Analyzing the Environmental Impacts and Empirical Limitations of Green Remodeling with Life Cycle Assessment

Abstract

1. Introduction

1.1. Background and Purpose of the Study

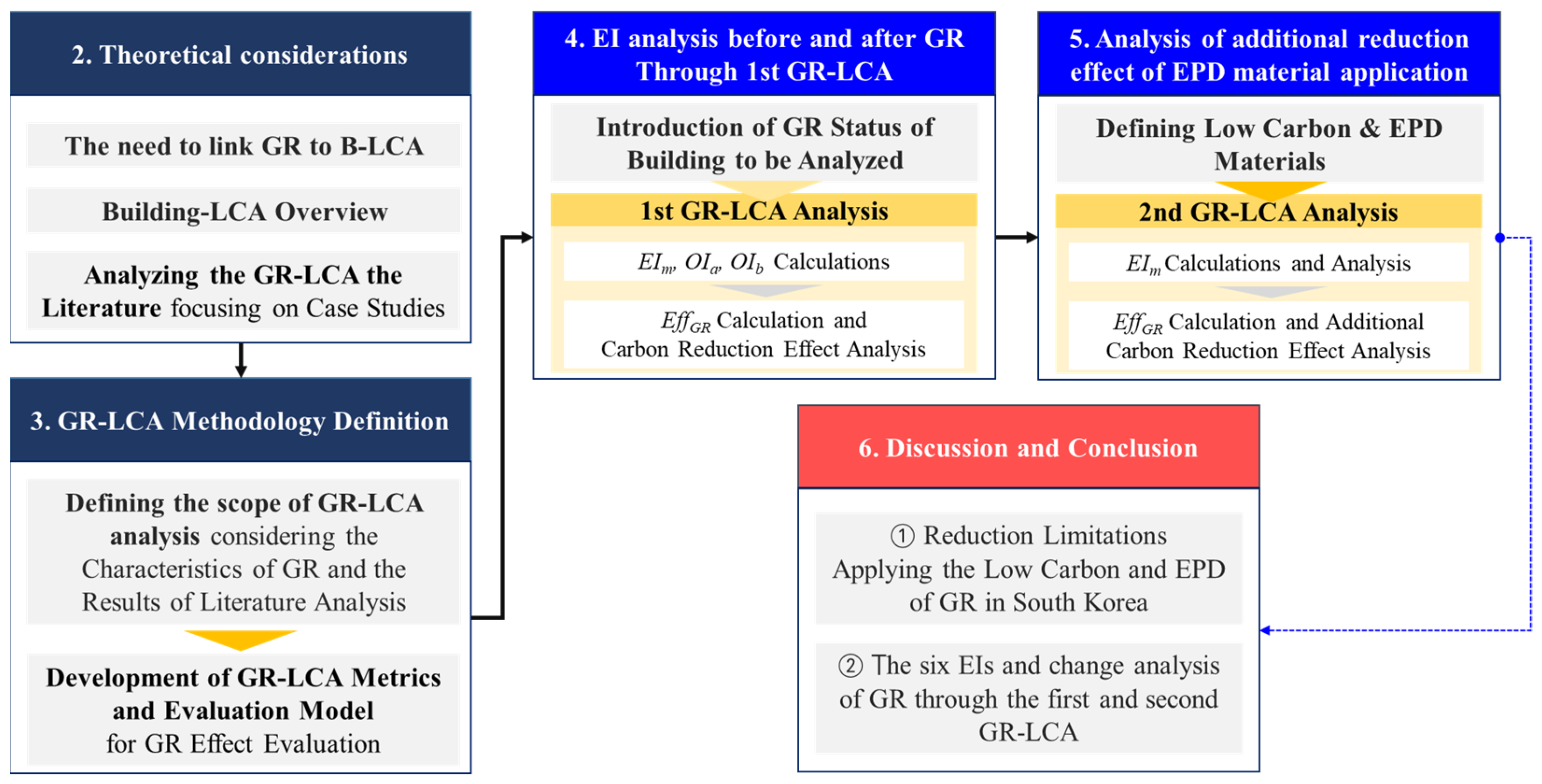

1.2. Research Structure and Procedures

2. Theoretical Considerations

2.1. The Need to Link GR to B-LCA

2.2. B-LCA Overview

2.3. Analyzing the GR-LCA Literature

- Given that GR primarily targets older buildings, baseline documentation such as original drawings or statements of the building condition before GR is often unavailable.

- In Korea, most buildings are steel–concrete structures, and energy-efficiency retrofits typically occur 15 years after construction, with structural reinforcement seldom integrated into these retrofits.

