How Building Information Modeling Technology Supports Safety on Construction Sites: The Case Study of a Water Reservoir in Italy

Abstract

1. Introduction

Aims of the Study

- How can BIM technology be effectively integrated with existing safety management practices in the construction industry to enhance worker safety and mitigate potential risks?

- What are the key challenges and barriers to the adoption of BIM for safety management in construction projects, and how can these be addressed?

- How can BIM models be leveraged to improve communication, coordination, and information sharing among project stakeholders, facilitating better safety planning and execution?

- What are the potential benefits and limitations of using BIM for construction site safety, and how can these be quantified and evaluated?

- To investigate the potential integration of BIM technology with current safety management strategies and regulations, such as Italy’s Legislative Decree 81/08, to optimize safety design on construction sites.

- To conduct a comprehensive case study to evaluate the application of BIM software in modeling construction sites, including structural and plant components, surrounding contexts, and proposed site organization.

- To analyze how a contextualized BIM model can provide valuable support for preliminary assessments, organization of work processes, drafting of safety and coordination plans, and informing maintenance decisions.

- To identify the advantages and limitations of using BIM for construction site safety through a detailed analysis of the case study and critical discussion of the results.

- To contribute to the understanding and promotion of innovative practices for improving construction site safety through the synergy of regulations and BIM technology.

2. Safety Legislation Timeline

Italian Safety Legislation

- construction, maintenance, repair, demolition, conservation, restoration, renovation, or equipping works;

- transformation, renewal, dismantling of structures;

- road, railway, hydraulic, maritime, and hydroelectric works;

- reclamation, forest management, excavation;

- excavations, assembly and disassembly of prefabricated elements.

