Sustainability Drivers and Sustainable Development Goals-Based Indicator System for Prefabricated Construction Adoption—A Case of Developing Economies

Abstract

1. Introduction

2. Background

2.1. Sustainability Drivers for the Adoption of Prefabricated Construction

2.2. Sustainable Development Goals

| Code | Major Sustainability Driver | References |

|---|---|---|

| D1 | Overall project cost savings | [18,19,20,32,33,34,35] |

| D2 | Reduce overall project time (Fast delivery) | [18,19,20,22,23,32,33,34,35,36,37] |

| D3 | Minimise weather-related delays | [18,19,20,22,23,34,37] |

| D4 | Ensure cost and time certainty | [18,19,23,36,38,39] |

| D5 | Waste reduction and potential for better waste management practices | [18,19,22,23,33,34,36,37,38] |

| D6 | Efficient consumption of materials | [18,19,22,35,36,38] |

| D7 | Potential to enhance energy efficiency and reduce carbon emissions | [18,19,22,23,36,37,38] |

| D8 | Less disturbance on-site from noise and dust | [18,19,20,23,34,36] |

| D9 | Improved health and safety and working conditions of workers | [18,19,22,23,32,33,34,36,37,39] |

| D10 | Higher end-product quality (e.g., finishing, tolerances) | [18,19,20,23,32,33,34,36,37,38,39] |

| D11 | Improved project quality control | [18,19,23,34,36] |

| D12 | Simplify construction activities | [18,19,34,36,38] |

| D13 | Improved technology integration, such as automation, 3D printing, BIM 1, Immersive technologies and IoT 2 | [18] |

