Simulation of Reinforced Concrete Beam–Column Joint Pouring Process Based on Three-Dimensional Particle Flow Method

Abstract

1. Introduction

2. Three-Dimensional Particle Flow Method

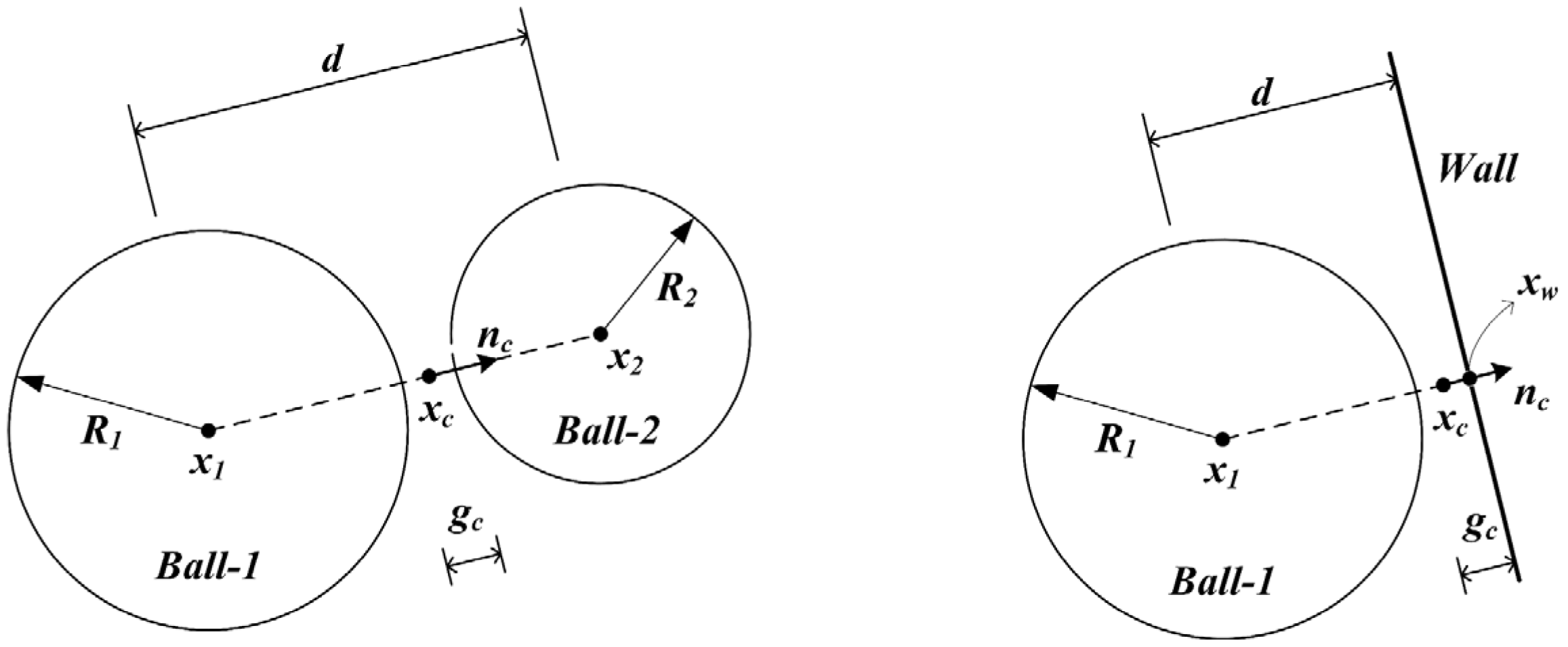

2.1. Basic Theory of Particle Flow Method

2.2. Rolling Resistance Linear Model

2.3. JKR Contact Model

