Investigation into the Dynamic Performance of a Reverse-Rotation Locking Sleeve Connection Method

Abstract

1. Introduction

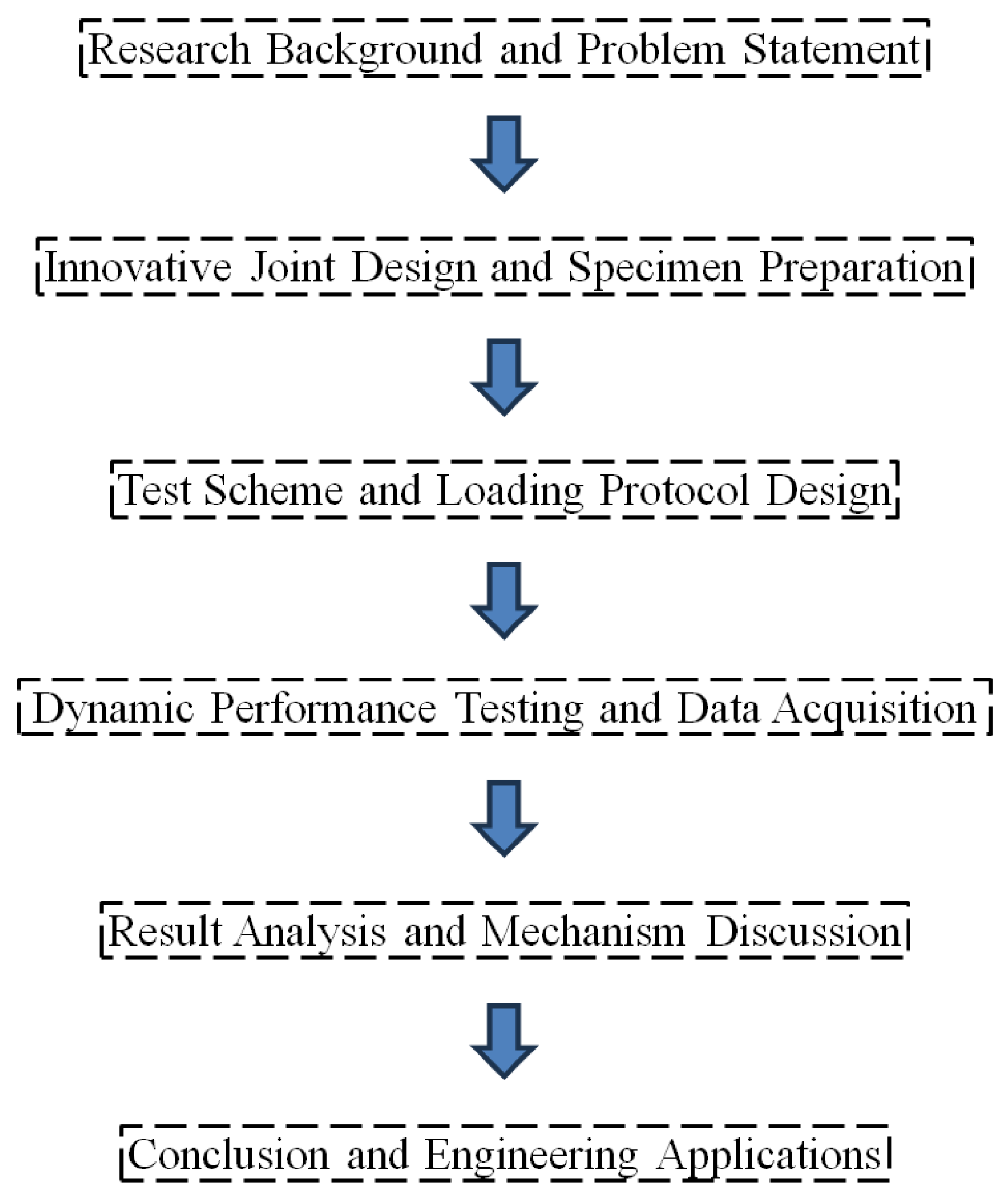

2. Research Methodology

- ➀

- The reverse-threaded nut is screwed onto the extreme left end of the threaded reserved rebar in precast beam A.

- ➁

- The sleeve is fully threaded onto the reserved rebar of precast beam A until contacting the reverse-threaded nut.

- ➂

- Reserved rebars of precast beams A and B are concentrically aligned utilizing the conical recess at the right end of the sleeve.

- ➃

- The sleeve is reversely rotated to the extreme right end of the reserved rebar in precast beam B, connecting both rebars.

- ➄

- The reverse-threaded nut on precast beam A’s rebar is reversely rotated to lock the sleeve, preventing leftward slippage along the thread direction.

- ➅

- Formwork is erected around the reverse-rotation locking sleeve connection, followed by C40 concrete casting. Demolding is performed after curing for the specified period.

