1. Introduction

Finding eco-friendly and cost-effective ways to deal with plastic (PL) waste is one of the most significant environmental challenges facing the modern world. Every year, millions of tons of PL are produced, used, and discarded, contributing to growing levels of pollution. The main problem with PL waste is its durability and thus, its persistence in the environment, making it a long-term threat to wildlife, ecosystems, and human health. Despite efforts to increase recycling rates, a staggering 87% of PL waste still ends up in landfills or the natural environment, while only 9% is recycled [

1,

2,

3,

4]. The consequences of our failure to appropriately dispose of PL waste are far-reaching; even marine life has been severely affected, and microplastics have infiltrated our food and water supply [

5,

6].

Traditional methods of waste disposal, e.g., incineration, tend to exacerbate the PL waste problem by releasing harmful pollutants into the atmosphere and contributing to climate change [

7,

8,

9]. Therefore, finding innovative disposal solutions is critical for both environmental sustainability and public health. One promising approach is the integration of recycled PL into construction materials, particularly concrete. Currently the most widely used construction material in the world, concrete is essential for building infrastructure, including housing and other structures. However, its production, especially the cement component, has a massive environmental impact [

10,

11,

12]. Cement production alone accounts for roughly 7% of global carbon dioxide (CO

2) emissions, making concrete a major contributor to greenhouse gas emissions and climate change [

13,

14,

15].

Moreover, the extraction of raw materials for concrete, such as sand and gravel, places considerable pressure on natural resources. Given the sheer scale of concrete production (approximately 30 billion tons per year globally), even small improvements in its environmental impact could have significant benefits [

5,

16,

17]. The idea of incorporating recycled PL waste into concrete presents a unique opportunity to address both the issue of PL pollution and the environmental footprint of concrete production. By using PL waste as a partial replacement for traditional materials like sand or gravel, or as an additive to improve the mechanical properties of concrete, we can create more sustainable construction materials that not only reduce the need for virgin raw materials but also provides a valuable outlet for large quantities of PL waste, diverting it from landfills, oceans, and incinerators.

Plastic, especially polypropylene (PP), has shown promising results in enhancing the properties of concrete [

17,

18]. The process involves collecting, sorting, and processing PL waste into particles or fibers that can be integrated into the concrete mix. When used correctly, these PL fibers can improve the tensile strength and flexibility of concrete, making it more resistant to cracking and deformation [

13,

19]. This is particularly important for applications such as pavements, bridges, and high-stress structures, where durability is critical. Compared with traditional aggregates like sand and gravel, the lightweight nature of PL also means that PL-reinforced concrete could make construction more efficient, including offering easier handling and potentially reduced transportation costs. In addition to improving the mechanical performance of concrete, the insulation properties of certain PLs offer further advantages. PL-reinforced concrete can enhance the thermal and acoustic performance of buildings, contributing to energy efficiency and improved living conditions [

20,

21]. This is especially relevant as the global construction industry is increasingly focusing on sustainability, seeking ways to reduce energy consumption and create buildings that are more comfortable and environmentally friendly [

22].

Furthermore, from an environmental perspective, the integration of PL waste into concrete fits well within the framework of the circular economy [

23]. A circular economic approach seeks to minimize waste by reusing, recycling, and repurposing materials, rather than discarding them after a single use [

24,

25]. By repurposing PL waste in construction, the lifecycle of materials can be extended, reducing the reliance on finite natural resources and mitigating the environmental damage caused by both PL waste and concrete production [

26].

This shift towards resource optimization and waste minimization aligns with global efforts to reduce the environmental impact of industrial activities and combat climate change. For example, Saudi Arabia, with its ambitious development projects and rapid urbanization, offers a particularly compelling context for the adoption of PL-reinforced concrete. Major infrastructure projects, such as the construction of NEOM, the Red Sea Project, and other urban expansions, require vast amounts of construction materials. Incorporating recycled PL into these projects could significantly reduce the environmental footprint of such large-scale developments, in line with the country’s Vision 2030 goals, which emphasize sustainability and environmental stewardship.

Saudi Arabia’s Vision 2030 prioritizes sustainability through initiatives such as the Saudi Green Initiative and national waste management policies. Incorporating recycled PP into concrete aligns with these efforts by reducing landfill waste and promoting circular economic practices. Moreover, as Saudi Arabia looks to become a leader in sustainable development in the Middle East, the use of innovative materials like PL-reinforced concrete could set an important precedent for the region. The potential benefits of using recycled PL in concrete extend beyond environmental considerations [

27]. Aligning this approach with existing construction standards and regulatory frameworks is crucial for ensuring its widespread adoption in the industry.

In addition, there are numerous economic advantages to utilizing PL waste as a construction material. By reducing the demand for virgin raw materials and minimizing waste disposal costs, the construction industry could achieve significant cost savings [

28]. Although initial investments in recycling infrastructure and technology may be required, the long-term economic benefits, combined with the environmental gains, make this approach a viable solution for both private and public sectors [

29]. Moreover, the lighter weight of PL particles compared with traditional aggregates opens new possibilities for design and construction, potentially lowering transportation costs and increasing efficiency on building sites [

30].

Despite these advantages, there are challenges that first need to be addressed to fully realize the potential of PL-reinforced concrete. For instance, the properties of different kinds of PL can vary widely, depending on polymer type, size, and method of integration into the concrete mix. Research is ongoing to determine the optimal types of PL waste and the appropriate mixing techniques to maximize the benefits of PL-reinforced concrete. At the same time, additional studies are needed to assess the long-term performance and durability of PL-reinforced concrete under various environmental conditions, including extreme temperatures and exposure to chemicals or moisture [

31,

32]. The originality of this approach lies not only in its ability to address two major environmental challenges—PL waste and the environmental impact of concrete production—but also in its specific focus on incorporating PP-PL, one of the most widely used plastics globally [

33].

Polypropylene is commonly found in packaging, textiles, and various consumer products, and its disposal presents a significant environmental challenge. Integrating recycled PP into concrete transforms a problematic waste material into a valuable resource for the construction industry, effectively addressing both pollution and the over-reliance on traditional raw materials [

34]. This strategy reduces pollution, conserves natural resources, and significantly lowers the carbon footprint of the construction sector. Furthermore, using PP-PL waste offers a new dimension of sustainability that aligns with global efforts to reduce waste while also mitigating the environmental impact of concrete production, one of the largest industrial sources of greenhouse gas emissions [

35]. PP enhances the material properties of concrete, contributing to improved durability and resistance to environmental degradation, making it an ideal candidate for applications in both infrastructure and building projects.

However, even with the promising advantages of integrating PP-PL into concrete, existing studies have focused primarily on mechanical properties, often overlooking aspects such as microstructural behavior, long-term durability, and scalability in real-world applications. A deeper exploration of cross-disciplinary solutions is needed, focusing on merging waste management, materials science, and sustainable construction into a unified strategy. The adoption of recycled PP in concrete is a forward-thinking solution that demonstrates how innovations in one sector can create far-reaching benefits across industries. As we move toward a greener future, the integration of PP waste into industrial processes is poised to play a crucial role, particularly in resource-intensive sectors like construction [

36].

Moreover, the use of this specific type of PL not only helps divert PL waste from landfills but also addresses the challenge of sourcing sustainable materials for use in the building industry. By continuing to explore and refine the incorporation of recycled PP into concrete, we can contribute to a more resilient, sustainable, and environmentally responsible construction industry. Advancements in PP processing, nanotechnology, and optimization of the concrete mix can further enhance the performance and integration of recycled PP in construction applications, paving the way for its adoption on an industrial scale. Recycling PP-PL waste into concrete presents a practical and scalable solution to the growing PL waste crisis [

37].

As research continues and the technology becomes more sophisticated, the use of PL-reinforced concrete—especially PP-PL-reinforced concrete—has the potential to become standard practice in sustainable construction [

31]. Therefore, the primary significance of this study lies in its contribution to the ongoing efforts to develop more sustainable and eco-friendly construction materials. As the construction industry grapples with environmental concerns, the use of recycled materials in concrete has gained substantial attention. PP-PL waste represents a significant environmental issue, and it is often discarded without recycling. This research investigates the integration of recycled PP-PL pellets into concrete mixtures, an innovative approach that not only addresses PL waste but also explores its potential benefits for enhancing the properties of concrete. By replacing a portion of conventional aggregates with PP-PL at varying percentages, this study provides valuable insights into the impact of this substitution on key properties such as compressive strength, workability, and weight reduction.

