Mechanical and Fatigue Performance of Recycled Concrete Aggregate Blended with Waste Tyre Rubber Stabilised with Slag for Pavement Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Proportions

2.3. Experimental Programme

2.3.1. Compaction

2.3.2. Unconfined Compression Strength (UCS)

2.3.3. Repeated Load Triaxial Test (RLT)

2.4. Flexural Characteristics

2.4.1. Flexural Strength Test

2.4.2. Flexural Modulus Test

2.4.3. Flexural Fatigue Test

3. Results and Discussion

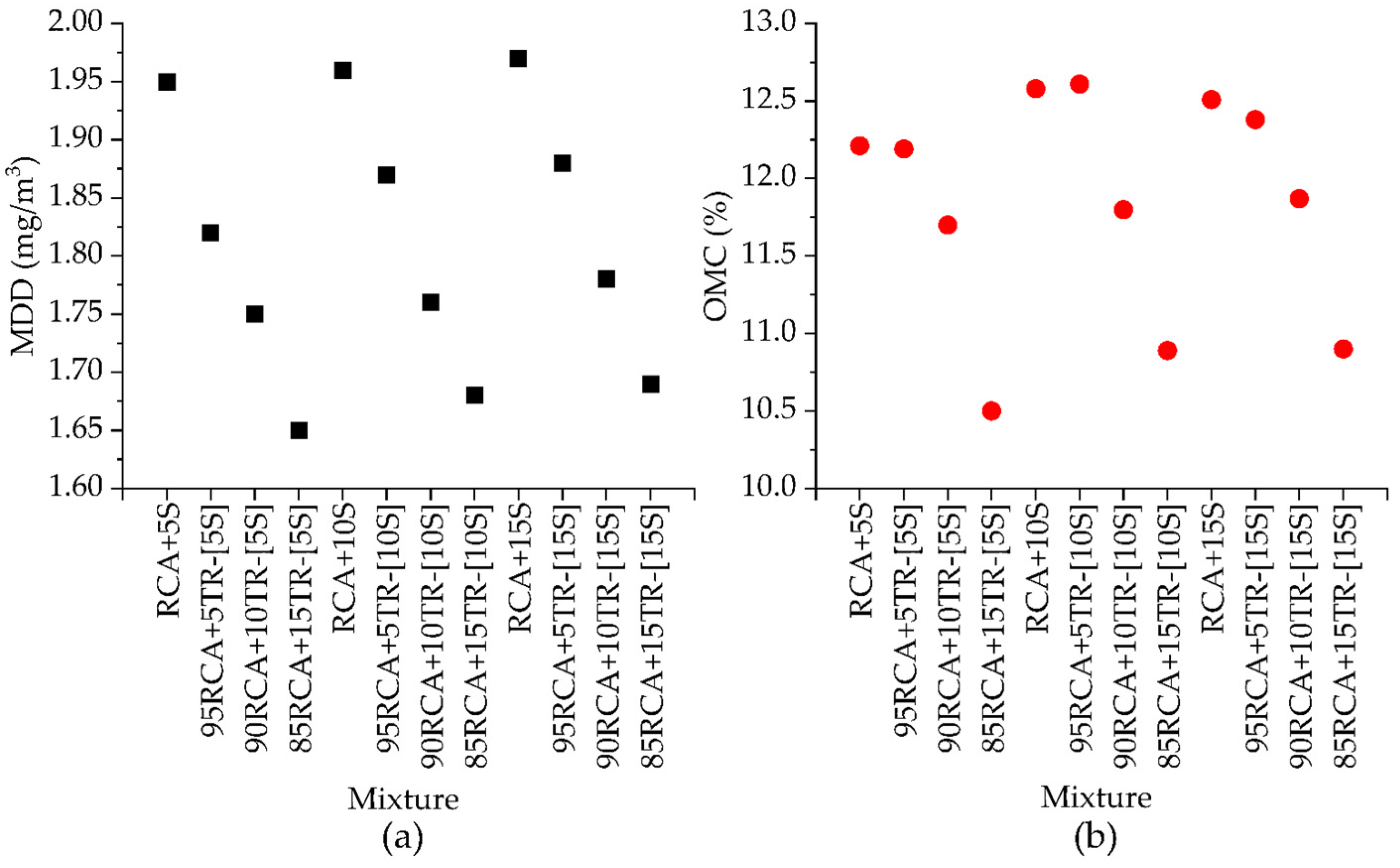

3.1. Compaction Characteristics

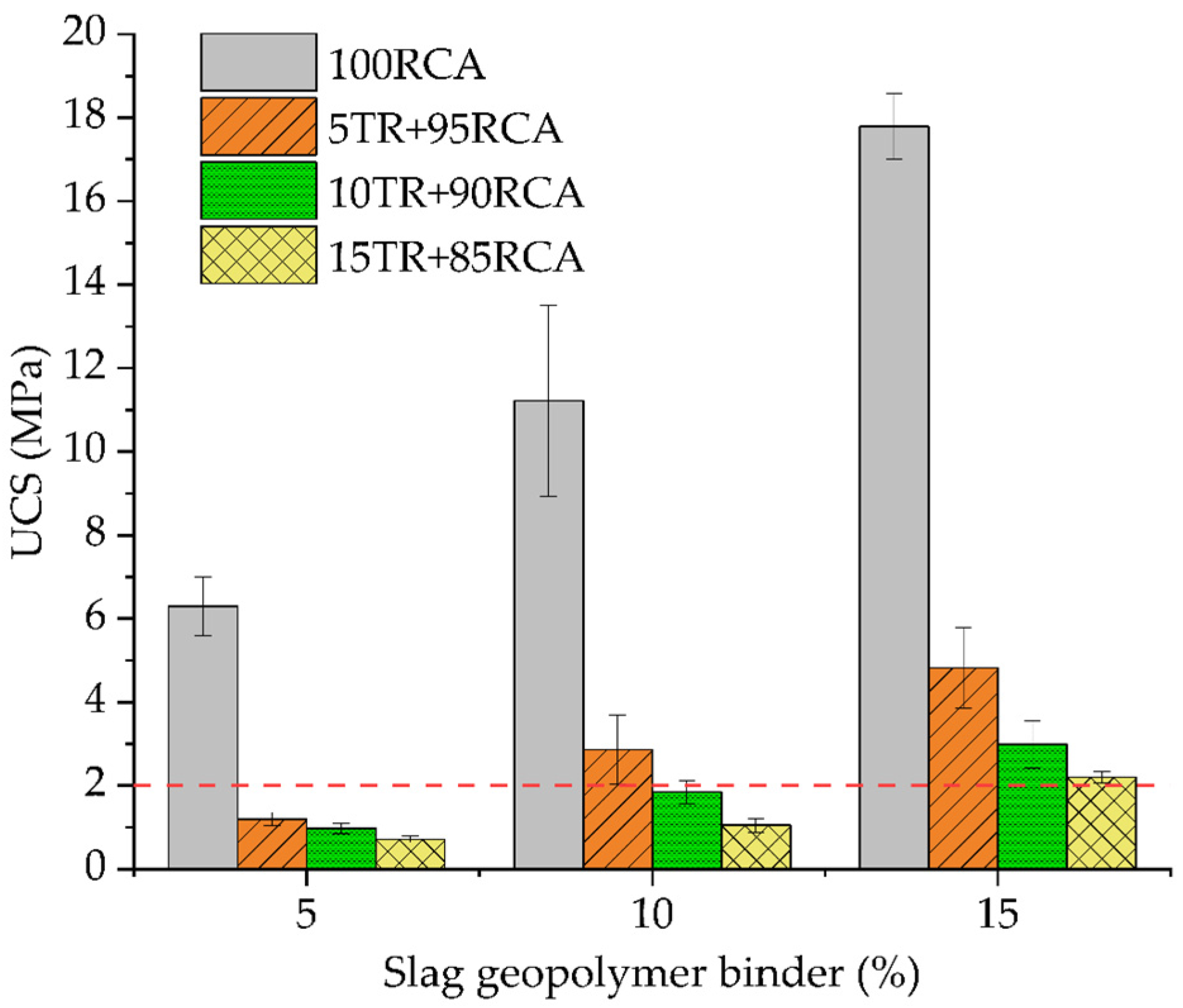

3.2. Unconfined Compressive Strength

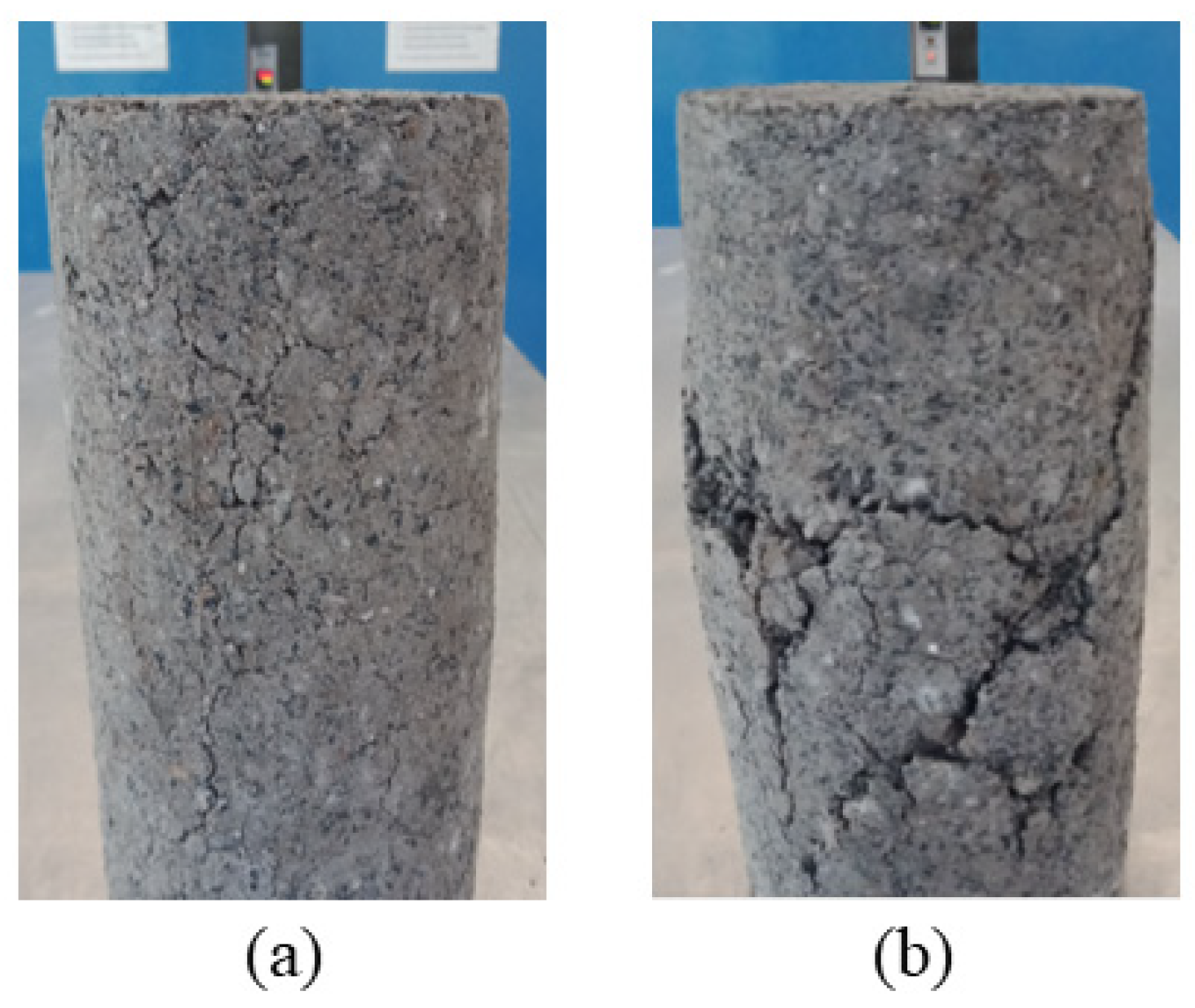

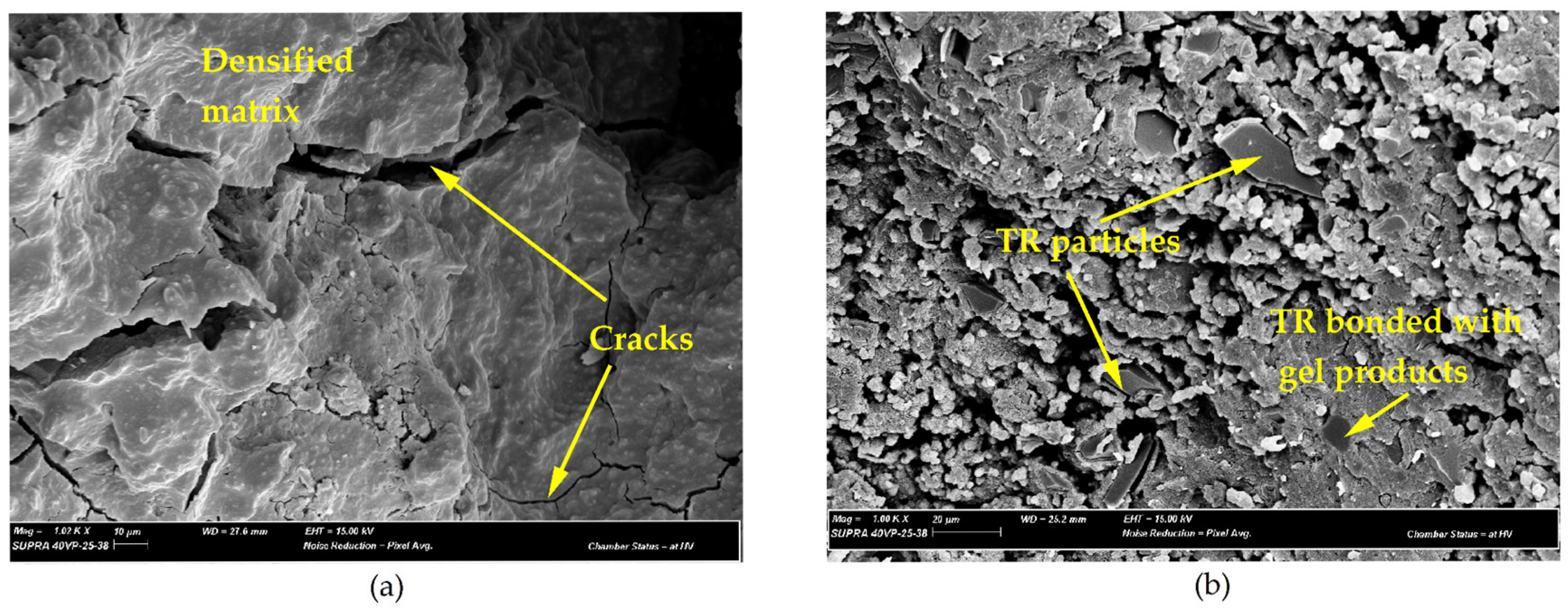

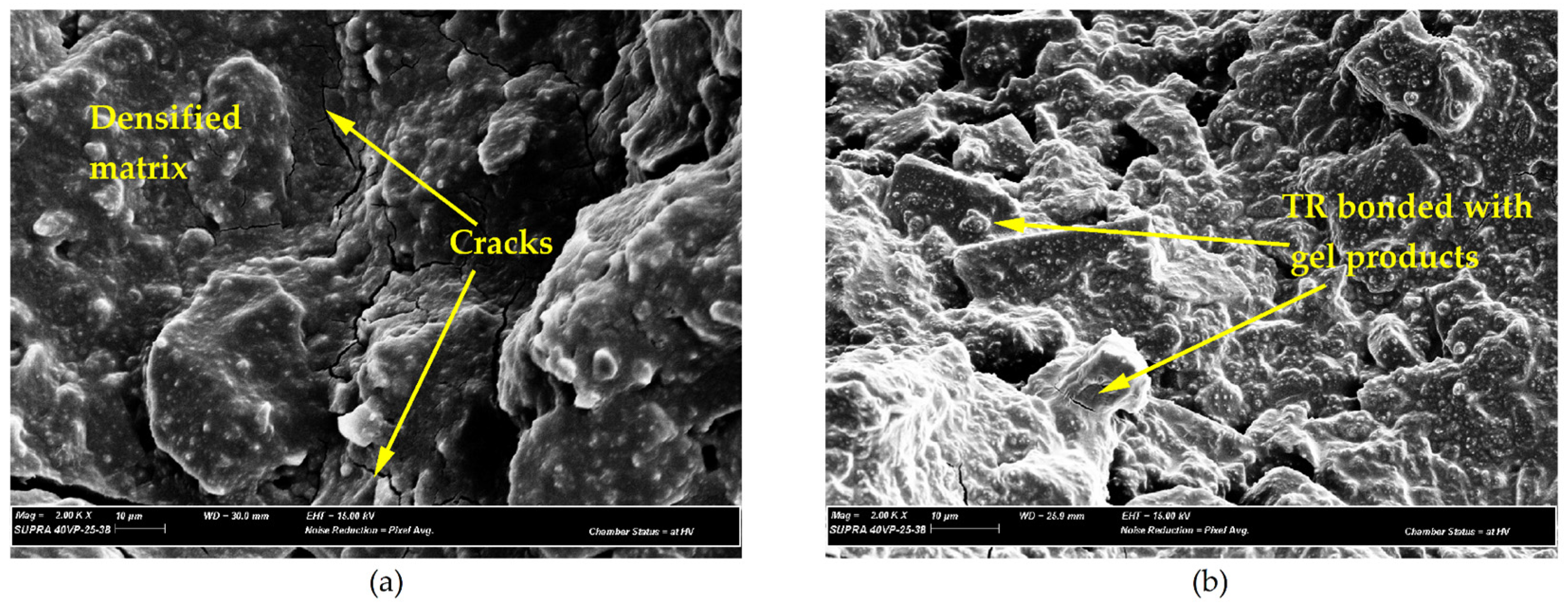

Failure Pattern of Slag-Stabilised TR + RCA Under Compression

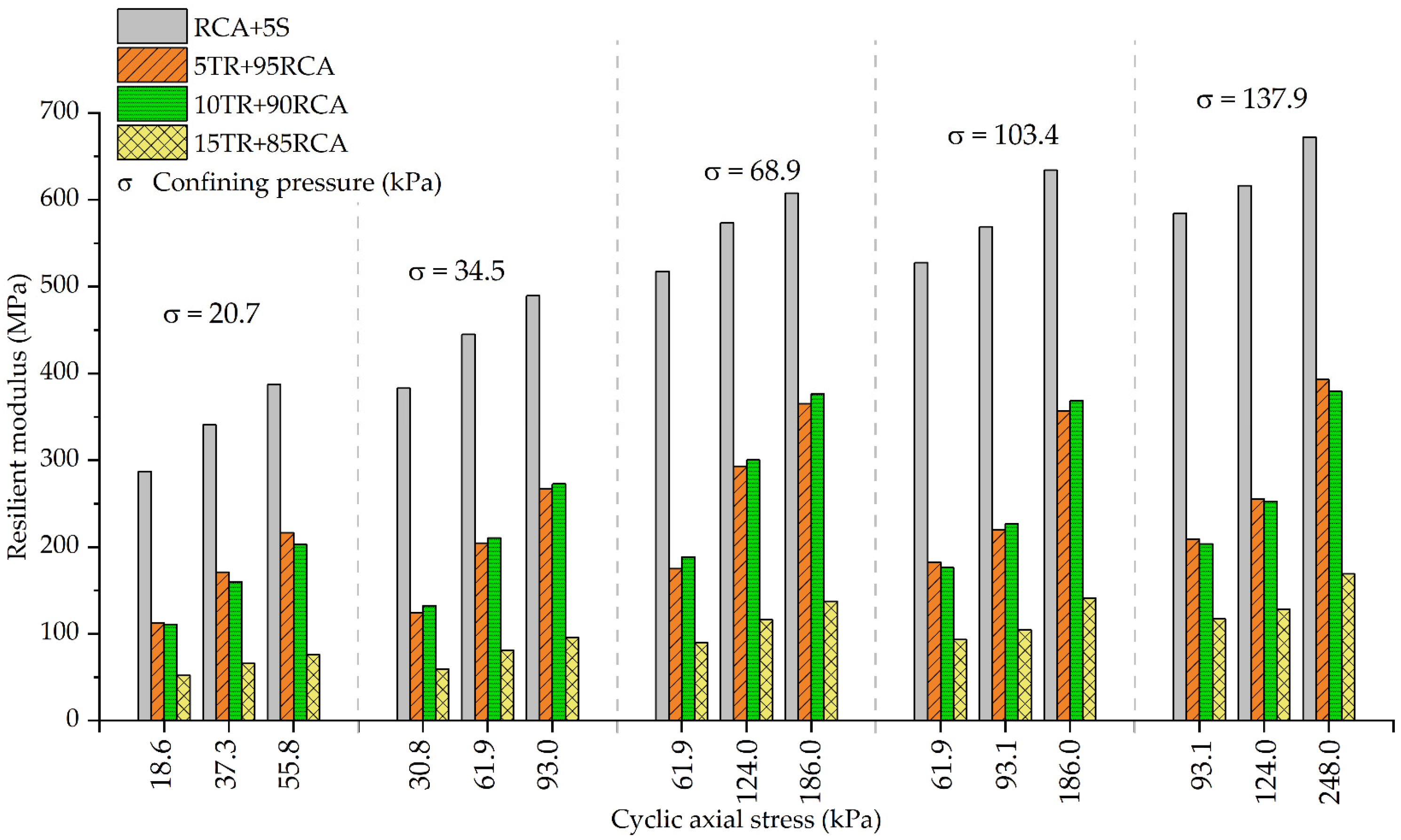

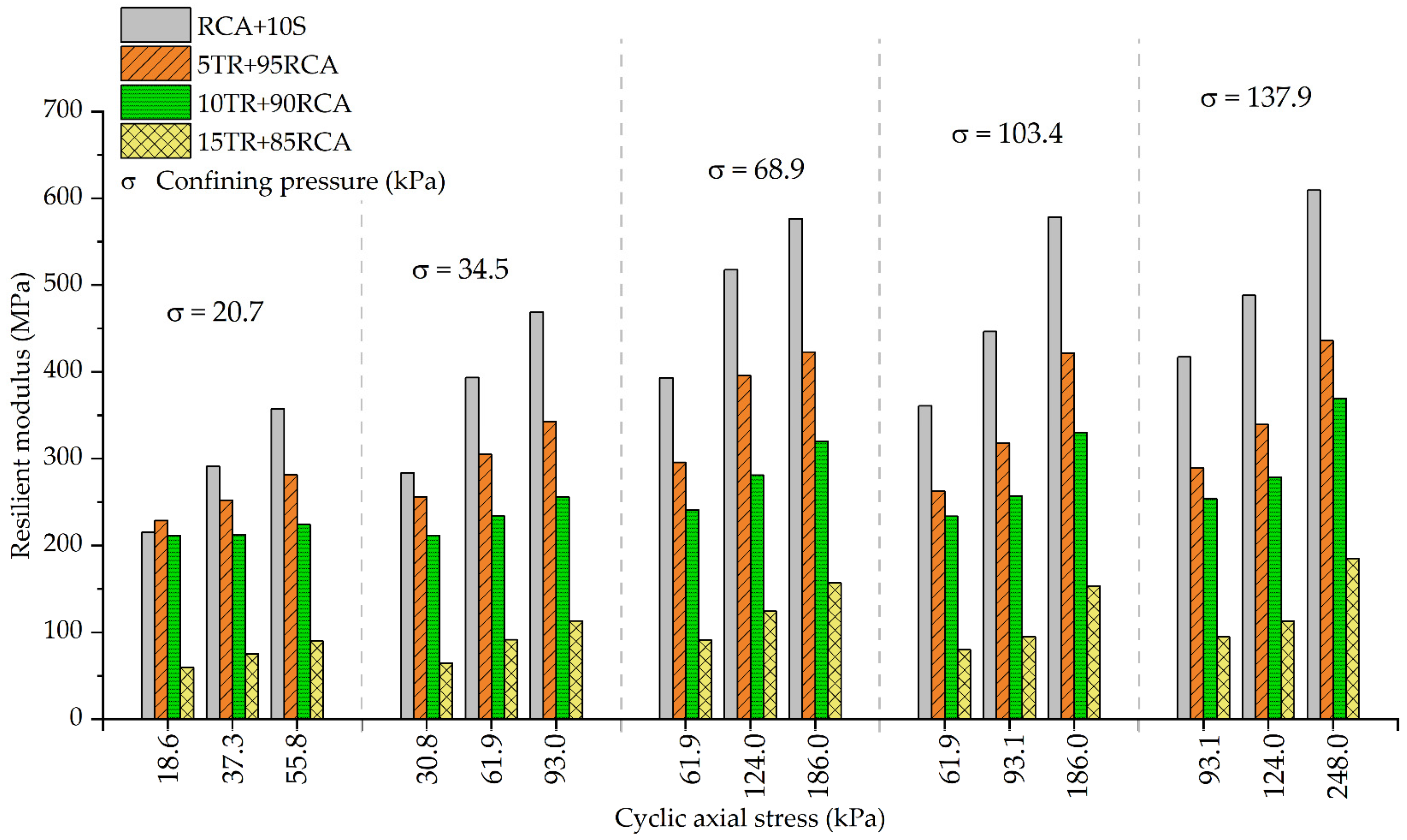

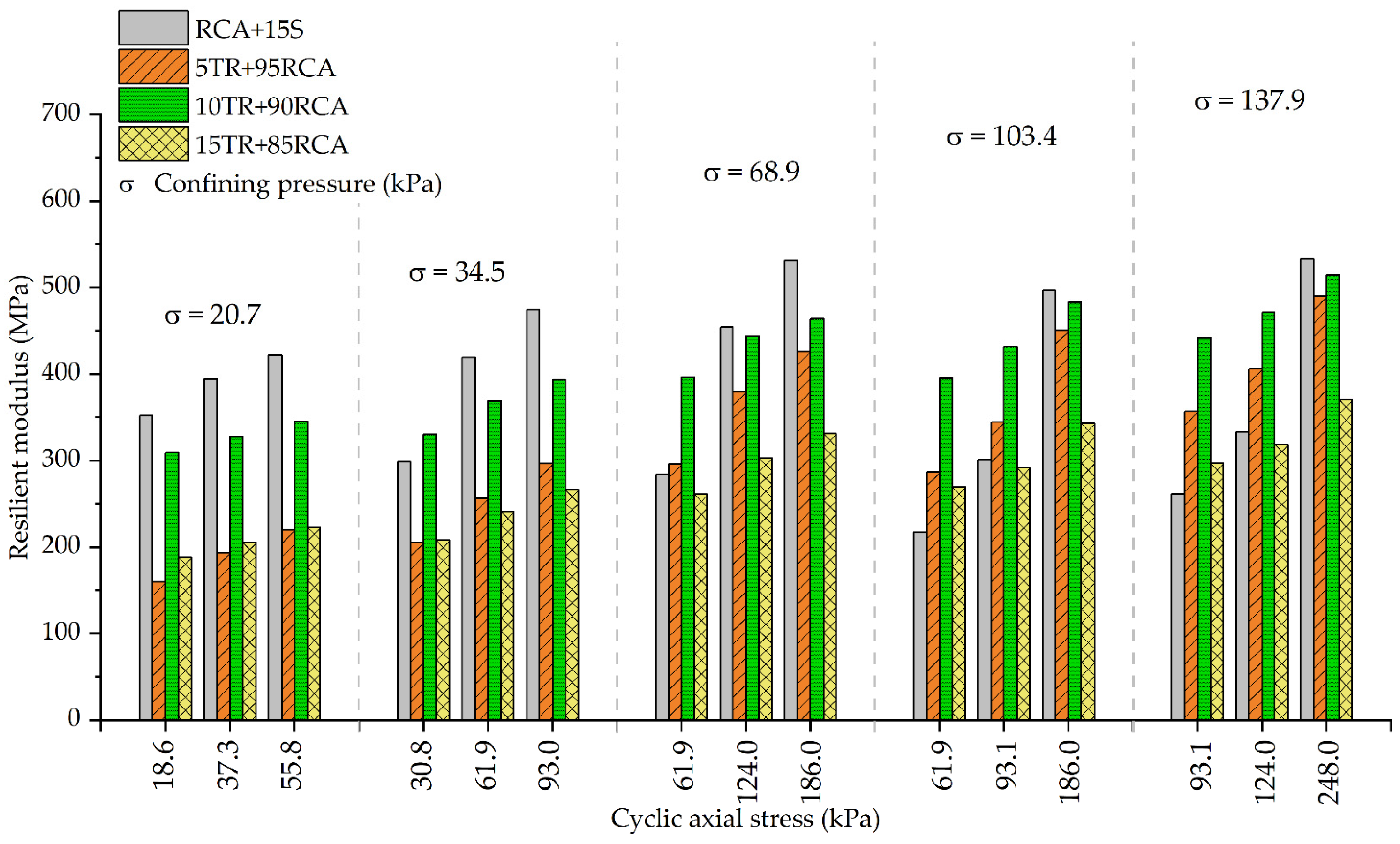

3.3. Evaluation of Resilient Modulus

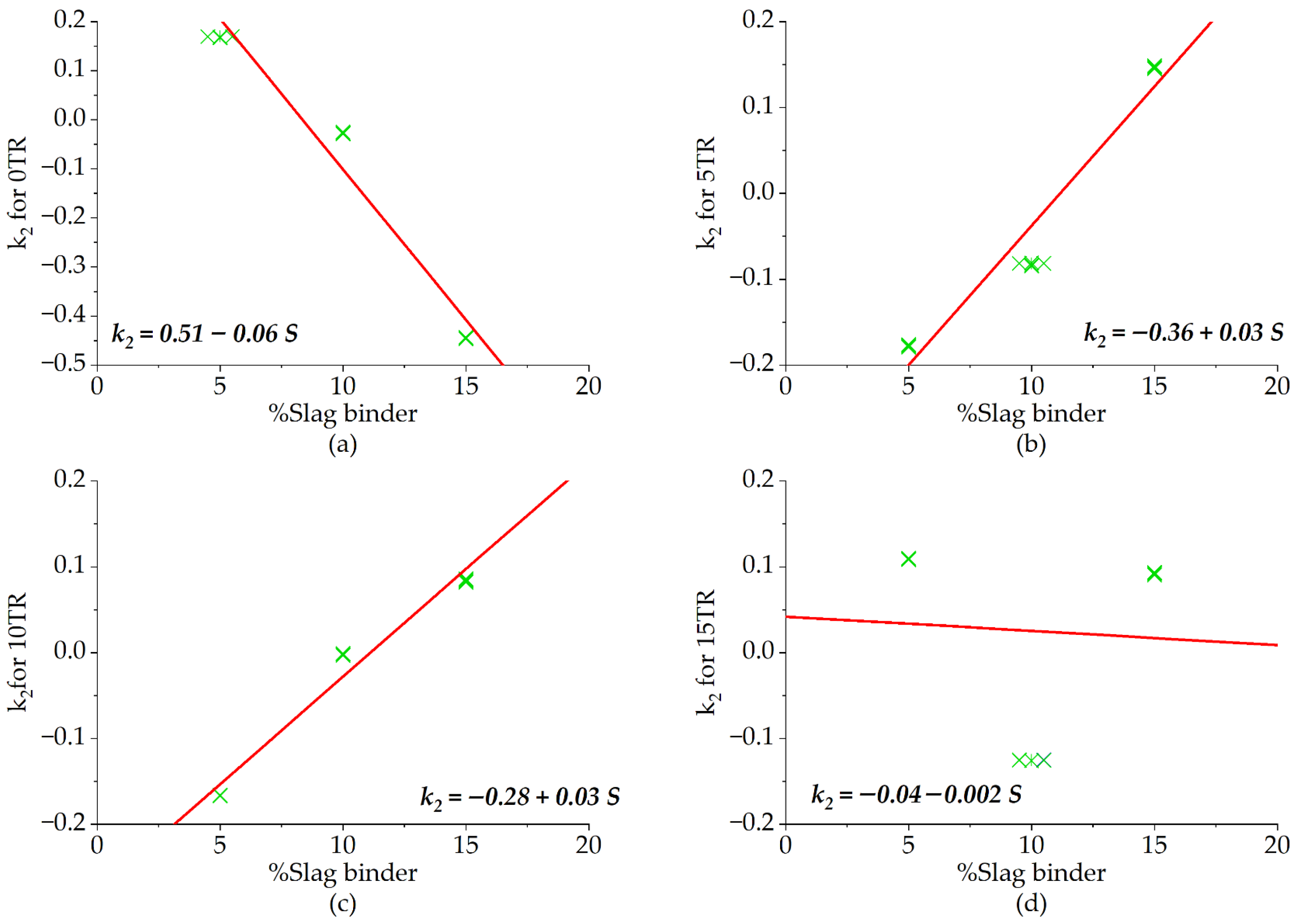

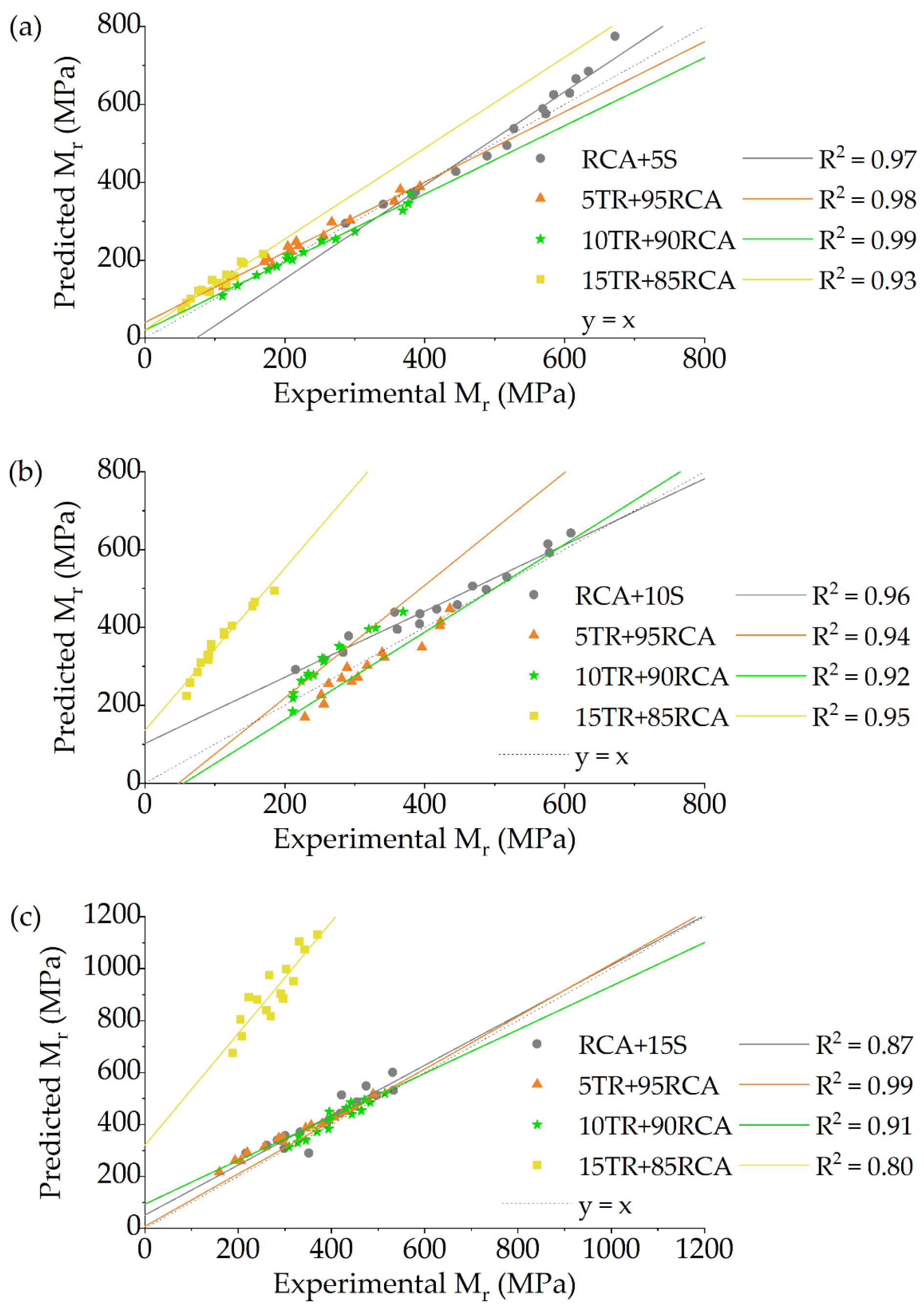

Estimation of the Resilient Modulus

3.4. Flexural Performance

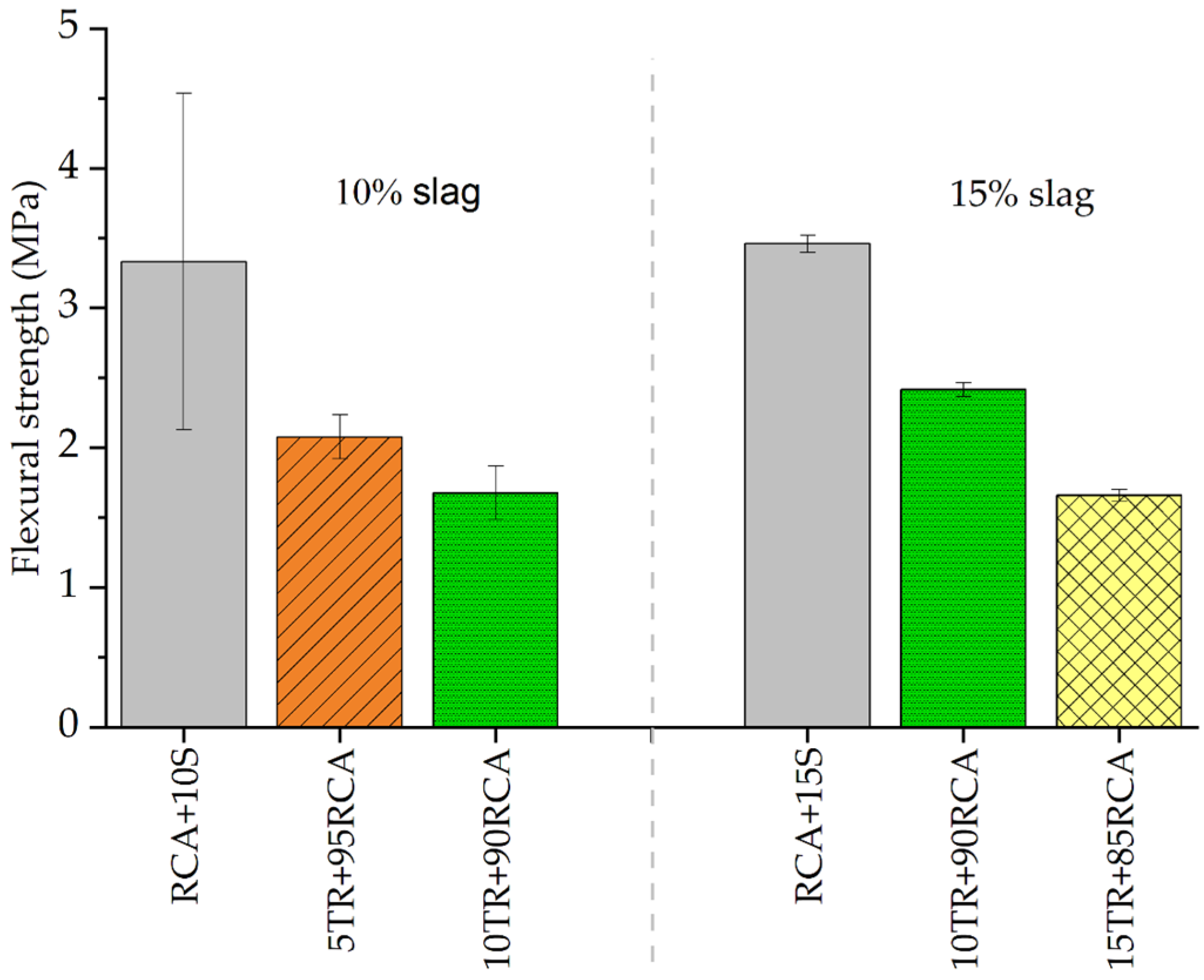

3.4.1. Flexural Strength

3.4.2. Flexural Modulus

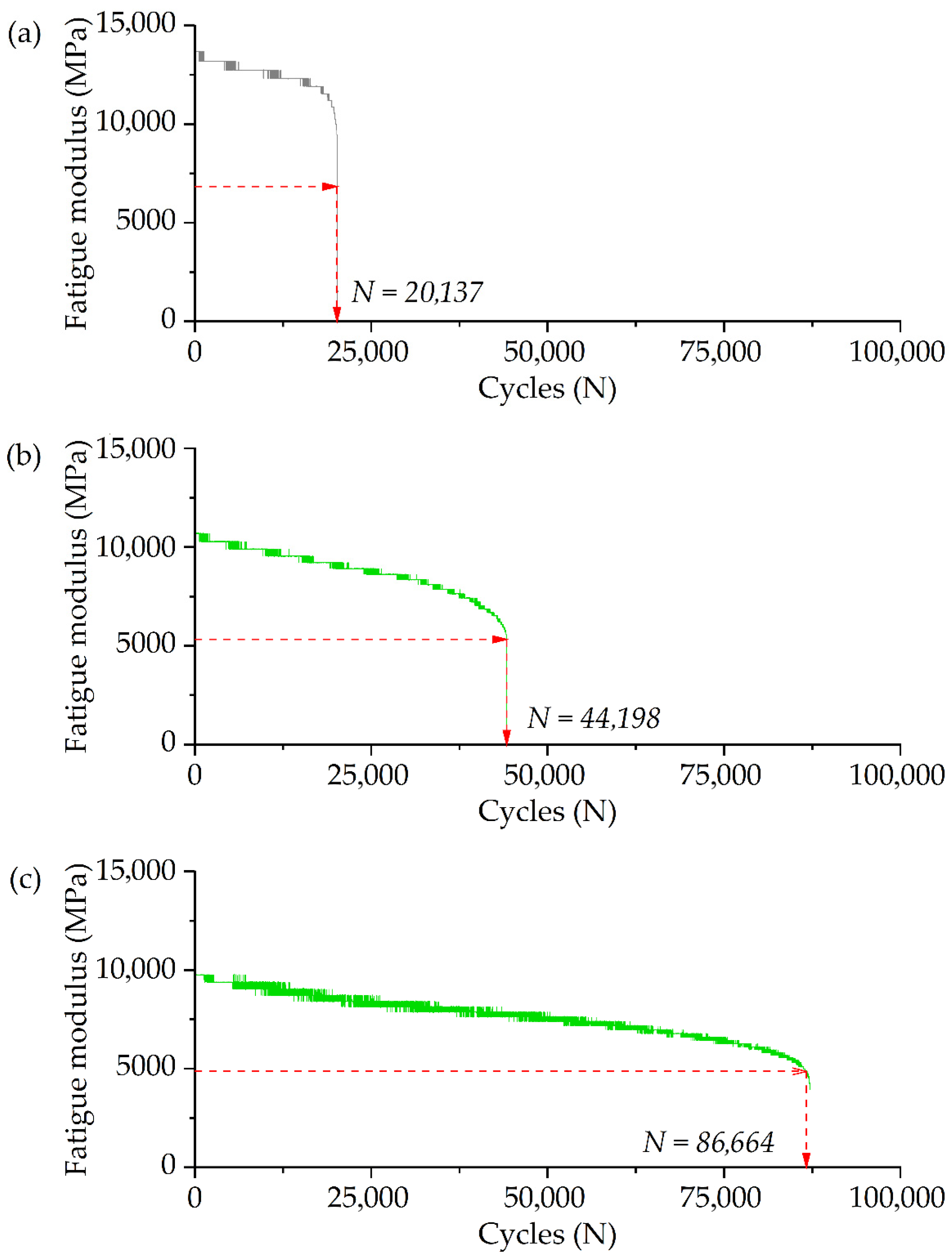

3.4.3. Flexural Fatigue

