Abstract

This research aims to identify an eco-friendly and low-mass substitute for fine aggregate (FA) in self-compacting concrete (SCC). The study specifically examines the potential of waste foundry sand (WFS) as an FA replacement. The primary objective is to explore the impact of processed WFS in SCC, addressing both the WFS disposal issues and enhancing the environmental performance of SCC. After collecting the WFS, it was sieved, segregated, washed thoroughly with water, and then oven dried to remove all clay, carbon, and hazardous content. Treated foundry sand (TFS) is utilized as a substitute for FA in SCC. This study examines the effects of TFS on SCC’s strength, flowability, durability, and microstructural characteristics. Various proportions of TFS are investigated, including replacing 0, 10, 20, 30, 40, and 50% of FA by weight with TFS in the concrete mixture. This research demonstrates that TFS can effectively replace FA in improving the flowability and passing ability of SCC. Furthermore, the findings on SCC’s strength and durability after incorporating TFS suggest that using 30–40% TFS is optimal, as it does not negatively impact the structural performance of SCC. Alternatively, the use of TFS in SCC results in a dense microstructure, improved gel formation, and better bonding of the constituents of ingredients used in SCC. Overall, the results of this study reveal that the use of TFS in SCC can help reduce the amount of waste and improve its sustainability. This also shows that the process can reduce the density of the mix.

1. Introduction

Construction and infrastructure projects frequently utilize concrete as a multipurpose material [1,2]. In recent times, India has encountered issues related to the exhaustion of natural resources and the management of industrial waste in landfills, which can be attributed to the processes of industrialization and urbanization [3]. Since 1900, there has been a substantial rise in the need for natural resources to support construction and infrastructure development [4]. The excessive extraction of materials like river sand and gravel has contributed to the depletion of these natural resources. Industrialization has resulted in waste being deposited in landfills, which can negatively impact the environment [5,6,7]. Waste foundry sand (WFS), a byproduct from the metal and alloy casting industry, offers a potential alternative to FA in concrete production, thus reducing the consumption of virgin materials [8,9]. Incorporating WFS into concrete can influence various aspects, including concrete quality and hydration, as well as setting time [10,11]. Treating foundry sand with water or chemicals can help reduce contaminants in the product and improve its durability and strength. Compared to the widely used WFS, the use of TFS provides a more advantageous solution for replacing FA in SCC [12,13]. Owing to the lack of awareness about its utilization, end-users have a hard time making informed decisions on handling WFS [14].

Alternatively, WFS or TFS has gained widespread acceptance as an increasing number of industries become aware of the potential practice of reusing it. It is also becoming increasingly accepted as a way to overcome disposal and landfilling issues [15]. In the past few years, the use of WFS or TFS in concrete mixtures has increased. Studies have shown that concrete made from waste can be more durable than concrete made from other virgin materials [16]. Various industrial activities responsible for creating waste materials are held responsible for their sources. They are recycled and disposed of in the global market. The attributes of WFS can vary depending on the type of industry and casting procedure [17].

While binders may contribute to this problem, current research presents contradictory findings regarding WFS’s effect on concrete durability. Certain investigations indicate that it might enhance resistance to chemicals and other forms of attack. Additionally, the pozzolanic reaction associated with WFS could potentially reduce concrete porosity. Similarly, some studies claim that the use of WFS does not improve the durability of concrete [18].

In addition to the quality of concrete, other factors such as the distribution of particle size and the presence of contaminants can also affect its performance [19]. Scientists have employed various techniques to examine the structural characteristics of concrete. Research findings have indicated that the incorporation of WFS leads to alterations in concrete’s properties, specifically its hydration products and pore structure [20]. This can affect their mechanical properties and durability. One of the most important factors that can be considered when considering the use of WFS/TFS in concrete is particle size. This can help prevent contaminants from entering the concrete. Researchers and producers can also make their mixtures more sustainable by selecting the appropriate materials [21]. However, the traditional method of using FA in SCC involves grinding hard granite into small particles.

According to researchers, the nonferrous industry produces approximately 6–10 MT of waste annually. Of this, only approximately 15% is recycled/reused in various forms. The remaining 85% (by weight) of the waste is deposited in landfills [22]. Owing to the increasing amount of industrial waste, the need for alternative disposal methods has become more urgent. This is because of the rising cost of disposal and the lack of available dumping sites [23]. One of the benefits of using WFS is its ability to reduce the impact of internal and external vibrations. Superior mechanical and appearance attributes, as well as faster production and placement, make SCC more suitable than the commonly used concrete [24].

In addition, other aspects such as placement and production are also considered to determine their success. The quality control procedures and finishing techniques used in a project are important factors that can affect the construction ability of concrete [25]. The characteristics of concrete can be influenced not only by the mixer type, but also by factors such as transportation time and final pouring techniques. To maintain the quality of the SCC production process, rigorous measures are put in place [26]. Compared with conventional concrete, pumping is the preferred method for SCC because it is more workable. However, excessive flow rates can cause air entrainment, which leads to bleeding and segregation. Compared with regular concrete, SCC has fewer surface flaws [27]. However, if proper placement and production are not followed, honeycombing and cracking can occur in SCC [27].

Compared with standard concrete, the use of WFS provides almost the same characteristics as FA. In a recent study, it was revealed that concrete made with 30% (by weight) TFS exhibited greater durability and performed better than a reference mix [28]. A study revealed that TFS can be utilized to produce high-strength concrete. Researchers have also discovered that WFS can act as a building material, and a program has been set up to recycle glass in concrete. Compared with natural sand, the utilization of WFS can be beneficial for the environment [29]. In addition to reducing greenhouse gas emissions, the use of WFS can help prevent landfills from expanding. A study conducted on concrete revealed that up to 30% (by weight) of the material can improve its hardness. In terms of lightweight, a concrete density of less than 1203kg/m3 with WFS can be considered as a feasible alternative to natural sand. The light weight of the concrete was attributed to the air voids formed by aerating agents, such as hydrogen peroxide and aluminum powder [30]. At the time of the study, the concrete produced with 40 wt% (by weight) TFS had a compressive strength of 30.5 MPa. Researchers also noted that concrete made with 20% (by weight) WFS and recycled aggregate exhibited better characteristics [31]. The study found that WFS can be a partial replacement for FA in concrete. It is also noted that this material can offer long-term performance and strength gains. This research also proposed a framework for the reclamation of WFS in India. Various factors that affect the development and use of WFS include the availability of natural resources, technology, and potential markets.

