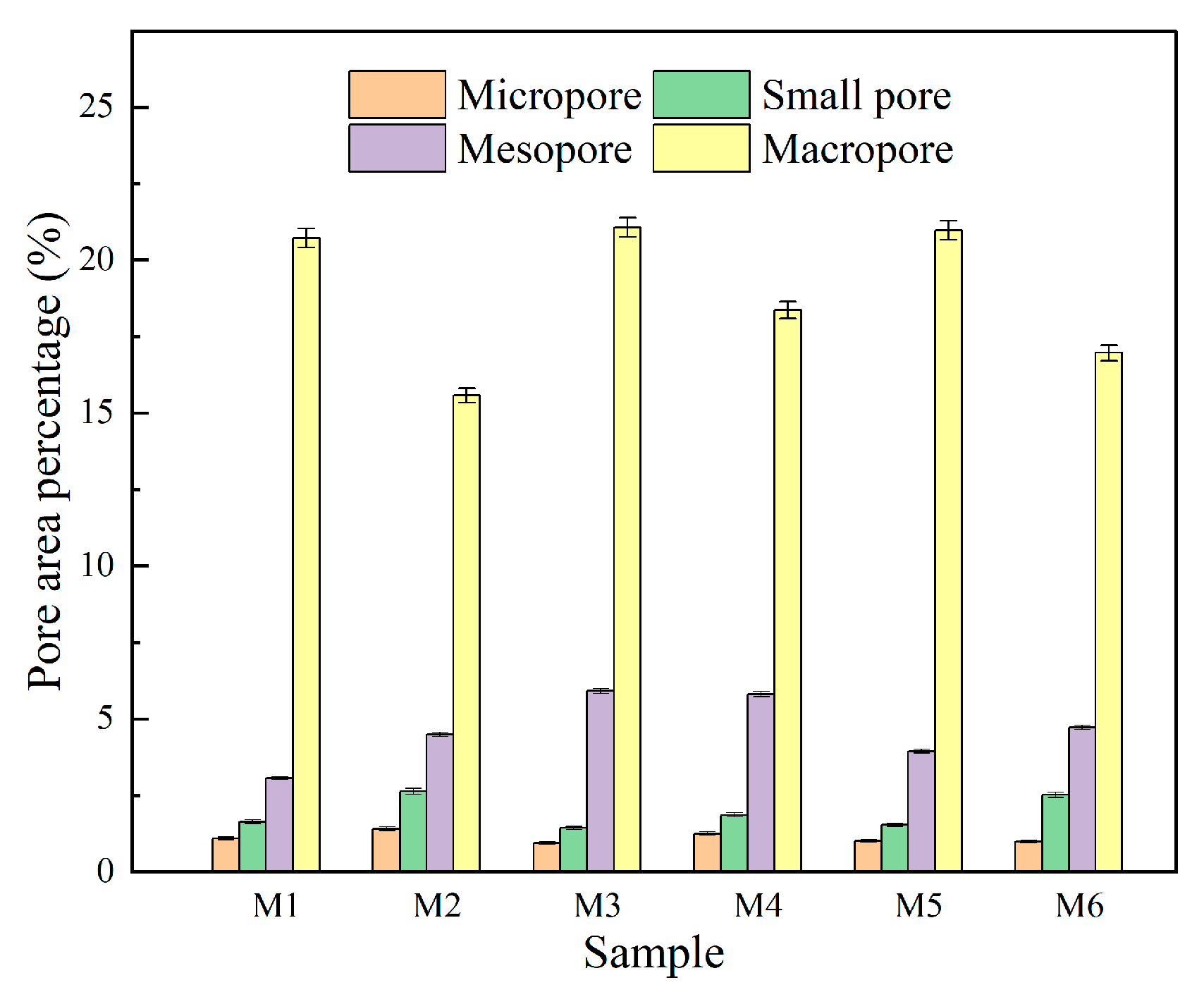

3.2.2. Quantitative Analysis

4. Constitutive Model

4.1. Elastic-Plastic Deformation Theory

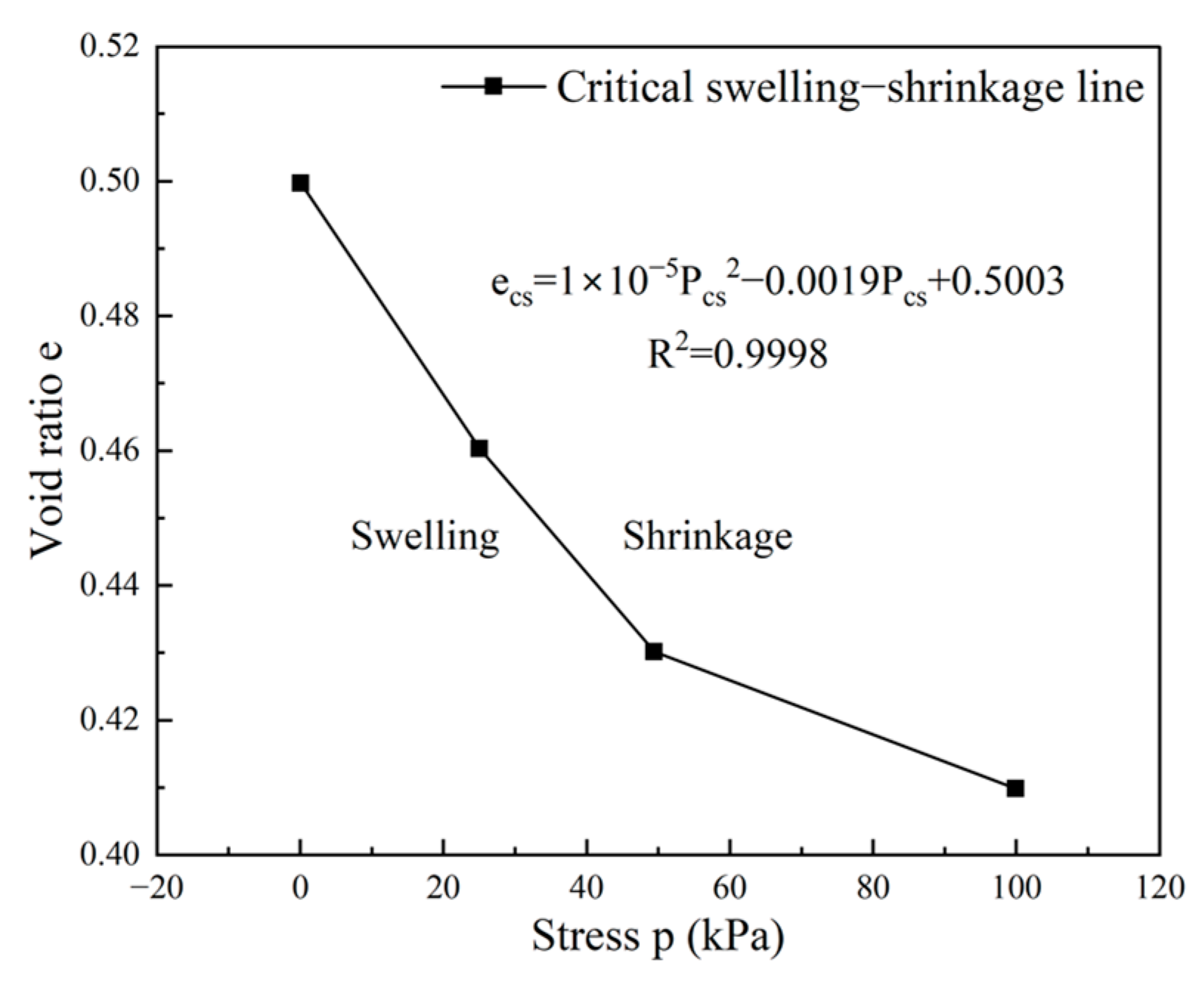

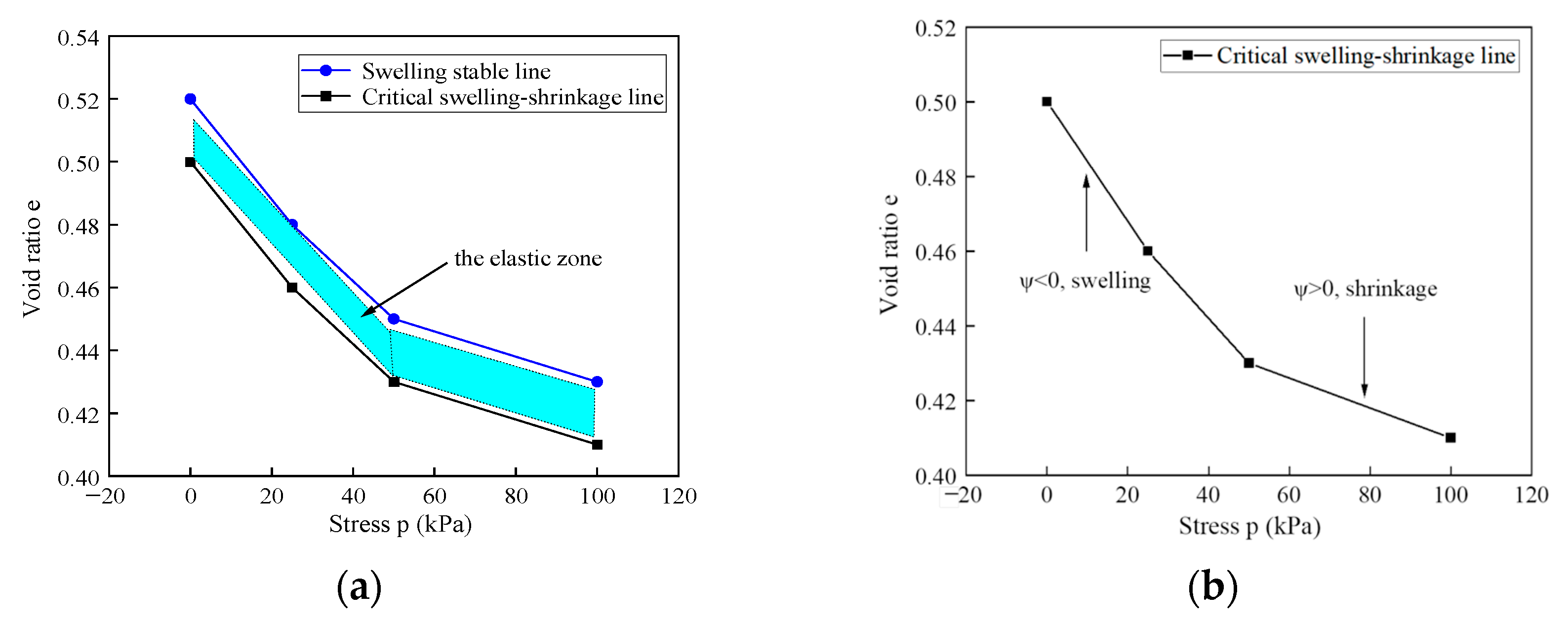

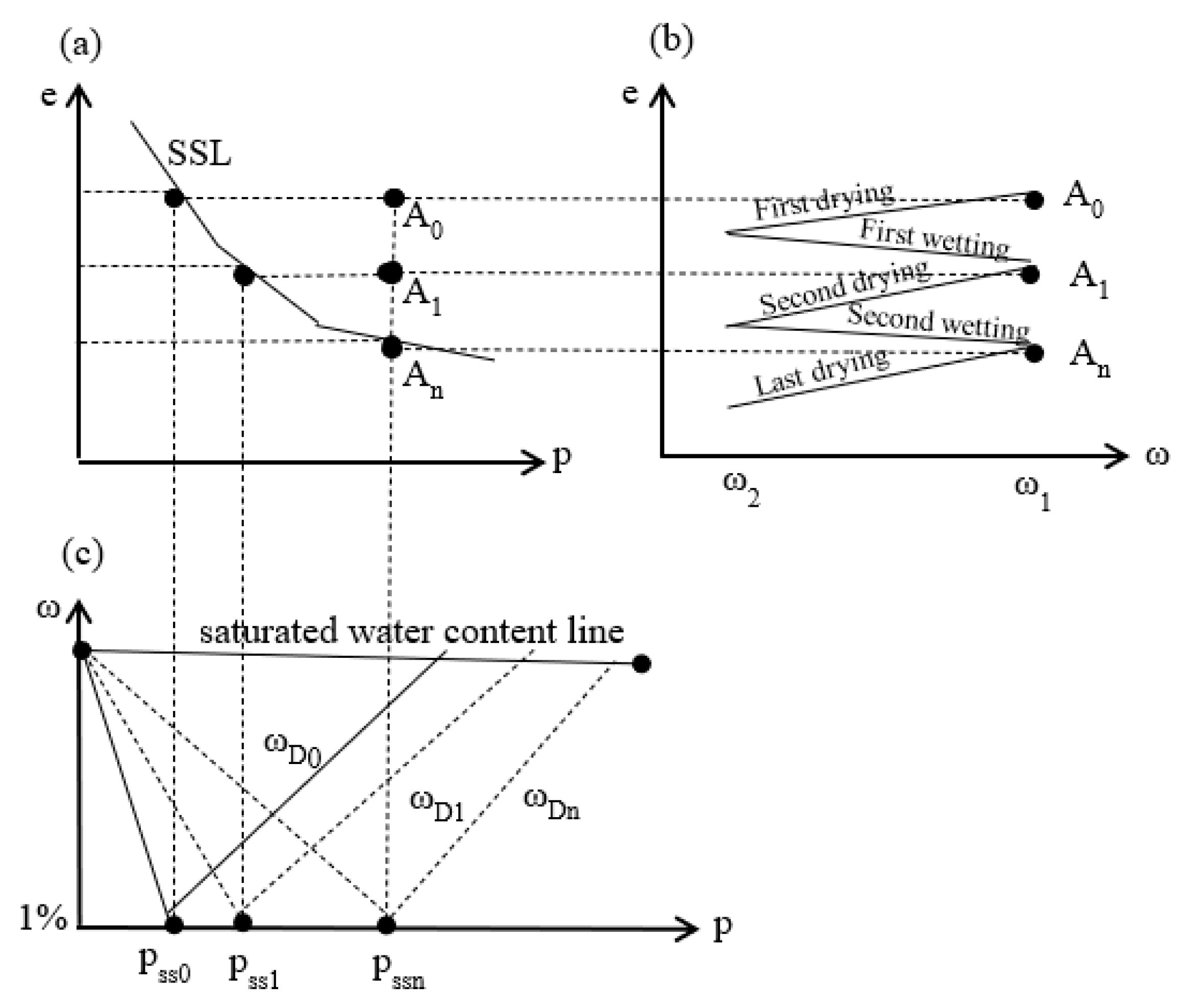

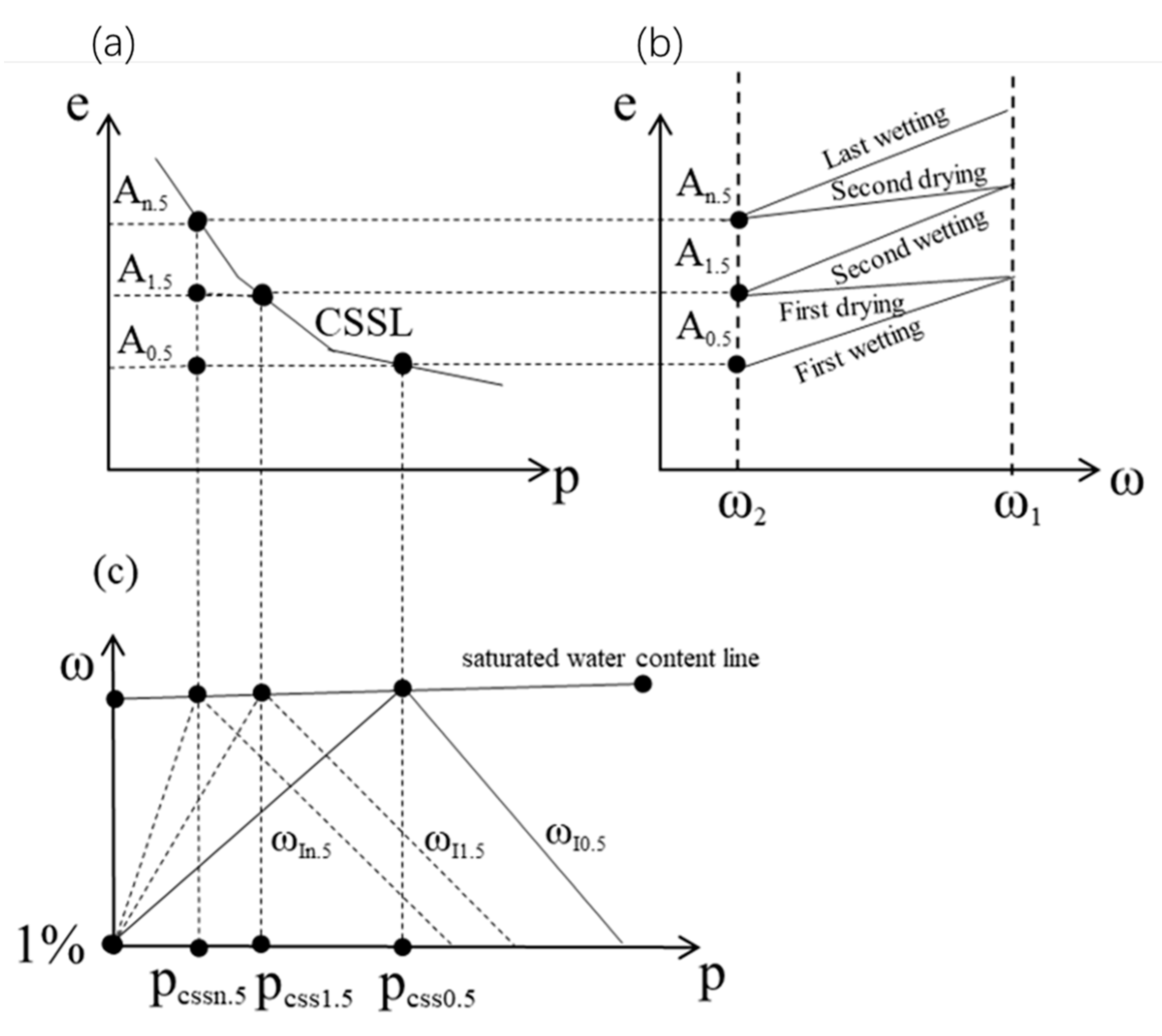

4.2. Critical Swelling and Shrinkage Lines

- (1)

- After the sample has undergone several D-W cycles, the swelling deformation is equal to the shrinkage deformation. At this point, the total deformation of the samples is the elastic deformation during the D-W cycles. Ultimately, the soil will reach an equilibrium state.

- (2)

- It can be observed that smaller loads are more likely to result in swelling deformation in the total deformation of the soil mass with a given initial dry density. Conversely, a larger load is more likely to cause shrinkage deformation in the total deformation. Therefore, it is crucial to determine the critical stress level at which the cumulative deformation of the soil with a given dry density reaches zero after a series of D-W cycles.

- (3)

- According to the test results, there exists a critical dry density such that the total deformation of the soil at this stress after D-W cycles is zero. For soils with different dry densities under the same loading condition, those with higher dry densities tend to generate swelling deformation, while those with lower dry densities tend to generate shrinkage deformation.