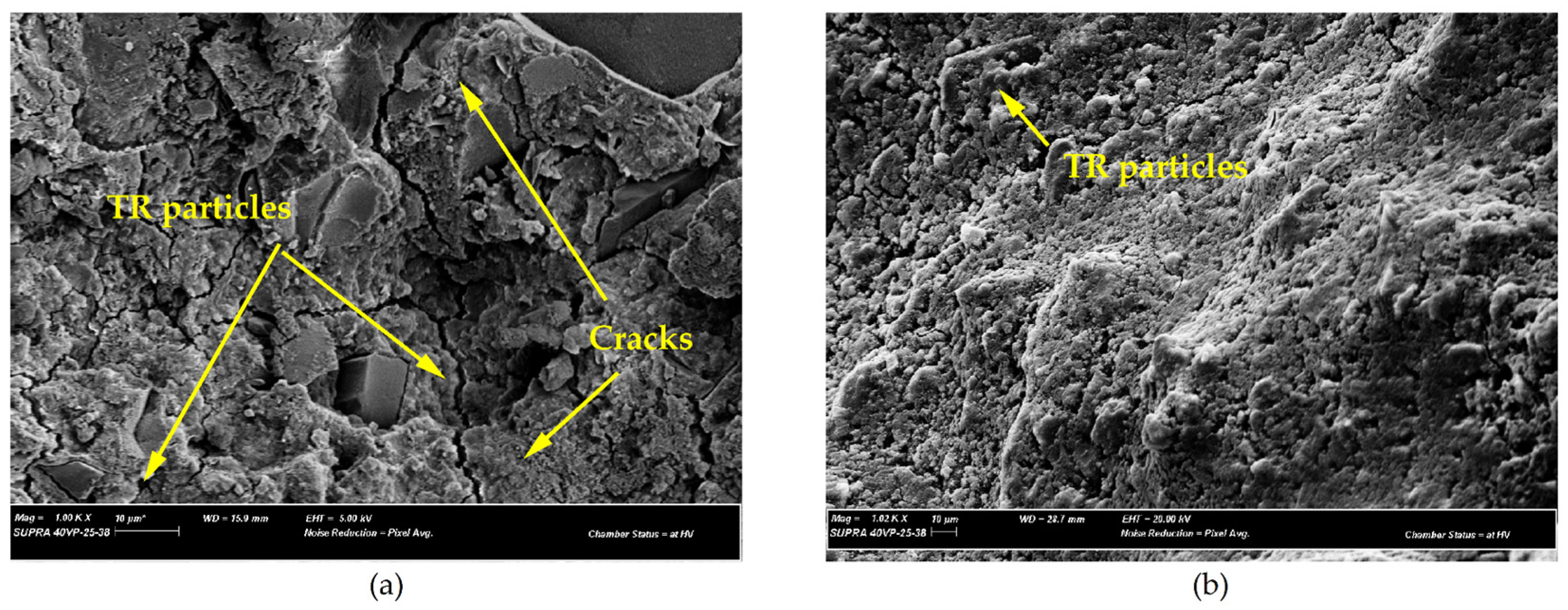

3.5. Microstructure of Slag Geopolymer-Stabilised TR + RCA Mixes

3.6. Leaching Characteristics

4. Conclusions

- The decrease in compaction characteristics of unbound TR + RCA mixes was compensated by the addition of slag geopolymer, which increased the overall density of the mix despite the inclusion of TR.

- Unconfined compressive strength (UCS) results and microstructural studies suggest that the performance of slag geopolymer-stabilised TR + RCA mixes is primarily influenced by improved binding due to the formation of geopolymer gel products, resulting in enhanced compressive strength. All mixes with 15% slag satisfied the minimum subbase UCS requirement of 2 MPa.

- The resilient modulus values of all TR + RCA mixes stabilised with 15% slag geopolymer satisfied the minimum required range of 80 MPa to 330 MPa for pavement bases as specified in AASHTO T-307. The predicted results from the octahedral stress model showed excellent correlations with the experimental test results.

- The highest flexural strength was recorded for control mixes with 15% slag. A consistent decrease in flexural strength was observed with increasing TR content. However, the reduction in flexural strength was less pronounced compared to compressive strength, as the TR particles help delay the onset of cracks.