Furthermore, this study identifies the optimal percentage of PP for balancing concrete strength, workability, and weight reduction, which could significantly contribute to the development of lightweight and high-performance concrete. These types of concrete can be particularly useful in applications where reduced weight is a critical factor, such as in structural and precast concrete elements. Ultimately, the findings of this research offer an innovative solution to a growing environmental problem and provide important data that could inform future studies on the long-term durability and microstructural behavior of concrete containing recycled PP. By advancing our understanding of the potential for integrating recycled PL into concrete, this study represents a step forward in promoting sustainable construction practices and encourages further research into novel materials for environmentally conscious development of infrastructure.

2. Methodology

The concrete specimens used in this study were prepared and tested in the laboratory at the University of Tabuk, Faculty of Engineering. The laboratory was equipped with essential testing devices to ensure precise measurements and reliable results. The key equipment utilized in this research included a slump test apparatus to assess the workability of fresh concrete, a compression testing machine for evaluating the compressive strength of cured samples, a digital thermometer for monitoring temperature conditions, an electric cement mixer for thorough mixing of materials, a digital weight scale for accurate measurement of ingredients, and a curing water tank to maintain optimal curing conditions for the concrete samples.

The experimental phase involved testing a total of 36 concrete samples, which were formulated into four distinct mixtures. Each mixture was designed in order to investigate the impact of incorporating PP-PL pellets in varying proportions on the properties of the concrete. The testing schedule was strategically structured over three specific days (the seventh, fourteenth, and twenty-eighth days of curing), with each day dedicated to evaluating three samples from each mixture. This systematic approach enabled a comprehensive analysis of the concrete’s performance over time, enabling the assessment of its early-age and long-term properties.

The first mixture served as a reference sample, providing a baseline for comparison against the other mixtures containing PP-PL. This reference mixture was prepared following standard concrete formulation practices, and consisted of conventional aggregates, cement, and water. The subsequent mixtures incorporated PP-PL pellets at varying ratios. The incorporation of these pellets aimed to enhance the sustainability of concrete by utilizing recycled materials while potentially improving specific mechanical properties.

The sampling period timeframe (25 February 2024 to 26 March 2024) permitted adequate curing of the concrete samples, as the specimens were subjected to controlled conditions to ensure the uniformity and reliability of the results.

To analyze the data obtained from the tests, various statistical methods were employed. The results were visualized using bar charts and line charts, which effectively illustrated the differences in compressive strength and workability among the various mixtures over the specified curing periods. The ANOVA (analysis of variance) test was conducted using Excel and Minitab 19 software to determine the statistical significance of the differences observed between the mixtures.

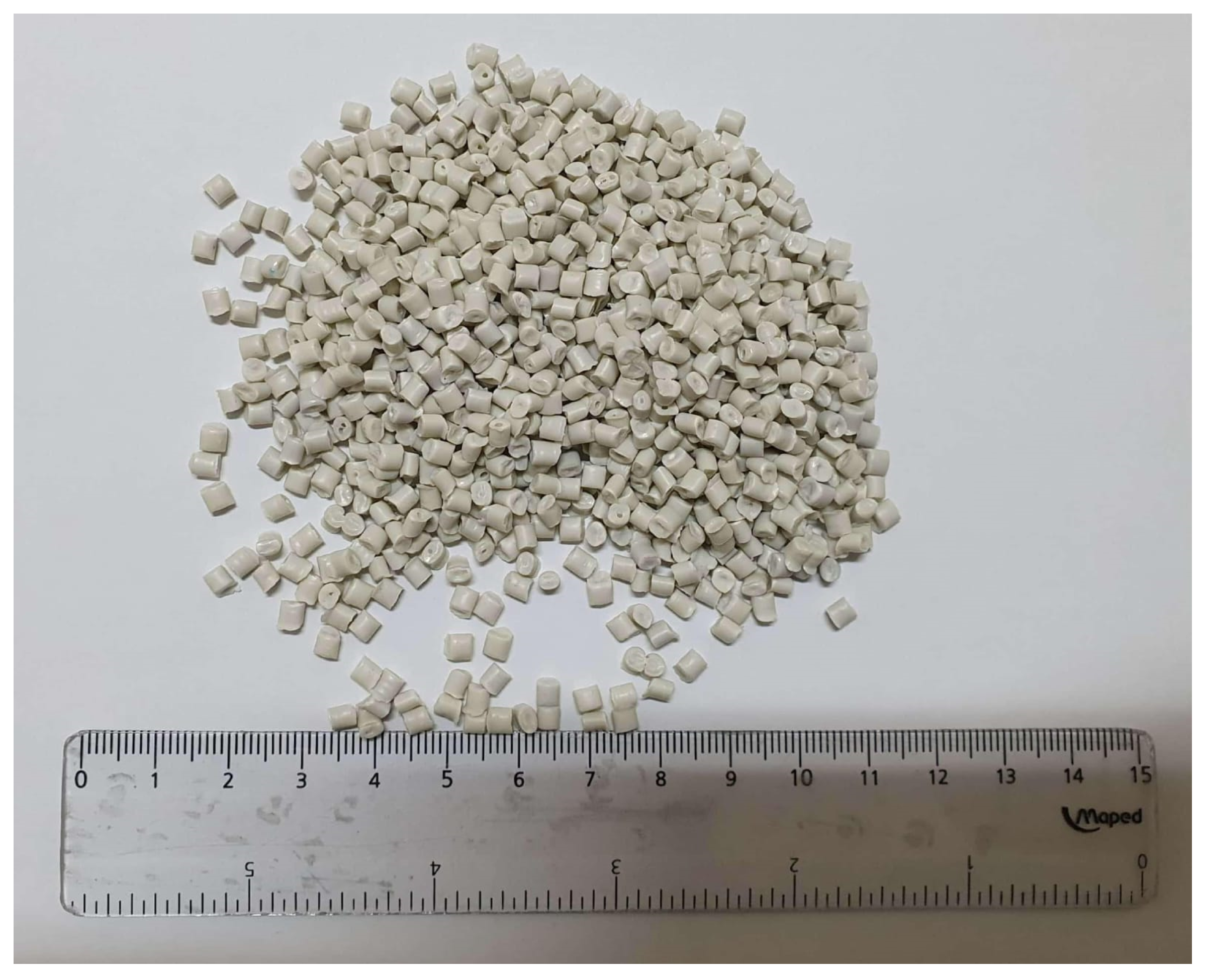

As shown in

Table 1,

Table 2 and

Figure 1, the masses of the materials used for the various tested concrete mixtures were standardized to ensure consistency and reliable comparisons across the experiments. The quantity of cement, the primary binding material, was kept constant at 20.25 kg. The aggregates were divided into two gravel fractions to ensure optimal particle size distribution; 3/4 gravel accounted for 27.99 kg, while 3/8 gravel contributed 21.24 kg. Coarse sand, at 11.7 kg, and fine sand, at 20.25 kg, were included to achieve the desired stability, workability, and overall cohesiveness of the mix. Water, critical for the hydration process, was added at a precise quantity of 8.235 L per cubic meter of concrete to maintain a consistent water-to-cement ratio, which was essential for achieving uniform strength and durability across all samples.

In addition to these primary components, chemical admixtures were included to enhance the mix’s properties. Sikament 850, a high-range water-reducing agent, was added at 0.225 L per cubic meter of concrete. This admixture played a vital role in improving workability and reducing the water demand without compromising strength. Plastiment PR150, a set retarder (Sika UAE L.L.C. (Head Office), Dubai, United Arab Emirates), was also incorporated at a dosage of 0.081 L per cubic meter of concrete, ensuring adequate working time and preventing premature setting during the mixing and placement stages. The total mass of coarse aggregate was 49.23 kg, while the total mass of fine aggregate was 31.95 kg. The masses of recycled PP-PL pellets used in each mixture were as follows: 1% = 0.32 kg, 3% = 0.96 kg, and 5% = 1.6 kg.

The selection of 1%, 3%, and 5% PP-PL replacement by weight in the concrete was based on an extensive review of previous studies examining the influence of PL waste incorporation on mechanical and durability properties. The decision to use these specific replacement percentages was guided by both theoretical considerations and preliminary experimental trials conducted to assess the feasibility of mixing and casting the concrete with PP-PL. Prior studies have demonstrated that incorporating small amounts of PP-PL into concrete can improve certain properties such as durability and crack resistance, while excessive amounts may significantly reduce compressive strength and workability due to the hydrophobic and flexible nature of the PL particles [

17,

38,

39,

40,

41].

Several researchers have explored PL aggregate replacement in varying percentages. Some studies suggest that replacement levels below 5% tend to have a minimal negative impact on compressive strength while offering benefits such as reduced density and enhanced thermal insulation [

42,

43]. Conversely, replacement percentages above 5% have been associated with significant reductions in load-bearing capacity, as PL particles introduce voids and disrupt the concrete matrix [

44,

45,

46]. By selecting 1%, 3%, and 5%, this study aimed to establish a comparative framework balancing sustainability and performance, ensuring that the findings were in alignment with practical engineering applications.

