Challenges and Benefits of Implementing AI in Timber Construction for Circular Economy Goals

Abstract

1. Introduction

1.1. Background

1.2. Aims and Objectives

- Analyze the potential contributions of AI applications in advancing a CE within timber construction;

- Identify potential benefits of integrating AI and a CE in timber construction;

- Uncover potential challenges to implementing AI in timber construction to promote CE purposes.

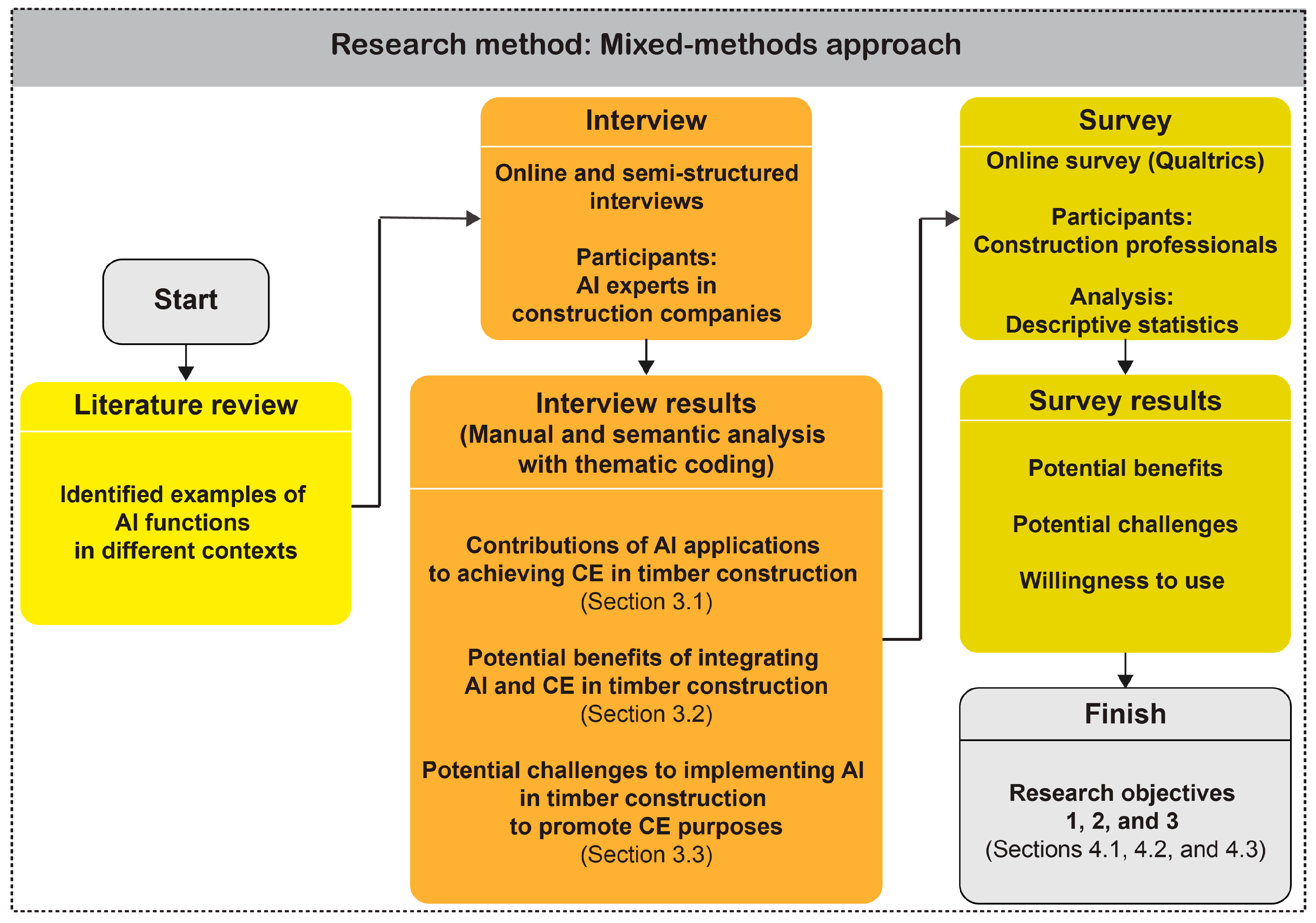

2. Materials and Methods

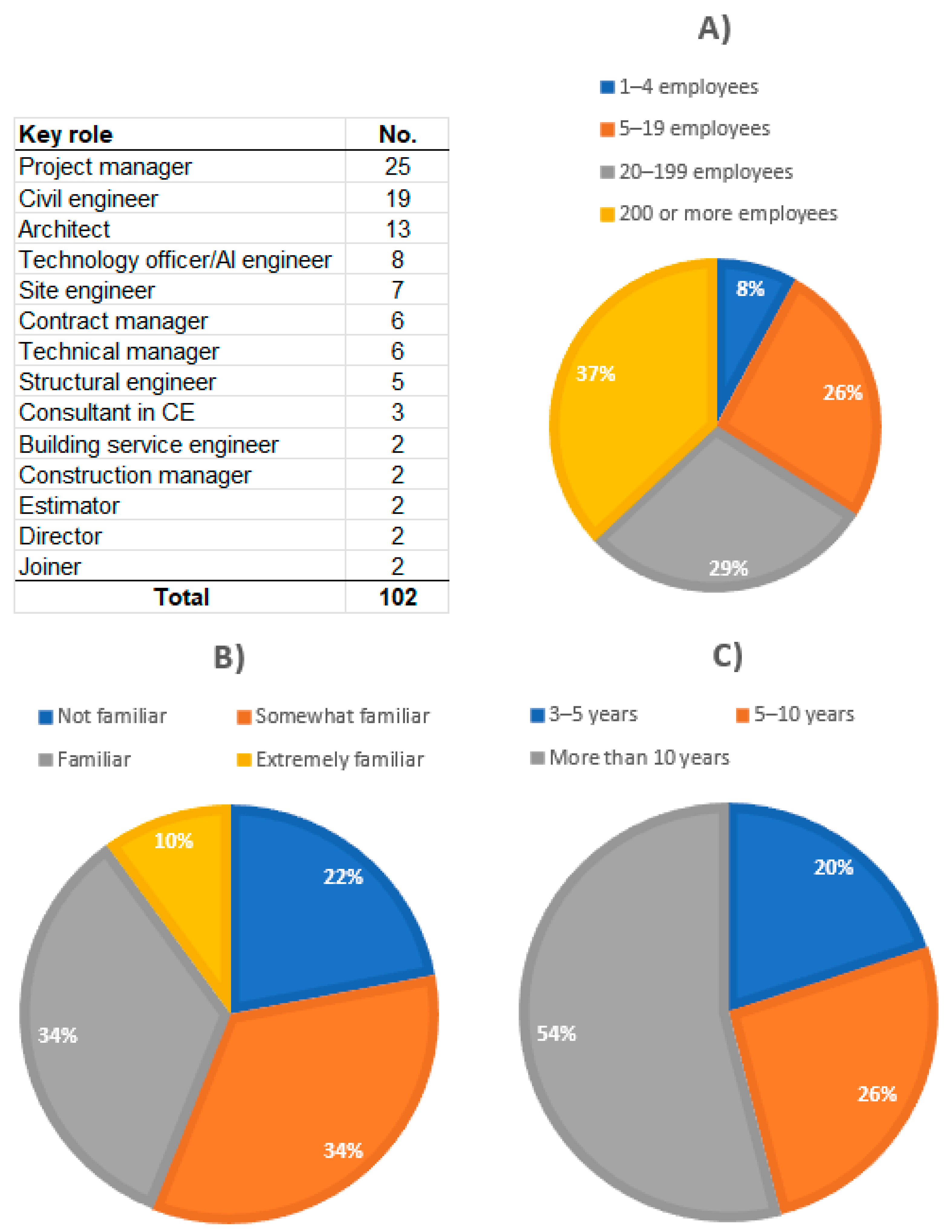

2.1. Interview

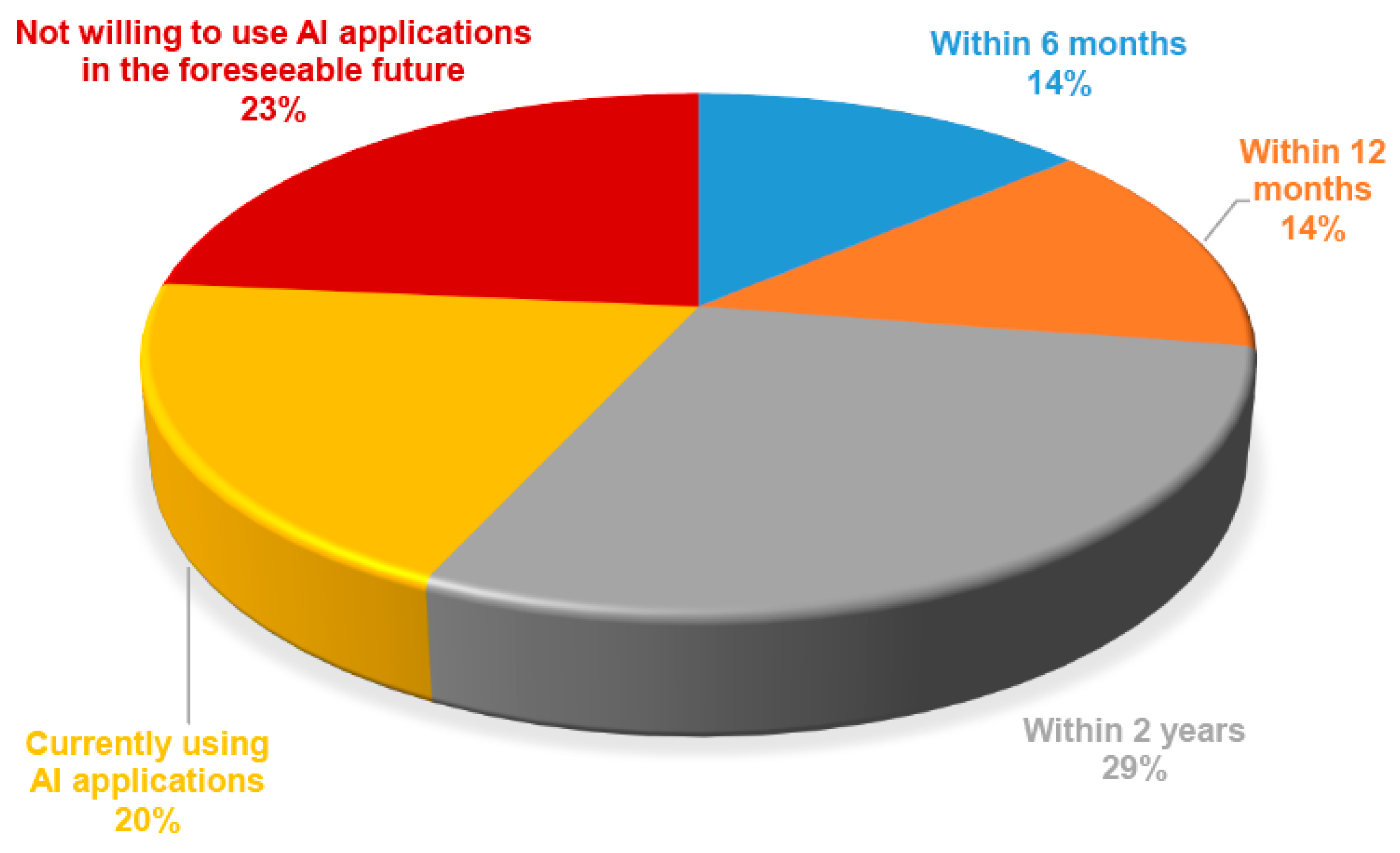

2.2. Survey

3. Results

3.1. Contributions of AI Applications to Achieving CE in Timber Construction

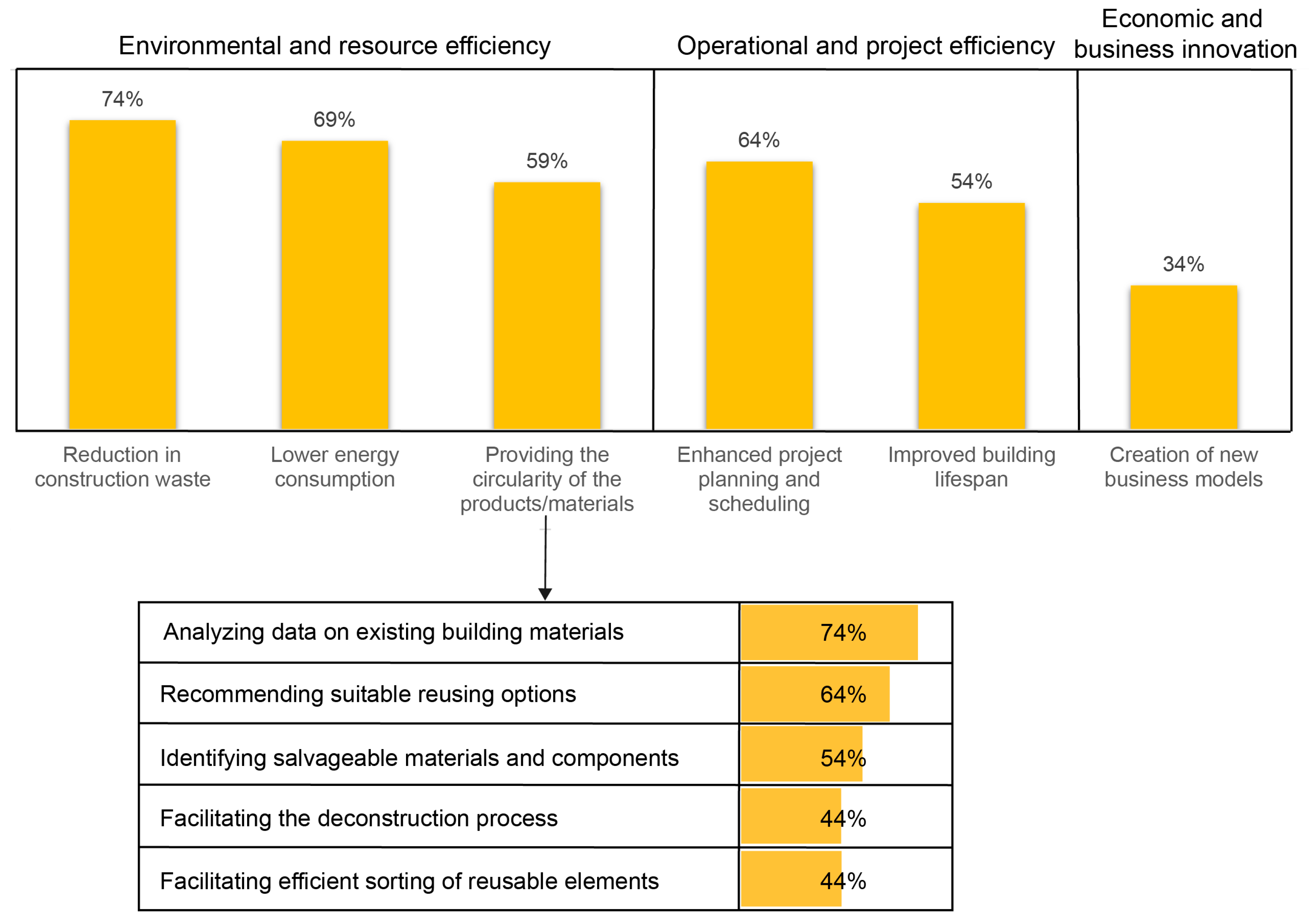

3.2. Potential Benefits of Integrating AI and CE in Timber Construction

“ML models that given enough data, you can begin to predict the behavior, and that would enable you to predict the maintenance requirements […] to increase the buildings’ lifespan”.(Int #2)

“In the future, when more of our buildings are prefabricated, like mass timber construction, you might be able to unbolt the beams and reuse the beams. AI will be able to assist with that, if you’ve got a big enough data set, and you know where all of the prefabricated beams are in all of the buildings across an entire city. And you can say, well, five buildings are coming towards the end of life that 35 years old, they’re not tenanted, maybe, instead of demolishing them, we’ll deconstruct those, and then over here, we can reuse them in a new building”.(Int #2)

