Study on Engineering Geopolymer Composites (EGCs) Under Sustained Thermal Environment: Linking Strain-Hardening Characteristics, Static/Impact Load Mechanical Properties, and Evolution Mechanism

Abstract

1. Introduction

2. Materials and Methods

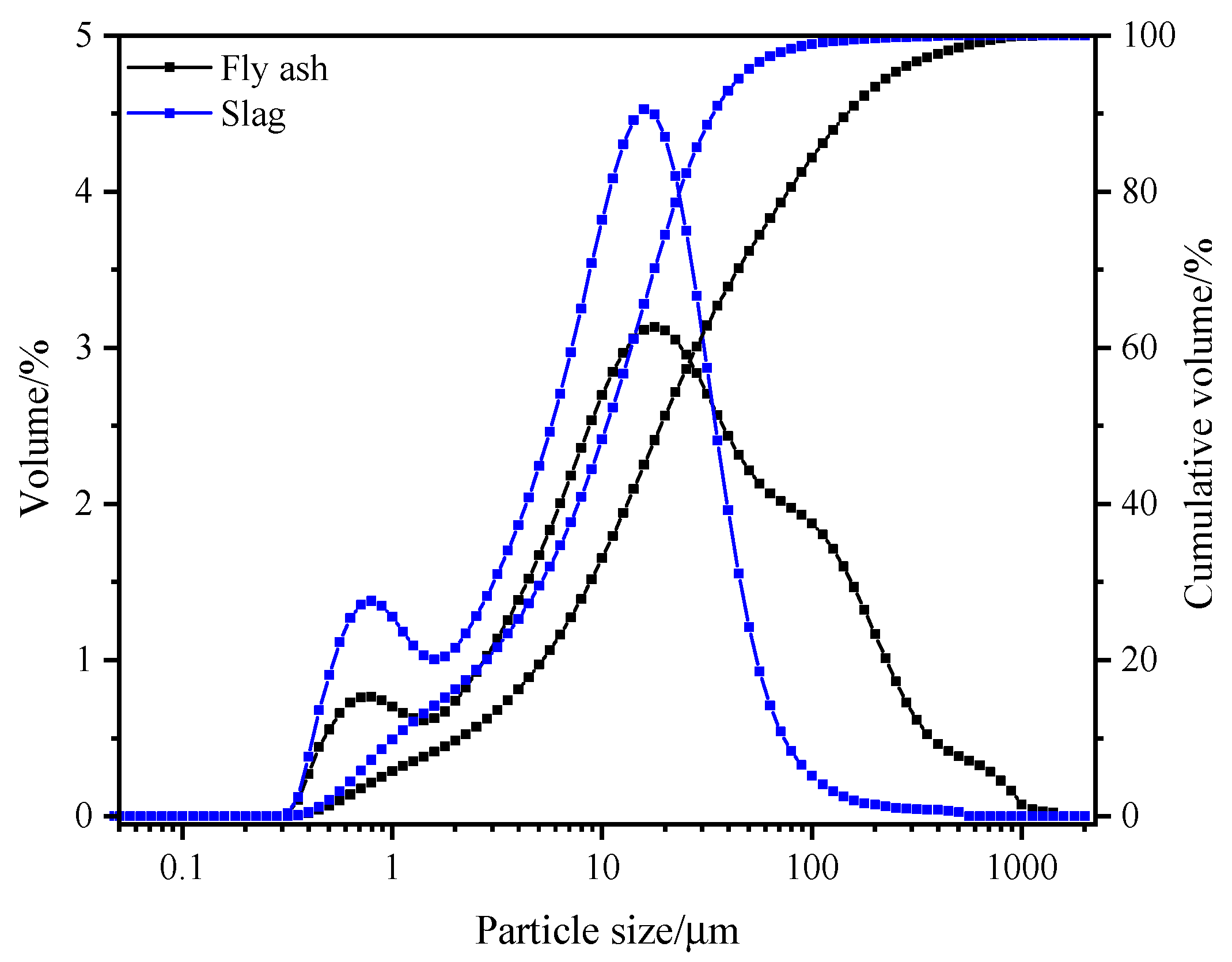

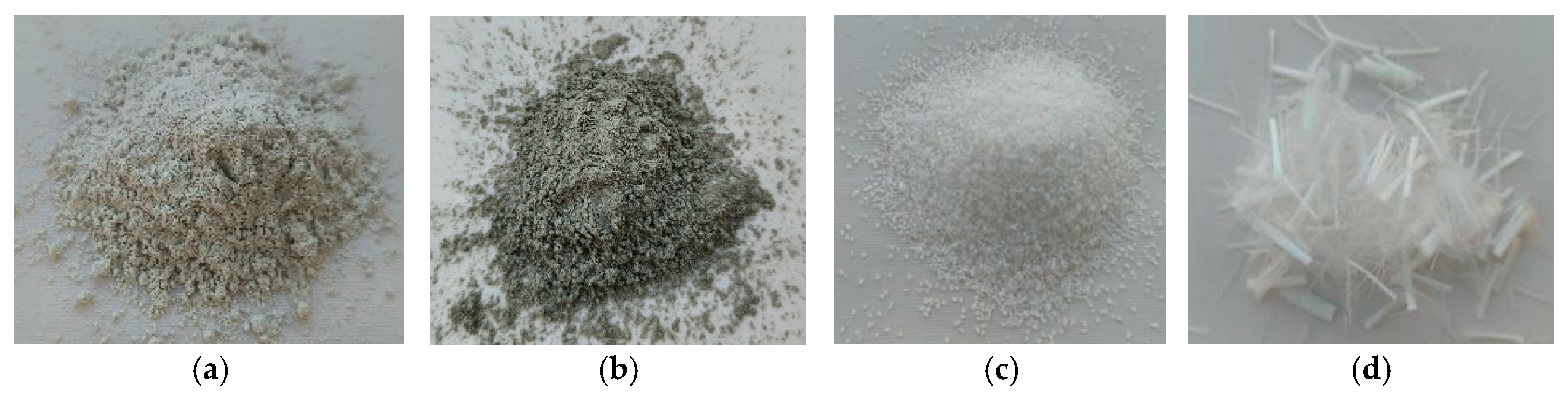

2.1. Raw Materials

2.2. Sample Preparation

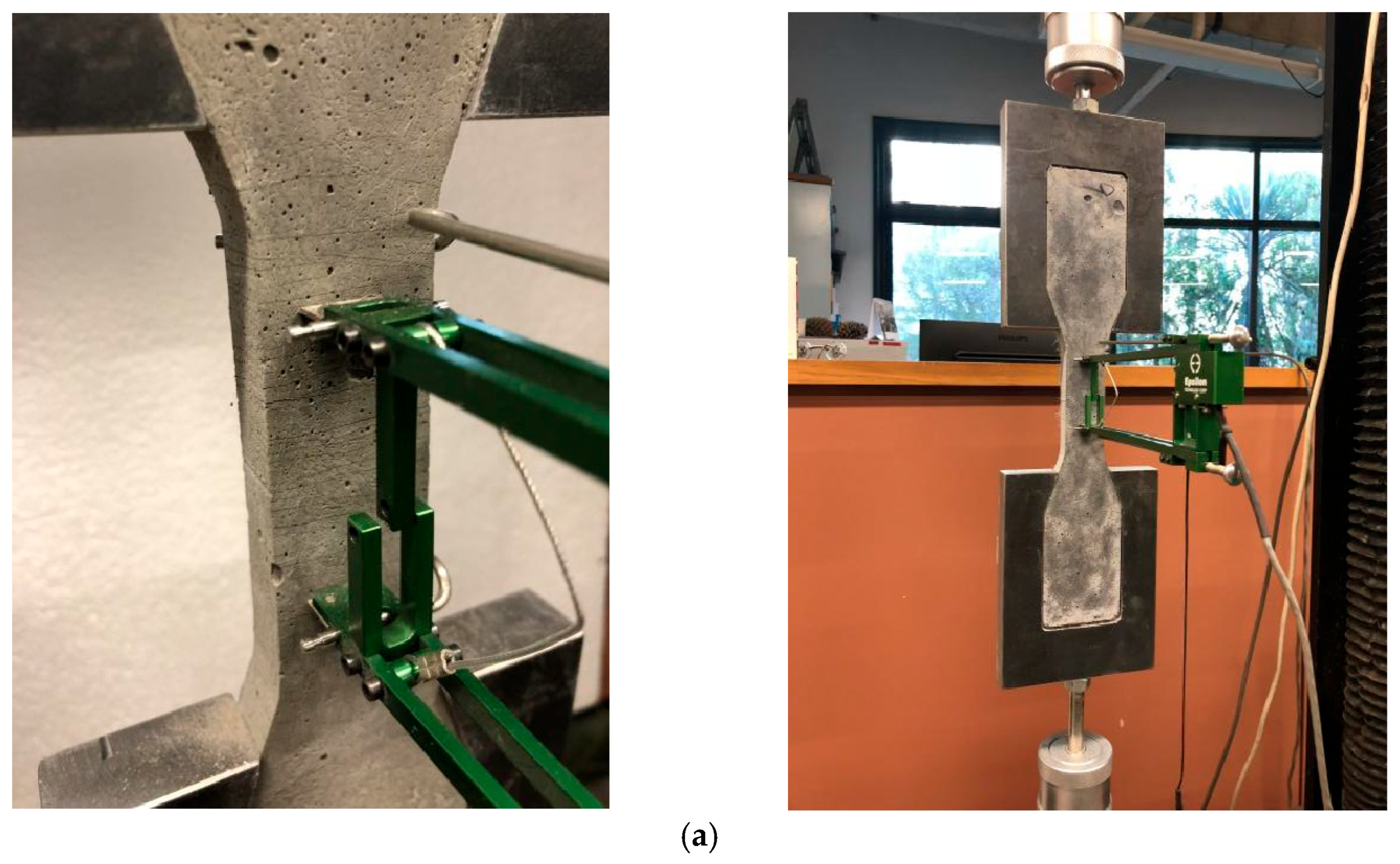

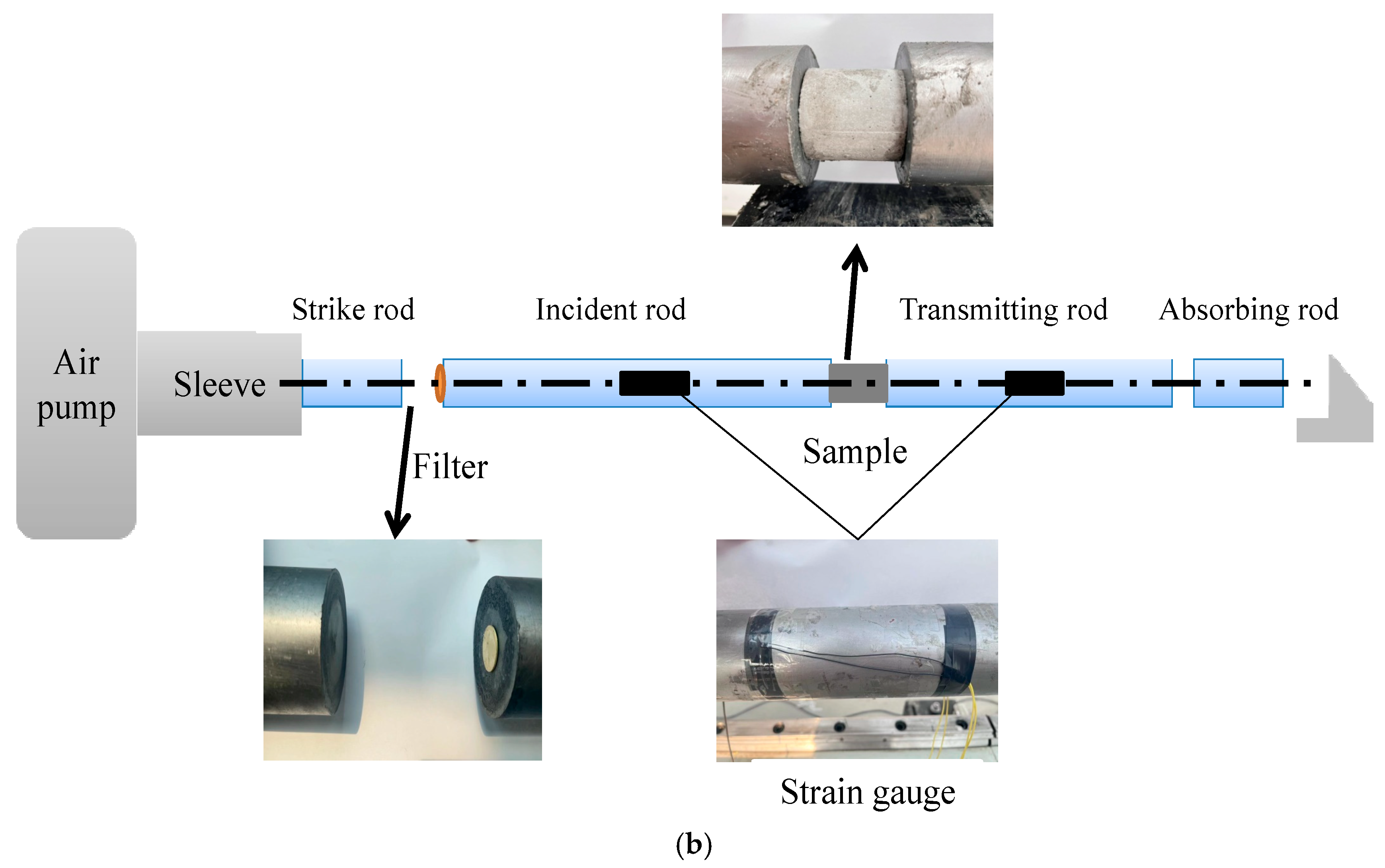

2.3. Sample Tests

