Noise Reducing Textile Diffuser of Building Ventilation System

Abstract

1. Introduction

2. Samples, Test Bench, and Methodology

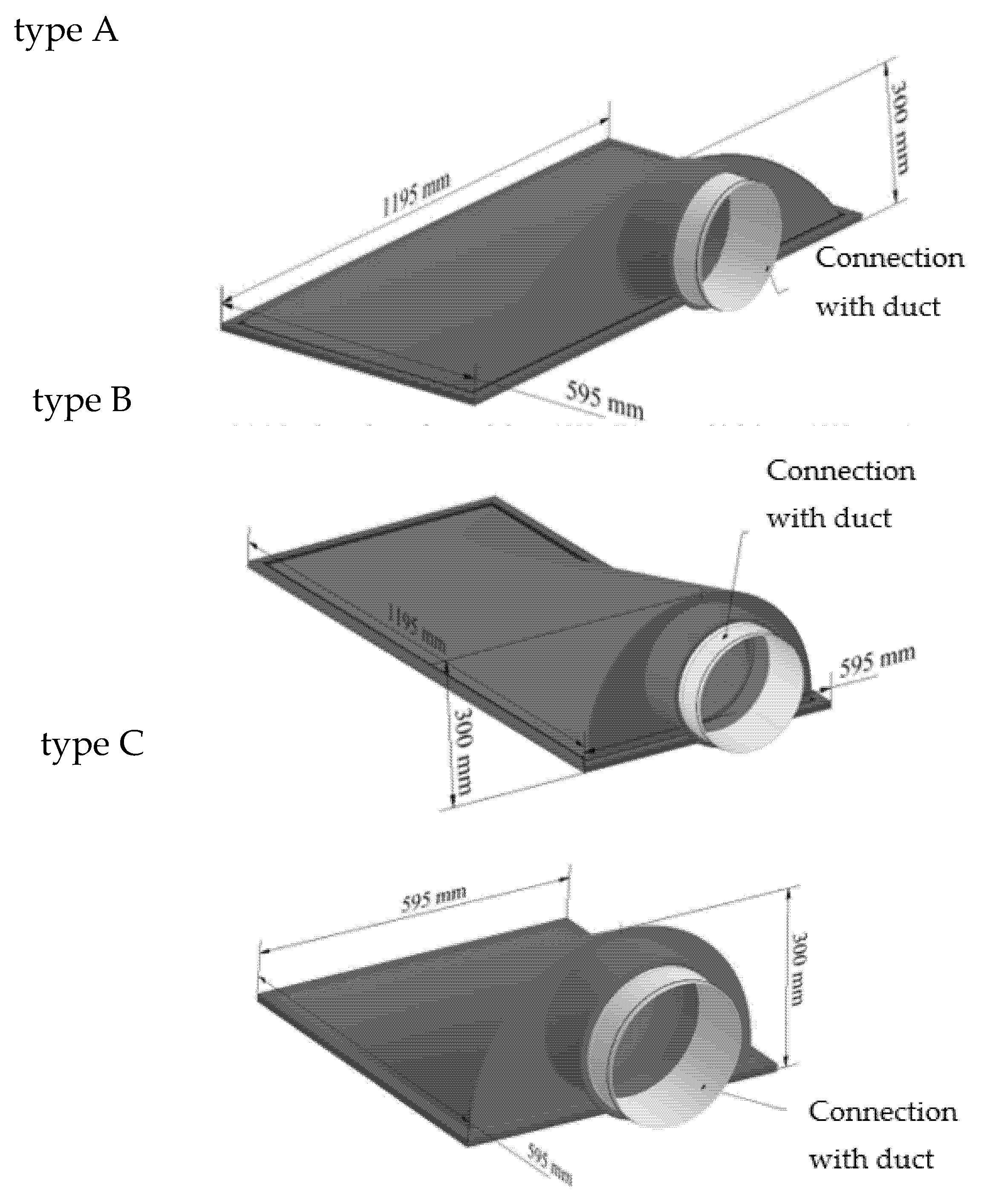

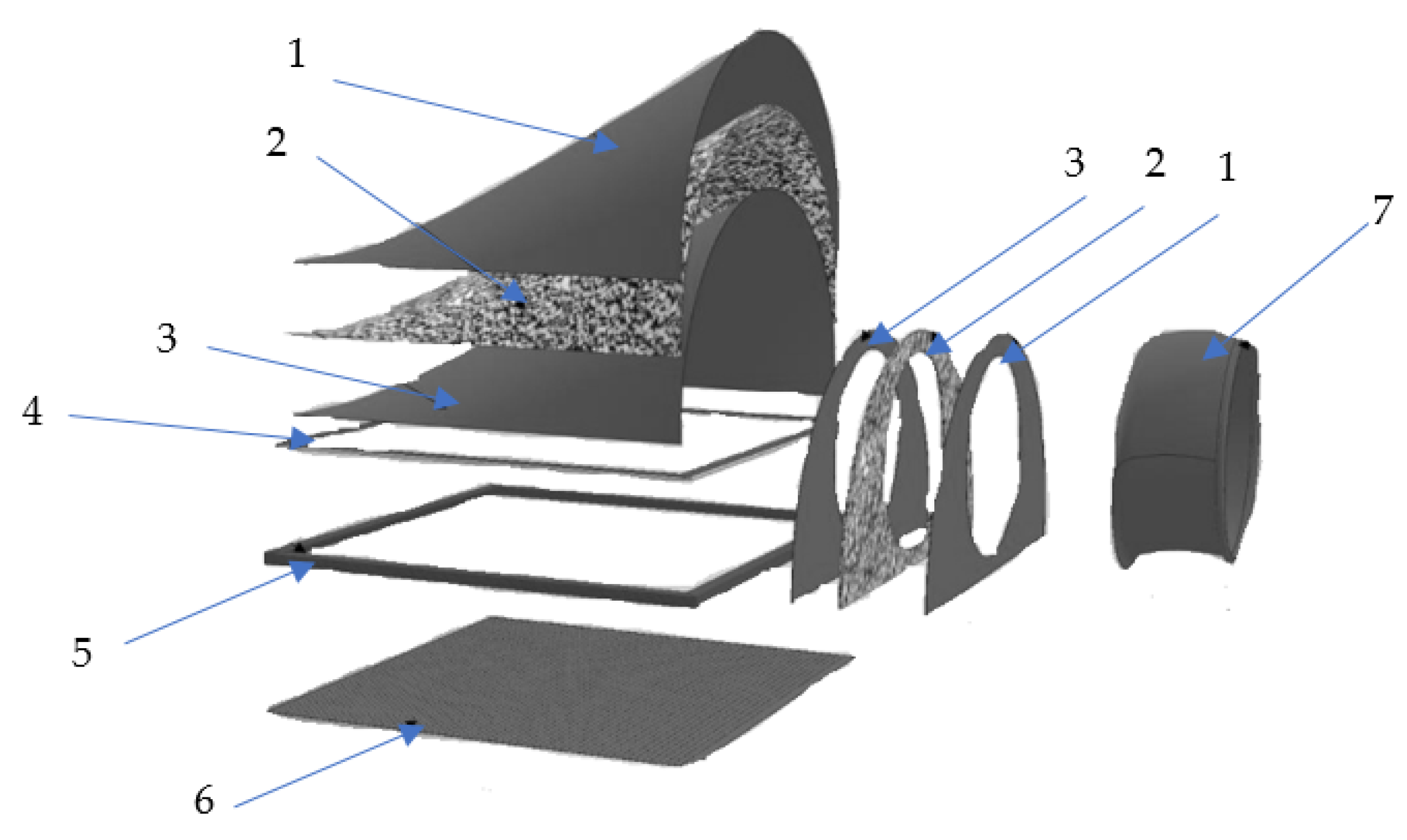

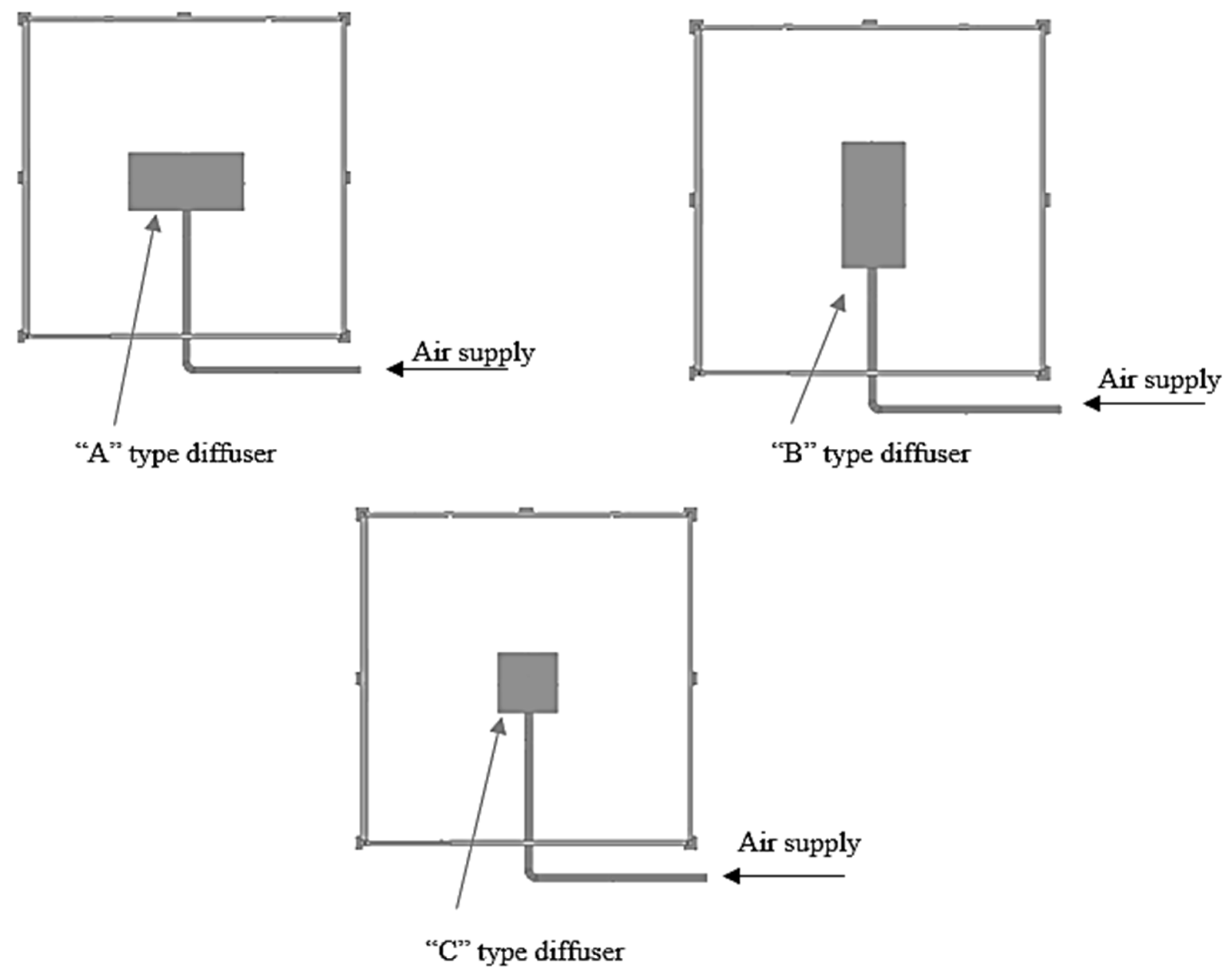

2.1. Samples

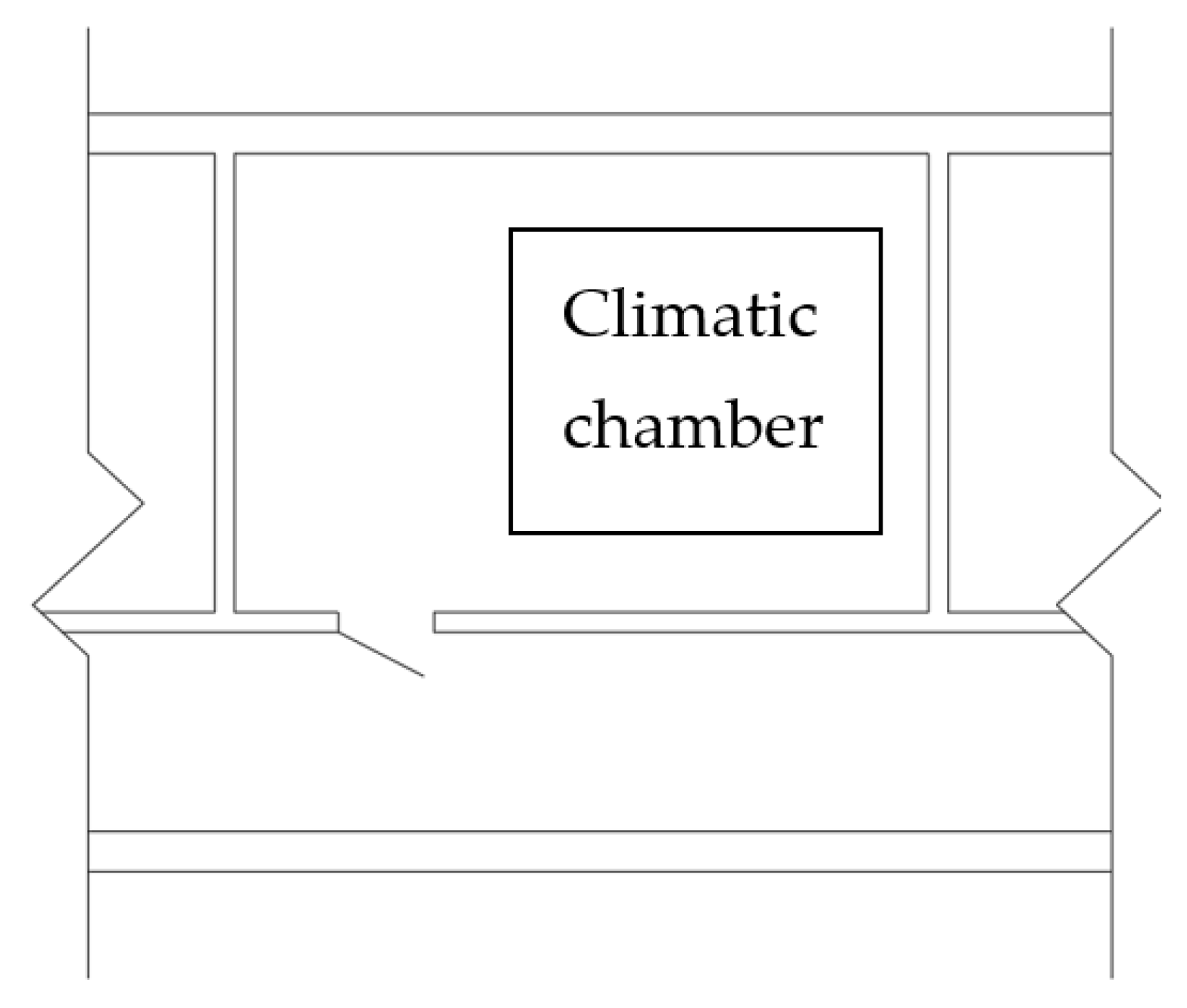

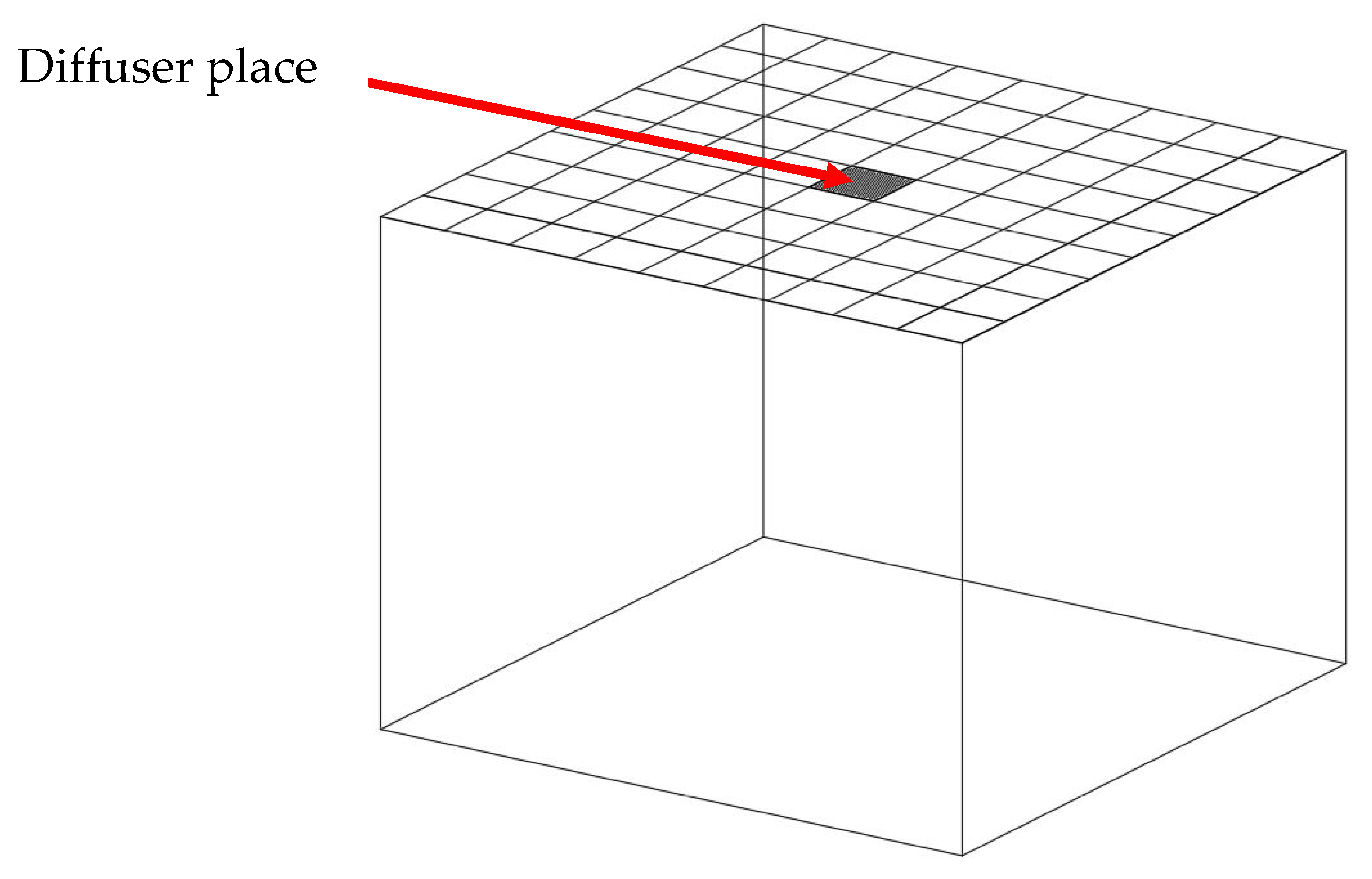

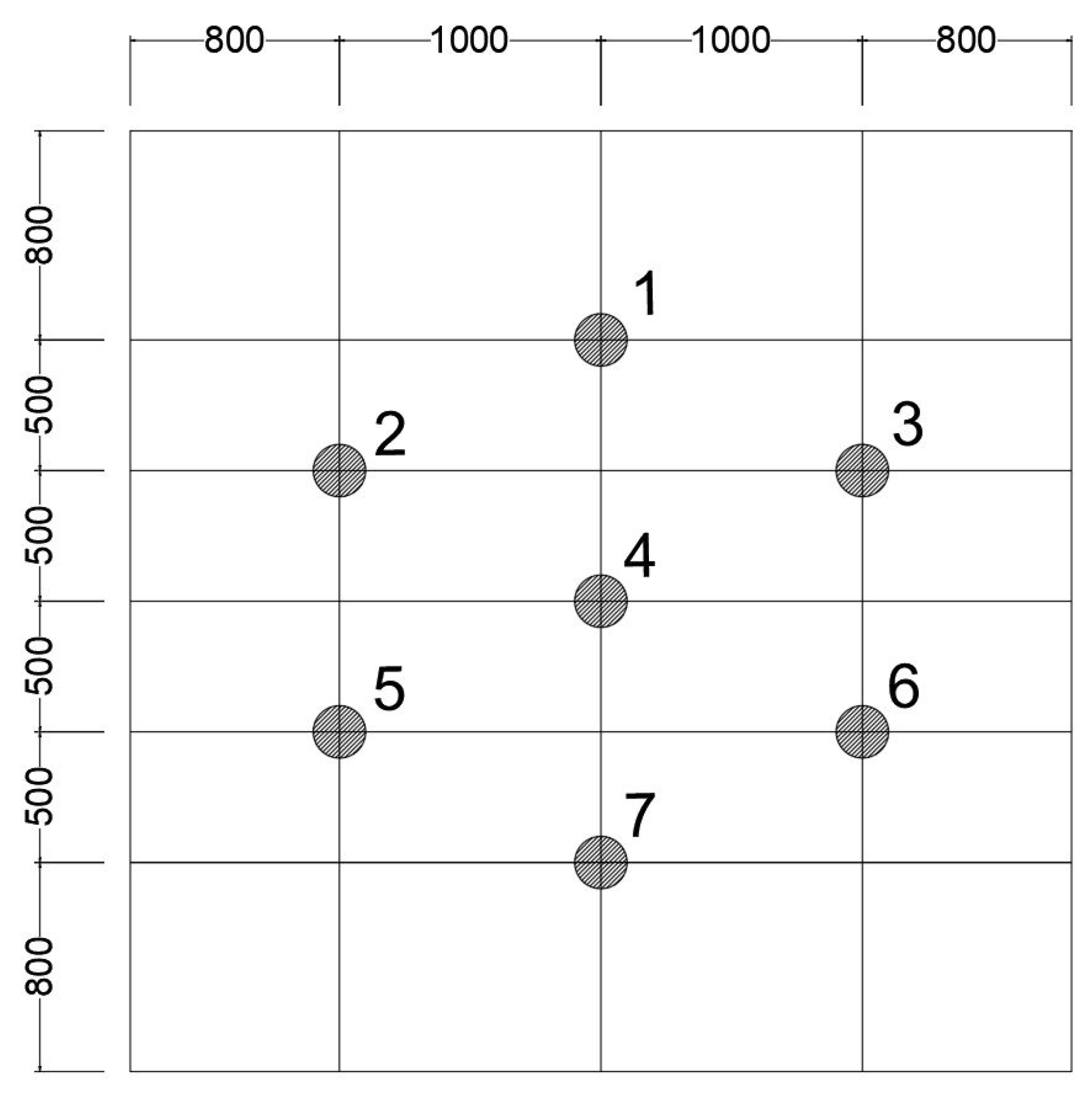

2.2. Test Bench

2.3. Measurement Equipment and Methodology

3. Results and Discussion

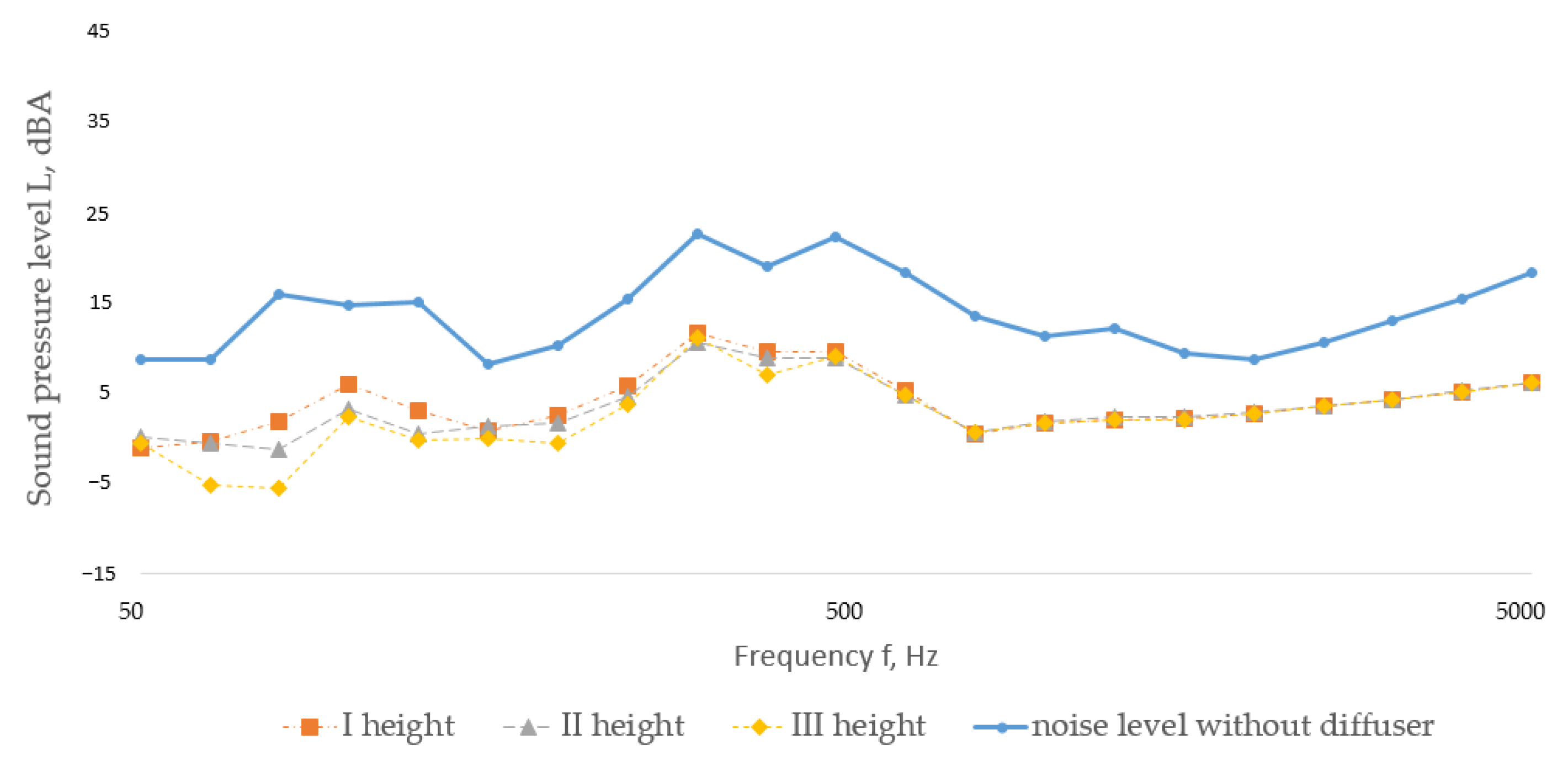

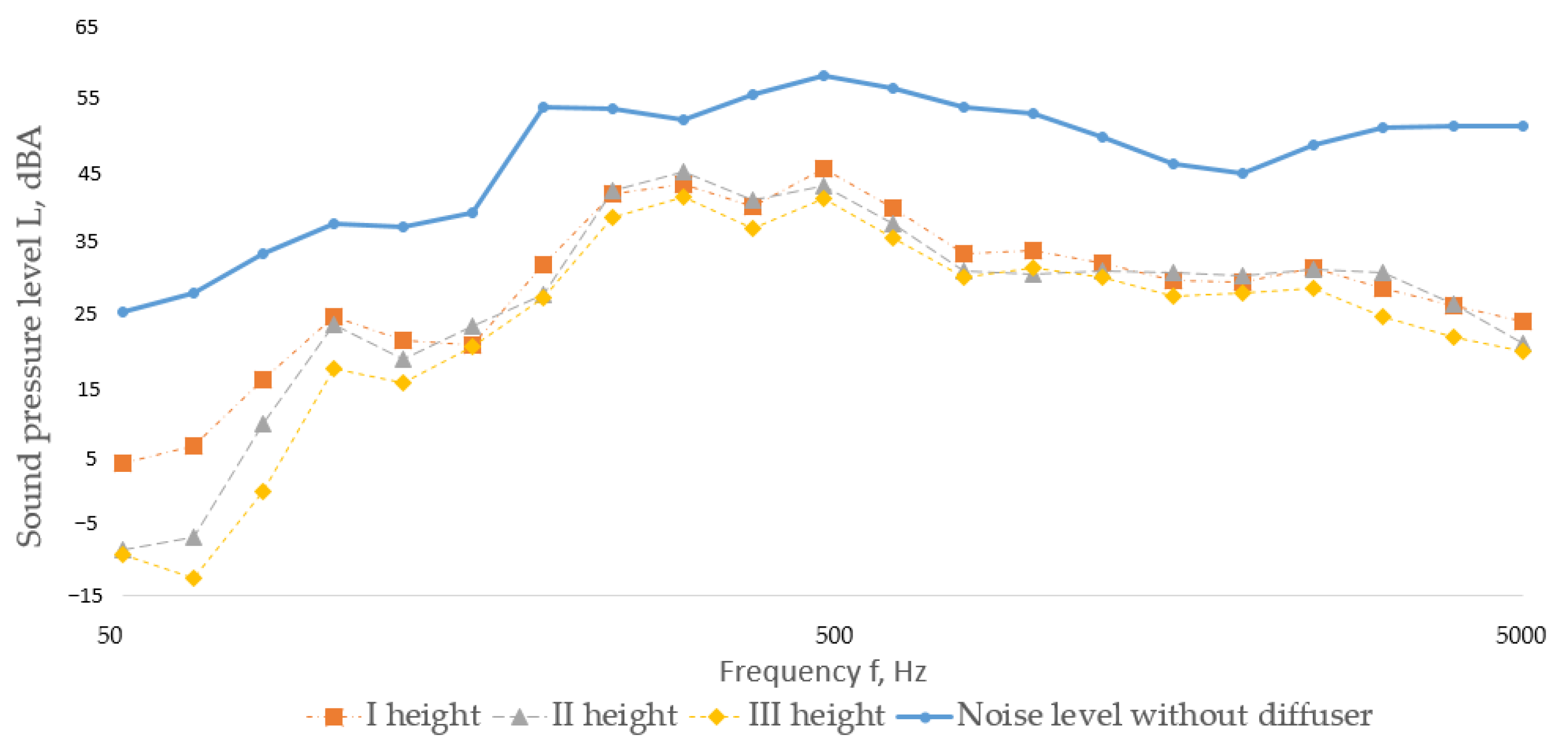

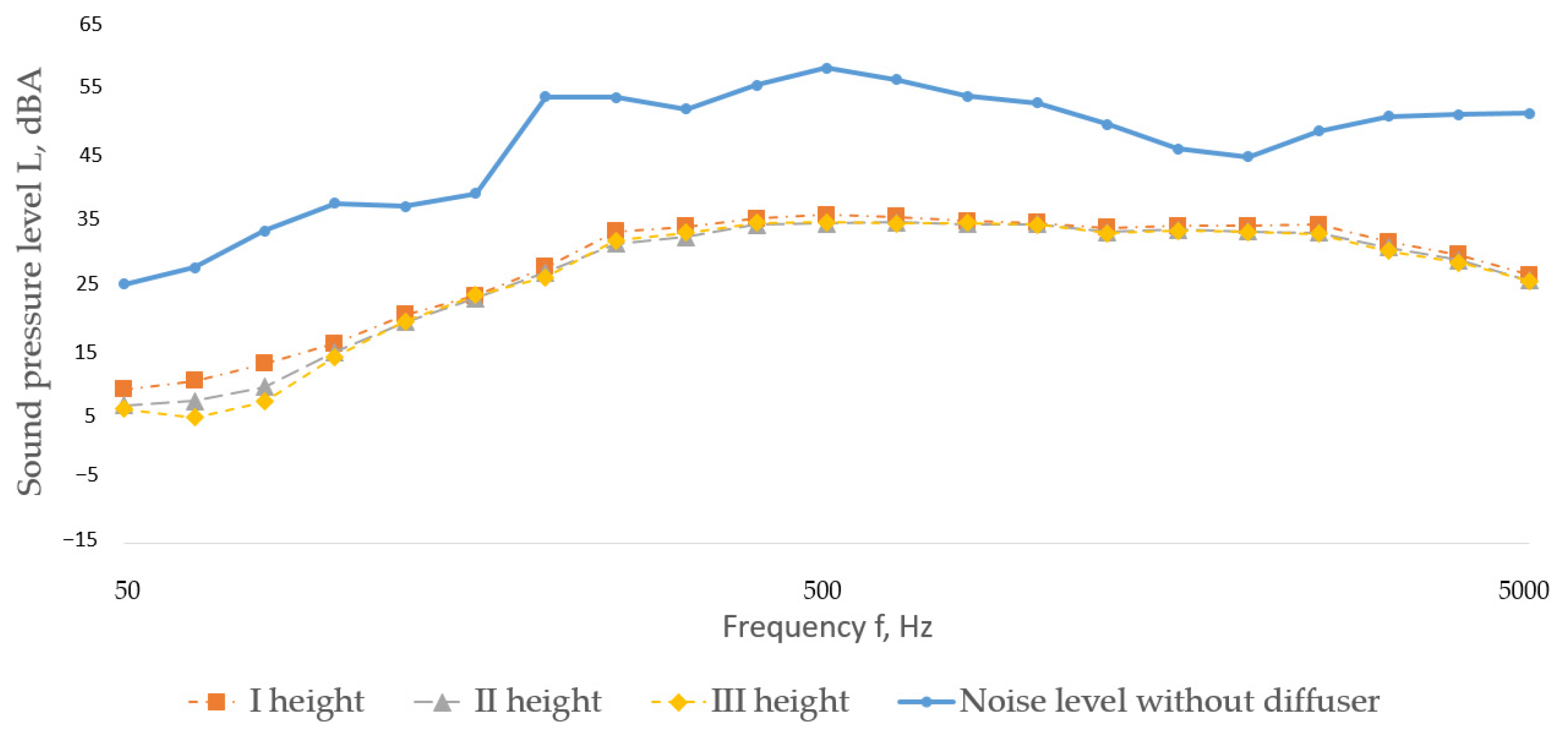

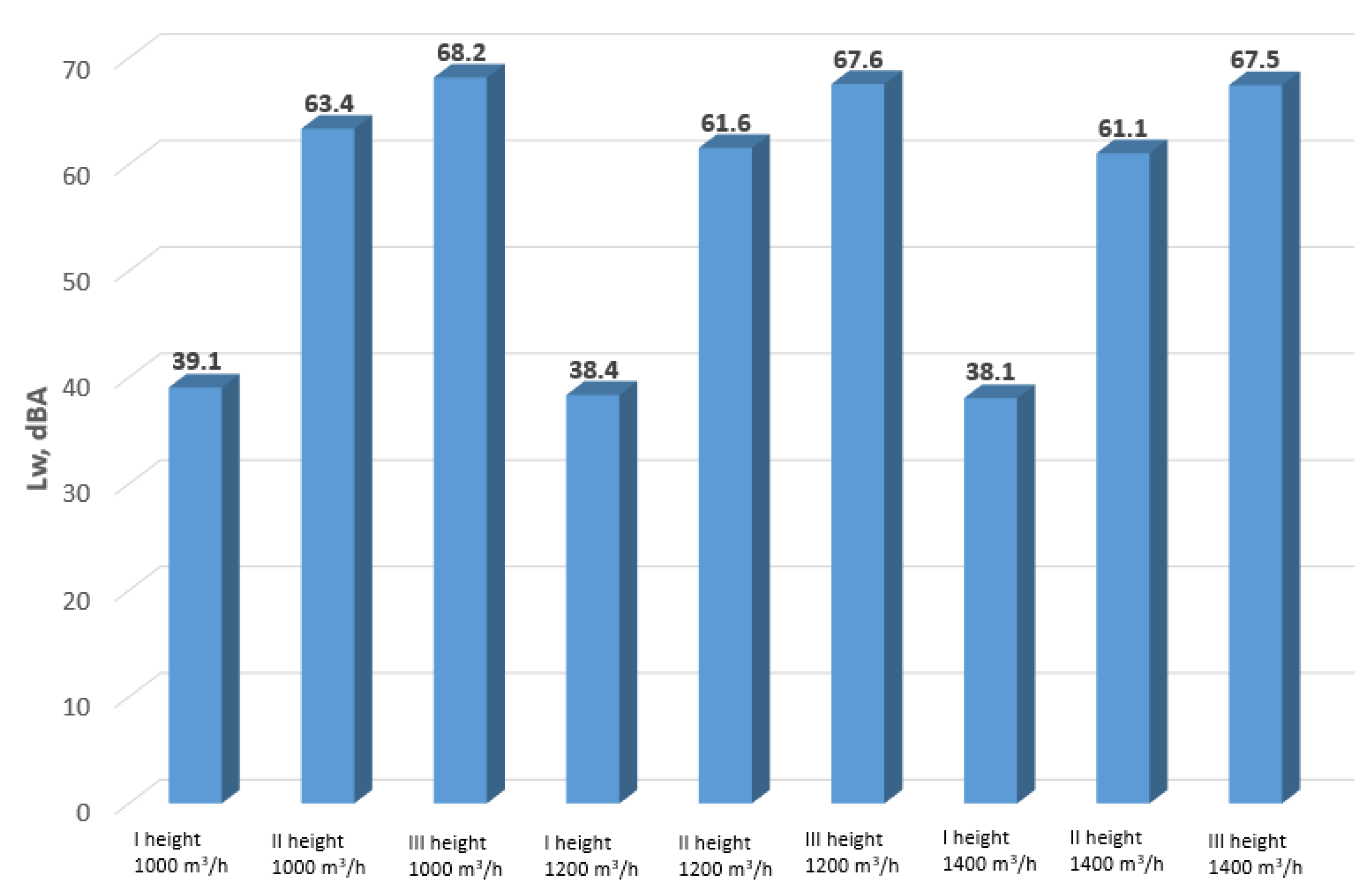

3.1. ‘A’ Type Diffuser

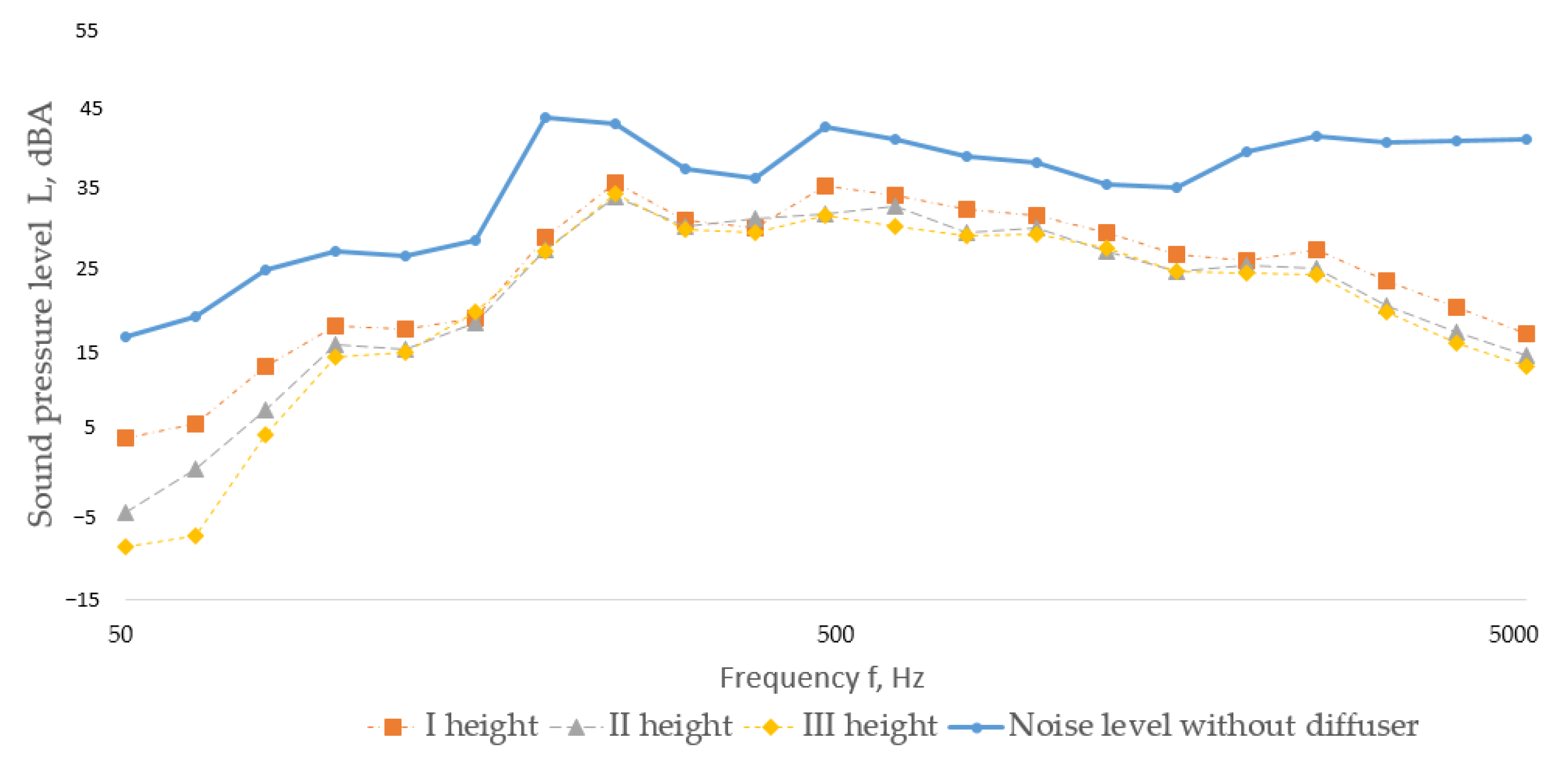

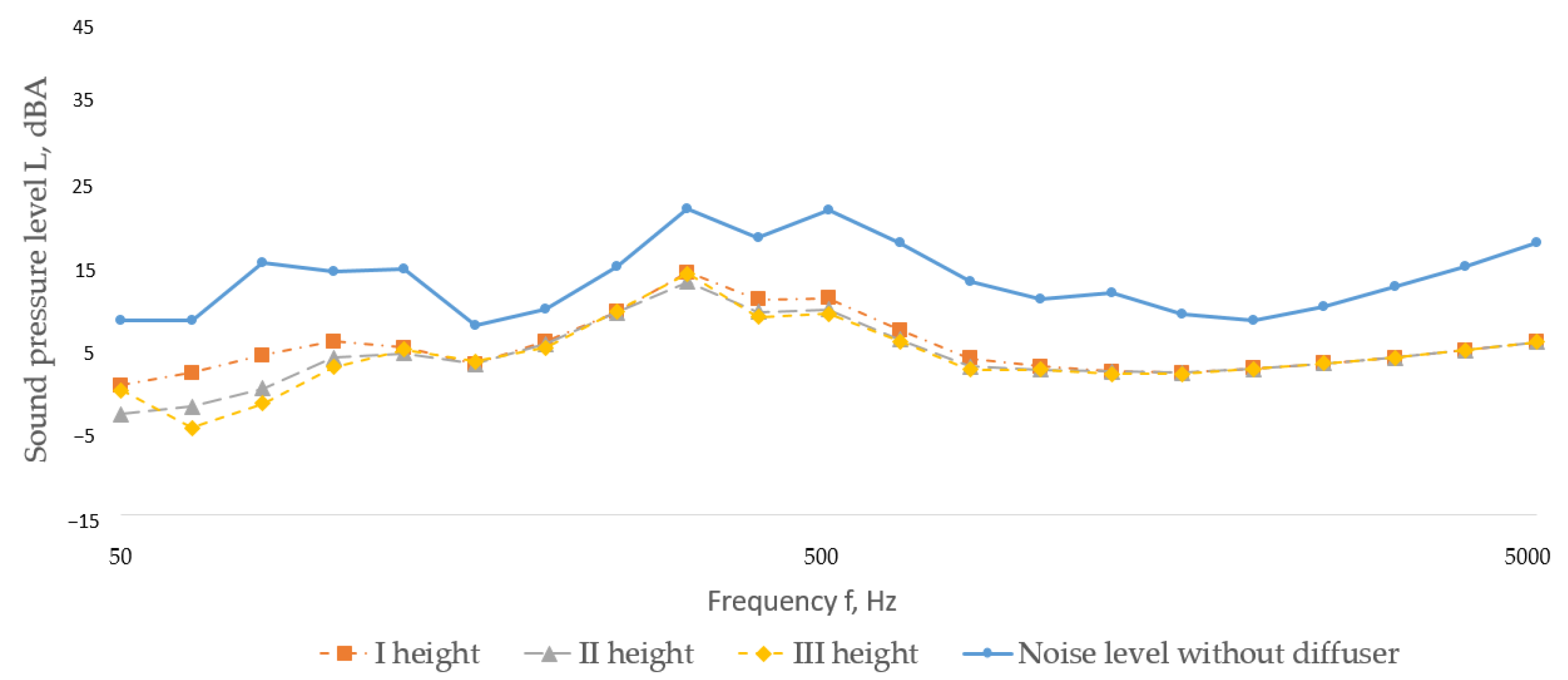

3.2. ‘B’ Type Diffuser

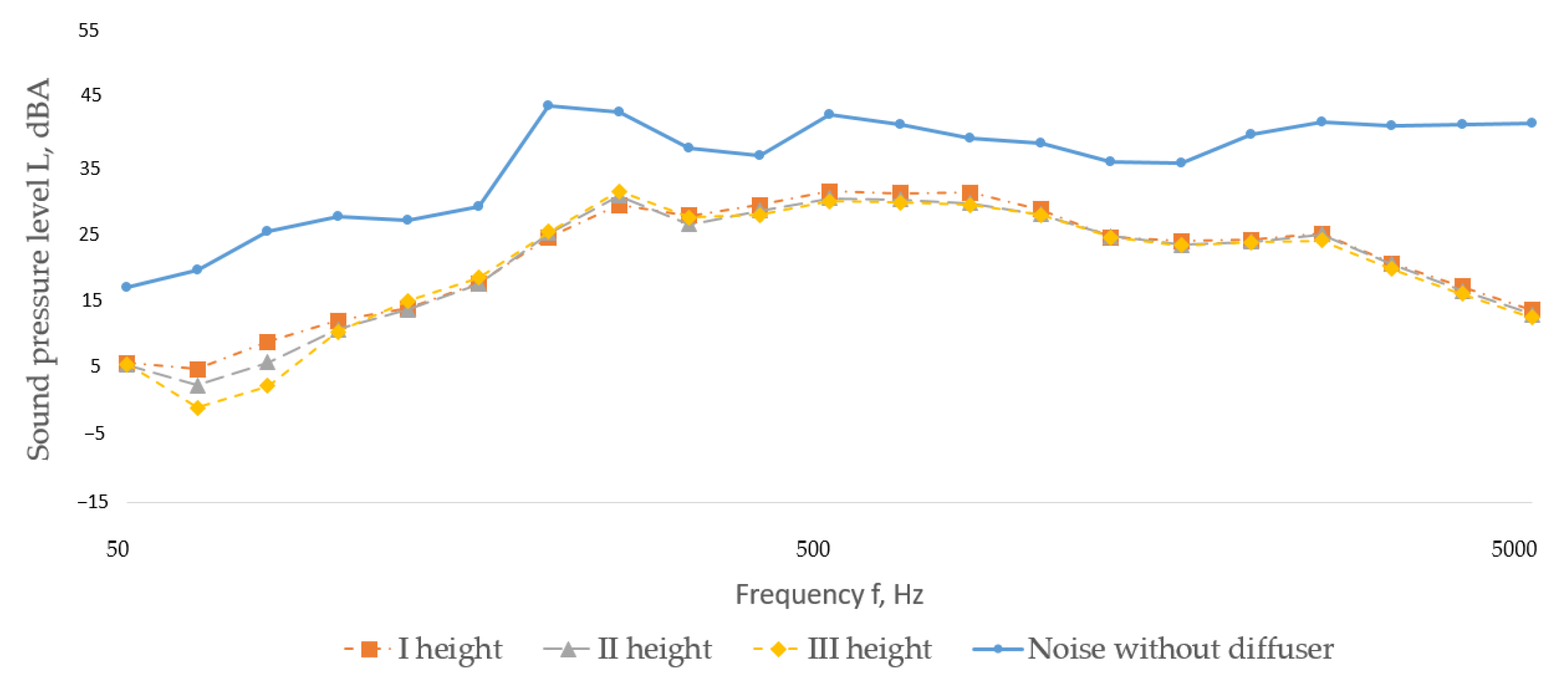