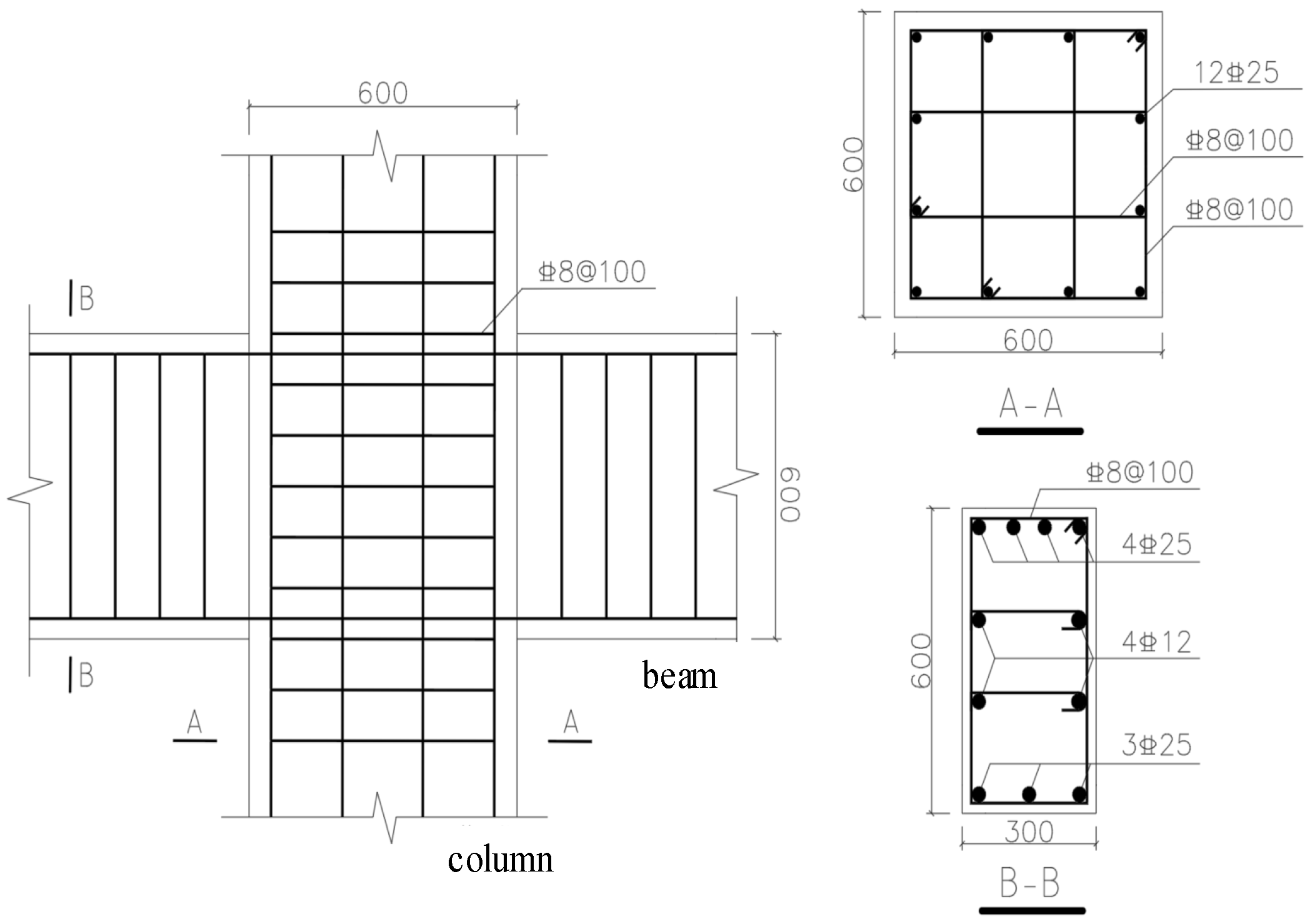

3. Materials and Methods

3.1. Experimental Materials

3.2. Standard Tests and Joint Pouring Test

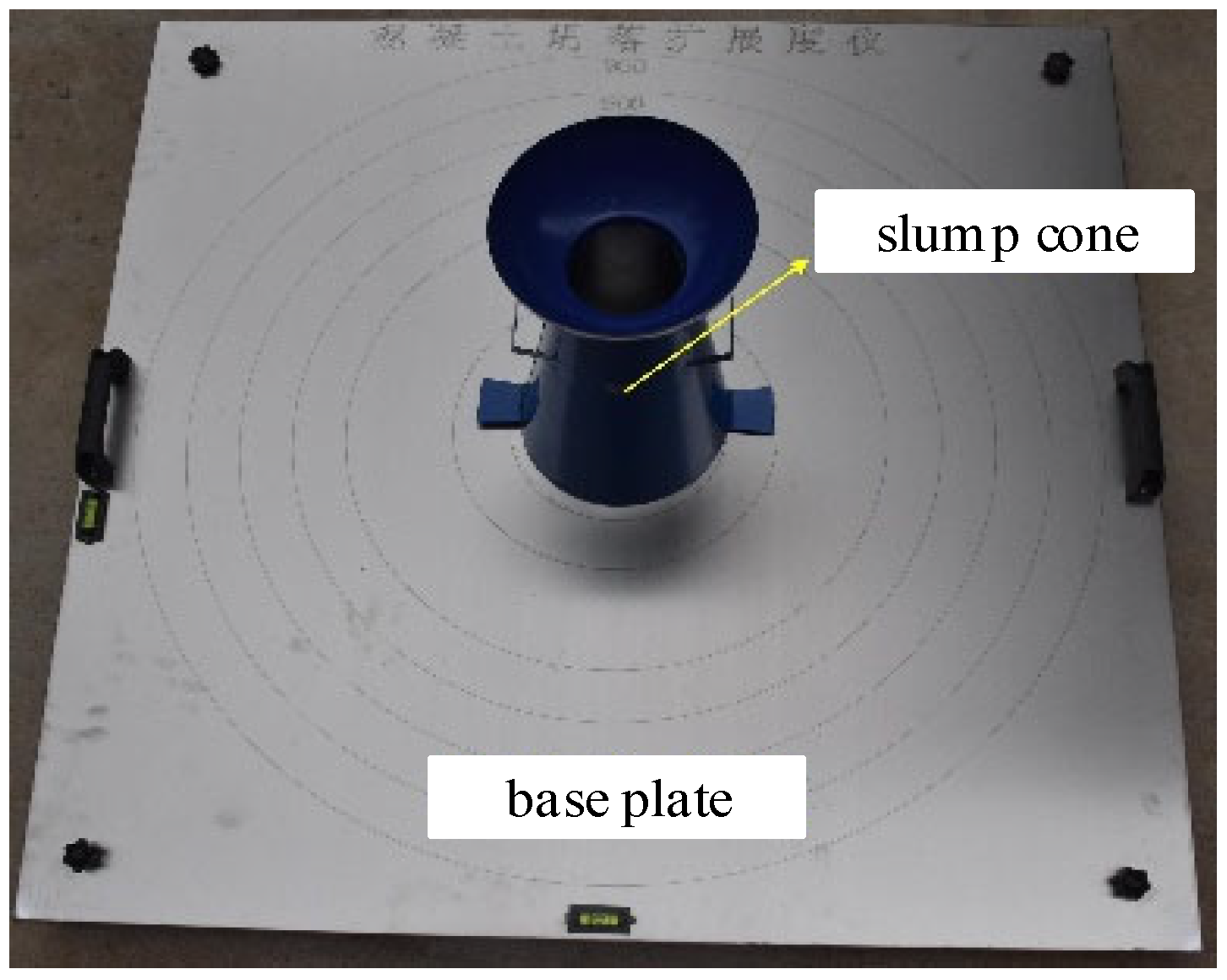

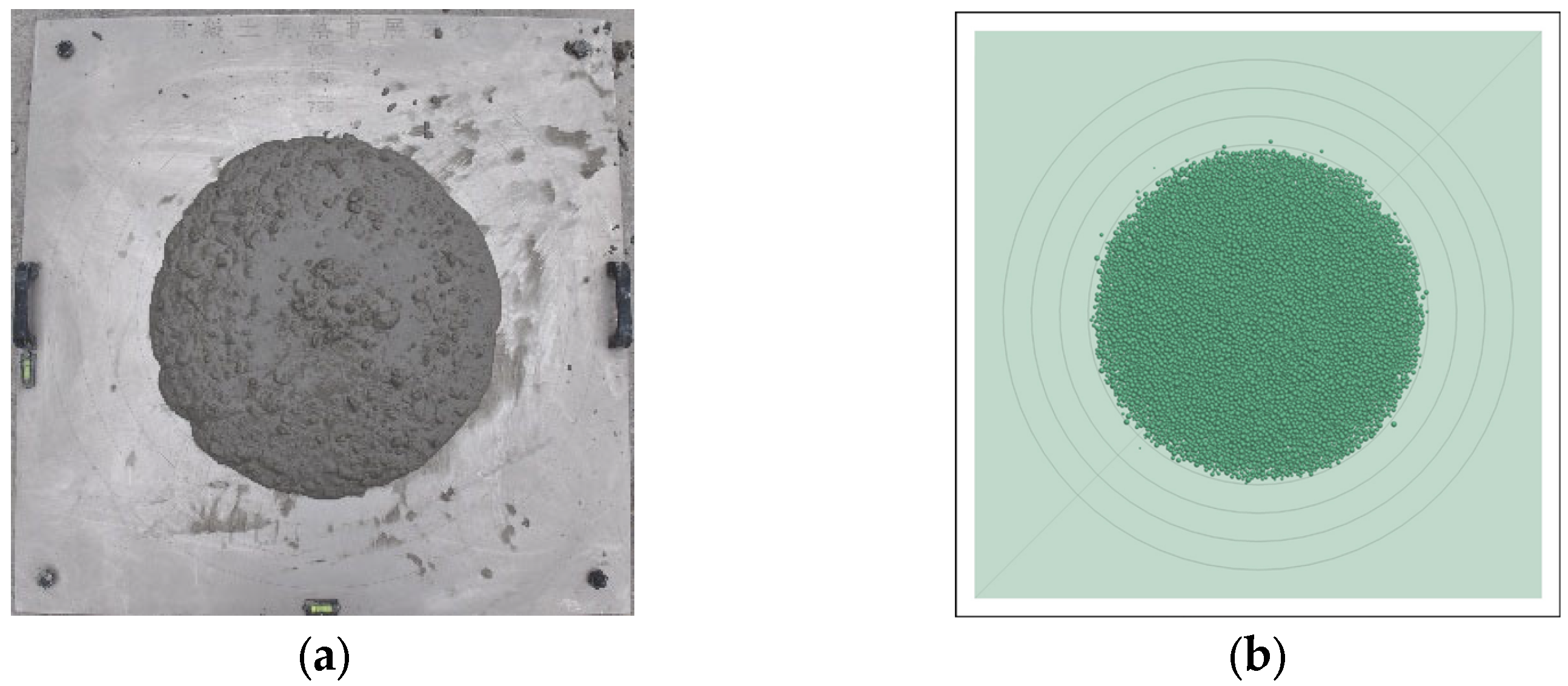

3.2.1. Slump Flow Test

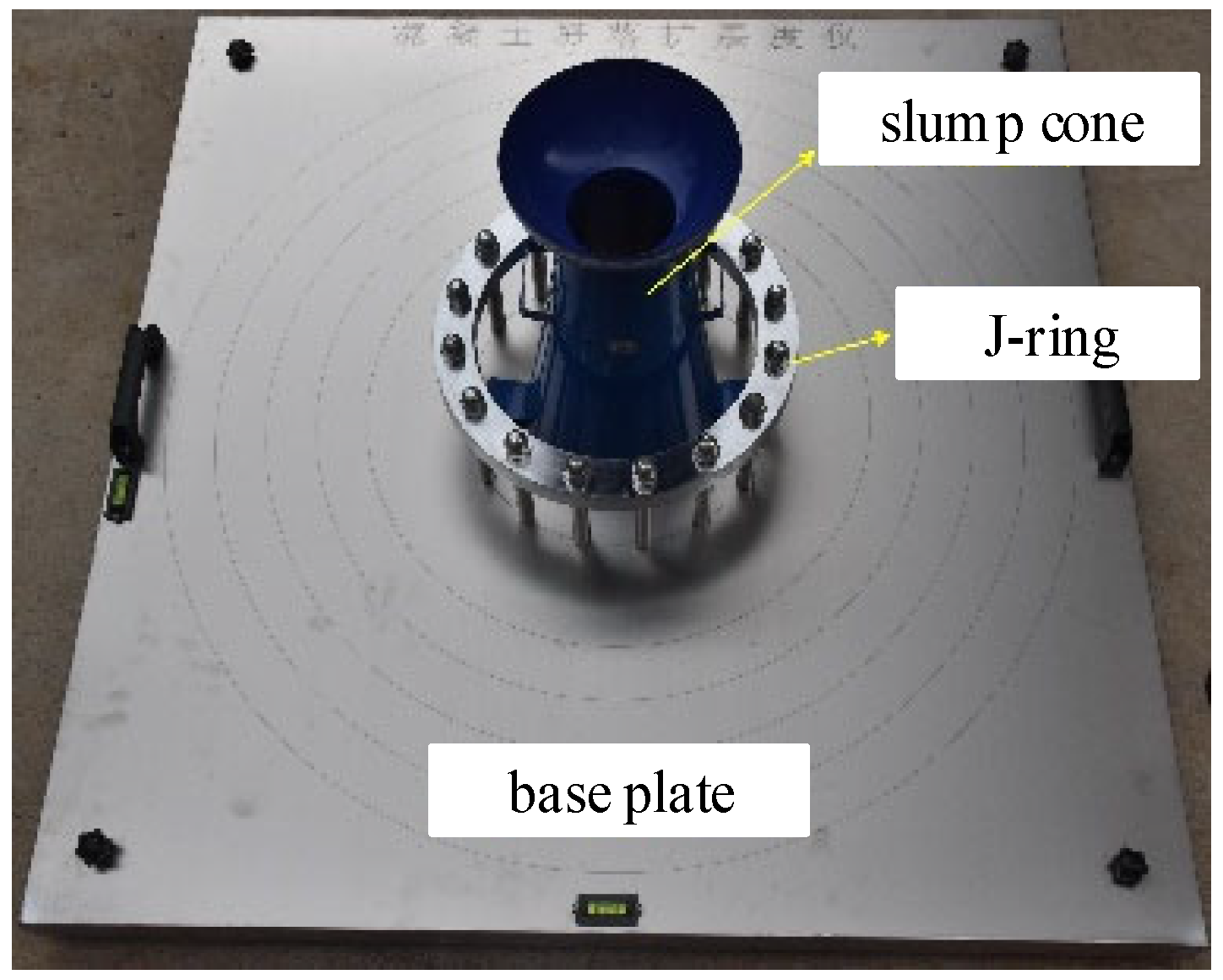

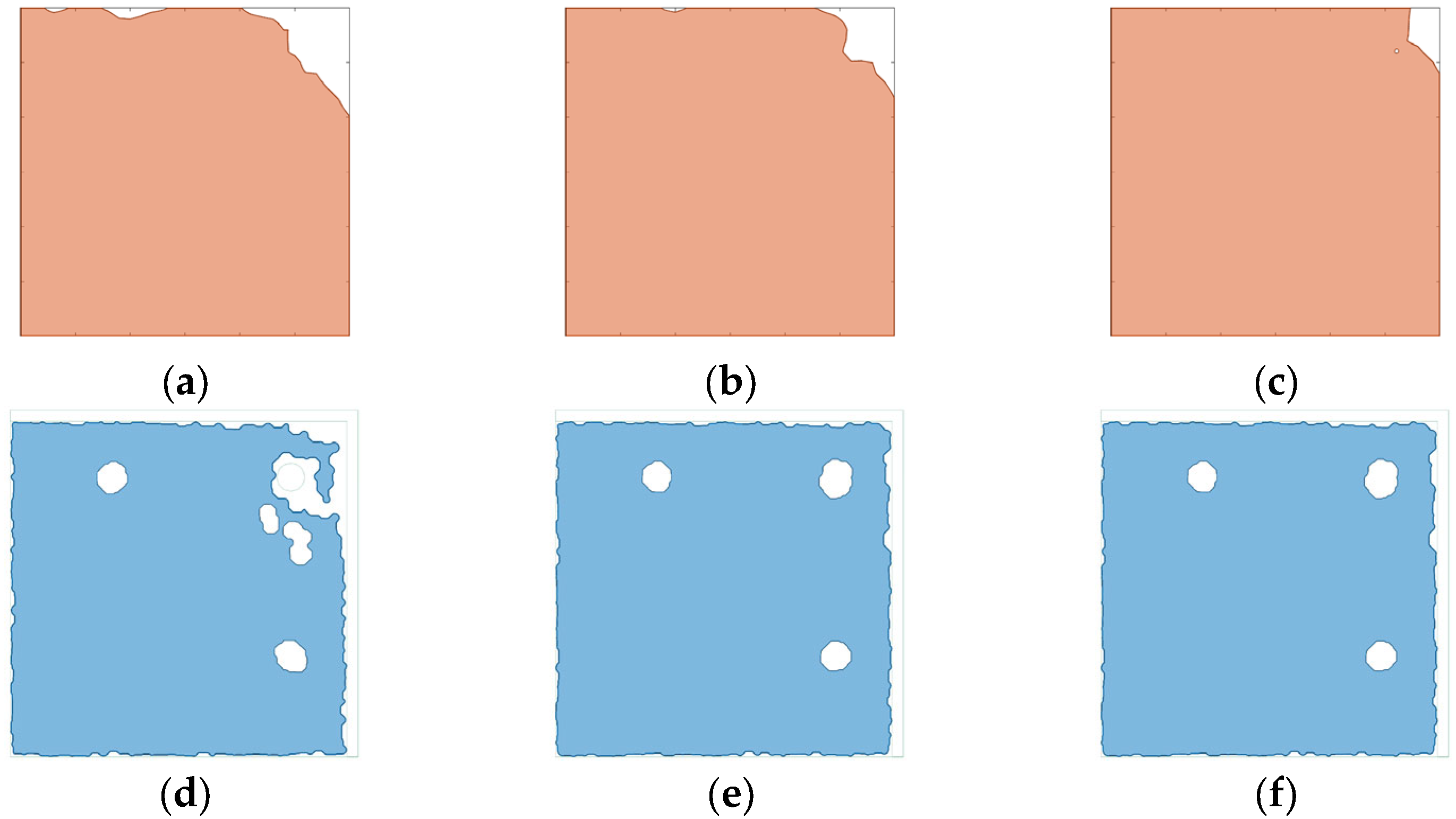