| D14 | Improved productivity | [20,22,23,33,35,37,38] |

| D15 | Addressing the industry skills shortage | [18,19,33,34,37,39] |

2.3. Research Significance

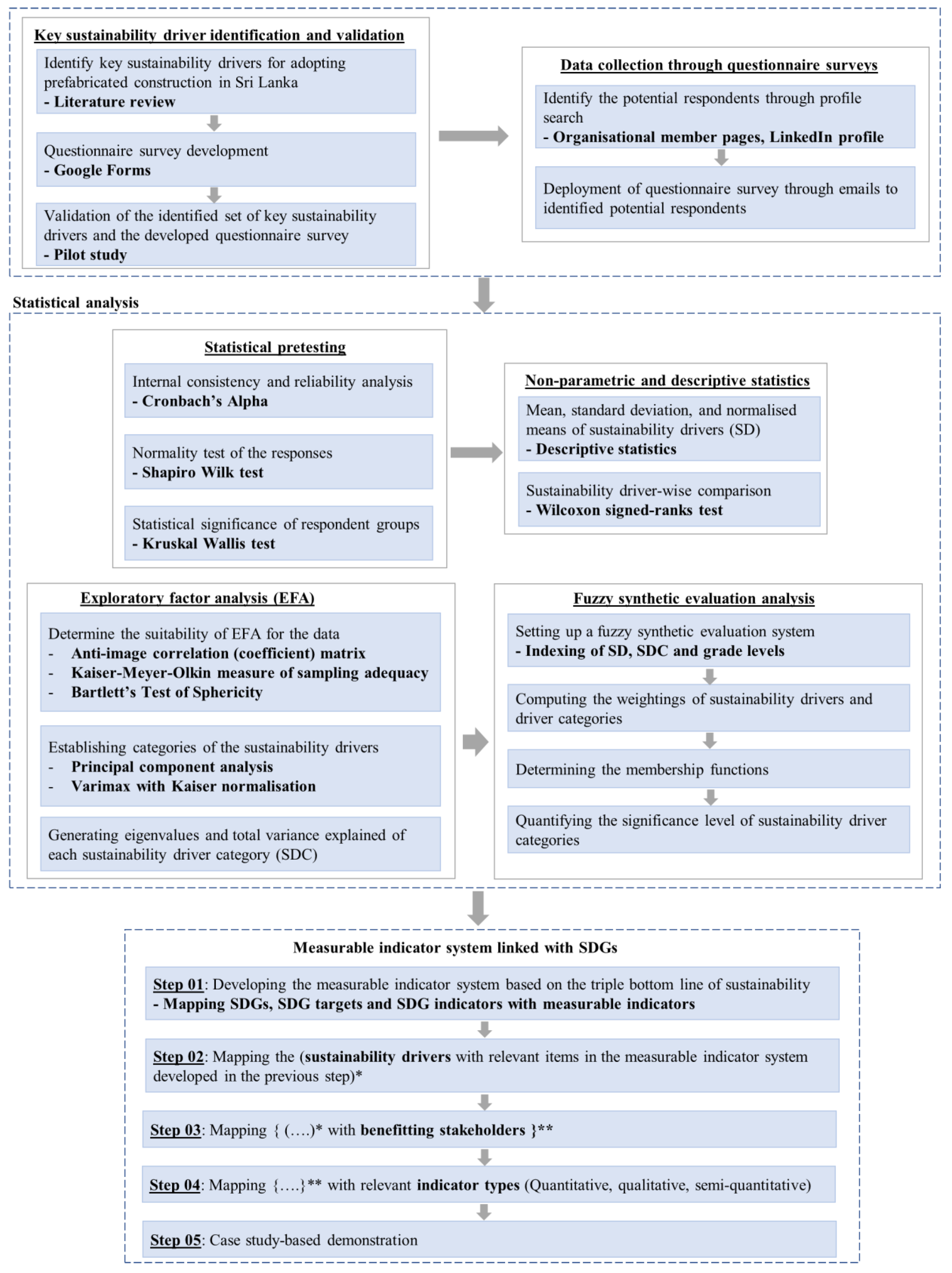

3. Research Methodology

3.1. Key Sustainability Driver Identification

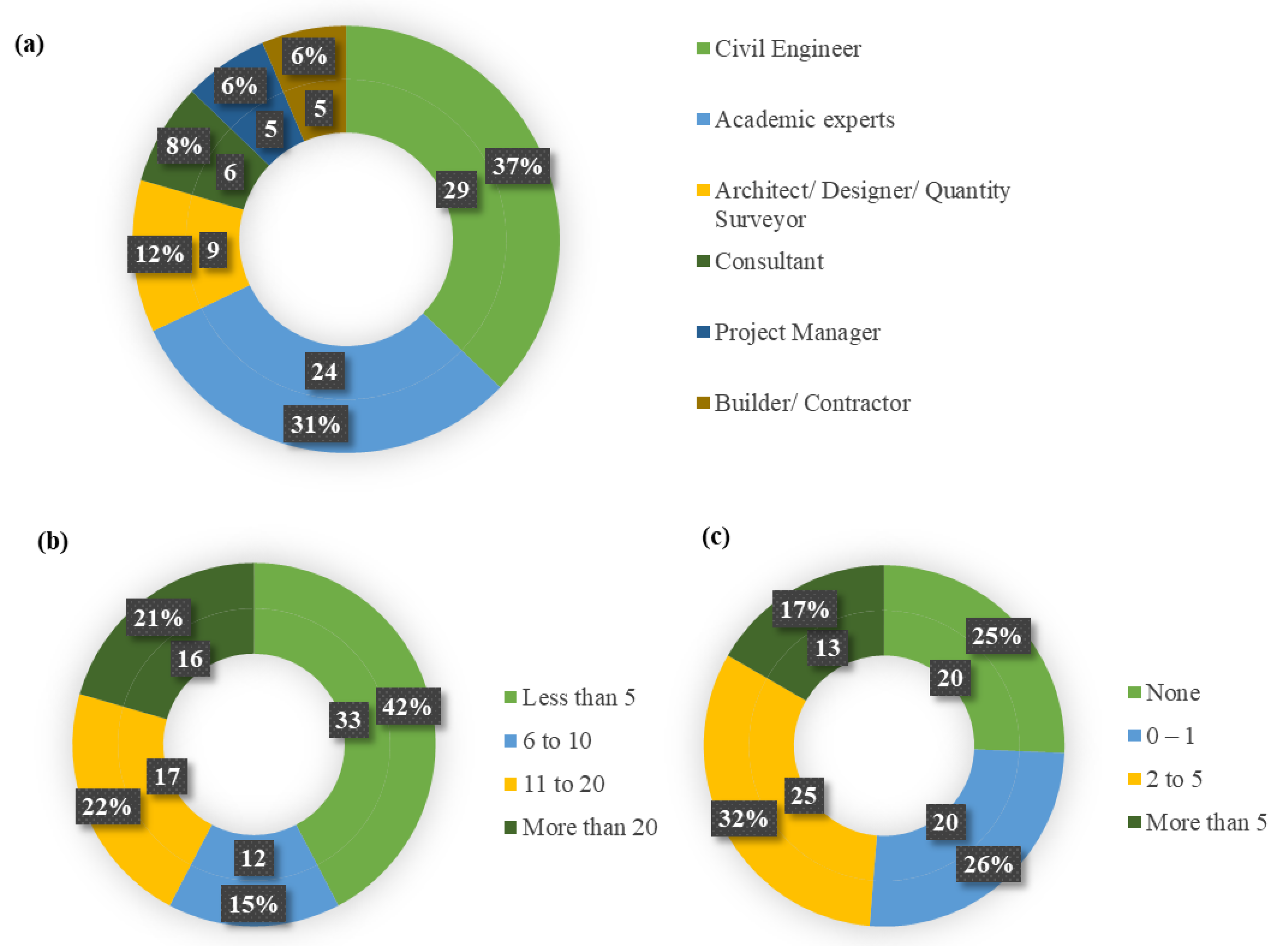

3.2. Data Collection Through Questionnaire Forms

3.3. Statistical Pre-Testing of Questionnaire Survey Responses

3.4. Descriptive Statistics and Sustainability Driver-Wise Comparison

3.5. Exploratory Factor Analysis

3.6. Fuzzy Synthetic Evaluation Analysis

3.6.1. Setting up the Fuzzy Synthetic Evaluation System

3.6.2. Calculating the Weights of Sustainability Drivers and Driver Categories

3.6.3. Calculation of Membership Functions for Sustainability Drivers and Their Respective Categories

3.6.4. Determining the Significant Levels of Sustainability Driver Categories

3.7. Measurable Indicator System for Sustainability Drivers Linked with Sustainable Development Goals

4. Statistical Analysis Results and Discussions

4.1. Primary Sustainability Drivers Influencing PFC in Sri Lanka

4.2. Exploratory Factor Analysis for Sustainability Drivers

4.3. Fuzzy Synthetic Evaluation Analysis Results

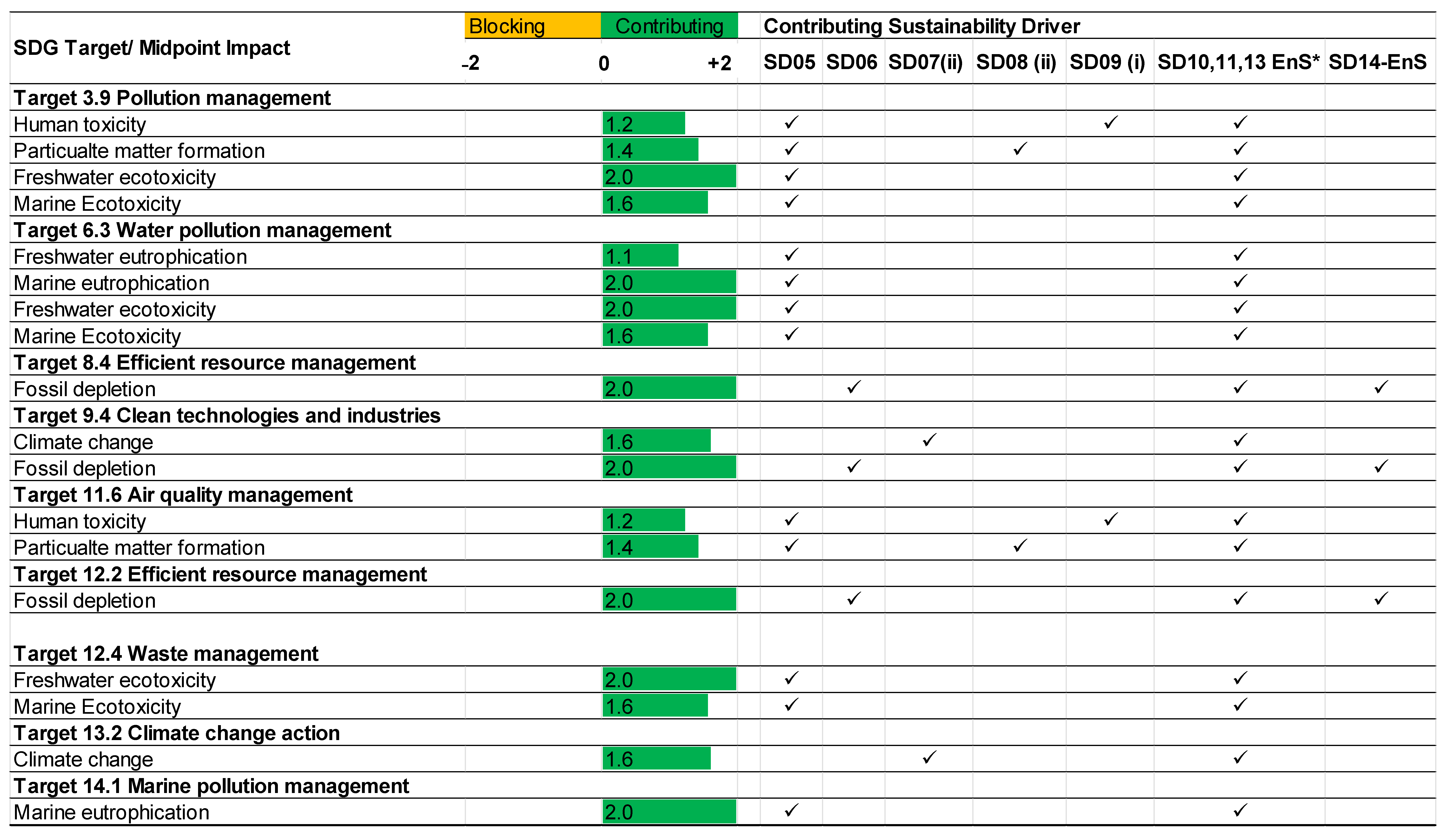

5. Sustainable Development Goals-Linked Measurable Indicator System

6. Case Study

7. Discussion

7.1. Policy, Global and Industry Implications

7.2. Geographical Implications

8. Conclusions, Study Constraints, and Future Directions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SD | Sustainability driver |