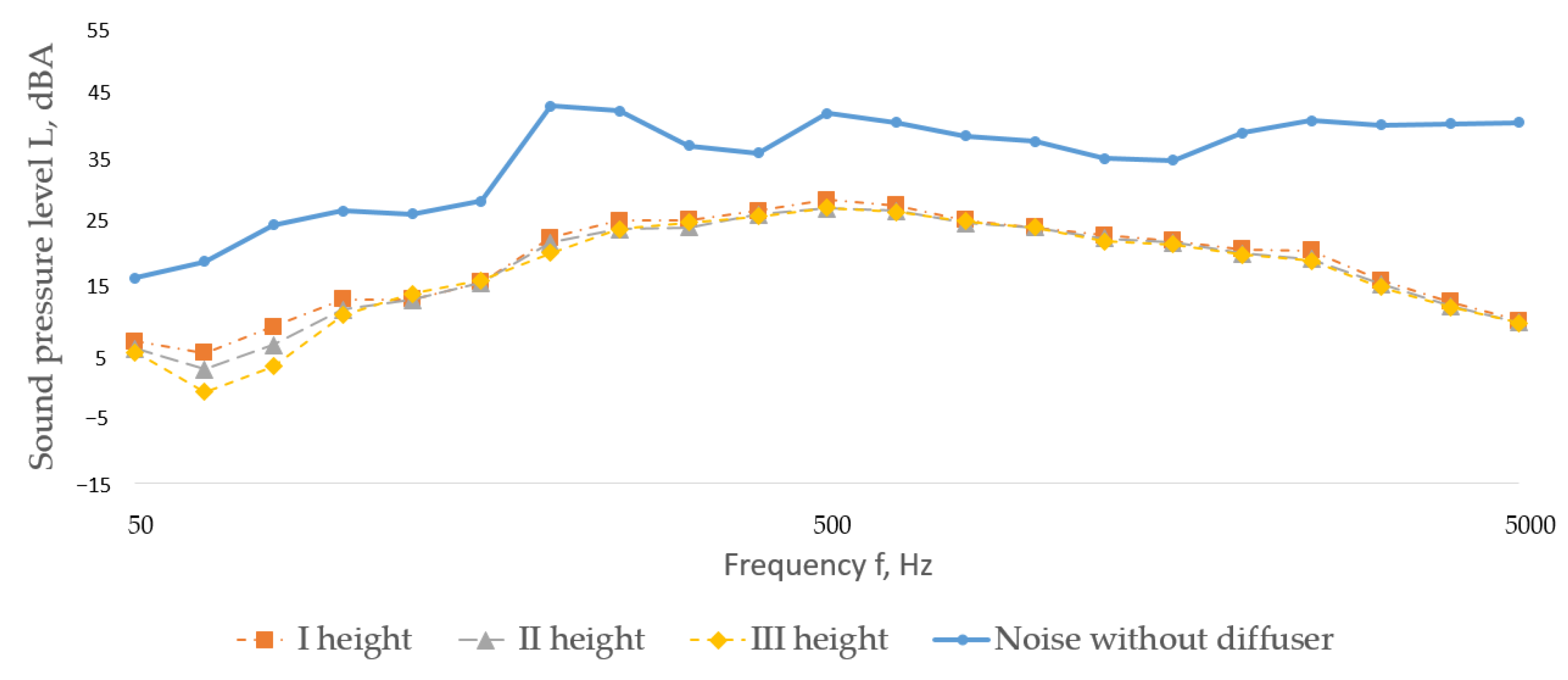

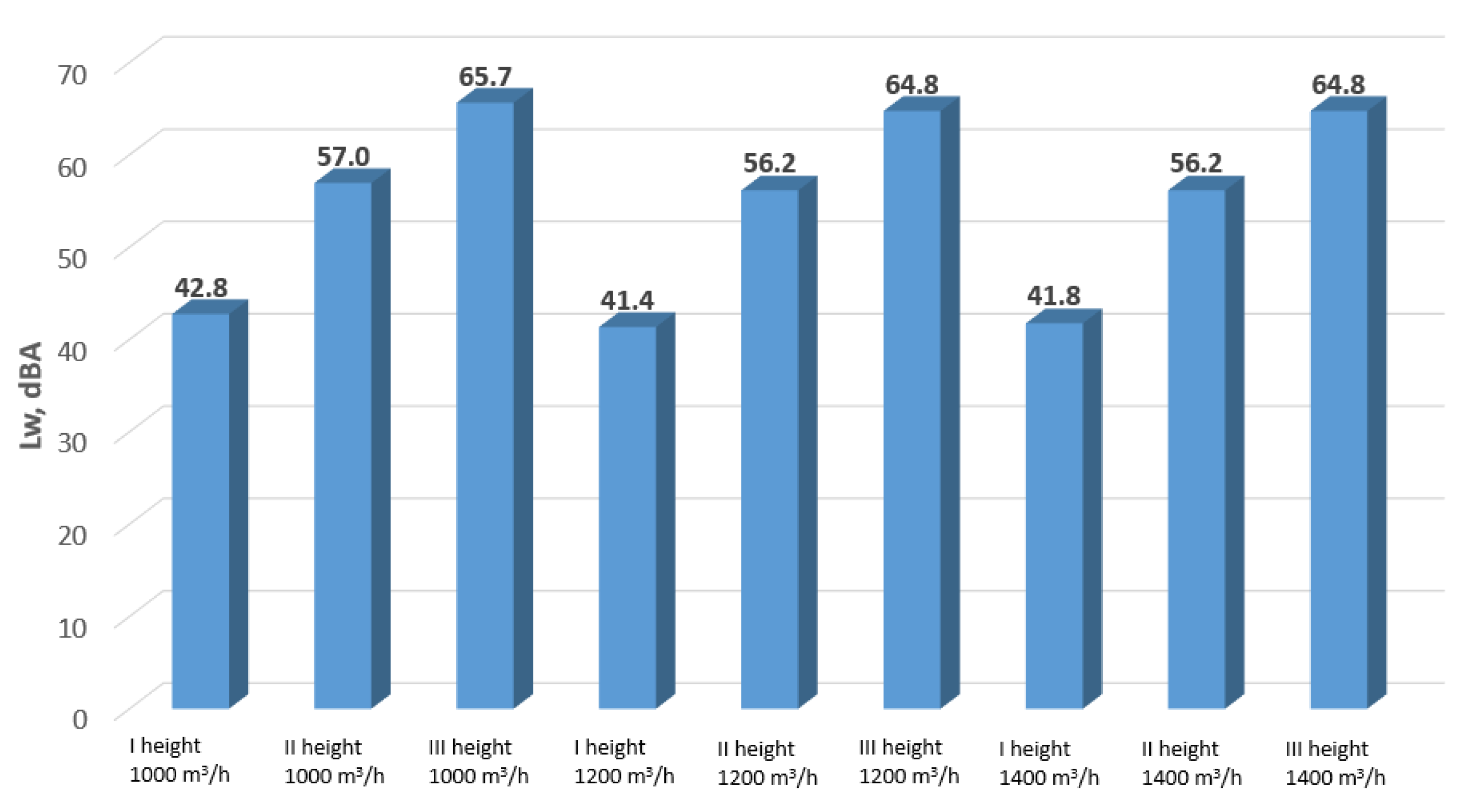

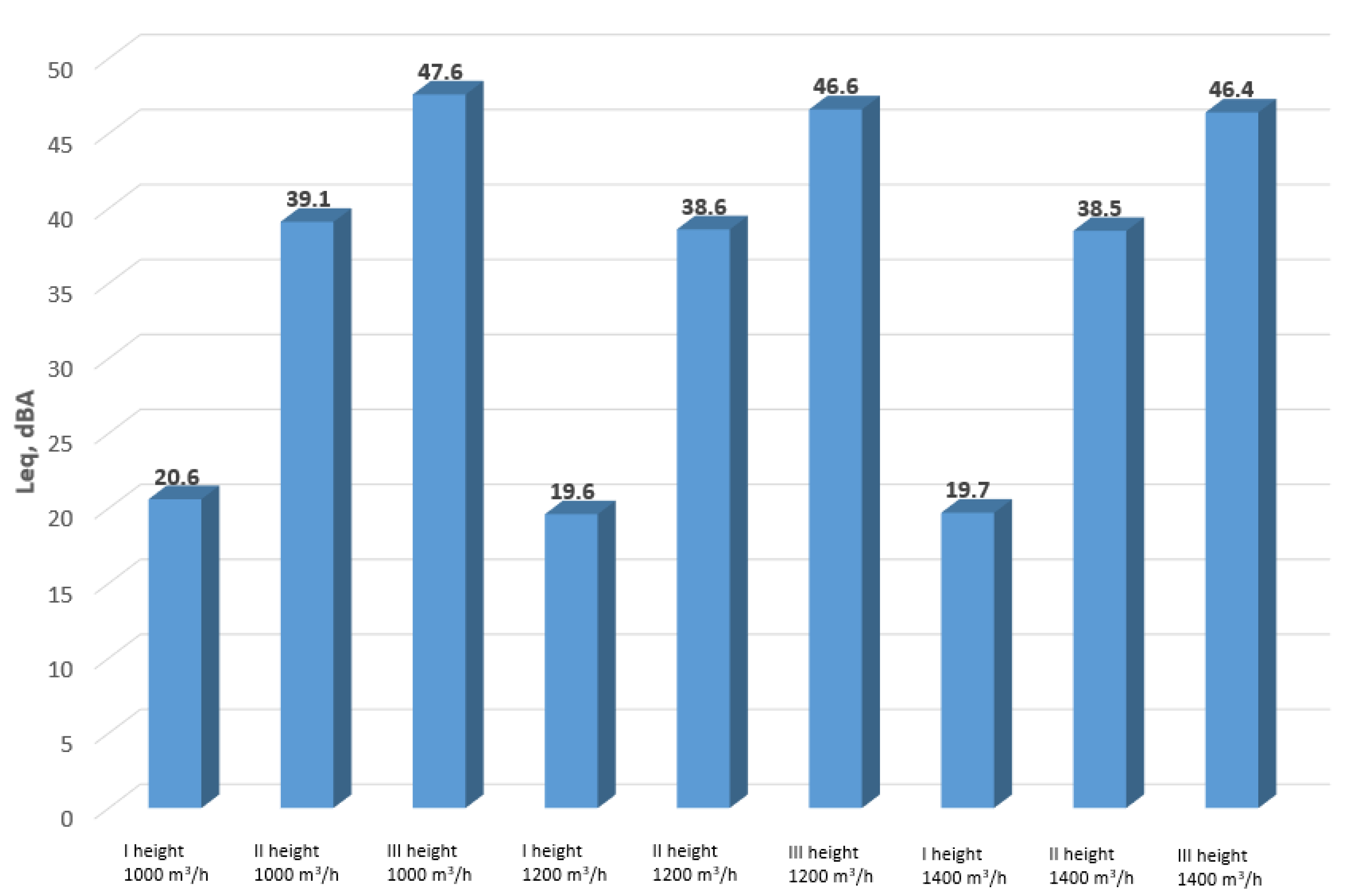

3.3. ‘C’ Type Diffuser

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mateus, N.M.; da Graça, G.C. Simulated and measured performance of displacement ventilation systems in large rotoms. Build. Environ. 2017, 114, 470–482. [Google Scholar] [CrossRef]

- Jing, G.; Cai, W.; Zhang, X.; Cui, C.; Liu, H.; Wang, C. An energy-saving control strategy for multi-zone demand controlled ventilation system with data-driven model and air balancing control. Energy 2020, 199, 117328. [Google Scholar] [CrossRef]

- Benabed, A.; Boulbair, A. Numerical analysis of thermal comfort and air freshness generated by a multi-cone diffuser with and without lobed inserts. J. Build. Eng. 2022, 54, 104632. [Google Scholar] [CrossRef]