3. Results Analysis

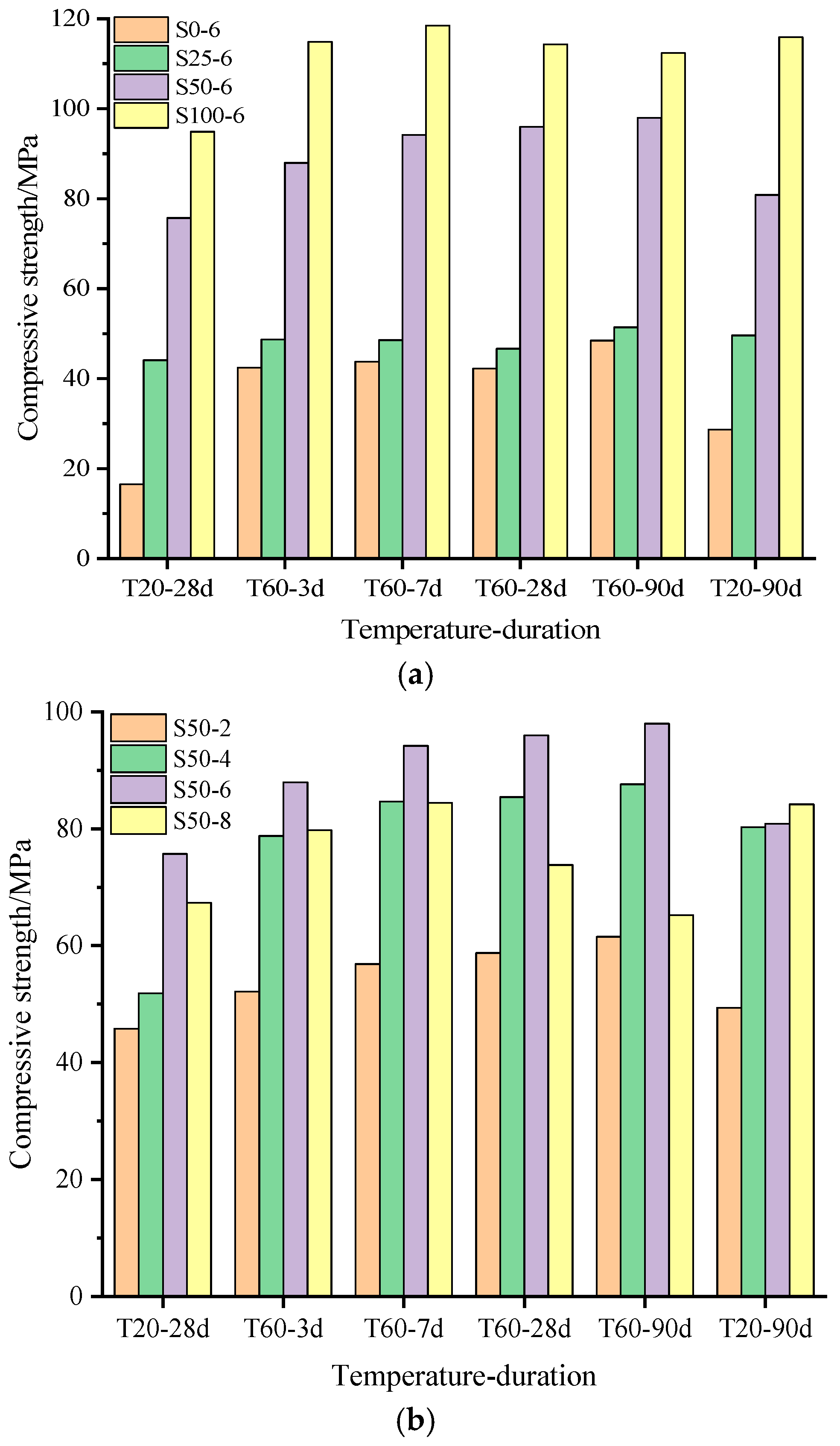

3.1. Static Compressive Strength Analysis

3.2. Tensile Strength Analysis

3.3. Impact Load Compressive Strength Analysis

3.3.1. Stress Equilibrium Check

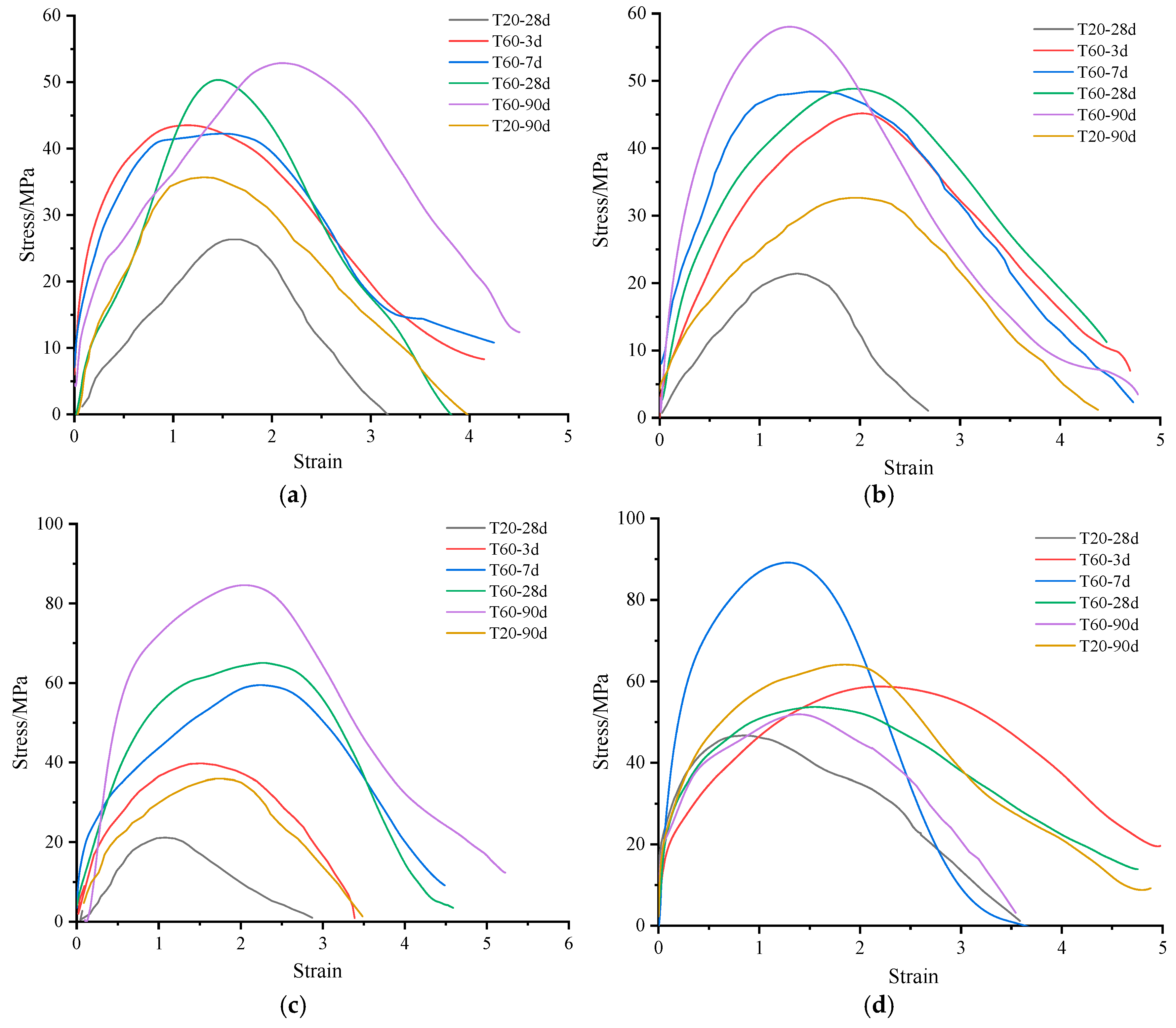

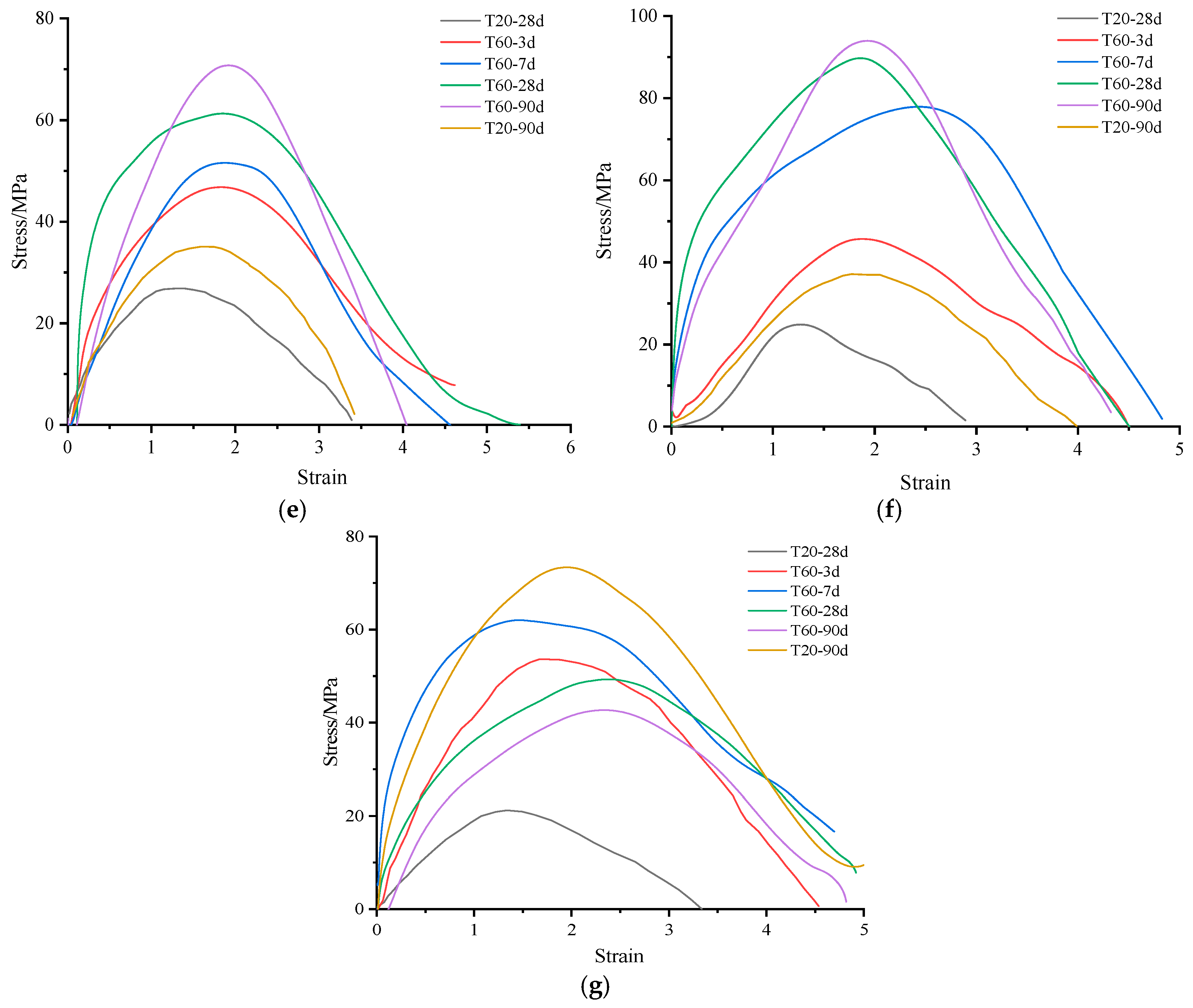

3.3.2. Stress–Strain Curve of Impact Load

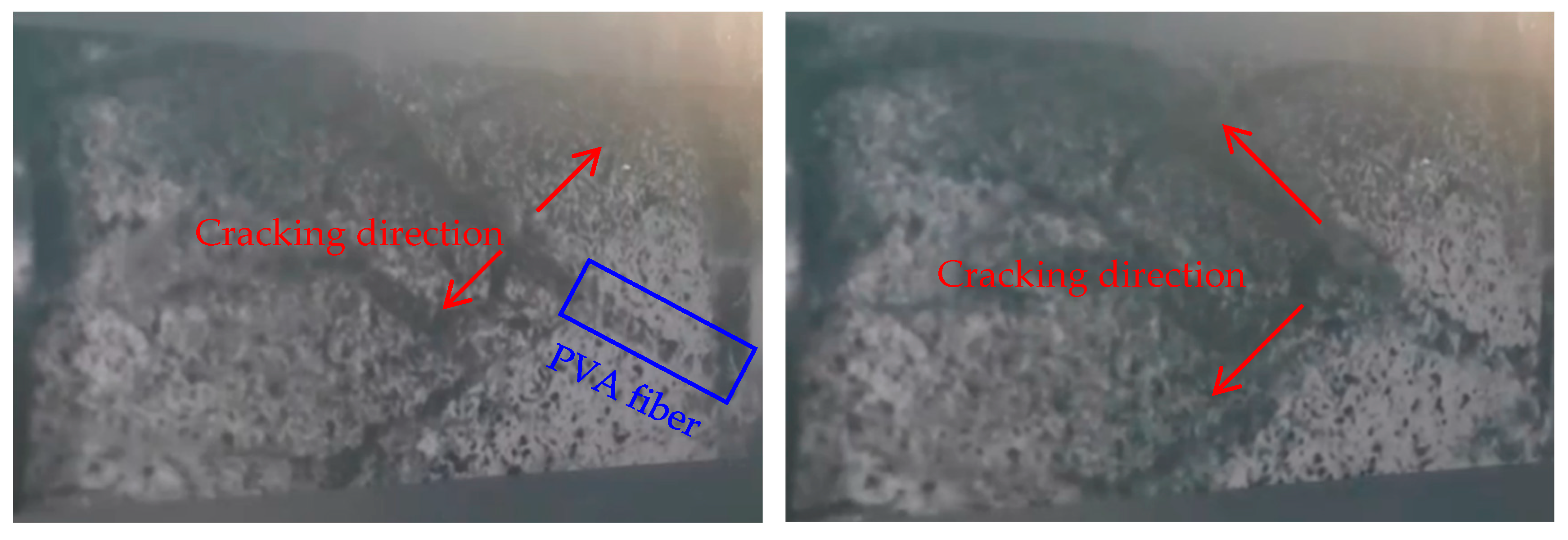

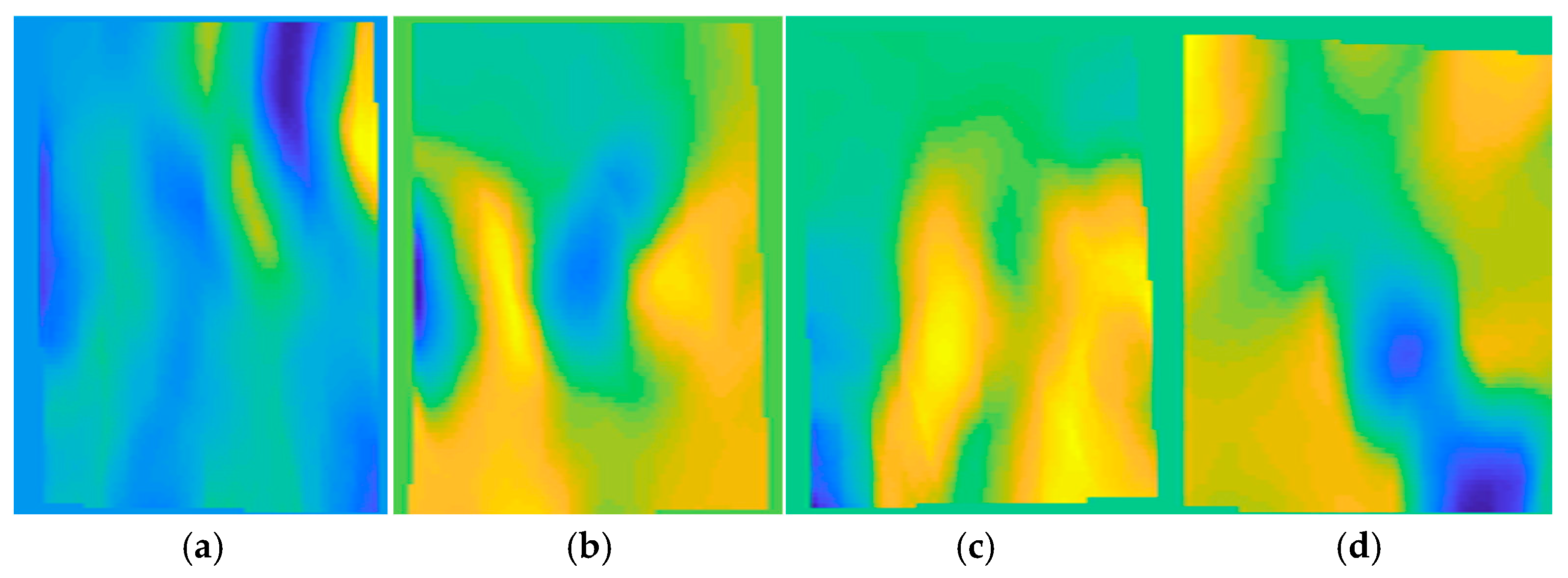

3.3.3. Digital Image Correlation (DIC) Analysis