Finding sustainable and lightweight alternatives to fine aggregate (FA) in SCC is crucial for addressing environmental concerns and improving the overall sustainability of construction materials. Previous studies have explored various waste materials as substitutes for FA in SCC, but the potential of waste foundry sand (WFS) remains under-researched. Despite the potential benefits, there is limited information on the performance of SCC incorporating treated waste foundry sand (TFS) in terms of strength, flowability, durability, and microstructure. The use of TFS instead of FA in SCC may offer a viable answer to the problems associated with WFS disposal and improve the environmental performance of SCC. This research aims to examine how treated waste foundry sand (TFS) impacts the strength, flowability, durability, and microstructural characteristics of SCC. The study proposes that the addition of TFS to SCC will enhance its flowability and passing ability while simultaneously preserving or boosting its strength and durability properties.

Significance of This Study

Owing to the rapid pace of construction, the materials used in the production of SCC must be considered for their environmental friendliness, consumption of virgin natural resources, and sustainability. This can be achieved by utilizing waste products from industrial facilities to replace FA in SCC. In addition to utilizing waste materials, there are other economical ways to improve process efficiency. Many studies have been conducted on the use of WFS in traditional concrete, but there is insufficient information on the subject to provide a comprehensive understanding of its applications. Studies [18,28,32] have revealed that fine aggregates are an ideal substitute for WFS in SCC. The use of both WFS and TFS can enhance the strength, durability, and microstructure of SCC. To explore the advantages of TFS in the preparation of SCC, researchers have conducted a study on its various properties, including strength, microstructure, durability, and flowability.

2. Materials and Methodology

2.1. Materials

2.1.1. Cement

This study used Indian standards compliant with Ordinary Portland Cement (OPC) 53 grade cement as a basic binding agent [33]. The physical and chemical properties of the binders are listed in Table 1 and Table 2, respectively. The binders used in this study are shown in Figure 1.

Table 1.

Physical properties of binders.

Table 2.

Chemical properties of materials used in this study.

Figure 1.

Binders used in this study.

2.1.2. Mineral Admixture

Mineral-based additives, known as mineral-based binders, are commonly utilized in certain types of construction materials (SCC) to improve their durability and strength [34,35]. For this investigation, we used a combination of alccofine and ground granulated blast furnace slag (GGBFS). The use of these mineral admixtures helps reduce the heat of hydration [36]. Similarly, it also improved the resistance criteria of binders in SCC. This investigation was conducted by collecting GGBFS from the local market. The material was obtained by processing iron waste. Alccofine 1203, made from GGBFS, is a waste product from India’s iron ore industry, which has a high concentration of both ore and glass [37]. Compared to other supplementary cementitious materials of this type, it exhibits reactive qualities.

2.1.3. Chemical Admixture

In addition to improving the flowability and durability of SCC, chemical admixtures can help strengthen their properties. In this study, polycarboxylate ether-based superplasticizers were used as chemical admixtures. The characteristics of the superplasticizers are listed in Table 3.

Table 3.

Physical characteristics of the superplasticizer.

2.1.4. Aggregates

In this study, the production of SCC involved the use of two types of aggregates: coarse aggregate (CA) with a maximum size of 20 mm and fine aggregate (FA) measuring less than 4.75 mm. Table 4 displays the physical characteristics of the CA, FA, WFS, and TFS utilized in the experiment.

Table 4.

Physical properties of FA and CA.

2.1.5. Waste Foundry Sand (WFS)

WFS is a byproduct generated by the metal and iron casting industry. This study utilized WFS obtained from a nearby foundry that produces substantial amounts of this waste material. After collection, the WFS was sieved, segregated, cleaned, and thoroughly washed with water (2–3 times). After the WFS was treated with water, it was dried completely at ambient temperature and sieved to remove the clay, carbon, metal, and hazardous content, and was considered treated foundry sand (TFS). The significant disparity in water absorption between WFS (3.15%) and TFS (0.52%) can be explained by various factors. WFS often contains a greater proportion of smaller particles, which results in a larger total surface area exposed to water, thus increasing absorption. Moreover, WFS typically exhibits a more textured and porous surface, allowing it to hold more water. On the other hand, TFS undergoes processing techniques (such as washing or stabilization) that diminish its roughness and porosity, resulting in reduced water absorption. Consequently, the observed differences can be attributed to the interplay of particle size distribution, surface characteristics, and processing methods. The basic physical properties of TFS are presented in Table 4. The chemical properties of TFS are presented in Table 2.

2.2. Methodology

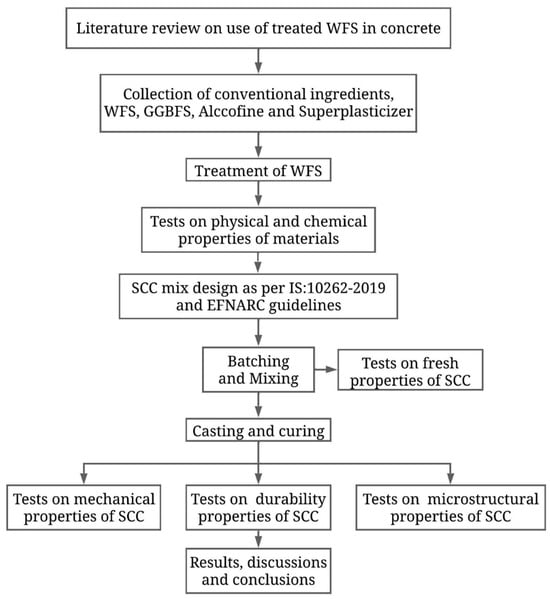

This research aimed to explore the potential use of treated foundry sand (TFS) as a substitute for FA in self-compacting concrete (SCC) at various proportions. The research approach, depicted in Figure 2, began with an examination of the chemical and physical characteristics of all materials utilized in the study. Subsequently, the investigation focused on assessing the fresh properties, strength, durability, and microstructural features of SCC incorporating TFS as an alternative to FA. The mix proportions of the SCC mixes were calculated according to Indian standards and EFNARC guidelines [38,39] and are presented in Table 5. The detailed methods and experimental program used in this study are presented in the Section 2.2.1.