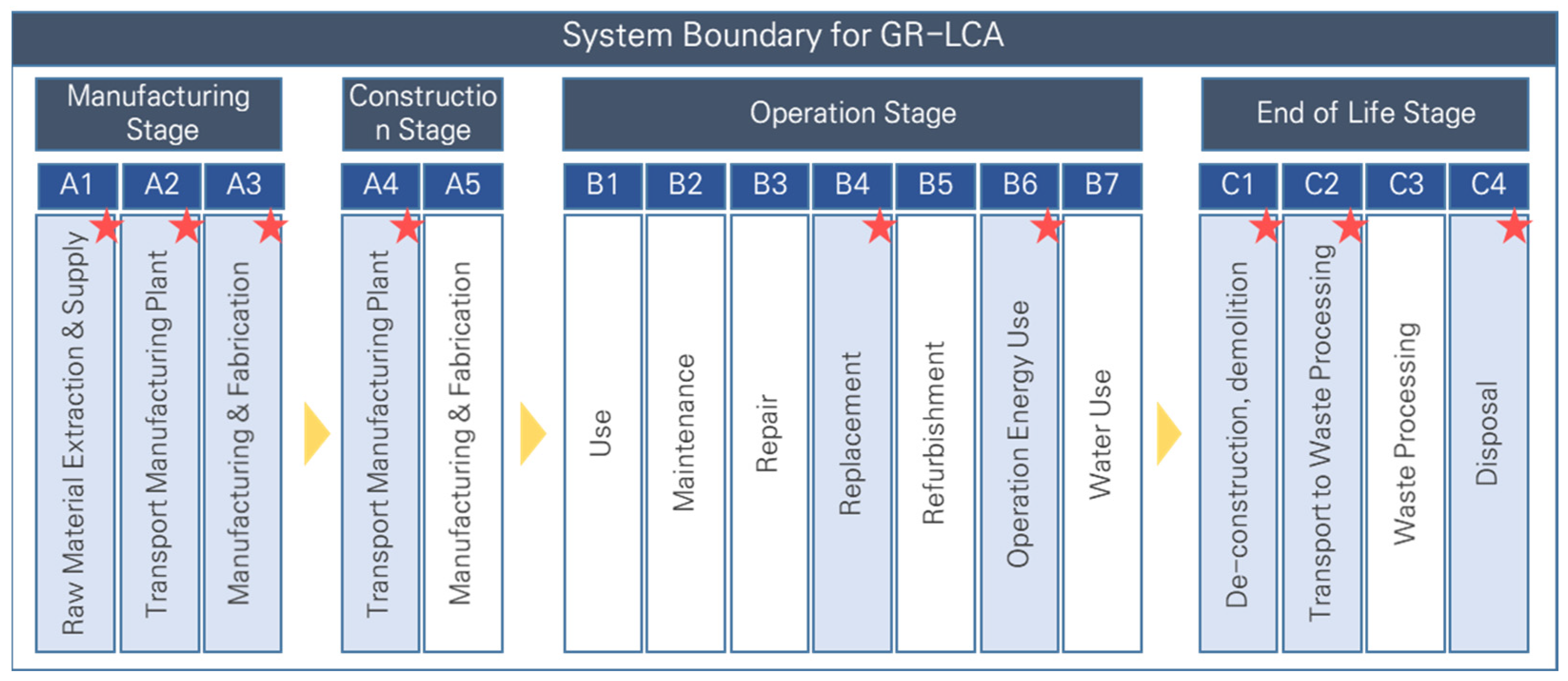

3. GR-LCA Methodology

3.1. GR-LCA Analysis Scope

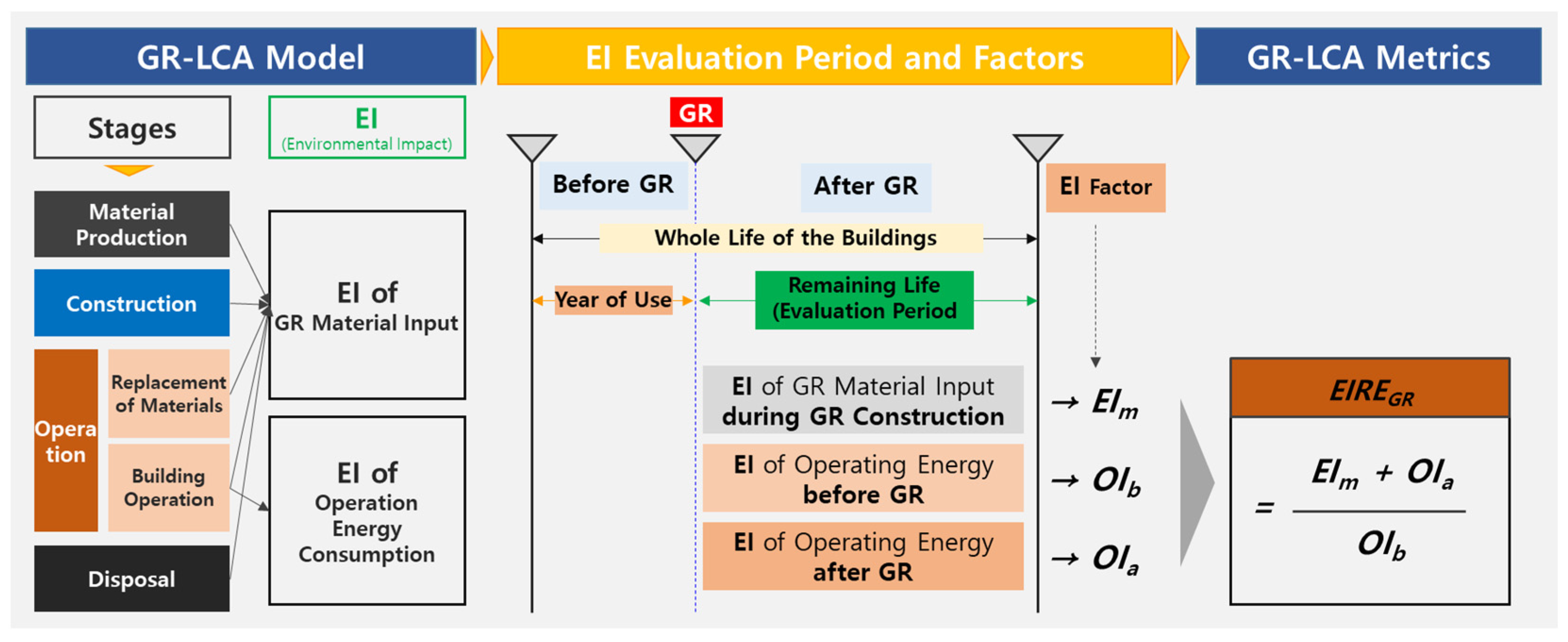

3.2. GR-LCA Metrics and Evaluation Model

4. The GR-LCA of the Target Building

4.1. Target Building’s GR Status

4.1.1. Target Building Overview

4.1.2. Performance Improvement Factors by GR

4.2. GR-LCA Analysis

4.2.1. First GR-LCA Analysis

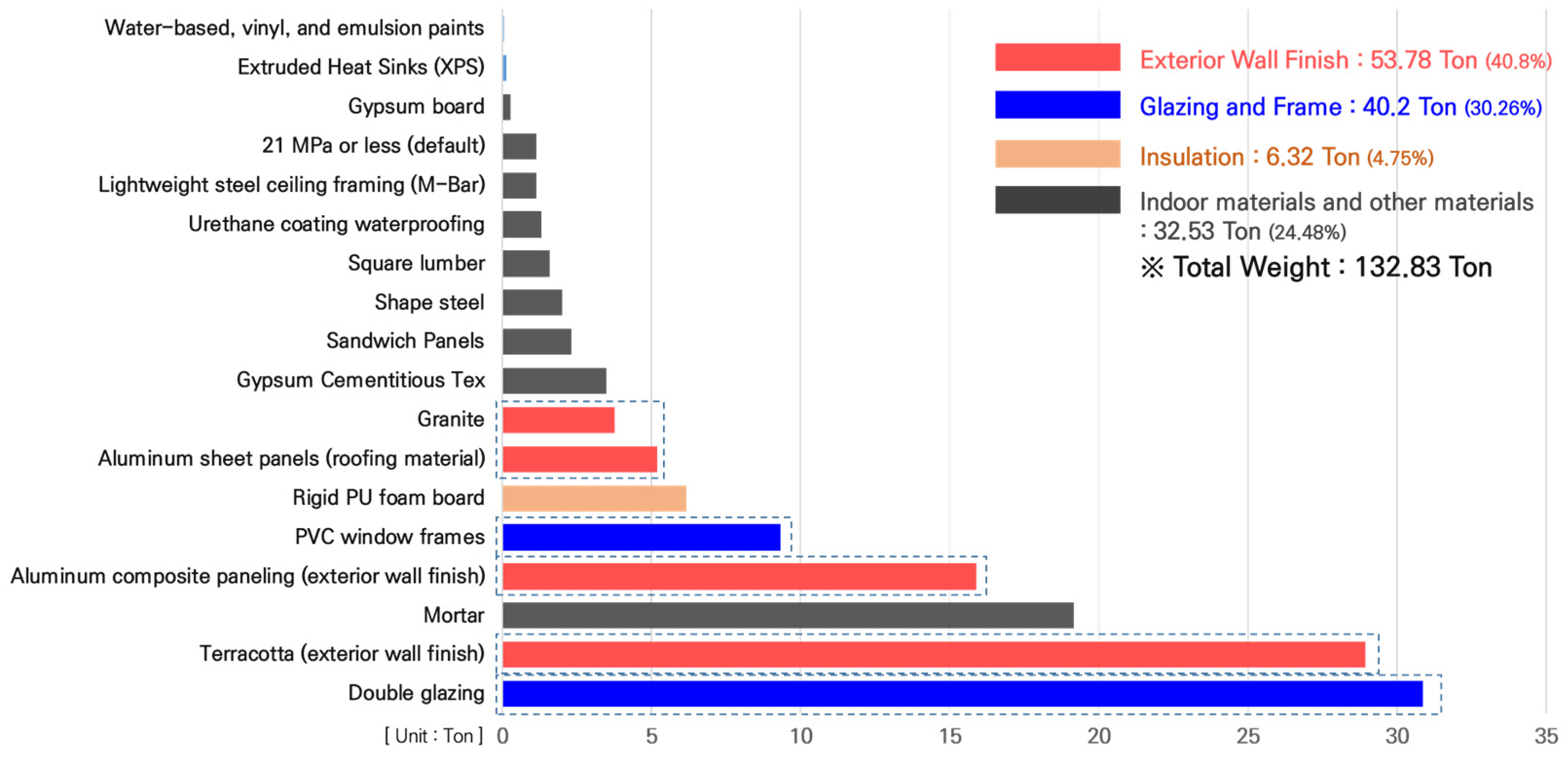

- (1) EIm Calculations and analysis

- (2) ECO2-based , Calculation and analysis

4.2.2. EIREGR Calculation and Analysis

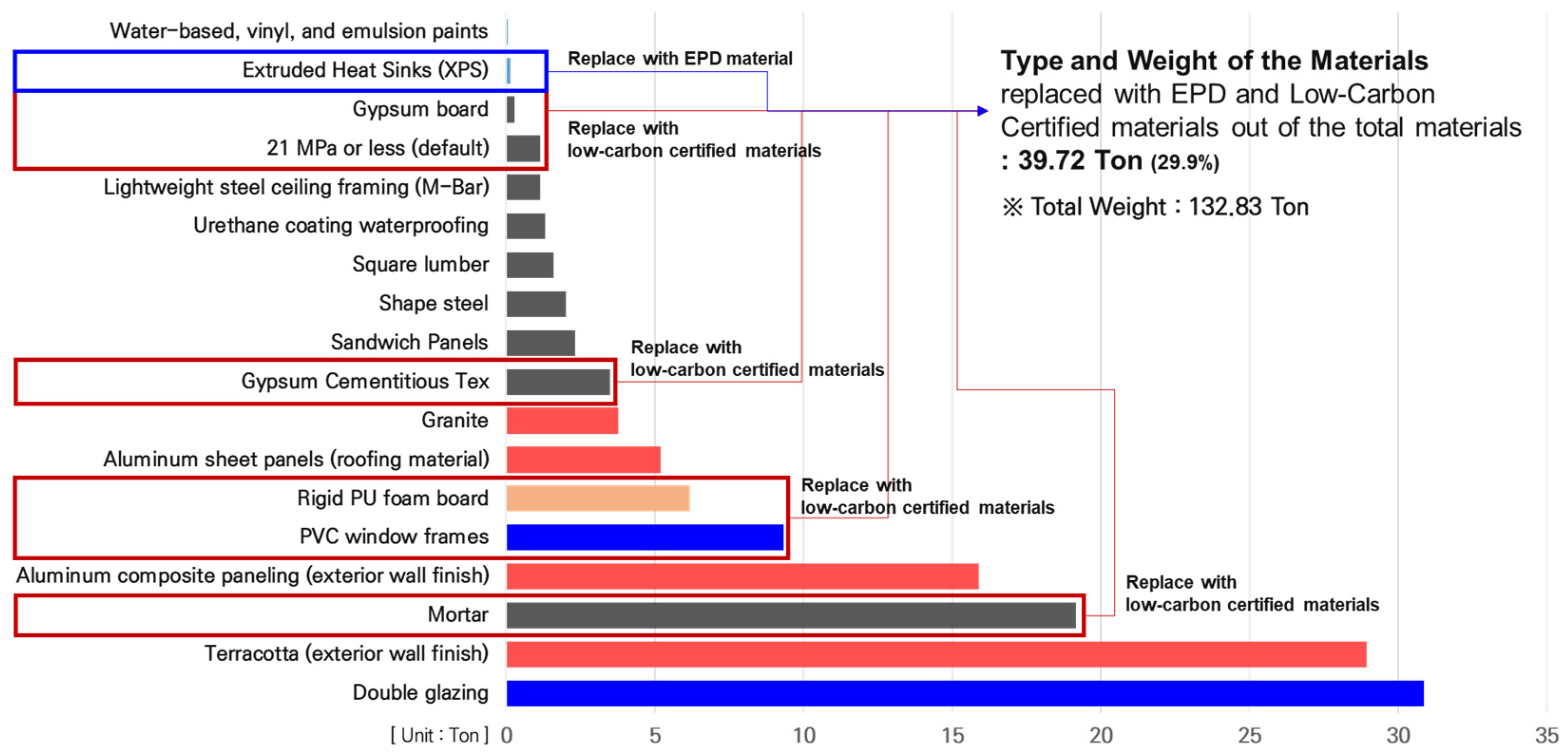

5. Second GR-LCA Analysis Applying Low-Carbon and EPD Materials

5.1. Defining EPD Materials

5.2. Analyze the EI of Applying Low-Carbon and EPD Materials

5.2.1. EI of Materials

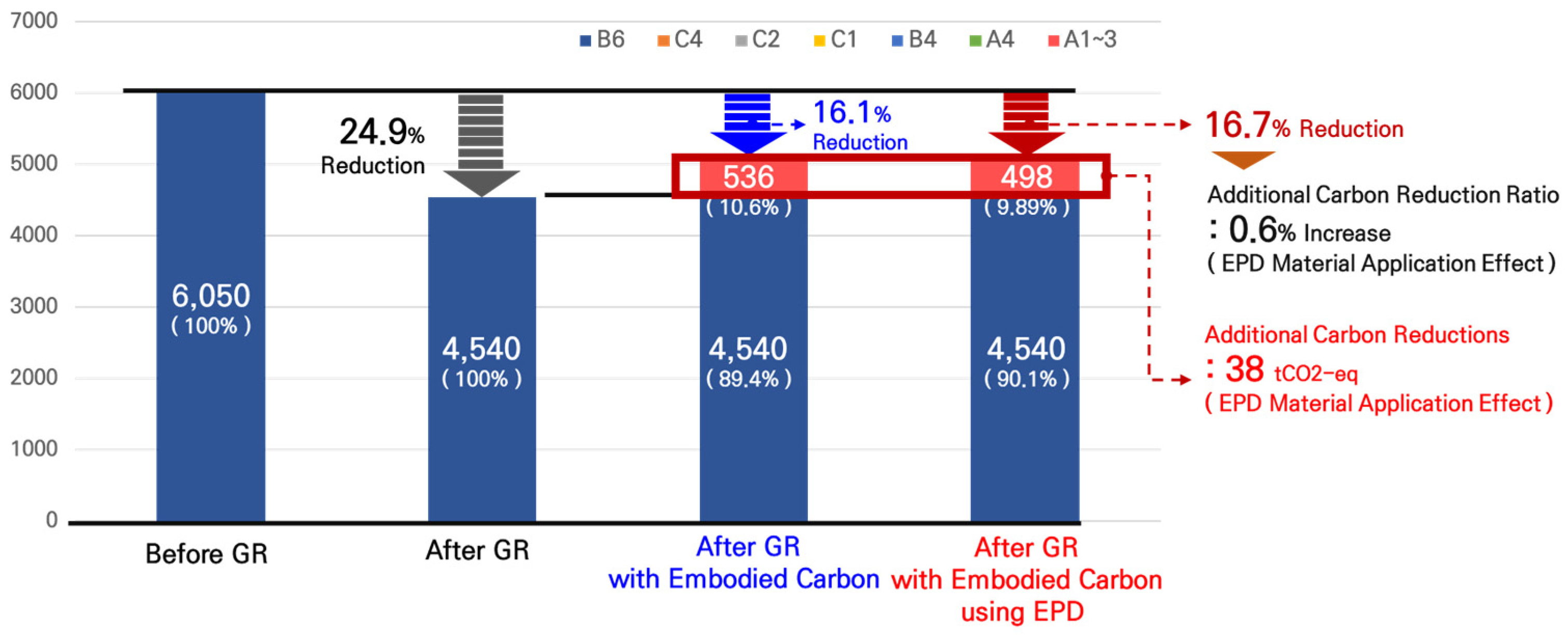

5.2.2. Second GR-LCA Results and Effects Analysis (Comparison with First GR-LCA Results)

6. Discussion and Conclusions

6.1. Limitations and Improvement Direction on Embodied Carbon Reduction in GR

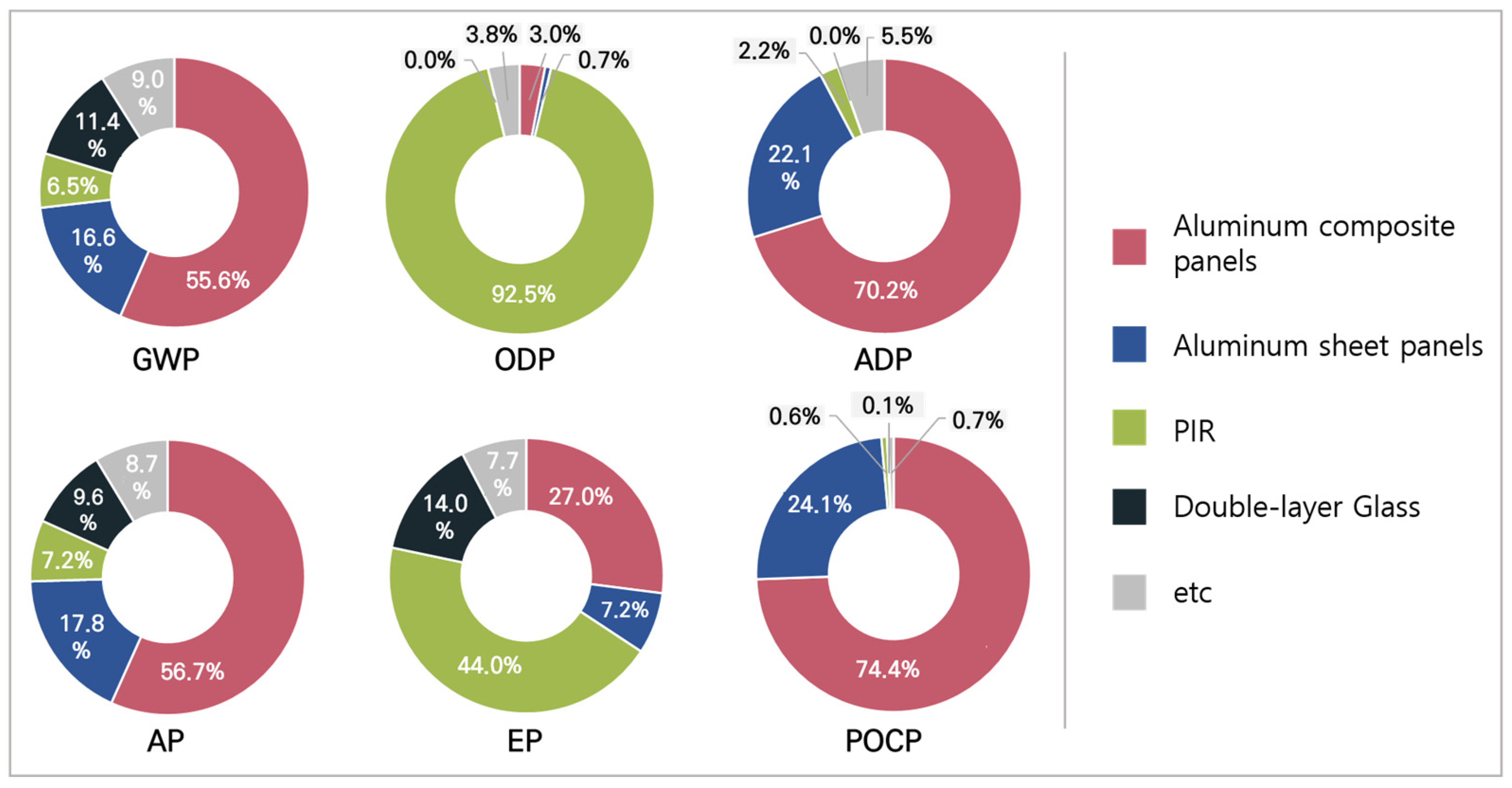

6.2. Discussion on the Results of Analyzing the Six Major Environmental Impacts

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| GR | Green remodeling |

| ZEB | Zero energy building |

| LCA | Life cycle assessment |

| EPD | Environmental product declaration |

| B-LCA | Building life cycle assessment |

| GR-LCA | Green remodeling life cycle assessment |

| MP Stage | Material production stage |

| EC | Embodied carbon |

| EI | Environmental impacts |

| EIm | Environmental impacts of materials |

| OIb | Environmental impacts before GR |

| OIa | Environmental impacts after GR |

| EIREGR | EI reduction efficiency of GR |

| GWP | Global warming potential |

| ODP | Ozone layer depletion potential |

| ADP | Abiotic resource depletion potential |