| SDG | Sustainable development goals |

| PFC | Prefabricated construction |

| LD | Linear dichroism |

| CIP | Construction industry practitioner |

| S-W | Shapiro-Wilk |

| K-W | Kruskal-Wallis |

| SDe | Standard deviation |

| WSRT | Wilcoxon signed-rank test |

| EFA | Exploratory factor analysis |

| KMO | Kaiser-Meyer-Olkin |

| BTS | Bartlett’s Test of Sphericity |

| FSE | Fuzzy synthetic evaluation |

| SDC | Sustainability driver category |

| MF | Membership function |

| GIF-SDGs | Global indicator framework for the SDGs |

| PEFCR | Product Environmental Footprint Category Rules |

| S-LCA | Social Life Cycle Assessment |

| DfMA | Design for manufacturing and assembly |

| EcS | Economic sustainability |

| ScS | Social sustainability |

| EnS | Environmental sustainability |

| QL | Qualitative |

| QN | Quantitative |

| SQN | Semi-quantitative |

| ILO | International labour organisation |

| BIM | Building information modelling |

| IoT | Internet of Things |

| LCA | Life-cycle assessment |

| DfD | Design for disassembly |

Appendix A

| Primary Keyword | Search String |

|---|---|

| Sustainability drivers | “sustainability drivers” OR “drivers” OR “pros” OR “advantage *” OR “opportunities” OR “influencing” OR “enabling factors” OR “success factors” |

| AND | |

| Prefabricated construction | “modular construction” OR “prefabricated construction” OR “prefab *” OR “pre-fab *” OR “modular building *” OR “modular home” OR “modular house” OR “off-site construction” OR “offsite construction” OR “industrialized building” OR “industrialized construction” OR “panelized construction” OR “precast construction” OR “prefabricated prefinished volumetric construction” OR “off-site manufacturing” OR “offsite production” OR “off-site production” OR “modular integrated construction” OR “modern method of construction” |

| LCA Stage | Description |

|---|---|

| Case A | |

| Goal and scope | System boundary: Cradle-to-gate |

| Functional unit: 1 m2 of the construction area | |

| Life cycle impact assessment | Method: ReCiPe Midpoint (H) |

| Case B | |

| Goal and scope | System boundary: Product, end-of-life, and benefits and loads beyond the life cycle |

| Functional unit: Modular unit | |

| Life-cycle impact assessment | Method: ReCiPe Midpoint (H) |

| Mid-Point Environmental Impact | Unit | Reduction * (%) |

|---|---|---|

| Global Warming Potential (GWP) | kg CO2 eq | 8.06 |

| Freshwater Eutrophication (FE) | kg P eq | 5.69 |

| Marine Eutrophication (ME) | kg N eq | 14.13 |

| Particulate Matter Formation (PMF) | kg PM10 eq | 7.17 |

| Human Toxicity (HT) | kg 1,4-DCB eq | 6.15 |

| Freshwater Ecotoxicity (FET) | kg 1,4-DCB eq | 11.93 |

| Marine Ecotoxicity (MET) | kg 1,4-DCB eq | 7.84 |

| Fossil Depletion (FD) | kg oil-eq | 12.89 |

| Mid-Point Environmental Impact | Unit | Reduction * (%) |

|---|---|---|

| Global Warming Potential (GWP) | kg CO2 eq | 63.24 |

| Freshwater Eutrophication (FE) | kg P eq | 40.00 |

| Particulate Matter Formation (PMF) | kg PM10 eq | 12.44 |

| Human Toxicity (HT) | kg 1,4-DCB eq | 90.60 |

| Terrestrial Ecotoxicity (TET) | kg 1,4-DCB eq | 24.53 |

| Freshwater Ecotoxicity (FET) | kg 1,4-DCB eq | 51.79 |

| Marine Ecotoxicity (MET) | kg 1,4-DCB eq | 74.24 |

| Metal depletion (MD) | kg Fe-eq | 70.21 |

| Fossil Depletion (FD) | kg oil-eq | 47.31 |

References

- Zimmermann, M.; Althaus, H.-J.; Haas, A. Benchmarks for sustainable construction: A contribution to develop a standard. Energy Build. 2005, 37, 1147–1157. [Google Scholar] [CrossRef]

- Xu, X.; Wang, Y.; Tao, L. Comprehensive evaluation of sustainable development of regional construction industry in China. J. Clean. Prod. 2019, 211, 1078–1087. [Google Scholar] [CrossRef]

- Sev, A. How can the construction industry contribute to sustainable development? A conceptual framework. Sustain. Dev. 2009, 17, 161–173. [Google Scholar] [CrossRef]

- Son, H.; Kim, C.; Chong, W.K.; Chou, J.S. Implementing sustainable development in the construction industry: Constructors’ perspectives in the US and Korea. Sustain. Dev. 2011, 19, 337–347. [Google Scholar] [CrossRef]

- López-Guerrero, R.E.; Vera, S.; Carpio, M. A quantitative and qualitative evaluation of the sustainability of industrialised building systems: A bibliographic review and analysis of case studies. Renew. Sustain. Energy Rev. 2022, 157, 112034. [Google Scholar]

- Yeheyis, M.; Hewage, K.; Alam, M.S.; Eskicioglu, C.; Sadiq, R. An overview of construction and demolition waste management in Canada: A lifecycle analysis approach to sustainability. Clean Technol. Environ. Policy 2013, 15, 81–91. [Google Scholar]

- Jayawardana, J.; Jayasinghe, J.A.S.C.; Kulatunga, A.K.; Sandanayake, M.; Zhang, G. Prefabricated Construction in Sri Lanka: From a Sustainability Perspective. In International Conference on Sustainable Built Environment; Springer: Kandy, Sri Lanka, 2022. [Google Scholar]

- Yin, X.; Liu, H.; Chen, Y.; Al-Hussein, M. Building information modelling for off-site construction: Review and future directions. Autom. Constr. 2019, 101, 72–91. [Google Scholar] [CrossRef]

- Tian, Y.; Spatari, S. Environmental life cycle evaluation of prefabricated residential construction in China. J. Build. Eng. 2022, 57, 104776. [Google Scholar] [CrossRef]

- Jayawardana, J.; Sandanayake, M.; Jayasinghe, J.A.S.C.; Kulatunga, A.K.; Zhang, G. A comparative life cycle assessment of prefabricated and traditional construction–A case of a developing country. J. Build. Eng. 2023, 72, 106550. [Google Scholar]

- Jayawardana, J.; Kulatunga, A.K.; Jayasinghe, J.A.S.C.; Sandanayake, M.; Zhang, G. Environmental Sustainability of Off-Site Construction in Developed and Developing Regions: A Systematic Review. J. Archit. Eng. 2023, 29, 04023008. [Google Scholar] [CrossRef]

- Jayawardana, J.; Jayasinghe, J.A.S.C.; Sandanayake, M.; Kulatunga, A.K.; Zhang, G. Prefabricated Construction in Sri Lanka: A Proposed Adoption Strategy and a Pilot Case Study from Sustainability Perspective. Engineer 2023, 56, 71–80. [Google Scholar] [CrossRef]

- De Silva, C.S.R. Prefabricated Building Method in Sri Lanka and User Attitude. 2017. Available online: http://dl.lib.uom.lk/bitstream/handle/123/13324/TH3520-1.pdf?sequence=1&isAllowed=y (accessed on 13 May 2024).