Preliminary trial mixes were prepared before finalizing the percentages to confirm that the selected levels provided workable mixtures without excessive segregation, ensuring homogeneity and adequate mechanical behavior during testing. The workability of fresh concrete incorporating PP-PL is a critical parameter that significantly influences the overall performance of the material. Previous research has indicated that incorporating PL aggregates in concrete mixtures generally leads to reduced slump values compared with conventional concrete, due to the hydrophobic and non-absorbent nature of PL particles [

17,

47,

48]. The lower specific gravity of PL compared with natural aggregates also alters the density and cohesion of the mix, leading to a reduction in flowability.

Various admixtures, such as high-range water reducers, have been successfully used to compensate for the above-mentioned effects, restoring workability to acceptable levels. In this study, Sikament 850, a high-range water-reducing agent, was incorporated into the mix to address reductions in workability and ensure uniform mixing. This approach was chosen to maintain consistency in the concrete mixture, particularly when incorporating PP-PL. From a mechanical performance perspective, replacing natural aggregates with PP-PL is generally associated with a decrease in compressive strength. This reduction is attributed to the lower stiffness of PL particles and their weaker bonding with the cement paste compared with traditional aggregates. However, the extent of this reduction in strength is influenced by the amount of PL used. At lower replacement levels (1–3%), the decrease in strength is typically minimal, and in some cases, slight improvements in durability and ductility have been observed. This study expands on these findings, offering deeper insights into the balance between sustainability and structural integrity when incorporating PP-PL into concrete.

Material & Mix Proportion

The materials for each mixture were prepared and weighed (

Figure 2a) and the inner surfaces of the molds were thoroughly cleaned (

Figure 2b). The ambient temperature and the temperature of the water were recorded prior to mixing (

Figure 2c). All the materials, except for the water and the recycled PP-PL pellets, were added to the mixer. The mixing process lasted for one-and-a-half minutes (

Figure 2d). Water and the recycled PL pellets were added gradually and the mixing continued for an additional 30 min without interruption (

Figure 2e). The temperature of the concrete was then measured (

Figure 2f), followed by a slump test.

The slump test involved pouring the concrete in three layers, with each layer being one-third of the total volume. The layers were individually compacted 25 times using a rod. After leveling the surface, the mold was raised vertically and the slump was measured (

Figure 2g). The concrete mixture was then poured in three layers into cubic molds measuring 150 × 150 × 150 mm. Each of these layers was also compacted 25 times with a rod, and the final surface was leveled (

Figure 2h).

The samples were left to cure 24 h before being removed from the molds. They were then placed into a curing water tank maintained at a temperature of 24 degrees Celsius (

Figure 2i). The samples were taken out of the water just before the compressive strength test was performed. Each sample was positioned in a machine designed to measure compressive strength, and the data were recorded (

Figure 2j).

3. Results and Discussion

3.1. Slump Test

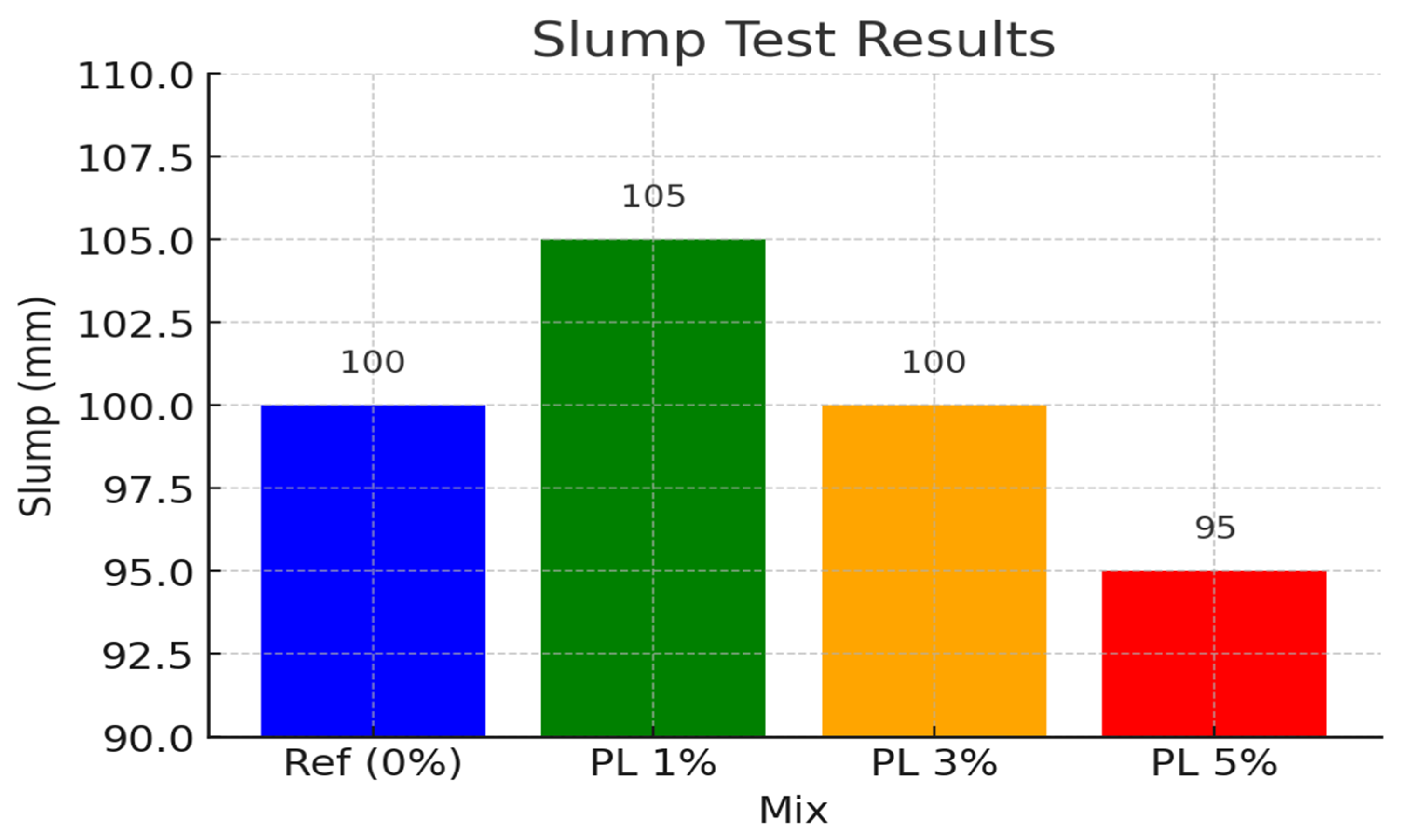

The slump test is widely used in concrete construction to measure the workability and consistency of fresh concrete. Workability refers to how easily the concrete can be mixed, placed, compacted, and finished without segregation or bleeding. The results obtained from the slump test in this experiment were critical for evaluating the effects of the PL additive on the fresh concrete’s workability.

The test results for the four concrete mixes—reference mix (Ref 0%), PL 1%, PL 3%, and PL 5%—showed varying degrees of slump, indicating changes in the consistency and flow of the concrete. The reference mix with no PL additive yielded a slump value of 100 mm. This was considered a moderate slump indicating good workability and a balanced mixture. A slump value of 100 mm typically signifies that the concrete is neither too dry nor too fluid, making it suitable for most general construction applications such as use in foundations, slabs, and columns. This value provided a baseline for comparing the effects of the PL additive on workability.

In the case of the PL 1% mix, the slump increased slightly to 105 mm. This minor increase suggests that the addition of 1% PL had a positive impact on the workability of the concrete, making it slightly more fluid and easier to handle. This increase in slump indicates better flowability, which can be advantageous in applications where concrete needs to be placed in complex forms or areas with congested reinforcement. However, the increase was not so significant as to cause concerns about segregation or excessive bleeding, which would indicate that the mix was too wet. The slight improvement in workability with 1% PL may have resulted from the additive’s ability to reduce friction between the cement particles and aggregates, allowing smoother placement and compaction.

The slump observed for the PL 3% mix returned to 100 mm, identical to that of the reference mix. This result suggests that the positive effect on workability that was observed with 1% PL did not continue as the dosage of the additive increased. At 3% PL, the concrete mixture behaved similarly to the reference mix in terms of workability, indicating that inclusion of the additive at this concentration neither improved nor hindered the slump. It is possible that the effect of PL on the water–cement ratio or the internal friction between particles plateaued at this concentration, resulting in no further changes in the slump value.