| AP | Acidification potential |

| EP | Eutrophication potential |

| POCP | Photochemical oxidants creation potential |

References

- United Nations Environment Programme. 2022 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector. Nairobi: Global Alliance for Buildings and Construction. 2022. Available online: https://globalabc.org/sites/default/files/2022-11/FULL%20REPORT_2022%20Buildings-GSR_1.pdf. (accessed on 30 December 2024).

- Architecture 2030. Why the Building Sector? 2022. Available online: https://www.architecture2030.org/old-why-the-built-environment/ (accessed on 30 December 2024).

- The Korean Government, Carbon-Neutral/Green Growth National Strategies and the First National Basic Pla. 2023.04. Available online: https://www.me.go.kr/home/web/policy_data/read.do?menuId=10259&seq=8084 (accessed on 30 December 2024).

- Ministry of Land, Infrastructure and Transport, Statistics on Building Permits and Construction, Statistical Information Report. 2022.12. Available online: https://www.narastat.kr/metasvc/index.do?confmNo=116005&inputYear=2023 (accessed on 30 December 2024).

- Kim, J.; Lim, S. A direction to improve EER (Energy Efficiency Retrofit) policy for residential buildings in South Korea by means of the recurrent EER policy. Sustain. Cities Soc. 2021, 72, 103049. [Google Scholar] [CrossRef]

- Nam, S.; Kim, J.; Lee, D. Current Status of Aged Public Buildings and Effect Analysis Prediction of Green Remodeling in South Korea. Sustainability 2021, 13, 6649. [Google Scholar] [CrossRef]

- Kim, J.M.; Nam, S.H. IEQ and energy effect analysis according to empirical Full Energy Efficiency Retrofit in South Korea. Energy Build. 2021, 235, 110629. [Google Scholar] [CrossRef]