- Szczepanik-Ścisło, N.; Flaga-Maryańczyk, A. Measurements and simulation of co2 concentration in a bedroom of a passive house. Technol. Trans. 2018, 9, 163–180. [Google Scholar]

- He, X.; Wen, Y.; Li, N.; Zou, Q.; Yang, S.; Wan, M.P.; Tang, C. Optimal fresh air distribution control strategy for multi-zone variable air volume air conditioning systems. Appl. Therm. Eng. 2025, 279 Pt C, 127696. [Google Scholar] [CrossRef]

- Ostmann, P.; Kremer, M.; Müller, D. Identifying and optimizing the aeroacoustic source regions of a slot air diffuser. Appl. Acoust. 2025, 241, 111002. [Google Scholar] [CrossRef]

- Guyot, G.; Shermanc, M.H.; Walker, I.S. Smart ventilation energy and indoor air quality performance in residential buildings: A review. Energy Build. 2018, 165, 416–430. [Google Scholar] [CrossRef]

- Polverini, D. Energy efficient ventilation units: The role of the Ecodesign and Energy Labelling regulations. Energy Build. 2018, 175, 141–147. [Google Scholar] [CrossRef]

- Canha, N.; Lage, J.; Candeias, S.; Alves, C.; Marta, S. Almeida Indoor air quality during sleep under different ventilation patterns. Atmos. Pollut. Res. 2017, 8, 1132–1142. [Google Scholar] [CrossRef]

- Hernandez, G.; Borge, R.; Blanchon, D.; Berry, T.A. Impact of positive pressure ventilation systems on indoor air quality in residential settings. Build. Environ. 2025, 283, 113323. [Google Scholar] [CrossRef]

- Krusaa, M.R.; Hviid, A.C. Combining suspended radiant ceiling with diffuse ventilation—Numerical performance analysis of low-energy office space in a temperate climate. J. Build. Eng. 2021, 38, 102161. [Google Scholar] [CrossRef]

