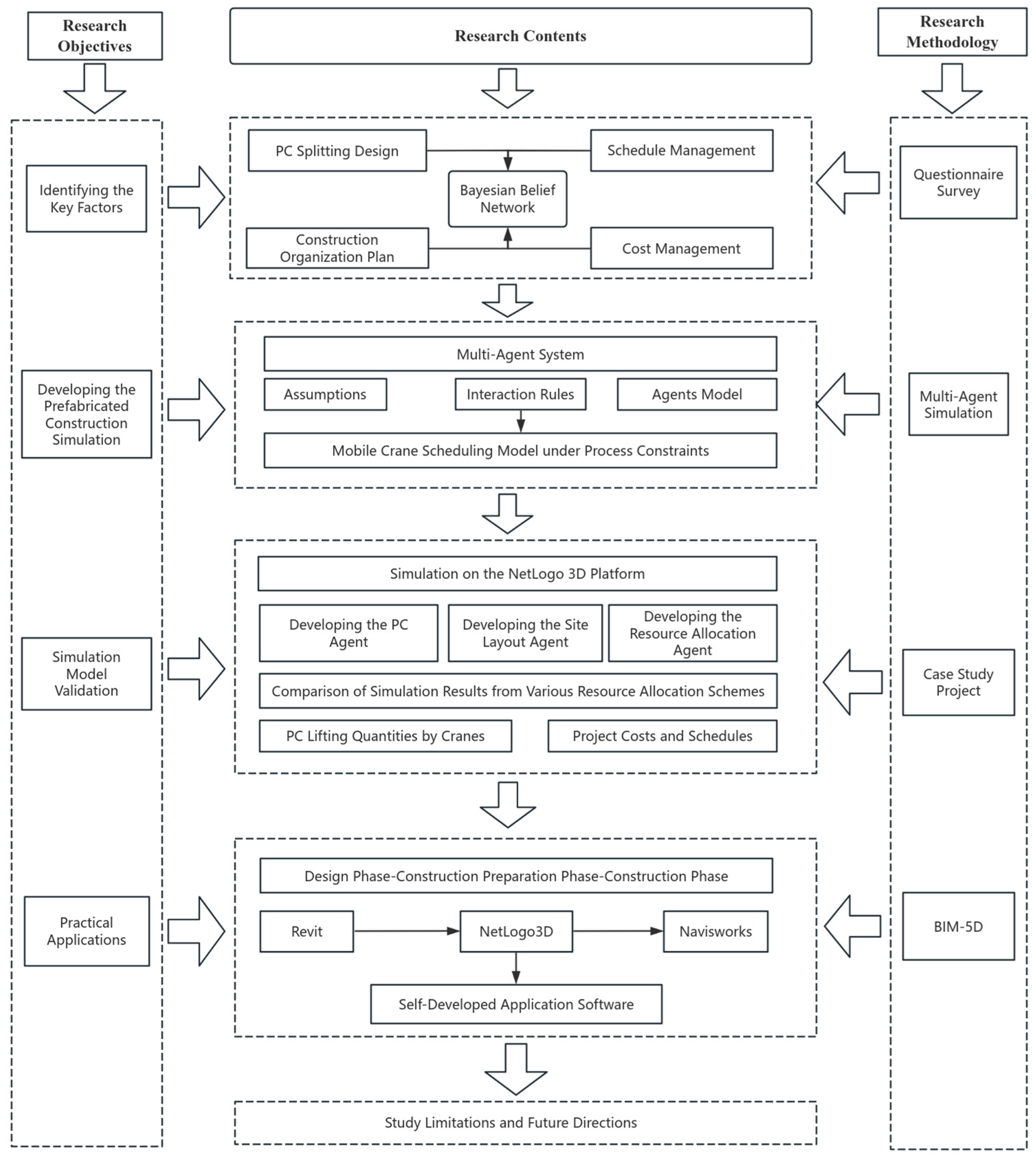

Integrating PC Splitting Design and Construction Organization Through Multi-Agent Simulation for Prefabricated Buildings