3. Building Information Modeling

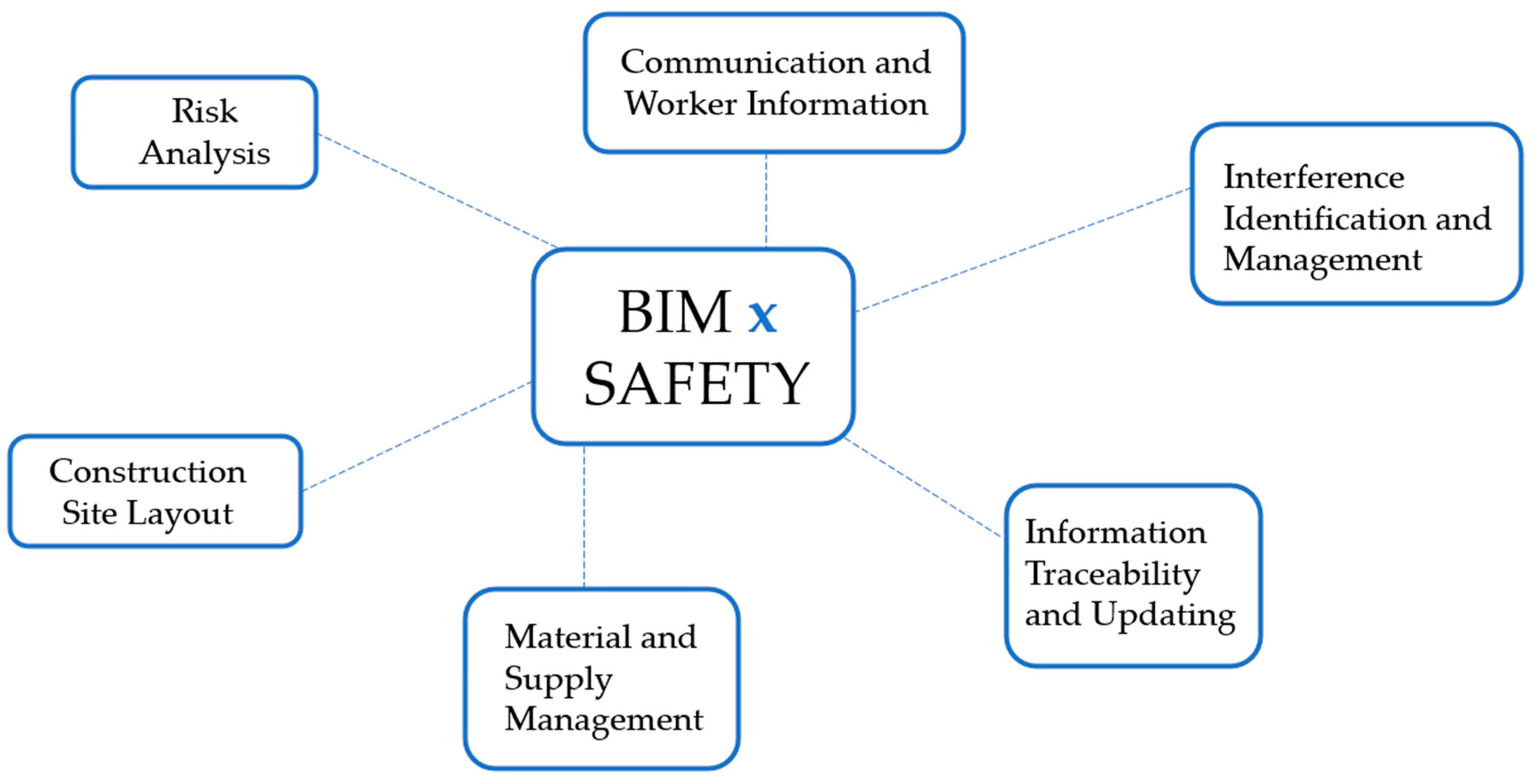

4. BIM and Construction Site Safety Interaction

4.1. Construction Site Layout

4.2. Risk Analysis

4.3. Communication and Worker Information

4.4. Material and Supply Management

4.5. Interference Identification and Management

4.6. Information Traceability and Updating

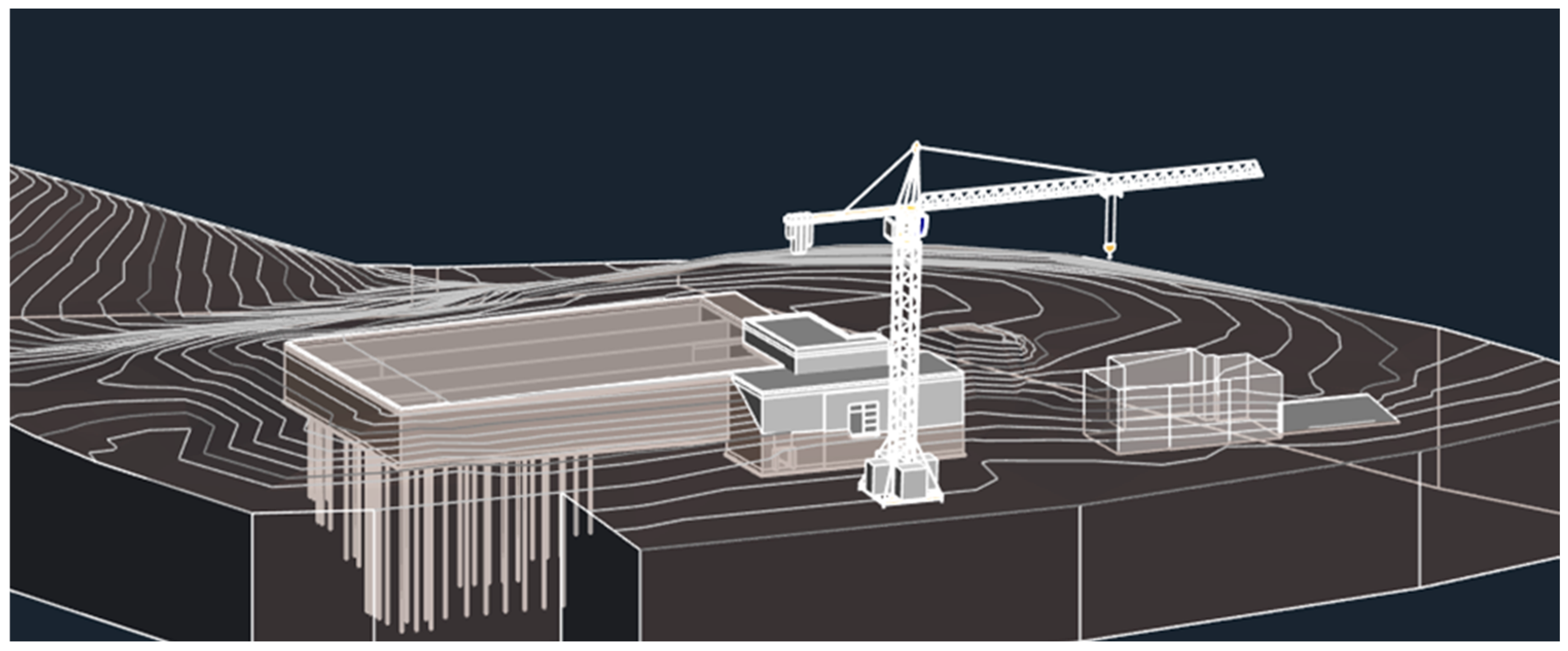

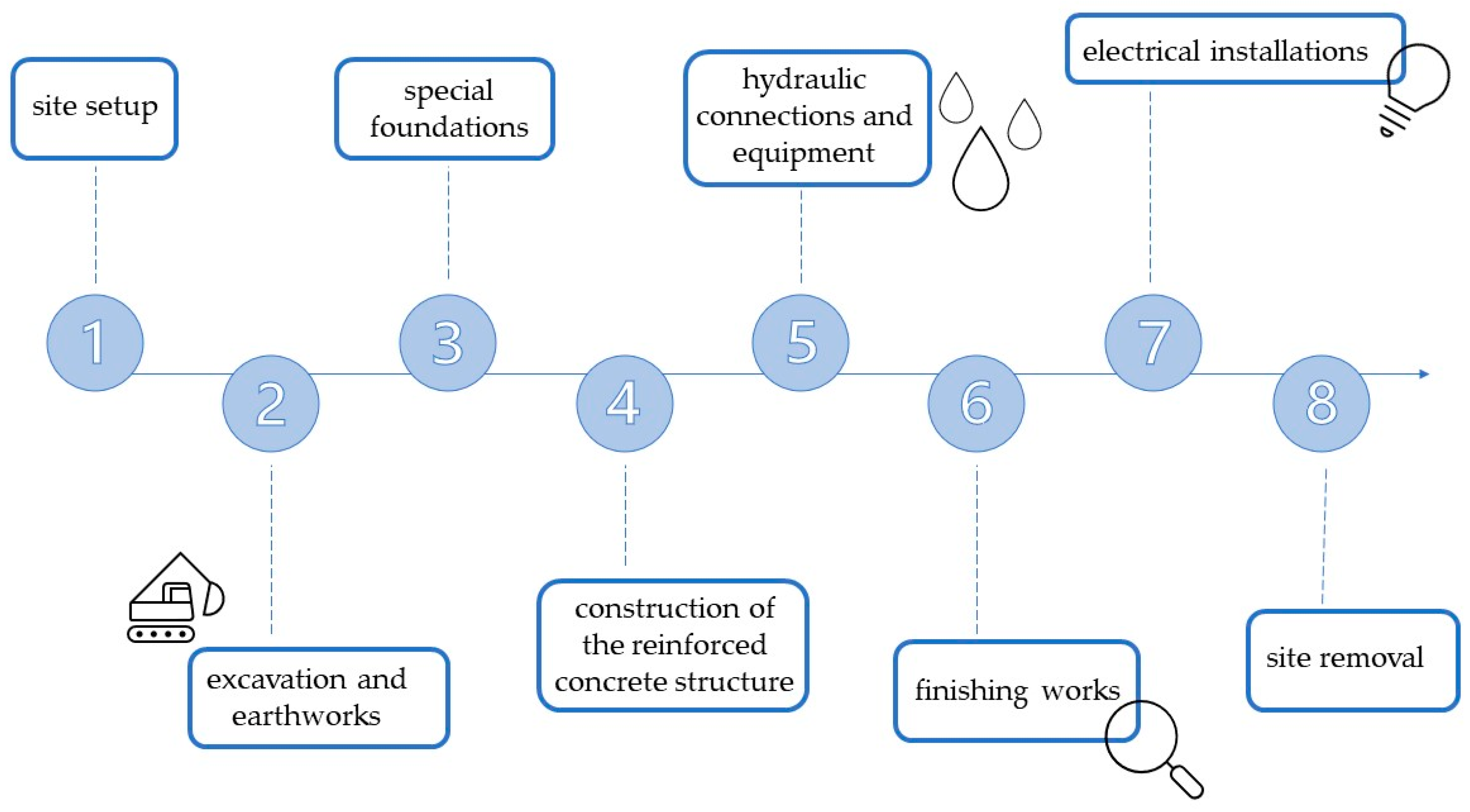

5. Methodology

- Geographic location: Situated on the “Altopiano Asiago” in a moderately steep area, making access for heavy vehicles more challenging. This required careful logistical planning to avoid overlapping deliveries and to organize them in a way that minimized the number of trips needed;

- Wartime risk zone: this required specific checks and prior demining;

- Foundation excavations exceeding 5 m in depth, involving the movement of over 5000 cubic meters of material, which required particular attention to fall prevention measures and the risk of excavation wall collapse. Excavation operations were therefore carried out in sections with the aid of self-sinking metal shoring, ensuring the constant protection of workers. Access to the excavation bottom was made possible through specific ramps, which were covered with gravel or lean concrete to reduce the risk of slipping. After the tank was poured, access was provided via internal scaffolding;

- Presence of other aqueduct utilities: Within the construction site area, there were underground systems and structures that could have interfered with excavation operations;

- Depth of the excavation and its morphological position, together with the presence of additional water utility structures and their related underground services in the surrounding area, posed the added risk of flooding in the excavation due to groundwater rise or potential pipe breakage. Therefore, a WellPoint pumping system was kept on-site throughout the duration of the operations exposed to this risk, in an easily accessible location for potential excavation drainage;

- Non-homogeneous foundation soil: This led to the decision to combine slab foundations for the more stable area with special micropile foundations under the main tank to ensure structural stability in the event of soil subsidence;

- The complexity of the project’s operation required close collaboration between multiple companies and technicians, adding spatial and temporal interference risks to an already variable-rich framework.

6. Results

7. Discussion

8. Conclusions and Practical Implications

9. Future Developments and Limitations

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Safety and Health at Work EU-OSHA. Estimating the Cost of Work-Related Accidents and Ill-Health: An Analysis of European Data Sources. Available online: https://osha.europa.eu/en/publications/estimating-cost-work-related-accidents-and-ill-health-analysis-european-data-sources (accessed on 13 January 2025).