Interestingly, the slump for the PL 5% mix decreased to 95 mm, the lowest value among the four mixes. This reduction in slump indicates a decrease in workability, meaning the concrete was slightly stiffer and less fluid. A slump value of 95 mm is still within a workable range, but these results suggest that adding 5% PL may have caused the mixture to become less cohesive or more resistant to flow. This reduction in workability could have been due to an excessive quantity of additives, which might have interfered with the cement’s ability to retain water or may have led to increased entrainment of air, either of which may have reduced the fluidity of the mixture. Excessive additives can sometimes disrupt the balance of the mix, leading to decreased flowability and making the concrete harder to place and compact, especially in areas with tight reinforcement or complex formwork.

In summary (

Figure 3), the slump test results demonstrated a nuanced relationship between the concentration of the PL additive and the workability of the concrete. The addition of 1% PL slightly improved the workability, making the concrete easier to handle, which could be beneficial in applications requiring high fluidity. At 3% PL, the workability returned to the baseline level of the reference mix, indicating no further improvement or deterioration in slump. However, at 5% PL, the workability decreased, suggesting that higher concentrations of the additive may reduce the fluidity of the concrete. These findings imply that while low concentrations of PL may enhance workability, higher dosages could have adverse effects, potentially leading to stiffer mixtures that are more difficult to work with. This knowledge is essential for optimizing the dosage of PL in concrete mixtures in order to achieve the desired balance between workability and mechanical properties in practical construction applications.

3.2. Compressive Strength Test

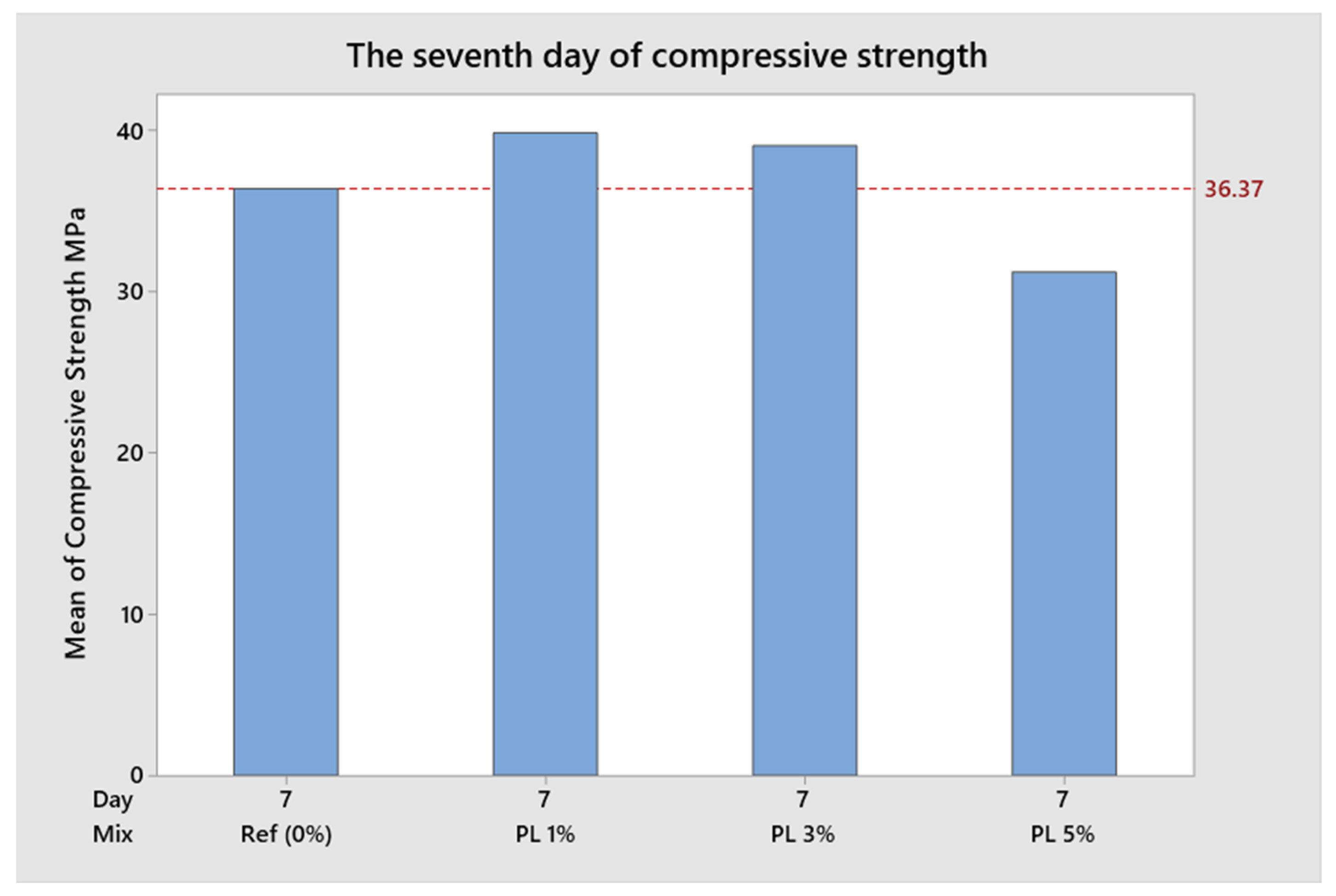

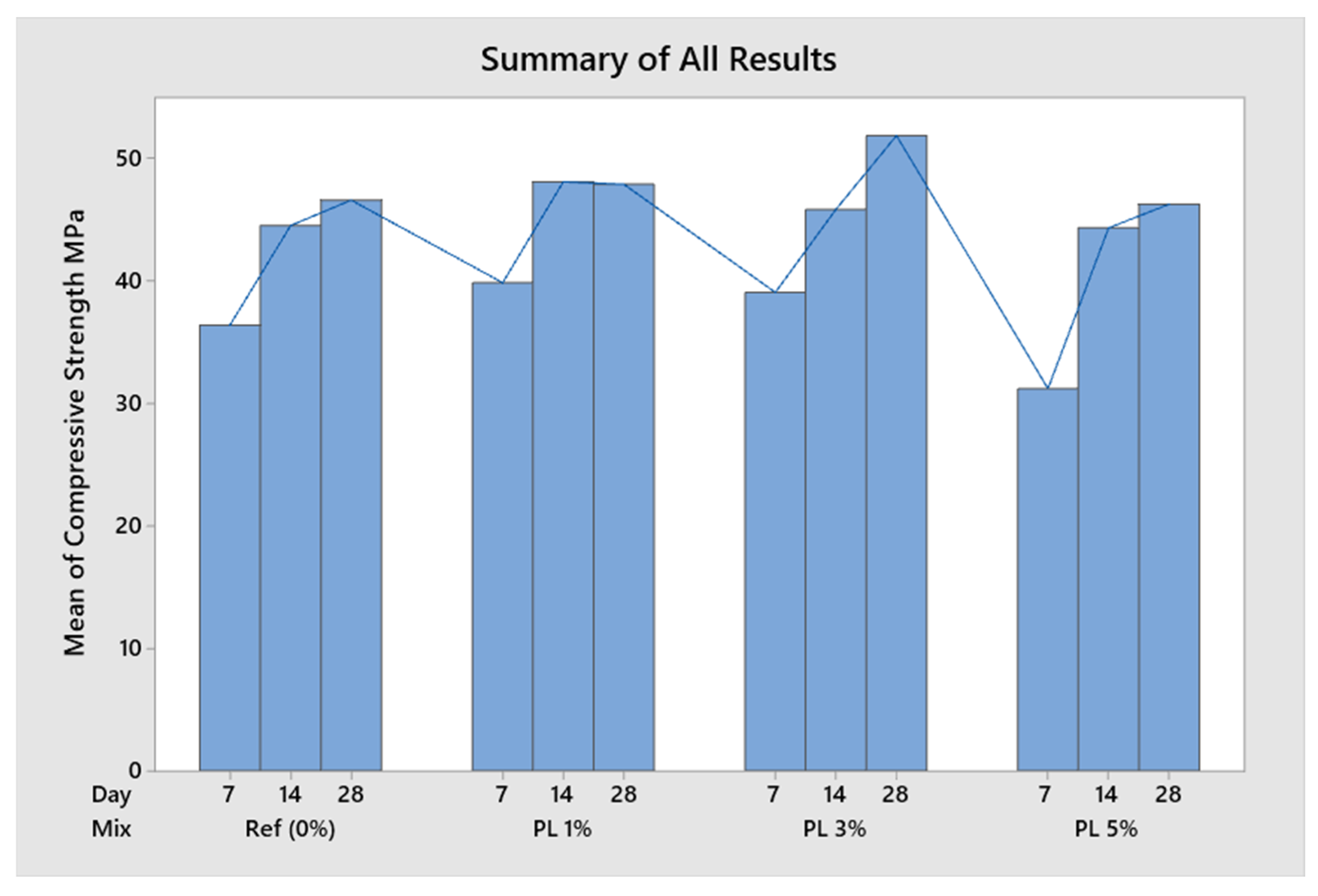

Compressive strength is a crucial factor for evaluating the mechanical performance of concrete. It measures the load that concrete can withstand before failure, serving as a direct indicator of its structural integrity. This parameter is fundamental in assessing the quality of concrete used in various structural applications, such as in columns, beams, and foundations. Utilizing the experimental setup described, this study focused on testing the compressive strength of four different concrete mixes at 7, 14, and 28 days of curing. These mixes included a reference mix and three others incorporating varying percentages of an additive referred to as PL: specifically, 1%, 3%, and 5%. The significance of compressive strength lies in its direct relationship with the ability of concrete to resist compressive forces.

