Strength Characteristics and Prediction of Ternary Blended Cement Building Material Using RSM and ANN

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mortar Preparation and Testing

2.3. Mathematical Models

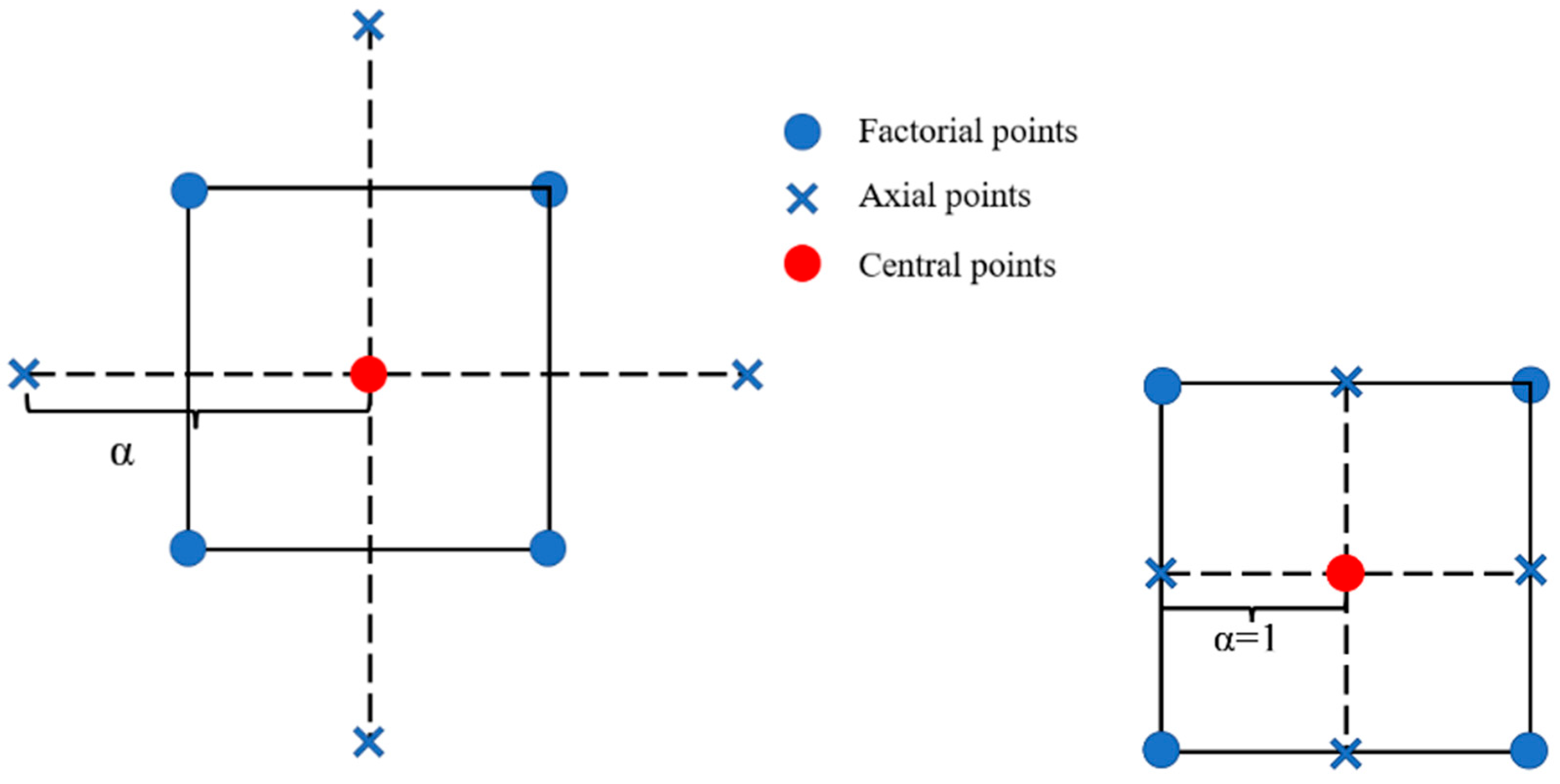

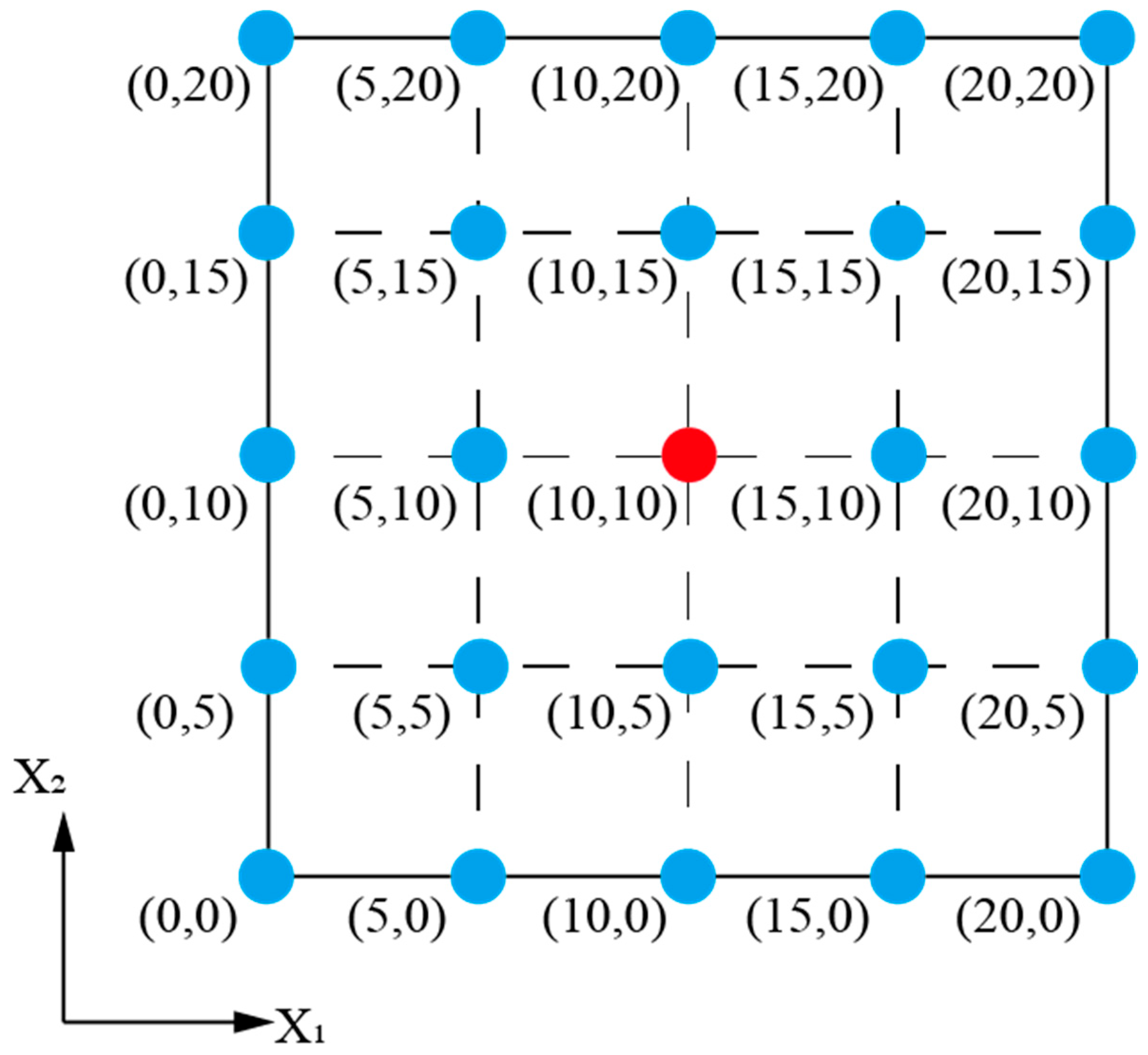

2.3.1. Response-Surface Methodology (RSM)

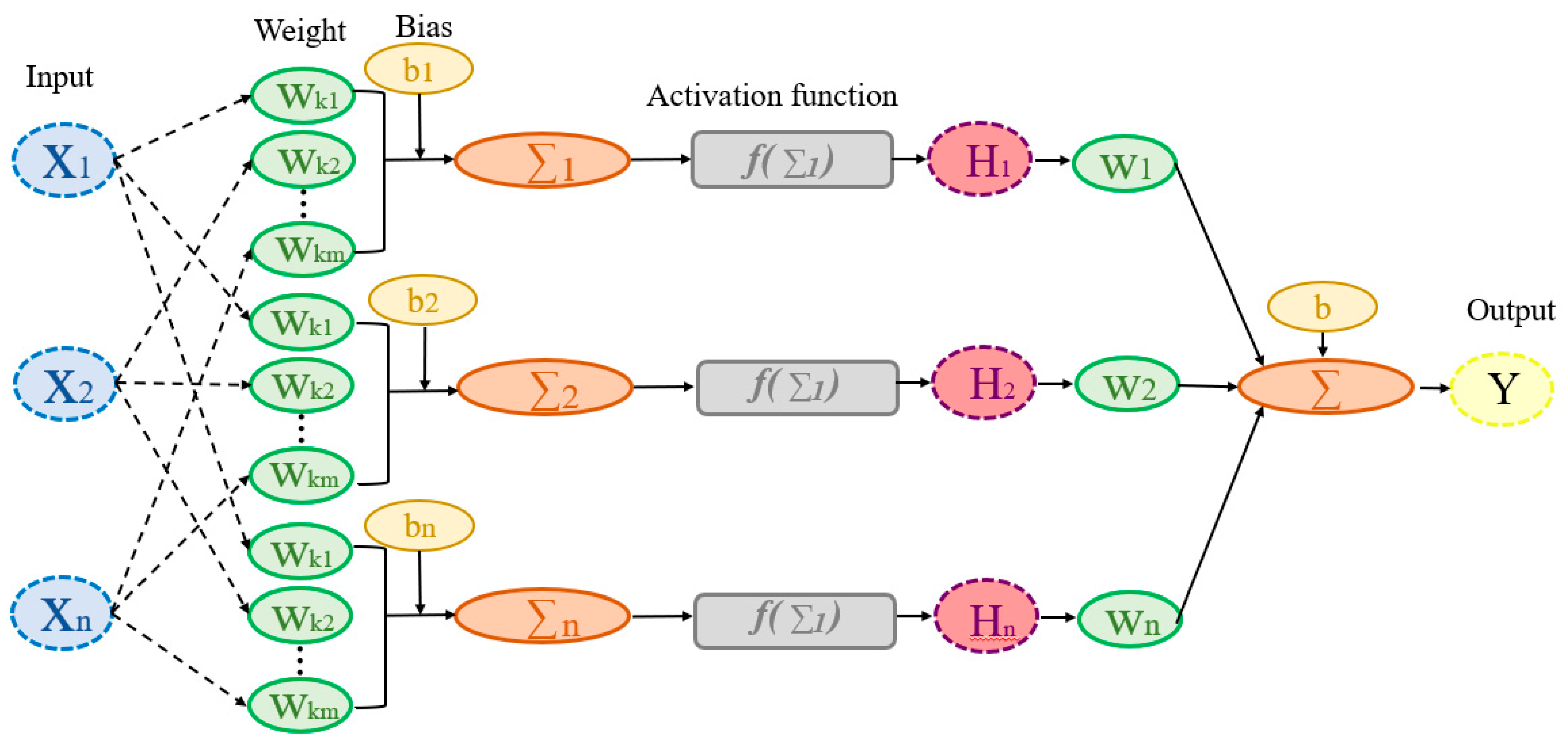