“AI could be applied to figuring out new ways with low energy to deconstruction or return them into the base components that could be then reused into something else”.(Int #9)

“I think it is just a matter of time until you have full AI designed buildings. And I’m sure this would probably be more effective from an energy point of view”.(Int #3)

“Using large language models and open AI to help businesses for optimizing business work. […] the main focus is about using AI or ML in a design process of like one product”.(Int #5)

“Over many years, you are doing hundreds of thousands of runs on several supercomputers. But to run a new timber slab on the ground model in the software that allows designers to significantly optimize the design, it would take two days to run an individual dwelling calculation. We’ve used ML techniques to take those hundreds of thousands of runs, and we used the heat three model that we can then insert into [a] software, which will run in a split second and deliver 99.9% accurate results. So, we hope to streamline a whole range of really demanding computational routines and, thus, improve our modeling capabilities”.(Int #1)

“There’s a company called Giraffe, trying to build in design options for building efficiency. So, they’ll give you an option, and they’ll give you an analysis, solid game, or shading”.(Int #2)

“Who does structural engineering calculations? You would be running the same calculations over and over, and that is very inefficient. But my point here is that they would have a very large library of calculations, which get run quite regularly and, like that, lends itself to a ML approach. I’m sure that they could make the calculation process much more efficient through that”.(Int #2)

“If you’re a big development company that has a lot of assets as probably a lot of land, and you have a series of projects to use as models, then potentially you could use AI to look at what the available materials are and try to run generative models to see how much the cost of potential developments could be impacted by using the available materials to reuse. The thing with AI is it’s not very easy to plan so much ahead. Like when you have the task in hand, and you see its benefits and its potential”.(Int #3)

“If it’s all about materials and reusing materials, I would say there would be potential to optimize how different materials are used on a project. For example, whether it be timber, minimizing those materials so you could deploy algorithms to kind of analyze and test how to do that”.(Int #6)

“Using drones and image capture software and then just using AI to analyze the imagery to understand the quality of material usefulness, to help with the kind of demolition process like the staging of demolition to understand which parts we need to break down further to better utilize those materials”.(Int #8)

