1. Introduction

Climate change phenomena are on the rise and their impact on the environment and society is also increasingly growing [

1]. This is mainly related to global warming, which has intensified considerably in recent decades. The increase in mean annual temperature is mainly driven by rising greenhouse gas emissions (GHG), particularly carbon dioxide (CO

2).

The building sector plays a significant role in global energy consumption and GHG emissions. According to a recent report by the International Energy Agency (IEA), buildings account for 37% of global energy consumption [

2], taking the embodied cradle-to-grave emissions into account [

3]. Of these, 27% are attributed to the operating activities of buildings, and 10% come from the production of building materials [

4].

In order to limit the effects of global warming, future ambitious targets have been set globally to reduce mean annual temperatures and reduce GHG emissions. A key milestone in this respect is the Paris Agreement, signed by 195 countries at the COP21 Conference in 2015, which aims to keep the global temperature rise below 1.5 °C. The main objective of this agreement is to prevent the effects of climate change from getting worse. To achieve it, a 7.6% annual reduction of GHG emissions by 2030 should be done [

5]. Moreover, the Paris Agreement specifies climate neutrality by 2050, committing the signatory states to achieving a balance between greenhouse gas emissions and their absorption by natural or technological methods by the middle of the century.

In addition to the Paris Agreement, several complementary measures have been globally adopted to support the achievement of the targets set and to reduce GHG emissions. In the European Union, the European Climate Law, part of the European Green Deal (Green Deal), sets climate neutrality targets for 2050 and GHG emissions reductions of 55% by 2030 compared to 1990 levels, which Romania also adheres to. In addition, the European Union adopted the “Fit for 55”, which includes policies to increase energy efficiency and expand the share of renewable energy, by 2030. Today, renewable energy sources constitute at least 40% of the EU’s total energy consumption. These include solar, wind, biomass, and hydropower.

In Romania, in 2023, a long-term strategy, named “Implementing the national energy and climate plan and developing the long-term strategy of Romania”, was adopted. This is a key strategic document to achieve the national climate neutrality target by 2050. This strategy is part of Romania’s commitments to the European Green Pact (Green Deal) and is perfectly consistent with the goals of the Paris Agreement.

In the United States of America, in 2021, the Infrastructure Investment and Jobs Act [

6] was adopted. It includes important measures to reduce greenhouse gas (GHG) emissions. These include incentives to promote electric vehicles, support renewable energies and develop clean energy infrastructure. The act also provides for significant research and development investments for innovative carbon capture technologies and advanced energy solutions. In the same year, another key step occurred: the US returned to the Paris Agreement, reaffirming the country’s commitment to fighting climate change.

China, the world’s largest CO2 emitter, has adopted strict regulations to reduce GHG emissions. Key objectives include:

Other Asian economies, such as Japan and South Korea, have introduced regulations and commitments to achieving carbon neutrality by 2050, setting clear targets for GHG emissions reductions by 2030.

In conclusion, in the European Union, the United States, and Asia, key legislative measures have been implemented to reduce GHG emissions. These regulations play a crucial role in fighting climate change and in achieving international goals. Although the approaches vary according to the specific economic and political context of each region, all these measures reflect global commitments to reduce greenhouse gas emissions and promote a sustainable future.

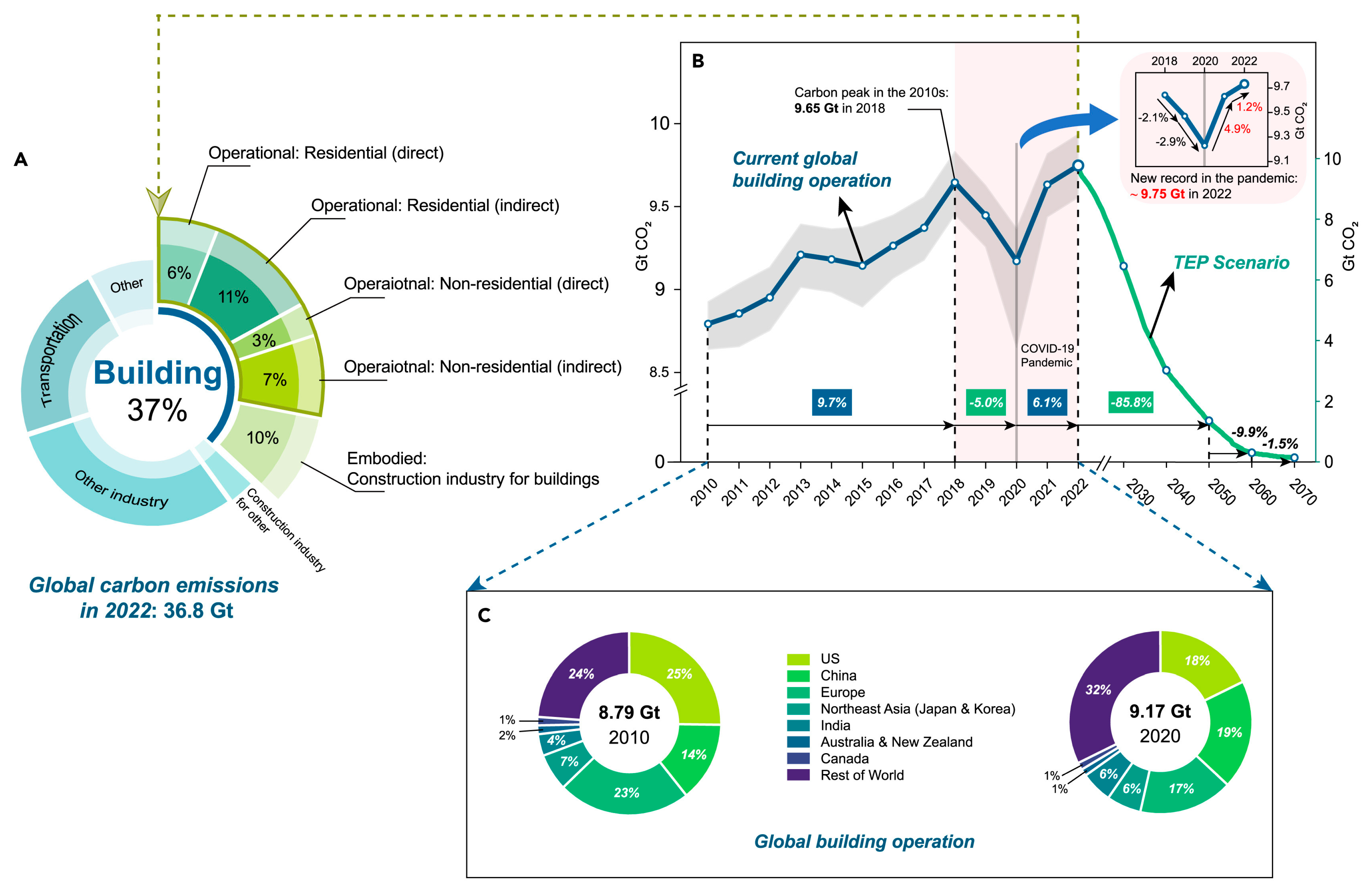

Figure 1 [

7] presents global collected data from Global Building Emissions [

8], representing the total global energy-related CO

2 emissions. According to these data, globally in 2022, the building sector was one of the three major carbon emitting sectors (along with transportation [

9] and industry [

10]), adding up to around 14 Gt (

Figure 1A) of the total energy-associated global CO

2 emissions (36 Gt). These carbon emissions from the operation of buildings, called operational carbon, reached a record level of almost 10 Gt (

Figure 1B) [

7]. Between 2000 and 2022, carbon emissions per usable area gradually decreased, reducing carbon intensity in global building operations by more than 1.5% per year. Although decarbonization efforts in emerging economies are progressing, they have proven to be less effective than those in developed economies (

Figure 1C).