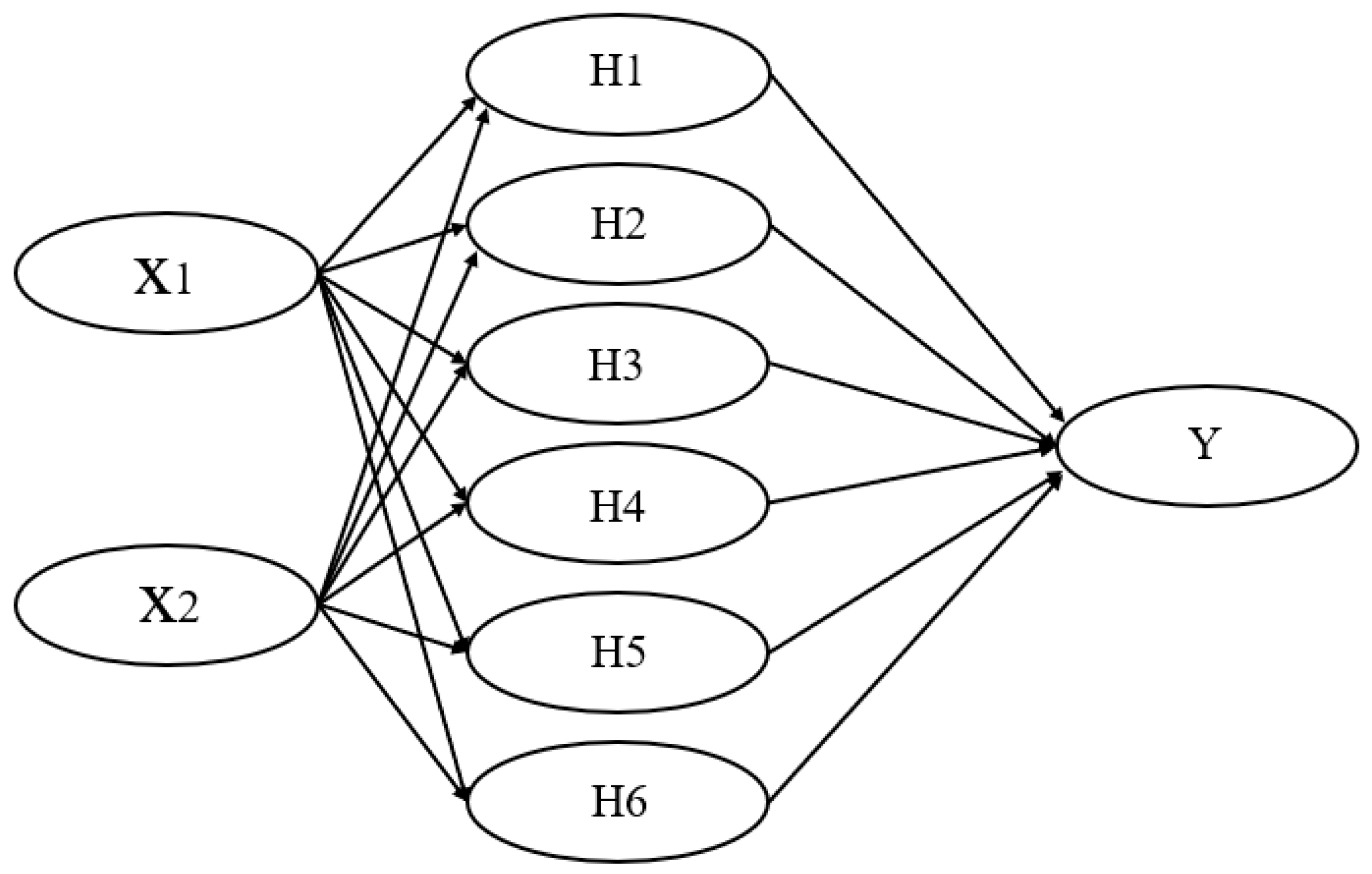

2.3.2. Artificial Neutral Network

2.3.3. Model Validation and Comparison

- (a)

- Coefficient of correlation (R)

- (b)

- Coefficient of determination (R2)

- (c)

- Chi-square (χ2)

- (d)

- Mean square error (MSE)

- (e)

- Root mean square error (RMSE)

- (f)

- Mean absolute error (MAE)

- (g)

- Standard error of prediction (SEP)