3.2.2. J-Ring Test

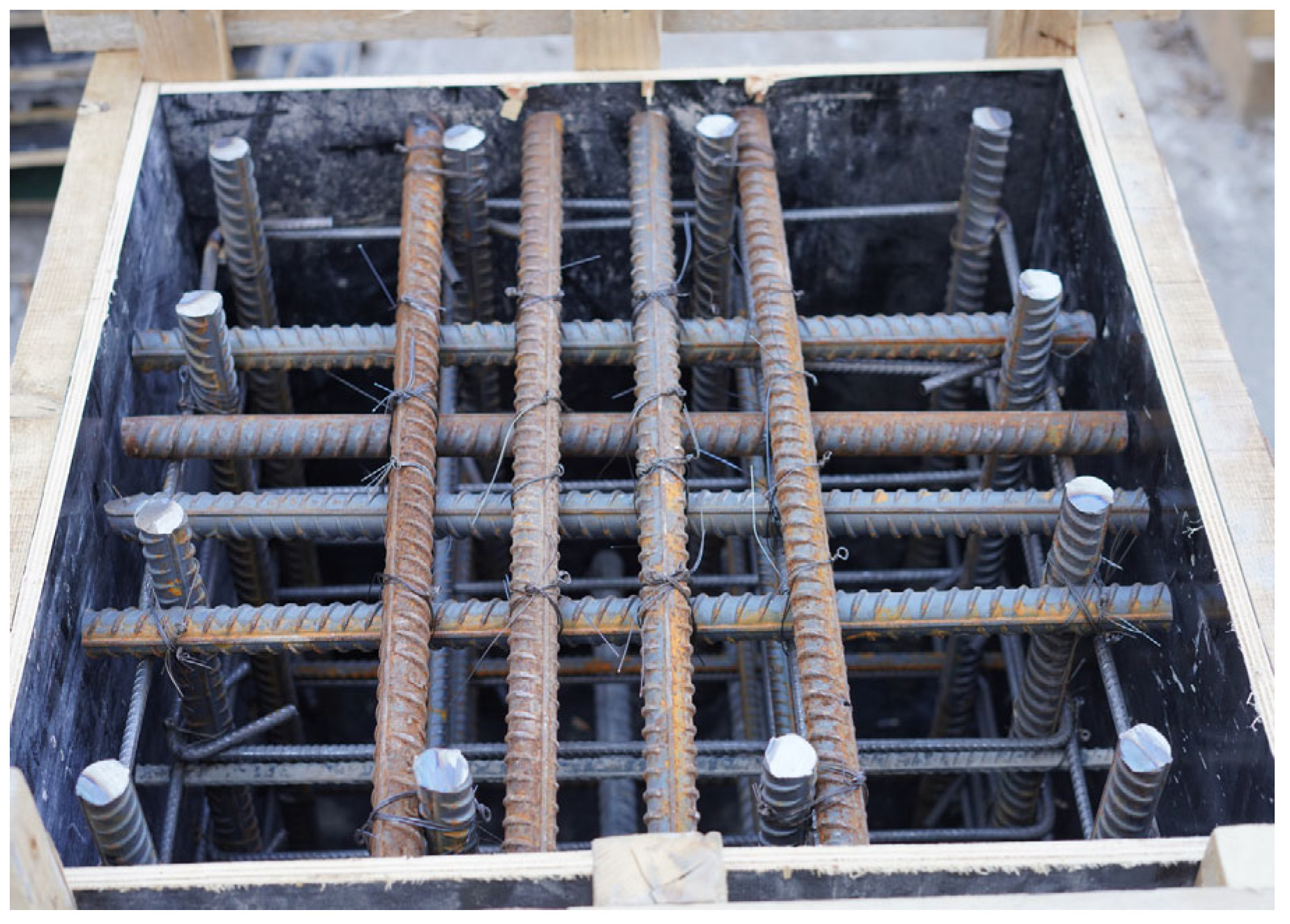

3.2.3. Joint Pouring Test

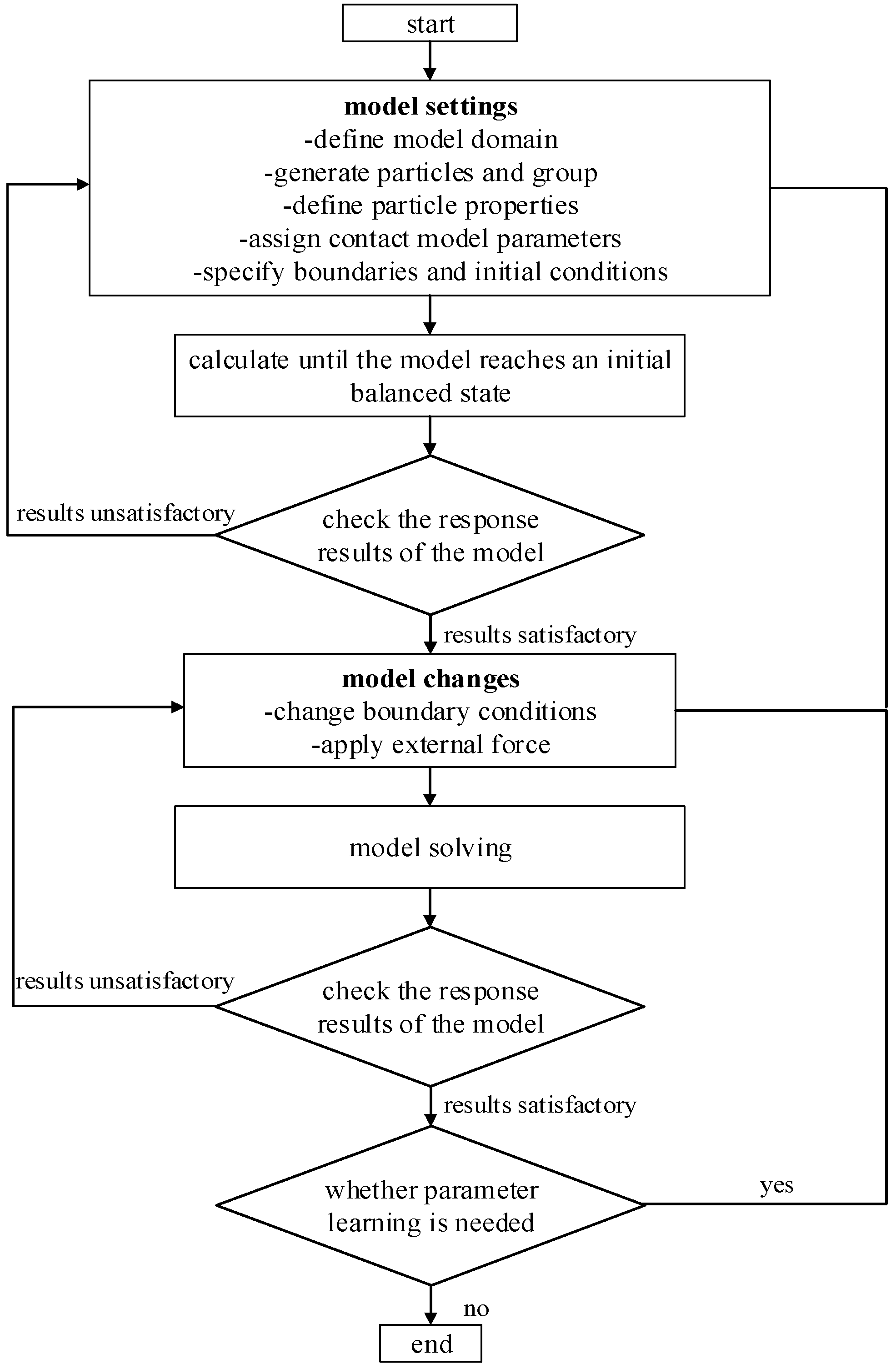

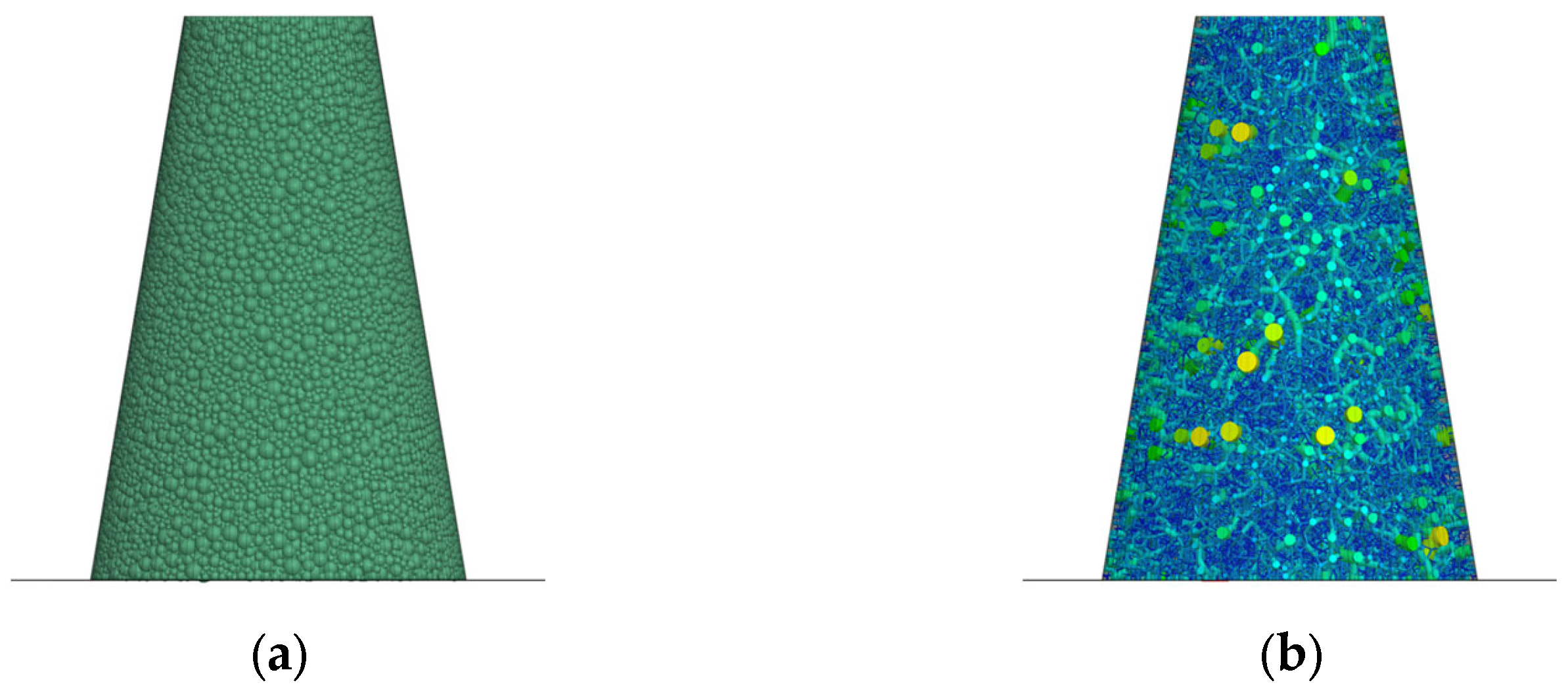

3.3. Numerical Simulation

3.3.1. Slump Model Establishment

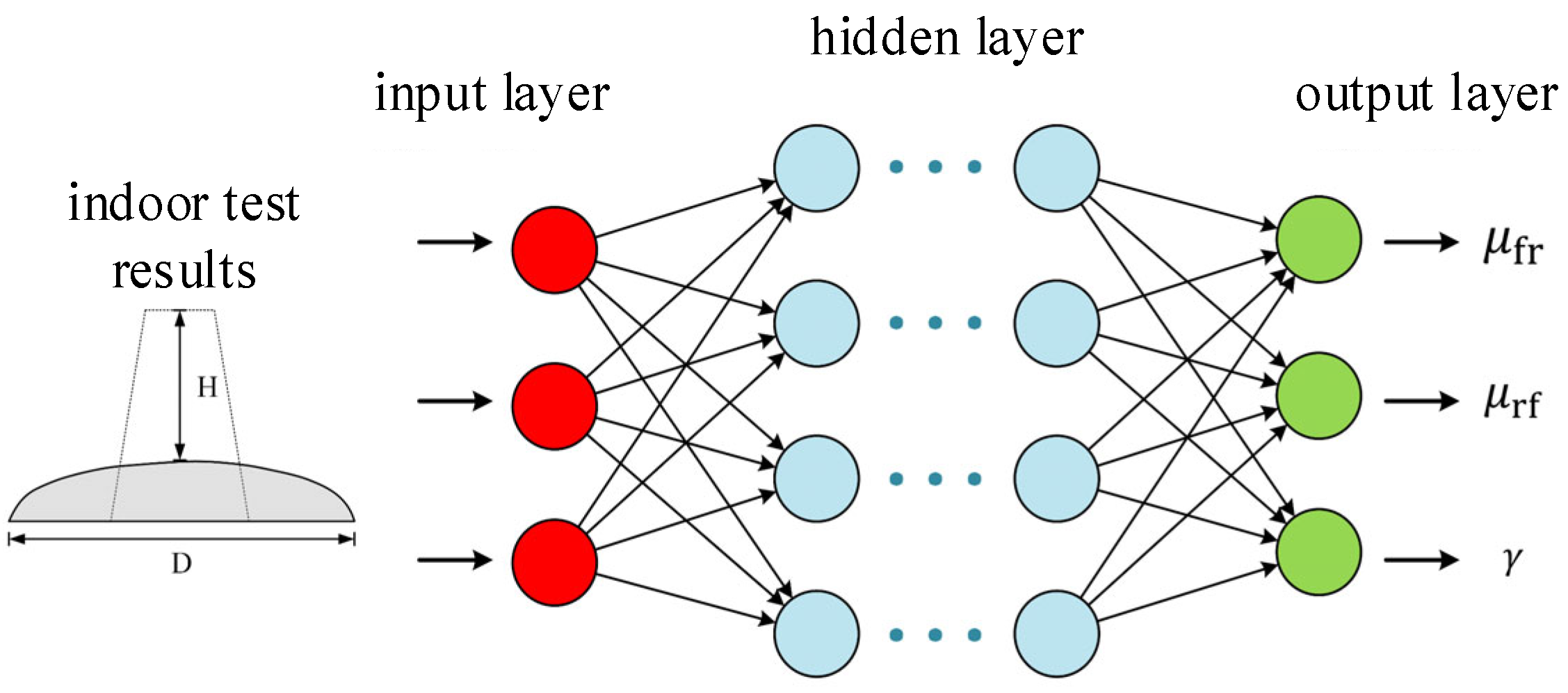

3.3.2. Model Parameter Calibration