- Neumann, W.P.; Winkelhaus, S.; Grosse, E.H.; Glock, C.H. Industry 4.0 and the human factor—A systems framework and analysis methodology for successful development. Int. J. Prod. Econ. 2021, 233, 127052. [Google Scholar] [CrossRef]

- Brocal, F.; Sebastián, M. Identification and Analysis of Advanced Manufacturing Processes Susceptible of Generating New and Emerging Occupational Risks. Procedia Eng. 2015, 132, 887–894. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Fathi, M.; Iranmanesh, M.; Maroufkhani, P.; Morales, M.E. Industry 4.0 ten years on: A bibliometric and systematic review of concepts, sustainability value drivers, and success determinants. J. Clean. Prod. 2021, 302, 127052. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Gonzalez, E.S. Understanding the adoption of Industry 4.0 technologies in improving environmental sustainability. Sustain. Oper. Comput. 2022, 3, 203–217. [Google Scholar] [CrossRef]

- Badri, A.; Boudreau-Trudel, B.; Souissi, A.S. Occupational health and safety in the industry 4.0 era: A cause for major concern? Saf. Sci. 2018, 109, 403–411. [Google Scholar] [CrossRef]

- International Labour Organization. The Role of Digital Labour Platforms in Transforming the World of Work. Available online: https://www.ilo.org/publications/flagship-reports/role-digital-labour-platforms-transforming-world-work (accessed on 13 January 2025).

- Montreuil, S.; Lippel, K. Telework and occupational health: A Quebec empirical study and regulatory implications. Saf. Sci. 2003, 41, 339–358. [Google Scholar] [CrossRef]

- Galanti, T.M.; Guidetti, G.; Mazzei, E.M.; Zappalà, S.; Toscano, F.M. Work from home during the COVID-19 outbreak: The impact on employees’ remote work productivity, engagement, and stress. J. Occup. Environ. Med. 2021, 63, e426–e432. [Google Scholar] [CrossRef]

- Charalampous, M.; Grant, C.A.; Tramontano, C.; Michailidis, E. Systematically reviewing remote e-workers’ well-being at work: A multidimensional approach. Eur. J. Work Organ. Psychol. 2019, 28, 51–73. [Google Scholar] [CrossRef]

- Vredenburgh, A.G. Organizational safety: Which management practices are most effective in reducing employee injury rates? J. Saf. Res. 2002, 33, 259–276. [Google Scholar] [CrossRef]

- Vinodkumar, M.; Bhasi, M. Safety management practices and safety behaviour: Assessing the mediating role of safety knowledge and motivation. Accid. Anal. Prev. 2010, 42, 2082–2093. [Google Scholar] [CrossRef]

- Fernández-Muñiz, B.; Montes-Peón, J.M.; Vázquez-Ordás, C.J. Relation between occupational safety management and firm performance. Saf. Sci. 2009, 47, 980–991. [Google Scholar] [CrossRef]

- Aksorn, T.; Hadikusumo, B. Critical success factors influencing safety program performance in Thai construction projects. Saf. Sci. 2008, 46, 709–727. [Google Scholar] [CrossRef]

- International Labour Organization. World Day for Safety and Health at Work 2022: Act Together to Build a Positive Safety and Health Culture. Available online: https://www.ilo.org/meetings-and-events/world-day-safety-and-health-work-2022-act-together-build-positive-safety (accessed on 13 January 2025).