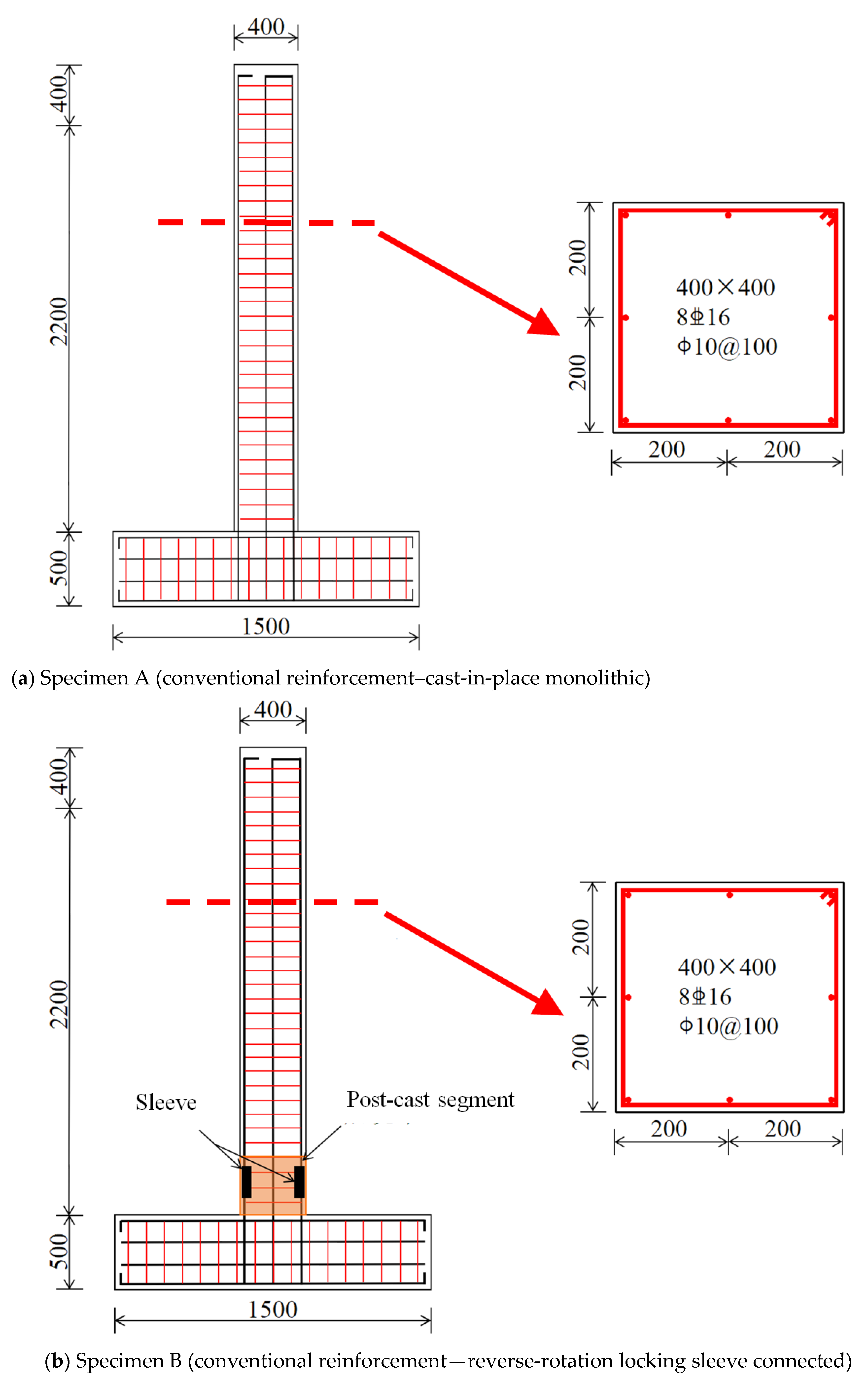

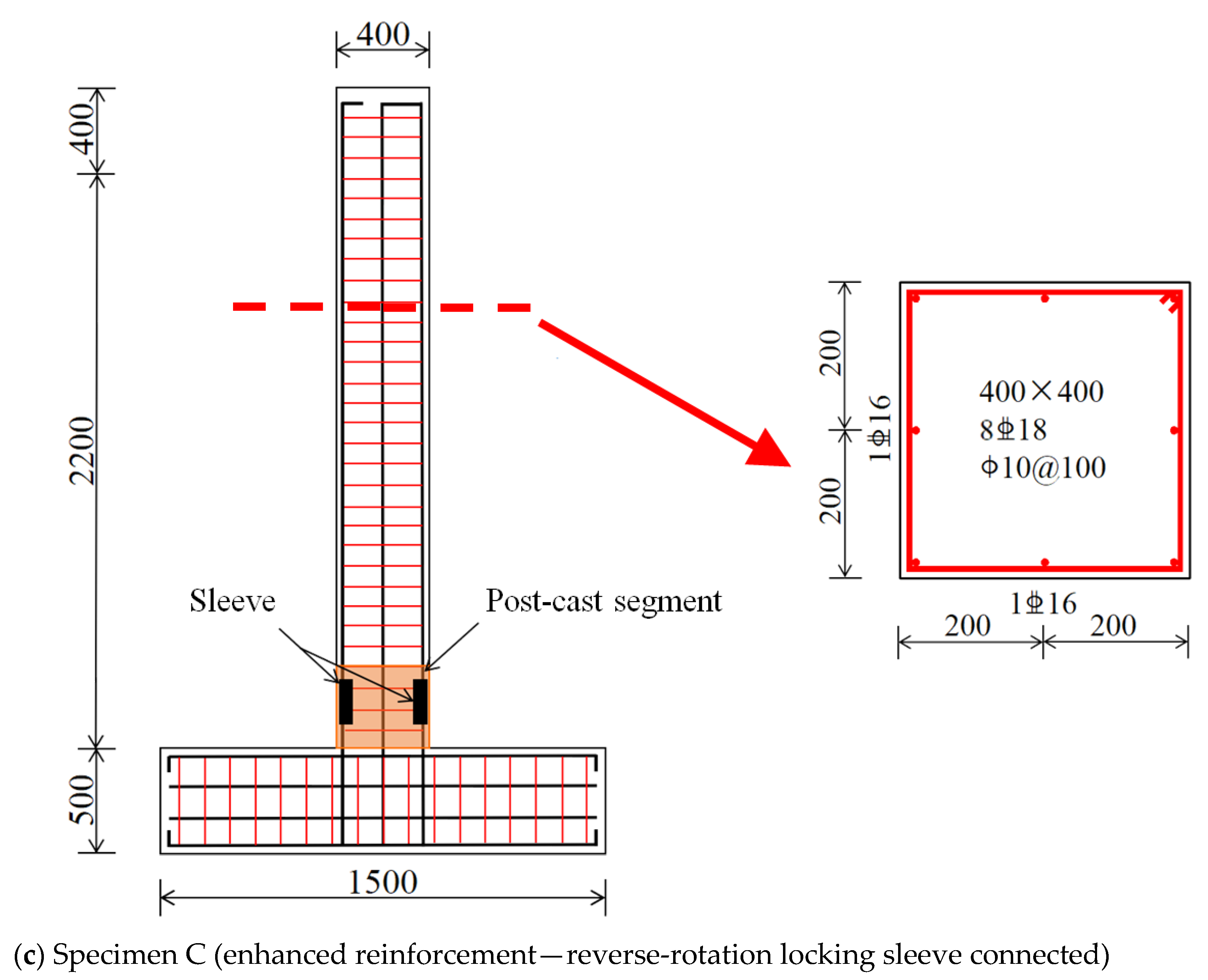

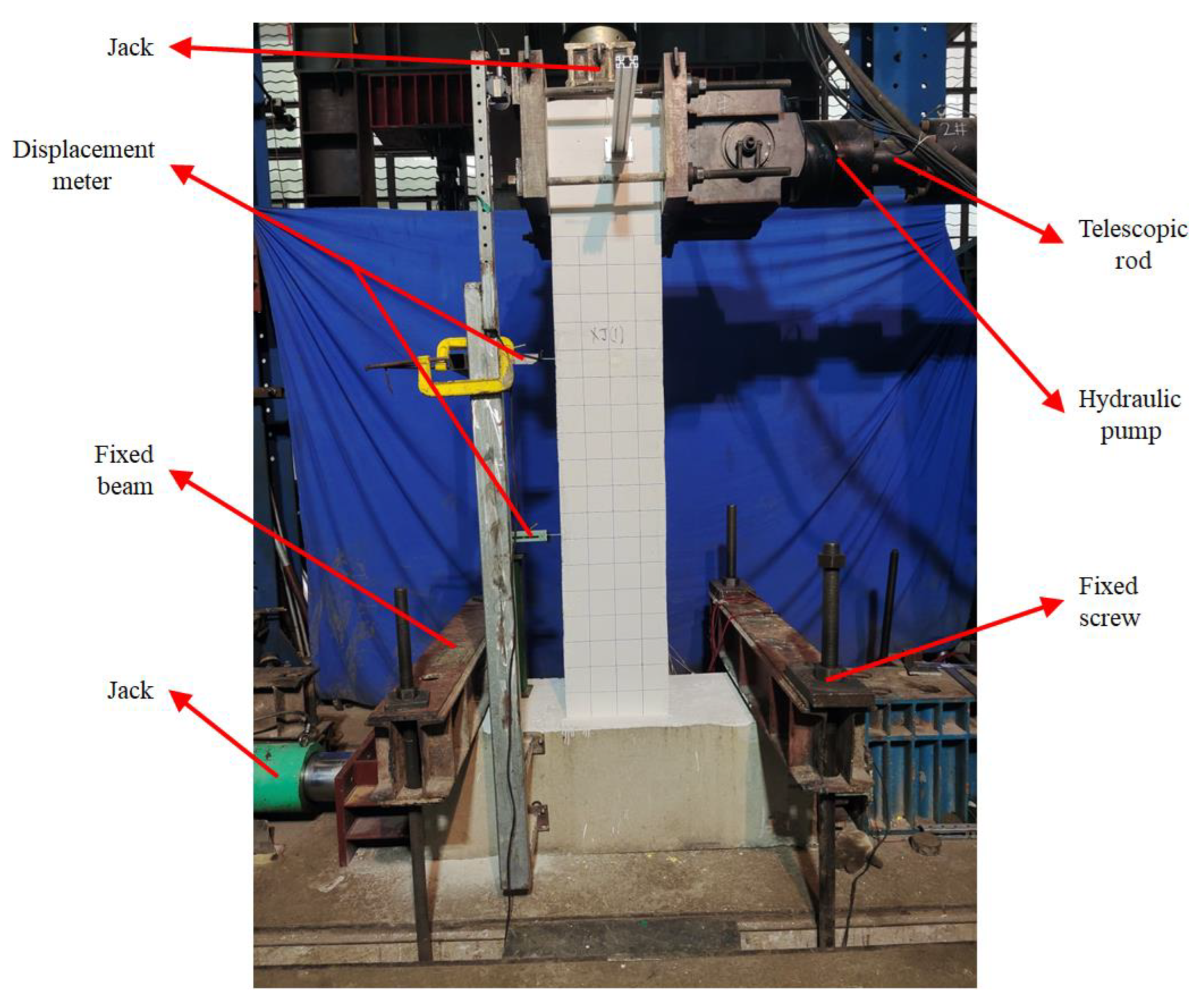

3. Experimental Investigation

4. Discussions and Results

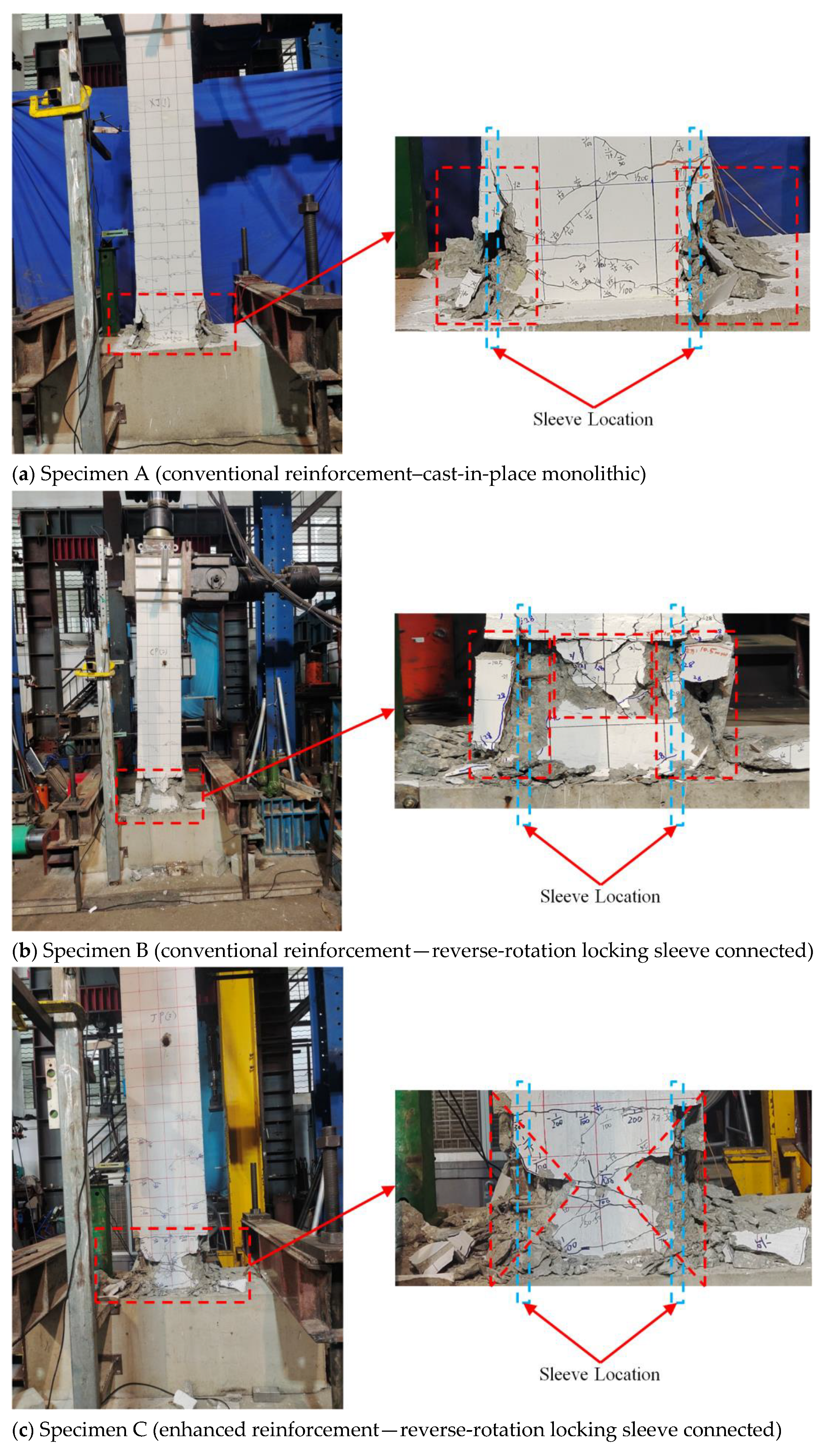

4.1. Specimen Failure Modes

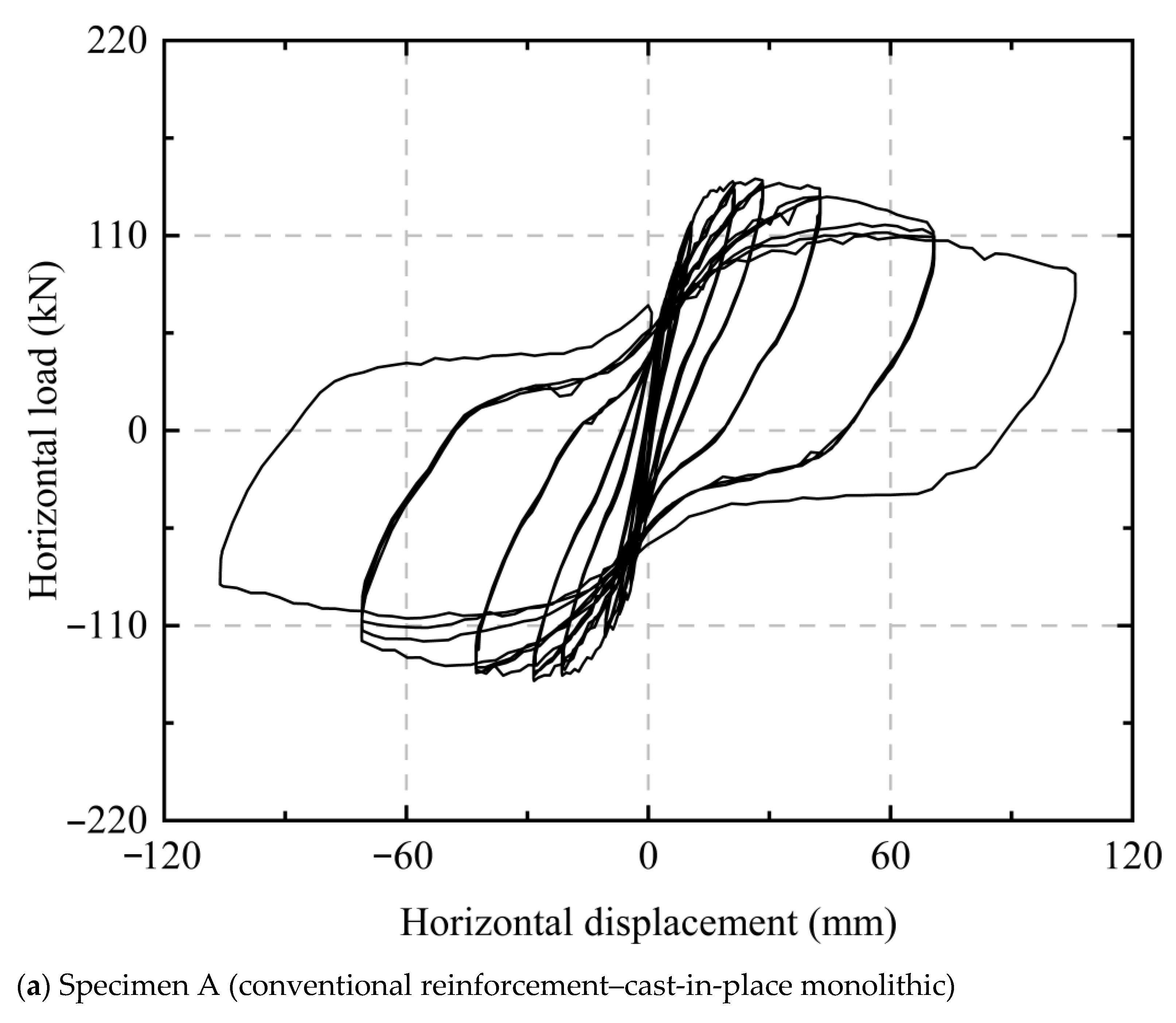

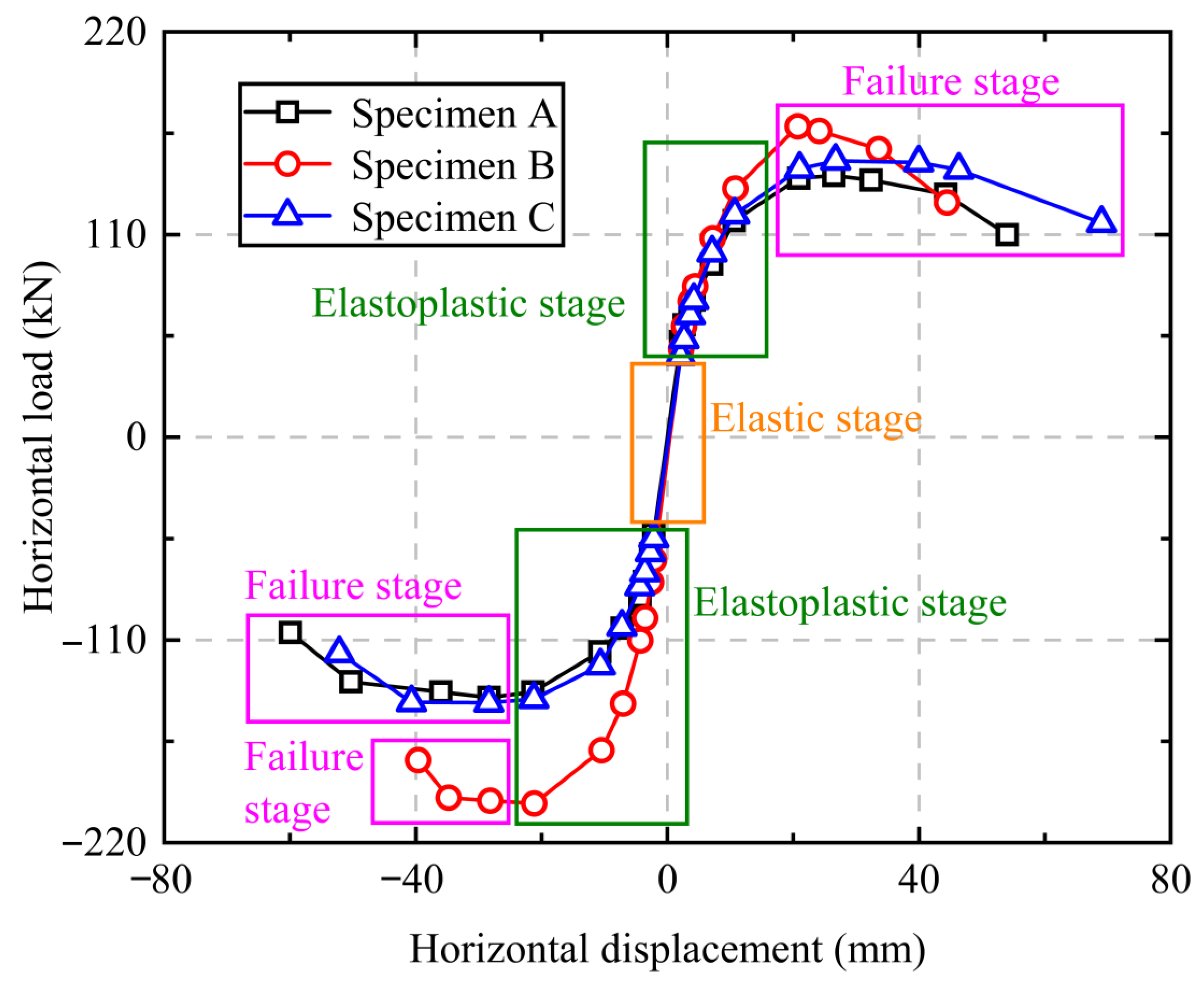

4.2. Hysteretic Curves and Skeleton Curves

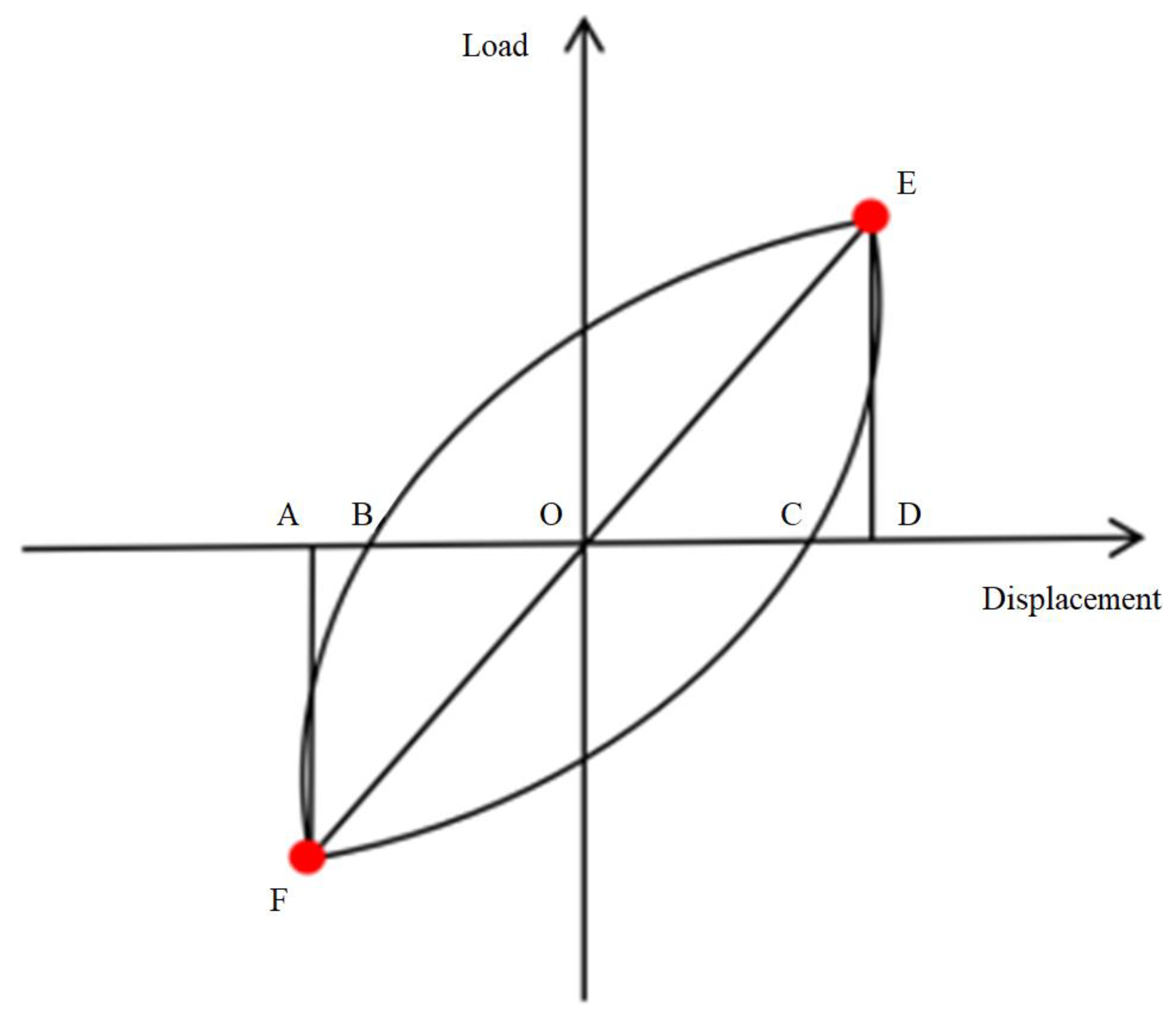

4.3. Ductility and Energy Dissipation Capacities

4.4. Load-Bearing Capacity Degradation and Stiffness Degradation

5. Conclusions

- Compared with traditional connection methods, the reverse-rotation locking sleeve connection demonstrates excellent comprehensive