4. Analysis of Test and Numerical Simulation Results

4.1. Slump Test Analysis

4.2. J-Ring Test Analysis

4.3. Joint Pouring Test Analysis

5. Analysis of Parameters Affecting Joint Pouring Quality

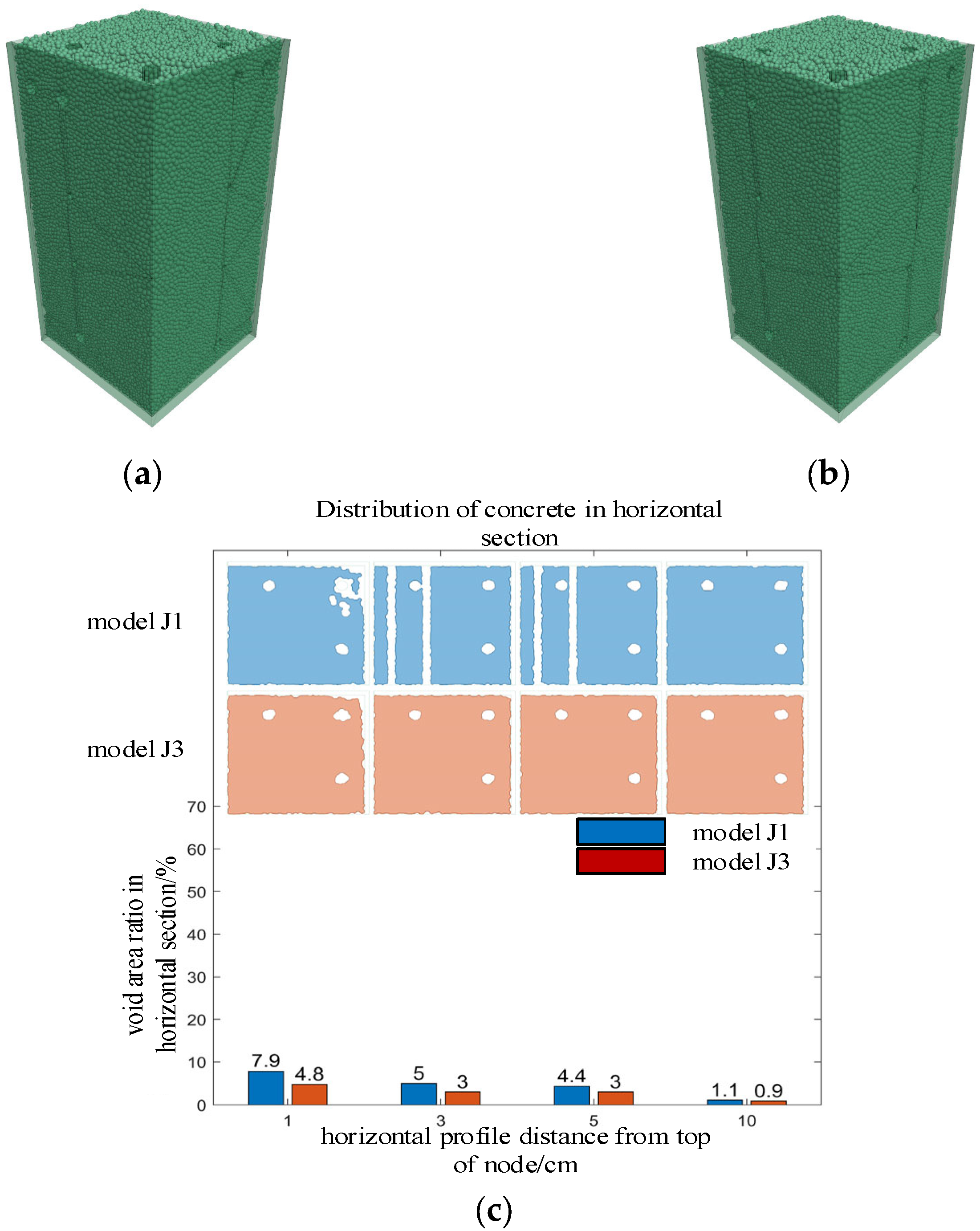

5.1. Number of Top Beam Longitudinal Bars

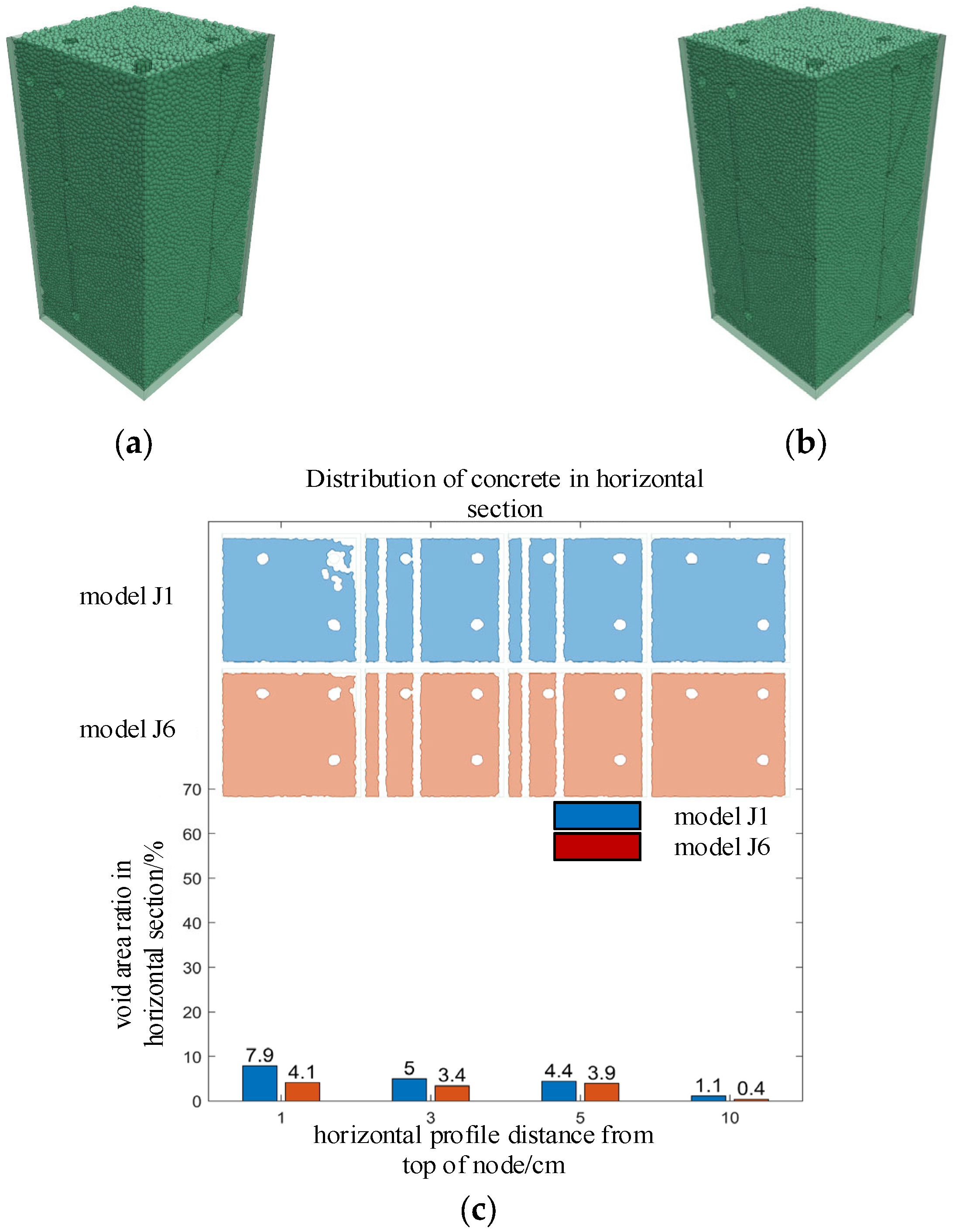