- The addition of TR decreased the flexural modulus of the material; however, it significantly improved the fatigue life of the material.

- No potential risk of soil and water contamination was detected when using slag geopolymer-stabilised TR + RCA.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AS | Australian standards |

| AIV | Aggregate impact value |

| CBR | California bearing ratio |

| LAAV | Los Angeles abrasion value |

| MDD | Maximum dry density |

| OMC | Optimum moisture content |

| OPC | Ordinary Portland cement |

| RAP | Reclaimed asphalt pavement |

| RCA | Recycled concrete aggregates |

| RLT | Repeated load triaxial |

| TR | Tyre rubber |

| UCS | Unconfined compression strength |

| XRD | X-ray diffraction |

| XRF | X-ray fluorescence |

References

- Pickin, J.; Wardle, C.; O’Farrell, K.; Stovell, L.; Nyunt, P.; Guazzo, S.; Lin, Y.; Caggiati-Shortell, G.; Chakma, P.; Edwards, C.; et al. National Waste Report; The Department of Climate Change, Energy, the Environment and Water: Parramatta, NSW, Australia; Blue Environment Pty Ltd.: Docklands, VIC, Australia, 2022. [Google Scholar]

- Pickin, J.; Wardle, C.; O’Farrell, K.; Nyunt, P.; Donovan, S. National Waste Report 2020; Department of Agriculture, Water and the Environment: Canberra, ACT, Australia, 2020. [Google Scholar]