Abstract

1. Introduction

1.1. Background

1.2. Problem Statement

1.3. Research Objectives

2. Literature Review

2.1. Multi-Agent Simulation Technology in Construction Project Management

2.2. Digital Solutions for Prefabricated Building Projects

2.3. The Methods of Multi-Tower Crane Operation Management

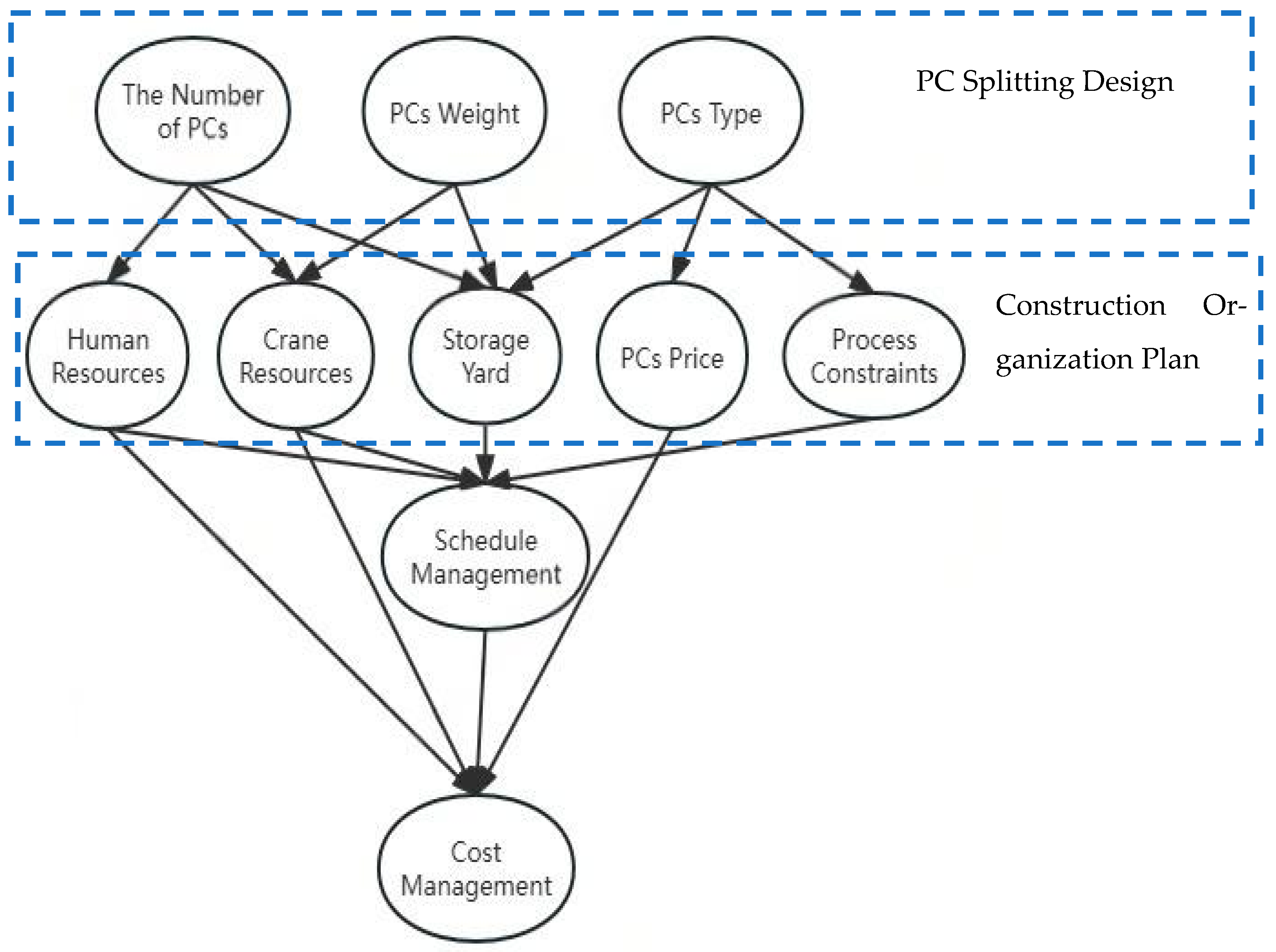

3. Methods

3.1. Questionnaire Survey

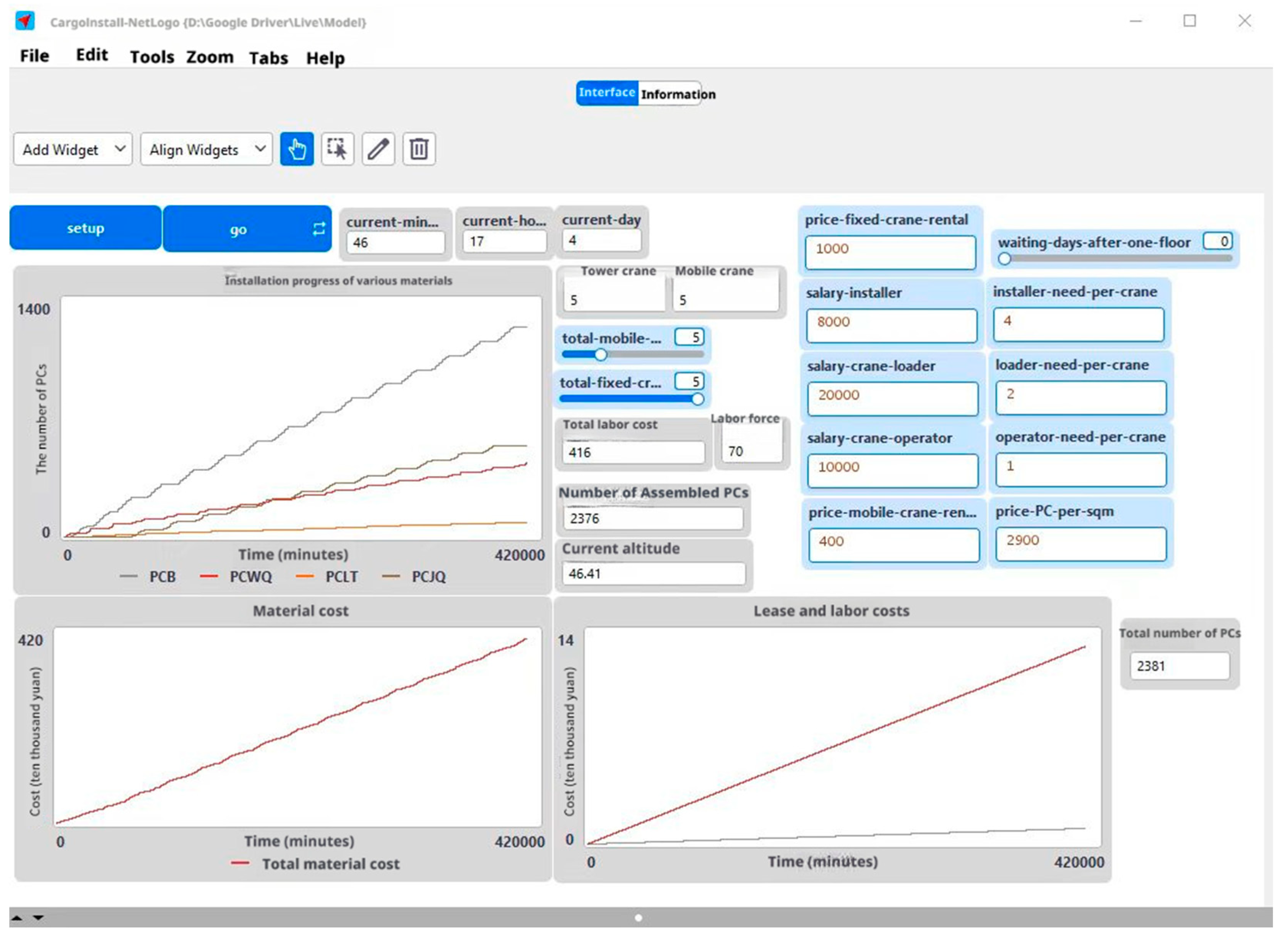

3.2. Developing the Prefabricated Construction Simulation

3.2.1. Assumptions

3.2.2. Interaction Rules

- PC Assembly Rules

- 2.

- Multi-Tower Crane Avoidance Rules

- (1)

- Lower cranes yield to higher cranes: Higher cranes are typically positioned in central locations and handle more intensive workloads. Lower cranes must evaluate the movement patterns of higher cranes prior to operation.

- (2)

- Later-arriving cranes yield to earlier-arriving cranes: In overlapping work zones, cranes entering the area subsequently must yield to those that arrived earlier.

- (3)

- Moving cranes yield to stationary cranes: Mobile cranes must yield to any stationary crane within shared operational zones.

- (4)

- Unloaded cranes yield to loaded cranes: During simultaneous operations, unloaded cranes must yield right-of-way to loaded cranes.