- Grossi, F.; Ge, H.; Zmeureanu, R.; Baba, F. Assessing the effectiveness of building retrofits in reducing GHG emissions: A Canadian school case study. J. Build. Eng. 2024, 91, 109622. [Google Scholar] [CrossRef]

- Liu, G.; Li, X.; Tan, Y.; Zhang, G. Building green retrofit in China: Policies, barriers and recommendations. Energy Policy 2020, 139, 111356. [Google Scholar] [CrossRef]

- Jagarajan, R.; Abdullah Mohd Asmoni, M.N.; Mohammed, A.H.; Jaafar, M.N.; Lee Yim Mei, J.; Baba, M. Green retrofitting—A review of current status, implementations and challenges. Renew. Sustain. Energy Rev. 2017, 67, 1360–1368. [Google Scholar] [CrossRef]

- Tan, Y.; Liu, G.; Zhang, Y.; Shuai, C.; Shen, G.Q. Green retrofit of aged residential buildings in Hong Kong: A preliminary study. Build. Environ. 2018, 143, 89–98. [Google Scholar] [CrossRef]

- Kim, K.; Jang, H. A Study on Building Methodology for LCA Evaluation of Green Remodeling Technology; Korean Institute of Architectural Sustainable Environment and Building System: Seoul, Republic of Korea, 2022; pp. 203–204. [Google Scholar]

- Kim, J.; Lee, D.; Nam, S. Potential for environmental impact reduction through building LCA (Life Cycle Assessment) of school facilities in material production stage. Build. Environ. 2023, 238, 110329. [Google Scholar] [CrossRef]

- National Legal Information Center, Chapter 6, Article 27 of the Green Building Construction Support Act. Available online: https://www.law.go.kr/LSW/lsInfoP.do?efYd=20220325&lsiSeq=235587#0000 (accessed on 30 December 2024).

- Yun, B.; Kim, S. Energy and carbon reduction evaluation through green remodeling of facilities for the elderly and children. J. Korean Archit. Assoc. Acad. Present. 2023, 43, 376–377. [Google Scholar]

- ISO TC 207 SC 5 14040:2006; Deginition of the Goal and Scope of the LCA. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 19 February 2025).