- Velvizhi, G.; Shanthakumar, S.; Das, B.; Pugazhendhi, A.; Priya, T.S.; Ashok, B.; Nanthagopal, K.; Vignesh, R.; Karthick, C. Biodegradable and non-biodegradable fraction of municipal solid waste for multifaceted applications through a closed loop integrated refinery platform: Paving a path towards circular economy. Sci. Total Environ. 2020, 731, 138049. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Bui Van, D.; Ubachukwu, O.; Ezugwu, C.; Salahudeen, B.; Nguyen Van, M.; Ikeagwuani, C.; Amhadi, T.; Sosa, F.; Wu, W. Recycling and reuse of solid wastes; a hub for ecofriendly, ecoefficient and sustainable soil, concrete, wastewater and pavement reengineering. Int. J. Low-Carbon Technol. 2019, 14, 440–451. [Google Scholar] [CrossRef]

- Huang, H.; Yuan, Y.; Zhang, W.; Zhu, L. Property assessment of high-performance concrete containing three types of fibers. Int. J. Concr. Struct. Mater. 2021, 15, 39. [Google Scholar] [CrossRef]

- Anburuvel, A.; Priyadarshana, H.; Kulathunga, R. Assessment of mechanical characteristics of crushed rock substituted with tyre crumb for the application of road base or subbase layers of road pavement. Int. J. Pavement Res. Technol. 2025, 18, 843–857. [Google Scholar] [CrossRef]