Figure 2.

The research methodology followed in this study.

Table 5.

Mix proportions of SCC (kg/m3).

2.2.1. Experimental Program

This research aims to examine the durability, strength, microstructure, and fresh characteristics of SCC (M60 grade) utilizing TFS as a substitute for FA. The SCC’s fresh properties, including passing ability and flowability, were evaluated in line with IS standards and EFNARC guidelines [38]. For each test and corresponding curing period, 3 specimens were considered and the average result of the 3 specimens was noted and examined further. Additionally, the SCC’s strength properties, encompassing flexural, compressive, and split tensile strength, were assessed at 3, 7, 28, and 90 days of curing in accordance with Indian standards [40]. For all mixtures, the durability characteristics of the SCC samples, including water absorption, sorptivity, and chloride penetration (utilizing the rapid chloride penetration test) were measured. These assessments were conducted in accordance with ASTM standards at both 28 and 90 days of curing [41]. Alternatively, resistance to chemical attacks, such as chloride, sulfate, and acid resistance of TFS test specimens, was studied (percentage weight and strength loss) at 28 and 90 days of curing based on Indian and ASTM standards [42]. After the experimental investigation, the test specimens were subjected to microstructural analysis to study the bond behavior, gel formation, and hydration of the constituent ingredients of the SCC.

3. Results and Discussion

3.1. Fresh Properties of SCC

3.1.1. Tests on Flowability Properties of SCC

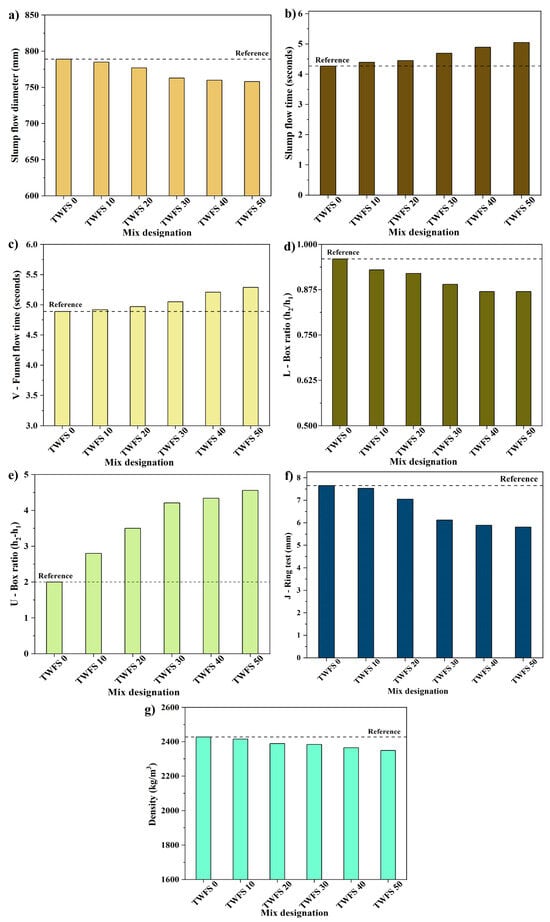

The various flowability properties of SCC prepared with WFS, such as slump flow, J-ring, L-box, and T500 mm, were evaluated using the mix combinations presented in Table 5. The flowability test results are shown in Figure 3. As shown in the figures, as the TFS content increases, the slump flow increases until TFS30; subsequently, a marginal decline in slump flow is observed. Alternatively, the T500 mm test results exhibited similar test results, including the slump flow. The main reason behind the increment in flowability properties is the increment in the finer content of SCC until TFS30; thereafter, finer content increased, but the presence of clay and other foreign matter in small quantities (even after treatment with water) in TFS resulted in water reaching its surface and decreased flowability properties. The V-funnel test, like the flowability assessment, was employed to evaluate the flowability and viscosity of the SCC mixtures. A slight reduction in viscosity was noted for all mixes as the TFS content increased compared to TFS0. This suggests that incorporating TFS enhanced the viscosity characteristics of SCC.

Figure 3.

Fresh properties test results of SCC mixes—(a) Slump flow diameter, (b) Slump flow time, (c) V-Funnel, (d) L-Box, (e) U-Box, (f) J-Ring and (g) Density.

3.1.2. Tests on Passing Ability Properties of SCC

The passing ability test outcomes for SCC mixtures containing TFS are depicted in Figure 3d–f. These results, obtained from L-box and U-box tests, demonstrate the segregation resistance and passing ability of the experimental mixes. The data reveal that as the TFS content increased, there was a slight reduction in L-Box values and a minor rise in U-Box test results compared to TFS0. This suggests that TFS has a minimal impact on the passing ability and segregation resistance of SCC mixtures. It also indicates that even small amounts of clay, carbon, and other impurities in TFS can noticeably affect SCC’s passing ability. Notably, all SCC mixtures met the criteria set by the EFNARC guidelines [38]. Furthermore, a similar pattern of slight decrease in passing ability was observed across all TFS mixes when compared to TFS0. This implies that TFS does not significantly impair SCC performance and that all mixtures satisfy the EFNARC guidelines [38] for the passing ability requirements of SCC.