3. Results and Analysis

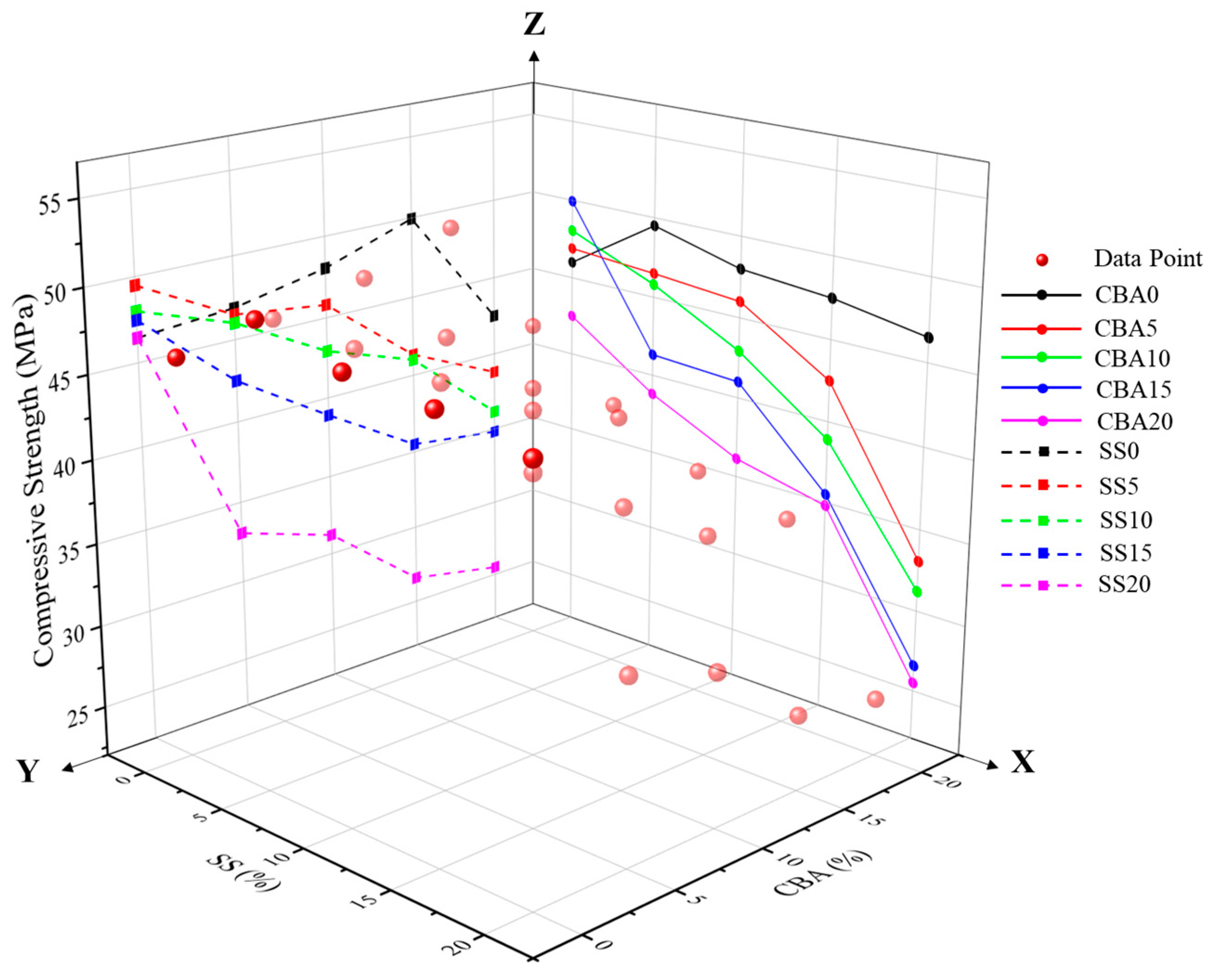

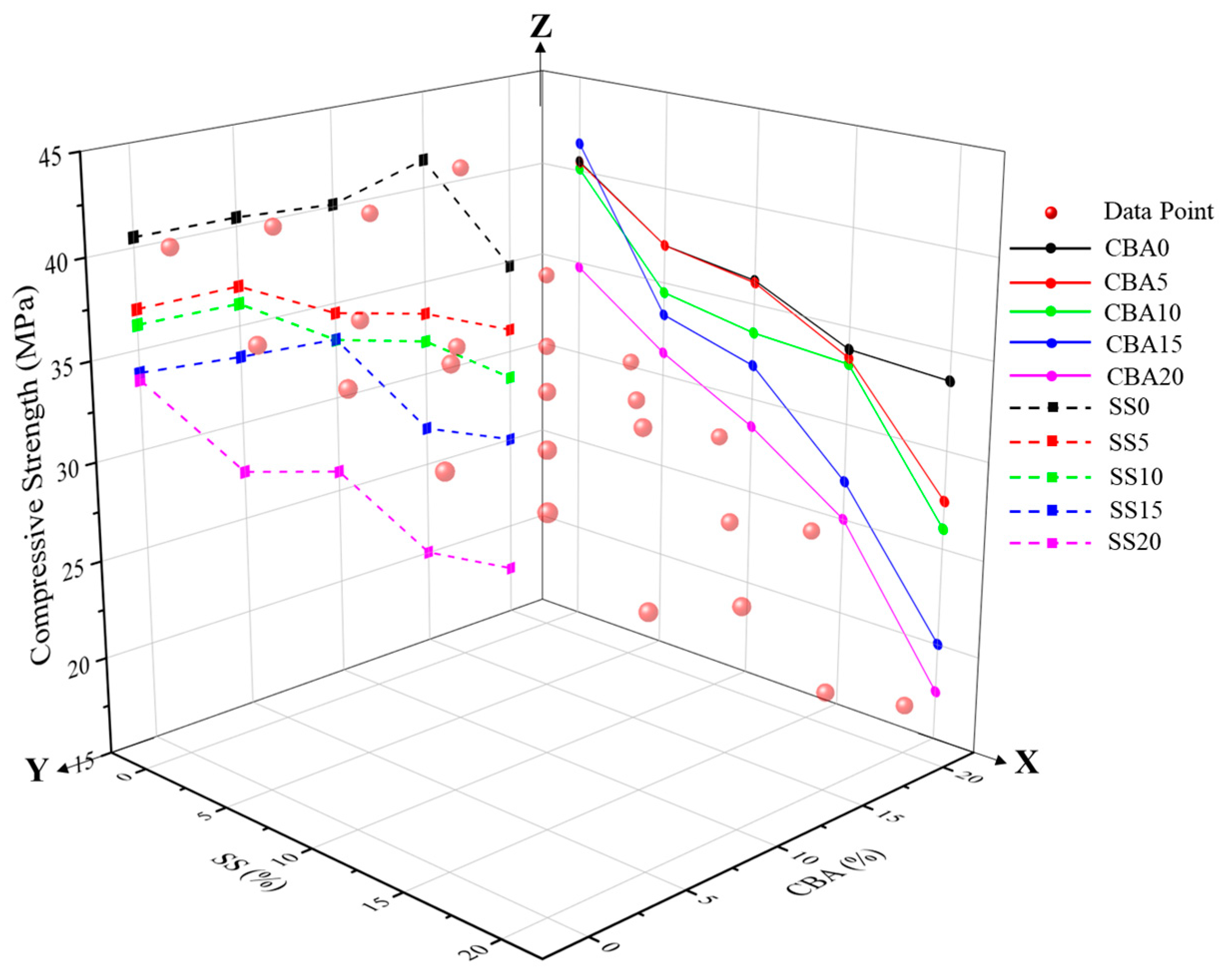

3.1. Compressive Strength

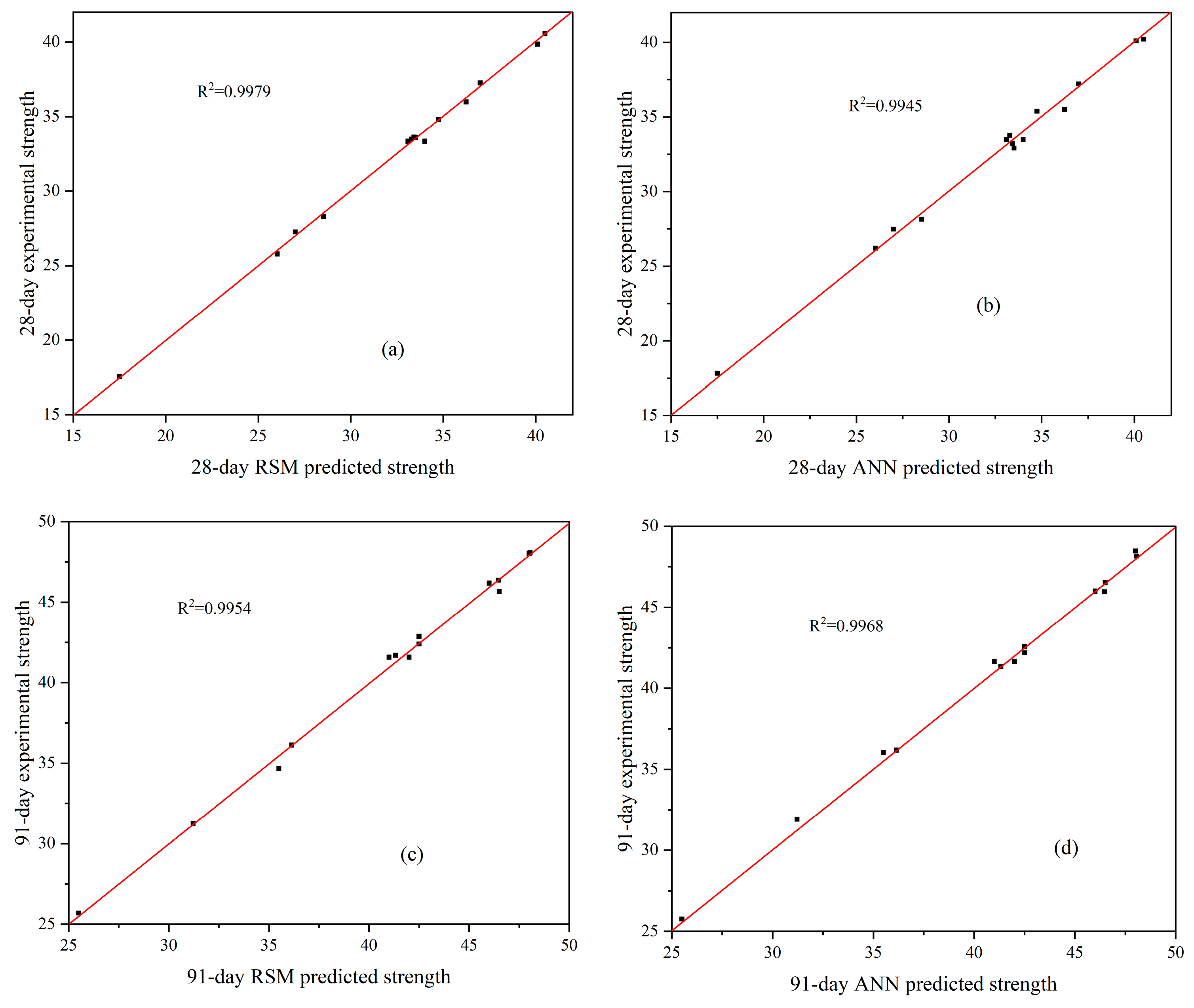

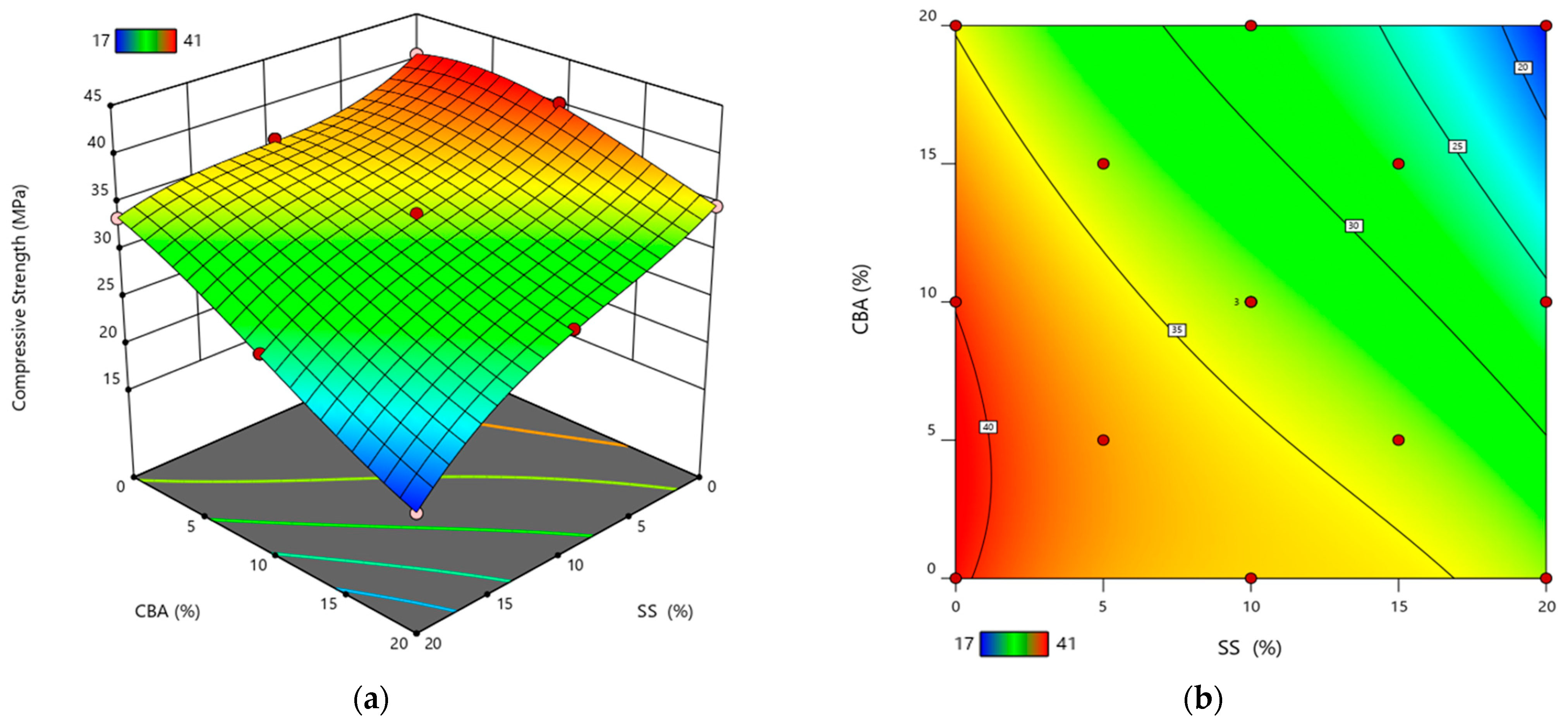

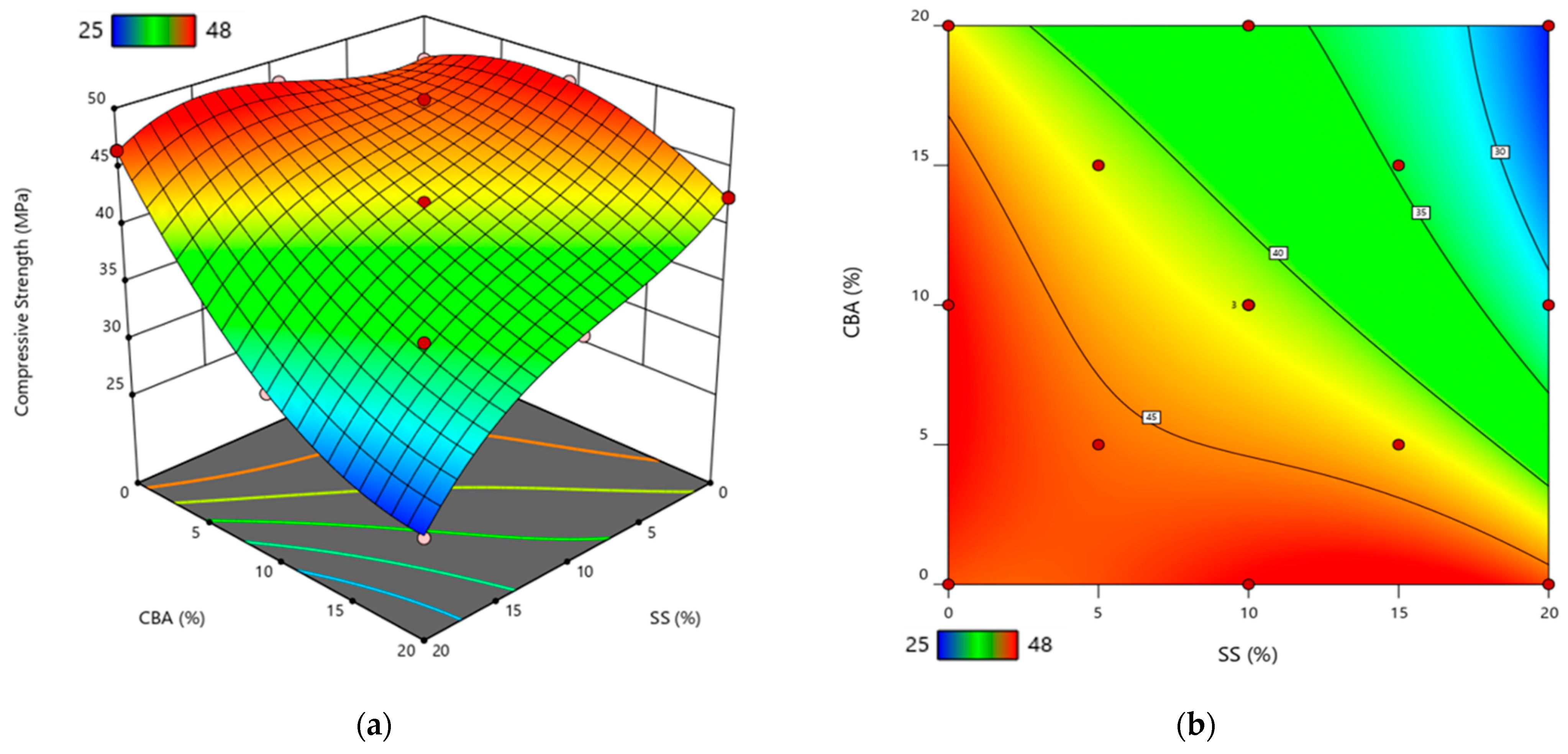

3.2. RSM Modeling

3.3. ANN

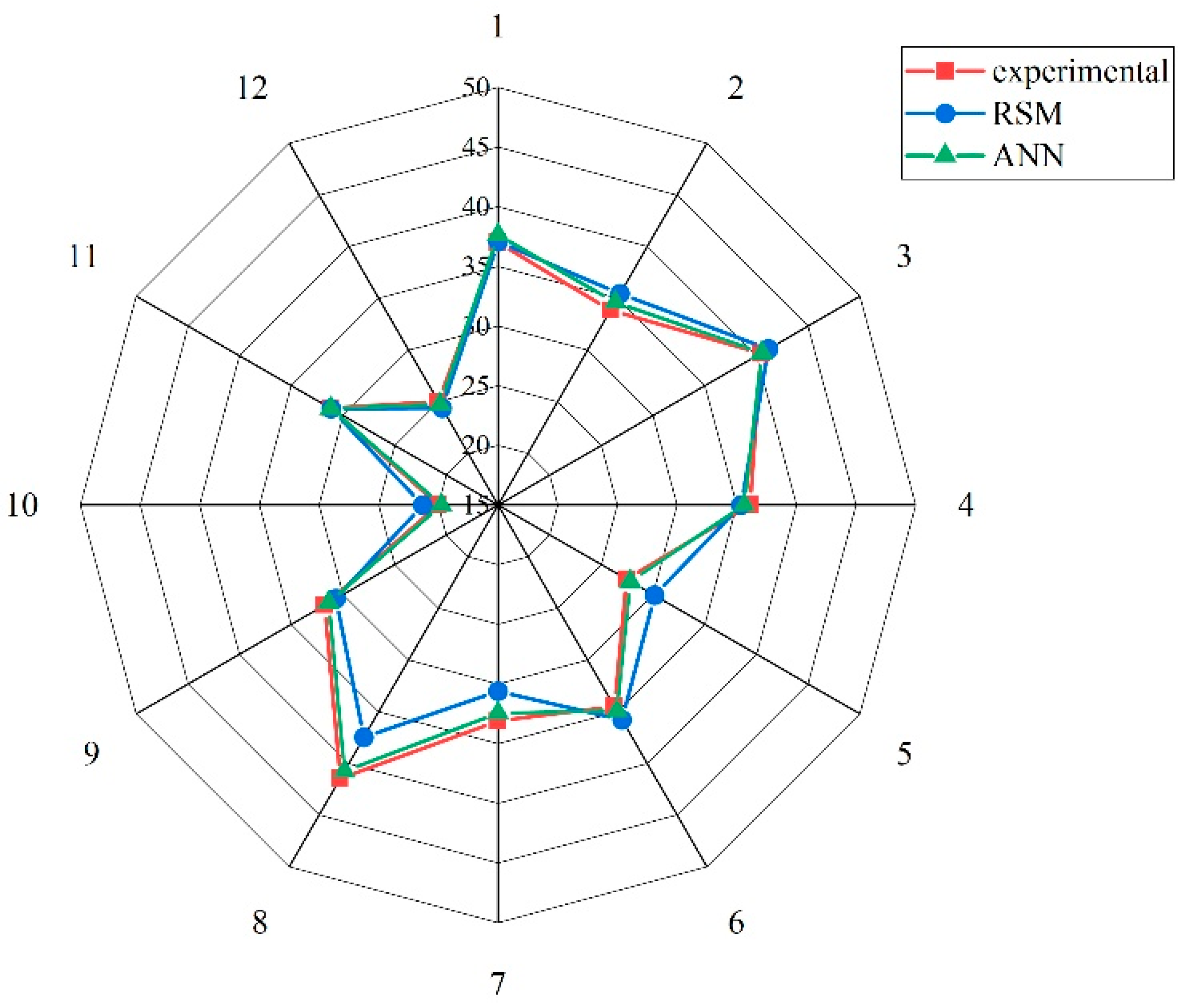

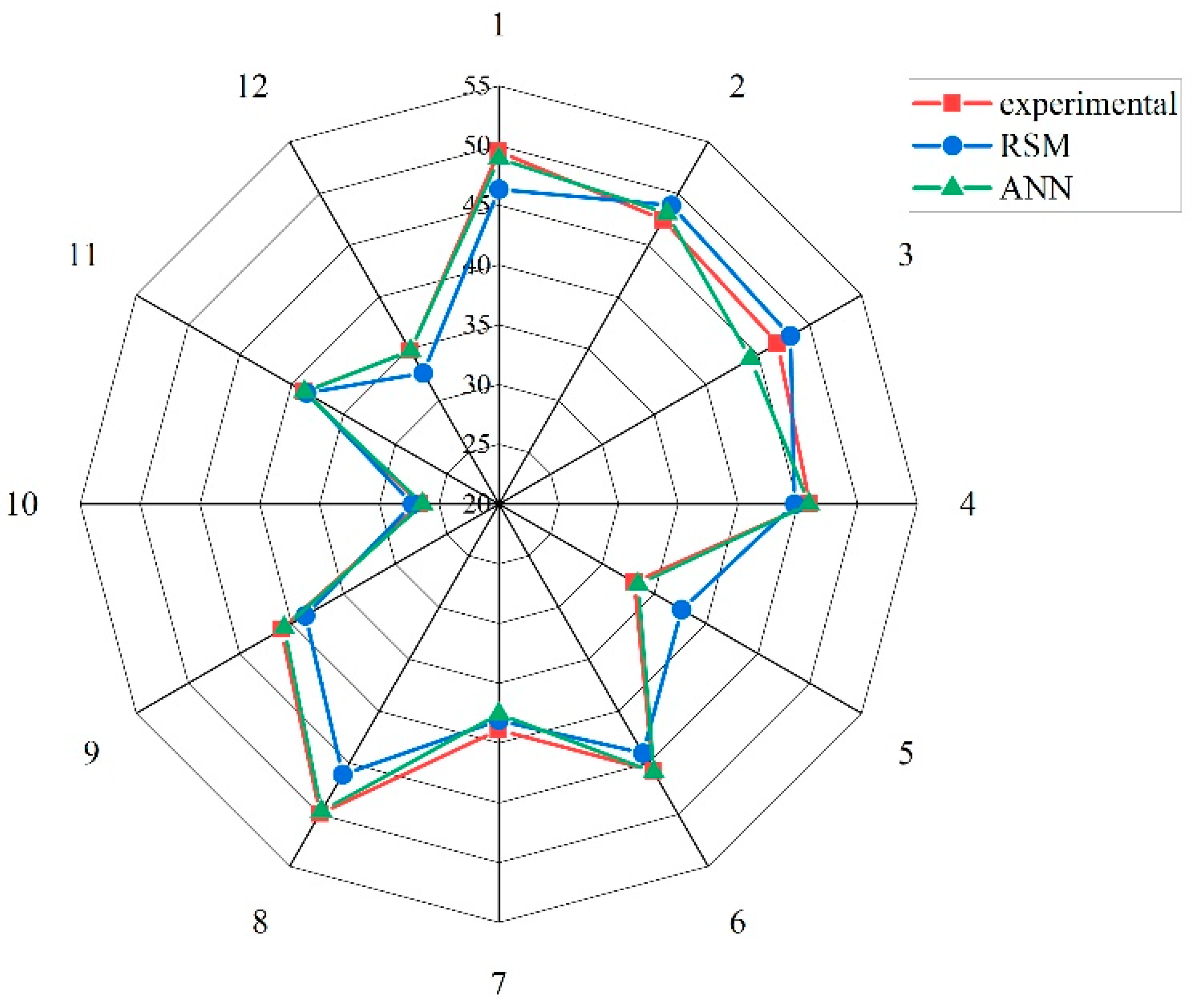

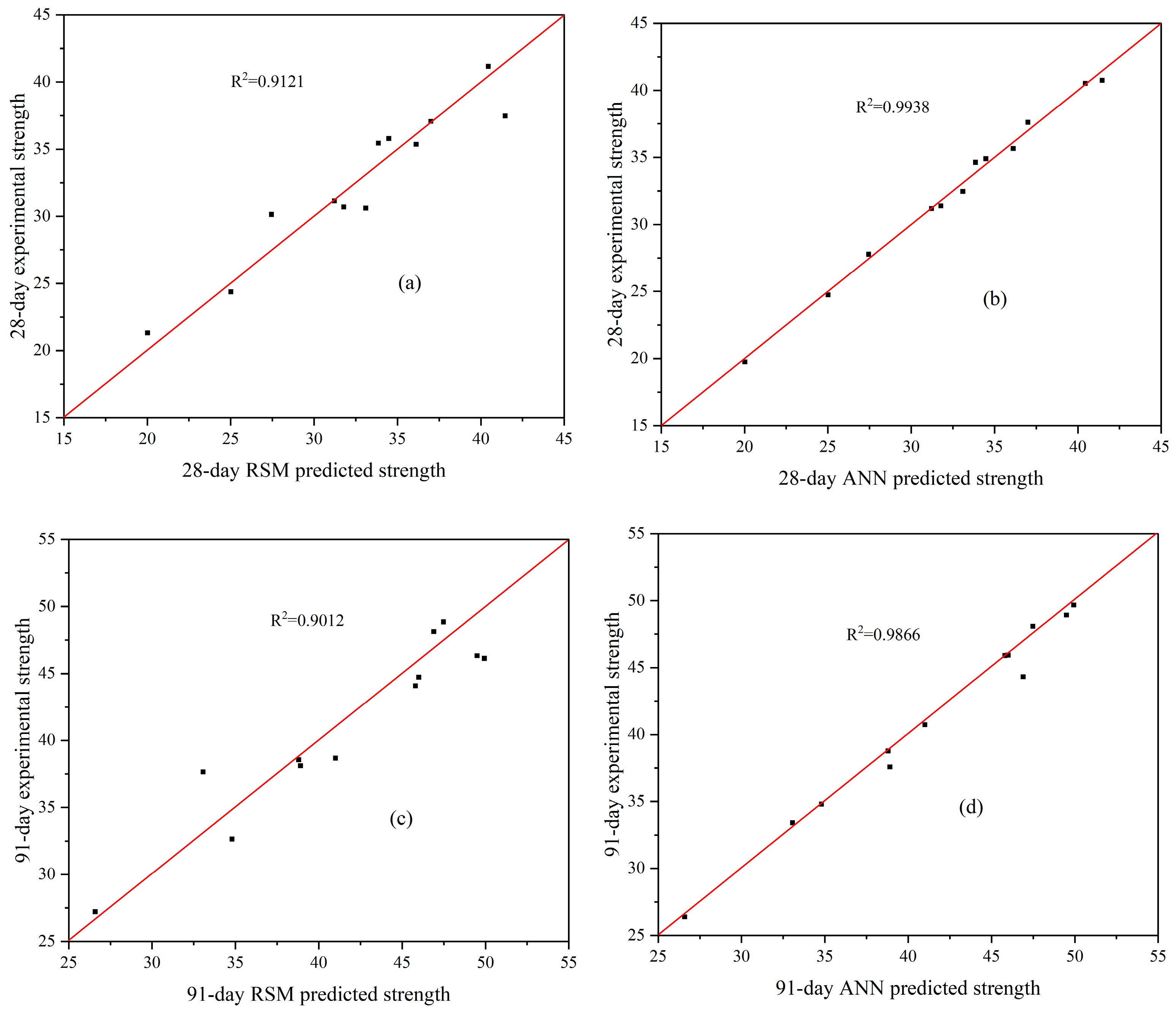

3.4. Validation and Comparison of RSM and ANN Models

4. Conclusions

- (a)

- At each fixed GCBA level, the increase in the SS content led to a reduction in the 28-day and 91-day strength. Similarly, at each fixed SS level, the increase in GCBA content led to a decrease in strength. By comparing the strength reduction, it was determined