- Ahmed, A.; Shah, S.K.H.; Ahmad, N.; Ali, U.; Malik, A.A.; Iqbal, M.J. Feasibility of utilizing recycled concrete aggregate blended with waste tire rubber and drywall waste as pavement subbase material. J. Mater. Cycles Waste Manag. 2024, 26, 2278–2293. [Google Scholar] [CrossRef]

- Juveria, F.; Rajeev, P.; Jegatheesan, P.; Sanjayan, J. Impact of stabilisation on mechanical properties of recycled concrete aggregate mixed with waste tyre rubber as a pavement material. Case Stud. Constr. Mater. 2023, 18, e02001. [Google Scholar] [CrossRef]

- Aly, A.M.; El-Feky, M.; Kohail, M.; Nasr, E.-S.A. Performance of geopolymer concrete containing recycled rubber. Constr. Build. Mater. 2019, 207, 136–144. [Google Scholar] [CrossRef]

- Siddika, A.; Al Mamun, M.A.; Alyousef, R.; Amran, Y.M.; Aslani, F.; Alabduljabbar, H. Properties and utilizations of waste tire rubber in concrete: A review. Constr. Build. Mater. 2019, 224, 711–731. [Google Scholar] [CrossRef]

- Migunthanna, J.; Rajeev, P.; Sanjayan, J. Waste Clay Bricks as a Geopolymer Binder for Pavement Construction. Sustainability 2022, 14, 6456. [Google Scholar] [CrossRef]

- Migunthanna, J.; Manjunatha, N.T.; Shatagar, V.G.; Raghu, D.H.; Zinzala, R.S.; Rajeev, P.; Sanjayan, J. Simplified life cycle analysis for rigid pavements constructed using waste materials as binders in concrete. Int. J. Stud. Proj. Report. 2022, 1, 143–165. [Google Scholar] [CrossRef]