3.3.4. Dynamic Increase Factor (DIF) Analysis

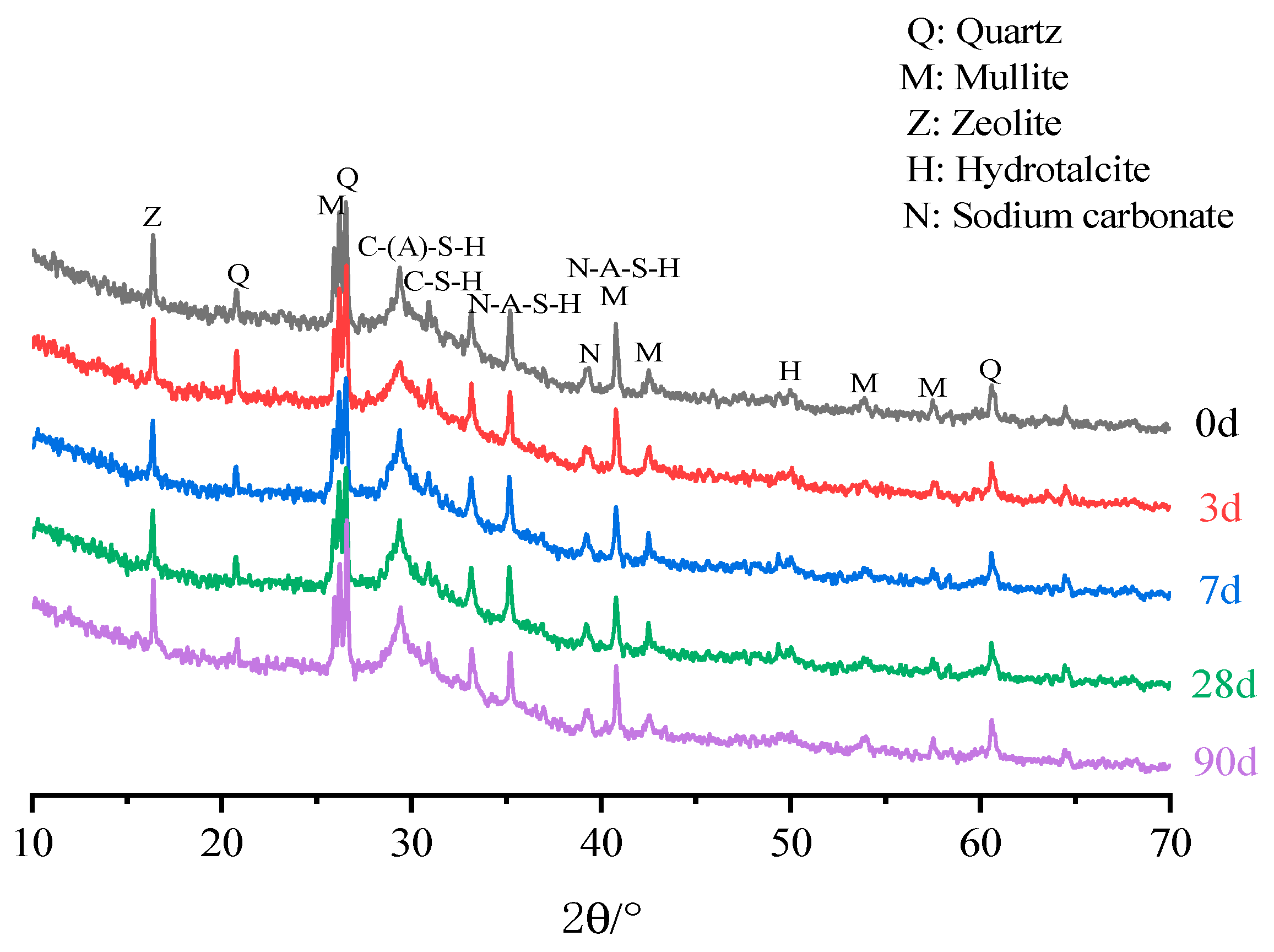

3.4. XRD Analysis

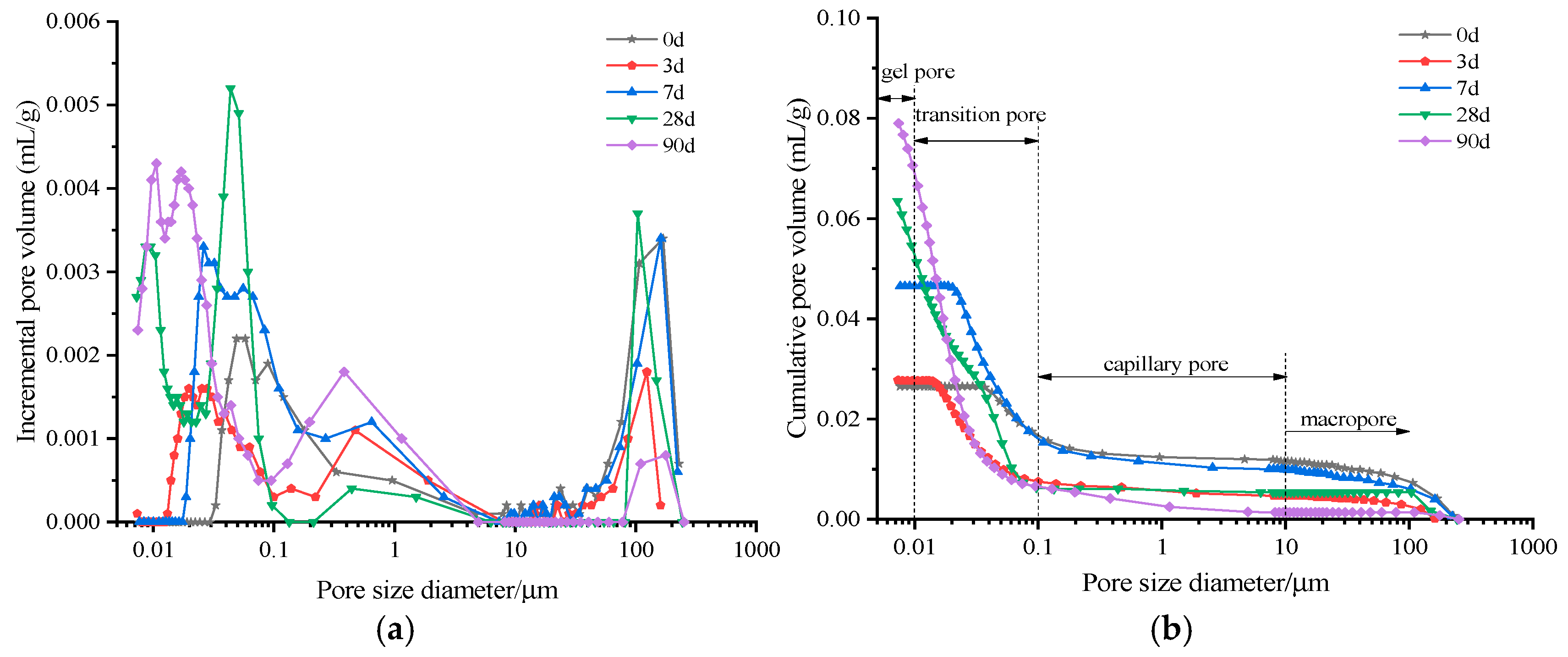

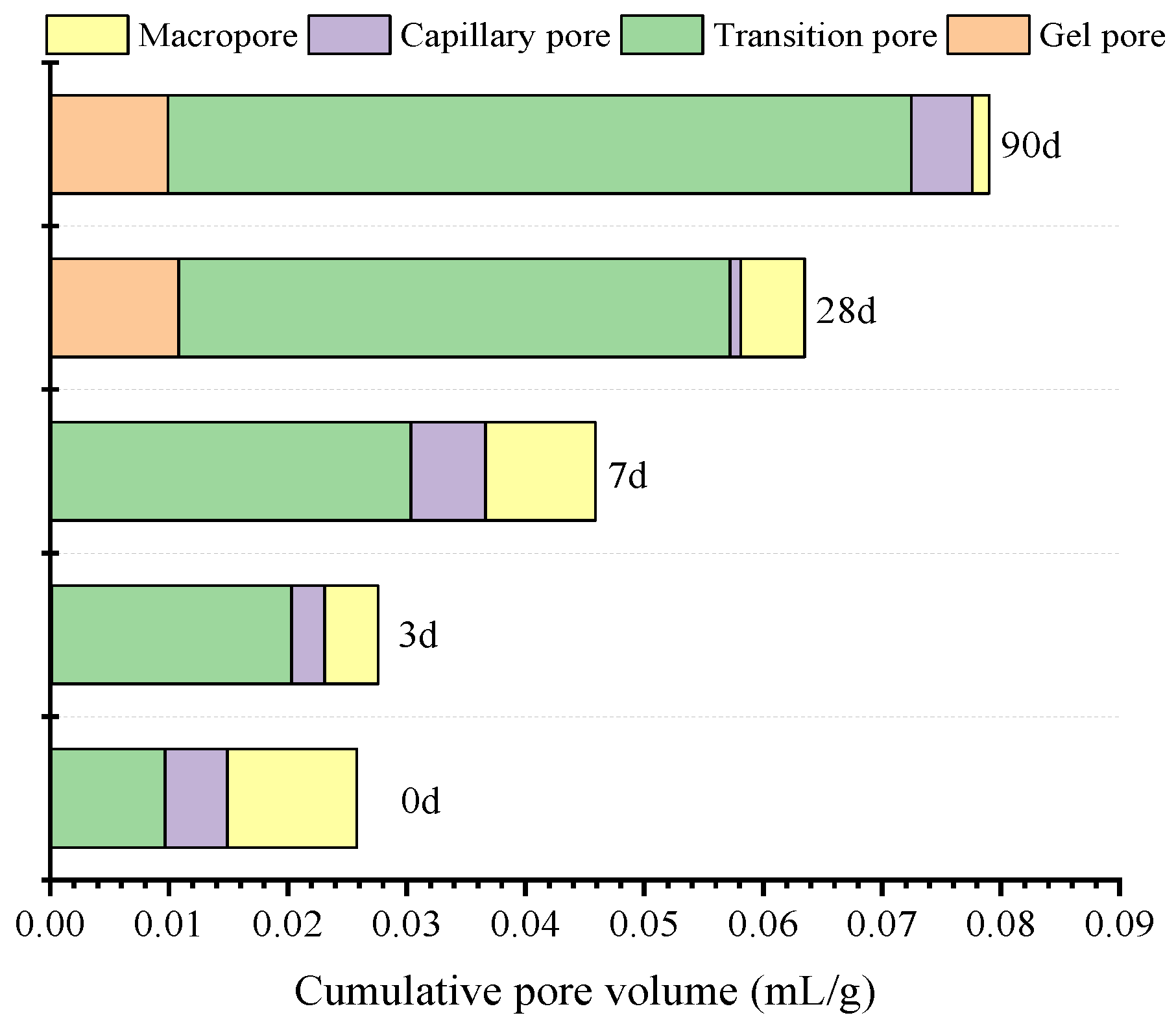

3.5. MIP Analysis

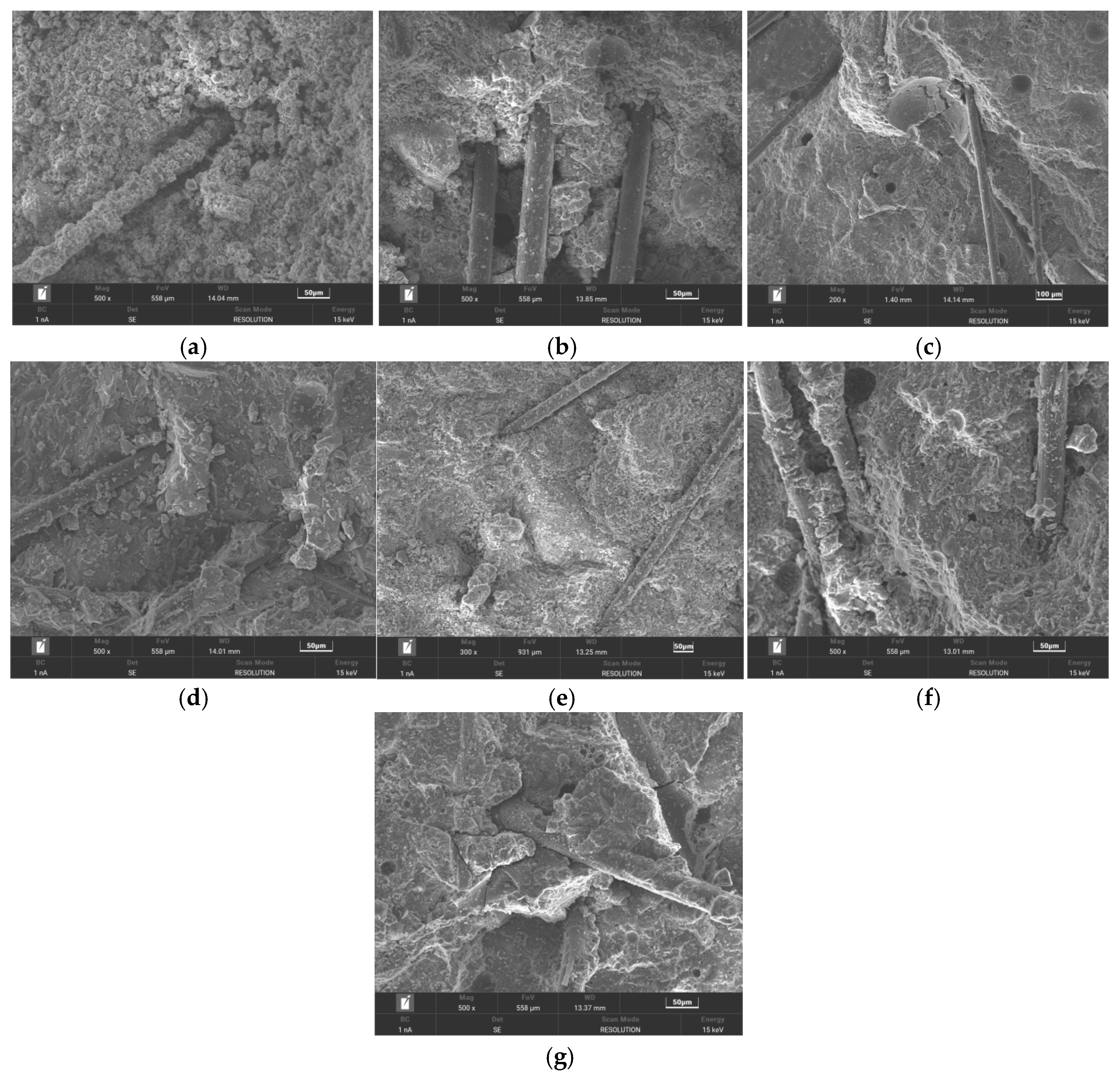

3.6. SEM Analysis

4. Evolution Mechanism of EGC System Performance Under Sustained Action at 60 °C

5. Conclusions

- (1)

- Sustained thermal exposure at 60 °C enhances EGC strength; however, long-term stability is optimal with a fly ash–slag mass ratio of 1:1 and moderate alkalinity (Na2O concentration of 4–6%). This recommended formulation ensures robust performance by fostering a stable, dense microstructured matrix, crucial for applications like geothermal well casings.

- (2)

- EGC samples exhibit excellent strain-hardening characteristics. After sustained elevated temperature, the tensile strain-hardening curve of EGC tends to become smoother, with a reduction in the number of cracks and an increase in crack width. The alteration in fiber–matrix interfacial bonding properties weakens the capacity for multiple crack propagation.

- (3)

- The impact load compressive strength of EGC after sustained elevated temperature reaches 2–3 times that of standard curing, where the bridging effect of PVA fibers and matrix densification significantly improves the energy dissipation capacity.

- (4)

- Sustained exposure to 60 °C promotes the formation of C-(A)-S-H gel and consumes quartz and zeolite phases. While increasing the porosity of the EGC system, sustained elevated temperature refines the pore distribution; the volumes of gel pores and transition pores increase significantly, leading to a shift in the pore structure from “macropore-dominated” to “micropore-dominated”. SEM observations show that a fly ash–slag ratio of 1:1 results in a dense fiber–matrix interface with high load transfer efficiency; however, excessive alkalinity induces microcracks and reduces mechanical properties.