that the addition of GCBA had a less negative effect at a low SS content level compared to a high SS content level. However, the use of individual SCMs enhanced mortar strength with 5% of SS and 15% of GCBA, respectively.

- (b)

- Prolonging the curing age resulted in the strength enhancement of each mix, demonstrating that the combined use of SS and GCBA did not have a negative effect on strength.

- (c)

- A set of data consisting of 15 data points was used to establish an RSM model of 28-day and 91-day strength. According to the ANOVA analysis, the R2 values of 0.9979 and 0.9954 for the 28-day and 91-day strength models indicate that the obtained models were well-fitted with the experimental data. The predicted R2 of 0.9688 and 0.9633 for the 28-day and 91-day strength models implies a good performance in prediction.

- (d)

- By analyzing the 3D response-surface plots and 2D contour plots of 28-day and 91-day strength, it was found that the synergy between the pozzolanic properties of GCBA and the low hydration rate of SS resulted in a difference in the strength distribution at the 28-day and 91-day curing ages.

- (e)

- A set of data consisting of 12 data points was used for validating the performance of the RSM models and ANN models by comparing the R2 of experimental values vs. RSM-predicted values and experimental values vs. ANN-predicted values. The higher R2 value indicates that the ANN has a better performance in the strength prediction of 28-day and 91-day strength.