In civil engineering, where concrete is predominantly used in structures subjected to these forces, ensuring optimal compressive strength is vital. The strength of concrete is typically measured in megapascals (MPa), a unit that quantifies the pressure the material can withstand per unit area. The aim of the current research was to examine the development of compressive strength over time and understand how the introduction of the PL additive at different percentages affected this important property. In general, concrete achieves approximately 60–70% of its final strength within the first 7 days, with the remainder of the strength being developed by 28 days. This 28-day strength is often used as the standard for evaluating a specific concrete’s performance.

The experimental results of this study are expected to provide insight into how each of these four concrete mixes behaves in terms of strength development. The reference mix, containing no additive, served as a control, while the other three mixes, with PL percentages ranging from 1% to 5%, enabled comparative analysis. The role of additives like PL is to modify the behavior of concrete, potentially improving certain properties such as workability or strength. Additives can enhance bond formation between cement particles and aggregates, resulting in stronger, denser concrete.

However, the impact of additives on compressive strength is not always straightforward and can vary depending on the dosage. In the case of the 1% PL mix, the expectation was that this low percentage of the additive would have a positive effect on compressive strength, particularly at early stages such as 7 and 14 days. Additives at this concentration are often beneficial because they can accelerate the hydration process without significantly disrupting the balance between water and cement. This may result in higher early strength compared with the reference mix, with the potential for a marginal increase in final strength at 28 days.

For the 3% PL mix, further improvements in compressive strength were anticipated, particularly at early stages. By enhancing the hydration process, the additive was able to promote faster strength gain, advantageous for projects requiring early removal of formwork or faster construction schedules. However, while early strength may increase, there is a possibility that the benefits might plateau or diminish at 28 days, as higher concentrations of additives can sometimes interfere with long-term bond formation within the concrete matrix.

In contrast, the 5% PL mix represented the highest concentration of the additive, with the potential to present diminishing returns in terms of strength improvement. While small to moderate amounts of additives are generally beneficial, excessive dosages can introduce negative effects such as increased entrainment of air or reduced cohesion between cement particles and aggregates. This could lead to a reduction in the material’s overall compressive strength, particularly at 28 days, when the concrete should have reached its full potential strength. Many additives can disrupt the uniform distribution of cement paste, leading to weaknesses in concrete structures. The compressive strength results for the different concrete mixes in this experiment provide valuable insights into the optimal dosage of PL additive. While low to moderate concentrations of additives are expected to improve strength, particularly in the early stages, higher concentrations could have adverse effects.