3.1.3. Density

The density test results of the SCC mixes incorporating TFS are shown in Figure 3f. From the figure, it is observed that the treatment of TFS with water reduced clay, carbon, heavy metals, and other foreign matter from WFS. The same is observed for the decrease in the density of TFS. As the percentage of TFS increased, a decrease in TFS was observed, and the use of TFS made SCC lighter in weight. The reduction in density observed after treating TFS with water can be attributed to the removal of finer and lighter impurities such as clay, carbon, and other foreign matter. These materials typically have lower specific gravities than sand matrices. Heavy metals, although denser individually, are often associated with finer particles or coatings on sand grains and can be washed away during the cleaning process. Our interpretation is supported by the significant decrease in turbidity and visible contaminants in the treated sand. Additionally, complementary SEM analysis was used to confirm the reduction in clay and carbon content, which correlated with the observed density reduction. This relationship between density and impurity removal has also been noted in other studies [43,44,45], where washing or treatment processes effectively removed lighter fractions and improved the purity of the sand materials.

3.2. Mechanical Properties of SCC

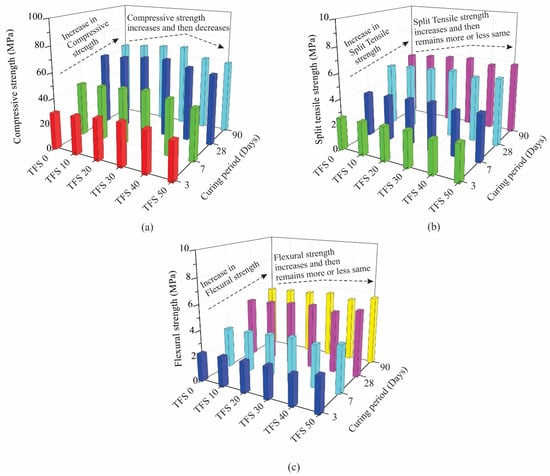

3.2.1. Compressive Strength (CS)

The mechanical properties of various SCC mixes were evaluated by performing a CS test for different curing periods (3, 7, 28, and 90 days). The CS results for the SCC mixes prepared with TFS are presented in Figure 4a. From the CS test results, it was observed that as the TFS content increased, a marginal increment in CS occurred. Compared to TFS0, the TFS30 mix achieved 6.3% and 7.05% increments in strength at 28 and 90 days of curing, respectively. Thereafter, a slight decrease in strength was observed. The 6.3% increase in strength is mainly attributed to the proper treatment and removal of foreign matter. Similarly, this increase may be due to the presence of silica in TFS and better bonding among the constituents of SCC. Thereafter (TFS30), a marginal decrease in CS was observed for the TFS40 and TFS50 mixtures. The reduction in strength could be attributed to the increasing presence of clay and other components as the TFS proportion rises. From a strength perspective, it is evident that TFS can serve as a viable substitute for FA in enhancing the CS of SCC, with replacement levels of up to 30% of FA.

Figure 4.

Strength test results SCC mixes—(a) CS, (b) STS and (c) Flexural strength.

3.2.2. Split Tensile Strength (STS)

STS tests were performed at different curing periods (3, 7, 28, and 90 days) for all SCC mixes incorporated with TFS. The STS test results for all mixes are presented in Figure 4b. Like CS test results, the STS test results of the SCC mixes prepared with TFS indicated that as the TFS content increased, STS increased. Compared to TFS0, the TFS30 mix achieved a 7.17% and 7.33% increment in strength at 28 and 90 days of curing, respectively. Thereafter, a slight decrease in strength was observed. The increments in strength of 7.17 and 7.33% were mainly attributed to the proper treatment and removal of foreign matter. Similarly, this increase may be due to the presence of silica in the TFS. A marginal decrease in STS was observed for the TFS40 and TFS50 mixtures. The decrease in strength may be due to the presence of clay and other contents as the TFS content increased. From a strength point of view, one can notice that TFS can be used as an alternative to FA to enhance the STS of SCC, replacing up to 30% of FA.

3.2.3. Flexural Strength

Like STS, the FS test was also performed at different curing periods (3,7,28, and 90 d) to assess the mechanical properties of SCC. The STS test results of all mixes prepared with varying proportions of TFS are presented in Figure 4c. Like the CS and STS test results, the FS test results of SCC mixes prepared with TFS indicate that as the TFS content increases, an increase in FS is observed. Compared to TFS0, the TFS30 mix achieved a 7.67 and 7.62% increase in strength at 28 and 90 days of curing, respectively. Thereafter, a slight decline in FS was observed. The increases in FS of 6.79 and 7.62% are mainly due to the proper treatment and removal of foreign matter and the presence of reactive silica and better binding of TFS with constituents of SCC. Thereafter (TFS30), a marginal decrease in STS was observed for the TFS40 and TFS50 mixtures. The reduction in strength could be attributed to the increasing presence of clay and other components as the TFS proportion rises. From a strength perspective, it is evident that TFS can serve as a viable substitute for FA in enhancing the FS of SCC, with replacement levels of up to 30% of FA. The statistical relationship between the strength properties of the SCC mixes is shown in Figure 5.

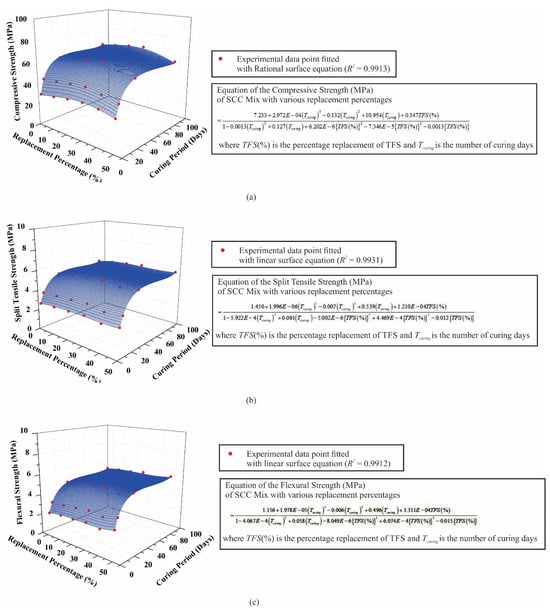

Figure 5.