- ISO TC 59 SC17 DIS 21930:2017; Environmental Declaration of Products. ISO: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/61694.html (accessed on 19 February 2025).

- Ministry of Legislation, Preparation Guidelines of Environmental Performance Mark. 2022. Available online: https://www.law.go.kr/LSW/admRulLsInfoP.do?admRulSeq=2100000083694 (accessed on 15 December 2024).

- Hawkins, D.; Mumovic, D. Evaluation of life cycle carbon impacts for higher education building redevelopment: A multiple case study approach. Energy Build. 2017, 150, 507–515. [Google Scholar] [CrossRef]

- Shirazi, A.; Ashri, B. Embodied Life Cycle Assessment (LCA) comparison of residential building retrofit measures in Atlanta. Build. Environ. 2020, 171, 106644. [Google Scholar] [CrossRef]

- Jo, K.; Tae, S.; Lee, H.; Kim, H. A Fundamental study on the proposal of building Life Cycle Assessment (LCA) certification item in green-remodeling certification in G-SEED. J. Korean Archit. Assoc. Acad. Present. 2021, 41, 423–424. [Google Scholar]

- Beccali, M.; Cellura, M.; Fontana, M.; Longo, S.; Mistretta, M. Energy retrofit of a single-family house: Life cycle net energy saving and environmental benefits. Renew. Sustain. Energy Rev. 2013, 27, 283–293. [Google Scholar] [CrossRef]

- Mabdeh, S.; Ghani, Y.; Obeidat, L.; Aloshan, M. Affordability assessment of passive retrofitting measure for residential buildings using life cycle assessment. Heliyon 2023, 9, e13574. [Google Scholar] [CrossRef]

- Zhou, Y.; Gong, G. Exergy analysis combined with LCA for building envelope Energy efficiency retrofit. J. Exergy 2011, 8, 379–391. [Google Scholar] [CrossRef]

- Wang, Q.; Laurent, R.; Holmberg, S. A novel hybrid methodology to evaluate sustainable retrofitting in exsisting Swedish residential buildings. Sustain. Cities Soc. 2015, 16, 24–38. [Google Scholar] [CrossRef]

- Frischknecht, R.; Birgisdottir, H.; Chae, C.U.; Lützkendorf, T.; Passer, A.; Alsema, E.; Balouktsi, M.; Berg, B.; Dowdell, D.; Martínez, A.G.; et al. Comparison of the environmental assessment of an identical office building with national methods. Sustain. Built Environ. Conf. Ser. Earth Environ. Sci. 2019, 323, 012037. [Google Scholar] [CrossRef]

- Brown, N.; Olsson, S.; Malmqvist, T. Embodied greenhouse gas emissions from refurbishment of residential building stock to achieve a 50% operational energy reduction. Build. Environ. 2014, 79, 46–56. [Google Scholar] [CrossRef]

- Roh, S.; Tae, S.; Bok, Y.; Sin, S. Suggestion of life cycle carbon emission assessment model for remodeling building. Archit. Inst. Korea 2015, 35, 435–436. [Google Scholar]

- Dodoo, A.; Gustavsson, L.; Sathre, R. Life cycle primary energy implication of retrofitting a wood-framed apartment building to passive house standard. Resour. Conserv. Recycl. 2010, 54, 1152–1160. [Google Scholar] [CrossRef]

- Luo, X.J.; Oyedele, L.O. Life cycle optimisation of building retrofitting considering climate change effects. Energy Build. 2022, 258, 111830. [Google Scholar] [CrossRef]

- Pombo, O.; Rivela, B.; Neila, J. The challenge of sustainable building renovation: Assessment of current criteria and future outlook. J. Clean. Prod. 2016, 123, 88–100. [Google Scholar] [CrossRef]

- Stazi, F.; Vegliò, A.; Perna, C.; Munafò, P. Retrofitting using a dynamic envelope to ensure thermal comfort, energy savings and low environmental impact in Mediterranean climates. Energy Build. 2012, 54, 350–362. [Google Scholar] [CrossRef]

- Xu, Y.; Yan, C.; Wang, G.; Shi, J.; Sheng, K.; Li, J.; Jiang, Y. Optimization research on energy-saving and life-cycle decarbonization retrofitting of existing school buildings: A case study of a school in Nanjing. Sol. Energy 2023, 254, 54–66. [Google Scholar] [CrossRef]

- Rabani, M.; Madessa, H.; Ljungström, M.; Aamodt, L.; Løvvold, S.; Nord, N. Life cycle analysis of GHG emissions from the building retrofitting: The case of a Norwegian office building. Build. Environ. 2021, 204, 108159. [Google Scholar] [CrossRef]

- Jo, K. A Study on Sustainable Remodeling Building Policy Suggestion through Remodeling Building System Analysis. Ph.D. Thesis, Hanyang University, Seoul, Republic of Korea, 2022. [Google Scholar]

- Korea Institute of Environmental Industry and Technology, Common Guidelines for Environmental Performance Signs (Building Materials). Available online: https://ecosq.or.kr/websquare.do#w2xPath=/ui/cer/ic/oh/ICOH110M03.xml&valVl=BBS0062&menuSn=20064000 (accessed on 19 February 2025).

- Ministry of Environment, Low Carbon Product Standards, 2020, Ministry of Environment Notice No. 2020-180. Available online: https://www.law.go.kr/admRulLsInfoP.do?admRulSeq=2100000192089 (accessed on 19 February 2025).

- Passer, A.; Kreiner, H.; Maydl, P. Assessment of the environmental performance of buildings: A critical evaluation of the influence of technical building equipment on residential buildings. Int. J. Life Cycle Assess. 2017, 17, 1116–1130. [Google Scholar] [CrossRef]

- Hurst, L.J.; O’Donovan, T.S. Embodied impacts of key materials for UK decarbonised domestic retrofit: Differences between sources of embodied carbon and embodied energy data. Energy Build. 2024, 319, 114515. [Google Scholar] [CrossRef]

- Lee, D.; Kim, J.; Kim, Y.I. Economic Evaluation of Small Public Office Buildings with Class 1 of Zero Energy Building (ZEB) in Korea by Reflecting Life Cycle Assessment (LCA). Buildings 2023, 13, 1693. [Google Scholar] [CrossRef]

- Kim, J.; Nam, S.; Lee, D. Current Status of Old Housing for Low-Income Elderly Households in Seoul and Green Remodeling Support Plan: Economic Analysis Considering the Social Cost of Green Remodeling. Buildings 2022, 12, 29. [Google Scholar] [CrossRef]

- Kim, J. Economic Analysis of Zero Energy Building in South Korea—Focusing on Cost-Benefit analysis considering Social Cost. J. Archit. Inst. Korea Struct. Constr. 2020, 36, 147–157. [Google Scholar] [CrossRef]

- Souaid, C.; Caat, P.N.T.; Meijer, A.; Visscher, H. Downsizing and the use of timber as embodied carbon reduction strategies for new-build housing: A partial life cycle assessment. Build. Environ. 2024, 253, 111285. [Google Scholar] [CrossRef]

- Mohammadpourkarbasi, H.; Riddle, B.; Liu, C.; Sharples, S. Life cycle carbon assessment of decarbonising UK’s hard-to-treat homes: A comparative study of conventional retrofit vs EnerPHit, heat pump first vs fabric first and ecological vs petrochemical retrofit approaches. Energy Build. 2023, 296, 113353. [Google Scholar] [CrossRef]

- Dani, A.A.; Feng, R.; Fang, Z.; Roy, K. Life Cycle Assessment of a Structural Insulated Panel Modular House in New Zealand. Buildings 2025, 15, 146. [Google Scholar] [CrossRef]