4.3. Swelling Stable Line

4.4. Elastic Zone and State Parameters

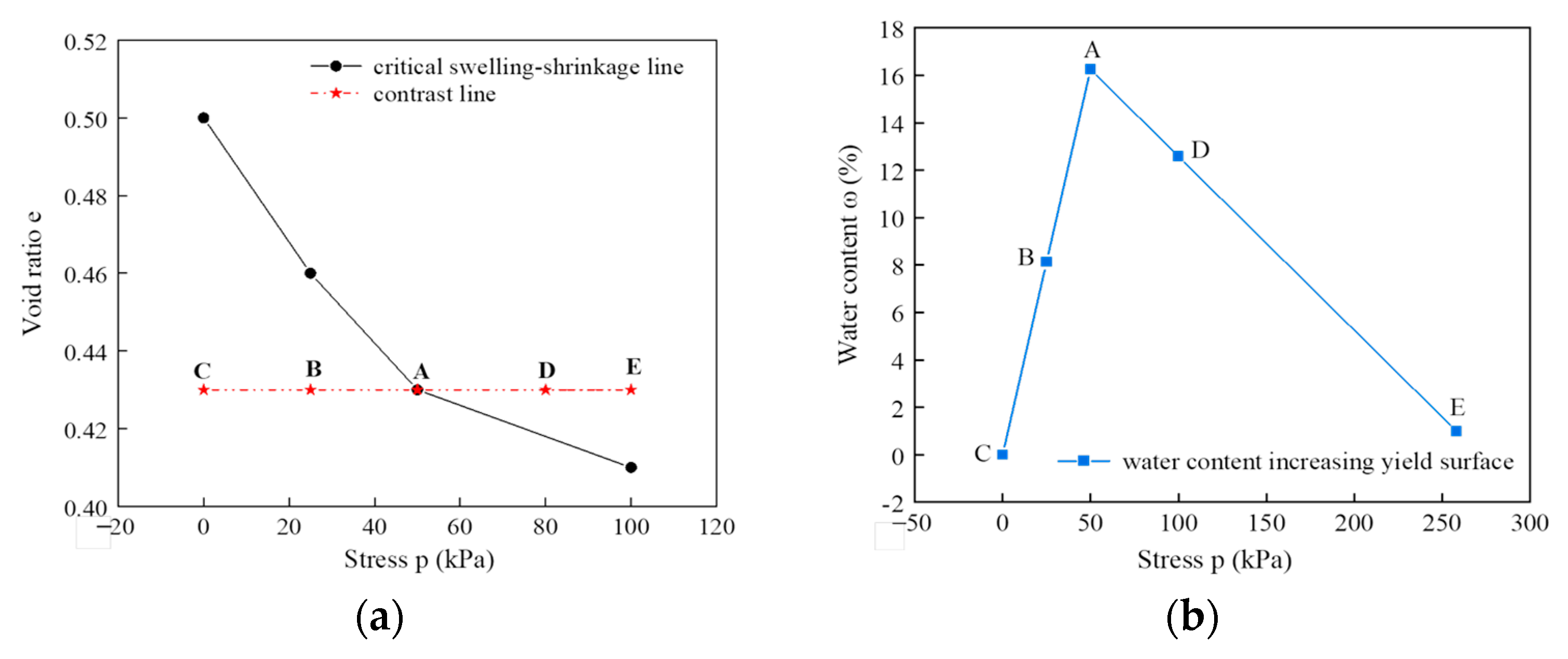

4.5. Water Content Yield Surface

- (1)

- Water content decreasing yield surface.

- (2)

- Water content increasing yield surface.