5.2. Diameter of Top Beam Longitudinal Bars

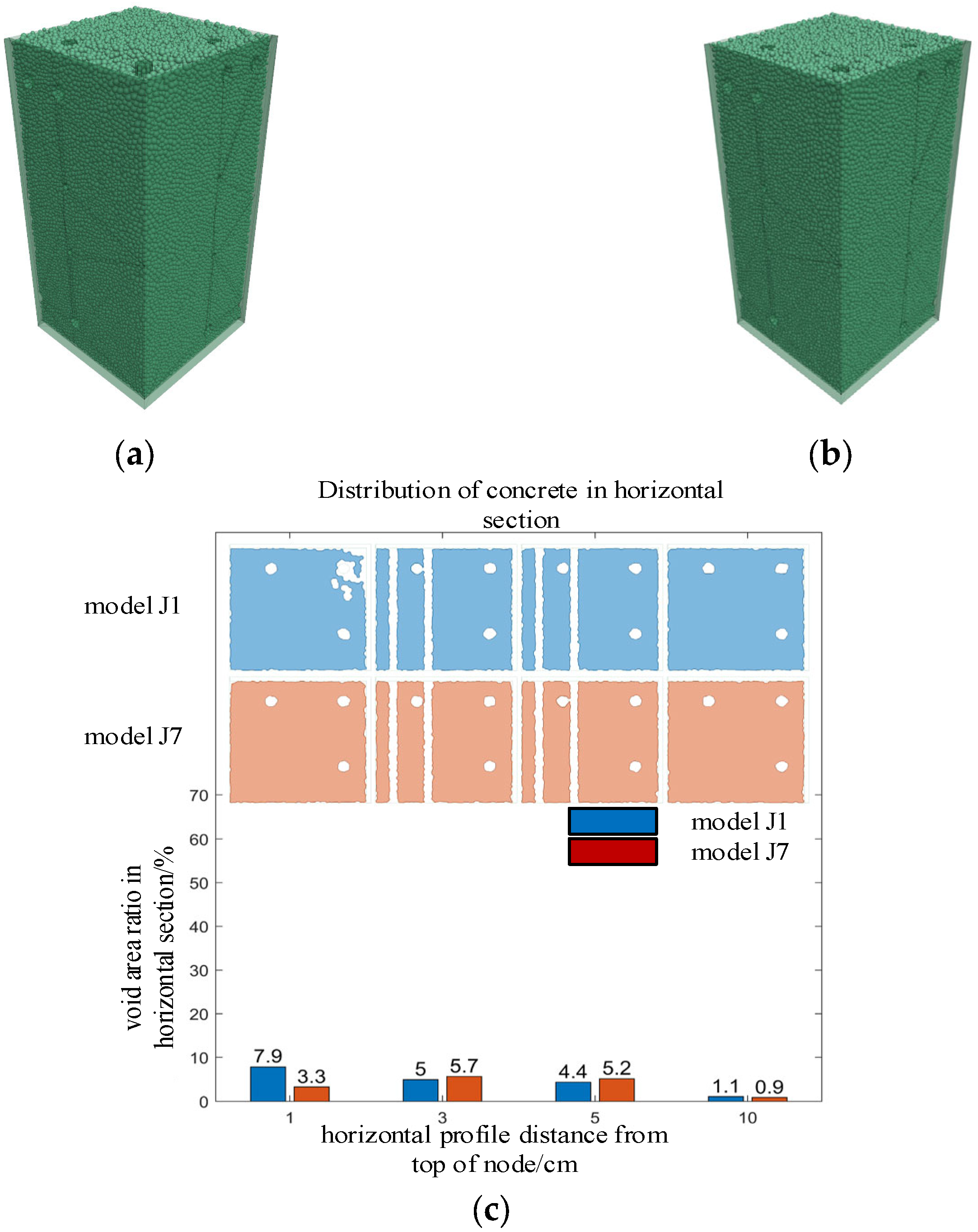

5.3. Column Stirrup Spacing

5.4. Concrete Fluidity

5.5. Maximum Coarse Aggregate Particle Size

5.6. Pouring Speed

6. Discussion and Conclusions

- (1)

- By selecting the rolling resistance linear model and the JKR model to simulate the contact between particles and the wall and between particles, respectively, a PFC numerical model suitable for concrete flow simulation was established using the appropriate modeling method. Numerical simulations of concrete workability tests such as the slump flow test and J-ring test were conducted, showing good agreement with laboratory test results.