- Zhang, S.; Teizer, J.; Lee, J.-K.; Eastman, C.M.; Venugopal, M. Building Information Modeling (BIM) and Safety: Automatic Safety Checking of Construction Models and Schedules. Autom. Constr. 2013, 29, 183–195. [Google Scholar] [CrossRef]

- Azhar, S. Role of Visualization Technologies in Safety Planning and Management at Construction Jobsites. Procedia Eng. 2017, 171, 215–226. [Google Scholar] [CrossRef]

- Steel, J.; Drogemuller, R.; Toth, B. Model interoperability in building information modelling. Softw. Syst. Model. 2012, 11, 99–109. [Google Scholar] [CrossRef]

- Cox, S.; Cox, T. The structure of employee attitudes to safety: A European example. Work. Stress 1991, 5, 93–106. [Google Scholar] [CrossRef]

- Ganah, A.; John, G.A. Integrating Building Information Modeling and Health and Safety for Onsite Construction. Saf. Health Work. 2015, 6, 39–45. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Yu, Y.; Skitmore, M. Visualization technology-based construction safety management: A review. Autom. Constr. 2017, 73, 135–144. [Google Scholar] [CrossRef]

- Hou, L.; Wu, S.; Zhang, G.; Tan, Y.; Wang, X. Literature review of digital twins applications in construction workforce safety. Appl. Sci. 2021, 11, 339. [Google Scholar] [CrossRef]

- Getuli, V.; Ventura, S.M.; Capone, P.; Ciribini, A.L. BIM-based Code Checking for Construction Health and Safety. Procedia Eng. 2017, 196, 454–461. [Google Scholar] [CrossRef]

- Riaz, Z.; Arslan, M.; Kiani, A.K.; Azhar, S. CoSMoS: A BIM and wireless sensor based integrated solution for worker safety in confined spaces. Autom. Constr. 2014, 45, 96–106. [Google Scholar] [CrossRef]

- Zou, Y.; Kiviniemi, A.; Jones, S.W. A review of risk management through BIM and BIM-related technologies. Saf. Sci. 2017, 97, 88–98. [Google Scholar] [CrossRef]

- Li, X.; Yi, W.; Chi, H.-L.; Wang, X.; Chan, A.P. A critical review of virtual and augmented reality (VR/AR) applications in construction safety. Autom. Constr. 2018, 86, 150–162. [Google Scholar] [CrossRef]

- Kirsten, W. The Evolution from Occupational Health to Healthy Workplaces. Am. J. Lifestyle Med. 2022, 18, 64–74. [Google Scholar] [CrossRef] [PubMed]

- Colombo, S.; Golzio, L.E.; Bianchi, G. The evolution of health-, safety- and environment-related competencies in Italy: From HSE technicians, to HSE professionals and, eventually, to HSE managers. Saf. Sci. 2019, 118, 724–739. [Google Scholar] [CrossRef]

- Bohle, P.; Quinlan, M. Managing Occupational Health and Safety: A Multidisciplinary Approach. 2013. Available online: https://www.researchgate.net/publication/264861589_Managing_Occupational_Health_and_Safety_A_Multidisciplinary_Approach (accessed on 13 January 2025).

- Aldrich, M. Safety First: Technology, Labor, and Business in the Building of American Work Safety, 1870–1939; JHU Press: Baltimore, MD, USA, 1997; p. 415. [Google Scholar]

- Alli, B.O. Fundamental Principles of Occupational Health and Safety. 2008; p. 220. Available online: https://www.ilo.org/publications/fundamental-principles-occupational-health-and-safety-second-edition (accessed on 13 January 2025).

- Neal, A.C.; Wright, F.B.; Wright, F.B.; Neal, A.C. European Communities’ Health and Safety Legislation. 2006; p. 425. Available online: https://books.google.com/books/about/The_European_Communities_Health_and_Safe.html?hl=it&id=TAaCkahdNsoC (accessed on 13 January 2025).

- Walters, D.R. Preventive Services in Occupational Health and Safety in Europe: Developments and Trends in the 1990s. Int. J. Health Serv. 1997, 27, 247–271. [Google Scholar] [CrossRef] [PubMed]

- Walters, D. Regulating Health and Safety Management in the European Union. P.I.E.-Peter Lang. 2021. Available online: https://www.peterlang.com/document/1093030 (accessed on 13 January 2025).

- Wang, C.-J.; Yang, I.-H. Why and how does empowering leadership promote proactive work behavior? An examination with a serial mediation model among hotel employees. Int. J. Environ. Res. Public Health 2021, 18, 2386. [Google Scholar] [CrossRef]

- Iavicoli, S.; Natali, E.; Deitinger, P.; Rondinone, B.M.; Ertel, M.; Jain, A.; Leka, S. Occupational health and safety policy and psychosocial risks in Europe: The role of stakeholders’ perceptions. Health Policy 2011, 101, 87–94. [Google Scholar] [CrossRef]

- Leka, S.; Jain, A.; Iavicoli, S.; Di Tecco, C. An Evaluation of the Policy Context on Psychosocial Risks and Mental Health in the Workplace in the European Union: Achievements, Challenges, and the Future. BioMed Res. Int. 2015, 2015, 213089. [Google Scholar] [CrossRef] [PubMed]

- Senato della Repubblica. La Costituzione. Available online: https://www.senato.it/istituzione/la-costituzione (accessed on 26 September 2024).