- Saad, M.; William, M.A.; Hassan, A.A.; Hanafy, A.A. Influence of air ceiling diffusers in enclosed spaces: An experimental and numerical investigation. Energy Rep. 2023, 9, 59–71. [Google Scholar] [CrossRef]

- Jaszczur, M.; Madejski, P.; Borowski, M.; Karch, M. Experimental Analysis of the Air Stream Generated by Square Ceiling Diffusers to Reduce Energy Consumption and Improve Thermal Comfort. Heat Transfer Eng. 2022, 43, 463–473. [Google Scholar] [CrossRef]

- Chen, F.; Hou, Y.; Yuan, X.; Fang, Z.; Cheng, W.; Wang, J.; Xie, T.; Yin, Z.; Du, Z. Characteristics of airflow under stratum ventilation induced by fabric air dispersion system with orifices. J. Build. Eng. 2025, 102, 111936. [Google Scholar] [CrossRef]

- Hekal, M.; El-Maghlany, W.M.; Eldrainy, Y.A.; El-Adawy, M. Hydro-thermal performance of fabric air duct (FAD): Experimental and CFD simulation assessments. Case Stud. Therm. Eng. 2023, 47, 103107. [Google Scholar] [CrossRef]

- Nielsen, P.V.; Topp, C.; Sønnichsen, M.; Andersen, H. Air distribution in rooms generated by a textile terminal-comparison with mixing and displacement ventilation. In Proceedings of the Winter Meeting of the American-Society-of-Heating, Refrigerating and Air-Conditioning Engineers, Orlando, FL, USA, 5–9 February 2005; American Society of Heating, Refrigeration and Air Conditioning Engineers: Atlanta, GA, USA, 2005. [Google Scholar]

- Fontanini, A.; Olsen, M.G.; Ganapathysubramanian, B. Thermal comparison between ceiling diffusers and fabric ductwork diffusers for green buildings. Energy Build. 2011, 43, 2973–2987. [Google Scholar] [CrossRef]

- Aziz, M.A.; Gad, I.A.M.; Mohammed, E.S.F.A.; Mohammed, R.H. Experimental and numerical study of influence of air ceiling diffusers on room air flow characteristics. Energy Build. 2012, 55, 738–746. [Google Scholar] [CrossRef]

- Awwada, A.; Mohameda, M.H.; Fatouh, M. Optimal design of a louver face ceiling diffuser using CFD to improve occupant’s thermal comfort. J. Build. Eng. 2017, 11, 134–157. [Google Scholar] [CrossRef]

- Srebric, J.; Chen, Q. Simplifiednumericalmodels for complex air supplydiffusers. HVAC R Res. 2002, 8, 277–294. [Google Scholar] [CrossRef]

- Okochi, G.S.; Yao, Y. A review of recent developments and technological advancements of variable-air-volume (VAV) air-conditioning systems. Renew. Sustain. Energy Rev. 2016, 59, 784–817. [Google Scholar] [CrossRef]