performance. In terms of failure modes, Specimen B exhibited more severe damage with potential stress concentration risks under strong earthquakes, while Specimen A showed the best integrity. Specimens A and C possessed nearly identical seismic energy dissipation capacities; however, Specimen B displayed significant rapid degradation in seismic energy dissipation capacity during the intermediate and late stages of testing, making Specimen C more suitable for high-intensity scenarios.

- The hysteretic curves of Specimens B and C were relatively full without obvious yield platforms, enabling greater energy absorption during seismic events; all three specimens exhibited S-shaped skeleton curves, with Specimens A and C reaching their peak loads at a lateral displacement of 21 mm, while Specimen B reached its peak load at 28 mm; compared to the cast-in-place monolithic Specimen A, the reverse-rotation locking sleeve connected Specimens B and C showed increases in ultimate load under positive cyclic loading by 18.7% and 5.5%, respectively, and under negative cyclic loading by 40.8% and 2.0%, respectively, indicating that the reverse-rotation locking sleeve connection method exhibits superior seismic performance during the plastic stage.

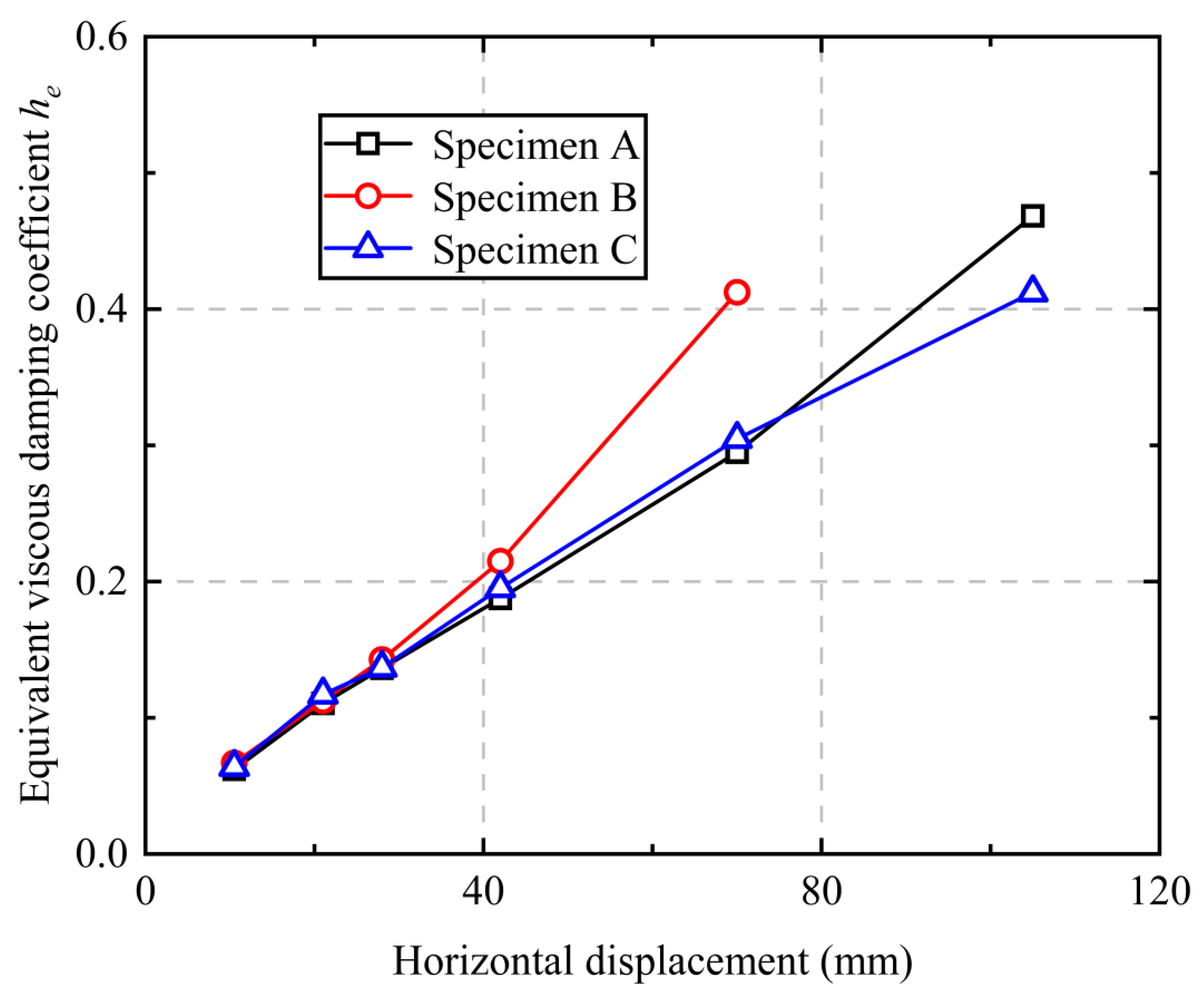

- The ductility coefficients of all three specimens met the requirement of being greater than 3.0 (Specimen A: 5.13; Specimen B: 3.56; Specimen C: 5.66), with Specimen C showing a 10.3% improvement over Specimen A, indicating that the reverse-rotation locking sleeve connection specimens possess favorable ductility and can effectively prevent sudden structural failure; analysis revealed that the equivalent viscous damping coefficient of Specimen C was approximately 0.06 higher than that of Specimen A, meaning Specimen C exhibited superior energy dissipation capacity compared to Specimen A, demonstrating that the reverse-rotation locking sleeve connection method can effectively absorb energy and enhance the seismic and energy dissipation characteristics of the specimens.