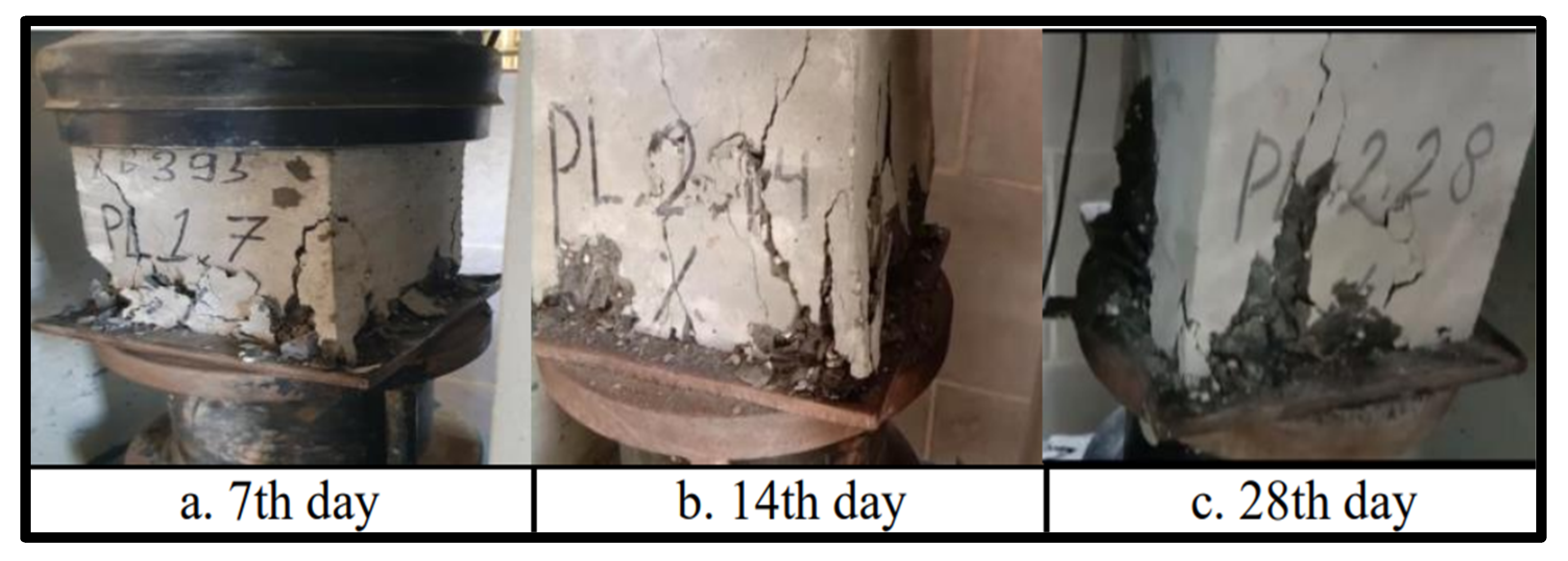

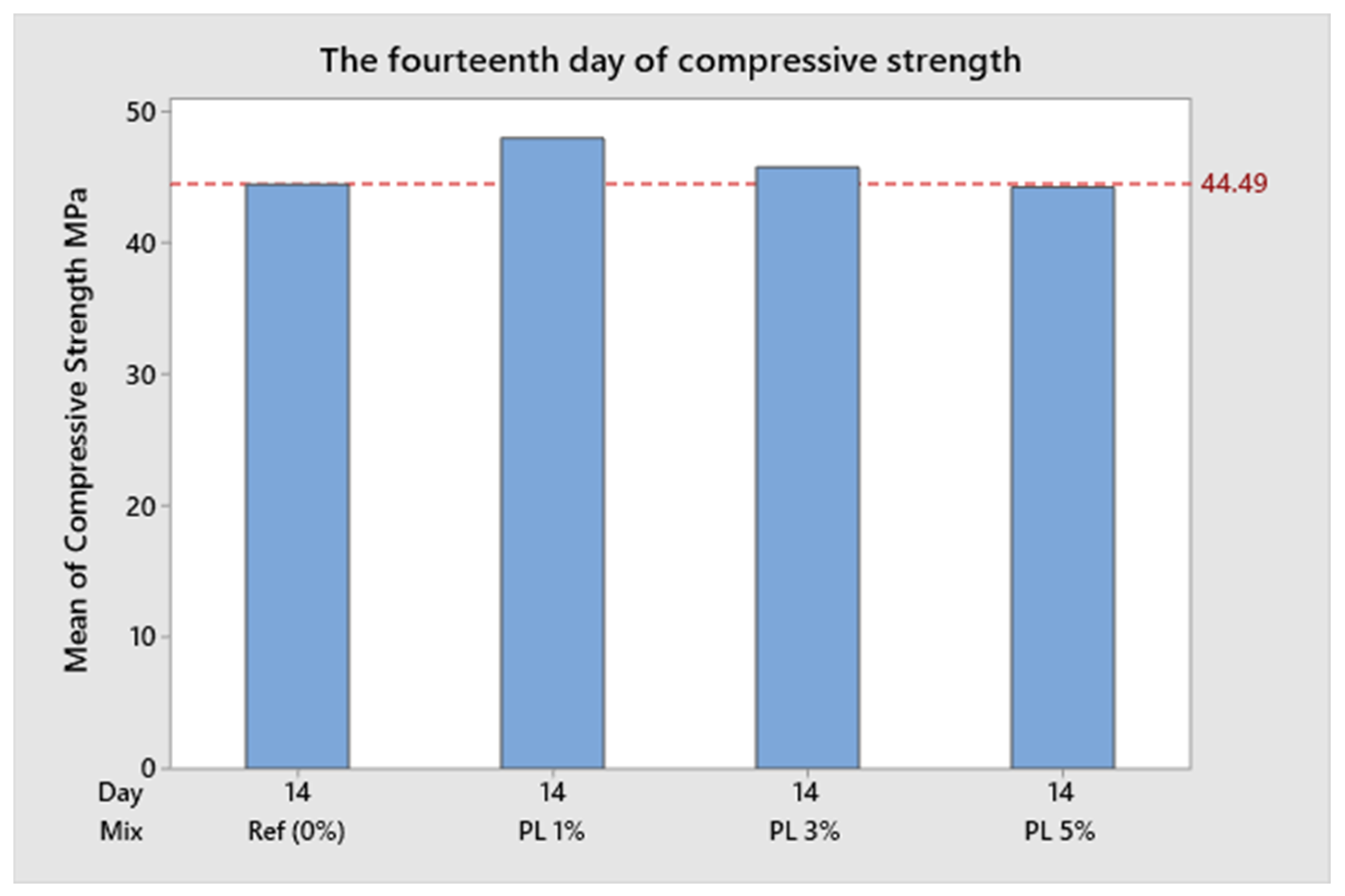

As shown in

Figure 4, the shape of the concrete cube containing 3% PL was analyzed after undergoing compressive strength testing at 7, 14, and 28 days of curing. The results indicated that despite the presence of visible surface cracks, the samples maintained remarkable mechanical performance, suggesting that the inclusion of PP fibers enhanced the structural integrity of the concrete. This improvement is likely to have been due to the uniform distribution of PP within the matrix, contributing to increased compressive strength and crack resistance. On days 7, 14, and 28, the samples demonstrated consistent gains in strength, confirming the positive impact of the PP additive on the material’s long-term performance. PP fibers act as micro-reinforcements, bridging microcracks and delaying their propagation under applied loads. This effect enhances durability and post-crack behavior, reducing brittleness and improving long-term performance. The fibers may also help mitigate shrinkage and thermal stresses, further stabilizing the material.

These findings highlight PP’s potential as a additive for enhancing the strength and durability of concrete. Further research is needed in order to optimize the dosage of fibers and evaluate long-term performance under various conditions. Incorporating PP into concrete could also contribute to more sustainable construction by improving the material’s efficiency and durability. The final results at 28 days were critical for determining whether the use of the PL additive enhanced or detracted from the structural performance of the concrete. The findings not only contribute to the understanding of concrete additives but also have practical implications for their use in construction (

Figure 5,

Figure 6,

Figure 7 and

Figure 8).

These tests results provide valuable insights into the use of recycled PP in concrete, highlighting its potential for improving sustainability in the construction industry. The impact of PP-PL pellets on compressive strength, workability, and the reduction of concrete weight was successfully demonstrated. The results are promising, especially with 3% PP content, which led to significant improvements in mechanical properties without negatively affecting workability.

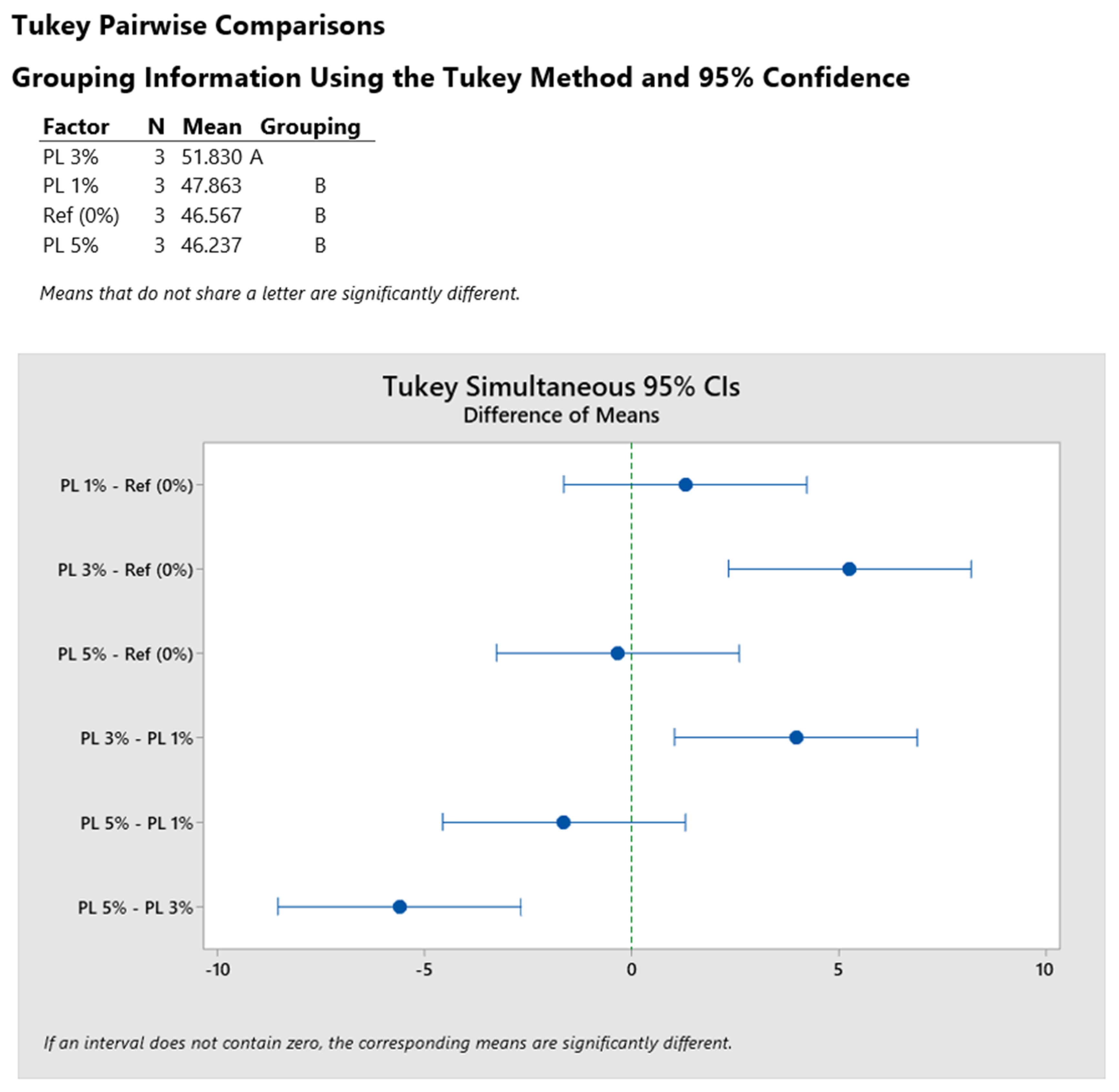

3.3. ANOVA Test for Day 28

Tukey pairwise comparison was employed for statistical analysis to evaluate whether there were significant differences between the means of different concrete mixes, each containing varying percentages of PL additive. This analysis used a 95% confidence interval to determine whether the differences between the means were statistically significant. If the confidence interval for the difference between two groups includes zero, it indicates that there is no statistically significant difference between the two groups. Conversely, if the interval does not include zero, the difference between the groups is considered significant.

In the grouping information provided, the different percentages of PL (1%, 3%, 5%) and the reference concrete mix without PL (0%) are grouped according to their statistical similarity. The mixes were divided into two groups based on their means: group A and group B. The PL 3% mix stood out as being in group A, separate from the others, indicating that its mean was statistically different from the other mixes. On the other hand, the reference mix (0% PL), PL 1%, and PL 5% were all grouped together in group B, meaning that the differences between their means were not statistically significant. This suggests that the addition of 1% and 5% PL to the concrete did not result in a meaningful change in measured properties compared with the reference mix.