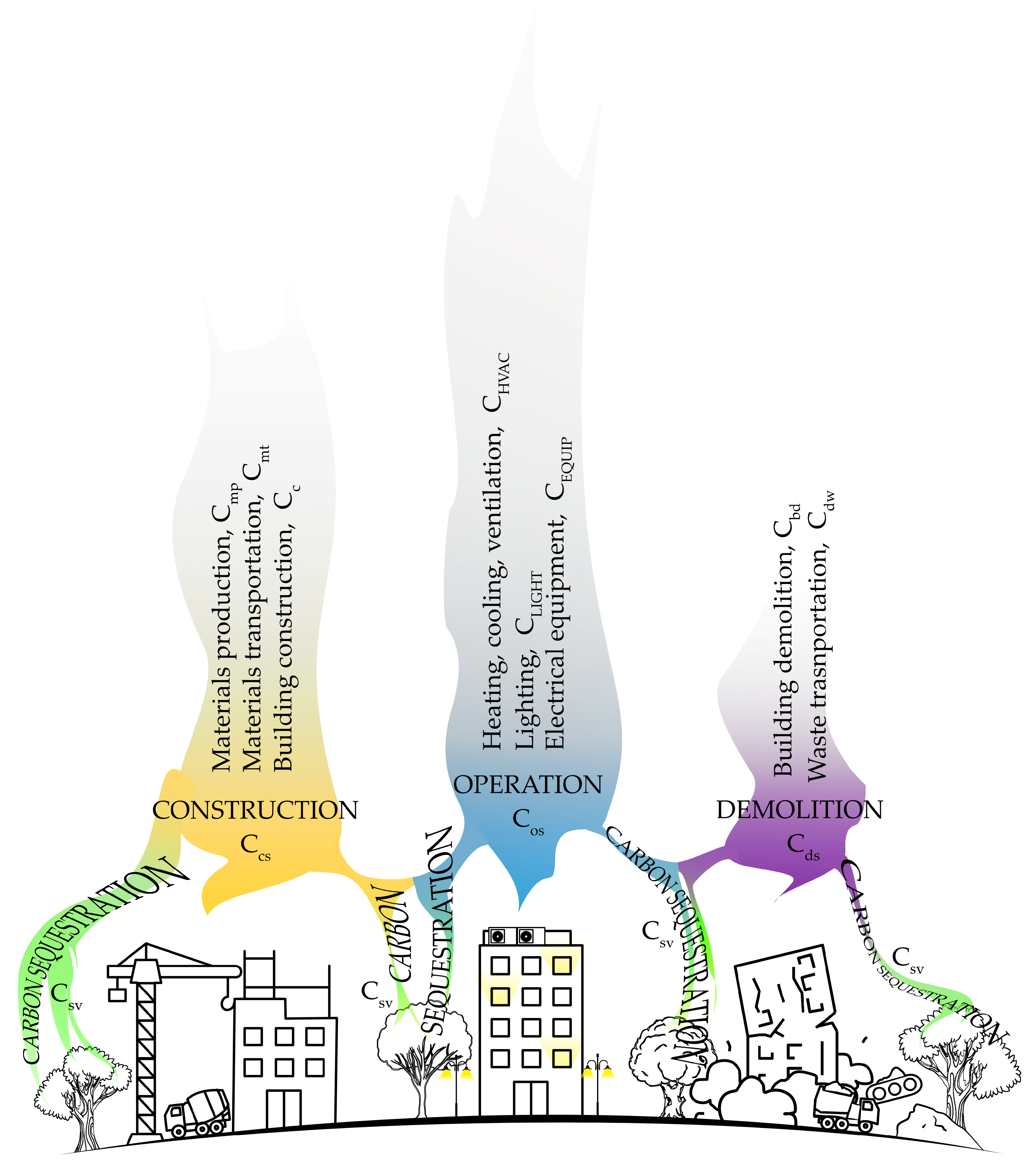

During the lifespan of the building several stages can be identified such as preconstruction, construction, operation, maintenance, and demolition [

11]. In all these stages, buildings emit GHG in different quantities [

12,

13,

14]. The operational GHG emissions of a building are considered to be higher than its incorporated emissions [

15], so an important role in reducing them is decreasing energy consumption and the use of renewable energy sources such as heat pumps systems [

16], solar assisted heat pump systems [

17], photovoltaics [

18], multi-purpose envelope like a Trombe Wall [

19], etc.

The challenge to decrease GHG emissions according to targets set within the Paris Agreement is two-fold:

- -

Reducing emissions associated with the energy demands during the operational phase of buildings, for which several different technologies already exist and are increasingly applied [

20,

21,

22,

23,

24];

- -

Lowering so-called embodied GHG emissions, associated with the manufacturing, maintenance and end-of-life of building materials, which are found to be a hidden major issue for effective decarbonisation of the built environment [

4,

25].

The main challenges that Romania specifically faces in the process of complying with the EU directives are firstly to modernise the electrical energy infrastructure inside the country and thus reducing the electricity cost. This will ensure an increased desire by the people to use efficient energy sources like heat pumps. Secondly, although the Romanian government has policies in place for installing photovoltaic panels and use of renewable sources with heat pumps for close to 10 years now [

26], the acquisition and instalment costs are still high for a common Romanian citizen. These combined result in efficient single-family residential buildings being available only for a minority of the population.

This research main objective is to analyse the carbon footprint for a typical single-family residential building in Romania. The study also aims to analyse the life cycle of single-family residential buildings, with an emphasis on the operational stage. The assessment is based on the data registered on a case study building and extrapolated for typical single-family residential buildings in Romania, encompassing new buildings as well as older existing buildings. Overall, this research paper aims to address the following questions:

- -

How are the building stages shares distributed for single-family residential buildings in Romania?

- -

What impact the energy efficiency measures (such as envelope insulation, heat pumps and photovoltaics) have for single-family residential buildings on the operational stage CO2 emissions?

- -

What can be improved for the existing single-family residential buildings in Romania according to the period when they were built?