- Gazzetta Ufficiale. Codice Civile REGIO DECRETO 16 Marzo 1942, n. 262. Available online: https://www.gazzettaufficiale.it/anteprima/codici/codiceCivile (accessed on 26 September 2024).

- DECRETO LEGISLATIVO 9 aprile 2008, n. 81. Available online: https://www.bosettiegatti.eu/info/norme/statali/2008_0081.htm (accessed on 26 September 2024).

- Matarneh, S.T.; Danso-Amoako, M.; Al-Bizri, S.; Gaterell, M.; Matarneh, R. Building information modeling for facilities management: A literature review and future research directions. J. Build. Eng. 2019, 24, 100755. [Google Scholar] [CrossRef]

- Lu, Q.; Xie, X.; Parlikad, A.K.; Schooling, J.M.; Konstantinou, E. Moving from building information models to digital twins for operation and maintenance. Proc. Inst. Civ. Eng. Smart Infrastruct. Constr. 2021, 174, 46–56. [Google Scholar] [CrossRef]

- Eastman, C.; Fisher, D.; Lafue, G.; Lividini, J.; Stoker, D.; Yessios, C. An Outline of the Building Description System; Carnegie-Mellon University: Pittsburgh, PA, USA, 1974. [Google Scholar]

- ScienceDirect Topics. Building Information Modeling—An Overview. Available online: https://www.sciencedirect.com/topics/engineering/building-information-modeling (accessed on 3 November 2024).

- Kubba, S. Building Information Modeling (BIM). In Handbook of Green Building Design and Construction; Elsevier: Amsterdam, The Netherlands, 2017; pp. 227–256. [Google Scholar] [CrossRef]

- Azhar, S. Building information modeling (BIM): Trends, benefits, risks, and challenges for the AEC industry. Leadersh. Manag. Eng. 2011, 11, 241–252. [Google Scholar] [CrossRef]

- Sampaio, A.Z. BIM training course improving skills of Construction industry professionals. Procedia Comput. Sci. 2023, 219, 2035–2042. [Google Scholar] [CrossRef]

- Eastman, C.M.; Teicholz, P.M.; Sacks, R.; Lee, G. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers and Contractors; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Succar, B. Building information modelling framework: A research and delivery foundation for industry stakeholders. Autom. Constr. 2009, 18, 357–375. [Google Scholar] [CrossRef]

- Tookey, J.; Ghaffarianhoseini, A.; Naismith, N.; Azhar, S.; Efimova, O.; Raahemifar, K. Building Information Modelling (BIM) uptake: Clear benefits, understanding its implementation, risks and challenges. Renew. Sustain. Energy Rev. 2017, 75, 1046–1053. [Google Scholar] [CrossRef]

- Akbarieh, A.; Jayasinghe, L.B.; Waldmann, D.; Teferle, F.N. BIM-Based End-of-Lifecycle Decision Making and Digital Deconstruction: Literature Review. Sustainability 2020, 12, 2670. [Google Scholar] [CrossRef]

- Charef, R.; Alaka, H.; Emmitt, S. Beyond the third dimension of BIM: A systematic review of literature and assessment of professional views. J. Build. Eng. 2018, 19, 242–257. [Google Scholar] [CrossRef]

- Gu, N.; London, K. Understanding and facilitating BIM adoption in the AEC industry. Autom. Constr. 2010, 19, 988–999. [Google Scholar] [CrossRef]

- Edirisinghe, R.; London, K. Comparative analysis of international and national level BIM standardization efforts and BIM adoption. In Proceedings of the 32nd CIB W78 Conference, Eindhoven, The Netherlands, 27–29 October 2015. [Google Scholar]

- Arayici, Y.; Coates, S.; Koskela, L.; Kagioglou, M.; Usher, C.; O’Reilly, K. Technology adoption in the BIM implementation for lean architectural practice. Autom. Constr. 2011, 20, 189–195. [Google Scholar] [CrossRef]

- Gao, G.; Liu, Y.-S.; Wang, M.; Gu, M.; Yong, J.-H. A query expansion method for retrieving online BIM resources based on Industry Foundation Classes. Autom. Constr. 2015, 56, 14–25. [Google Scholar] [CrossRef]

- Bryde, D.; Broquetas, M.; Volm, J.M. The project benefits of Building Information Modelling (BIM). Int. J. Proj. Manag. 2013, 31, 971–980. [Google Scholar] [CrossRef]

- Abualdenien, J.; Borrmann, A. A meta-model approach for formal specification and consistent management of multi-LOD building models. Adv. Eng. Inform. 2019, 40, 135–153. [Google Scholar] [CrossRef]

- Gerrish, T.; Ruikar, K.; Cook, M.; Johnson, M.; Phillip, M.; Lowry, C. BIM application to building energy performance visualisation and management: Challenges and potential. Energy Build. 2017, 144, 218–228. [Google Scholar] [CrossRef]

- Eleftheriadis, S.; Mumovic, D.; Greening, P. Life cycle energy efficiency in building structures: A review of current developments and future outlooks based on BIM capabilities. Renew. Sustain. Energy Rev. 2017, 67, 811–825. [Google Scholar] [CrossRef]

- Volk, R.; Stengel, J.; Schultmann, F. Building Information Modeling (BIM) for existing buildings—Literature review and future needs. Autom. Constr. 2014, 38, 109–127. [Google Scholar] [CrossRef]

- Liu, Y.; van Nederveen, S.; Hertogh, M. Understanding effects of BIM on collaborative design and construction: An empirical study in China. Int. J. Proj. Manag. 2017, 35, 686–698. [Google Scholar] [CrossRef]

- Papadonikolaki, E.; Vrijhoef, R.; Wamelink, H. The interdependences of BIM and supply chain partnering: Empirical explorations. Arch. Eng. Des. Manag. 2016, 12, 476–494. [Google Scholar] [CrossRef]