- (2)

- The contact parameters between particles and wall units were calibrated by using the laboratory test. The nonlinear mapping relationship between microscopic parameters and macroscopic rheological properties was established by the neural network parameter inversion algorithm, so as to calibrate the inter-particle contact parameters. The results showed that the inversion algorithm could accurately calibrate the microscopic parameters of the contact model.

- (3)

- Through pouring tests and numerical simulations of reinforced concrete beam–column joint pieces, it was found that the void volume and distribution patterns from both were basically consistent. The established numerical model could accurately simulate the rheological behavior of concrete and predict the size and location distribution of pouring defects.

- (4)

- The established numerical simulations of seven sets of beam–column joints with different design parameters showed that the number and diameter of the top beam longitudinal bars affected the hindering effect of the mesh structure at the joint top on concrete. Column stirrup spacing affected the particle flow path, and the maximum coarse aggregate particle size and pouring speed also influenced the concrete pouring results.

- (5)

- Based on comprehensive experimental and numerical studies, to avoid potential void defects in practical concrete pouring projects, it is recommended that the number and diameter of joint longitudinal bars be selected reasonably and the spacing of column stirrups be increased appropriately. In addition, it is recommended to appropriately reduce the maximum coarse aggregate particle size and choose concrete with better fluidity and filling ability.

- (1)

- In the discrete element model of fresh concrete, spherical particles were used to simulate irregular coarse aggregates. Future studies can employ irregular polyhedral particles to more accurately simulate coarse aggregates, enabling more precise simulation of the accumulation and blocking behavior of fresh concrete.

- (2)

- When using the particle flow method for numerical simulation, a large number of particles results in low computational efficiency, while practical engineering has strict time constraints. Therefore, future work can explore parallel computing or other approaches to reduce computation time and better meet the demands of engineering applications.

- (3)

- This study focused solely on reinforced concrete beam–column joints. Future research can extend to pouring simulations of other structural forms, such as steel–concrete composite structures. By incorporating more factors influencing the pouring process, more widely applicable construction optimization techniques can be developed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, J. Study on Seismic Behavior of New Cast-In-Situ Joints in Reinforced Concrete Frames. Master’s Dissertation, Qingdao University of Technology, Qingdao, China, 2018. [Google Scholar]

- Huang, Q.L. Analysis of common problems in construction of steel and concrete frame structure. Sci. Technol. Inf. 2014, 12, 29. [Google Scholar]

- Zheng, Z.; Li, S.X.; Zhang, Q.; Tang, H.; Liu, G.F.; Pei, S.F.; Lu, G.M. True triaxial test and DEM simulation of rock mechanical behaviors, meso-cracking mechanism and precursor subject to underground excavation disturbance. Eng. Geol. 2024, 337, 107567. [Google Scholar] [CrossRef]

- Jiang, L.; Zhao, C.; Zhang, S.; Qiu, M.; Zhang, R.; Li, Y.; Zhang, W.; Yu, S. Failure mechanisms of basalt fiber concrete under splitting tensile tests and DEM simulations. Buildings 2025, 15, 3035. [Google Scholar] [CrossRef]

- Roussel, N.; Geiker, M.R.; Frédéric, D.; Thrane, L.N.; Szabo, P. Computational modeling of concrete flow: General overview. Cem. Concr. Res. 2007, 37, 1298–1307. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Gram, A.; Krenzer, K.; Schwabe, J.H.; Shyshko, S.; Roussel, N. Simulation of fresh concrete flow using Discrete Element Method (DEM): Theory and applications. Mater. Struct. 2014, 47, 615–630. [Google Scholar] [CrossRef]

- Cao, G.D.; Li, Z.J.; Jiang, S.Q.; Tan, Y.Q.; Li, Z.G.; Long, S.G.; Tong, Z.G. Experimental analysis and numerical simulation of flow behavior of fresh steel fibre reinforced concrete in magnetic field. Constr. Build. Mater. 2022, 347, 128505. [Google Scholar] [CrossRef]

- Li, Z.J.; Cao, G.D.; Jiang, S.Q.; Zhou, H.M.; Hu, X.Y.; Liu, J.W.; Wei, H.; Zhang, Y.C. Fluidity and mechanical properties of magnetic-field-enhanced steel fibre reinforced coral mortar. Powder Technol. 2025, 452, 120524. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Xu, P.J.; Gao, X.J. Multi-scale particles optimization for some rheological properties of Eco-SCC: Modelling and experimental study. Constr. Build. Mater. 2021, 308, 125151. [Google Scholar] [CrossRef]

- Xiao, Q.; Hu, X.; Li, X.; Zhang, G.; Zhao, J. Study on the basic mechanical properties and discrete element method simulation of permeable concrete. Sustainability. 2023, 15, 13310. [Google Scholar] [CrossRef]

- Zhou, X.; Xie, Y.J.; Long, G.C.; Zeng, X.H.; Li, J.T.; Wang, F. Simulating passing ability of self-compacting concrete in the J-ring test using cohesive particle liquid bridge model. Powder Technol. 2023, 416, 118218. [Google Scholar] [CrossRef]

- Wu, J.Q.; Zhao, L.J.; Zhou, X.L. Discrete element analysis of the effect of aggregate morphology on the flowability of self-compacting concrete. Case Stud. Constr. Mater. 2023, 18, e02010. [Google Scholar] [CrossRef]

- Noor, M.A.; Uomoto, T. Three-dimensional discrete element simulation of rheology tests of self-compacting concrete. In Proceedings of the 1st International RILEM Symposium on Self-Compacting Concrete, Stockholm, Sweden, 1 January 1999. [Google Scholar]

- Petersson, Ö. Simulation of self-compacting concrete-laboratory experiments and numerical modelling of testing methods, J-ring and L-box tests. In Proceedings of the 3rd International RILEM Symposium on Selfcompacting Concrete, Reykjavik, Iceland, 17–20 August 2003. [Google Scholar]

- Mechtcherine, V.; Shyshko, S. Simulating the behaviour of fresh concrete with the Distinct Element Method–Deriving model parameters related to the yield stress. Cem. Concr. Compos. 2015, 55, 81–90. [Google Scholar] [CrossRef]

- Hoornahad, H.; Koenders, E.A.B. Simulating macroscopic behavior of self-compacting mixtures with DEM. Cem. Concr. Compos. 2014, 54, 80–88. [Google Scholar] [CrossRef]

- Li, M. Numerical simulating workability of fresh SCC flow based on DEM. Master’s Dissertation, Tianjin University, Tianjin, China, 2017. [Google Scholar]

- Anjneya, K.; Deb, A. Effect of material fabric on gravity flow in fresh concrete. Int. J. Solids Struct. 2025, 316, 113386. [Google Scholar] [CrossRef]

- Anjneya, K.; Deb, A.; Mukherjee, S. Simulating Fresh Concrete Behavior Through Discrete Element Approach. In Recent Developments in Structural Engineering; Goel, M.D., Vyavahare, A.Y., Khatri, A.P., Eds.; Springer: Singapore, 2024; Volume 4, pp. 243–253. [Google Scholar]