5. Recommendations

- (a)

- It is recommended that future studies incorporate comprehensive chemical analyses of GCBA and SS to establish a clearer understanding of their compositions and reactivity.

- (b)

- The application of advanced machine-learning algorithms should be considered to refine predictive models of the mechanical properties of ternary blended mortars.

- (c)

- Future research could investigate a broader spectrum of replacement ratios beyond the 0% to 40% range used in this study. Investigating higher replacement ratios could provide valuable information on the point of diminishing returns regarding strength and performance criteria.

- (d)

- Long-term studies examining the durability and degradation of ternary blended mortars over time under various environmental conditions should also be investigated. This will help to assess the longevity and resilience of using GCBA and SS as supplementary cementitious materials.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- US Geological Survey. Mineral Commodity Summaries; US Geological Survey: Reston, VA, USA, 2022. Available online: https://pubs.usgs.gov/publication/mcs2022 (accessed on 31 January 2022).

- He, Z.; Zhu, X.; Wang, J.; Mu, M.; Wang, Y. Comparison of CO2 emissions from OPC and recycled cement production. Constr. Build. Mater. 2019, 211, 965–973. [Google Scholar] [CrossRef]

- Naqi, A.; Jang, J.G. Recent progress in green cement technology utilizing low-carbon emission fuels and raw materials: A review. Sustainability 2019, 11, 537. [Google Scholar] [CrossRef]

- Nie, S.; Zhou, J.; Yang, F.; Lan, M.; Li, J.; Zhang, Z.; Chen, Z.; Xu, M.; Li, H.; Sanjayan, J.G. Analysis of theoretical carbon dioxide emissions from cement production: Methodology and application. J. Clean. Prod. 2022, 334, 130270. [Google Scholar] [CrossRef]

- Pavlíková, M.; Zemanová, L.; Záleská, M.; Pokorný, J.; Lojka, M.; Jankovský, O.; Pavlík, Z. Ternary blended binder for production of a novel type of lightweight repair mortar. Materials 2019, 12, 996. [Google Scholar] [CrossRef] [PubMed]

- Hamada, H.M.; Al-Attar, A.; Shi, J.; Yahaya, F.; Al Jawahery, M.S.; Yousif, S.T. Optimization of sustainable concrete characteristics incorporating palm oil clinker and nano-palm oil fuel ash using response surface methodology. Powder Technol. 2023, 413, 118054. [Google Scholar] [CrossRef]

- Raghav, M.; Park, T.; Yang, H.-M.; Lee, S.-Y.; Karthick, S.; Lee, H.-S. Review of the effects of supplementary cementitious materials and chemical additives on the physical, mechanical and durability properties of hydraulic concrete. Materials 2021, 14, 7270. [Google Scholar] [CrossRef]

- Aydın, S. A ternary optimisation of mineral additives of alkali activated cement mortars. Constr. Build. Mater. 2013, 43, 131–138. [Google Scholar] [CrossRef]

- Shubbar, A.A.; Jafer, H.; Dulaimi, A.; Hashim, K.; Atherton, W.; Sadique, M. The development of a low carbon binder produced from the ternary blending of cement, ground granulated blast furnace slag and high calcium fly ash: An experimental and statistical approach. Constr. Build. Mater. 2018, 187, 1051–1060. [Google Scholar] [CrossRef]

- Özkan, Ö.; Yüksel, I.; Muratoğlu, Ö. Strength properties of concrete incorporating coal bottom ash and granulated blast furnace slag. Waste Manag. 2007, 27, 161–167. [Google Scholar] [CrossRef]

- Chen, J.; Ng, P.L.; Chu, S.; Guan, G.; Kwan, A. Ternary blending with metakaolin and silica fume to improve packing density and performance of binder paste. Constr. Build. Mater. 2020, 252, 119031. [Google Scholar] [CrossRef]

- Kumar, R.; Shafiq, N.; Kumar, A.; Jhatial, A.A. Investigating embodied carbon, mechanical properties, and durability of high-performance concrete using ternary and quaternary blends of metakaolin, nano-silica, and fly ash. Environ. Sci. Pollut. Res. 2021, 28, 49074–49088. [Google Scholar] [CrossRef] [PubMed]

- Vance, K.; Kumar, A.; Sant, G.; Neithalath, N. The rheological properties of ternary binders containing Portland cement, limestone, and metakaolin or fly ash. Cem. Concr. Res. 2013, 52, 196–207. [Google Scholar] [CrossRef]

- Cheah, C.B.; Liew, J.J.; Le Ping, K.K.; Siddique, R.; Tangchirapat, W. Properties of ternary blended cement containing ground granulated blast furnace slag and ground coal bottom ash. Constr. Build. Mater. 2022, 315, 125249. [Google Scholar] [CrossRef]

- Izadifar, M.; Ukrainczyk, N.; Koenders, E. Atomistic Insights into Silicate Dissolution of Metakaolinite under Alkaline Conditions: Ab Initio Quantum Mechanical Investigation. Langmuir 2024, 40, 19332–19342. [Google Scholar] [CrossRef] [PubMed]

- Sekkal, W.; Izadifar, M.; Zaoui, A.; Ukrainczyk, N.; Koenders, E. Theoretical investigation of protective graphene-coated metakaolin geopolymer interface under moisture and chemical composition effects. Powder Technol. 2023, 430, 119007. [Google Scholar] [CrossRef]

- Alani, A.H.; Johari, M.A.M.; Aldahdooh, M.; Muhamad Bunnori, N. Development of engineering and transport properties of green high strength concrete utilizing ternary blended binders. Eur. J. Environ. Civil Eng. 2021, 25, 1251–1267. [Google Scholar] [CrossRef]

- Juenger, M.C.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterization, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Talefirouz, D. Use of Granulated Blast Furnace Slag, Steel slag and Fly Ash in Cement Bentonite Slurry Wall Construction. Master’s Thesis, Middle East Technical University, Ankara, Turkey, 2013. [Google Scholar]

- Martins, A.C.P.; De Carvalho, J.M.F.; Costa, L.C.B.; Andrade, H.D.; de Melo, T.V.; Ribeiro, J.C.L.; Pedroti, L.G.; Peixoto, R.A.F. Steel slags in cement-based composites: An ultimate review on characterization, applications and performance. Constr. Build. Mater. 2021, 291, 123265. [Google Scholar] [CrossRef]

- Gao, D.; Wang, F.-P.; Wang, Y.-T.; Zeng, Y.-N. Sustainable utilization of steel slag from traditional industry and agriculture to catalysis. Sustainability 2020, 12, 9295. [Google Scholar] [CrossRef]

- Reddy, K.R.; Gopakumar, A.; Chetri, J.K. Critical review of applications of iron and steel slags for carbon sequestration and environmental remediation. Rev. Environ. Sci. Bio/Technol. 2019, 18, 127–152. [Google Scholar] [CrossRef]

- Yüksel, İ. A review of steel slag usage in construction industry for sustainable development. Environ. Dev. Sustain. 2017, 19, 369–384. [Google Scholar] [CrossRef]

- Hu, R.; Xie, J.; Wu, S.; Yang, C.; Yang, D. Study of toxicity assessment of heavy metals from steel slag and its asphalt mixture. Materials 2020, 13, 2768. [Google Scholar] [CrossRef] [PubMed]

- Navarro, C.; Díaz, M.; Villa-García, M.A. Physico-chemical characterization of steel slag. Study of its behavior under simulated environmental conditions. Environ. Sci. Technol. 2010, 44, 5383–5388. [Google Scholar] [CrossRef]

- Rosales, J.; Cabrera, M.; Agrela, F. Effect of stainless steel slag waste as a replacement for cement in mortars. Mechanical and statistical study. Build. Mater. 2017, 142, 444–458. [Google Scholar] [CrossRef]

- Saly, F.; Guo, L.; Ma, R.; Gu, C.; Sun, W. Properties of steel slag and stainless steel slag as cement replacement materials: A comparative study. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2018, 33, 1444–1451. [Google Scholar] [CrossRef]

- Wang, Q.; Yang, J.; Yan, P. Cementitious properties of super-fine steel slag. Powder Technol. 2013, 245, 35–39. [Google Scholar] [CrossRef]

- Palod, R.; Deo, S.; Ramtekkar, G. Effect on mechanical performance, early age shrinkage and electrical resistivity of ternary blended concrete containing blast furnace slag and steel slag. Mater. Today Proc. 2020, 32, 917–922. [Google Scholar] [CrossRef]

- Li, X.; Doh, S.; Ho, C.; Jing, G.; Ashraf, T. The investigation on properties of sodium sulfate-activated mortar incorporating steel slag with various replacement ratio and particle size. Phys. Chem. Earth Parts A/B/C 2022, 128, 103241. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, D.; Yan, P. Design and experimental study of a ternary blended cement containing high volume steel slag and blast-furnace slag based on Fuller distribution model. Constr. Build. Mater. 2017, 140, 248–256. [Google Scholar] [CrossRef]

- Liao, Y.; Jiang, G.; Wang, K.; Al Qunaynah, S.; Yuan, W. Effect of steel slag on the hydration and strength development of calcium sulfoaluminate cement. Constr. Build. Mater. 2020, 265, 120301. [Google Scholar] [CrossRef]

- Roslan, N.H.; Ismail, M.; Abdul-Majid, Z.; Ghoreishiamiri, S.; Muhammad, B. Performance of steel slag and steel sludge in concrete. Constr. Build. Mater. 2016, 104, 16–24. [Google Scholar] [CrossRef]