- Dani, A.A.; Roy, K.; Masood, R.; Fang, Z.; Lim, J.B.P. A Comparative Study on the Life Cycle Assessment of New Zealand Residential Buildings. Buildings 2022, 12, 50. [Google Scholar] [CrossRef]

| Year | Study Name | Existing Building EI Evaluation | Incoming Material Assessment System Boundaries | Trial Period | ||||

|---|---|---|---|---|---|---|---|---|

| Production (A1–A3) | Construction (A4–A5) | Operations (B1–B5) | Discard (C1–C4) | |||||

| 1 | 2010 | Life cycle primary energy implications of retrofitting a wood-framed apartment building to passive house standard | O | O | O | O | O | Total lifetime |

| 2 | 2011 | Exergy analysis combined with LCA for energy-efficient retrofitting of building envelopes | - | O | - | - | - | Consider only certain steps |

| 3 | 2012 | Methods and concepts for sustainable renovation of buildings | - | O | O | - | - | Total lifetime |

| 4 | 2013 | Energy retrofit of a single-family house: Life cycle net energy savings and environmental benefits | - | O | O | - | - | Total lifetime |

| 5 | 2014 | A decision-making LCA for energy refurbishment of buildings: Comfort Conditions | - | O | O | O | O | Residual Lifetime |

| 6 | 2015 | Proposed life cycle carbon footprint assessment model for remodeled buildings | - | O | O (Transportation Only) | - | O | Residual Lifetime |

| 7 | 2017 | Evaluation of life cycle carbon impacts for higher education building redevelopment: a multiple case study approach | - | O | - | O | O | Total Lifetime |

| 8 | 2017 | Evaluation of life cycle carbon impacts for higher education building redevelopment: an archetype approach | - | O | O | O | O | Total Lifetime |

| 9 | 2019 | Comparison of the environmental assessment of an using national methods | - | - | Total Lifetime | |||

| 10 | 2020 | Embodied Life Cycle Assessment (LCA) comparison of residential building retrofit measures in Atlanta | - | O | - | - | O | Consider only certain steps |

| 11 | 2021 | Green Remodeling Basic Research for Proposing Life Cycle Assessment (LCA) Certification Items in the Green Building Certification System | - | O | O | - | O | On an Annual Basis |

| 12 | 2021 | Life cycle analysis of GHG emissions from the building retrofitting: the case of a Norwegian office building | - | O | O | O | O | Total Lifetime |

| 13 | 2022 | Life cycle optimisation of building retrofitting considering climate change effects | - | O | O | O | O | Total Lifetime |

| 14 | 2023 | Optimization research on energy-saving and life-cycle decarbonization retrofitting of existing school buildings: A case study from a school in Nanjing | O | O | O | O | O | Total Lifetime |

| 15 | 2023 | Affordability assessment of passive retrofitting measure for residential buildings using life cycle assessment | O | O | O (Transportation Only) | O | - | Total Lifetime |

| Architectural Overview | Before GR | After GR | |

|---|---|---|---|

| Location | Daegu, Republic of Korea |  |  |

| Completion of Building | 26 June 2003 | ||

| Building Uses | Public Office Building | ||

| Land Area | 11,032.0 m2 | ||

| Gross Floor Area | 3099.7 m2 | ||

| Number of Floors | B1/5F | ||

| Structure | Reinforced Concrete | ||

| Separation | GWP [tCO2-eq] | ODP [tCFC-11-eq] | ADP [tSb-eq] | AP [tSO2-eq] | EP [tPO43-eq] | POCP [tC2H4-eq] | ||

|---|---|---|---|---|---|---|---|---|

| Material Production | A1 to A3 | Materialization | 4.898 × 102 | 9.247 × 10−5 | 1.111 × 10 | 2.338 | 3.123 × 10−1 | 1.053 × 10 |

| 91.3% | 97.6% | 98.8% | 65.7% | 90.3% | 99.7% | |||

| Construction | A4 | Material Handling | 2.036 | 7.371 × 10−7 | 1.383 × 10−2 | 1.009 × 10−2 | 1.654 × 10−3 | 4.873 × 10−3 |

| 0.4% | 0.8% | 0.1% | 0.3% | 0.5% | 0.0% | |||

| Operations | B4 | Replacement Materials | 3.126 × 10 | 4.989 × 10−7 | 8.494 × 10−2 | 1.230 × 10−1 | 2.243 × 10−2 | 2.210 × 10−2 |

| 5.8% | 0.5% | 0.8% | 3.5% | 6.5% | 0.2% | |||

| Deconstruction Discard Steps | C1 | Deconstruction | 1.279 | 5.017 × 10−11 | 8.553 × 10−3 | 1.035 | 4.459 × 10−4 | 9.230 × 10−5 |

| 0.2% | 0.0% | 0.1% | 29.1% | 0.1% | 0.0% | |||

| C2 | Transportation | 1.988 | 7.435 × 10−7 | 1.351 × 10−2 | 9.685 × 10−3 | 1.577 × 10−3 | 4.718 × 10−3 | |

| 0.4% | 0.8% | 0.1% | 0.3% | 0.5% | 0.0% | |||

| C4 | Disposal | 9.826 | 3.160 × 10−7 | 1.391 × 10−2 | 4.270 × 10−2 | 7.573 × 10−3 | 3.299 × 10−3 | |

| 1.8% | 0.3% | 0.1% | 1.2% | 2.2% | 0.0% | |||

| The total (EIm) | 5.361 × 10−2 | 9.477 × 10−5 | 1.125 × 10 | 3.559 | 3.459 × 10−1 | 1.057 × 10 | ||

| Separation | Primary Energy Consumption per Unit Area (kWh/m2, Year) | ||||||||

| Heating | Cooling | Lighting | Hot Water | Ventilation | Subtotal | Total | |||

| ECO2 | Before GR | Power | 91.50 | 214.90 | 86.20 | 27.30 | 5.60 | 389.90 | 389.90 |

| Gas | -. | -. | -. | -. | -. | -. | |||

| After GR | Power | 41.31 | 154.17 | 64.10 | 27.30 | 16.30 | 303.48 | 314.30 | |

| Gas | 2.26 | 8.53 | -. | -. | -. | 10.82 | |||

| The following table data display the energy (B6) EI assessment results for the building operations phase, based on ECO2. | |||||||||

| Separation | GWP [tCO2-eq] | ODP [tCFC-11-eq] | ADP [tSb-eq] | AP [tSO2-eq] | EP [tPO43-eq] | POCP [tC2H4-eq] | |||

| (Before GR) | 6.05 × 103 | 1.67 × 10−7 | 3.82 × 10 | 1.02 × 10 | 1.90 | 4.31 × 10−2 | |||

| (After GR) | 4.54 × 103 | 9.96 × 10−6 | 2.87 × 10 | 8.30 | 1.48 | 2.03 × 10−1 | |||

| Increase/Decrease | 1.50 × 103 reduction | 9.80 × 10−6 increase | 9.55 reduction | 1.92 reduction | 4.20 × 10−1 reduction | 1.60 × 10−1 increase | |||

| Increase/Decrease Ratio | 25% reduction | 5.96% increase | 25% reduction | 19% reduction | 22% reduction | 472% increase | |||

| Separation | GWP [tCO2-eq] | ODP [tCFC-11-eq] | ADP [tSb-eq] | AP [tSO2-eq] | EP [tPO43-eq] | POCP [tC2H4-eq] | |||

|---|---|---|---|---|---|---|---|---|---|

| Before GR | B6 | Operational Energy | 6.05 × 103 | 1.67 × 10−7 | 3.82 × 10 | 1.02 × 10 | 1.90 | 4.31 × 10−2 | |

| 100.0% | 100.0% | 100.0% | 100.0% | 100.0% | 100.0% | ||||

| After GR | m | A1 to A3 | Materialization | 4.90 × 102 | 9.25 × 10−5 | 1.11 × 10 | 2.34 | 3.12 × 10−1 | 1.05 × 10 |

| 9.6% | 88.3% | 27.8% | 19.7% | 17.1% | 97.8% | ||||

| A4 | Material Handling | 2.04 | 7.37 × 10−7 | 1.38 × 10−2 | 1.01 × 10−2 | 1.65 × 10−3 | 4.87 × 10−3 | ||