The confidence interval plot further supports these findings. The plot visually displays pairwise comparisons between the mixes, with horizontal lines representing the confidence intervals for each comparison. Where the confidence interval crosses the vertical zero line, it indicates no significant difference between the two compared groups. For instance, the comparison between PL 1% and the reference mix revealed a confidence interval that crosses zero, confirming that the difference between these two was not statistically significant. Similarly, the confidence interval for the comparison between PL 5% and the reference mix also crossed zero, indicating no significant difference. In contrast, the comparison between PL 3% and the reference mix did not cross the zero line, signifying a statistically significant difference between these two groups. This means that adding 3% PL to the concrete mix led to a notable change in the measured properties (compressive strength in this case, or other relevant parameters), unlike the 1% or 5% PL additions, which did not have such a pronounced effect.

The Tukey pairwise comparison revealed that while the addition of 1% and 5% PL to the concrete mix did not result in a statistically significant change compared with the reference mix, the addition of 3% PL caused a significant alteration in the concrete’s properties. This suggests that the optimal level of PL additive for modifying the concrete’s performance lies around 3%, as this is where the most meaningful changes occurred, as shown in

Figure 9.

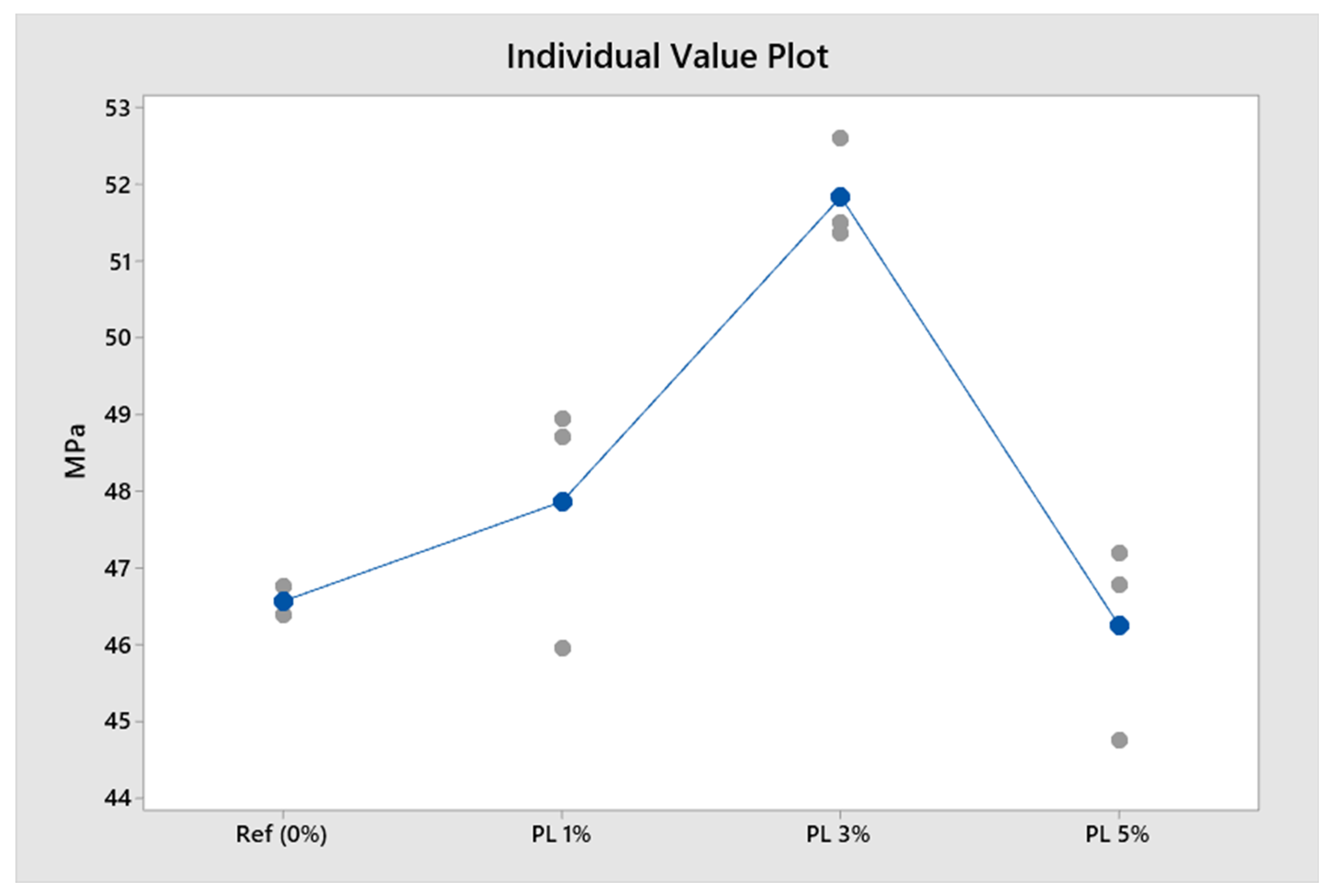

The individual value plot provides a visual representation of the performance of the different concrete mixes containing various percentages of PL additive (0%, 1%, 3%, and 5%) on a particular measured property. Each point represents an individual observation or data point for each mix, and the connected line highlights the trend of changes across the different percentages of PL. From the plot, it is evident that the mix with 3% PL exhibited the highest value, suggesting a peak in performance for this mix. The individual data points for this group are closely clustered around the mean value, indicating low variability within this group and further confirming that the 3% PL mix consistently performed better than the others.

For the reference mix (0% PL), the individual points are more spread out, but the overall performance was lower compared with the 3% PL mix. The reference mix showed consistency, with no extreme outliers, suggesting stable performance but without any notable improvement or enhancement compared with the other mixes.

The mix with 1% PL showed a slight increase in performance compared with the reference mix. However, the improvement was minimal, and the individual points exhibited more variability, indicating some inconsistency in how the 1% PL mix performed across the different tests. While there was a small upward trend from the reference mix to the 1% PL mix, this was not a significant change.

In contrast, the 5% PL mix displayed a noticeable decline in performance compared with the 3% PL mix. The downward trend from 3% to 5% was sharp, suggesting that adding more than 3% PL diminished the beneficial effects seen at the lower percentage. The individual points for the 5% PL mix are also more scattered, indicating greater variability and suggesting that 5% PL mix may introduce inconsistencies or negatively affect the properties being measured. The 5% PL mix’s performance was comparable to that of the reference mix, indicating that adding too much PL may not yield any additional benefits and might even reduce performance.

The individual value plot shows that the concrete mix with 3% PL yielded the best performance among the four groups, with clear superiority over the reference mix and other PL percentages. The 1% PL mix offered marginal improvement over the reference mix, while the 5% PL mix resulted in a drop in performance, indicating that increasing the amount of PL beyond 3% was detrimental. This suggests that 3% PL is the optimal amount for enhancing this specific property of the concrete mix, and further increases do not offer additional advantages, as shown in

Figure 10.

The ANOVA test summary presented in

Table 3 offers insights into the statistical analysis conducted on the concrete samples. It includes details such as the number of levels and the different percentages of recycled PP-PL pellets examined in the mixes. The ANOVA assessed whether statistically significant differences existed between the means of the various groups, indicating when at least one mix exhibited a different compressive strength to the others. The model summary includes R-squared values indicating how well the independent variables explain the variability of the dependent variable, compressive strength. A high R-squared value suggests a good fit of the model to the data, while the means and confidence intervals provide estimates of central tendency and the uncertainty relating to the estimates.