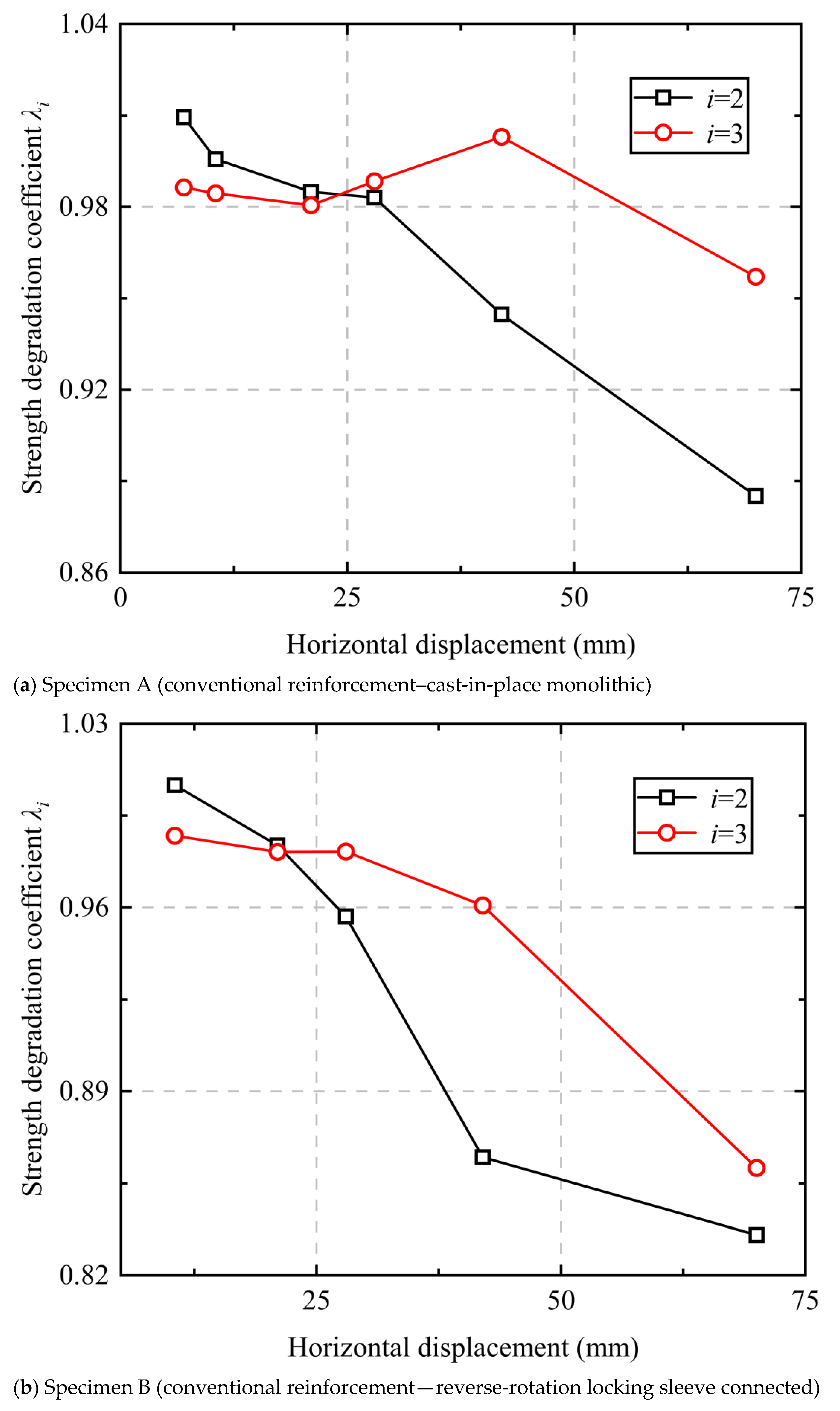

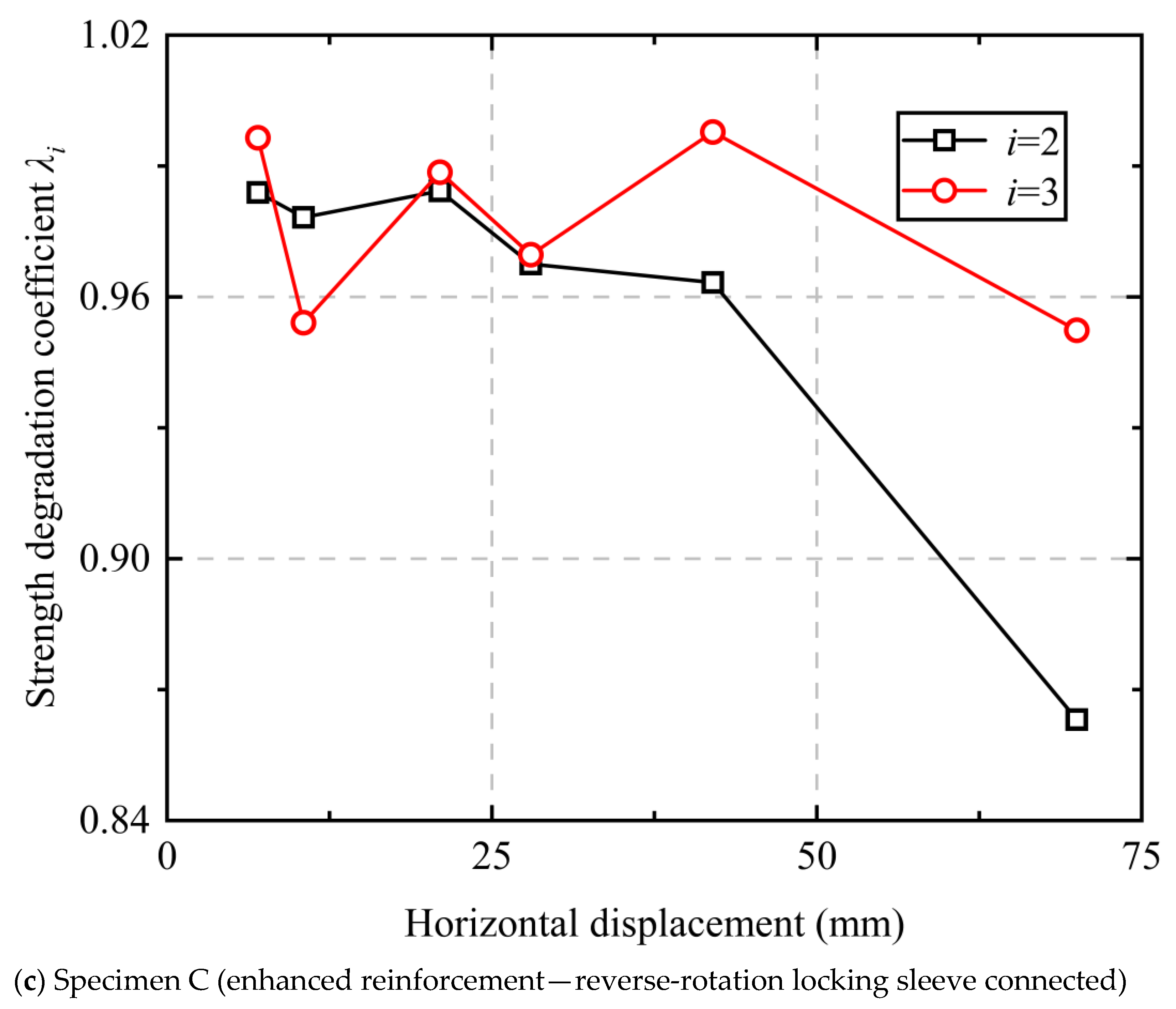

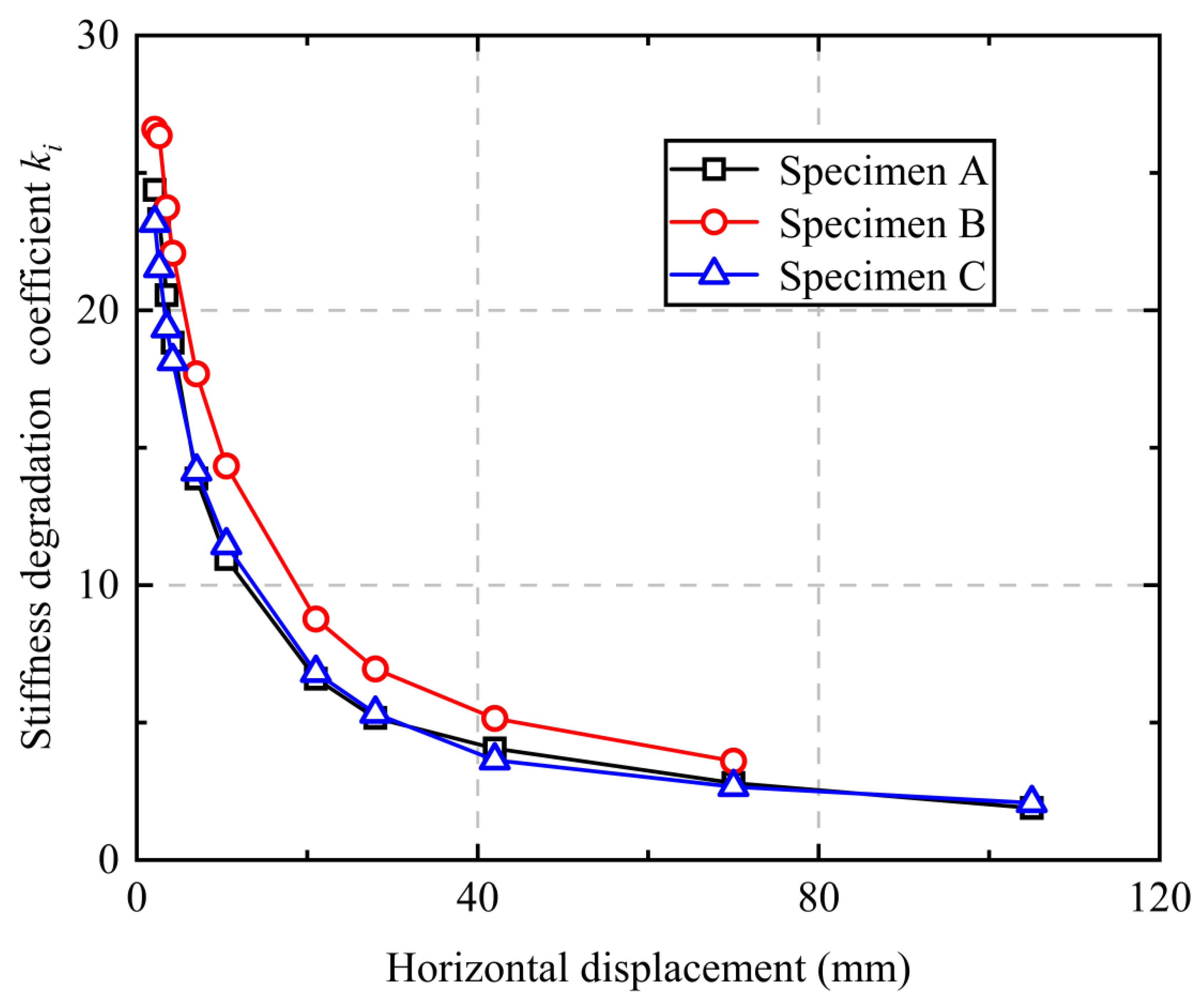

- The load-bearing capacity degradation coefficients of all three specimens fluctuated between 0.83 and 1.01, showing an initial stable phase followed by a gradual declining trend; the stiffness degradation coefficients exhibited rapid initial decline, followed by a deceleration in the attenuation rate, and eventual stabilization. This indicates that the reverse-rotation locking sleeve connection specimens can maintain stable strength and favorable seismic performance during the plastic deformation stage.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, C.; Li, X.; Li, X. Construction technology for connecting prefabricated components and vertical cast-in-situ belt reinforcement in prefabricated buildings. Build. Technol. 2024, 55, 1868–1870. [Google Scholar]

- Tang, T.; Song, J.; Zhu, C.; Peng, L.; Lei, X. Research on energy dissipation and seismic reduction of joints in prefabricated concrete frame-shear wall structures. Build. Struct. 2023, 53 (Suppl. S2), 861–866. [Google Scholar]

- Du, Y.; Sun, X.; Yang, J.; Quan, Y.; Bian, D. Research on detection method for grouting fullness of sleeves in prefabricated structures based on piezoelectric principle. J. Railw. Sci. Eng. 2024, 21, 860–872. [Google Scholar]

- You, J.; Jia, H.; Tang, C.; Yang, H.; Mao, J. Relaxation behavior of bolt tension force in concrete member connections in cold regions. Shanxi Archit. 2024, 50, 6–9+15. [Google Scholar]

- Zang, X.; Zhu, Z. Quasi-static test study on prefabricated shear walls with spiral stirrup-constrained bellows grouted connection. Constr. Technol. 2018, 47, 82–87. [Google Scholar]

- Chouery, E.; Fan, K.; Jia, L. Research status of seismic performance and design methods for symmetric and asymmetric friction energy dissipation connections. Eng. Mech. 2021, 38, 22–37+49. [Google Scholar]

- Zhou, Z.; Pan, Z. Seismic performance analysis of fully prefabricated RCS hybrid structure with friction splicing energy dissipation joints. Build. Struct. 2014, 44, 51+72–76. [Google Scholar]