“The inspection [of a timber] could be done through cameras through some sensors through some devices that could measure, maybe not on a brick spoke timber, you can look to log, maybe each log, maybe you need to sample some logs statistically, and then you can evaluate those or the evaluate endurance with specific devices that meant to measure the difference, you can have a visual inspection of this, again, sample blog. And then you can have a visual inspection of those. And absolutely, an AI model can help you with those evaluations with endurance and quality assessments that are not visual”.(Int #4)

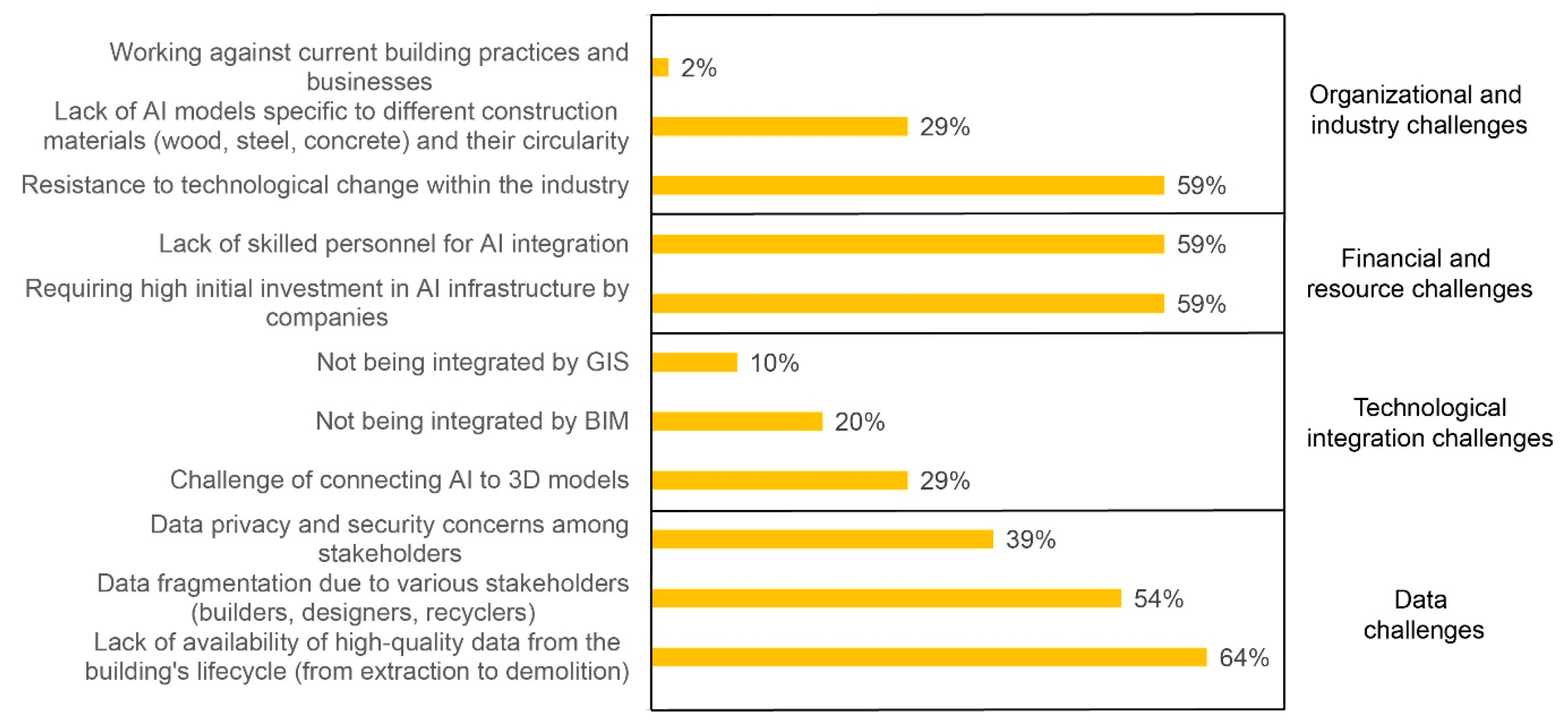

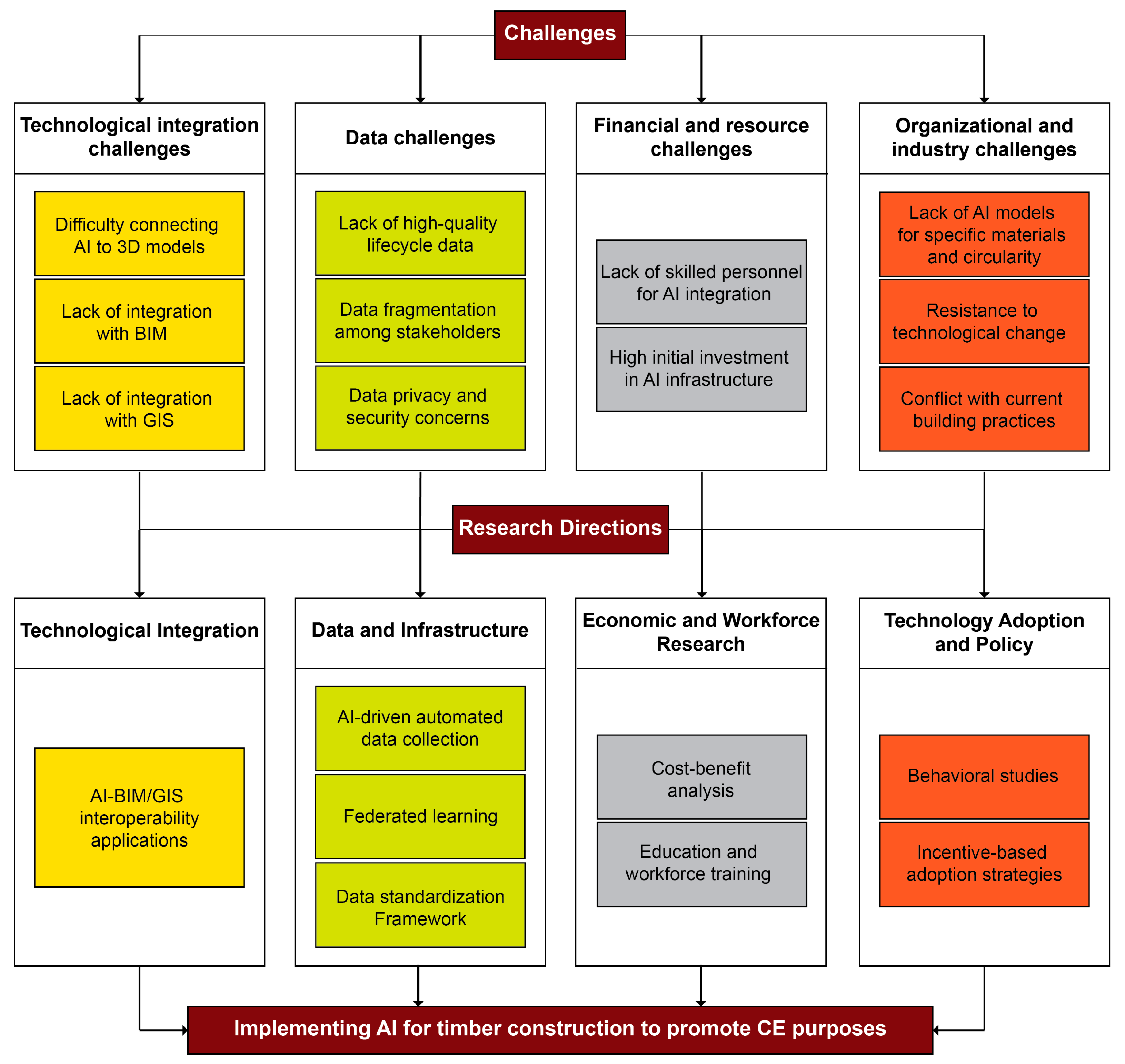

3.3. Potential Challenges to Implementing AI in Timber Construction to Promote CE Purposes

“If you’ve got a good BIM model to start with when you create like the digital twin of the building and then by pairing that model with the images and the drone surveys and the geospatial orientation, it can probably be ok”.(Int #8)

“The actual construction companies will be very slow to update anything new unless it definitely is shown to provide a net benefit. For example, BIM has been pushed for years and has not become a mainstream software system because it is expensive and requires specific training for a nice-looking model that does not provide the returns on investment it promises”.“The focus needs to be on providing the industry with something that provides real-world tangible results and not theoretical ideas that do not work in reality. Construction is a business so any innovations need to provide time or cost-benefit, or they will simply not be utilized”.

4. Discussion

4.1. Contributions of AI Applications to Achieving CE in Timber Construction

4.2. Potential Benefits of Integrating AI and CE in Timber Construction

4.3. Potential Challenges to Implementing AI in Timber Construction to Promote CE Purposes

4.4. Limitations and Future Directions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Balasbaneh, A.T.; Sher, W. Economic and environmental life cycle assessment of alternative mass timber walls to evaluate circular economy in building: MCDM method. Environ. Dev. Sustain. 2022, 26, 239–268. [Google Scholar] [CrossRef]

- Cavalliere, C.; Dell’Osso, G.R.; Favia, F.; Lovicario, M. BIM-based assessment metrics for the functional flexibility of building designs. Autom. Constr. 2019, 107, 102925. [Google Scholar] [CrossRef]

- Ogunmakinde, O.E.; Sher, W.; Egbelakin, T. Circular economy pillars: A semi-systematic review. Clean Technol. Environ. Policy 2021, 23, 899–914. [Google Scholar]