| 0.0% | 0.7% | 0.0% | 0.1% | 0.1% | 0.0% | ||||

| B4 | Replacement materials | 3.13 × 10 | 4.99 × 10−7 | 8.49 × 10−2 | 1.23 × 10−1 | 2.24 × 10−2 | 2.21 × 10−2 | ||

| 0.6% | 0.5% | 0.2% | 1.0% | 1.2% | 0.2% | ||||

| C1 | Deconstruction | 1.28 | 5.02 × 10−11 | 8.55 × 10−3 | 1.04 | 4.46 × 10−4 | 9.23 × 10−5 | ||

| 0.0% | 0.0% | 0.0% | 8.7% | 0.0% | 0.0% | ||||

| C2 | Transportation | 1.99 | 7.44 × 10−7 | 1.35 × 10−2 | 9.69 × 10−3 | 1.58 × 10−3 | 4.72 × 10−3 | ||

| 0.0% | 0.7% | 0.0% | 0.1% | 0.1% | 0.0% | ||||

| C4 | Disposal | 9.83 × 100 | 3.16 × 10−7 | 1.39 × 10−2 | 4.27 × 10−2 | 7.57 × 10−3 | 3.30 × 10−3 | ||

| 0.2% | 0.3% | 0.0% | 0.4% | 0.4% | 0.0% | ||||

| B6 | Operational Energy | 4.54 × 103 | 9.96 × 10−6 | 2.87 × 10 | 8.30 | 1.48 | 2.03 × 10−1 | ||

| 89.4% | 9.5% | 71.8% | 70.0% | 81.1% | 1.9% | ||||

| Subtotal () | 5.08 × 103 | 5.08 × 103 | 1.05 × 10−4 | 3.99 × 10 | 1.19 × 10 | 1.83 | |||

| 100.0% | 100.0% | 100.0% | 100.0% | 100.0% | 100.0% | ||||

| 0.84 | 626.76 | 1.04 | 1.16 | 0.96 | 250.09 | ||||

| The Six Impact Assessments | GWP [tCO2-eq] | ODP [tCFC11-eq] | ADP [tSb-eq] | AP [tSO2-eq] | EP [tPO43-eq] | POCP [tC2H4-eq] | |

|---|---|---|---|---|---|---|---|

| Cement Mortar (Remittal) | Existing Materials | 4.310 × 10−1 | 1.460 × 10−8 | 1.780 × 10−3 | 7.370 × 10−4 | 1.140 × 10−4 | 2.370 × 10−4 |

| EPD With Low-Carbon | 1.867 × 10−1 | 6.365 × 10−9 | 8.017 × 10−4 | 3.009 × 10−4 | 3.704 × 10−5 | 1.736 × 10−4 | |

| Ratio (%) | −56.67% | −56.40% | −54.96% | −59.17% | −67.51% | −26.77% | |

| Windows | Existing Materials | 1.398 | 3.093 × 10−8 | 1.675 × 10−2 | 3.073 × 10−3 | 6.387 × 10−4 | 1.734 × 10−3 |

| EPD With Low-Carbon | 1.373 | 7.561 × 10−5 | 1.593 × 10−2 | 2.784 × 10−3 | 6.933 × 10−4 | 6.459 × 10−3 | |

| Ratio (%) | −1.81% | 244,327.4% | −4.92% | −9.42% | 8.53% | 272.49% | |

| Insulation (PIR) | Existing Materials | 5.138 | 1.383 × 10−5 | 4.000 × 10−2 | 2.725 × 10−2 | 2.224 × 10−2 | 1.105 × 10−2 |

| EPD With Low-Carbon | 4.931 | 6.297 × 10−7 | 4.062 × 10−2 | 2.452 × 10−2 | 1.233 × 10−2 | 5.104 × 10−3 | |

| Ratio (%) | −4.03% | −95.45% | 1.54% | −10.01% | −44.57% | −53.81% | |

| Board-Tex/ Gypsum-Cement-Based Tex | Existing Materials | 9.063 × 10−1 | 1.176 × 10−7 | 4.534 × 10−3 | 3.401 × 10−3 | 6.528 × 10−4 | 9.616 × 10−4 |

| EPD With Low-Carbon | 1.027 × 10−1 | 4.203 × 10−6 | 7.768 × 10−4 | 3.469 × 10−4 | 4.631 × 10−5 | 3.100 × 10−5 | |

| Ratio (%) | −88.67% | 3475.54% | −82.87% | −89.80% | −92.91% | −96.78% | |

| Concrete/ 21 MPa or less | Existing Materials | 1.780 × 10−1 | 2.023 × 10−8 | 8.757 × 10−4 | 2.965 × 10−4 | 3.460 × 10−5 | 5.135 × 10−4 |

| EPD With Low-Carbon | 9.098 × 10−2 | 3.891 × 10−9 | 3.635 × 10−4 | 1.354 × 10−4 | 1.729 × 10−5 | 7.644 × 10−5 | |

| Ratio (%) | −48.89% | −80.77% | −58.49% | −54.34% | −50.02% | −85.11% | |

| Board-Tex/ Gypsum Board | Existing Materials | 1.378 × 10−1 | 1.418 × 10−8 | 1.035 × 10−3 | 7.823 × 10−4 | 1.319 × 10−4 | 2.718 × 10−4 |

| EPD With Low-Carbon | 1.964 × 10−2 | 4.237 × 10−6 | 1.413 × 10−4 | 7.419 × 10−5 | 1.170 × 10−5 | 1.579 × 10−5 | |

| Ratio (%) | −85.75% | 29778.42% | −86.35% | −90.52% | −91.13% | −94.19% | |

| Insulation (XPS) | Existing Materials | 3.405 | 1.412 × 10−7 | 5.459 × 10−6 | 1.930 × 10−2 | 1.075 × 10−3 | 5.262 × 10−3 |

| EPD Materials | 2.445 | 1.220 × 10−4 | 2.225 × 10−2 | 5.587 × 10−3 | 7.155 × 10−4 | 8.763 × 10−3 | |

| Ratio (%) | −28.19% | 86,273.90% | 407,532.3% | −71.05% | −33.43% | 66.54% | |

| EI Assessment | GWP [tCO2-eq] | ODP [tCFC-eq] | ADP [tSb-eq] | AP [tSO2-eq] | EP [tPO43-eq] | POCP [tC2H4-eq] | |

|---|---|---|---|---|---|---|---|

| Material Production [A1–A3] | Original | 4.898 × 102 | 9.247 × 10−5 | 1.111 × 10 | 2.338 | 3.123 × 10−1 | 1.053 × 10 |

| Proposed | 4.805 × 102 | 7.485 × 10−4 | 1.108 × 10 | 2.297 | 2.478 × 10−1 | 1.054 × 10−2 | |

| Ratio (%) | −1.89 | 709.44 | −0.30 | −1.75 | −20.64 | 0.03 | |

| Construction [A4] | Original | 2.036 | 7.371 × 10−7 | 1.383 × 10−2 | 1.009 × 10−2 | 1.654 × 10−3 | 4.873 × 10−3 |

| Proposed | Same as original draft | ||||||

| Ratio (%) | -. | ||||||

| Operational (material replacement) [B4] | Draft | 3.126 × 10 | 4.989 × 10−7 | 8.494 × 10−2 | 1.230 × 10−1 | 2.243 × 10−2 | 2.210 × 10−2 |

| Suggestion | 2.979 × 10 | 1.856 × 10−5 | 7.794 × 10−2 | 1.174 × 10−1 | 2.133 × 10−2 | 2.105 × 10−2 | |

| Ratio (%) | −4.72 | 3619.88 | −8.24 | −4.58 | −4.92 | −4.72 | |

| Operational [B6] | Original | 4.541 × 103 | 9.964 × 10−6 | 2.867 × 10 | 8.296 | 1.483 | 2.033 × 10−1 |