- Jayasooriya, J.; Denagama, T. Comparative Analysis of Precast Construction and Conventional Construction of Small-scale Concrete Building in Terms of Cost. J. Civ. Eng. Sci. Technol. 2022, 10, 44229. [Google Scholar]

- Uthpala, H.; Ramachandra, T. Study on Modern Methods of Constructions Used in Sri Lanka. Constr. Mater. Syst. 2015, 155. [Google Scholar]

- Eberle, U.; Wenzig, J.; Mumm, N. Assessing the contribution of products to the United Nations’ Sustainable Development Goals: A methodological proposal. Int. J. Life Cycle Assess. 2022, 27, 959–977. [Google Scholar] [CrossRef]

- Alejandrino, C.; Mercante, I.; Bovea, M.D. Life cycle sustainability assessment: Lessons learned from case studies. Environ. Impact Assess. Rev. 2021, 87, 106517. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Holistic review and conceptual framework for the drivers of offsite construction: A total interpretive structural modelling approach. Buildings 2019, 9, 117. [Google Scholar] [CrossRef]

- Ismail, S.; Hon, C.K.; Crowther, P.; Skitmore, M.; Lamari, F. The drivers and challenges of adopting the Malaysia industrialised building system for sustainable infrastructure development. Constr. Innov. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar]

- Hwang, B.-G.; Shan, M.; Looi, K.-Y. Key constraints and mitigation strategies for prefabricated prefinished volumetric construction. J. Clean. Prod. 2018, 183, 183–193. [Google Scholar]

- Bello, A.O.; Eje, D.O.; Idris, A.; Semiu, M.A.; Khan, A.A. Drivers for the implementation of modular construction systems in the AEC industry of developing countries. J. Eng. Des. Technol. 2023, 22, 2043–2062. [Google Scholar] [CrossRef]

- Khan, A.; Yu, R.; Liu, T.; Guan, H.; Oh, E. Drivers towards adopting modular integrated construction for affordable sustainable housing: A Total Interpretive Structural Modelling (TISM) method. Buildings 2022, 12, 637. [Google Scholar] [CrossRef]

- Ahn, S.; Crouch, L.; Kim, T.W.; Rameezdeen, R. Comparison of worker safety risks between onsite and offsite construction methods: A site management perspective. J. Constr. Eng. Manag. 2020, 146, 05020010. [Google Scholar] [CrossRef]

- Boafo, F.E.; Kim, J.-H.; Kim, J.-T. Performance of modular prefabricated architecture: Case study-based review and future pathways. Sustainability 2016, 8, 558. [Google Scholar] [CrossRef]

- Sutrisna, M.; Ramnauth, V.; Zaman, A. Towards adopting off-site construction in housing sectors as a potential source of competitive advantage for builders. Archit. Eng. Des. Manag. 2022, 18, 165–183. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.-S.; Chiang, Y.H. Quantifying the waste reduction potential of using prefabrication in building construction in Hong Kong. Waste Manag. 2009, 29, 309–320. [Google Scholar]

- Lu, W.; Yuan, H. Investigating waste reduction potential in the upstream processes of offshore prefabrication construction. Renew. Sustain. Energy Rev. 2013, 28, 804–811. [Google Scholar] [CrossRef]

- Resolution, G.A. Transforming Our World: The 2030 Agenda for Sustainable Development, in UN Doc. A/RES/70/1 (25 September 2015). 2015. Available online: https://www.un.org/en/development/desa/population/migration/generalassembly/docs/globalcompact/A_RES_70_1_E.pdf (accessed on 13 May 2024).

- Cordella, M.; Horn, R.; Hong, S.H.; Bianchi, M.; Isasa, M.; Harmens, R.; Sonderegger, T.; Pihkola, H. Addressing sustainable development goals in life cycle sustainable assessment: Synergies, challenges and needs. J. Clean. Prod. 2023, 415, 137719. [Google Scholar] [CrossRef]

- Omer, M.A.; Noguchi, T. A conceptual framework for understanding the contribution of building materials in the achievement of Sustainable Development Goals (SDGs). Sustain. Cities Soc. 2020, 52, 101869. [Google Scholar]

- Razkenari, M.; Fenner, A.; Shojaei, A.; Hakim, H.; Kibert, C. Perceptions of offsite construction in the United States: An investigation of current practices. J. Build. Eng. 2020, 29, 101138. [Google Scholar]

- Wong, P.S.; Zwar, C.; Gharaie, E. Examining the drivers and states of organizational change for greater use of prefabrication in construction projects. J. Constr. Eng. Manag. 2017, 143, 04017020. [Google Scholar] [CrossRef]

- Senarathna, D.; Perera, B. Managing concrete wastes by implementing contemporary construction practices in Sri Lanka. In Proceedings of the 9th World Construction Symposium, Moratuwa, Sri Lanka, 9–10 July 2021. [Google Scholar]

- Li, Z.; Shen, G.Q.; Ji, C.; Hong, J. Stakeholder-based analysis of drivers and constraints in the use of off-site construction. In Proceedings of the ICCREM 2014, Smart Construction and Management in the Context of New Technology, Kunming, China, 31 October 2014; pp. 26–36. [Google Scholar]

- Kamar, K.A.M.; Azman, M.N.A.; Nawi, M.N.M. IBS survey 2010, Drivers, barriers and critical success factors in adopting industrialised building system (IBS) construction by G7 contractors in Malaysia. J. Eng. Sci. Technol. 2014, 9, 490–501. [Google Scholar]

- Hu, X.; Chong, H.-Y.; Wang, X. Sustainability perceptions of off-site manufacturing stakeholders in Australia. J. Clean. Prod. 2019, 227, 346–354. [Google Scholar] [CrossRef]

- Arif, M.; Bendi, D.; Sawhney, A.; Iyer, K.C. State of offsite construction in India-Drivers and barriers. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2012. [Google Scholar]

- Hao, J.L.; Cheng, B.; Lu, W.; Xu, J.; Wang, J.; Bu, W.; Guo, Z. Carbon emission reduction in prefabrication construction during materialization stage: A BIM-based life-cycle assessment approach. Sci. Total Environ. 2020, 723, 137870. [Google Scholar]

- Hong, J.; Shen, G.Q.; Mao, C.; Li, Z.; Li, K. Life-cycle energy analysis of prefabricated building components: An input–output-based hybrid model. J. Clean. Prod. 2016, 112, 2198–2207. [Google Scholar] [CrossRef]

- Hao, J.; Chen, Z.; Zhang, Z.; Loehlein, G. Quantifying construction waste reduction through the application of prefabrication: A case study in Anhui, China. Environ. Sci. Pollut. Res. 2021, 28, 24499–24510. [Google Scholar]