- (5)

- Guest cranes yield to host cranes: Cranes entering another crane’s designated primary work zone must yield to the host crane operating in that zone.

- (6)

- Synchronized operations: All cranes must coordinate lifting and lowering operations according to specified timeframes.

- 3.

- Crane Operation Rules

- 4.

- Site Layout Rules

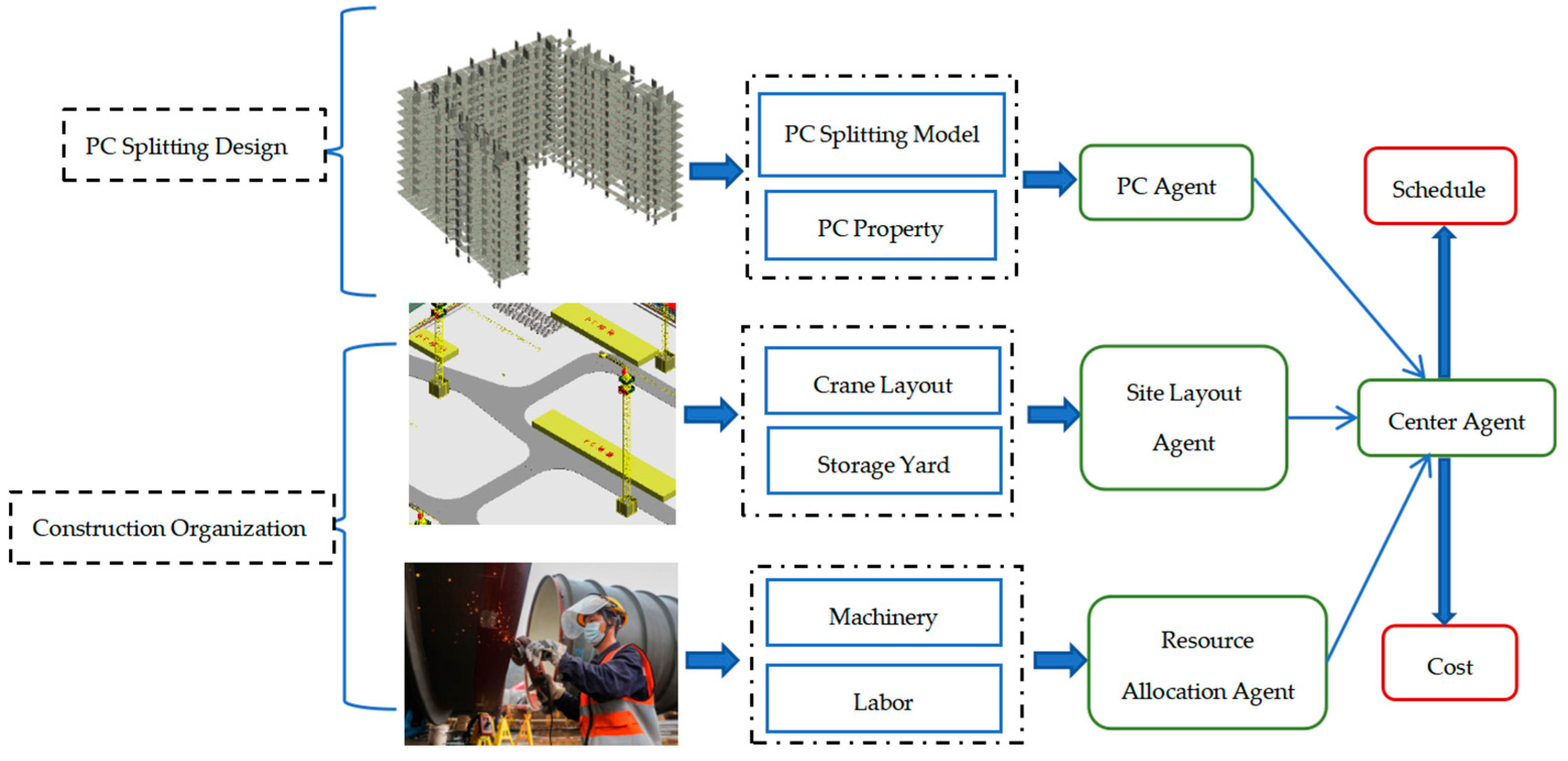

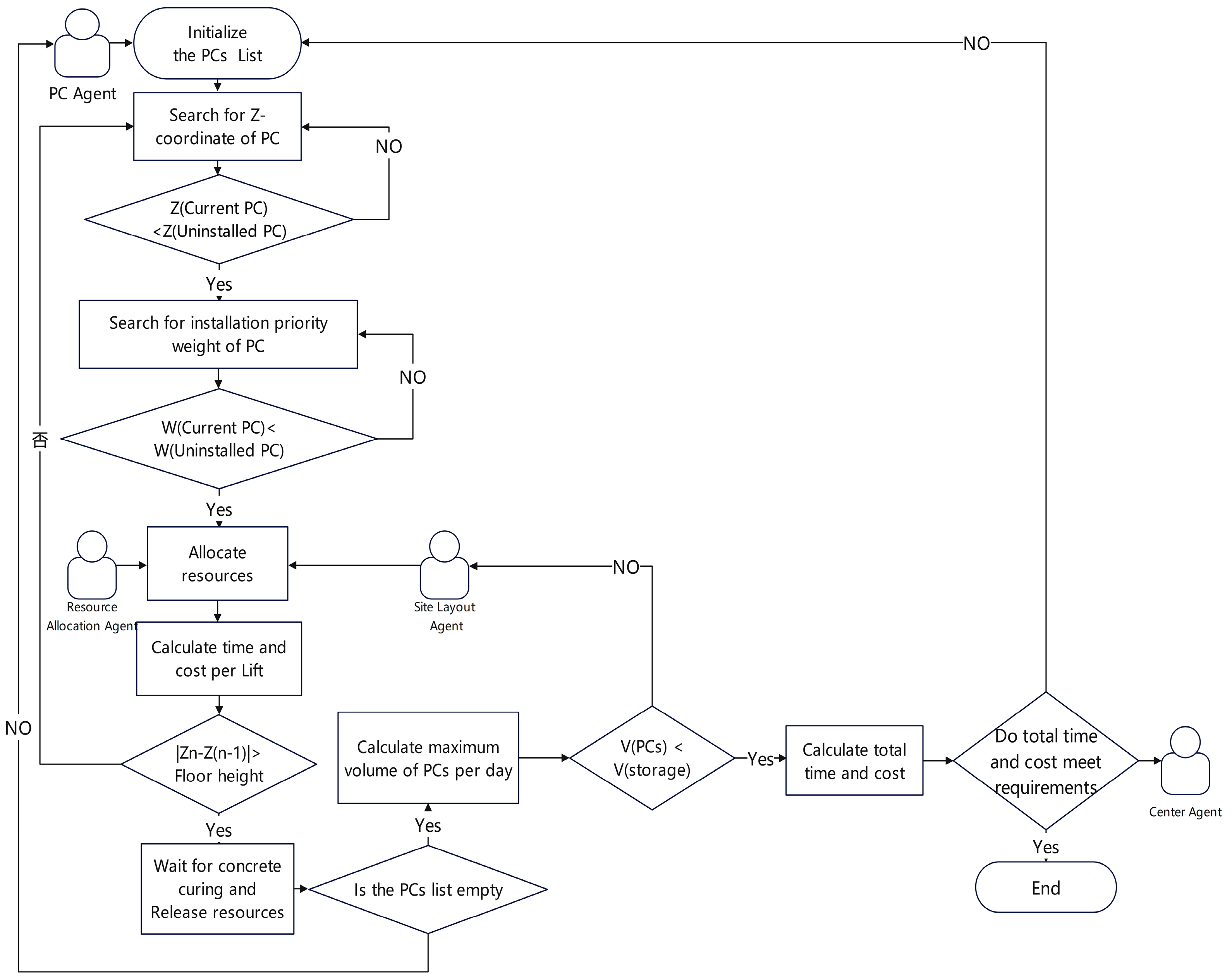

3.2.3. Multi-Agent Model

- (1)

- The PC Agent is composed of the PC Splitting Model Agent and the PC Property Agent. The list of PCs pending assembly is generated based on PC assembly rules.

- (2)

- The Site Layout Agent consists of the Crane Layout Agent and the Storage Yard Agent. The Crane Layout Agent undertakes assembly tasks initiated by the PC Agent based on crane avoidance and operational rules. The Storage Yard Agent continuously monitors whether the storage capacity limit is reached according to the site layout rules and promptly reports to the Main Agent if the limit is exceeded.

- (3)

- The Resource Allocation Agent, composed of the Mechanical Equipment Agent and the Workforce Agent, is activated by the PC Agent. A higher task load triggers greater deployment of mechanical equipment, which in turn requires increased allocation of labor.