- Halog, A.; Balanay, R.; Anieke, S.; Yu, T.Y. Circular Economy across Australia: Taking Stock of Progress and Lessons. Circ. Econ. Sustain. 2021, 1, 283–301. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Hybrid input-output analysis for life-cycle energy consumption and carbon emissions of China’s building sector. Build. Environ. 2016, 104, 188–197. [Google Scholar]

- Dean, B.; Dulac, J.; Petrichenko, K.; Graham, P. Towards Zero-Emission Efficient and Resilient Building. Global Status Report; Global Alliance for Buildings and Construction: Paris, France, 2016. [Google Scholar]

- Rowcon Recycling. Construction and Demolition Waste: An Overview of Australia’s Growing Problem. Available online: https://rowconrecycling.com.au/the-feed/construction-and-demolition-waste-an-overview-of-australia-s-growing-problem#:~:text=Of%20this%20figure%2C%20approximately%2027,dollars%20added%20to%20the%20economy (accessed on 4 March 2025).

- Hafner, A.; Schäfer, S. Environmental aspects of material efficiency versus carbon storage in timber buildings. Eur. J. Wood Wood Prod. 2018, 76, 1045–1059. [Google Scholar] [CrossRef]

- Silvestre, B.S.; Ţîrcă, D.M. Innovations for sustainable development: Moving toward a sustainable future. J. Clean. Prod. 2019, 208, 325–332. [Google Scholar] [CrossRef]

- Abioye, S.O.; Oyedele, L.O.; Akanbi, L.; Ajayi, A.; Delgado, J.M.D.; Bilal, M.; Akinade, O.O.; Ahmed, A. Artificial intelligence in the construction industry: A review of present status, opportunities and future challenges. J. Build. Eng. 2021, 44, 103299. [Google Scholar] [CrossRef]

- Baduge, S.K.; Thilakarathna, S.; Perera, J.S.; Arashpour, M.; Sharafi, P.; Teodosio, B.; Shringi, A.; Mendis, P. Artificial intelligence and smart vision for building and construction 4.0: Machine and deep learning methods and applications. Autom. Constr. 2022, 141, 104440. [Google Scholar]

- Asif, M.; Naeem, G.; Khalid, M. Digitalization for sustainable buildings: Technologies, applications, potential, and challenges. J. Clean. Prod. 2024, 450, 141814. [Google Scholar] [CrossRef]

- Nishant, R.; Kennedy, M.; Corbett, J. Artificial intelligence for sustainability: Challenges, opportunities, and a research agenda. Int. J. Inf. Manag. 2020, 53, 102104. [Google Scholar] [CrossRef]

- Acerbi, F.; Forterre, D.A.; Taisch, M. Role of artificial intelligence in circular manufacturing: A systematic literature review. IFAC-Pap. 2021, 54, 367–372. [Google Scholar] [CrossRef]

- Chien, C.-F.; Dauzère-Pérès, S.; Huh, W.T.; Jang, Y.J.; Morrison, J.R. Artificial intelligence in manufacturing and logistics systems: Algorithms, applications, and case studies. Int. J. Prod. Res. 2020, 58, 2730–2731. [Google Scholar] [CrossRef]