| Proposed | Same as original draft | ||||||

| Ratio (%) | -. | ||||||

| Disposal [C1~C2,C4] | Original | 1.309 × 10 | 1.060 × 10−6 | 3.597 × 10−2 | 1.087 | 9.596 × 10−3 | 8.109 × 10−3 |

| Proposed | Same as original draft | ||||||

| Ratio (%) | -. | ||||||

| Total | Original | 5.077 × 103 | 1.047 × 10−4 | 3.992 × 10 | 1.185 × 10 | 1.829 | 1.077 × 10 |

| Proposed | 5.066 × 103 | 7.788 × 10−4 | 3.988 × 10 | 1.181 × 10 | 1.763 | 1.077 × 10 | |

| Ratio (%) | −0.21 | 643.64 | −0.10 | −0.39 | −3.58 | 0.02 | |

| Separation | GWP [tCO2-eq] | ODP [tCFC-11-eq] | ADP [tSb-eq] | AP [tSO2-eq] | EP [tPO43-eq] | POCP [tC2H4-eq] | |||

|---|---|---|---|---|---|---|---|---|---|

| Original (First GR-LCA) | Before GR | B6 | 6.05 × 103 | 1.67 × 10−7 | 3.82 × 10 | 1.02 × 10 | 1.90 | 4.31 × 10−2 | |

| 100.00% | 100.00% | 100.00% | 100.00% | 100.00% | 100.00% | ||||

| After GR | m | A1 to A3 | 4.90 × 102 | 9.25 × 10−5 | 1.11 × 10 | 2.34 | 3.12 × 10−1 | 1.05 × 10 | |

| 9.60% | 88.30% | 27.80% | 19.70% | 17.10% | 97.80% | ||||

| A4 | 2.04 | 7.37 × 10−7 | 1.38 × 10−2 | 1.01 × 10−2 | 1.65 × 10−3 | 4.87 × 10−3 | |||

| 0.00% | 0.70% | 0.00% | 0.10% | 0.10% | 0.00% | ||||

| B4 | 3.13 × 10 | 4.99 × 10−7 | 8.49 × 10−2 | 1.23 × 10−1 | 2.24 × 10−2 | 2.21 × 10−2 | |||

| 0.60% | 0.50% | 0.20% | 1.00% | 1.20% | 0.20% | ||||

| C1 | 1.28 | 5.02 × 10−11 | 8.55 × 10−3 | 1.04 × 100 | 4.46 × 10−4 | 9.23 × 10−5 | |||

| 0.00% | 0.00% | 0.00% | 8.70% | 0.00% | 0.00% | ||||

| C2 | 1.99 | 7.44 × 10−7 | 1.35 × 10−2 | 9.69 × 10−3 | 1.58 × 10−3 | 4.72 × 10−3 | |||

| 0.00% | 0.70% | 0.00% | 0.10% | 0.10% | 0.00% | ||||

| C4 | 9.83 | 3.16 × 10−7 | 1.39 × 10−2 | 4.27 × 10−2 | 7.57 × 10−3 | 3.30 × 10−3 | |||

| 0.20% | 0.30% | 0.00% | 0.40% | 0.40% | 0.00% | ||||

| B6 | 4.54 × 103 | 9.96 × 10−6 | 2.87 × 10 | 8.30 × 100 | 1.48 | 2.03 × 10−1 | |||

| 89.40% | 9.50% | 71.80% | 70.00% | 81.10% | 1.90% | ||||

| Subtotal () | 5.08 × 103 | 1.05 × 10−4 | 3.99 × 10 | 1.19 × 10 | 1.83 | 1.08 × 10 | |||

| 100.00% | 100.00% | 100.00% | 100.00% | 100.00% | 100.00% | ||||

| 0.840 | 626.764 | 1.044 | 1.160 | 0.961 | 250.090 | ||||

| Proposed (Second GR-LCA) | Before GR | B6 | 6.05 × 103 | 1.67 × 10−7 | 3.82 × 10 | 1.02 × 10 | 1.90 | 4.31 × 10−2 | |

| 100.00% | 100.00% | 100.00% | 100.00% | 100.00% | 100.00% | ||||

| After GR | m | A1 to A3 | 4.80 × 102 | 7.49 × 10−4 | 1.11 × 10 | 2.30 × 100 | 2.48 × 10−1 | 1.05 × 10 | |

| 9.50% | 96.10% | 27.80% | 19.50% | 14.10% | 97.80% | ||||

| A4 | 2.04 | 7.37 × 10−7 | 1.38 × 10−2 | 1.01 × 10−2 | 1.65 × 10−3 | 4.87 × 103 | |||

| 0.00% | 0.10% | 0.00% | 0.10% | 0.10% | 0.00% | ||||

| B4 | 2.98 × 10 | 1.86 × 10−5 | 7.79 × 10−2 | 1.17 × 10−1 | 2.13 × 10−2 | 2.11 × 10−2 | |||

| 0.60% | 2.40% | 0.20% | 1.00% | 1.20% | 0.20% | ||||

| C1 | 1.28 | 5.02 × 10−11 | 8.55 × 10−3 | 1.04 × 100 | 4.46 × 10−4 | 9.23 × 10−5 | |||

| 0.00% | 0.00% | 0.00% | 8.80% | 0.00% | 0.00% | ||||

| C2 | 1.99 | 7.44 × 10−7 | 1.35 × 10−2 | 9.69 × 10−3 | 1.58 × 10−3 | 4.72 × 10−3 | |||

| 0.00% | 0.10% | 0.00% | 0.10% | 0.10% | 0.00% | ||||

| C4 | 9.83 | 3.16 × 10−7 | 1.39 × 10−2 | 4.27 × 10−2 | 7.57 × 10−3 | 3.30 × 10−3 | |||

| 0.20% | 0.00% | 0.00% | 0.40% | 0.40% | 0.00% | ||||

| B6 | 4.54 × 103 | 9.96 × 10−6 | 2.87 × 10 | 8.30 × 100 | 1.48 | 2.03 × 10−1 | |||

| 89.60% | 1.30% | 71.90% | 70.30% | 84.10% | 1.90% | ||||

| Subtotal () | 5.07 × 103 | 7.79 × 10−4 | 3.99 × 10 | 1.18 × 1 | 1.76 | 1.08 × 10 | |||

| 100.00% | 100.00% | 100.00% | 100.00% | 100.00% | 100.00% | ||||

| 0.838 | 4660.892 | 1.043 | 1.155 | 0.927 | 250.131 | ||||

| Original vs. Proposal Percentage Increase or Decrease | −0.21 | 643.64 | −0.10 | −0.39 | −3.58 | 0.02 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Ko, W.; Kim, J.; Byun, J.; Nam, S.; Jeong, S. Analyzing the Environmental Impacts and Empirical Limitations of Green Remodeling with Life Cycle Assessment. Buildings 2025, 15, 783. https://doi.org/10.3390/buildings15050783

Kim J, Ko W, Kim J, Byun J, Nam S, Jeong S. Analyzing the Environmental Impacts and Empirical Limitations of Green Remodeling with Life Cycle Assessment. Buildings. 2025; 15(5):783. https://doi.org/10.3390/buildings15050783

Chicago/Turabian StyleKim, Jaemoon, Wonkyeong Ko, Jaehee Kim, Jiyeon Byun, Seonghoon Nam, and Subin Jeong. 2025. "Analyzing the Environmental Impacts and Empirical Limitations of Green Remodeling with Life Cycle Assessment" Buildings 15, no. 5: 783. https://doi.org/10.3390/buildings15050783

APA StyleKim, J., Ko, W., Kim, J., Byun, J., Nam, S., & Jeong, S. (2025). Analyzing the Environmental Impacts and Empirical Limitations of Green Remodeling with Life Cycle Assessment. Buildings, 15(5), 783. https://doi.org/10.3390/buildings15050783