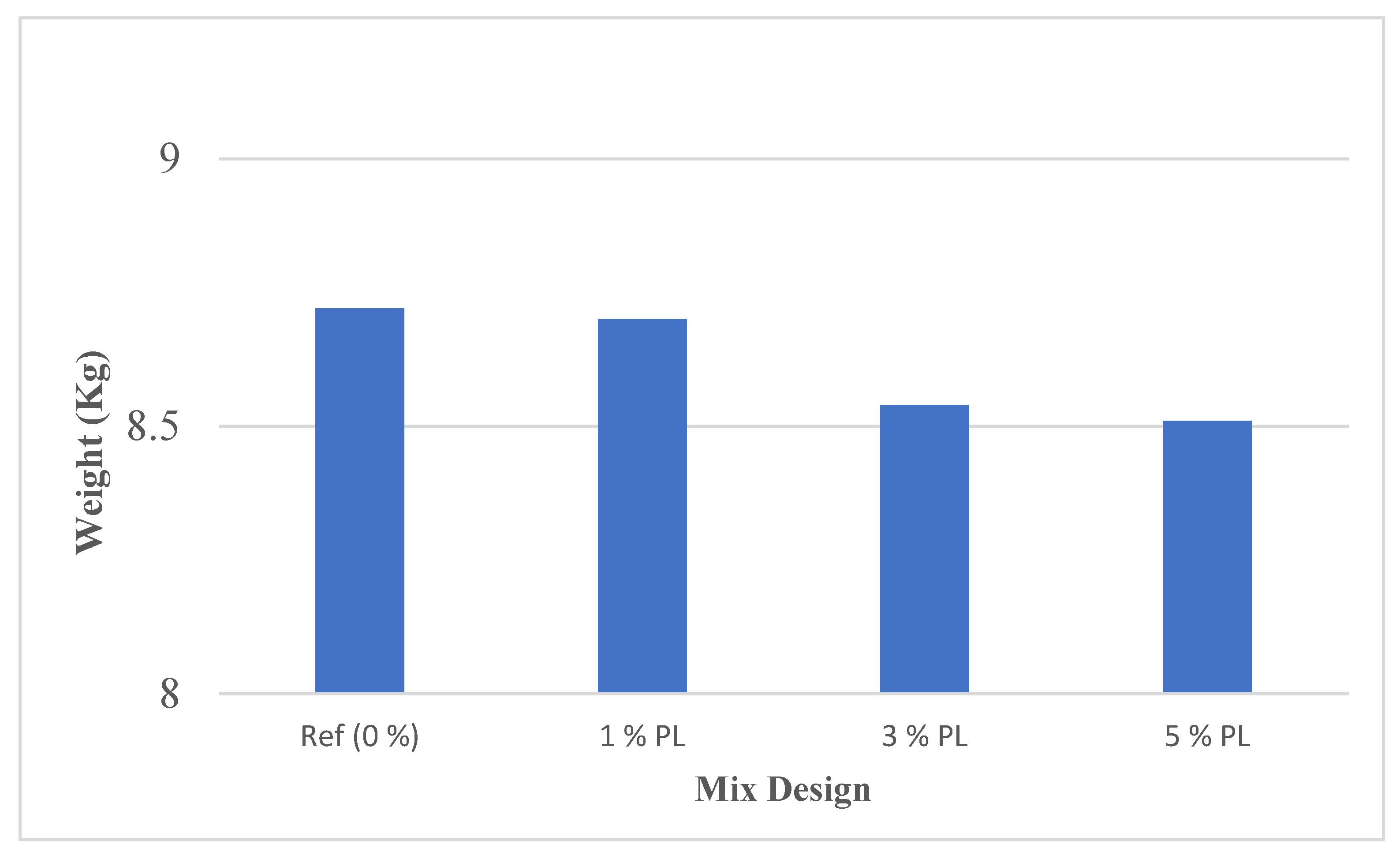

Figure 11 illustrates that as the percentage of recycled PP increased, the weight of the concrete samples decreased. This negative correlation may be attributable to the lower density of PP in comparison to traditional aggregates used in concrete. This reduction in weight could offer benefits in structural design by decreasing the overall load on structures, potentially resulting in material savings.

Table 4 illustrates the efficiency of different mixes based on their compressive strength values. The reference mix, which contained no PP, had a mean compressive strength of 46.57 MPa, serving as a baseline for comparison. The mix containing 3% PP showed a significant increase in compressive strength, with an 11.3% improvement, indicating that a moderate amount of recycled material was able to enhance its strength. The 1% PP mix showed a slight increase of 2.8%, suggesting a marginal benefit from this lower percentage. In contrast, the mix with 5% PP exhibited a decrease in compressive strength, with a reduction of 0.7%, indicating that excessive PP negatively impacted the concrete’s performance.

The above analysis suggests that incorporating recycled PP in concrete significantly impacts its physical properties. While moderate percentages can enhance compressive strength, excessively high amounts may have detrimental effects. Furthermore, the reduction in weight associated with increased PP content presents potential structural advantages. These findings underscore the importance of optimizing the design of the mix in order to achieve the desired mechanical and physical properties while promoting sustainability through recycling.

4. Conclusions

The results of this study provide valuable insights into the integration of recycled PP-PL pellets into concrete mixtures, emphasizing both the enhancement of the concrete’s mechanical properties and the potential environmental benefits. This research explored a novel approach to addressing two significant challenges in modern construction: the demand for stronger materials and the growing need for sustainable solutions that reduce PL waste. By demonstrating the efficacy of incorporating PP-PL, a widely available form of PL waste, into concrete mixtures, this study contributes to improving the performance of concrete and also to promoting environmental sustainability. The novelty of this work lies not only in its approach to using recycled PL but also in the identification of the optimal PP content for maximizing compressive strength and sustainability.

One of the key findings of this study is the identification of the optimal percentage of PP-PL pellets in the concrete mixture. At a concentration of 3%, the inclusion of PP resulted in a significant (11.3%) increase in compressive strength compared with the control mix (0% PP). This result underscores the potential for enhancing concrete’s structural performance through the incorporation of recycled PL. Such an increase in compressive strength represents a notable advancement in the search for sustainable alternatives to traditional concrete mixtures, which are typically dependent on non-renewable resources. The addition of 3% PP thus offers a new and valuable approach for improving the mechanical properties of concrete, providing a sustainable pathway for addressing both the requirements for materials and the environmental challenges faced by the construction industry.

In addition to the improvement in compressive strength, this study revealed that the 3% PP mix maintained a workability comparable to that of the reference mix, as indicated by the slump test results. This finding is particularly noteworthy because workability is a critical parameter relating to the production and application of concrete. The ability to maintain the workability of concrete while incorporating waste material such as recycled PP suggests that the 3% level is not only effective in enhancing the mechanical properties of concrete but also does not interfere with its practical use in construction. This balance between strength and workability is crucial, as it addresses one of the primary challenges when introducing recycled materials into construction mixes: the potential for compromised workability.

However, the current study also demonstrated that beyond the 3% threshold, the workability of the concrete mixes declined in a manner consistent with the increasing presence of PL material. This result highlights the importance of identifying the optimal dosage for recycled PL in concrete to avoid negative effects on the ease of mixing and pouring, which could have practical implications during construction.

Another significant finding of this research was the reduction in the weight of the concrete as the percentage of PP increased. This reduction in weight represents a key feature for a range of applications; combined with the improved mechanical properties of the concrete, this suggests that PP can play a crucial role in the development of lightweight concrete. Lightweight concrete has numerous advantages, including reduced transportation costs, easier handling, and the potential to decrease the load on structural elements. Given the increasing demand for lighter construction materials in various industries, the use of recycled PP-PL presents an attractive solution for developing concrete that is not only more sustainable but also more versatile in its applications. This finding opens up new possibilities for the construction of buildings, infrastructure, and precast concrete products where reduced weight is desirable without sacrificing strength or durability.

The potential for using recycled PP-PL in concrete is not limited to improving performance and sustainability in the short term. Long-term considerations, such as the durability and environmental impact of PP-modified concrete, are essential for assessing its broader applicability in the construction industry. Future studies could investigate the long-term behavior of PP-modified concrete, including its performance under various environmental conditions, such as exposure to freezing and thawing cycles or chemical attacks. The effect of PP on the microstructure of concrete could provide valuable insights into how PL interacts with the cement matrix over time, affecting the material’s durability and lifespan. Furthermore, an analysis of the environmental impact of using recycled PP in concrete, considering factors such as carbon footprint reduction, energy consumption during production, and the potential for large-scale recycling of PL waste, will be valuable for making a comprehensive assessment of its sustainability. Not only can these areas of future research enhance our understanding of the long-term viability of PP-modified concrete, but they can also contribute to the development of more environmentally friendly construction practices.

In short, the findings of this study highlight the potential of recycled PP as an innovative material for use in concrete production, offering a feasible solution that addresses both the growing concerns relating to PL waste and the need for stronger, more sustainable construction materials. The positive impact of 3% PP inclusion on the compressive strength, coupled with the minimal effect on workability, indicates a promising direction for future concrete formulations that combine high performance with sustainability. The reduction in weight of the PP-modified concrete suggests that recycled PL could also play an essential role in the development of lightweight concrete, which is becoming increasingly important in construction projects that prioritize cost-effectiveness and efficient use of materials.

This research underscores the importance of using alternative materials, such as recycled PL, to meet the demands of modern construction while also addressing environmental challenges. By incorporating PL waste into concrete mixtures, the construction industry can contribute to reducing the accumulation of non-biodegradable PL in landfills, oceans, and other ecosystems, turning waste into a valuable resource. The ability to recycle PL into building materials represents a significant step toward a more sustainable, circular economy. While this study offers valuable insights into the potential of using recycled PP in concrete, further research is necessary to gauge the full range of possibilities and limitations associated with this approach. Exploring the environmental benefits of using recycled PP in concrete, such as reductions in carbon emissions and the potential for recycling large volumes of PL waste, is expected to solidify the case for its wide-scale application in the construction industry.