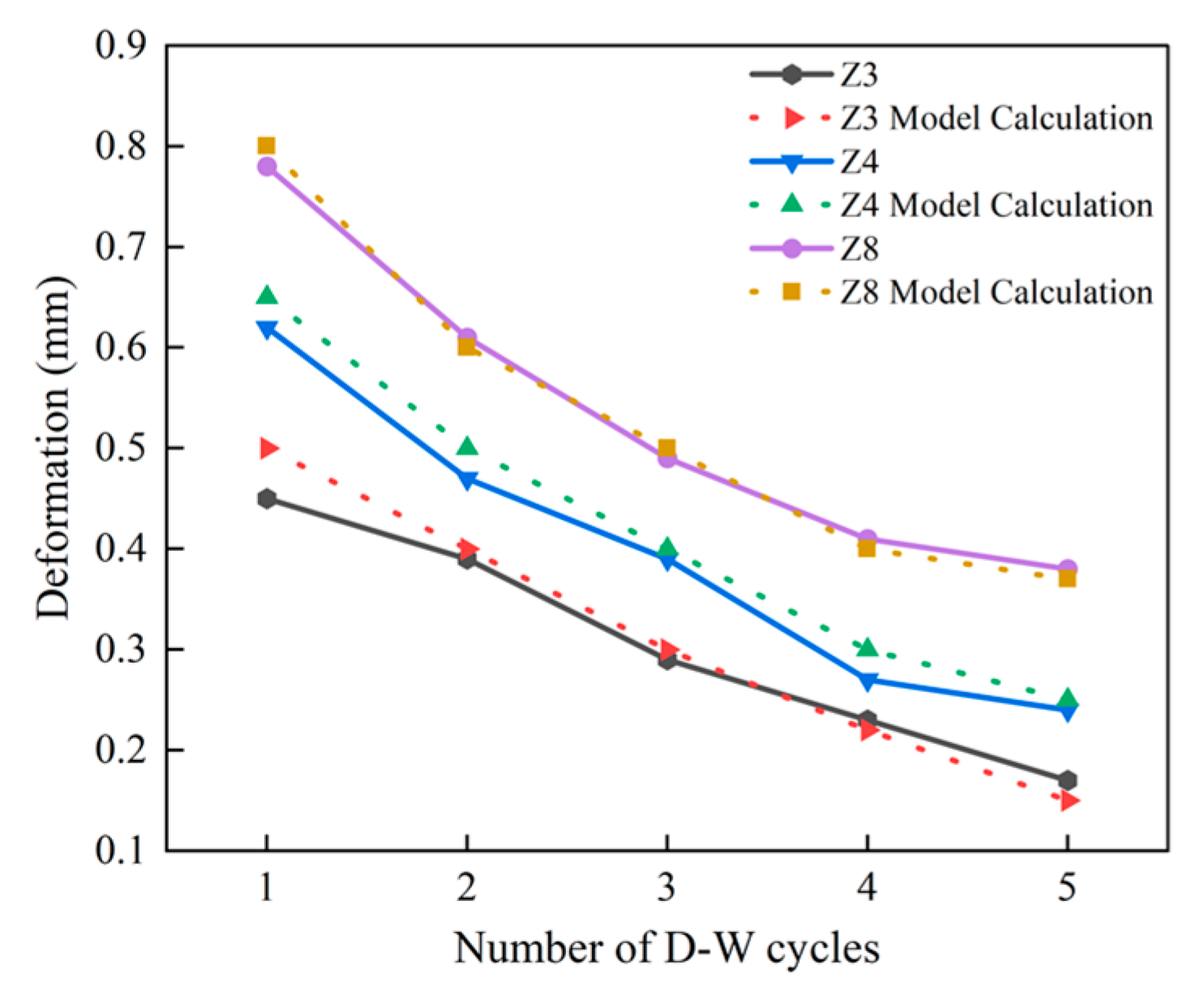

4.6. Model Verification

4.6.1. Model Calculation Methods

4.6.2. Comparative Verification

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, Z.J.; Miao, P.Y. Simulation experiment on surface deformation evolution regulation of loess slope under dry-wet alternate environment. Sci. Technol. Eng. 2018, 18, 117–123. [Google Scholar]

- Feng, H.X.; Xing, X.G.; Su, L.C. Insights into saline soil cracking subjected to drying-wetting cycles. Acta Geophys. 2025, 73, 619–633. [Google Scholar] [CrossRef]

- Li, C.; Deng, W.D.; Cui, X.K. The study on resilient modulus of remolded loess in moisture circulation process. J. Transp. Sci. 2009, 25, 8–12. [Google Scholar]

- Mao, Y.C.; Li, G.Y.; Lei, J.X. Experimental study on the effects of wetting-drying cycles of compacted loess. Adv. Mater. Res. 2014, 831, 326–330. [Google Scholar] [CrossRef]

- Niu, L.S.; Zhang, A.J.; Zhao, J.M. Study on Soil-Water Characteristics of Expansive Soil under the Dry-Wet Cycle and Freeze-Thaw Cycle considering Volumetric Strain. Adv. Civ. Eng. 2021, 2021, 6622370. [Google Scholar] [CrossRef]

- Yuliana, Y.; Arwan, A.; Viroon, K. Seasonal dynamics of root growth and desiccation cracks and their effects on soil hydraulic conductivity. Eng. Geol. 2025, 349, 107973. [Google Scholar] [CrossRef]

- Guo, H.; Li, W.y.; Dang, F. The shrinkage crack characteristics of jute fiber-modified clay under wet-dry cycle conditions. Constr. Build. Mater. 2025, 472, 140840. [Google Scholar] [CrossRef]

- Tang, C.; Shi, B.; Liu, C. Influencing factors of geometrical structure of surface shrinkage cracks in clayey soils. Eng. Geol. 2008, 101, 204–217. [Google Scholar] [CrossRef]

- Pires, L.F.; Bacchi, O.O.S.; Reichardt, K. Gamma ray computed tomography to evaluate wetting/drying soil structure changes. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2005, 229, 443–456. [Google Scholar] [CrossRef]

- Ye, W.J.; Li, C.Q.; Ma, W.C. Mechanism Fractured Loess Expansion Joints under the Effect of Wet-dry Cycle. Sci. Technol. Eng. 2016, 16, 122–127. [Google Scholar]

- Ye, W.J.; Li, C.Q.; Yang, G.S. Evolution of loess crack under action of dehumidification-humidification. J. Eng. Geol. 2017, 25, 376–383. [Google Scholar] [CrossRef]