- Oraee, M.; Hosseini, M.R.; Papadonikolaki, E.; Palliyaguru, R.; Arashpour, M. Collaboration in BIM-based construction networks: A bibliometric-qualitative literature review. Int. J. Proj. Manag. 2017, 35, 1288–1301. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X.; Shou, W.; Chong, H.-Y.; Guo, J. Building information modeling-based integration of MEP layout designs and constructability. Autom. Constr. 2016, 61, 134–146. [Google Scholar] [CrossRef]

- Pärn, E.A.; Edwards, D.J.; Sing, M.C.P. The building information modelling trajectory in facilities management: A review. Autom. Constr. 2017, 75, 45–55. [Google Scholar] [CrossRef]

- Marzouk, M.; Abdelaty, A. BIM-based framework for managing performance of subway stations. Autom. Constr. 2014, 41, 70–77. [Google Scholar] [CrossRef]

- Lee, S.; Yu, J. Comparative Study of BIM Acceptance between Korea and the United States. J. Constr. Eng. Manag. 2015, 142, 05015016. [Google Scholar] [CrossRef]

- Zanni, M.A.; Soetanto, R.; Ruikar, K. Towards a BIM-enabled sustainable building design process: Roles, responsibilities, and requirements. Arch. Eng. Des. Manag. 2017, 13, 101–129. [Google Scholar] [CrossRef]

- Wong, J.K.W.; Zhou, J. Enhancing environmental sustainability over building life cycles through green BIM: A review. Autom. Constr. 2015, 57, 156–165. [Google Scholar] [CrossRef]

- Eadie, R.; Browne, M.; Odeyinka, H.; McKeown, C.; McNiff, S. BIM implementation throughout the UK construction project lifecycle: An analysis. Autom. Constr. 2013, 36, 145–151. [Google Scholar] [CrossRef]

- Dainty, A.; Leiringer, R.; Fernie, S.; Harty, C. BIM and the small construction firm: A critical perspective. Build. Res. Inf. 2017, 45, 696–709. [Google Scholar] [CrossRef]

- Martinez-Aires, M.D.; López-Alonso, M.; Martínez-Rojas, M. Building information modeling and safety management: A systematic review. Saf. Sci. 2018, 101, 11–18. [Google Scholar] [CrossRef]

- Chatzimichailidou, M.; Ma, Y. Using BIM in the safety risk management of modular construction. Saf. Sci. 2022, 154, 105852. [Google Scholar] [CrossRef]

- Kulinan, A.S.; Park, M.; Aung, P.P.W.; Cha, G.; Park, S. Advancing construction site workforce safety monitoring through BIM and computer vision integration. Autom. Constr. 2024, 158, 105227. [Google Scholar] [CrossRef]

- Zhang, S.; Sulankivi, K.; Kiviniemi, M.; Romo, I.; Eastman, C.M.; Teizer, J. BIM-based fall hazard identification and prevention in construction safety planning. Saf. Sci. 2015, 72, 31–45. [Google Scholar] [CrossRef]

- Yuan, J.; Li, X.; Xiahou, X.; Tymvios, N.; Zhou, Z.; Li, Q. Accident prevention through design (PtD): Integration of building information modeling and PtD knowledge base. Autom. Constr. 2019, 102, 86–104. [Google Scholar] [CrossRef]

- Collinge, W.H.; Farghaly, K.; Mosleh, M.H.; Manu, P.; Cheung, C.M.; Osorio-Sandoval, C.A. BIM-based construction safety risk library. Autom. Constr. 2022, 141, 104391. [Google Scholar] [CrossRef]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a semantic Construction Digital Twin: Directions for future research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

- Zhang, P.; Li, N.; Jiang, Z.; Fang, D.; Anumba, C.J. An agent-based modeling approach for understanding the effect of worker-management interactions on construction workers’ safety-related behaviors. Autom. Constr. 2019, 97, 29–43. [Google Scholar] [CrossRef]

- Shuang, D.; Heng, L.; Skitmore, M.; Qin, Y. An experimental study of intrusion behaviors on construction sites: The role of age and gender. Saf. Sci. 2019, 115, 425–434. [Google Scholar] [CrossRef]

- Heng, L.; Shuang, D.; Skitmore, M.; Qinghua, H.; Qin, Y. Intrusion warning and assessment method for site safety enhancement. Saf. Sci. 2016, 84, 97–107. [Google Scholar] [CrossRef]

- Boguslawski, P.; Mahdjoubi, L.; Zverovich, V.; Fadli, F. Automated construction of variable density navigable networks in a 3D indoor environment for emergency response. Autom. Constr. 2016, 72, 115–128. [Google Scholar] [CrossRef]

- Peng, Y.; Li, S.-W.; Hu, Z.-Z. A self-learning dynamic path planning method for evacuation in large public buildings based on neural networks. Neurocomputing 2019, 365, 71–85. [Google Scholar] [CrossRef]

- Abed, H.R.; Hatem, W.A.; Jasim, N.A. Adopting BIM Technology in Fall Prevention Plans. Civ. Eng. J. 2019, 5, 2270–2281. [Google Scholar] [CrossRef]

- Zhang, J.; Seet, B.-C.; Lie, T.T. Building information modelling for smart built environments. Buildings 2015, 5, 100–115. [Google Scholar] [CrossRef]

- Akram, R.; Thaheem, M.J.; Khan, S.; Nasir, A.R.; Maqsoom, A. Exploring the Role of BIM in Construction Safety in Developing Countries: Toward Automated Hazard Analysis. Sustainability 2022, 14, 12905. [Google Scholar] [CrossRef]

- Ganbat, T.; Chong, H.-Y.; Liao, P.-C. Mapping BIM Uses for Risk Mitigation in International Construction Projects. Adv. Civ. Eng. 2020, 2020, 5143879. [Google Scholar] [CrossRef]