- (5)

- Outlook: The thermal stability of an EGC system is related to the mix proportion. Tensile tests show that sustained thermal environments weaken the fiber’s crack resistance efficiency, but through mix proportion optimization (including multi-source reactive precursors and appropriate alkalinity), a “gel strengthening–fiber toughening–pore regulation” multiscale action mechanism is formed, collectively determining the macroscopic mechanical behavior of EGCs. It is important to note that this study focused on a dry thermal environment. Real-world applications in tunnels or industrial settings often involve humidity and thermal cycles, which could lead to more complex performance evolution mechanisms. Future work should investigate EGC performance under coupled thermal–hydraulic–mechanical cycling conditions to better predict long-term durability. This study provides experimental guidance and a theoretical basis for the practical application of EGC systems in thermal environments, demonstrating significant scientific and engineering value.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, C.; Zhao, X.; Zhang, X.Y.; Zhao, Y.; Wang, Y.T.; Zhao, J.J. Effects of alkali equivalent and polypropylene fibres on performance of alkali-activated municipal waste incineration bottom ash-slag mortar. J. Build. Eng. 2024, 84, 108496. [Google Scholar] [CrossRef]

- Feng, H.; Xin, X.; Guo, A.F.; Yu, Z.Y.; Shao, Q.; Sheikh, M.N.; Sun, Z.H. Effect of mix proportion parameters on chloride erosion resistance of fly ash/slag-based engineered geopolymer composites. J. Clean. Prod. 2024, 438, 140785. [Google Scholar] [CrossRef]

- He, S.; Huang, X.J.; Yu, P.; Zhou, Y.T.; Luo, Y.J. Mechanical properties and durability of alkali-activated fly ash-municipal sludge concrete. Constr. Build. Mater. 2024, 419, 135515. [Google Scholar] [CrossRef]

- Ma, H.Q.; Yi, C.; Wu, C. Review and outlook on durability of engineered cementitious composite (ECC). Constr. Build. Mater. 2021, 287, 122719. [Google Scholar] [CrossRef]

- Hou, M.J.; Zhang, D. Crack width control and mechanical properties of low carbon engineered cementitious composites (ECC). Constr. Build. Mater. 2022, 348, 128692. [Google Scholar] [CrossRef]

- Hu, Z.H.; Elchalakani, M.; Yehia, S.; Ran, H.Y.; Sadakkathulla, M.A.; Guo, X. Engineered cementitious composite (ECC) strengthening of reinforced concrete structures: A state-of-the-art review. J. Build. Eng. 2024, 86, 108941. [Google Scholar] [CrossRef]

- Lyu, B.C.; Ding, C.; Guo, L.P.; Chen, B.; Wang, A.G. Basic performance and potential research problems of strain hardening geopolymer composites: A critical review. Constr. Build. Mater. 2021, 287, 123030. [Google Scholar] [CrossRef]

- Lao, J.C.; Huang, B.T.; Xu, L.Y.; Khan, M.; Fang, Y.; Dai, J.G. Seawater sea-sand engineered geopolymer composites (EGC) with high strength and high ductility. Cem. Concr. Compos. 2023, 138, 104998. [Google Scholar] [CrossRef]

- Zhong, W.L.; Zhang, Y.H.; Fan, L.F. High-ductile engineered geopolymer composites (EGC) prepared by calcined natural clay. J. Build. Eng. 2023, 63, 105456. [Google Scholar] [CrossRef]

- Artyk, Z.; Kuan, Y.; Zhang, D.C.; Shon, C.S.; Ogwumeh, C.M.; Kim, J. Development of engineered geopolymer composites containing low-activity fly ashes and ground granulated blast furnace slags with hybrid fibers. Constr. Build. Mater. 2024, 422, 135760. [Google Scholar] [CrossRef]

- Elmesalami, N.; Celik, K. A critical review of engineered geopolymer composite: A low-carbon ultra-high-performance concrete. Constr. Build. Mater. 2022, 346, 128491. [Google Scholar]

- Ling, Y.F.; Wang, K.J.; Li, W.G.; Shi, G.Y.; Lu, P. Effect of slag on the mechanical properties and bond strength of fly ash-based engineered geopolymer composites. Compos. Part B Eng. 2019, 164, 747–757. [Google Scholar] [CrossRef]

- Han, J.S.; Cai, J.M.; Lin, Y.Z.; Sun, Y.Q.; Pan, J.L. Impact resisitance of engineered geopolymer composite (EGC) in cold temperatures. Constr. Build. Mater. 2022, 343, 128150. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, M.Z. Engineered geopolymer composites: A state-of-the-art review. Cem. Concr. Compos. 2023, 135, 104850. [Google Scholar]

- Yaswanth, K.K.; Revathy, J.; Gajalakshmi, P. Influence of copper slag on mechanical durability and microstructural properties of GGBS and RHA blended strain hardening geopolymer composites. Constr. Build. Mater. 2022, 342, 128042. [Google Scholar] [CrossRef]

- Briffaut, M.; Benboudjema, F.; Torrenti, J.M.; Nahas, G. A thermal active restrained shrinkage ring test to study the early age concrete behaviour of massive structures. Cem. Concr. Res. 2011, 41, 56–63. [Google Scholar] [CrossRef]

- Ma, H.Q.; Fu, C.C.; Dai, E.T.; Huang, K.; Zhang, S.C.; Feng, J.J. Research on the effect of 60 °C thermal cycling on the properties of alkali-activated fly ash-slag materials: A new perspective. Constr. Build. Mater. 2024, 416, 135192. [Google Scholar] [CrossRef]

- Chan, C.L.; Zhang, M.Z. Behavior of strain hardening geopolymer composites at elevated temperatures. Cem. Concr. Compos. 2022, 132, 104634. [Google Scholar] [CrossRef]

- Zhang, Z.G.; Liu, J.C.; Li, J.X.; Qin, F.J.; Di, J. Micromechanics-based analysis of PVA-ECC after thermal exposure. Arch. Civ. Mech. Eng. 2023, 23, 213. [Google Scholar] [CrossRef]

- Cai, J.M.; Pan, J.L.; Han, J.S.; Lin, Y.Z.; Sheng, Z.L. Impact behaviours of engineered geopolymer composite exposed to elevated temperatures. Constr. Build. Mater. 2021, 312, 125421. [Google Scholar] [CrossRef]

- Trindade, A.C.C.; Liebscher, M.; Curosu, I.; Silva, F.D.A.; Mechtcherine, V. Influence of elevated temperatures on the residual and quasi in-situ flexural strength of strain-hardening geopolymer composites (EGC) reinforced with PVA and PE fibers. Constr. Build. Mater. 2022, 314, 125649. [Google Scholar]

- Humur, G.; Cevik, A. Mechanical characterization of lightweight engineered geopolymer composites exposed to elevated temperatures. Ceram. Int. 2022, 48, 13634–13650. [Google Scholar] [CrossRef]

- Li, F.P.; Zhou, Z.Z.; Lu, Y.Y.; Li, S. Effect of PVA fibers grafted with MWCNTs on the shrinkage behaviors of engineered geopolymer composite (EGC). Constr. Build. Mater. 2024, 449, 138508. [Google Scholar] [CrossRef]

- Cheng, Z.J.; An, J.P.; Li, F.P.; Lu, Y.Y.; Li, S. Investigation of dynamic compression properties of lightweight engineered geopolymer composites containing different ceramsites (LW-EGC). Constr. Build. Mater. 2024, 425, 136001. [Google Scholar]

- Ma, H.Q.; Fu, H.; Cao, C.Y.U.; Xu, Z.S.; Niu, X.Y. Effect of 60 °C sustained temperature conditions on the mechanical properties and microstructure of alkali-activated fly ash-slag pastes and mortars. J. Build. Eng. 2024, 95, 110346. [Google Scholar]

- Li, Y.Z.; Li, J.X.; Yang, E.H.; Guan, X.C. Multiple cracking and strain-hardening criteria of Engineered Cementitious Composites (ECC) with river sand. Cem. Concr. Res. 2024, 180, 107511. [Google Scholar] [CrossRef]

- Wang, F.; Zhai, J.B.; Ding, Y.; Nishiwaki, T.; Yu, J.T.; Li, V.C.; Yu, K.Q. Design-driven approach for engineered geopolymer composite with recorded low fiber content. Compos. Part B Eng. 2024, 287, 111834. [Google Scholar] [CrossRef]