- Awwad, A.; Abdelsamie, A.; Mohamed, M.H.; Fatouh, M. A new generation of a ceiling air outlet using multi-objective optimization technique. Energy 2023, 278, 127827. [Google Scholar] [CrossRef]

- Pieren, R.; Schäffer, B.; Schoenwald, S.; Eggenschwiler, K. Sound absorption of textile curtains—Theoretical models and validations by experiments and simulations. Text. Res. J. 2016, 88, 36–48. [Google Scholar] [CrossRef]

- Prasetiyo, I.; Muqowi, E.; Putra, A.; Novenbrianty, M.; Desendra, G.; Adhika, D.R. Modelling sound absorption of tunable double layer woven fabrics. Appl. Acoust. 2020, 157, 107008. [Google Scholar] [CrossRef]

- Thilagavathi, G.; Krishnan, S.N.; Muthukumar, N. Investigations on Sound Absorption Properties of Luffa Fibrous. Mats. J. Nat. Fibers 2017, 15, 445–451. [Google Scholar] [CrossRef]

- Koruk, H.; Ozcan, A.C.; Genc, G.; Sanliturk, K.Y. Jute and Luffa Fiber-Reinforced Biocomposites: Effects of Sample Thickness and Fiber/Resin Ratio on Sound Absorption and Transmission Loss Performance. J. Nat. Fibers 2022, 19, 6239–6254. [Google Scholar] [CrossRef]

- Chen, F.; Chen, H.; Xie, J.; Shu, Z.; Mao, J. Air distribution in room ventilated by fabric air dispersion system. Build. Environ. 2011, 46, 2121–2129. [Google Scholar] [CrossRef]

- Raphe, P.; Fellouah, H.; Poncet, S.; Ameur, M. Ventilation effectiveness of uniform and non-uniform perforated duct diffusers at office room. Build. Environ. 2021, 204, 108118. [Google Scholar] [CrossRef]

- Chen, F.; Chen, H.; Wang, H.; Wang, S.; Wang, J.; Wang, X.; Qian, Z. Parametrical analysis on characteristics of airflow generated by fabric air dispersion system in penetration mode. Energy Build. 2013, 67, 365–373. [Google Scholar] [CrossRef]

- Wang, X.; Li, A. Airflow characteristics generated by fabric air dispersion ventilation. Indoor Built Environ. 2015, 24, 1059–1068. [Google Scholar] [CrossRef]

- Chen, F.-J.; Wu, Q.-Y.; Huang, D.-D.; Wang, H. Indoor air flow motions caused by the fabric air dispersion system: A simplified method for CFD simulations. Indoor Built Environ. 2015, 26, 841–854. [Google Scholar] [CrossRef]

- ISO 3741:2010; Determination of Sound Power Levels and Sound Energy Levels of Noise Sources Using Sound Pressure—Precision Methods for Reverberation Test Rooms. International Organization for Standardization: Geneva, Switzerland, 2010.

- ISO 5135:2020; Determination of Sound Power Levels of Noise From Air-Terminal Devices, Air-Terminal Units, Dampers and Valves by Measurement in a Reverberation Test Room. International Organization for Standardization: Geneva, Switzerland, 2020.

- ISO 3382-2:2008; Acoustics—Measurement of Room Acoustic Parameters—Part 2: Reverberation Time in Ordinary Rooms. International Organization for Standardization: Geneva, Switzerland, 2008.

- Lithuanian Hygiene Standards HN 33:2011; Noise Limit Values in Residential and Public Buildings and Their Surroundings. Ministry of Health of the Republic of Lithuania: Vilnius, Lithuania, 2011.

| Flow m3/h | 1000 | 1200 | 1400 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Diffuser/Height | I | II | III | I | II | III | I | II | III |

| A | 39.1 | 63.4 | 68.2 | 38.4 | 61.6 | 67.6 | 38.1 | 61.6 | 67.5 |

| B | 41.1 | 59.6 | 68.1 | 40.1 | 59.1 | 67.1 | 40.2 | 59.0 | 66.9 |

| C | 42.8 | 57.0 | 65.7 | 41.4 | 56.2 | 64.8 | 41.8 | 56.2 | 64.8 |

| Flow m3/h | 1000 | 1200 | 1400 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Diffuser/Height | I | II | III | I | II | III | I | II | III |

| A | 18.6 | 42.9 | 47.7 | 17.9 | 41.1 | 47.1 | 17.6 | 40.6 | 47.0 |

| B | 20.6 | 39.1 | 47.6 | 19.6 | 38.6 | 46.6 | 19.7 | 38.5 | 46.4 |

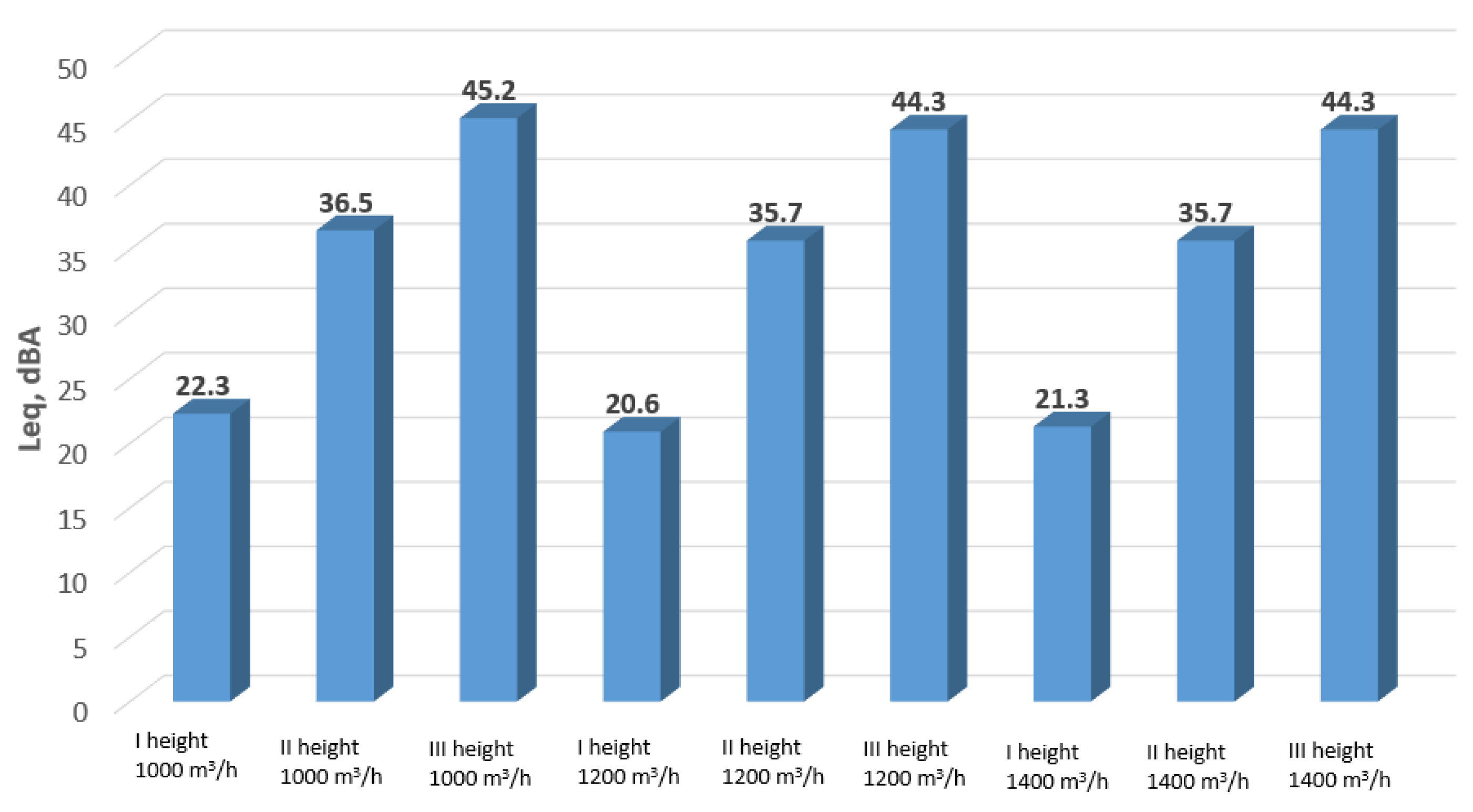

| C | 22.3 | 36.5 | 45.2 | 20.9 | 35.7 | 44.3 | 21.3 | 35.7 | 44.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miškinis, K.; Žilys, M.; Jucienė, M.; Dobilaitė, V. Noise Reducing Textile Diffuser of Building Ventilation System. Buildings 2025, 15, 3775. https://doi.org/10.3390/buildings15203775

Miškinis K, Žilys M, Jucienė M, Dobilaitė V. Noise Reducing Textile Diffuser of Building Ventilation System. Buildings. 2025; 15(20):3775. https://doi.org/10.3390/buildings15203775

Chicago/Turabian StyleMiškinis, Kęstutis, Mindaugas Žilys, Milda Jucienė, and Vaida Dobilaitė. 2025. "Noise Reducing Textile Diffuser of Building Ventilation System" Buildings 15, no. 20: 3775. https://doi.org/10.3390/buildings15203775

APA StyleMiškinis, K., Žilys, M., Jucienė, M., & Dobilaitė, V. (2025). Noise Reducing Textile Diffuser of Building Ventilation System. Buildings, 15(20), 3775. https://doi.org/10.3390/buildings15203775