- Regona, M.; Yigitcanlar, T.; Xia, B.; Li, R.Y.M. Opportunities and adoption challenges of AI in the construction industry: A PRISMA review. J. Open Innov. Technol. Mark. Complex. 2022, 8, 45. [Google Scholar] [CrossRef]

- Yigitcanlar, T. Greening the artificial intelligence for a sustainable planet: An editorial commentary. Sustainability 2021, 13, 13508. [Google Scholar] [CrossRef]

- Momade, M.H.; Durdyev, S.; Estrella, D.; Ismail, S. Systematic review of application of artificial intelligence tools in architectural, engineering and construction. Front. Eng. Built Environ. 2021, 1, 203–216. [Google Scholar] [CrossRef]

- Alonso, S.L.N.; Forradellas, R.F.R.; Morell, O.P.; Jorge-Vazquez, J. Digitalization, circular economy and environmental sustainability: The application of artificial intelligence in the efficient self-management of waste. Sustainability 2021, 13, 2092. [Google Scholar] [CrossRef]

- Kroell, N.; Thor, E.; Göbbels, L.; Schönfelder, P.; Chen, X. Deep learning-based prediction of particle size distributions in construction and demolition waste recycling using convolutional neural networks on 3D laser triangulation data. Constr. Build. Mater. 2025, 466, 140214. [Google Scholar] [CrossRef]

- Omer, M.; Wang, Y.C.; Quintana Roma, M.; Bedrich, S.; Nežerka, V.; Ferriz-Papi, J.; Moros Montanes, J.J.; Diez Ortiz, I. Development of a 3D Digital Model of End-of-Service-Life Buildings for Improved Demolition Waste Management through Automated Demolition Waste Audit. Environments 2024, 11, 138. [Google Scholar] [CrossRef]

- Cabral, S.; Klimenka, M.; Bademosi, F.; Lau, D.; Pender, S.; Villaggi, L.; Stoddart, J.; Donnelly, J.; Storey, P.; Benjamin, D. A Contactless Multi-Modal Sensing Approach for Material Assessment and Recovery in Building Deconstruction. Sustainability 2025, 17, 585. [Google Scholar] [CrossRef]

- Rane, N.; Choudhary, S.; Rane, J. Artificial Intelligence (AI) and Internet of Things (IoT)-Based Sensors for Monitoring and Controlling in Architecture, Engineering, and Construction: Applications, Challenges, and Opportunities; Available at SSRN 4642197; SSRN: Rochester, NY, USA, 2023. [Google Scholar]

- Mehmood, M.U.; Chun, D.; Zeeshan; Han, H.; Jeon, G.; Chen, K. A review of the applications of artificial intelligence and big data to buildings for energy-efficiency and a comfortable indoor living environment. Energy Build. 2019, 202, 109383. [Google Scholar] [CrossRef]

- Namlı, E.; Erdal, H.; Erdal, H.I. Artificial Intelligence-Based Prediction Models for Energy Performance of Residential Buildings. In Recycling and Reuse Approaches for Better Sustainability; Balkaya, N., Guneysu, S., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 141–149. [Google Scholar]

- Farzaneh, H.; Malehmirchegini, L.; Bejan, A.; Afolabi, T.; Mulumba, A.; Daka, P.P. Artificial Intelligence Evolution in Smart Buildings for Energy Efficiency. Appl. Sci. 2021, 11, 763. [Google Scholar] [CrossRef]

- Ji, S.; Lee, B.; Yi, M.Y. Building life-span prediction for life cycle assessment and life cycle cost using machine learning: A big data approach. Build. Environ. 2021, 205, 108267. [Google Scholar] [CrossRef]

- D’Amico, A.; Ciulla, G.; Traverso, M.; Lo Brano, V.; Palumbo, E. Artificial Neural Networks to assess energy and environmental performance of buildings: An Italian case study. J. Clean. Prod. 2019, 239, 117993. [Google Scholar] [CrossRef]

- Ulucan, M.; Yildirim, G.; Alatas, B.; Esat Alyamac, K. Modelling and evaluation of mechanical performance and environmental impacts of sustainable concretes using a multi-objective optimization based innovative interpretable artificial intelligence method. J. Environ. Manag. 2024, 372, 123364. [Google Scholar] [CrossRef]

- Roberts, H.; Zhang, J.; Bariach, B.; Cowls, J.; Gilburt, B.; Juneja, P.; Tsamados, A.; Ziosi, M.; Taddeo, M.; Floridi, L. Artificial intelligence in support of the circular economy: Ethical considerations and a path forward. AI Soc. 2022, 39, 1451–1464. [Google Scholar]

- Okorie, O.; Salonitis, K.; Charnley, F.; Moreno, M.; Turner, C.; Tiwari, A. Digitisation and the circular economy: A review of current research and future trends. Energies 2018, 11, 3009. [Google Scholar] [CrossRef]

- Bressanelli, G.; Adrodegari, F.; Perona, M.; Saccani, N. Exploring how usage-focused business models enable circular economy through digital technologies. Sustainability 2018, 10, 639. [Google Scholar] [CrossRef]

- Blunck, E.; Salah, Z.; Kim, J. Industry 4.0 Ai and circular economy-opportunities and challenges for a sustainable development. In Proceedings of the 4th Dubrovnik International Economic Meeting (DIEM), Dubrovnik, Croatia, 27–28 September 2019; pp. 17–42. [Google Scholar]

- Oluleye, B.I.; Chan, D.W.; Antwi-Afari, P. Adopting Artificial Intelligence for enhancing the implementation of systemic circularity in the construction industry: A critical review. Sustain. Prod. Consum. 2023, 35, 509–524. [Google Scholar] [CrossRef]

- Man, N.X. Automating the design and assembly process of timber block construction system. In Proceedings of the International Conference on Construction Digitalisation for Sustainable Development: Transformation Through Innovation, Hanoi, Vietnam, 24–25 November 2020. [Google Scholar]

- Bianconi, F.; Filippucci, M. WOOD, CAD AND AI: Digital Modelling as Place of Convergence of Natural and Artificial Intelligent to Design Timber Architecture. In Digital Wood Design: Innovative Techniques of Representation in Architectural Design; Bianconi, F., Filippucci, M., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 3–60. [Google Scholar]