- Salzano, A.; Cascone, S.; Zitiello, E.P.; Nicolella, M. Construction Safety and Efficiency: Integrating Building Information Modeling into Risk Management and Project Execution. Sustainability 2024, 16, 4094. [Google Scholar] [CrossRef]

- Cascone, S. Digital Technologies and Sustainability Assessment: A Critical Review on the Integration Methods between BIM and LEED. Sustainability 2023, 15, 5548. [Google Scholar] [CrossRef]

- Kumar, S.S.; Cheng, J.C. A BIM-based automated site layout planning framework for congested construction sites. Autom. Constr. 2015, 59, 24–37. [Google Scholar] [CrossRef]

- Hire, S.; Sandbhor, S.; Ruikar, K. A Conceptual Framework for BIM-Based Site Safety Practice. Buildings 2024, 14, 272. [Google Scholar] [CrossRef]

- Botín-Sanabria, D.M.; Mihaita, A.-S.; Peimbert-García, R.E.; Ramírez-Moreno, M.A.; Ramírez-Mendoza, R.A.; Lozoya-Santos, J.d.J. Digital Twin Technology Challenges and Applications: A Comprehensive Review. Remote Sens. 2022, 14, 1335. [Google Scholar] [CrossRef]

- Attaran, M.; Celik, B.G. Digital Twin: Benefits, use cases, challenges, and opportunities. Decis. Anal. J. 2023, 6, 100165. [Google Scholar] [CrossRef]

- Chen, L.; Luo, H. A BIM-based construction quality management model and its applications. Autom. Constr. 2014, 46, 64–73. [Google Scholar] [CrossRef]

- BorjeGhaleh, R.M.; Sardroud, J.M. Approaching Industrialization of Buildings and Integrated Construction Using Building Information Modeling. Procedia Eng. 2016, 164, 534–541. [Google Scholar] [CrossRef]

- Sarvari, H.; Chan, D.W.M.; Rakhshanifar, M.; Banaitiene, N.; Banaitis, A. Evaluating the Impact of Building Information Modeling (BIM) on Mass House Building Projects. Buildings 2020, 10, 35. [Google Scholar] [CrossRef]

- Cao, Y.; Kamaruzzaman, S.N.; Aziz, N.M. Green Building Construction: A Systematic Review of BIM Utilization. Buildings 2022, 12, 1205. [Google Scholar] [CrossRef]

- Yu, Q.; Li, K.; Luo, H. A BIM-based Dynamic Model for Site Material Supply. Procedia Eng. 2016, 164, 526–533. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, T.; Hu, H.; Gong, J.; Ren, X.; Xiao, Q. Blockchain-based framework for improving supply chain traceability and information sharing in precast construction. Autom. Constr. 2020, 111, 103063. [Google Scholar] [CrossRef]

- Kiviniemi, M.; Sulankivi, K.; Kähkönen, K.; Mäkelä, T.; Merivirta, M.-L. BIM-Based Safety Management and Communication for Building Construction; VTT Technical Research Centre of Finland: Espoo, Finland, 2011; Available online: https://cris.vtt.fi/en/publications/bim-based-safety-management-and-communication-for-building-constr (accessed on 13 January 2025).

- Afzal, M.; Li, R.Y.M.; Shoaib, M.; Ayyub, M.F.; Tagliabue, L.C.; Bilal, M.; Ghafoor, H.; Manta, O. Delving into the Digital Twin Developments and Applications in the Construction Industry: A PRISMA Approach. Sustainability 2023, 15, 16436. [Google Scholar] [CrossRef]

- Sharma, A.; Kosasih, E.; Zhang, J.; Brintrup, A.; Calinescu, A. Digital Twins: State of the art theory and practice, challenges, and open research questions. J. Ind. Inf. Integr. 2022, 30, 100383. [Google Scholar] [CrossRef]

- Brandín, R.; Abrishami, S. IoT-BIM and blockchain integration for enhanced data traceability in offsite manufacturing. Autom. Constr. 2024, 159, 105266. [Google Scholar] [CrossRef]

- Sriyolja, Z.; Harwin, N.; Yahya, K. Barriers to Implement Building Information Modeling (BIM) in Construction Industry: A Critical Review. IOP Conf. Ser. Earth Environ. Sci. 2021, 738, 012021. [Google Scholar] [CrossRef]

- Hire, S.; Sandbhor, S.; Ruikar, K.; Amarnath, C.B. BIM usage benefits and challenges for site safety application in Indian construction sector. Asian J. Civ. Eng. 2021, 22, 1249–1267. [Google Scholar] [CrossRef]

- Barlish, K.; Sullivan, K. How to measure the benefits of BIM—A case study approach. Autom. Constr. 2012, 24, 149–159. [Google Scholar] [CrossRef]

- Ebrahimi, H.; Akhbari, H. Construction of Management and Sustainable Construction in the Engineering by Building Information Modeling. Int. J. Mater. Eng. 2015, 5, 64–75. [Google Scholar]

- Ahmed, S. Barriers to implementation of building information modeling (BIM) to the construction industry: A review. J. Civ. Eng. Constr. 2018, 7, 107–113. [Google Scholar] [CrossRef]

- Wang, C.C.; Chien, O. The Use of BIM in Project Planning and Scheduling in the Australian Construction Industry. In Proceedings of the ICCREM 2014: Smart Construction and Management in the Context of New Technology, Kunming, China, 27–28 September 2014; pp. 126–133. [Google Scholar] [CrossRef]

- Sacks, R.; Perlman, A.; Barak, R. Construction safety training using immersive virtual reality. Constr. Manag. Econ. 2013, 31, 1005–1017. [Google Scholar] [CrossRef]

- Tah, J.H.M.; Carr, V. A proposal for construction project risk assessment using fuzzy logic. Constr. Manag. Econ. 2000, 18, 491–500. [Google Scholar] [CrossRef]