- Qiu, P.; Yang, L.; Huang, C.; Hu, J.; Meng, Q. An efficient discrete element method-enhanced mesoscale modeling method for multi-phase concrete-like composites with high volume fraction. Buildings 2025, 15, 1716. [Google Scholar] [CrossRef]

- Remond, S.; Pizette, P. A DEM hard-core soft-shell model for the simulation of concrete flow. Cem. Concr. Res. 2014, 58, 169–178. [Google Scholar] [CrossRef]

- Cui, W.; Ji, T.Z.; Li, M.; Wu, X.L. Simulating the workability of fresh self-compacting concrete with random polyhedron aggregate based on DEM. Mater. Struct. 2017, 50, 92. [Google Scholar] [CrossRef]

- Ramyar, E.; Cusatis, G. Discrete fresh concrete model for simulation of ordinary, self-consolidating, and printable concrete flow. J. Eng. Mech. 2021, 148, 04021142. [Google Scholar] [CrossRef]

- Noor, M.A.; Uomoto, T. Numerical simulation of fresh concrete(1): Three-dimensional discrete element model for fresh concrete. Seisan Kenkyu. 1999, 51, 169–172. [Google Scholar]

- Zhang, K.; Yu, T.X.; Yu, W.D.; Zou, D.F.; Zhang, S.Y. Calibration of concrete discrete element parameters based on JKR bond model. Concrete 2020, 08, 46–50+55. [Google Scholar]

- Anjneya, K.; Deb, A. Uncertainty propagation in discrete element models using PDEM. Structures 2023, 57, 105326. [Google Scholar] [CrossRef]

- Cao, G.D.; Tan, T.; Jiang, S.Q.; Deng, D.Q.; Liu, Y.; Su, H.W. Measurement and calibration of discrete element parameters of fresh concrete. J. Xiangtan Univ. Nat. Sci. 2024, 46, 13–21. [Google Scholar]

- Li, Y.J.; Cui, W.; Qi, L.; Li, M. Numerical simulation of performance of fresh SCC based on DEM. Eng. J. Wuhan Univ. 2019, 52, 33–39. [Google Scholar]

- Yang, Y.; Tang, S.G. Discrete element method simulation of granular flow and its advances. China Powder Sci. Technol. 2006, 12, 38–43. [Google Scholar]

- Shi, C.; Zhang, Q.; Wang, S.N. Numerical simulation technology and application with particle flow code(PFC5.0). Rock Soil Mech. 2018, 39, 36. [Google Scholar]

- Johnson, K.L.; Kendall, K.; Roberts, A.D. Surface energy and the contact of elastic solids. Proc. R. Soc. Lond. A. 1971, 324, 301–313. [Google Scholar]

- Tabor, D.J. Surface forces and surface interaction. J. Colloid Interface Sci. 1977, 58, 2–13. [Google Scholar] [CrossRef]

- Johnson, K.L.; Greenwood, J.A. An adhesion map for the contact of elastic spheres. J. Colloid Interface Sci. 1997, 192, 326–333. [Google Scholar] [CrossRef]

- Li, Y.; Hao, J.; Jin, C.; Wang, Z.G.; Liu, J.L. Simulation of the flowability of fresh concrete by discrete element method. Front. Mater. 2021, 7, 603154. [Google Scholar] [CrossRef]

- Qi, L.; Liu, C.P.; Cui, W.; Li, Y.J. Calibration of contact parameters of DEM for fresh self-compacting concrete. J. Funct. Mater. 2018, 49, 7050–7056. [Google Scholar]

- Marshall, J.S. Discrete-element modeling of particulate aerosol flows. J. Comput. Phys. 2009, 228, 1541–1561. [Google Scholar] [CrossRef]

- JGJ/T 283-2012; Technical Specification for Application of Self-Compacting Concrete. China Architecture & Building Press: Beijing, China, 2012; pp. 8–9.

- GB/T50080-2016; Standard for test method of performance of ordinary fresh concrete. China Architecture & Building Press: Beijing, China, 2012; pp. 7–8.

| Component | Usage/(kg/m3) |

|---|---|

| coarse aggregate | 1145 |

| fine aggregate | 763 |

| PO42.5 cement | 375 |

| flyash | 45 |

| water reducer | 4.4 |

| water | 181 |

| Size Distribution/mm | Volume Fraction/% |

|---|---|

| 0~5 | 0 |

| 5~10 | 4.43 |

| 10~15 | 46.27 |

| 15~20 | 30.28 |

| 20~25 | 19.02 |

| total | 100.00 |

| Test Results | Parameters | Test | Numerical Simulation | Relative Error/% |

|---|---|---|---|---|

| slump test | divergence/mm | 582.4 | 587.0 | 0.79 |

| height/mm | 249.0 | 246.9 | 0.83 |

| Test Results | Parameters | Test | Numerical Simulation | Relative Error/% |

|---|---|---|---|---|

| J-ring test | divergence/mm | 539.6 | 542.5 | 0.54 |

| height/mm | 223.0 | 224.5 | 0.67 |

| Parameters | Test Result/% | Simulation Result/% | Relative Error/% |

|---|---|---|---|

| Depletion volume ratio | 0.48 | 0.47 | 2.08 |

| Proportion of void area in the section 1 cm away from the roof | 6.58 | 7.90 | 19.88 |

| Proportion of void area in the section 2 cm away from the roof | 5.74 | 6.60 | 14.98 |

| Proportion of void area in the section 3 cm away from the roof | 4.60 | 5.00 | 8.70 |

| Number | SCC Fluidity | Number of Longitudinal Beams | Top Beam Longitudinal Bars Diameter/mm | Maximum Aggregate Size/mm | Pouring Speed/(m3/h) | Spacers Spacing/mm |

|---|---|---|---|---|---|---|

| J1 | SCC1 | 4 | 25 | 20 | 15 | 100 |

| J2 | SCC1 | 2 | 25 | 20 | 15 | 100 |

| J3 | SCC1 | 4 | 20 | 20 | 15 | 100 |

| J4 | SCC1 | 4 | 25 | 20 | 15 | 50 |

| J5 | SCC2 | 4 | 25 | 20 | 15 | 100 |

| J6 | SCC1 | 4 | 25 | 16 | 15 | 100 |

| J7 | SCC1 | 4 | 25 | 20 | 30 | 100 |

| This Study | Previous Studies |

|---|---|

| PFC3D was used to simulate standard concrete tests, providing clearer comparison with experimental results. | Hoornahad and others used PFC2D to simulate concrete flow, which only offers a vertical plane view and is less clear than a 3D visualization. |

| Compared to experimental results, the simulation errors for both the slump test and J-ring test were controlled within 1%, demonstrating high accuracy. | Li used PFC for numerical simulation of standard concrete tests, controlling the error within 7%. |

| Simulating the pouring of beam–column joints from engineering projects held greater practical application value. | Most scholars such as Cui primarily simulated standard concrete tests without applying the method to practical engineering. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Tao, M.; Ding, R.; Fan, J.; Zhang, X.; Zhou, M.; Zhang, Q. Simulation of Reinforced Concrete Beam–Column Joint Pouring Process Based on Three-Dimensional Particle Flow Method. Buildings 2025, 15, 3795. https://doi.org/10.3390/buildings15203795

Zhang X, Tao M, Ding R, Fan J, Zhang X, Zhou M, Zhang Q. Simulation of Reinforced Concrete Beam–Column Joint Pouring Process Based on Three-Dimensional Particle Flow Method. Buildings. 2025; 15(20):3795. https://doi.org/10.3390/buildings15203795

Chicago/Turabian StyleZhang, Xiao, Muxuan Tao, Ran Ding, Jiansheng Fan, Xinhao Zhang, Mengjia Zhou, and Qiang Zhang. 2025. "Simulation of Reinforced Concrete Beam–Column Joint Pouring Process Based on Three-Dimensional Particle Flow Method" Buildings 15, no. 20: 3795. https://doi.org/10.3390/buildings15203795

APA StyleZhang, X., Tao, M., Ding, R., Fan, J., Zhang, X., Zhou, M., & Zhang, Q. (2025). Simulation of Reinforced Concrete Beam–Column Joint Pouring Process Based on Three-Dimensional Particle Flow Method. Buildings, 15(20), 3795. https://doi.org/10.3390/buildings15203795