- Naser, M.Z. Fire resistance evaluation through artificial intelligence—A case for timber structures. Fire Saf. J. 2019, 105, 1–18. [Google Scholar] [CrossRef]

- Olimat, A.N.; Al-Shawabkeh, A.F.; Al-Qadi, Z.A.; Al-Najdawi, N.A. Forecasting the influence of the guided flame on the combustibility of timber species using artificial intelligence. Case Stud. Therm. Eng. 2022, 38, 102379. [Google Scholar] [CrossRef]

- Floridi, L.; Cowls, J.; King, T.C.; Taddeo, M. How to design AI for social good: Seven essential factors. In Ethics, Governance, and Policies in Artificial Intelligence; Springer: Cham, Switzerland, 2021; pp. 125–151. [Google Scholar]

- Płoszaj-Mazurek, M.; Ryńska, E. Artificial Intelligence and Digital Tools for Assisting Low-Carbon Architectural Design: Merging the Use of Machine Learning, Large Language Models, and Building Information Modeling for Life Cycle Assessment Tool Development. Energies 2024, 17, 2997. [Google Scholar] [CrossRef]

- Perez, H.; Tah, J.H.M.; Mosavi, A. Deep Learning for Detecting Building Defects Using Convolutional Neural Networks. Sensors 2019, 19, 3556. [Google Scholar] [CrossRef]

- Pathan, M.S.; Richardson, E.; Galvan, E.; Mooney, P. The Role of Artificial Intelligence within Circular Economy Activities—A View from Ireland. Sustainability 2023, 15, 9451. [Google Scholar] [CrossRef]

- Mason, H.E.; Walsh, S.D.; DuFrane, W.L.; Carroll, S.A. Determination of diffusion profiles in altered wellbore cement using X-ray computed tomography methods. Environ. Sci. Technol. 2014, 48, 7094–7100. [Google Scholar] [CrossRef]

- Corbin, J.; Strauss, A. Basics of Qualitative Research: Techniques and Procedures for Developing Grounded Theory; Sage Publications: Thousand Oaks, CA, USA, 2014. [Google Scholar]

- Gentles, S.J.; Charles, C.; Ploeg, J.; McKibbon, K.A. Sampling in qualitative research: Insights from an overview of the methods literature. Qual. Rep. 2015, 20, 1772–1789. [Google Scholar] [CrossRef]

- Braun, V.; Clarke, V. Using thematic analysis in psychology. Qual. Res. Psychol. 2006, 3, 77–101. [Google Scholar] [CrossRef]

- Sharma, N.; Kalbar, P.P.; Salman, M. Global review of circular economy and life cycle thinking in building Demolition Waste Management: A way ahead for India. Build. Environ. 2022, 222, 109413. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, A.O.; Oyedele, L.O.; Salami, R.O. Deep learning model for Demolition Waste Prediction in a circular economy. J. Clean. Prod. 2020, 274, 122843. [Google Scholar] [CrossRef]

- Aziz, N.A.; Adnan, N.A.A.; Wahab, D.A.; Azman, A.H. Component design optimisation based on artificial intelligence in support of additive manufacturing repair and restoration: Current status and future outlook for remanufacturing. J. Clean. Prod. 2021, 296, 126401. [Google Scholar] [CrossRef]

- Lu, W.; Lou, J.; Webster, C.; Xue, F.; Bao, Z.; Chi, B. Estimating construction waste generation in the Greater Bay Area, China using machine learning. Waste Manag. 2021, 134, 78–88. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Wang, J.; Xu, X. Machine learning in construction and demolition waste management: Progress, challenges, and future directions. Autom. Constr. 2024, 162, 105380. [Google Scholar] [CrossRef]

- Jogarao, M.; Lakshmanna, B.C.; Naidu, S.T. AI-Enabled Circular Economy Management for Sustainable Smart Cities: Integrating Artificial Intelligence in Resource Optimization and Waste Reduction. In Smart Cities and Circular Economy; Kandpal, V., Santibanez-Gonzalez, E.D.R., Chatterjee, P., Nallapaneni, M.K., Eds.; Emerald Publishing Limited: Leeds, UK, 2024; pp. 83–96. [Google Scholar]

- Wilson, M.; Paschen, J.; Pitt, L. The circular economy meets artificial intelligence (AI): Understanding the opportunities of AI for reverse logistics. Manag. Environ. Qual. Int. J. 2022, 33, 9–25. [Google Scholar]

- European Commission. A New Circular Economy Action Plan: For a Cleaner and More Competitive Europe. Available online: https://ec.europa.eu/environment/circular-economy/index_en.htm (accessed on 4 March 2025).

- Andeobu, L.; Wibowo, S.; Grandhi, S. Artificial intelligence applications for sustainable solid waste management practices in Australia: A systematic review. Sci. Total Environ. 2022, 834, 155389. [Google Scholar] [CrossRef]

- Ali, A.; Al-rimy, B.A.S.; Tin, T.T.; Altamimi, S.N.; Qasem, S.N.; Saeed, F. Empowering Precision Medicine: Unlocking Revolutionary Insights through Blockchain-Enabled Federated Learning and Electronic Medical Records. Sensors 2023, 23, 7476. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Davis, S. Digital Construction Technology and Job-Site Equipment Demonstration: Modelling Relationship Strategies for Technology Adoption. Buildings 2019, 9, 158. [Google Scholar] [CrossRef]

| AI Function Categories | Examples in Various Contexts |

|---|---|

| Design optimization | AI is used in engineering and construction to optimize design solutions by analyzing multiple constraints and objectives. ML and deep learning techniques assist in generative design, enabling architects and engineers to create high-performing and resource-efficient structures [10]. In architectural applications, AI enhances material selection and composite development, optimizing for criteria such as structural durability and energy efficiency [11]. |

| Environmental impact assessment | Deep learning algorithms help assess the life cycle costs of buildings, supporting data-driven sustainability decisions [27]. AI-driven models, including ML and big data analytics, are applied to predict the environmental impact of buildings across their life cycle [28]. In architectural engineering, AI assists in real-time carbon footprint estimation and optimization of low-carbon designs [40]. |