- Mi, Z.; Deng, Q. Aligning building information modeling and prefabricated construction with sustainable development goals: A framework for sustainable urbanization. Appl. Comput. Eng. 2024, 70, 48–53. [Google Scholar]

- Wu, Z.; Luo, L.; Li, H.; Wang, Y.; Bi, G.; Antwi-Afari, M.F. An analysis on promoting prefabrication implementation in construction industry towards sustainability. Int. J. Environ. Res. Public Health 2021, 18, 11493. [Google Scholar] [CrossRef]

- Gallo, P.; Romano, R.; Belardi, E. Smart green prefabrication: Sustainability performances of industrialized building technologies. Sustainability 2021, 13, 4701. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Development of performance criteria for sustainability evaluation of modular versus conventional construction methods. J. Clean. Prod. 2017, 142, 3592–3606. [Google Scholar]

- Wuni, I.Y.; Shen, G.Q. Exploring the critical production risk factors for modular integrated construction projects. J. Facil. Manag. 2023, 21, 50–68. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.C. Strategies to promote green building technologies adoption in developing countries: The case of Ghana. Build. Environ. 2018, 130, 74–84. [Google Scholar]

- Wuni, I.Y.; Shen, G.Q. Developing critical success factors for integrating circular economy into modular construction projects in Hong Kong. Sustain. Prod. Consum. 2022, 29, 574–587. [Google Scholar]

- Ngo, J.; Hwang, B.-G.; Zhang, C. Factor-based big data and predictive analytics capability assessment tool for the construction industry. Autom. Constr. 2020, 110, 103042. [Google Scholar]

- Yong, A.G.; Pearce, S. A beginner’s guide to factor analysis: Focusing on exploratory factor analysis. Tutor. Quant. Methods Psychol. 2013, 9, 79–94. [Google Scholar]

- Ali, A.H.; Kineber, A.F.; Qaralleh, T.J.O.; Alaboud, N.S.; Daoud, A.O. Classifying and evaluating enablers influencing modular construction utilization in the construction sector: A fuzzy synthetic evaluation. Alex. Eng. J. 2023, 78, 45–55. [Google Scholar]

- Bijivemula, S.K.R.; Sai, S.J.; Chepuri, A. A structural equation model of stakeholder roles in the implementation of green construction strategies in the Indian construction industry. Int. J. Constr. Manag. 2023, 24, 486–494. [Google Scholar]

- Buniya, M.K.; Othman, I.; Sunindijo, R.Y.; Kineber, A.F.; Mussi, E.; Ahmad, H. Barriers to safety program implementation in the construction industry. Ain Shams Eng. J. 2021, 12, 65–72. [Google Scholar]

- Zhao, X.; Hwang, B.-G.; Gao, Y. A fuzzy synthetic evaluation approach for risk assessment: A case of Singapore’s green projects. J. Clean. Prod. 2016, 115, 203–213. [Google Scholar]

- Xu, Y.; Yeung, J.F.; Chan, A.P.; Chan, D.W.; Wang, S.Q.; Ke, Y. Developing a risk assessment model for PPP projects in China—A fuzzy synthetic evaluation approach. Autom. Constr. 2010, 19, 929–943. [Google Scholar]

- Wuni, I.Y.; Shen, G.Q.; Osei-Kyei, R.; Agyeman-Yeboah, S. Modelling the critical risk factors for modular integrated construction projects. Int. J. Constr. Manag. 2022, 22, 2013–2026. [Google Scholar] [CrossRef]

- UN General Assembly. Global Indicator Framework for the Sustainable Development Goals and Targets of the 2030 Agenda for Sustainable Development. 2016. Available online: https://unstats.un.org/sdgs/indicators/Global%20Indicator%20Framework%20after%202022%20refinement_Eng.pdf (accessed on 13 May 2024).

- European Commission. Product Environmental Footprint Category Rules Guidance; Kluwer Academic Publishers: Drive Norwell, MA, USA, 2018. [Google Scholar]

- United Nations Environment Programme. Guidelines for Social Life Cycle Assessment of Products and Organisations 2020. 2020. Available online: https://wedocs.unep.org/20.500.11822/34554 (accessed on 13 May 2024).

- United Nations Environment Programme. Methodological Sheets for Subcategories in Social Life Cycle Assessment (S-LCA) 2021. 2021. Available online: https://www.lifecycleinitiative.org/library/methodological-sheets-for-subcategories-in-social-life-cycle-assessment-s-lca-2021/ (accessed on 13 May 2024).

- ISO 15686-5:2017; Buildings and Constructed Assets-Service Life Planning-Part 5. ISO Life-Cycle Costing: Geneva, Switzerland, 2017.

- Life Cycle Initiative. Linking UN SDGs to Life Cycle Impact Pathway Frameworks. 2020. Available online: https://www.lifecycleinitiative.org/activities/life-cycle-assessment-data-and-methods/linking-un-sdgs-to-life-cycle-impact-pathway-frameworks/ (accessed on 15 March 2025).

- PRé Sustainability. Linking LCA and SDG 12. 2020. Available online: https://www.lifecycleinitiative.org/wp-content/uploads/2021/02/SDG-12-Sustainable-consumption-and-production.pdf (accessed on 15 March 2025).

- Navaratnam, S.; Satheeskumar, A.; Zhang, G.; Nguyen, K.; Venkatesan, S.; Poologanathan, K. The challenges confronting the growth of sustainable prefabricated building construction in Australia: Construction industry views. J. Build. Eng. 2022, 48, 103935. [Google Scholar] [CrossRef]

- Wasim, M.; Serra, P.V.; Ngo, T.D. Design for manufacturing and assembly for sustainable, quick and cost-effective prefabricated construction–a review. Int. J. Constr. Manag. 2022, 22, 3014–3022. [Google Scholar] [CrossRef]

- Agapiou, A. Barriers to offsite construction adoption: A quantitative study among housing associations in England. Buildings 2022, 12, 283. [Google Scholar] [CrossRef]

- Aghasizadeh, S.; Tabadkani, A.; Hajirasouli, A.; Banihashemi, S. Environmental and economic performance of prefabricated construction: A review. Environ. Impact Assess. Rev. 2022, 97, 106897. [Google Scholar] [CrossRef]

- Tsz Wai, C.; Wai Yi, P.; Ibrahim Olanrewaju, O.; Abdelmageed, S.; Hussein, M.; Tariq, S.; Zayed, T. A critical analysis of benefits and challenges of implementing modular integrated construction. Int. J. Constr. Manag. 2021, 23, 1–24. [Google Scholar] [CrossRef]

- Gumusburun Ayalp, G.; Ay, I. Model validation of factors limiting the use of prefabricated construction systems in Turkey. Engineering, Constr. Archit. Manag. 2021, 28, 2610–2636. [Google Scholar] [CrossRef]

- Blismas, N.G.; Pendlebury, M.; Gibb, A.; Pasquire, C. Constraints to the use of off-site production on construction projects. Archit. Eng. Des. Manag. 2005, 1, 153–162. [Google Scholar] [CrossRef]