- Arulrajah, A.; Perera, S.; Wong, Y.C.; Maghool, F.; Horpibulsuk, S. Stabilization of PET plastic-demolition waste blends using fly ash and slag-based geopolymers in light traffic road bases/subbases. Constr. Build. Mater. 2021, 284, 122809. [Google Scholar] [CrossRef]

- Luhar, S.; Chaudhary, S.; Luhar, I. Development of rubberized geopolymer concrete: Strength and durability studies. Constr. Build. Mater. 2019, 204, 740–753. [Google Scholar] [CrossRef]

- Jallu, M.; Arulrajah, A.; Saride, S.; Evans, R. Flexural fatigue behavior of fly ash geopolymer stabilized-geogrid reinforced RAP bases. Constr. Build. Mater. 2020, 254, 119263. [Google Scholar] [CrossRef]

- Mohamed, O.A. Effects of the curing regime, acid exposure, alkaline activator dosage, and precursor content on the strength development of mortar with alkali-activated slag and fly ash binder: A critical review. Polymers 2023, 15, 1248. [Google Scholar] [CrossRef]

- AS 1289.5.2.1; Methods of Testing Soils for Engineering Purposes Soil Compaction and Density Tests—Determination of the Dry Density/Moisture Content Relation of a Soil Using Modified Compactive Effort. Australian Standards: Sydney, NSW, Australia, 2017.