Envelopes for variations in (a) CS, (b) STS, and (c) FS of SCC prepared with TFS.

3.3. Durability Properties

3.3.1. Water Absorption

All SCC test mixes incorporating TFS underwent water absorption testing in accordance with ASTM standards at both 28 and 90 days of curing [41]. The outcomes are displayed in Figure 6a. The results demonstrate that as the TFS content increases, the SCC’s densification markedly improves. This suggests that the inclusion of a minor amount of TFS contributes to the densification of SCC’s structure and reduces water absorption in mixtures containing up to 30% of TFS. Thereafter, a marginal decrease in water absorption was observed for TFS40 and TFS50. This is mainly due to the presence of burnt carbon and other foreign matter, such as resins, dust, and hazards. While the TFS was thoroughly washed during the experimental procedure, some residual impurities, such as burnt carbon, resins, fine dust, and other foreign matter may persist. This can occur because certain contaminants strongly adhere to the sand particles or are embedded within micropores, making it challenging to remove them entirely through washing alone. However, residual contaminants such as burnt carbon and resins can form a thin film on sand particles, which are not always fully eliminated through conventional washing techniques. Based on the use of TFS in SCC, one notices that TFS can be used effectively to improve the durability of SCC by up to 30% as an alternative for FA.

Figure 6.

Durability test results of SCC mixes—(a) Water absorption, (b) Ssorptivity, and (c) RCPT.

3.3.2. Sorptivity

Another parameter used to assess the durability of SCC is sorptivity. This test measures the capillary rise of water from the bottom of the specimen into the concrete. Figure 6b displays the sorptivity test results for all mixtures containing TFS. The findings reveal an inverse relationship between TFS content and sorptivity values in SCC mixes—as the amount of TFS increases, the sorptivity of the SCC mixtures decreases. This indicates that, when comparing TFS0, TFS10, TFS20, and TFS30 mixes exhibiting lower sorptivity, densification indicates improved durability. Consequently, a decrease in sorptivity was observed. It is also noticed that there is not much difference in the other mixes, such as TFS40 and TFS50, when compared to TFS0. This indicates that the incorporation of TFS into SCC as an alternative to FA has a greater impact on densification and sorptivity.

3.3.3. Rapid Chloride Penetration Test (RCPT)

All SCC mixtures containing varying amounts of TFS underwent the RCPT. This test was conducted to evaluate the durability and long-term performance of SCC in accordance with ASTM standards [42]. Figure 6c displays the RCPT results for all mixtures. The findings reveal that every mixture falls within the low permeability category (1000–2000 coulombs), as defined by ASTM standards [42]. This classification suggests that the SCC mixtures demonstrate strong resistance to chloride ion penetration and reinforcement corrosion, even in harsh environments. Additionally, the TFS-containing mixtures showed reduced chloride ion penetration compared to TFS0, indicating enhanced durability and long-term performance. This is mainly due to the complete hydration, densification, and better bonding among the constituents of the SCC ingredients.

3.3.4. Resistance to Chemical Attack

Resistance to chemical attack tests were performed on SCC test specimens to study the durability and long-term performance of SCC in aggressive environments. Chemical attacks can occur in concrete mainly in harsh environments owing to the presence of acids, salts, sulfate, and other harmful ingredients. Tests on resistance to chemical attack, such as chloride, sulfate, and acid resistance (H2SO4 and HCL) were conducted on all test specimens. Resistance to chemical attack was performed, and the resistance of the chemical was measured in two ways (strength and weight loss) at 28 and 90 d of curing. The test results for all mixes on resistance to chemical attack are presented in Figure 7. Figure 7a shows the effect of chloride resistance on the SCC test specimens. From the Figure, it is observed that the chloride effects in terms of strength and weight loss are marginal in all mixes. Similarly, TFS mixes exhibited better resistance (strength and weight loss) than TFS0 mixes. Similar results of marginal effect of sulphate resistance were also noticed on all the SCC test specimens (Figure 7b). Acid resistance (H2SO4 and HCL) tests were performed on all the mixes and are presented in Figure 7c,d. The influence of an acid attack is more pronounced in terms of both weight and strength loss. Compared to TFS0, other mixes, such as TFS10, TFS20, TFS30, TFS40, and TFS50, exhibited better resistance. Better resistance in terms of acid attack indicates that the deterioration of the ingredients in SCC mixes incorporated with TFS is marginally less than that of TFS0. Overall, the TFS mixes exhibited better resistance to chemical attacks than TFS0. Similarly, based on the test results, the TFS30 mix exhibited improved resistance/optimum use for SCC.

Figure 7.

Results of the resistance to chemical attacks—(a) Chloride resistance, (b) Sulphate resistance, (c) Acid resistance (HCL) and (d) Acid resistance (H2SO4).