- Singh, N.; Bhardwaj, A. Reviewing the role of coal bottom ash as an alternative of cement. Constr. Build. Mater. 2020, 233, 117276. [Google Scholar] [CrossRef]

- Heidrich, C.; Feuerborn, H.-J.; Weir, A. Coal combustion products: A global perspective. In Proceedings of the World of Coal Ash Conference, Lexington, KY, USA, 24 April 2013; Volume 22, p. 25. [Google Scholar]

- Kim, H.-K. Utilization of sieved and ground coal bottom ash powders as a coarse binder in high-strength mortar to improve workability. Constr. Build. Mater. 2015, 91, 57–64. [Google Scholar] [CrossRef]

- Mangi, S.A.; Ibrahim, M.W.; Jamaluddin, N.; Arshad, M.; Ramadhansyah, P. Effects of ground coal bottom ash on the properties of concrete. J. Eng. Sci. Technol. 2019, 14, 338–350. [Google Scholar]

- Ibrahim, M.W.; Hamzah, A.; Jamaluddin, N.; Ramadhansyah, P.; Fadzil, A. Split tensile strength on self-compacting concrete containing coal bottom ash. Procedia Soc. Behav. Sci. 2015, 195, 2280–2289. [Google Scholar] [CrossRef][Green Version]

- Rafieizonooz, M.; Mirza, J.; Salim, M.R.; Hussin, M.W.; Khankhaje, E. Investigation of coal bottom ash and fly ash in concrete as replacement for sand and cement. Constr. Build. Mater. 2016, 116, 15–24. [Google Scholar] [CrossRef]

- Poudel, S.; Menda, S.; Useldinger-Hoefs, J.; Guteta, L.E.; Dockter, B.; Gedafa, D.S. The Use of Ground Coal Bottom Ash/Slag as a Cement Replacement for Sustainable Concrete Infrastructure. Materials 2024, 17, 2316. [Google Scholar] [CrossRef]

- Khan, R.A.; Ganesh, A. The effect of coal bottom ash (CBA) on mechanical and durability characteristics of concrete. J. Build. Mater. Struct. 2016, 3, 31–42. [Google Scholar] [CrossRef]

- Kasaniya, M.; Thomas, M.D.; Moffatt, E.G. Pozzolanic reactivity of natural pozzolans, ground glasses and coal bottom ashes and implication of their incorporation on the chloride permeability of concrete. Cem. Concr. Res. 2021, 139, 106259. [Google Scholar] [CrossRef]

- Abdulmatin, A.; Tangchirapat, W.; Jaturapitakkul, C. An investigation of bottom ash as a pozzolanic material. Constr. Build. Mater. 2018, 186, 155–162. [Google Scholar] [CrossRef]

- Hashemi, S.S.G.; Mahmud, H.B.; Djobo, J.N.Y.; Tan, C.G.; Ang, B.C.; Ranjbar, N. Microstructural characterization and mechanical properties of bottom ash mortar. J. Clean. Prod. 2018, 170, 797–804. [Google Scholar] [CrossRef]

- Habibi, A.; Ramezanianpour, A.M.; Mahdikhani, M.; Bamshad, O. RSM-based evaluation of mechanical and durability properties of recycled aggregate concrete containing GGBFS and silica fume. Constr. Build. Mater. 2021, 270, 121431. [Google Scholar] [CrossRef]

- Hammoudi, A.; Moussaceb, K.; Belebchouche, C.; Dahmoune, F. Comparison of artificial neural network (ANN) and response surface methodology (RSM) prediction in compressive strength of recycled concrete aggregates. Constr. Build. Mater. 2019, 209, 425–436. [Google Scholar] [CrossRef]

- Vishnupriyan, M.; Annadurai, R. A study on the macro-properties of PCB fiber-reinforced concrete from recycled electronic waste and validation of results using RSM and ANN. Asian J. Civil Eng. 2023, 24, 1667–1680. [Google Scholar] [CrossRef]

- Li, Z.; Lu, D.; Gao, X. Optimization of mixture proportions by statistical experimental design using response surface method—A review. J. Build. Eng. 2021, 36, 102101. [Google Scholar] [CrossRef]

- Poorarbabi, A.; Ghasemi, M.; Moghaddam, M.A. Concrete compressive strength prediction using non-destructive tests through response surface methodology. Ain Shams Eng. J. 2020, 11, 939–949. [Google Scholar] [CrossRef]

- Wang, X.; Wu, D.; Zhang, J.; Yu, R.; Hou, D.; Shui, Z. Design of sustainable ultra-high performance concrete: A review. Constr. Build. Mater. 2021, 307, 124643. [Google Scholar] [CrossRef]

- Ho, C.; Doh, S.; Li, X.; Chin, S.; Ashraf, T. RSM-based modelling of cement mortar with various water to cement ratio and steel slag content. Phys. Chem. Earth Parts A/B/C 2022, 128, 103256. [Google Scholar] [CrossRef]

- Moein, M.M.; Saradar, A.; Rahmati, K.; Mousavinejad, S.H.G.; Bristow, J.; Aramali, V.; Karakouzian, M. Predictive models for concrete properties using machine learning and deep learning approaches: A review. J. Build. Eng. 2023, 63, 105444. [Google Scholar] [CrossRef]

- Dabbaghi, F.; Rashidi, M.; Nehdi, M.L.; Sadeghi, H.; Karimaei, M.; Rasekh, H.; Qaderi, F. Experimental and informational modeling study on flexural strength of eco-friendly concrete incorporating coal waste. Sustainability 2021, 13, 7506. [Google Scholar] [CrossRef]

- Awolusi, T.; Oke, O.; Akinkurolere, O.; Sojobi, A. Application of response surface methodology: Predicting and optimizing the properties of concrete containing steel fibre extracted from waste tires with limestone powder as filler. Case Stud. Constr. Mater. 2019, 10, e00212. [Google Scholar] [CrossRef]

- BS EN 197-1:2011; Methods of Testing Composition, Specifications and Conformity Criteria for Common Cements. BSI: London, UK, 2011.

- BS EN 12620:2013; Aggregates for Concrete. BSI: London, UK, 2013.

- Argiz, C.; Sanjuán, M.Á.; Menéndez, E. Coal bottom ash for Portland cement production. Adv. Mater. Sci. Eng. 2017, 2017, 6068286. [Google Scholar] [CrossRef]

- Jing, W.; Jiang, J.; Ding, S.; Duan, P. Hydration and Microstructure of Steel Slag as Cementitious Material and Fine Aggregate in Mortar. Molecules 2020, 25, 4456. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Suraneni, P. Experimental methods to determine the feasibility of steel slags as supplementary cementitious materials. Constr. Build. Mater. 2019, 204, 458–467. [Google Scholar] [CrossRef]

- Ray, S.; Haque, M.; Ahmed, T.; Nahin, T.T. Comparison of artificial neural network (ANN) and response surface methodology (RSM) in predicting the compressive and splitting tensile strength of concrete prepared with glass waste and tin (Sn) can fiber. J. King Saud Univ. Eng. Sci. 2023, 35, 185–199. [Google Scholar] [CrossRef]

- Shi, C. Steel slag—Its production, processing, characteristics, and cementitious properties. J. Mater. Civ. Eng. 2004, 16, 230–236. [Google Scholar] [CrossRef]

- Yildirim, I.Z.; Prezzi, M. Chemical, mineralogical, and morphological properties of steel slag. Adv. Civ. Eng. 2011, 2011, 463638. [Google Scholar] [CrossRef]

- Wang, Q.; Yan, P.; Feng, J. A discussion on improving hydration activity of steel slag by altering its mineral compositions. J. Hazard. Mater. 2011, 186, 1070–1075. [Google Scholar] [CrossRef]

- Khongpermgoson, P.; Boonlao, K.; Ananthanet, N.; Thitithananon, T.; Jaturapitakkul, C.; Tangchirapat, W.; Ban, C.C. The mechanical properties and heat development behavior of high strength concrete containing high fineness coal bottom ash as a pozzolanic binder. Constr. Build. Mater. 2020, 253, 119239. [Google Scholar] [CrossRef]

- Menéndez, E.; Argiz, C.; Sanjuán, M.Á. Reactivity of ground coal bottom ash to be used in Portland cement. J 2021, 4, 223–232. [Google Scholar] [CrossRef]

- Dahmoune, F.; Remini, H.; Dairi, S.; Aoun, O.; Moussi, K.; Bouaoudia-Madi, N.; Adjeroud, N.; Kadri, N.; Lefsih, K.; Boughani, L. Ultrasound assisted extraction of phenolic compounds from P. lentiscus L. leaves: Comparative study of artificial neural network (ANN) versus degree of experiment for prediction ability of phenolic compounds recovery. Ind. Crops Prod. 2015, 77, 251–261. [Google Scholar] [CrossRef]

- Wang, Q.; Yan, P. Hydration properties of basic oxygen furnace steel slag. Constr. Build. Mater. 2010, 24, 1134–1140. [Google Scholar] [CrossRef]

- Al Biajawi, M.I.; Embong, R.; Muthusamy, K.; Ismail, N.; Obianyo, I.I. Recycled coal bottom ash as sustainable materials for cement replacement in cementitious Composites: A review. Constr. Build. Mater. 2022, 338, 127624. [Google Scholar] [CrossRef]

- Paquin, F.; Rivnay, J.; Salleo, A.; Stingelin, N.; Silva, C. Multi-phase semicrystalline microstructures drive exciton dissociation in neat plastic semiconductors. arXiv 2013, arXiv:1310.8002. [Google Scholar]