- ASTM D5102; Standard Test Method for Unconfined Compressive Strength of Compacted Soil-Lime Mixtures. American Society for Testing and Materials: West Conshohocken, PA, USA, 2024.

- AASHTO T-307; Standard Method of Test for Determining the Resilient Modulus of Soils and Aggregate Materials. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2021.

- AS 1012.11; 2014 Methods of Testing Concrete, Methods 11: Determination of the Modulus of Rupture. Australian Standards: Sydney, NSW, Australia, 2014.

- Austroads. Austroads Test Method AGPT/T600: Flexural Beam Test Methods for Cemented Materials; Austroads: Sydney, NSW, Australia, 2018.

- TxDOT. Standard Specifications for Construction and Maintenance of Highways, Streets, and Bridges: Adopted by the Texas Department of Transportation, November 1, 2014; Texas Department of Transportation: Austin, TX, USA, 2014.

- AS 4439.3; Wastes, Sediments and Contaminated Soils-Part 3: Preparation of Bottle Leaching Procedure. Australian Standard: Sydney, NSW, Australia, 2019.

- EPA Victoria. Industrial Waste Resource Guidelines: Solid Industrial Waste Hazard Categorisation and Management; Environmental Protection Agency, Victoria: Carlton, VIC, Australia, 2009. [Google Scholar]

- EPA. National Primary Drinking Water Regulations. Drinking Water Contaminants. Available online: https://www.epa.gov/ground-water-and-drinking-water/national-primary-drinking-water-regulations (accessed on 20 July 2025).

- European Union. Directive (EU) 2020/2184 of the European Parliament and of the Council on the Quality of Water Intended for Human Consumption; European Union: Brussels, Belgium, 2020. [Google Scholar]

- National End-of-Waste Decision EoW-N001/2023 of 12th September 2023. Establishing Criteria Determining When Recycled Aggregate Ceases to Be Waste Under Regulation 28 of the European Union (Waste Directive) Regulations 2011–2020. Available online: https://www.epa.ie/publications/licensing--permitting/waste/Final-Decision---National-End-of-Waste-Criteria-N001-2023.pdf (accessed on 20 October 2025).

- Cabalar, A.F.; Karabash, Z.; Mustafa, W.S. Stabilising a clay using tyre buffings and lime. Road Mater. Pavement Des. 2014, 15, 872–891. [Google Scholar] [CrossRef]

- Yadav, J.; Tiwari, S. Evaluation of the strength characteristics of cement-stabilized clay–crumb rubber mixtures for its sustainable use in geotechnical applications. Environ. Dev. Sustain. 2018, 20, 1961–1985. [Google Scholar] [CrossRef]

- Yadav, J.; Tiwari, S. A study on the potential utilization of crumb rubber in cement treated soft clay. J. Build. Eng. 2017, 9, 177–191. [Google Scholar] [CrossRef]

- Abdila, S.R.; Abdullah, M.M.A.B.; Ahmad, R.; Rahim, S.Z.A.; Rychta, M.; Wnuk, I.; Nabiałek, M.; Muskalski, K.; Tahir, M.F.M.; Syafwandi; et al. Evaluation on the mechanical properties of ground granulated blast slag (GGBS) and fly ash stabilized soil via geopolymer process. Materials 2021, 14, 2833. [Google Scholar] [CrossRef]

- Zabielska-Adamska, K.; Wasil, M.; Dobrzycki, P. Resilient response of cement-treated coarse post-glacial soil to cyclic load. Materials 2021, 14, 6495. [Google Scholar] [CrossRef]

- Arulrajah, A.; Maghool, F.; Yaghoubi, M.; Phetchuay, C.; Horpibulsuk, S. Temperature and Duration Impact on the Strength Development of Geopolymerized Granulated Blast Furnace Slag for Usage as a Construction Material. J. Mater. Civ. Eng. 2021, 33, 04020474. [Google Scholar] [CrossRef]

- Migunthanna, J.; Rajeev, P.; Sanjayan, J. Waste Clay Brick as a Part Binder for Pavement Grade Geopolymer Concrete. Int. J. Pavement Res. Technol. 2023, 17, 1450–1467. [Google Scholar] [CrossRef]

- Samantasinghar, S.; Singh, S.P. Strength and durability of granular soil stabilized with FA-GGBS geopolymer. J. Mater. Civ. Eng. 2021, 33, 06021003. [Google Scholar] [CrossRef]

- Lang, L.; Chen, B.; Chen, B. Strength evolutions of varying water content-dredged sludge stabilized with alkali-activated ground granulated blast-furnace slag. Constr. Build. Mater. 2021, 275, 122111. [Google Scholar] [CrossRef]

- Saberian, M.; Li, J.; Perera, S.T.A.M.; Zhou, A.; Roychand, R.; Ren, G. Large-scale direct shear testing of waste crushed rock reinforced with waste rubber as pavement base/subbase materials. Transp. Geotech. 2021, 28, 100546. [Google Scholar]

- Huang, J.; Kogbara, R.B.; Hariharan, N.; Masad, E.A.; Little, D.N. A state-of-the-art review of polymers used in soil stabilization. Constr. Build. Mater. 2021, 305, 124685. [Google Scholar] [CrossRef]

- Farhan, A.H.; Dawson, A.R.; Thom, N.H. Characterization of rubberized cement bound aggregate mixtures using indirect tensile testing and fractal analysis. Constr. Build. Mater. 2016, 105, 94–102. [Google Scholar] [CrossRef]

- Zhao, X.; Dong, Q.; Chen, X.; Ni, F. Meso-cracking characteristics of rubberized cement-stabilized aggregate by discrete element method. J. Clean. Prod. 2021, 316, 128374. [Google Scholar] [CrossRef]

- Liu, F.; Meng, L.-Y.; Ning, G.-F.; Li, L.-J. Fatigue performance of rubber-modified recycled aggregate concrete (RRAC) for pavement. Constr. Build. Mater. 2015, 95, 207–217. [Google Scholar] [CrossRef]

- Puppala, A.J.; Mohammad, L.N.; Allen, A. Engineering behavior of lime-treated Louisiana subgrade soil. Transp. Res. Rec. 1996, 1546, 24–31. [Google Scholar] [CrossRef]

- AASHTO. American Association of State Highway and Transportation Officials, Guide for Design of Pavement Structures; AASHTO: Washington, DC, USA, 1993. [Google Scholar]

- Khasawneh, M.A.; Al-jamal, N.F. Modeling resilient modulus of fine-grained materials using different statistical techniques. Transp. Geotech. 2019, 21, 100263. [Google Scholar] [CrossRef]

- Zhang, J.; Gu, F.; Zhang, Y. Use of building-related construction and demolition wastes in highway embankment: Laboratory and field evaluations. J. Clean. Prod. 2019, 230, 1051–1060. [Google Scholar] [CrossRef]

- Hicks, R.G. Factors Influencing the Resilient Properties of Granular Materials; University of California: Berkeley, CA, USA, 1970. [Google Scholar]

- Mohammadinia, A.; Arulrajah, A.; Sanjayan, J.; Disfani, M.M.; Bo, M.W.; Darmawan, S. Laboratory evaluation of the use of cement-treated construction and demolition materials in pavement base and subbase applications. J. Mater. Civ. Eng. 2015, 27, 04014186. [Google Scholar] [CrossRef]

- Puppala, A.J.; Hoyos, L.R.; Potturi, A.K. Resilient moduli response of moderately cement-treated reclaimed asphalt pavement aggregates. J. Mater. Civ. Eng. 2011, 23, 990–998. [Google Scholar] [CrossRef]

- Fakhri, M. The effect of waste rubber particles and silica fume on the mechanical properties of roller compacted concrete pavement. J. Clean. Prod. 2016, 129, 521–530. [Google Scholar] [CrossRef]

- Gnanendran, C.; Paul, D.K. Fatigue characterization of lightly cementitiously stabilized granular base materials using flexural testing. J. Mater. Civ. Eng. 2016, 28, 04016086. [Google Scholar] [CrossRef]

- González, A.; Jameson, G.; de Carteret, R.; Yeo, R. Laboratory fatigue life of cemented materials in Australia. Road Mater. Pavement Des. 2013, 14, 518–536. [Google Scholar] [CrossRef]

- Badiger, M.; Mamatha, K.; Dinesh, S. Mechanical Evaluation of Granular Sub-base Reinforced with Recycled Tyres: A Way Towards Sustainability. Geotech. Geol. Eng. 2025, 43, 189. [Google Scholar] [CrossRef]