2. Residential Buildings Sector in Romania

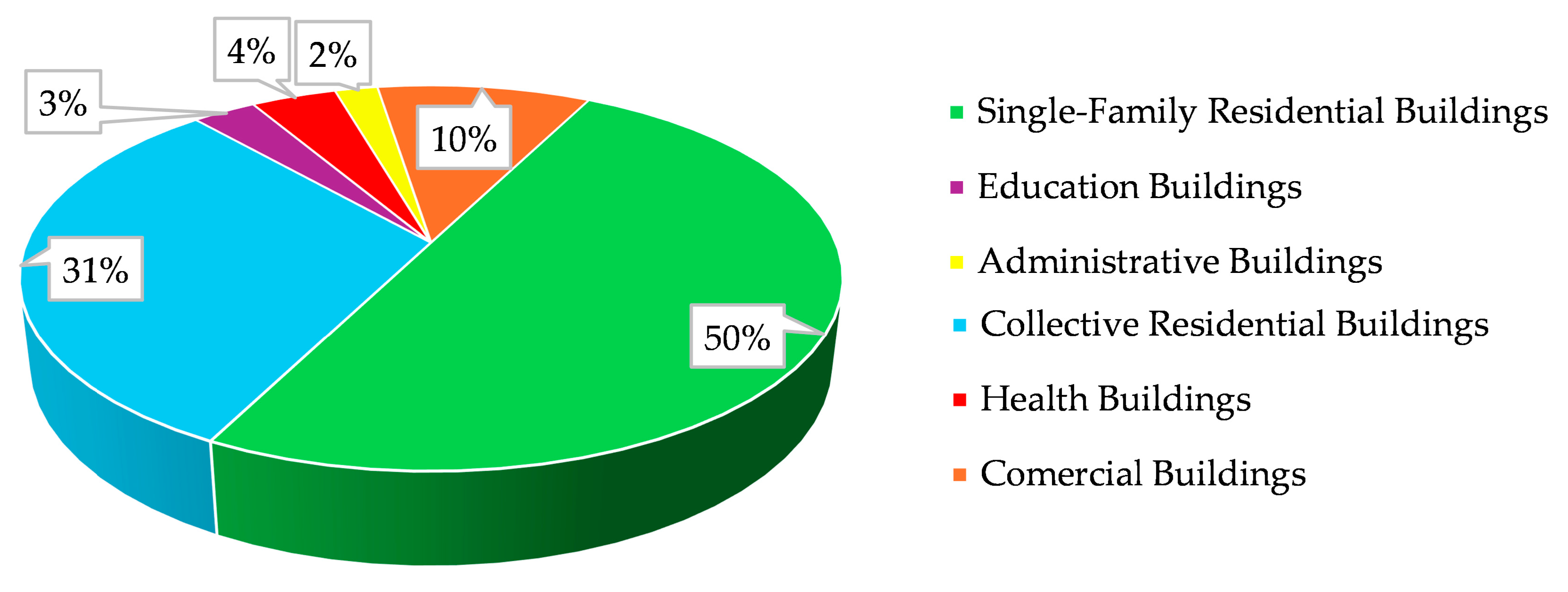

The building sector consists of approximately 5.6 million buildings, covering a total heated useful area [

27]. The largest share is represented by residential buildings, which account for approximately 90% of the entire building sector, adding up to 582 million m

2, as seen in

Figure 2.

Nationwide, the total energy consumption for buildings is approximately 9.52 Mtoe, with over 81% consumed by residential buildings and the remaining 19% by other types of buildings, as seen in

Figure 3. Because of this, it can be considered that the building sector is the one with the highest potential to make significant reductions in energy consumption and GHG emissions reduction through thermal rehabilitation and using renewable energy sources.

At the end of 2023, the housing stock in Romania included 9,722,223 homes, with a total liveable area of 474,517,092 m2. Of these, 58% were in urban areas, representing 55% of the country’s habitable area, while the rest were in rural areas.

In recent years, there has been a slow growth in housing stock in Romania. New-build houses annually have a small share, approximately 0.7%, of the total existing ones, and the data are presented in

Table 1. The replacement of old buildings is performed at a very slow pace, the percentage of demolished houses annually being only 0.06% of the total existing ones.