- Kursuncu, B.; Gencel, O.; Bayraktar, O.Y.; Shi, J.; Nematzadeh, M.; Kaplan, G. Optimization of foam concrete characteristics using response surface methodology and artificial neural networks. Constr. Build. Mater. 2022, 337, 127575. [Google Scholar] [CrossRef]

| Binder | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SiO3 | K2O | Na2O |

|---|---|---|---|---|---|---|---|---|

| % | % | % | % | % | % | % | % | |

| OPC | 63.37 | 19.26 | 3.64 | 4.22 | 1.49 | 1.71 | 0.25 | 0.18 |

| SS | 39.12 | 13.34 | 8.41 | 24.31 | 3.53 | 1.22 | 0.46 | 0.27 |

| CBA | 29.4 | 24.55 | 14.79 | 20.02 | 1.55 | 4.98 | 2.67 | 0.44 |

| SS (%) | ||||||

|---|---|---|---|---|---|---|

| 0 | 5 | 10 | 15 | 20 | ||

| CBA (%) | 0 | S0A0 * | S0A5 | S0A10 * | S0A15 | S0A20 * |

| 5 | S5A0 | S5A5 * | S5A10 | S5A15 * | S5A20 | |

| 10 | S10A0 * | S10A5 | S10A10 * | S10A15 | S10A20 * | |

| 15 | S15A0 | S15A5 * | S15A10 | S15A15 * | S15A20 | |

| 20 | S20A0 * | S20A5 | S20A10 * | S20A15 | S20A20 * | |

| Mix | SS% | CBA% | 28-Day | 91-Day | ||||

|---|---|---|---|---|---|---|---|---|

| Experimental | Predicted | Experimental | Predicted | |||||

| RSM | ANN | RSM | ANN | |||||

| S0A0 | 0 | 0 | 40.50 | 40.56 | 40.22 | 46.00 | 46.19 | 45.99 |

| S10A0 | 10 | 0 | 36.23 | 35.99 | 35.50 | 48.00 | 48.03 | 48.48 |

| S20A0 | 20 | 0 | 33.51 | 33.58 | 32.91 | 46.47 | 46.37 | 45.96 |

| S5A5 | 5 | 5 | 37.00 | 37.26 | 37.22 | 46.50 | 45.67 | 46.52 |

| S15A5 | 15 | 5 | 33.42 | 33.61 | 33.23 | 42.50 | 42.87 | 42.18 |

| S0A10 | 0 | 10 | 40.10 | 39.86 | 40.10 | 48.05 | 48.08 | 48.16 |

| S10A10 | 10 | 10 | 34.00 | 33.33 | 33.48 | 42.00 | 41.58 | 41.65 |

| S10A10 | 10 | 10 | 33.10 | 33.33 | 33.48 | 41.00 | 41.58 | 41.65 |

| S10A10 | 10 | 10 | 33.09 | 33.33 | 33.48 | 41.00 | 41.58 | 41.65 |

| S20A10 | 20 | 10 | 26.03 | 25.78 | 26.21 | 31.21 | 31.24 | 31.91 |

| S5A15 | 5 | 15 | 33.28 | 33.48 | 33.77 | 41.32 | 41.69 | 41.33 |

| S15A5 | 15 | 15 | 27.00 | 27.26 | 27.49 | 35.50 | 34.67 | 36.04 |

| S0A20 | 0 | 20 | 34.75 | 34.82 | 35.39 | 42.50 | 42.39 | 42.56 |

| S10A20 | 10 | 20 | 28.53 | 28.29 | 28.15 | 36.14 | 36.13 | 36.19 |

| S20A20 | 20 | 20 | 17.50 | 17.56 | 17.84 | 25.50 | 25.69 | 25.77 |

| Variables | Symbol | Unit | Coded Factor Levels | ||||

|---|---|---|---|---|---|---|---|

| −1 | −0.5 | 0 | 0.5 | 1 | |||

| SS | X1 | % | 0 | 5 | 10 | 15 | 20 |

| CBA | X2 | % | 0 | 5 | 10 | 15 | 20 |

| 28 Days | 91 Days | ||||||

|---|---|---|---|---|---|---|---|

| Df | Ss | F-Value | p-Value | Ss | F-Value | p-Value | |

| Model | 9 | 478.3 | 258.34 | <0.0001 | 577.42 | 119.22 | <0.0001 |

| X1 | 1 | 11.5 | 55.91 | 0.0007 | 14.81 | 27.53 | 0.0033 |

| X2 | 1 | 13.53 | 65.78 | 0.0005 | 20.46 | 38.02 | 0.0016 |

| X1X2 | 1 | 28.13 | 136.75 | <0.0001 | 75.62 | 140.51 | <0.0001 |

| X12 | 1 | 0.6884 | 3.35 | 0.1269 | 9.82 | 18.24 | 0.0079 |

| X22 | 1 | 3.77 | 18.35 | 0.0078 | 0.6756 | 1.26 | 0.3134 |

| X12X2 | 1 | 3.36 | 16.35 | 0.0099 | 0.0375 | 0.0697 | 0.8023 |

| X1X22 | 1 | 1.27 | 6.18 | 0.0554 | 24.57 | 45.66 | 0.0011 |

| X13 | 1 | 2.67 | 12.96 | 0.0156 | 4.59 | 8.53 | 0.033 |

| X23 | 1 | 0.5156 | 2.51 | 0.1742 | 0.0072 | 0.0133 | 0.9127 |

| Residual | 5 | 1.03 | 2.69 | ||||

| Lack of Fit | 3 | 0.4825 | 0.5891 | 0.6787 | 1.88 | 1.56 | 0.4141 |

| Pure Error | 2 | 0.5461 | 0.8067 | ||||

| R2 | 0.9979 | 0.9954 | |||||

| Adjusted R2 | 0.994 | 0.987 | |||||

| Predicted R2 | 0.9688 | 0.9233 | |||||

| Adeq pre | 62.1075 | 37.3744 | |||||

| Cor Total | 14 | 479.33 | 580.11 | ||||

| Mix | SS% | CBA% | 28-Day | 91-Day | ||||

|---|---|---|---|---|---|---|---|---|

| Experimental | Predicted | Experimental | Predicted | |||||

| RSM | ANN | RSM | ANN | |||||

| 1 | 5 | 0 | 37.00 | 37.08 | 37.61 | 49.50 | 46.33 | 48.93 |

| 2 | 15 | 0 | 33.86 | 35.45 | 34.63 | 47.48 | 48.86 | 48.08 |

| 3 | 0 | 5 | 40.45 | 41.16 | 40.53 | 46.90 | 48.13 | 44.31 |

| 4 | 10 | 5 | 36.12 | 35.37 | 35.65 | 46.00 | 44.73 | 45.93 |

| 5 | 20 | 5 | 27.45 | 30.14 | 27.78 | 33.06 | 37.66 | 33.41 |

| 6 | 5 | 10 | 34.48 | 35.79 | 34.89 | 45.80 | 44.09 | 45.90 |

| 7 | 15 | 10 | 33.10 | 30.61 | 32.46 | 38.90 | 38.11 | 37.58 |

| 8 | 0 | 15 | 41.46 | 37.47 | 40.75 | 49.94 | 46.13 | 49.68 |

| 9 | 10 | 15 | 31.78 | 30.70 | 31.39 | 41.00 | 38.68 | 40.74 |

| 10 | 20 | 15 | 20.02 | 21.31 | 19.75 | 26.58 | 27.22 | 26.40 |

| 11 | 5 | 20 | 31.22 | 31.15 | 31.19 | 38.79 | 38.56 | 38.78 |

| 12 | 15 | 20 | 25.01 | 24.38 | 24.75 | 34.80 | 32.65 | 34.81 |

| Parameter | 28-Day | 91-Day | ||

|---|---|---|---|---|

| RSM | ANN | RSM | ANN | |

| R | 0.9550 | 0.9969 | 0.9493 | 0.9933 |

| R2 | 0.9121 | 0.9938 | 0.9012 | 0.9866 |

| X2 | 1.1476 | 0.0784 | 1.5798 | 0.2201 |

| MSE | 2.5519 | 0.17843 | 4.3181 | 0.6294 |

| RMSE | 1.5975 | 0.42241 | 2.07799 | 0.7933 |

| MAE | 1.3900 | 0.4142 | 1.9417 | 0.5267 |

| SEP | 4.8908 | 1.2933 | 4.9997 | 1.9088 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Ho, C.M.; Doh, S.I.; Al Biajawi, M.I.; Ma, Q.; Zhao, D.; Liu, R. Strength Characteristics and Prediction of Ternary Blended Cement Building Material Using RSM and ANN. Buildings 2025, 15, 733. https://doi.org/10.3390/buildings15050733

Li X, Ho CM, Doh SI, Al Biajawi MI, Ma Q, Zhao D, Liu R. Strength Characteristics and Prediction of Ternary Blended Cement Building Material Using RSM and ANN. Buildings. 2025; 15(5):733. https://doi.org/10.3390/buildings15050733

Chicago/Turabian StyleLi, Xiaofeng, Chia Min Ho, Shu Ing Doh, Mohammad I. Al Biajawi, Quanjin Ma, Dan Zhao, and Rusong Liu. 2025. "Strength Characteristics and Prediction of Ternary Blended Cement Building Material Using RSM and ANN" Buildings 15, no. 5: 733. https://doi.org/10.3390/buildings15050733

APA StyleLi, X., Ho, C. M., Doh, S. I., Al Biajawi, M. I., Ma, Q., Zhao, D., & Liu, R. (2025). Strength Characteristics and Prediction of Ternary Blended Cement Building Material Using RSM and ANN. Buildings, 15(5), 733. https://doi.org/10.3390/buildings15050733