- Karimi, H.R.; Aliha, M.; Ebneabbasi, P.; Salehi, S.; Khedri, E.; Haghighatpour, P.J. Mode I and mode II fracture toughness and fracture energy of cement concrete containing different percentages of coarse and fine recycled tire rubber granules. Theor. Appl. Fract. Mech. 2023, 123, 103722. [Google Scholar] [CrossRef]

- Liu, F.; Zheng, W.; Li, L.; Feng, W.; Ning, G. Mechanical and fatigue performance of rubber concrete. Constr. Build. Mater. 2013, 47, 711–719. [Google Scholar] [CrossRef]

- Liu, M.; Lu, J.; Jiang, W.; Ming, P. Study on fatigue damage and fatigue crack propagation of rubber concrete. J. Build. Eng. 2023, 65, 105718. [Google Scholar] [CrossRef]

| Composition | Slag | RCA | Composition | Slag | RCA |

|---|---|---|---|---|---|

| Al2O3 | 12.42 | 7.29 | P2O5 | 0.016 | 0.147 |

| CaO | 43.82 | 10.83 | SO3 | 4.398 | 0.41 |

| Cr2O3 | - | 0.02 | SiO2 | 33.03 | 65.97 |

| Fe2O3 | 0.38 | 4.88 | TiO2 | 0.57 | 0.81 |

| K2O | 0.31 | 0.82 | BaO | - | 0.03 |

| MgO | 5.57 | 2.71 | Total | 96.64 | 100.09 |

| MnO | 0.17 | 0.07 | LOI a | 0.1 | - |

| Na2O | 0.19 | 1.89 | |||

| Test Type | Material Composition (%) | Slag (wt%) | Testing Standard and Details |

|---|---|---|---|

| Compaction | 100RCA (Control) | 5, 10, 15 | AS 1289.5.2.1 [17] |

| 5TR + 95RCA | 5, 10, 15 | Determination of OMC and MDD using modified Proctor compaction. | |

| 10TR + 90RCA | 5, 10, 15 | ||

| 15TR + 90RCA | 5, 10, 15 | ||

| UCS | 100RCA (Control) | 5, 10, 15 | ASTM D5102 [18] |

| 5TR + 95RCA | 5, 10, 15 | Unconfined compressive strength after 7 days of curing. | |

| 10TR + 90RCA | 5, 10, 15 | ||

| 15TR + 90RCA | 5, 10, 15 | ||

| RLT | 100RCA (Control) | 5, 10, 15 | AASHTO T-307 [19] |

| 5TR + 95RCA | 5, 10, 15 | Repeated load triaxial test after 7 days of curing. | |

| 10TR + 90RCA | 5, 10, 15 | ||

| 15TR + 90RCA | 5, 10, 15 | ||

| Flexure test | 100RCA | 10, 15 | AS 1012.11 [20] |

| 5TR + 95RCA | 10, 15 | Flexural strength studies after 28 days of curing | |

| 10TR + 90RCA | 10, 15 | ||

| 15TR + 85RCA | 15 | ||

| Flexural modulus | 100RCA | 10, 15 | Austroads AGPT/T600 [21] |

| 5TR + 95RCA 10TR + 9RCA | 10, 15 15 | Flexural resilient and fatigue modulus after 28 days of curing. | |

| 15TR + 85RCA | 15 | ||

| Fatigue test | 5TR + 95RCA | 10 | Austroads AGPT/T600 [21] |

| 10TR + 90RCA | 15 | Flexural resilient and fatigue modulus after 28 days of curing. | |

| 15TR + 85RCA | 15 | ||

| SEM | 10TR + 90RCA | 10, 15 | Standard electron microscopy after 7 days of curing. |

| 15TR + 85RCA | 10, 15 |

| Slag Geopolymer Binder Content | TR + RCA Composition% | 7-Day Average UCS (MPa) | Alignment with TxDOT Criteria [22] (UCS ≥ 2 MPa) |

|---|---|---|---|

| 5% | 5TR + 95RCA | 1.20 | ✘ |

| 10TR + 90RCA | 0.98 | ✘ | |

| 15TR + 85RCA | 0.72 | ✘ | |

| 10% | 5TR + 95RCA | 2.87 | ✔ |

| 10TR + 90RCA | 1.85 | ✘ | |

| 15TR + 85RCA | 1.05 | ✘ | |

| 15% | 5TR + 95RCA | 4.82 | ✔ |

| 10TR + 90RCA | 2.99 | ✔ | |

| 15TR + 85RCA | 2.21 | ✔ |

| % Slag | RMSE | |||

|---|---|---|---|---|

| 0% TR | 5% TR | 10% TR | 15% TR | |

| 5 | 19.67 | 6.58 | 9.02 | 3.70 |

| 10 | 18.06 | 15.81 | 14.73 | 6.26 |

| 15 | 38.56 | 9.92 | 5.75 | 3.38 |

| Mix | Initial Flexural Fatigue Modulus (MPa) | Cycles to Reach Half of Initial Modulus |

|---|---|---|

| RCA + 15S | 13,690 | 20,137 |

| 5TR + 95RCA [10S] | 10,650 | 44,198 |

| 10TR + 90RCA [15S] | 9740 | 86,664 |

| Leachate Employed in ASLP | Solid Inert Waste Category | ||||

|---|---|---|---|---|---|

| Contaminant | Acetic Acid with pH = 5 (mg/L) | Tetraborate with pH = 9.2 (mg/L) | Maximum Allowable ASLP (mg/L) EPA Victoria [24] | Drinking Water Standards Maximum Allowable (mg/L) EPA USA [25] | Drinking Water Standards Maximum Allowable (mg/L) EU [26] |

| Silver | n-d a | n-d | 5 | 0.05 | N/A |

| Arsenic | 0.0002 | 0.0008 | 0.35 | 0.05 | 0.01 |

| Barium | 0.000204 | 0.000208 | 35 | 2 | N/A |

| Cadmium | n-d | n-d | 0.1 | 0.005 | 0.005 |

| Chromium | n-d | 0.01 | 2.5 | 0.1 | 0.025 |

| Copper | n-d | 0.03 | 100 | 1.3 | 0.002 |

| Mercury | n-d | n-d | 0.05 | 0.002 | 0.001 |

| Nickel | n-d | n-d | 1 | N/A b | 0.02 |

| Lead | n-d | n-d | 1.5 | 0.015 | 0.005 |

| Cyanide | n-d | n-d | 4 | N/A | 0.05 |

| Selenium | n-d | n-d | 0.5 | 0.002 | 0.02 |

| Zinc | n-d | n-d | 150 | N/A | N/A |

| Leachate Employed in TC (mg/kg) | Fill Material Category | Solid Inert Waste Category | General Use | |

|---|---|---|---|---|

| Contaminant | Deionised Water (pH = 4.93) (mg/kg) | Maximum Allowable TC (mg/kg) EPA Victoria [24] | Maximum Allowable TC (mg/kg) EPA Victoria [24] | Maximum Allowable TC (mg/kg) EU [27] |

| Silver | 0.00001 | 10 | 180 | N/A |

| Arsenic | 0.0021 | 20 | 500 | 0.063 |

| Barium | 0.2891 | N/A b | 6250 | 5.1 |

| Cadmium | 0.00025 | 3 | 100 | 0.0074 |

| Chromium | n-d a | 1 | 500 | 0.25 |

| Copper | n-d | 100 | 5000 | 7.3 |

| Mercury | n-d | 1 | 75 | 0.0057 |

| Nickel | 0.01 | 60 | 3000 | 0.069 |

| Lead | n-d | 300 | 1500 | 0.05 |

| Cyanide | n-d | 50 | 2500 | N/A |

| Selenium | 0.0015 | 10 | 50 | 0.15 |

| Zinc | 0.01 | 200 | 35,000 | 0.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Juveria, F.; Migunthanna, J.; Rajeev, P.; Sanjayan, J. Mechanical and Fatigue Performance of Recycled Concrete Aggregate Blended with Waste Tyre Rubber Stabilised with Slag for Pavement Application. Buildings 2025, 15, 3852. https://doi.org/10.3390/buildings15213852

Juveria F, Migunthanna J, Rajeev P, Sanjayan J. Mechanical and Fatigue Performance of Recycled Concrete Aggregate Blended with Waste Tyre Rubber Stabilised with Slag for Pavement Application. Buildings. 2025; 15(21):3852. https://doi.org/10.3390/buildings15213852

Chicago/Turabian StyleJuveria, Fatima, Janitha Migunthanna, Pathmanathan Rajeev, and Jay Sanjayan. 2025. "Mechanical and Fatigue Performance of Recycled Concrete Aggregate Blended with Waste Tyre Rubber Stabilised with Slag for Pavement Application" Buildings 15, no. 21: 3852. https://doi.org/10.3390/buildings15213852

APA StyleJuveria, F., Migunthanna, J., Rajeev, P., & Sanjayan, J. (2025). Mechanical and Fatigue Performance of Recycled Concrete Aggregate Blended with Waste Tyre Rubber Stabilised with Slag for Pavement Application. Buildings, 15(21), 3852. https://doi.org/10.3390/buildings15213852