3.4. Microstructure Analysis

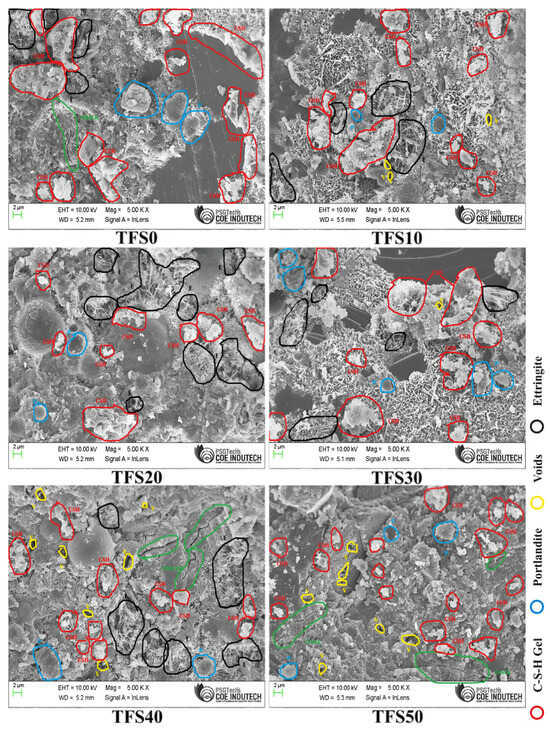

Scanning electron microscopy (SEM) was employed to conduct microstructure analysis. SEM serves as an effective method for evaluating the microstructure of self-compacting concrete (SCC) that incorporates tunnel furnace slag (TFS) as a substitute for fly ash (FA). Figure 8 displays the outcomes of the SEM analysis for all SCC mixtures containing TFS. The examination revealed that increasing the TFS content led to a decrease in pore formation when compared to the TFS0 mix. Specifically, the TFS10, TFS20, TFS30, and TFS40 mixes exhibited reduced pore formation in contrast to the TFS0 mixture. This indicates that TFS aids in the densification of SCC. Similarly, improved bonding between the cement and aggregate phases was observed in the TFS10, TFS20, and TFS30 mixes, exhibiting proper hydration of the constituent ingredients in SCC. This is mainly due to the treatment of the WFS and the presence of silica in the TFS. Similarly, improvements in crystalline gel formation, such as portlandite and CSH gel, were observed for the TFS10, TFS20, TFS30, and TFS40 mixes compared to the reference mix TFS0. This indicates that the hydration of SCC and the constituent particles of SCC help to improve the strength and durability of concrete incorporated with TFS. Overall, using SEM, this investigation revealed critical statistics regarding the microstructural properties of SCC when it is used as an alternative to FA. The outcome of this study will help improve the design of concrete mixes and allow for sustainable construction. Researchers and engineers can then integrate TFS into their projects/construction to balance its environmental benefits with its performance and make SCC lightweight, sustainable, durable, and environmentally friendly.

Figure 8.

Microstructural analysis of SCC mixtures.

4. Conclusions

An extensive investigation of the use of TFS as an alternative to FA in SCC based on fresh, mechanical, durability, microstructural characteristics, and sustainability considerations led to the following conclusions:

- -

- The incorporation of TFS into SCC generally results in a slight reduction in workability compared with TFS0. This is because of the presence of clay, specific surface area, and other foreign matter present in the WFS, which increases the water demand towards its surface. However, the use of TFS in SCC marginally enhanced its passing and flowability properties. Based on the passing and flowability properties of SCC, all TFS mixes satisfied the workability requirements as per the EFNARC guidelines.

- -

- The strength properties of SCC mixes incorporated with TFS as an alternative to FA indicate that the TFS30 mix achieved a 6.5–7.5% improvement in CS, STS, and FS in comparison to TFS0 at 28 and 90 days of curing. A slight decrease in strength was observed in comparison to TFS0. The enhancement in the strength of SCC was mainly attributed to densification, better bonding, and the presence of silica in the TFS.

- -

- In addition to the fresh and strength properties of SCC, the durability characteristics of SCC exhibit improved durability and long-term performance. Compared to TFS0, all the SCC mixes prepared with varying proportions of TFS exhibited enhanced durability characteristics such as water absorption, sorptivity, RCPT, and resistance to chemical attack. TFS was proven to be suitable for buildings, even in harsh environments.

- -

- SEM analysis revealed that the TFS concrete had a denser microstructure with a well-bonded interfacial transition zone between the TFS and other constituents of SCC. The presence of TFS contributes to the formation of a continuous and homogenous crystalline gel and reduces micro-cracking and voids. This improved microstructure is crucial for the development of both the mechanical strength and durability.

- -

- Utilizing TFS as an FA in SCC offers substantial environmental benefits by lowering the demand for virgin raw materials and promoting the salvage of industrial waste. This practice not only conserves natural resources but also helps reduce waste management, landfill usage, and the environmental impact associated with sand extraction. Consequently, the TFS in SCC supports green construction practices and circular economic principles.

- -

- While TFS shows promise as a sustainable alternative to FA, its optimal replacement levels need careful consideration to balance performance with environmental benefits. Challenges, such as variability in the chemical composition and physical properties of TFS, must be addressed through thorough material characterization and quality control. Adapting a mixed design to accommodate the specific characteristics of TFS can help overcome these challenges and ensure consistent performance across different batches.

- -

- Overall, the use of TFS as an alternative to FA in SCC offers numerous advantages, including enhanced strength, durability, and significant sustainability benefits. By addressing challenges related to variability and workability, WFS can be effectively included in SCC, supporting the development of high-performance, eco-friendly, and green concrete. However, its widespread adoption in the construction industry has several practical considerations, such as steady supply, thermal or chemical treatment, quality control, economic benefits, and industrial and commercial adoption. In conclusion, the widespread availability of WFS presents a great opportunity for academicians, contractors, and engineering professionals to adopt the usage of TFS/WFS as an alternative to FA to reduce the depletion of natural resources and to overcome the challenges associated with handling WFS.

Author Contributions

Conceptualization, R.B.T. and P.T.R.; Methodology, R.B.T.; Software, R.B.T.; Validation, P.T.R.; Formal Analysis, R.B.T.; Investigation, R.B.T.; Resources, R.B.T.; Data Curation, P.T.R.; Writing—Original Draft Preparation, R.B.T.; Writing—Review and Editing, P.T.R.; Supervision, P.T.R. All authors have read and agreed to the published version of the manuscript.

Funding

The authors declare that no funding was received for this research.

Data Availability Statement

The data that supports the findings of this study are available upon request from the corresponding author.

Conflicts of Interest

The authors declare that they have no conflicts of interest relevant to this study.