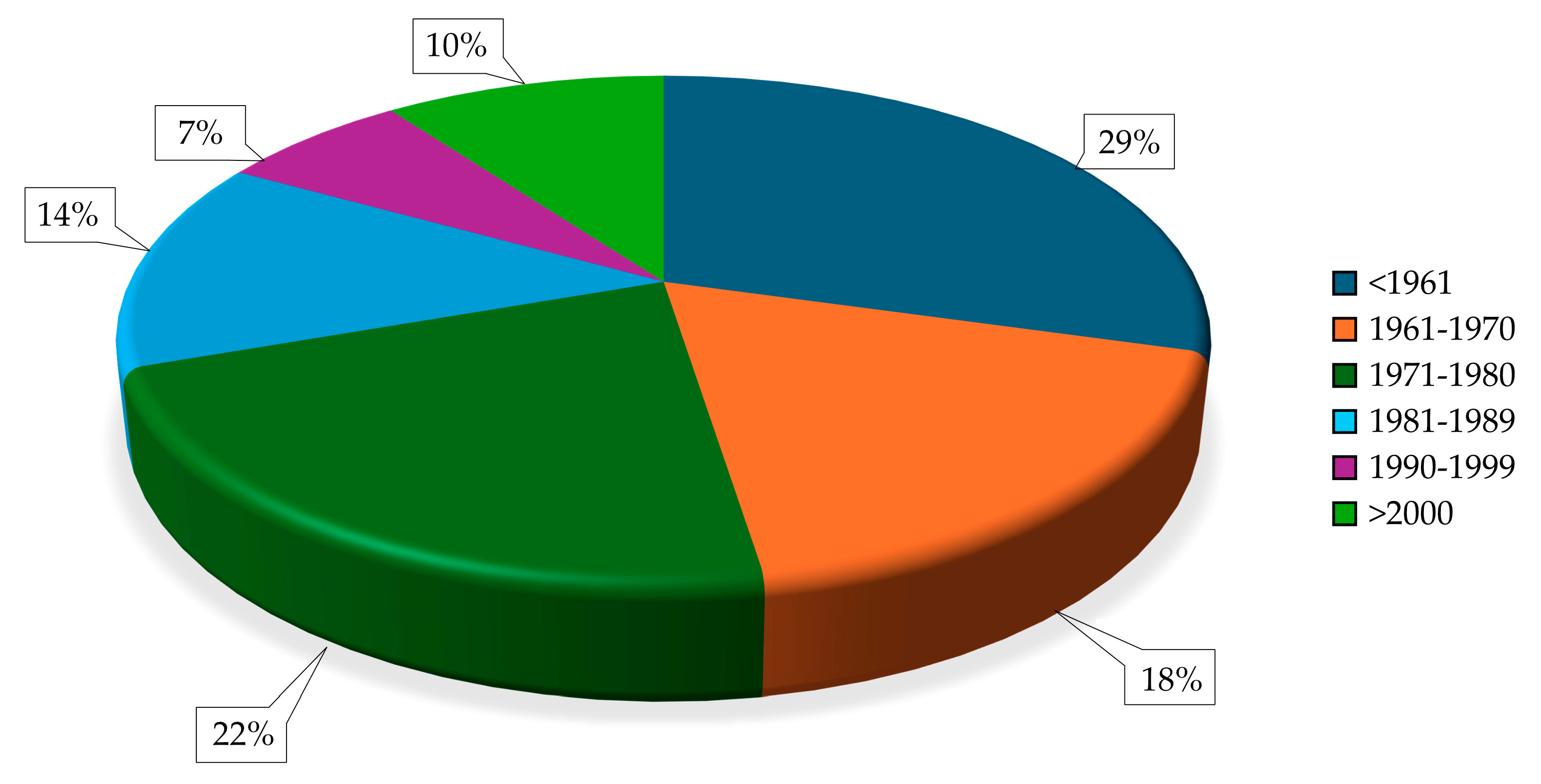

A defining aspect of the housing stock is that about 98% of existing houses are privately owned. This makes it difficult to rehabilitate them on a large scale without adequate awareness of the owners regarding the advantages brought by modernization. Additionally, about 47% of houses were built before 1970, and over 83% of them date back to 1989, as presented in

Figure 4.

The residential buildings built before 1989 are distinguished by a low level of energy performance, having an energy consumption between 150 and 400 kWh/m

2 year. Thermal energy is the dominant component of total energy consumption in the residential sector, reaching values of up to 55% for collective residential buildings and up to 80% for single-family residential buildings [

29].

A real improvement in the energy performance of residential buildings was achieved after 2000, when the energy consumption decreased below 200 kWh/m

2 year. Energy-efficient buildings are those constructed after the implementation of the methodology for calculating the energy performance of buildings, indicative Mc 001-2022 [

30] and have an energy consumption of less than 80 (kWh/m

2 year, presented in

Table 2.

This housing stock structure underlines the importance of modernizing and energy efficiency of existing buildings to reduce energy consumption and increase sustainability in the Romanian construction sector. Due to the fact that 58% of the building sector in Romania represents single-family houses and that 50% of the primary energy consumption is used for the operation of residential single-family buildings, this study undergoes a life cycle assessment (LCA) for single-family buildings. For this, a case study building was analysed, and multiple solutions for decreasing CO2 emissions are investigated.

6. Conclusions

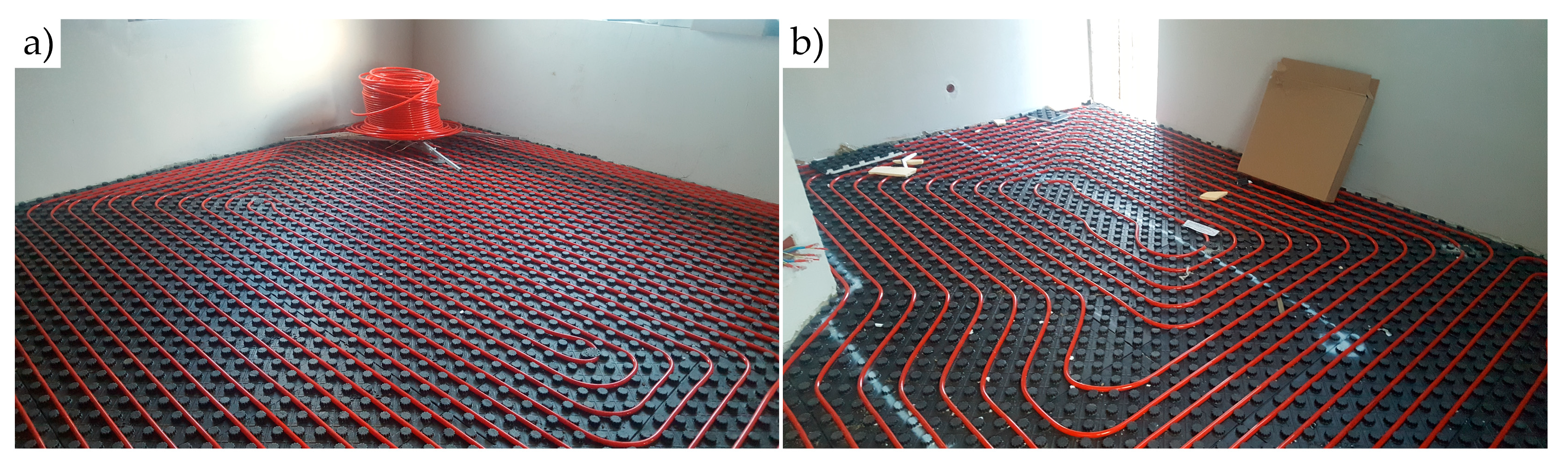

This study aims to establish a direct link between operational stage of a building life cycle and the CO2 emissions that the building will emit for the entire lifespan, for the single-family residential buildings in Romania. Consequently, the construction and demolition stages were considered while analysing a case study building built in 2019, in Romania. The case study building is energy efficient, residing between a Romanian Energetic Class A+ and a passive house standard.

Furthermore, the case study building was used to create plausible other cases for single-family residential buildings in Romania, focusing on a wide array:

From older than 1989 buildings to new after 2023 buildings;