- Pan, Z.X.; Yang, G.S.; Ye, W.J. Study on mechanical properties and microscopic damage of undisturbed loess under dry and wet cycles. J. Eng. Geol. 2020, 28, 1186–1192. [Google Scholar] [CrossRef]

- Archie, G.E. The electrical resistivity log as aid in determining some reservoir characteristics. Pet. Technol. 1942, 146, 54–61. [Google Scholar] [CrossRef]

- Alibrahim, B.; Eris, U. Influence of compaction method and effort on electrical resistivity and volume change of cohesive soils. KSCE J. Civ. Eng. 2021, 25, 2381–2393. [Google Scholar]

- Filho, A.M.S.; Furriel, G.P.; Calixto, W.P. Alves Methodology to correlate the humidity, compaction and soil apparent electrical conductivity. In Proceedings of the 2015 CHILEAN Conference on Electrical, Electronics Engineering, Information and Communication Technologies (CHILECON), Santiago, Chile, 28–30 October 2015; pp. 729–734. [Google Scholar] [CrossRef]

- Liu, Z.B.; Zhang, Y.; Fang, W. Experimental research on relationship between electrical resistivity and compactibility of loess. J. Xi’an Univ. Sci. Technol. 2013, 33, 84–90. [Google Scholar]

- Zhu, C.H.; Li, N. Mesoscopic deformation mechanism of loess high-fill foundation based on soil electrical resistivity. Chin. J. Rock Mech. Eng. 2013, 32, 640–648. [Google Scholar]

- Dong, X.Q.; Huang, F.F.; Su, N.N. Experimental study of AC electrical resistivity of unsaturated loess during compression. Chin. J. Rock Mech. Eng. 2015, 34, 189–197. [Google Scholar] [CrossRef]

- Qin, P.J.; Liu, Y.B.; Song, Z.W. An electrical resistivity method of characterizing hydromechanical and structural properties of compacted loess during constant rate of strain compression. Sensors 2020, 20, 4783. [Google Scholar] [CrossRef]

- Xu, J.; Li, Y.; Ren, C. Damage of saline intact loess after dry-wet and its interpretation based on SEM and NMR. Soils Found. 2020, 60, 911–928. [Google Scholar] [CrossRef]

- Yuan, K.; Ni, W.; Lü, X. Influence of wetting–drying cycles on the compression behavior of a compacted loess from microstructure analysis. Bull. Eng. Geol. Environ. 2022, 81, 348. [Google Scholar] [CrossRef]

- Ye, W.; Wu, Y.; Bai, Y. Study of Macro- and Mesodamage of Remolded Loess under Alternating Dry and Wet Conditions in an Acid Rain Environment. Adv. Mater. Sci. Eng. 2021, 2021, 5158150. [Google Scholar] [CrossRef]

- Kong, D.H.; Wu, T.; Xu, H.Q. Variation and correlation between water retention capacity and gas permeability of compacted loess overburden during wetting-drying cycles. Environ. Res. 2024, 252, 118895. [Google Scholar] [CrossRef] [PubMed]

- Qin, B.; Li, X.A.; Wang, L. Model interpretation and microscopic characteristics of collapsibility evolution of compacted loess under dry-wet cycles. Catena 2024, 246, 108413. [Google Scholar] [CrossRef]

- Alonso, E.E.; Gens, A.; Josa, A. A constitutive model for partially saturated soils. Géotechnique 1990, 40, 405–430. [Google Scholar] [CrossRef]

- Alonso, E.E.; Vaunat, J.; Gens, A. Modelling the mechanical behaviour of expansive clays. Eng. Geol. 1999, 54, 173–183. [Google Scholar] [CrossRef]

- Zhao, N.F.; Ye, W.M.; Chen, Y.G. Investigation on swelling-shrinkage behavior of unsaturated compacted GMZ bentonite on wetting-drying cycles. Bull. Eng. Geol. Environ. 2019, 78, 617–627. [Google Scholar] [CrossRef]

- Zhao, N.F.; Ye, W.M.; Chen, B. Modeling of the swelling-shrinkage behavior of expansive clays during wetting-drying cycles. Acta Geotech. 2019, 14, 1325–1335. [Google Scholar] [CrossRef]

- Qin, P.J.; Song, Z.W.; Wang, Y.B. Experimental studies on structure properties of compacted loess during constant strain rate compaction. J. Taiyuan Univ. Technol. 2020, 51, 620–626. [Google Scholar] [CrossRef]

- Hu, Z.; Ai, P.; Li, Z.C. Electrical resistivity evolution of compacted silty clay under wetting-drying cycles sequentially coupled with dynamic loads. Rock Soil Mech. 2021, 42, 2722–2732. [Google Scholar] [CrossRef]

- Wu, G.; Wang, K.; Zhao, M. Analysis of damage evolution of sandstone under uniaxial loading and unloading conditions based on resistivity characteristics. Adv. Civ. Eng. 2019, 2019, 9286819. [Google Scholar] [CrossRef]

- Duan, Z.; Yan, X.S.; Sun, Q. Effects of water content and salt content on electrical resistivity of loess. Environ. Earth Sci. 2021, 80, 469. [Google Scholar] [CrossRef]