References

- Iyer, N.R. 1—An Overview of Cementitious Construction Materials. In New Materials in Civil Engineering; Samui, P., Kim, D., Iyer, N.R., Chaudhary, S., Eds.; Butterworth-Heinemann: Oxford, UK, 2020; pp. 1–64. ISBN 978-0-12-818961-0. [Google Scholar]

- Chunchu, B.R.K.; Putta, J. Effect of Recycled Plastic Granules as a Partial Substitute for Natural Resource Sand on the Durability of SCC. Resources 2019, 8, 133. [Google Scholar] [CrossRef]

- Bahij, S.; Omary, S.; Feugeas, F.; Faqiri, A. Fresh and Hardened Properties of Concrete Containing Different Forms of Plastic Waste—A Review. Waste Manag. 2020, 113, 157–175. [Google Scholar] [CrossRef]

- Junaid, M.F.; ur Rehman, Z.; Kuruc, M.; Medveď, I.; Bačinskas, D.; Čurpek, J.; Čekon, M.; Ijaz, N.; Ansari, W.S. Lightweight Concrete from a Perspective of Sustainable Reuse of Waste Byproducts. Constr. Build. Mater. 2022, 319, 126061. [Google Scholar] [CrossRef]

- Miraldo, S.; Lopes, S.; Pacheco-Torgal, F.; Lopes, A. Advantages and Shortcomings of the Utilization of Recycled Wastes as Aggregates in Structural Concretes. Constr. Build. Mater. 2021, 298, 123729. [Google Scholar] [CrossRef]

- Nair, A.T.; Mathew, A.; Archana, A.R.; Akbar, M.A. Use of Hazardous Electric Arc Furnace Dust in the Construction Industry: A Cleaner Production Approach. J. Clean. Prod. 2022, 377, 134282. [Google Scholar] [CrossRef]

- Rashad, A.M. Effect of Nanoparticles on the Properties of Geopolymer Materials. Mag. Concr. Res. 2019, 71, 1283–1301. [Google Scholar] [CrossRef]

- de Matos, P.R.; Marcon, M.F.; Schankoski, R.A.; Prudêncio, L.R. Novel Applications of Waste Foundry Sand in Conventional and Dry-Mix Concretes. J. Environ. Manag. 2019, 244, 294–303. [Google Scholar] [CrossRef]

- Behnood, A.; Golafshani, E.M. Machine Learning Study of the Mechanical Properties of Concretes Containing Waste Foundry Sand. Constr. Build. Mater. 2020, 243, 118152. [Google Scholar] [CrossRef]

- Manjunatha, M.; Seth, D.; Balaji, K.V.G.D. Role of engineered fibers on fresh and mechanical properties of concrete prepared with GGBS and PVC waste powder–An experimental study. Mater. Today Proc. 2021, 47, 3683–3693. [Google Scholar] [CrossRef]

- Rahman, A.; Mazumder, D.; Haque, R.; Sutradhar, G.; Haidar, S. Repurposing Waste Foundry Sand as a Sustainable Building Material with Improved Thermal Performance. Springer Proc. Mater. 2023, 25, 157–166. [Google Scholar] [CrossRef]

- Aslani, M.; Akbardoost, J.; Delnavaz, M. Investigating the Effect of the Foundry Sand and Waste Foundry Sand on the Fracture Toughness of Concrete. Arab. J. Geosci. 2021, 14, 464. [Google Scholar] [CrossRef]

- Bilal, H.; Yaqub, M.; Ur Rehman, S.K.; Abid, M.; Alyousef, R.; Alabduljabbar, H.; Aslam, F. Performance of Foundry Sand Concrete under Ambient and Elevated Temperatures. Materials 2019, 12, 2645. [Google Scholar] [CrossRef]

- Ali, M.; Khan, M.I.; Masood, F.; Alsulami, B.T.; Bouallegue, B.; Nawaz, R.; Fediuk, R. Central Composite Design Application in the Optimization of the Effect of Waste Foundry Sand on Concrete Properties Using RSM. Structures 2022, 46, 1581–1594. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z.; Martínez-García, R.; Vatin, N.I.; De-Prado-gil, J.; El-Shorbagy, M.A. Waste Foundry Sand in Concrete Production Instead of Natural River Sand: A Review. Materials 2022, 15, 2365. [Google Scholar] [CrossRef]

- Mehta, V. Machine Learning Approach for Predicting Concrete Compressive, Splitting Tensile, and Flexural Strength with Waste Foundry Sand. J. Build. Eng. 2023, 70, 106363. [Google Scholar] [CrossRef]

- Rahim Zai, A.A.; Salhotra, S. Effect of Waste Foundry Sand and Glass Fiber on Mechanical Properties and Fire Resistance of High-Strength Concrete. Mater. Today Proc. 2019, 33, 1733–1740. [Google Scholar] [CrossRef]

- Ashish, D.K.; Verma, S.K.; Ju, M.; Sharma, H. High Volume Waste Foundry Sand Self-Compacting Concrete—Transitioning Industrial Symbiosis. Process Saf. Environ. Prot. 2023, 173, 666–692. [Google Scholar] [CrossRef]

- Dharek, M.S.; Manjunatha, M.; Brijbhushan, S.; Vengala, J.; Tangadagi, R.B. Performance Evaluation of Hybrid Fiber Reinforced Concrete on Engineering Properties and Life Cycle Assessment: A Sustainable Approach. J. Clean. Prod. 2024, 458, 142498. [Google Scholar] [CrossRef]

- Dyer, P.P.O.L.; de Lima, M.G.; Klinsky, L.M.G.; Silva, S.A.; Coppio, G.J.L. Environmental Characterization of Foundry Waste Sand (WFS) in Hot Mix Asphalt (HMA) Mixtures. Constr. Build. Mater. 2018, 171, 474–484. [Google Scholar] [CrossRef]

- Raja, K.C.P.; Thaniarasu, I.; Elkotb, M.A.; Ansari, K.; Saleel, C.A. Shrinkage Study and Strength Aspects of Concrete with Foundry Sand and Coconut Shell as a Partial Replacement for Coarse and Fine Aggregate. Materials 2021, 14, 7420. [Google Scholar] [CrossRef]

- Mushtaq, S.M.; Siddique, R.; Goyal, S.; Kaur, K. Experimental Studies and Drying Shrinkage Prediction Model for Concrete Containing Waste Foundry Sand. Clean. Eng. Technol. 2021, 2, 100071. [Google Scholar] [CrossRef]