- Rehman, M.S.U.; Shafiq, M.T.; Ullah, F. Automated Computer Vision-Based Construction Progress Monitoring: A Systematic Review. Buildings 2022, 12, 1037. [Google Scholar] [CrossRef]

- Son, H.; Bosché, F.; Kim, C. As-built data acquisition and its use in production monitoring and automated layout of civil infrastructure: A survey. Adv. Eng. Inform. 2015, 29, 172–183. [Google Scholar] [CrossRef]

- Hatami, M.; Flood, I.; Franz, B.; Zhang, X. State-of-the-Art Review on the Applicability of AI Methods to Automated Construction Manufacturing. In Proceedings of the ASCE International Conference on Computing in Civil Engineering 2019, Atlanta, GA, USA, 17–19 June 2019; pp. 368–375. [Google Scholar] [CrossRef]

- Teizer, J. Wearable, wireless identification sensing platform: Self-Monitoring Alert and Reporting Technology for Hazard Avoidance and Training (SmartHat). ITcon 2015, 20, 295–312. [Google Scholar]

- Han, S.; Lee, S. A vision-based motion capture and recognition framework for behavior-based safety management. Autom. Constr. 2013, 35, 131–141. [Google Scholar] [CrossRef]

- Nath, N.D.; Behzadan, A.H.; Paal, S.G. Deep learning for site safety: Real-time detection of personal protective equipment. Autom. Constr. 2020, 112, 103085. [Google Scholar] [CrossRef]

- Fang, W.; Ding, L.; Luo, H.; Love, P.E.D. Falls from heights: A computer vision-based approach for safety harness detection. Autom. Constr. 2018, 91, 53–61. [Google Scholar] [CrossRef]

- Ding, L.; Fang, W.; Luo, H.; Love, P.E.; Zhong, B.; Ouyang, X. A deep hybrid learning model to detect unsafe behavior: Integrating convolution neural networks and long short-term memory. Autom. Constr. 2018, 86, 118–124. [Google Scholar] [CrossRef]

- Chiu, C.-K.; Lin, Y.-F. Multi-objective decision-making supporting system of maintenance strategies for deteriorating reinforced concrete buildings. Autom. Constr. 2014, 39, 15–31. [Google Scholar] [CrossRef]

- Hu, S.; Fang, Y. Automating Crane Lift Path through Integration of BIM and Path Finding Algorithm. In Proceedings of the 37th International Symposium on Automation and Robotics in Construction, Kitakyushu, Japan, 27–28 October 2020; pp. 522–529. [Google Scholar]

- Zeng, L.; Guo, S.; Wu, J.; Markert, B. Autonomous mobile construction robots in built environment: A comprehensive review. Dev. Built Environ. 2024, 19, 100484. [Google Scholar] [CrossRef]

- Hussien, A.; Waraich, A.; Paes, D. A review of mixed-reality applications in Construction 4.0. In Construction 4.0; Routledge: London, UK, 2020; pp. 131–141. [Google Scholar] [CrossRef]

- Moore, H.F.; Gheisari, M. A Review of Virtual and Mixed Reality Applications in Construction Safety Literature. Safety 2019, 5, 51. [Google Scholar] [CrossRef]

- Behzadan, A.H.; Dong, S.; Kamat, V.R. Augmented reality visualization: A review of civil infrastructure system applications. Adv. Eng. Inform. 2015, 29, 252–267. [Google Scholar] [CrossRef]

- Wang, P.; Wu, P.; Wang, J.; Chi, H.-L.; Wang, X. A critical review of the use of virtual reality in construction engineering education and training. Int. J. Environ. Res. Public Health 2018, 15, 1204. [Google Scholar] [CrossRef]

- Sampaio, A.Z.; Ferreira, M.M.; Rosário, D.P.; Martins, O.P. 3D and VR models in Civil Engineering education: Construction, rehabilitation and maintenance. Autom. Constr. 2010, 19, 819–828. [Google Scholar] [CrossRef]

| Contents | Description |

|---|---|

| Identification and description of the work |

|

| Brief description of the project |

|

| Identification of those responsible for safety |

|

| Risk report |

|

| Design and organizational choices |

|

| Operational prescriptions for task interferences |

|

| Coordination measures for shared use |

|

| Organizational procedures |

|

| Planned organization for emergency services |

|

| Planned duration of work |

|

| Advantages | Disadvantages |

|---|---|

| Improved communication and organization | Software licensing costs |

| Cost efficiency | Training/hiring of technical specialists |

| Reduced errors and inconsistencies between parties | Need to adhere to unambiguous standards and coding |

| Reduced delivery times | Longer design times |

| Optimal management of the work life cycle | Disruption of traditional work method |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Cet, G.; Miazzi, N.; Paparella, R.; Boso, D.P. How Building Information Modeling Technology Supports Safety on Construction Sites: The Case Study of a Water Reservoir in Italy. Buildings 2025, 15, 403. https://doi.org/10.3390/buildings15030403

De Cet G, Miazzi N, Paparella R, Boso DP. How Building Information Modeling Technology Supports Safety on Construction Sites: The Case Study of a Water Reservoir in Italy. Buildings. 2025; 15(3):403. https://doi.org/10.3390/buildings15030403

Chicago/Turabian StyleDe Cet, Giulia, Natasha Miazzi, Rossana Paparella, and Daniela P. Boso. 2025. "How Building Information Modeling Technology Supports Safety on Construction Sites: The Case Study of a Water Reservoir in Italy" Buildings 15, no. 3: 403. https://doi.org/10.3390/buildings15030403

APA StyleDe Cet, G., Miazzi, N., Paparella, R., & Boso, D. P. (2025). How Building Information Modeling Technology Supports Safety on Construction Sites: The Case Study of a Water Reservoir in Italy. Buildings, 15(3), 403. https://doi.org/10.3390/buildings15030403