- Han, J.; Zhang, H.; Qiao, Y. Experimental study on hysteretic behavior of friction dampers with sliding long hole and high-strength bolts. J. Build. Struct. 2018, 39 (Suppl. S2), 315–320. [Google Scholar]

- Xu, X.; Kong, Z.; Sun, W.; Yu, Z.; Fan, X. Research on seismic performance and mechanical model of T-shaped steel energy dissipation hinge dampers. Earthq. Eng. Eng. Vib. 2024, 44, 136–147. [Google Scholar]

- Arapati, A.; Chen, G. A review of connection methods for joints in prefabricated concrete structures. Struct. Eng. 2020, 36, 224–233. [Google Scholar]

- Yan, L.; Wu, T.; Tuo, W.; Wei, Y.; Zhao, W.; Zheng, Y. A review of research progress on connection joints of prefabricated structures. Build. Sci. 2020, 36, 126–132. [Google Scholar]

- Ou, W.; Liu, K.; Ma, G. A review of research on connection joints of prefabricated frames. Constr. Sci. Technol. 2020, 401, 59–62. [Google Scholar]

- Liu, L.; Xiao, J. Research progress on grouted sleeve connection of steel bars. J. Build. Struct. 2023, 44, 235–247. [Google Scholar]

- Ling, J.; Abd, A.; Ibrahim, I.; Abdul, Z. Tensile capacity of grouted splice sleeves. Eng. Struct. 2016, 111, 285–296. [Google Scholar] [CrossRef]

- Wang, H.; Wang, G. Research on joints of fully prefabricated concrete structures. Bricks Tiles 2024, 7, 91–94. [Google Scholar]

- Pan, Z.; Bao, X.; Wang, S. Seismic performance and structural parameters of RCS beam-column joints with asymmetric friction connections. J. Jiangsu Univ. Sci. Technol. (Nat. Sci. Ed.) 2024, 38, 91–97. [Google Scholar]

- Zhao, B.; Lü, X.; Liu, L. Experimental study on seismic performance of fully prefabricated concrete beam-column composite members. Earthq. Eng. Eng. Vib. 2005, 01, 81–87. [Google Scholar]

- Zhang, W.; Shan, H.; Han, X. Experimental study on shear performance of prefabricated gutters with high-strength bolt cone hole grouting connections. Build. Struct. 2024, 54, 132–137. [Google Scholar]

- Wu, D.; Yang, Y.; Li, C. Experimental study on mechanical performance of bolted connections in prefabricated reinforced concrete beams. J. Water Resour. Archit. Eng. 2023, 21, 146–151+186. [Google Scholar]