- Manjunatha, M.; Seth, D.; KVGD, B.; Roy, S.; Tangadagi, R.B. Utilization of Industrial-Based PVC Waste Powder in Self-Compacting Concrete: A Sustainable Building Material. J. Clean. Prod. 2023, 428, 139428. [Google Scholar] [CrossRef]

- Singh, A.P.; Sharma, A. Predicting Strength of Concrete Containing Waste Foundry Sand and Glass Waste Using Artificial Neural Network. Asian J. Civ. Eng. 2024, 25, 787–804. [Google Scholar] [CrossRef]

- Suji, D.; Adesina, A.; Mirdula, R. Optimization of Self-Compacting Composite Composition Using Taguchi-Grey Relational Analysis. Materialia 2021, 15, 101027. [Google Scholar] [CrossRef]

- Kavitha, S.; Kala, T.F. Effect of Bamboo Fiber in Self Compacting Concrete Partially Replacing Cement with GGBS and Alccofine. Int. J. Civ. Eng. Technol. 2017, 8, 158–166. [Google Scholar]

- Faraj, R.H.; Hama Ali, H.F.; Sherwani, A.F.H.; Hassan, B.R.; Karim, H. Use of Recycled Plastic in Self-Compacting Concrete: A Comprehensive Review on Fresh and Mechanical Properties. J. Build. Eng. 2020, 30, 101283. [Google Scholar] [CrossRef]

- Ashish, D.K.; Verma, S.K. Robustness of Self-Compacting Concrete Containing Waste Foundry Sand and Metakaolin: A Sustainable Approach. J. Hazard. Mater. 2021, 401, 123329. [Google Scholar] [CrossRef]

- Martins, M.A.d.B.; da Silva, L.R.R.; Ranieri, M.G.A.; Barros, R.M.; Dos Santos, V.C.; Gonçalves, P.C.; Rodrigues, M.R.B.; Lintz, R.C.C.; Gachet, L.A.; Martinez, C.B.; et al. Physical and Chemical Properties of Waste Foundry Exhaust Sand for Use in Self-Compacting Concrete. Materials 2021, 14, 5629. [Google Scholar] [CrossRef]

- Sathurshan, M.; Yapa, I.; Thamboo, J.; Jeyakaran, T.; Navaratnam, S.; Siddique, R.; Zhang, J. Untreated Rice Husk Ash Incorporated High Strength Self-Compacting Concrete: Properties and Environmental Impact Assessments. Environ. Chall. 2021, 2, 100015. [Google Scholar] [CrossRef]

- Güneyisi, E.; Atewi, Y.R.; Hasan, M.F. Fresh and Rheological Properties of Glass Fiber Reinforced Self-Compacting Concrete with Nanosilica and Fly Ash Blended. Constr. Build. Mater. 2019, 211, 349–362. [Google Scholar] [CrossRef]

- Parashar, A.; Aggarwal, P.; Saini, B.; Aggarwal, Y.; Bishnoi, S. Study on Performance Enhancement of Self-Compacting Concrete Incorporating Waste Foundry Sand. Constr. Build. Mater. 2020, 251, 118875. [Google Scholar] [CrossRef]

- 12269-2013; Ordinary Portland Cement, 53 Grade—Specifications. Bureau of Indian Standards: New Delhi, India, 2013; pp. 1–17.

- Danish, P.; Mohan Ganesh, G. Study on Influence of Metakaolin and Waste Marble Powder on Self-Compacting Concrete—A State of the Art Review. Mater. Today Proc. 2020, 44, 1428–1436. [Google Scholar] [CrossRef]

- Kumar, R.N.; Patnaikuni, C.K.; Balaji, K.V.G.D.; Kumar, B.S. Strength Effect of Ggbs and Broken Tiles in M30 Grade Self Compacting Concrete (SCC). Int. J. Civ. Eng. Technol. 2018, 9, 1446–1455. [Google Scholar]

- Rahla, K.M.; Mateus, R.; Bragança, L. Comparative Sustainability Assessment of Binary Blended Concretes Using Supplementary Cementitious Materials (SCMs) and Ordinary Portland Cement (OPC). J. Clean. Prod. 2019, 220, 445–459. [Google Scholar] [CrossRef]

- Srinath, B.L.N.S.; Patnaikuni, C.K.; Balaji, K.V.G.D.; Kumar, B.S.; Manjunatha, M. A Prospective Review of Alccofine as Supplementary Cementitious Material. Mater. Today Proc. 2021, 47, 3953–3959. [Google Scholar] [CrossRef]

- EFNARC; BIBM; CEMBUREAU; EFCA; ERMCO. The European Guidelines for Self-Compacting Concrete; ASTM International: West Conshohocken, PA, USA, 2005; Volume 63. [Google Scholar]

- IS 10262-2019; Concrete Mix Proportioning-Guidelines. Bureau of Indian Standards: NewDelhi, India, 2019; pp. 1–40.

- IS 516-1959; Method of Tests for Strength of Concrete. Bureau of Indian Standards: New Delhi, India, 2004.

- ASTM C20-00(2010); Standard Test Methods for Apparent Porosity, Water Absorption, Apparent Specific Gravity, and Bulk Density of Burned Refractory Brick and Shapes by Boiling Water 1. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- ASTM D570—98; Standard Test Method for Water Absorption of Plastics. ASTM International: West Conshohocken, PA, USA, 2018. Available online: https://www.astm.org/Standards/D570 (accessed on 28 February 2025).

- Iloh, P.; Fanourakis, G.; Ogra, A. Evaluation of Physical and Chemical Properties of South African Waste Foundry Sand (WFS) for Concrete Use. Sustainability 2019, 11, 193. [Google Scholar] [CrossRef]

- Siddique, R.; Singh, G. Utilization of Waste Foundry Sand (WFS) in Concrete Manufacturing. Resour. Conserv. Recycl. 2011, 55, 885–892. [Google Scholar] [CrossRef]

- Alterary, S.S.; Marei, N.H. Fly Ash Properties, Characterization, and Applications: A Review. J. King Saud Univ.-Sci. 2021, 33, 101536. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).