- Ren, L.; Yu, X.M.; Guo, Z.Z.; Xiao, L.F. Numerical investigation of the dynamic increase factor of ultra-high performance concrete based on SHPB technology. Constr. Build. Mater. 2022, 325, 126756. [Google Scholar] [CrossRef]

- Kim, K.M.; Lee, S.H.; Cho, J.Y. Influence of friction on the dynamic increase factor of concrete compressive strength in a split Hopkinson pressure bar test. Cem. Concr. Compos. 2022, 129, 104517. [Google Scholar] [CrossRef]

- Zhang, M.; Wu, H.J.; Li, Q.M.; Huang, F.L. Further investigation on the dynamic compressive strength enhancement of concrete-like materials based on split Hopkinson pressure bar tests. Part I: Experiments. Int. J. Impact Eng. 2009, 36, 1327–1334. [Google Scholar] [CrossRef]

- Huang, R.Y.; Guan, Z.H.; Qin, J.; Wen, Y.B.; Lai, Z.C. Strain rate effect of concrete based on split Hopkinson pressure bar (SHPB) test. J. Build. Eng. 2024, 86, 108856. [Google Scholar] [CrossRef]

- Fang, X.F. A one-dimensional stress wave model for analytical design and optimization of oscillation-free force measurement in high-speed tensile test specimens. Int. J. Impact Eng. 2021, 149, 103770. [Google Scholar] [CrossRef]

- Feng, H.; Bilal, I.; Sun, Z.H.; Guo, A.F.; Yu, Z.Y.; Du, Y.X.; Su, Y.F.; Zheng, Y.L. Mechanical and shrinkage properties of cellulose nanocrystal modified alkali-activated fly ash/slag pastes. Cem. Concr. Compos. 2024, 154, 105753. [Google Scholar] [CrossRef]

- He, R.; Nantung, T.; Lu, N. Unraveling microstructural evolution in air-entrained mortar and paste: Insights from MIP and micro-CT tomography amid cyclic freezing-thawing damage. J. Build. Eng. 2024, 94, 109922. [Google Scholar] [CrossRef]

- Song, Y.; Zhou, J.W.; Bian, Z.N.; Dai, G.Z. Pore structure characterization of hardened cement paste by multiple methods. Adv. Mater. Sci. Eng. 2019, 3726953. [Google Scholar] [CrossRef]

- Xu, W.R.; Tang, Z.; Xie, Y.J.; Long, G.C.; Kai, M.F.; Zhang, Z.R.; Bu, M.X.; Zaland, S. Understanding the impact of synthesis parameters on the pore structure properties of fly ash-based geopolymers. Constr. Build. Mater. 2024, 411, 134640. [Google Scholar] [CrossRef]

- Zhang, L.N.; Yamauchi, K.; Li, Z.J.; Zhang, X.X.; Ma, H.Y.; Ge, S.G. Novel understanding of calcium silicate hydrate from dilute hydration. Cem. Concr. Res. 2017, 99, 95–105. [Google Scholar] [CrossRef]

- Ramadan, M.; Kohail, M.; Abadel, A.A.; Alharbi, Y.A.; Soilman, A.M.; Mohsen, A. Exploration of mechanical performance, porous structure, and self-cleaning behavior for hydrothermally cured sustainable cementitious composites containing de-aluminated metakaolin waste and TiO2 nanoparticles. J. Mater. Res. Technol. 2023, 25, 3998–4019. [Google Scholar] [CrossRef]

- Tu, W.L.; Fang, G.H.; Dong, B.Q.; Hu, Y.K.; Zhang, M.Z. Behaviour of alkali-activated fly ash-slag paste at elevated temperatures: An experimental study. Cem. Concr. Compos. 2024, 147, 105438. [Google Scholar] [CrossRef]

- Gong, J.H.; Ma, Y.W.; Wang, Y.R.; Cao, Y.B.; Fu, J.Y.; Wang, H. Assessment of the performance of alkali-activated slag/fly ash using liquid and solid activators: Early-age properties and efflorescence. J. Sustain. Cem.-Based Mater. 2024, 13, 300–310. [Google Scholar] [CrossRef]

- Yu, Z.; Wang, B.M.; Li, T.R.; Wang, W.L. Toughness study of polyacrylamide-modified slag/fly ash-based alkali-activated cementitious materials. Constr. Build. Mater. 2024, 450, 138622. [Google Scholar] [CrossRef]

| Oxide | Fly Ash | Slag |

|---|---|---|

| SiO2 | 55.71 | 36.10 |

| Al2O3 | 32.79 | 16.32 |

| MgO | 0.24 | 7.16 |

| CaO | 2.66 | 35.58 |

| Fe2O3 | 4.43 | 0.23 |

| SO3 | — | 1.71 |

| TiO2 | 1.66 | — |

| K2O | 1.54 | — |

| LOI | 0.97 | 2.90 |

| Fiber Type | Diameter /μm | Tensile Strength /GPa | Young’s Modulus /GPa | Rupture Elongation /% | Density g/cm3 |

|---|---|---|---|---|---|

| PVA | 40 | 1.56 | 41 | 6.5 | 1.3 |

| Sample No. | Fly Ash | Slag | Na2O Concentration | Alkali Activator Modulus | Liquid–Solid Ratio | Silica Sand/Binder Ratio | PVA |

|---|---|---|---|---|---|---|---|

| S0-6 | 100% | 0% | 6% | 1.3 | 0.3 | 0.3 | 2 vt% |

| S25-6 | 75% | 25% | 6% | ||||

| S50-6 | 0.5 | 0.5 | 6% | ||||

| S100-6 | 0 | 1 | 6% | ||||

| S50-2 | 0.5 | 0.5 | 2% | ||||

| S50-4 | 0.5 | 0.5 | 4% | ||||

| S50-8 | 0.5 | 0.5 | 8% |

| Sample No. | Curing Condition | Quasi-Static Strength fs (MPa) | Dynamic Strength fd (MPa) | DIF (fd/fs) |

|---|---|---|---|---|

| S50-6 | T20-28d | 78.5 | 145.2 | 1.85 |

| S50-6 | T60-3d | 85.2 | 176.8 | 2.08 |

| S50-6 | T60-28d | 95.7 | 224.9 | 2.35 |

| S100-6 | T20-28d | 88.3 | 161.5 | 1.83 |

| S100-6 | T60-28d | 82.1 | 165.4 | 2.01 |

| S0-6 | T60-28d | 64.5 | 138.1 | 2.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Wang, W.; Liu, H.; Huang, A.; Ma, H. Study on Engineering Geopolymer Composites (EGCs) Under Sustained Thermal Environment: Linking Strain-Hardening Characteristics, Static/Impact Load Mechanical Properties, and Evolution Mechanism. Buildings 2025, 15, 3792. https://doi.org/10.3390/buildings15203792

Wang S, Wang W, Liu H, Huang A, Ma H. Study on Engineering Geopolymer Composites (EGCs) Under Sustained Thermal Environment: Linking Strain-Hardening Characteristics, Static/Impact Load Mechanical Properties, and Evolution Mechanism. Buildings. 2025; 15(20):3792. https://doi.org/10.3390/buildings15203792

Chicago/Turabian StyleWang, Shuo, Wei Wang, Haoxing Liu, Ao Huang, and Hongqiang Ma. 2025. "Study on Engineering Geopolymer Composites (EGCs) Under Sustained Thermal Environment: Linking Strain-Hardening Characteristics, Static/Impact Load Mechanical Properties, and Evolution Mechanism" Buildings 15, no. 20: 3792. https://doi.org/10.3390/buildings15203792

APA StyleWang, S., Wang, W., Liu, H., Huang, A., & Ma, H. (2025). Study on Engineering Geopolymer Composites (EGCs) Under Sustained Thermal Environment: Linking Strain-Hardening Characteristics, Static/Impact Load Mechanical Properties, and Evolution Mechanism. Buildings, 15(20), 3792. https://doi.org/10.3390/buildings15203792