| AI-driven building and material performance | AI enables real-time monitoring of structural health, energy consumption, and environmental conditions in the built environment [23]. In material selection, AI predicts the strength and reuse potential of construction materials based on CE principles [34]. Additionally, deep learning models enhance defect detection in buildings by identifying deterioration patterns such as mold growth, paint deterioration, and structural weaknesses from image-based analyses [41]. |

| Modeling, simulation, and decision support | AI-powered decision-support systems improve the efficiency and feasibility of complex modeling tasks in the AEC. ML algorithms enable predictive simulations for structural analysis, risk assessment, and construction planning. These AI-driven models provide enhanced accuracy and speed in evaluating construction scenarios, supporting data-driven decision-making processes [18]. |

| Energy efficiency and prediction | AI-based predictive models analyze building energy consumption patterns to optimize efficiency [25]. In residential and commercial buildings, AI is used for energy load estimation, demand forecasting, and automated control of smart building systems. ML and deep learning techniques improve energy management strategies by predicting future consumption and enabling real-time adjustments to minimize waste [26]. |

| No. | Current Role | Years of Experience | Areas of Expertise | Company Size |

|---|---|---|---|---|

| 1 | Project manager | 20 | AI expert familiar with CE | 200 or more employees |

| 2 | General manager | 20 | AI expert somewhat familiar with CE | 5–19 employees |

| 3 | Computational designer | 10 | AI expert somewhat familiar with CE | 200 or more employees |

| 4 | Principal machine learning engineer | >16 | AI expert familiar with CE | 200 or more employees |

| 5 | Senior software engineer | >20 | AI expert familiar with CE | 1–4 employees |

| 6 | Digital innovation leader | 10 | AI expert somewhat familiar with CE | 200 or more employees |

| 7 | CEO | 25 | AI expert familiar with CE | 1–4 employees |

| 8 | Associate urban designer | 6 | AI expert familiar with CE | 20–199 employees |

| 9 | Engineering director | 18 | AI expert familiar with CE | 200 or more employees |

| 10 | Co-founder and CEO | 7 | AI expert familiar with CE | 5–19 employees |

| AI Application/AI Function | Blockchain | Computer Vision | ML | Predictive Analytics |

|---|---|---|---|---|

| Optimizing building designs |  |  | ||

| Suggesting energy- efficient design |  |  | ||

| Generating building design |  |  | ||

| Optimizing building cost |  |  | ||

| Simplifying/improving modeling processes |  | |||

| Conducting material selection for building construction |  |  |  | |

| Minimizing waste |  |  | ||

| Detecting material defects |  |  |  | |

| Real-time monitoring of building performance and conditions |  |  |  | |

| Estimating energy rating of buildings |  |  | ||

| Analyzing building energy efficiency |  |  | ||

| Predicting maintenance needs |  |  | ||

| Recording real-time building and elemental performance |  |  |  | |

| Predicting lifecycle assessments of buildings |  |  | ||

| Analyzing environmental impacts |  |  |

| Challenges (Transcription Codes) | Selected Quotes |

|---|---|

| Lack of availability of high-quality data from the building’s lifecycle (from extraction to demolition) | “There are no large datasets to draw on to help with the design process, so a lot of architecture and engineering practices are now going through the process of standardizing and storing data”. (Int #6) “More collaboration between firms and the standardization of design data essentially is the issue”. (Int #6) “The data is available, but the consistency and quality of the data are questionable”. (Int #8) “The technology has limitations if you don’t have the right data, you need then the application of that data is not possible”. (Int #9) |

| Data fragmentation due to various stakeholders | “To gather all information and data, it is not trivial to find the relevant experts, labs, and equipment”. (Int #4) “Quality data exists but it needs to be usable, consistent, available, and in the usable format”. (Int #7) “There is a need to collect big enough dataset, […] need for an interconnected dataset that pulling from a different dataset”. (Int #2) “The challenge and why it’s a manual task is because this information was scattered across a lot of different systems, and it might be unstructured data”. (Int #9) |

| Data privacy and security concerns among stakeholders | “Sometimes it’s hard to get data as an outsider. Construction companies have their own data, but they also hate sharing it”. (Int #10) |

| Challenges of connecting AI to 3D models | “There is a challenge of connecting AI to 3D models”. (Int #3) “We’re using stable diffusion and Midjourney to generate images. You can’t control the structural layout of an image”. (Int #8) |

| Lack of AI models specific to different construction materials and their circularity | “[…] technical challenge of building the relevant model”. (Int #4) |

| Requiring high initial investment in AI infrastructure by companies | “[…] not economically feasible”. (Int #2) “These projects cost huge amounts of money”. (Int #7) “It’s not always in our best interest to start pursuing new technologies or innovative ways of doing things because we just don’t have the time or the money to do that”. (Int #8) |

| Resistance to technological change within the industry | “There is not a clear stakeholder who owns the information, […] architects do not care about stakeholder downstream”. (Int #2) “Construction is such an old-fashioned or traditional industry, very resistant to change”. (Int #7) “Change management is a big challenge if there are entrenched processes. Getting people to change the way they do things is difficult”. (Int #9) “Construction industry moved very slowly. It’s very conservative”. (Int #10) |

| Lack of skilled personnel for AI integration | “There is a need for skills and expertise in this area”. (Int #7) “We don’t have many people that know about both AI and construction”. (Int #10) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghobadi, M.; Sepasgozar, S.M.E. Challenges and Benefits of Implementing AI in Timber Construction for Circular Economy Goals. Buildings 2025, 15, 1073. https://doi.org/10.3390/buildings15071073

Ghobadi M, Sepasgozar SME. Challenges and Benefits of Implementing AI in Timber Construction for Circular Economy Goals. Buildings. 2025; 15(7):1073. https://doi.org/10.3390/buildings15071073

Chicago/Turabian StyleGhobadi, Mohsen, and Samad M. E. Sepasgozar. 2025. "Challenges and Benefits of Implementing AI in Timber Construction for Circular Economy Goals" Buildings 15, no. 7: 1073. https://doi.org/10.3390/buildings15071073

APA StyleGhobadi, M., & Sepasgozar, S. M. E. (2025). Challenges and Benefits of Implementing AI in Timber Construction for Circular Economy Goals. Buildings, 15(7), 1073. https://doi.org/10.3390/buildings15071073