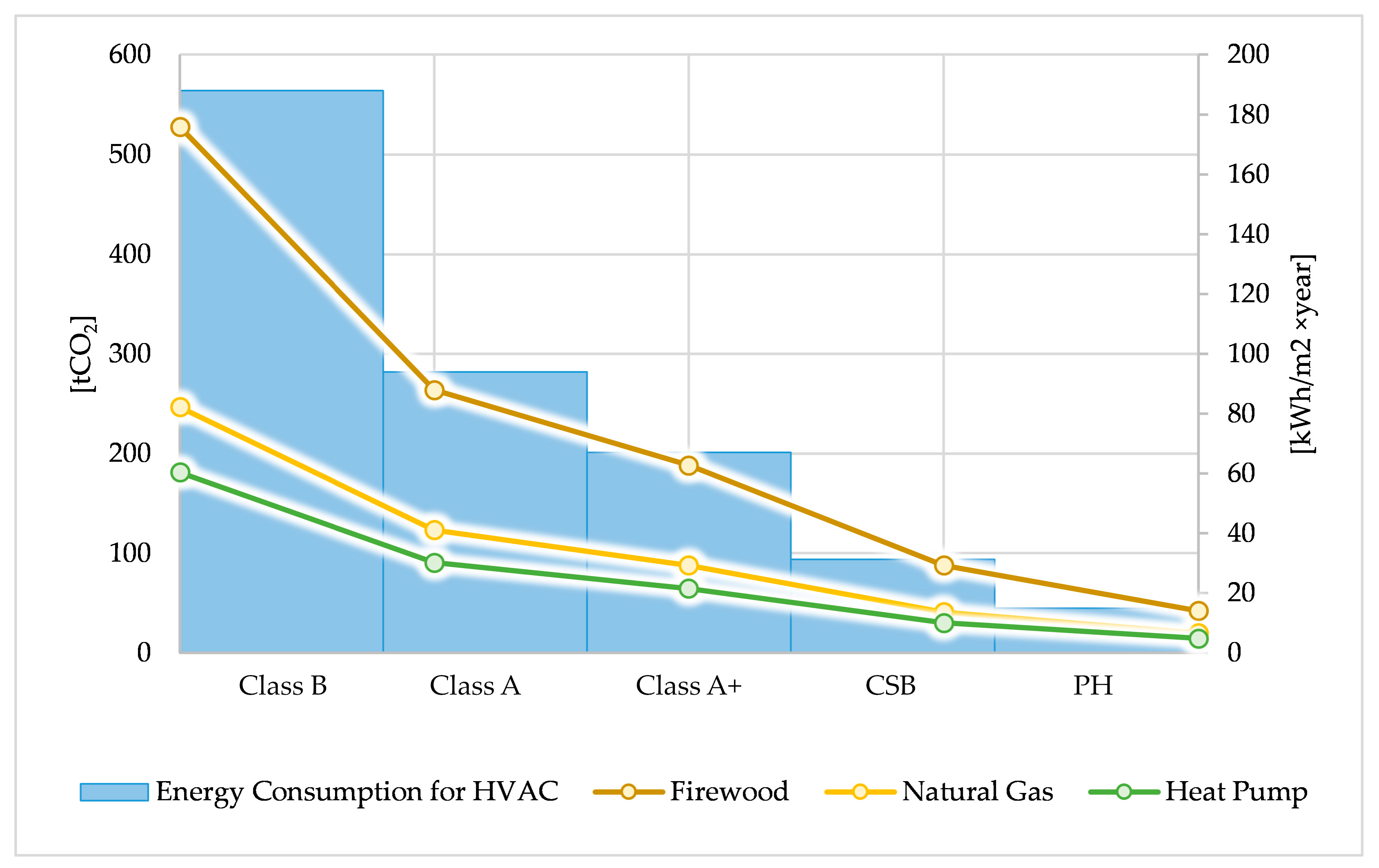

From high energy consumption buildings (Class B: 257 kWh/m2 year) to low energy consumption buildings (passive house: <15 kWh/m2 year), including the case study building;

For not using renewable energy sources with equipment such as heat pump or photovoltaic panels and for the cases of renewable energy usage.

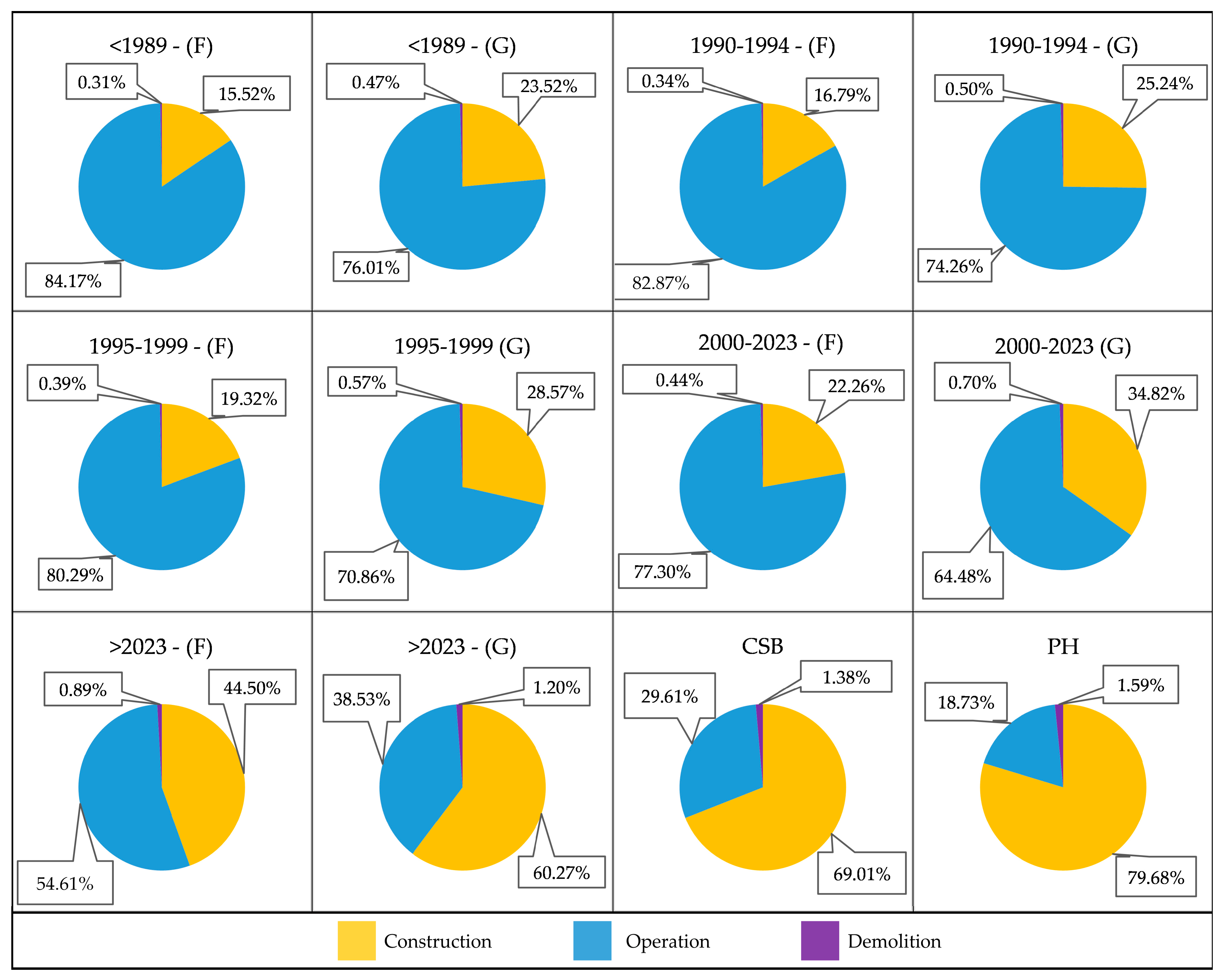

This provided a meaningful insight over the current situation of single-family residential buildings in Romania, regarding the energy consumption and carbon footprint for the entire lifespan of a building, with an emphasis on the operational stage. The most important observation being that as buildings in Romania started to be more energy efficient, their construction cost increased but their CO2 emissions over the entire lifespan decreased considerably.

Moreover, after analysing the economical aspect of building with energy efficiency in mind, the results showed that because of the high electrical energy cost compared with the natural gas cost in Romania, if the building is not reaching a thermal insulation degree higher than what is required for Energetic Class A+, the operational stage cost in time will be less using a gas boiler instead of a heat pump, which in return will emit much more CO2 into the atmosphere in the long run.