- Elnaas, H.; Gidado, K.; Philip, A. Factors and drivers effecting the decision of using off-site manufacturing (OSM) systems in house building industry. J. Eng. Proj. Prod. Manag. 2014, 4, 51–58. [Google Scholar] [CrossRef]

- Hossain, M.A.; Nadeem, A. Towards digitizing the construction industry: State of the art of construction 4.0. In Proceedings of the ISEC, Riverside, CA, USA, 1 August 2019. [Google Scholar]

- Chan, J.K.; Chan, A.P.; Kung, F.W. Using innovative prefabrications as the source of competitive advantage for contractors—Case studies in Hong Kong. Archit. Sci. Rev. 2004, 47, 183–192. [Google Scholar] [CrossRef]

- Hammad, A.W.; Akbarnezhad, A.; Wu, P.; Wang, X.; Haddad, A. Building information modelling-based framework to contrast conventional and modular construction methods through selected sustainability factors. J. Clean. Prod. 2019, 228, 1264–1281. [Google Scholar] [CrossRef]

- Liu, S.; Qian, S. Evaluation of social life-cycle performance of buildings: Theoretical framework and impact assessment approach. J. Clean. Prod. 2019, 213, 792–807. [Google Scholar] [CrossRef]

- Leadership Council of the Sustainable Development Solutions Network. Indicators and a Monitoring Framework for the Sustainable Development Goals; Leadership Council of the Sustainable Development Solutions Network: Selangor, Malaysia, 2015. [Google Scholar]

- Costa, D.; Quinteiro, P.; Dias, A. A systematic review of life cycle sustainability assessment: Current state, methodological challenges, and implementation issues. Sci. Total Environ. 2019, 686, 774–787. [Google Scholar] [CrossRef]

- Jayawardana, J.; Sandanayake, M.; Kulatunga, A.K.; Jayasinghe, J.A.S.C.; Zhang, G.; Osadith, S.U. Evaluating the Circular Economy Potential of Modular Construction in Developing Economies—A Life Cycle Assessment. Sustainability 2023, 15, 16336. [Google Scholar] [CrossRef]

- Gao, Y.; Tian, X.-L. Prefabrication policies and the performance of construction industry in China. J. Clean. Prod. 2020, 253, 120042. [Google Scholar] [CrossRef]

- Wang, J.; Qin, Y.; Zhou, J. Incentive policies for prefabrication implementation of real estate enterprises: An evolutionary game theory-based analysis. Energy Policy 2021, 156, 112434. [Google Scholar]

- Wang, Y.; Li, Y.; Zhuang, J. Research on the green development path of prefabricated building industry based on intelligent technology. Eng. Constr. Archit. Manag. 2024. ahead-of-print. [Google Scholar]

- Zhou, J.; Ren, D. A hybrid model of external environmental benefits compensation to practitioners for the application of prefabricated construction. Environ. Impact Assess. Rev. 2020, 81, 106358. [Google Scholar]

- Chippagiri, R.; Bras, A.; Sharma, D.; Ralegaonkar, R.V. Technological and sustainable perception on the advancements of prefabrication in construction industry. Energies 2022, 15, 7548. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, J.; Ye, M.; Huang, Q.; Si, X. An evaluation of supply chain performance of China’s prefabricated building from the perspective of sustainability. Sustainability 2022, 14, 1299. [Google Scholar] [CrossRef]

- Wang, S.; Sinha, R. Life cycle assessment of different prefabricated rates for building construction. Buildings 2021, 11, 552. [Google Scholar] [CrossRef]

| Code | Sustainability Driver | Mean | SDe | Rank | K–W Test (p-Values) |

|---|---|---|---|---|---|

| SD02 | Reduce overall project time (Fast delivery) | 4.641 | 0.558 | 1 | 0.363 |

| SD06 | Efficient consumption of materials | 4.346 | 0.753 | 2 | 0.266 |

| SD01 | Overall project cost savings | 4.282 | 0.851 | 3 | 0.315 |

| SD11 | Improved project quality control | 4.205 | 0.745 | 4 | 0.241 |

| SD05 | Waste reduction and potential for better waste management practices | 4.179 | 0.833 | 5 | 0.897 |

| SD03 | Minimise weather-related delays | 4.179 | 0.849 | 6 | 0.462 |

| SD04 | Ensure cost and time certainty | 4.167 | 0.692 | 7 | 0.465 |

| SD12 | Simplify construction activities | 4.167 | 0.844 | 8 | 0.019 * |

| SD14 | Improved productivity | 4.141 | 0.801 | 9 | 0.083 |

| SD10 | Higher end-product quality (e.g., finishing, tolerances) | 4.128 | 0.917 | 10 | 0.018 * |

| SD13 | Improved technology integration, such as automation, 3D printing, BIM, Immersive technologies and IoT | 4.064 | 0.931 | 11 | 0.033 * |

| SD09 | Improved health and safety and working conditions of workers | 4.026 | 0.821 | 12 | 0.067 |

| SD08 | Less disturbance on-site from noise and dust | 4.013 | 0.860 | 13 | 0.089 |

| SD15 | Addressing the industry skills shortage | 3.962 | 0.874 | 14 | 0.365 |

| SD07 | Potential to enhance energy efficiency and reduce carbon emissions | 3.962 | 0.904 | 15 | 0.186 |

| SD02 | SD06 | SD01 | SD11 | SD05 | SD03 | SD04 | SD12 | SD14 | SD10 | SD13 | SD09 | SD08 | SD07 | SD15 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SD02 | X | 0.003 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * |

| SD06 | X | 0.573 | 0.179 | 0.052 | 0.095 | 0.065 | 0.097 | 0.042* | 0.047* | 0.016 * | 0.002 * | <.001 * | <.001 * | 0.001 * | |

| SD01 | X | 0.297 | 0.348 | 0.413 | 0.206 | 0.204 | 0.162 | 0.155 | 0.050* | 0.043* | 0.029 * | 0.014 * | 0.008 * | ||

| SD11 | X | 0.880 | 0.848 | 0.636 | 0.842 | 0.457 | 0.294 | 0.154 | 0.059 | 0.056 | 0.019 * | 0.008 * | |||

| SD05 | X | 0.856 | 0.906 | 0.946 | 0.856 | 0.59 | 0.358 | 0.204 | 0.118 | 0.028 * | 0.069 * | ||||

| SD03 | X | 0.938 | 0.988 | 0.958 | 0.802 | 0.387 | 0.179 | 0.091 | 0.087 | 0.130 | |||||

| SD04 | X | 0.894 | 0.956 | 0.625 | 0.506 | 0.169 | 0.110 | 0.098 | 0.064 | ||||||

| SD12 | X | 0.582 | 0.681 | 0.221 | 0.105 | 0.142 | 0.063 | 0.029 * | |||||||

| SD14 | X | 0.717 | 0.333 | 0.140 | 0.106 | 0.097 | 0.011 | ||||||||

| SD10 | X | 0.616 | 0.286 | 0.252 | 0.153 | 0.138 | |||||||||

| SD13 | X | 0.699 | 0.605 | 0.287 | 0.225 | ||||||||||

| SD09 | X | 0.853 | 0.446 | 0.425 | |||||||||||

| SD08 | X | 0.554 | 0.554 | ||||||||||||

| SD07 | X | 1.000 | |||||||||||||

| SD15 | X |

| Code | Sustainability Driver Category/Sustainability Driver | Factor Loadings of Sustainability Driver Categories | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||