- Liu, K.; Ye, W.J.; Gao, H.J. Multi-scale effects of mechanical property degradation of expansive soils under drying-wetting environments. Chin. J. Rock Mech. Eng. 2020, 39, 2148–2159. [Google Scholar] [CrossRef]

- Lei, X. The types of loess pores in China and their relationship with collapsibility. Sci. Sin. Ser. B Chem. Biol. Agric. Med. Earth Sci. 1988, 31, 1398–1410. [Google Scholar]

- Nie, Y.; Ni, W.; Lü, X.; Tuo, W.; Yuan, K. Macroscopic mechanical behavior and microstructural evolution of compacted loess in the Chinese Loess Plateau. Soil Tillage Res. 2023, 232, 105767. [Google Scholar] [CrossRef]

- Zhao, G.T.; Zou, W.L.; Han, Z. Evolution of soil-water and shrinkage characteristics of an expansive clay during freeze-thaw and drying-wetting cycles. Cold Reg. Sci. Technol. 2021, 186, 103275. [Google Scholar] [CrossRef]

| Specific Gravity | Maximum Dry Density (g·cm−3) | Optimum Water Content (%) | Liquid Limit (%) | Plastic Limit (%) | Plasticity Index | Collapsibility Coefficient |

|---|---|---|---|---|---|---|

| Gs | ρmax | ωopt | ωL | ωP | IP | ∆s |

| 2.77 | 1.72 | 15.3 | 22.8 | 13.1 | 9.71 | 0.02 |

| Number | Initial Dry Density ρd (g·cm−3) | Initial Height (mm) | Initial Water Content (%) | Final Water Content (%) | Number of Dry–Wet Cycles |

|---|---|---|---|---|---|

| Z1 | 1.54 | 10.07 | 5.42 | 5.13 | 1 |

| Z2 | 1.62 | 10.04 | 5.33 | 15.02 | 3 |

| Z3 | 1.68 | 9.87 | 5.24 | 24.87 | 5 |

| Z4 | 1.62 | 10.03 | 14.72 | 4.96 | 5 |

| Z5 | 1.69 | 9.96 | 14.84 | 14.87 | 1 |

| Z6 | 1.53 | 10.12 | 15.13 | 25.12 | 3 |

| Z7 | 1.71 | 10.02 | 25.22 | 5.07 | 3 |

| Z8 | 1.50 | 10.01 | 24.84 | 15.02 | 5 |

| Z9 | 1.62 | 10.06 | 25.13 | 24.95 | 1 |

| M1 | 1.51 | 9.93 | 15 | 15 | 0 |

| M2 | 1.71 | 9.96 | 15 | 15 | 0 |

| M3 | 1.49 | 10.08 | 15 | 15 | 3 |

| M4 | 1.71 | 9.95 | 15 | 15 | 3 |

| M5 | 1.5 | 10.01 | 15 | 5 | 3 |

| M6 | 1.71 | 9.93 | 15 | 5 | 3 |

| Number | Vertical Strain | Resistivity Ratio | Crack Ratio |

|---|---|---|---|

| Z1 | 0.005 | 14.37 | 0.28 |

| Z2 | 0.014 | 1.49 | 1.57 |

| Z3 | 0.017 | 0.85 | 2.44 |

| Z4 | 0.024 | 21.40 | 2.04 |

| Z5 | 0.002 | 1.43 | 0.12 |

| Z6 | 0.015 | 1.05 | 2.06 |

| Z7 | 0.014 | 0.74 | 1.25 |

| Z8 | 0.038 | 2.59 | 2.92 |

| Z9 | 0.004 | 0.49 | 0.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, P.; Liu, Y.; Yang, C.; Yan, Q.; Liu, Y.; Gong, L.; Zhu, X. Effect of Drying and Wetting Cycles on Deformation Characteristics of Compacted Loess and Constitutive Model. Buildings 2025, 15, 1124. https://doi.org/10.3390/buildings15071124

Qin P, Liu Y, Yang C, Yan Q, Liu Y, Gong L, Zhu X. Effect of Drying and Wetting Cycles on Deformation Characteristics of Compacted Loess and Constitutive Model. Buildings. 2025; 15(7):1124. https://doi.org/10.3390/buildings15071124

Chicago/Turabian StyleQin, Pengju, Yuqi Liu, Chungang Yang, Qingchen Yan, Yubo Liu, Li Gong, and Xingji Zhu. 2025. "Effect of Drying and Wetting Cycles on Deformation Characteristics of Compacted Loess and Constitutive Model" Buildings 15, no. 7: 1124. https://doi.org/10.3390/buildings15071124

APA StyleQin, P., Liu, Y., Yang, C., Yan, Q., Liu, Y., Gong, L., & Zhu, X. (2025). Effect of Drying and Wetting Cycles on Deformation Characteristics of Compacted Loess and Constitutive Model. Buildings, 15(7), 1124. https://doi.org/10.3390/buildings15071124