- Zhao, L.; Hu, S.; Qi, H.; Nie, Y.; Tao, X.; Zhao, X.; Luo, L. Experimental study on seismic performance of square steel tube concrete splice columns with novel corrugated pipe connections. Build. Struct. 2024, 54, 1–7. [Google Scholar]

- Xu, Y.; Wei, K.; Li, M. Seismic performance study on precast pier-cap beam joints based on bundled bars–grouted corrugated duct connections. China Civ. Eng. J. 2023, 56, 12–22. [Google Scholar]

- Yan, X.; Zhang, H.; Yang, T.; He, W.; Zhang, X. Seismic performance analysis of precast bridge piers with grouted corrugated duct connections. Spec. Struct. 2025, 42, 87–91. [Google Scholar]

- Liu, R.; Wu, J.; Yan, G.; Wang, H. Experimental study on seismic performance of friction-bearing energy dissipation connections for beam-column joints. Eng. Mech. 2025, 42, 146–157. [Google Scholar] [CrossRef]

- Yang, Y.; Diao, Y.; Ren, Y.; Liu, Y.; Liu, X. Seismic performance study on replaceable spliced connection joints with friction energy dissipation components. Prog. Steel Build. Struct. 2023, 25, 22–34. [Google Scholar]

- Xu, L.; Huang, C.; Xie, X. Performance study on self-centering braced steel frames with friction assembled joints. J. Vib. Eng. 2024, 37, 1239–1249. [Google Scholar]

- Zhou, Q. Study on Mechanical Characteristics and Shear Performance of Joints in Hinged Prefabricated Frame-Anchor Structures. Master’s Thesis, Changsha University of Science & Technology, Changsha, China, 2022. [Google Scholar]

- Wang, H. Research on Seismic Performance and Design Methods of Prefabricated Concrete Beam-Column Hinged Frame-Shear Wall Systems. Master’s Thesis, Shandong Jianzhu University, Jinan, China, 2021. [Google Scholar]

- Zhang, J.; Ma, Z.; Liang, H. Numerical analysis of seismic performance of energy-dissipating steel hinged joints in prefabricated concrete frames. Build. Technol. 2018, 49 (Suppl. S1), 188–190. [Google Scholar]

- Wang, Y.; Gao, G.; Hong, Z.; Wang, J.; Liu, T. Fire resistance performance analysis of bolted connections in prefabricated beam-column joints. J. Shenyang Jianzhu Univ. (Nat. Sci.) 2024, 40, 658–667. [Google Scholar]

- GB/T 51231-2016; Technical Standard for Prefabricated Concrete Buildings. Anhui Jianzhu University: Hefei, China, 2016.

- GB/T 50011-2010; Code for Seismic Design of Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2010.

- Li, C.; Qi, Y.; Xu, C.; Sun, J. Study on mechanical behavior of T-stub connections between square concrete-filled steel tubular columns and steel beams. J. Build. Struct. 2017, 38 (Suppl. S1), 409–416. [Google Scholar]

- Shen, P. Explanation of Difficult Problems in High-Rise Building Structures: Prepared According to Code JGJ3-2010, 2nd ed.; China Architecture & Building Press: Beijing, China, 2011. [Google Scholar]

- Li, J.; Xia, Z.; Yu, Z. Bidirectional quasi-static test study on prefabricated concrete double-column piers with grouted sleeve connections. Earthq. Eng. Eng. Vib. 2020, 40, 193–203. [Google Scholar]

- Liu, X.; Pu, S.; Xu, A.; Ni, Z.; Zhang, A.; Ynag, Z. Experimental study on static and seismic behavior of fully bolted connections in modular prefabricated multi-story steel structures. J. Build. Struct. 2015, 36, 43–51. [Google Scholar]

- Ge, J.; Xia, Z.; Jiang, H. Bidirectional quasi-static test on prefabricated bridge piers with grouted corrugated ducts. China J. Highw. Transp. 2018, 31, 221–230+266. [Google Scholar]

- Wei, R. Quasi-static test study on new prefabricated rotating friction beam-column cross-shaped energy dissipation joints. Fujian Archit. 2024, 5, 104–110. [Google Scholar]

- JGJ/T 101-2015; Specification for Seismic Test of Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2015.

- Zhao, H. Steel and Concrete Composite Structures; Science Press: Beijing, China, 2001. [Google Scholar]

- Cao, F.; Lu, Z.; Zhao, G.; Lu, Y. Experimental study on seismic performance of interior joints in PEC column-steel beam frames. J. Build. Struct. 2020, 41, 30–41. [Google Scholar]

- Zhang, Z.; Chen, D.; Jiang, Z.; Zhang, Q. Experimental study on seismic performance of steel frame-cold-formed thin-walled steel shear wall structures. Prog. Steel Build. Struct. 2022, 24, 11–19. [Google Scholar]

| Control Displacement (mm) | ±2.1 | ±2.625 | ±3.5 | ±4.2 | ±7 | ±10.5 | ±21 | ±28 | ±42 | ±70 | ±105 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tilt angle | ±1/1000 | ±1/800 | ±1/600 | ±1/500 | ±1/300 | ±1/200 | ±1/100 | ±1/75 | ±1/50 | ±1/30 | ±1/20 |

| Direction | Specimen A | Specimen B | Specimen C | ||||

|---|---|---|---|---|---|---|---|

| Positive | Negative | Positive | Negative | Positive | Negative | ||

| Yield State | Δx (mm) | 9.6 | −5.9 | 10.8 | −7.5 | 10.68 | −9.5 |

| Δy (kN) | 140 | −95 | 134.97 | −147.5 | 120.87 | −115.1 | |

| Failure State | Δu (mm) | 49.2 | −12.5 | 38.5 | −10.46 | 60.5 | −10.67 |

| Δv (kN) | 120.8 | −120 | 143.4 | −168.9 | 127.5 | −122.4 | |

| Direction | Specimen A | Specimen B | Specimen C | |||

|---|---|---|---|---|---|---|

| Positive | Negative | Positive | Negative | Positive | Negative | |

| μΔ | 5.13 | 2.12 | 3.56 | 1.39 | 5.66 | 1.12 |

| Connection Technique | Ductility Coefficient μΔ | Reference |

|---|---|---|

| Reverse-rotation locking sleeve connection | 5.66 | — |

| Grouted sleeve connection | 5.84 | [34] |

| Bolted connection | 5.55 | [35] |

| Corrugated duct grouted anchor connection | 5.50 | [36] |

| Friction-type energy dissipation connection | 5.45 | [37] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, X.-M.; Gu, R.-G.; Hong, C.-H.; Liang, R.-Q.; Gao, K.; Zhang, X.-F. Investigation into the Dynamic Performance of a Reverse-Rotation Locking Sleeve Connection Method. Buildings 2025, 15, 3790. https://doi.org/10.3390/buildings15203790

Tang X-M, Gu R-G, Hong C-H, Liang R-Q, Gao K, Zhang X-F. Investigation into the Dynamic Performance of a Reverse-Rotation Locking Sleeve Connection Method. Buildings. 2025; 15(20):3790. https://doi.org/10.3390/buildings15203790

Chicago/Turabian StyleTang, Xue-Mei, Ren-Guo Gu, Chuan-Hai Hong, Rui-Qing Liang, Kang Gao, and Xiao-Feng Zhang. 2025. "Investigation into the Dynamic Performance of a Reverse-Rotation Locking Sleeve Connection Method" Buildings 15, no. 20: 3790. https://doi.org/10.3390/buildings15203790

APA StyleTang, X.-M., Gu, R.-G., Hong, C.-H., Liang, R.-Q., Gao, K., & Zhang, X.-F. (2025). Investigation into the Dynamic Performance of a Reverse-Rotation Locking Sleeve Connection Method. Buildings, 15(20), 3790. https://doi.org/10.3390/buildings15203790