| SDC01 | Worker health and safety, working conditions and skills | ||||

| SD09 | Improved health and safety and working conditions of workers | 0.778 | |||

| SD08 | Less disturbance on-site from noise and dust | 0.773 | |||

| SD15 | Addressing the industry skills shortage | 0.658 | |||

| SDC02 | Project performance optimisation and technology integration | ||||

| SD12 | Simplify construction activities | 0.796 | |||

| SD11 | Improved project quality control | 0.723 | |||

| SD13 | Improved technology integration, such as automation, 3D printing, BIM, Immersive technologies and IoT | 0.576 | |||

| SD10 | Higher end-product quality (e.g., finishing, tolerances) | 0.542 | |||

| SD14 | Improved productivity | 0.519 | |||

| SDC03 | Economic optimisation | ||||

| SD02 | Reduce overall project time (Fast delivery) | 0.782 | |||

| SD04 | Ensure cost and time certainty | 0.763 | |||

| SD03 | Minimise weather-related delays | 0.752 | |||

| SD01 | Overall project cost savings | 0.451 | |||

| SDC04 | Environmental and resource management | ||||

| SD05 | Waste reduction and potential for better waste management practices | 0.808 | |||

| SD06 | Efficient consumption of materials | 0.768 | |||

| SD07 | Potential to enhance energy efficiency and reduce carbon emissions | 0.482 | |||

| Rotation Sums of Squared Loadings | |||||

| Eigenvalue | 3.209 | 2.755 | 2.402 | 2.355 | |

| Variance explained (%) | 21.396 | 18.368 | 16.012 | 15.703 | |

| Cumulative variance explained (%) | 21.396 | 39.763 | 55.775 | 71.478 | |

| Code | Mean | Local Weights | MFs (Level 03) | MFs (Level 02) |

|---|---|---|---|---|

| SDC01 | 12.000 | 0.192 | (0.00, 0.04, 0.21, 0.44, 0.30) | |

| SD09 | 4.026 | 0.335 | (0.00, 0.04, 0.21, 0.45, 0.31) | |

| SD08 | 4.013 | 0.334 | (0.00, 0.06, 0.17, 0.46, 0.31) | |

| SD15 | 3.962 | 0.330 | (0.01, 0.03, 0.24, 0.42, 0.30) | |

| SDC02 | 20.705 | 0.331 | (0.01, 0.03, 0.15, 0.43, 0.38) | |

| SD12 | 4.167 | 0.201 | (0.01, 0.03, 0.13, 0.45, 0.39) | |

| SD11 | 4.205 | 0.203 | (0.00, 0.01, 0.15, 0.45, 0.39) | |

| SD13 | 4.064 | 0.196 | (0.03, 0.03, 0.17, 0.42, 0.36) | |

| SD10 | 4.128 | 0.199 | (0.00, 0.06, 0.17, 0.35, 0.42) | |

| SD14 | 4.141 | 0.200 | (0.01, 0.01, 0.14, 0.49, 0.35) | |

| SDC03 | 17.269 | 0.276 | (0.00, 0.02, 0.09, 0.41, 0.47) | |

| SD02 | 4.641 | 0.269 | (0.00, 0.00, 0.04, 0.28, 0.68) | |

| SD04 | 4.167 | 0.241 | (0.00, 0.01, 0.13, 0.54, 0.32) | |

| SD03 | 4.179 | 0.242 | (0.00, 0.05, 0.13, 0.41, 0.41) | |

| SD01 | 4.282 | 0.248 | (0.01, 0.04, 0.06, 0.42, 0.46) | |

| SDC04 | 12.487 | 0.200 | (0.00, 0.03, 0.16, 0.40, 0.40) | |

| SD05 | 4.179 | 0.335 | (0.00, 0.04, 0.15, 0.40, 0.41) | |

| SD06 | 4.346 | 0.348 | (0.00, 0.01, 0.13, 0.54, 0.32) | |

| SD07 | 3.962 | 0.317 | (0.01, 0.05, 0.19, 0.45, 0.30) |

| Code | Sustainability Driver Category | Significant Index | Significance * |

|---|---|---|---|

| SDC01 | Worker health and safety, working conditions and skills | 4.003 | Significant |

| SDC02 | Project performance optimisation and technology integration | 4.143 | Significant |

| SDC03 | Economic optimisation | 4.324 | Significant |

| SDC04 | Environmental and resource management | 4.167 | Significant |

| Overall significant index | 4.171 | Significant | |

| Code | SDC/SD | SDG Target | SDG Indicator | Impact Category | Benefitting Stakeholders | Measurable Indicator *** | Indicator Type * | ||

|---|---|---|---|---|---|---|---|---|---|

| QL | QN | SQN | |||||||

| SDC01 | Worker health and safety, working conditions and skills | ||||||||

| SD09 (i) | Improved health and safety | 1.3 | 1.3.1 | Health and safety | Workers | Coverage of social security support | ✓ | ✓ | |

| 3.8 | 3.8.1 | Health Insurance | ✓ | ✓ | |||||

| 3.9, 8.8 | 3.9.1, 3.9.2, 3.9.3, 8.8.1 | Occupational injuries | ✓ | ||||||

| Access to personal protective equipment | ✓ | ✓ | |||||||

| 3.9 | 3.9.1, 3.9.2, 3.9.3 | Workers, Society | Human toxicity: cancer and non-cancer | ✓ | |||||

| Photochemical ozone creation potential | ✓ | ||||||||

| 6.1 | 6.1.1 | Workers | Drinking water at work | ✓ | ✓ | ||||

| 6.2 | 6.2.1 | Adequate sanitation at work | ✓ | ✓ | |||||

| 6.3 | 6.3.1, 6.3.2 | Workers, Society | Wastewater treatment | ✓ | ✓ | ||||

| 6.4 | 6.4.1, 6.4.2 | Scarcity-adjusted water use | ✓ | ||||||

| SD09 (ii) | Improved working conditions of workers | 1.1 | 1.1.1 | Working conditions (Fair salary) | Workers | Workers earning below UN poverty line of $1.90 per day | ✓ | ||

| 4.5 | 4.5.1 | Human rights | Equal share of training for men and women | ✓ | ✓ | ||||

| 5.1, 8.5 | 5.1.1, 8.5.1, 8.5.2 | Equal wages for men and women | ✓ | ✓ | |||||

| 5.5 | 5.5.2 | Equal managerial positions for men and women | ✓ | ||||||

| 8.7 | 8.7.1 | Working conditions | Fulfilment of ILO ** conventions: child work andminimum age, forced labour | ✓ | ✓ | ✓ | |||

| 8.8 | 8.8.2 | Fulfilment of ILO conventions: freedom ofassociation, discrimination, collective bargaining for all employees, equal remuneration of workers | ✓ | ✓ | |||||