Therefore, the main conclusions of this case study with an extrapolated building life cycle analysis are:

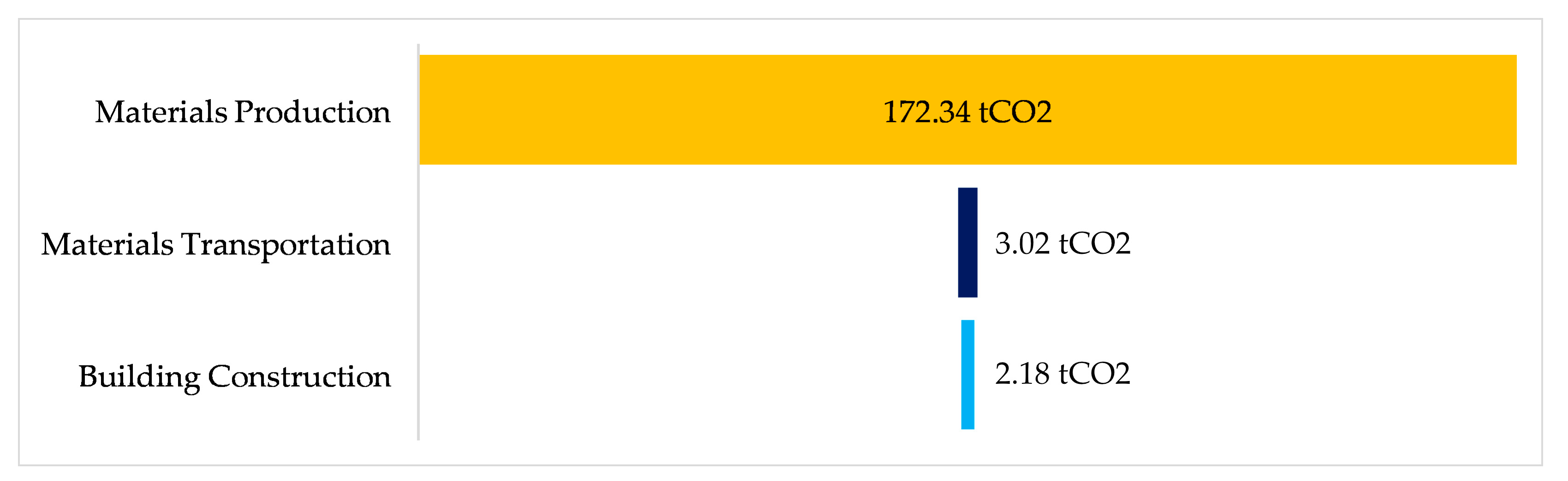

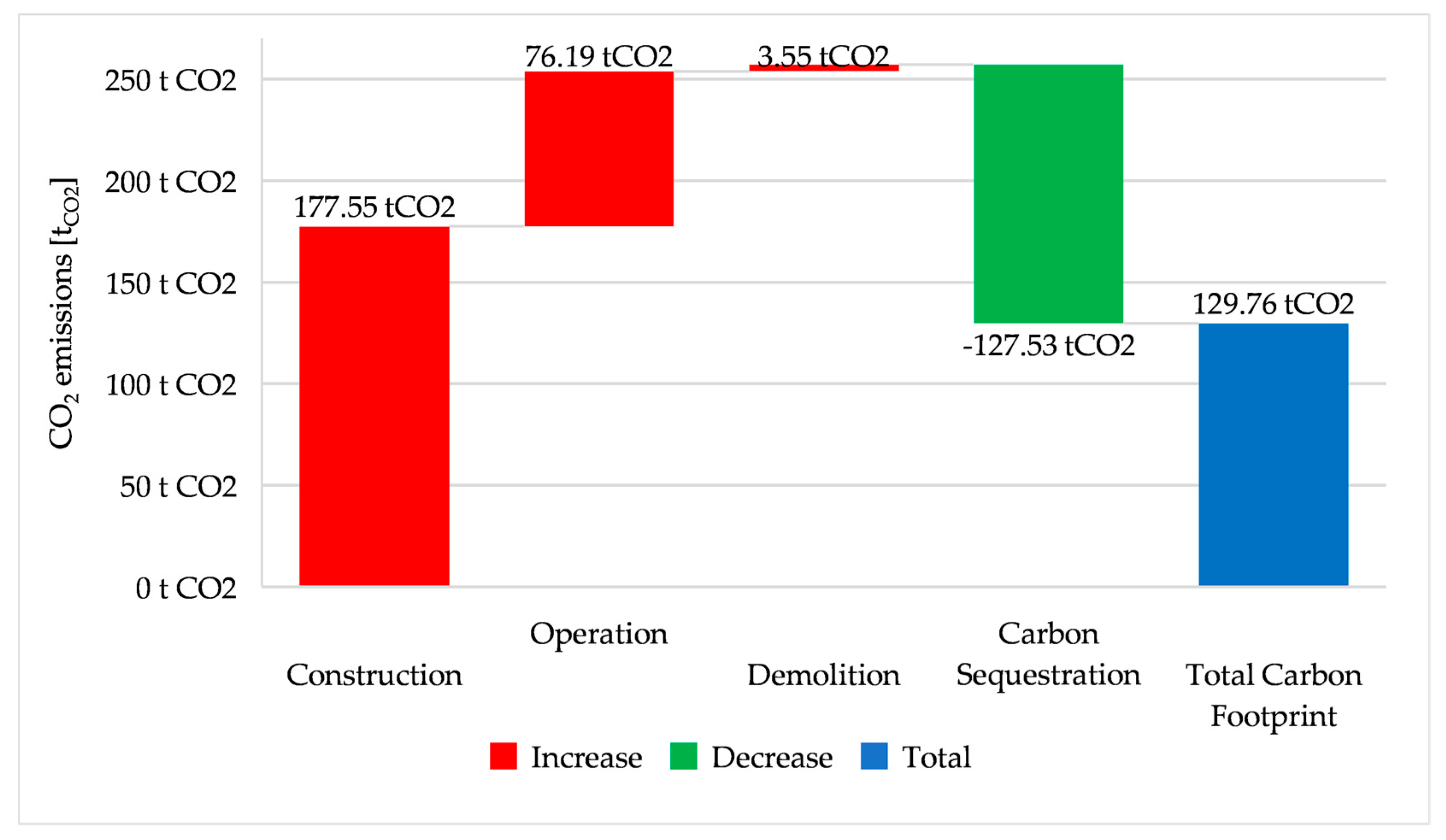

For the case study building, the total CO2 emissions for the entire life cycle was 257.29 tCO2;

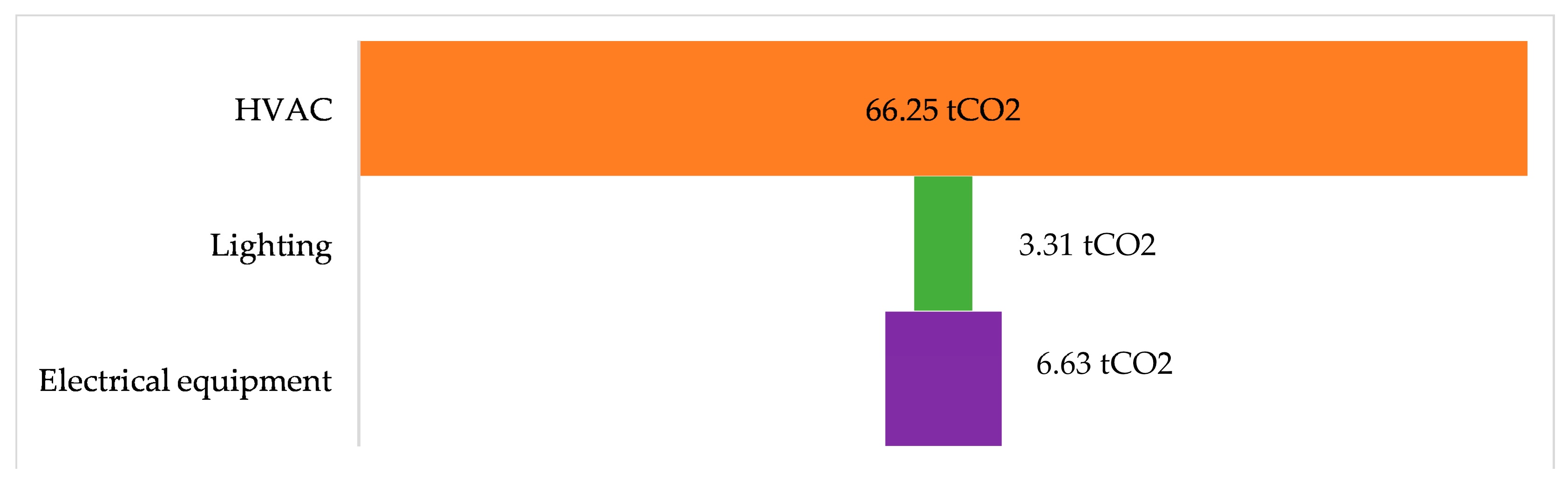

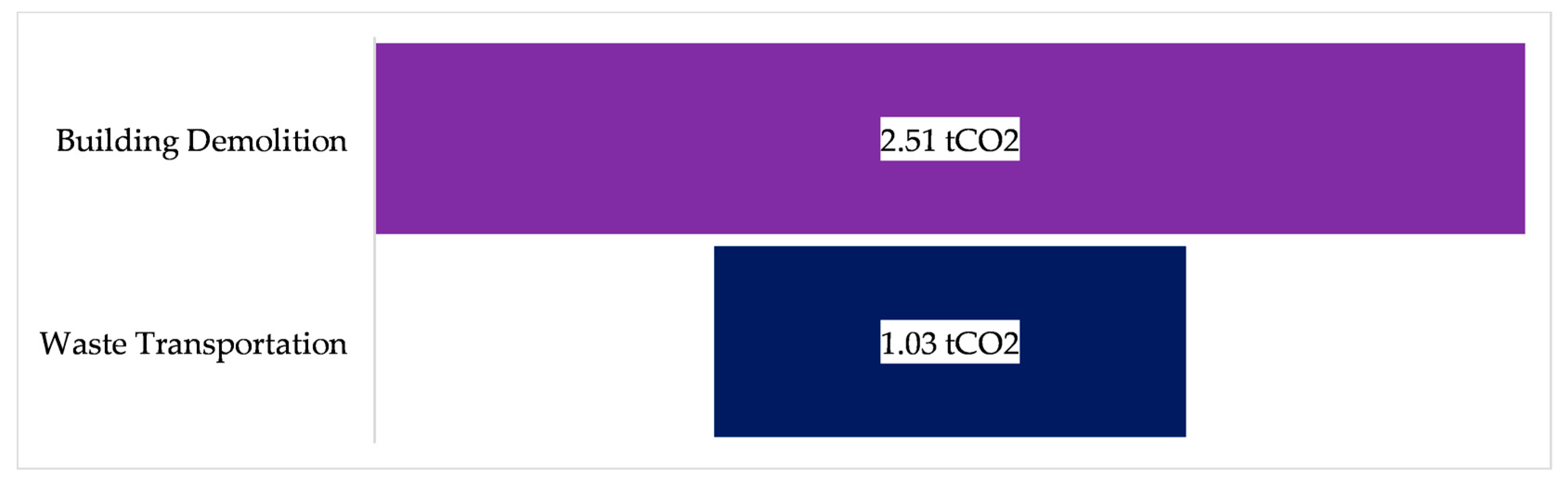

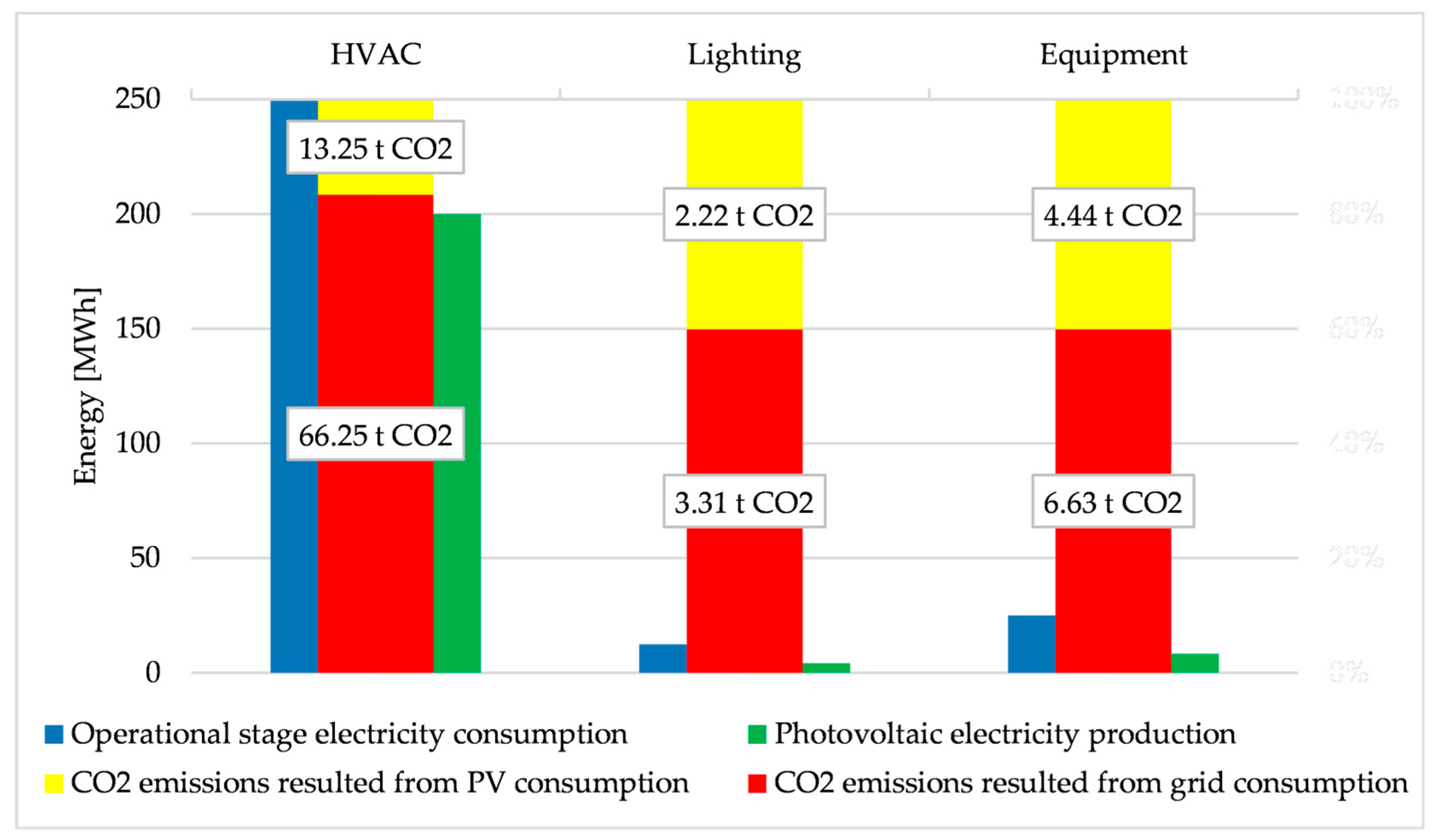

For the case study building, the highest CO2 emissions represent the construction stage with 66.99%, while the HVAC share is 25.75%;

For the case study building, the carbon sequestration from vegetation absorbs 127.53 tCO2, lowering the total carbon footprint to 129.76 tCO2, meaning 50% less;

Compared to the case study building, a building constructed before 1989 will mostly reside in Energetic Classes C to G and will emit 12.67 times more CO2 when heated with firewood and 7.55 times more when heated with natural gas for the operational HVAC sub-stage;

Compared to the case study building, a passive house will emit 1.8 times less CO2 for the operational HVAC sub-stage;

For the total life cycle of the building, the operational stage share for the case study building is 29.61%, while for a building heated with firewood built before 1989, the share is 84.17%, and that for natural gas is 76.01%;

In order to achieve Class A+ energy consumption, the buildings need to be insulated with at least 15 cm of thermal insulation;

Using a heat pump in the detriment of a firewood boiler will decrease the HVAC sub-stage CO2 emissions by 34%, while using it in the detriment of a natural gas boiler will decrease the CO2 emissions by 26%;

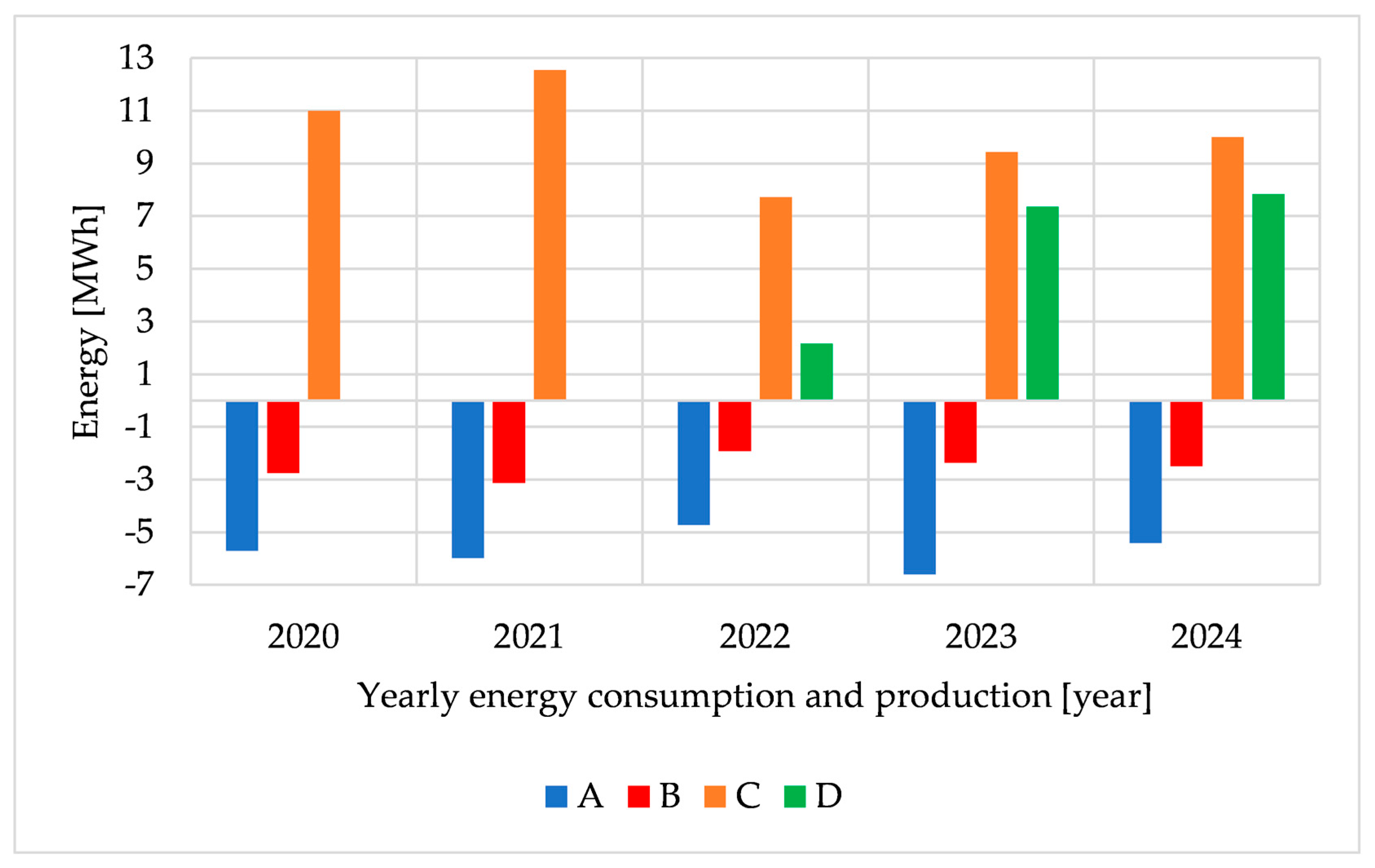

Using photovoltaic panels to produce electrical energy for the heat pump will reduce the CO2 emissions by 80% for HVAC sub stage and 73.8% for the entire operational stage for the current electricity cost in Romania;

The operational stage cost share for the case study building is 20%, with 68% representing the construction stage and 12% the demolition stage;

For a Class B building, heated with natural gas the operational stage cost share is 38%, while for heating with a heat pump, the cost share is 41%;

For a passive house, the cost share for the operational stage is 10% and the construction stage share is 77%, the rest representing demolition.

This study results are important to be taken seriously when designing single-family residential buildings. The fine line between implementation cost and CO2 emissions in the entire building life cycle needs careful and thoughtful assessment for each individual building, including creating green vegetation areas to combat the building’s carbon footprint.

Future research should focus on improving the embodied carbon footprint due to the fact that after decreasing the operational carbon footprint, the construction share increases to approximately 65% according to the case study building results. Furthermore, research for other building sub-sectors should be the focus in order to analyse potential measures to be taken to decrease their operational carbon footprint as well.