| 10.1, 10.3 | 10.1.1, 10.3.1 | Income spread | ✓ | ✓ | ✓ | ||||

| SD08 (i) | Less disturbance on-site from noise | SDG 03 | Health and safety | Workers, Local community | Noise levelsRefs: [74] | ✓ | |||

| SD08 (ii) | Less disturbance on-site from dust | 3.9, 11.6 | 3.9.1, 11.6.2 | Disease incidences (Particulate matter) | ✓ | ||||

| SD15 | Addressing the industry skills shortage | 4.4 | 4.4.1 | Governance | Workers, Society | Training in relevant skills (e.g., technical and vocational) | ✓ | ✓ | |

| 4.7 | 4.7.1 | Training in sustainability issues: sustainability in general | ✓ | ✓ | |||||

| 9.5 | 9.5.1, 9.5.2 | Investments in research and development | ✓ | ✓ | |||||

| SDC03 | Economic optimisation | ||||||||

| SD02 | Reduce overall project time | 8.2, 9.2 | 8.2.1, 9.2.1 | Inventory indicator | All project stakeholders | Construction project time | ✓ | ||

| SD04 (i) | Ensure cost certainty | 8.2, 9.2 | Cost certainty compared to conventional construction | ✓ | |||||

| SD04 (ii) | Ensure time certainty | 8.2, 9.2 | Time certainty compared to conventional construction | ✓ | |||||

| SD03 | Minimise weather-related delays | 8.2, 9.2 | 8.2.1, 9.2.1 | (a) Weather-related time savings compared to conventional construction, (b) Time certainty gained due to less weather disruptions | ✓ | ✓ | |||

| SD01 | Overall project cost savings | 8.2, 9.2 | 8.2.1, 9.2.1 | Construction project cost | ✓ | ||||

| 12.2 | 12.2.1, 12.2.2 | Cost savings by efficient use of materials | ✓ | ||||||

| SDC04 | Environmental and resource management | ||||||||

| SD05 | Waste reduction and potential for better waste management practices | 3.9, 11.6 | 3.9.1, 3.9.2, 3.9.3, 11.6.1, 11.6.2 | Health and safety | Workers, Society | Human toxicity: cancer and non-cancer | ✓ | ||

| Photochemical ozone creation potential | ✓ | ||||||||

| 11.6 | 11.6.1 | Inventory indicator | Ecosystems, Society, Resources | Amount of waste generated | ✓ | ||||

| 11.6 | 11.6.2 | Health and safety | Workers, Society | Disease incidences (Particulate matter) | ✓ | ||||

| 6.3, 12.4 | 6.3.1, 6.3.2, 12.4.1, 12.4.2 | Ecotoxicity | Ecosystems | Comparative Toxic Unit for ecosystems (Ecotoxicity) | ✓ | ||||

| Eutrophication | P-equivalents (Fresh water eutrophication) | ✓ | |||||||

| 12.4 | 12.4.1, 12.4.2 | Ionising radiation | Workers, Society | Ionising radiation potential | ✓ | ||||

| 12.5 | 12.5.1 | Inventory indicator | Resources | Use of recycled material | ✓ | ✓ | |||

| 14.1, 14.2 | 14.1.1 | Eutrophication | Ecosystems | N-equivalents (Marine eutrophication) | ✓ | ||||

| SD06 | Efficient consumption of materials | 8.4, 9.4, 12.2 | 8.4.1, 8.4.2, 12.2.1, 12.2.2 | Resource depletion | Resources | Abiotic resource depletion: minerals and metals, fossils | ✓ | ||

| SD07 (i) | Potential to enhance energy efficiency | 7.3 | 7.3.1 | Inventory indicator | Energy use: non-renewable | ✓ | |||

| SD07 (ii) | Potential to reduce carbon emissions | 9.4 | 9.4.1 | Climate change | Society | Global Warming Potential | ✓ | ||

| 13.2 | 13.2.1 | ||||||||

| 13.3 | 13.3.2 | Governance | Workers | Training in sustainability issues: climate change | ✓ | ✓ | |||

| SDC02 | Project performance optimisation and technology integration | ||||||||

| SD12 | Simplify construction activities | ||||||||

| SD12-EcS 1 | Ensure cost and time certainty | See SD04 (i) and SD04 (ii) | |||||||

| SD12-SoS 2 | Improved health and safety and working conditions | See SD09 (i), SD09 (ii) and SD08 | |||||||

| SD11 | Improved project quality control | ||||||||

| SD11-EnS 3 | Potential for SD05, SD06, SD07 | See SD05-07 | |||||||

| SD11-EcS | Ensure cost and time certainty | See SD04 (i) and SD04 (ii) | |||||||

| SD11-SoS | Potential to ensure consumer health and well-being | SDG03, SDG11 | Health and safety | Consumers | (a) Functionality and usability, (b) Health and comfortRefs: [59,75] | ✓ | |||

| SD13 | Improved technology integration | ||||||||

| SD13-EnS | Potential for SD05, SD06, SD07 | See SD05-07 | |||||||

| SD13-EcS | Ensure cost and time certainty | See SD04 (i) and SD04 (ii) | |||||||

| SD13-SoS | Potential to address industry skill shortage | See SD15 | |||||||

| Potential to ensure consumer health and well-being | See SD11-SoS | ||||||||

| SD10 | Higher end-product quality | ||||||||

| SD10-EnS | SD05, SD06, SD07 | See SD05-07 | |||||||

| SD10-EcS | Ensure cost and time certainty | See SD04 (i) and SD04 (ii) | |||||||

| SD10-SoS | Ensure consumer health and well-being | See SD11-SoS | |||||||

| SD14 | Improved productivity | ||||||||

| SD14EnS, EcS | Efficient material use | See SD06 and SD01 | |||||||

| SD14-EcS | Reduce overall project time and cost | See SD01 and SD02 | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jayawardana, J.; Sandanayake, M.; Jayasinghe, J.A.S.C.; Kulatunga, A.K.; Zhang, G. Sustainability Drivers and Sustainable Development Goals-Based Indicator System for Prefabricated Construction Adoption—A Case of Developing Economies. Buildings 2025, 15, 1037. https://doi.org/10.3390/buildings15071037

Jayawardana J, Sandanayake M, Jayasinghe JASC, Kulatunga AK, Zhang G. Sustainability Drivers and Sustainable Development Goals-Based Indicator System for Prefabricated Construction Adoption—A Case of Developing Economies. Buildings. 2025; 15(7):1037. https://doi.org/10.3390/buildings15071037

Chicago/Turabian StyleJayawardana, Janappriya, Malindu Sandanayake, J. A. S. C. Jayasinghe, Asela K. Kulatunga, and Guomin Zhang. 2025. "Sustainability Drivers and Sustainable Development Goals-Based Indicator System for Prefabricated Construction Adoption—A Case of Developing Economies" Buildings 15, no. 7: 1037. https://doi.org/10.3390/buildings15071037

APA StyleJayawardana, J., Sandanayake, M., Jayasinghe, J. A. S. C., Kulatunga, A. K., & Zhang, G. (2025). Sustainability Drivers and Sustainable Development Goals-Based Indicator System for Prefabricated Construction Adoption—A Case of Developing Economies. Buildings, 15(7), 1037. https://doi.org/10.3390/buildings15071037

_Zhang.png)