- (4)

- The Center Agent acts as a play maker or a control room that interacts with other agents and directs the process. When simulation results (e.g., schedule or cost) deviate from preset values, the Center Agent will adjust the resource allocation plan and relaunch the simulation.

3.2.4. Mobile Crane Scheduling Model Under Process Constraints

3.3. Selecting the Simulation Method

4. Case Study Project

4.1. Developing the PC Agent

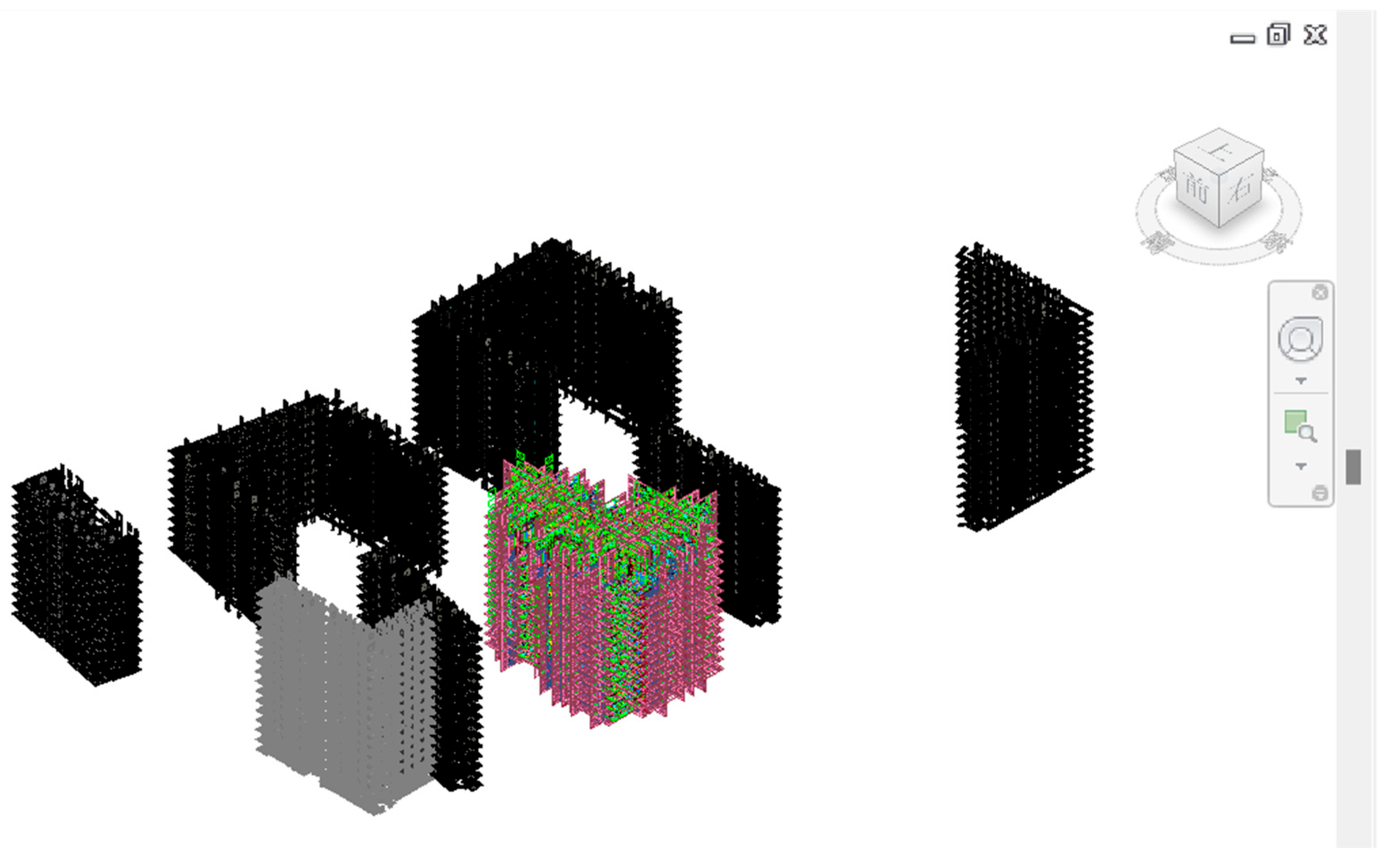

4.1.1. Developing the PC Splitting Model Agent

4.1.2. Developing the PC Property Agent

4.2. Developing the Site Layout Agent

4.2.1. Developing the Crane Layout Agent

4.2.2. Developing the Storage Yard Agent

4.3. Developing the Resource Allocation Agent

4.3.1. Developing the Machinery Resource Agent

4.3.2. Developing the Labor Resource Agent

5. Results and Discussion

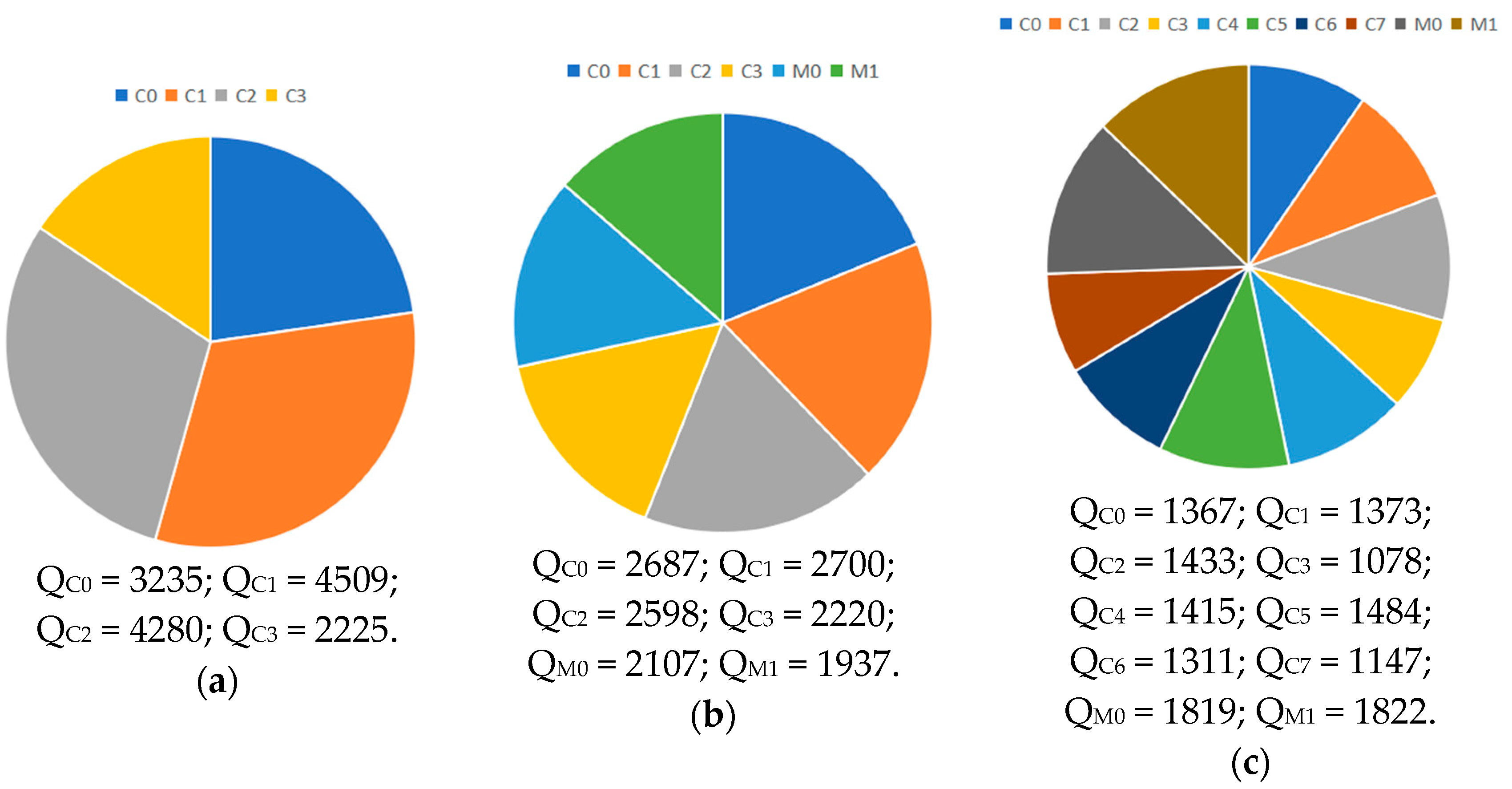

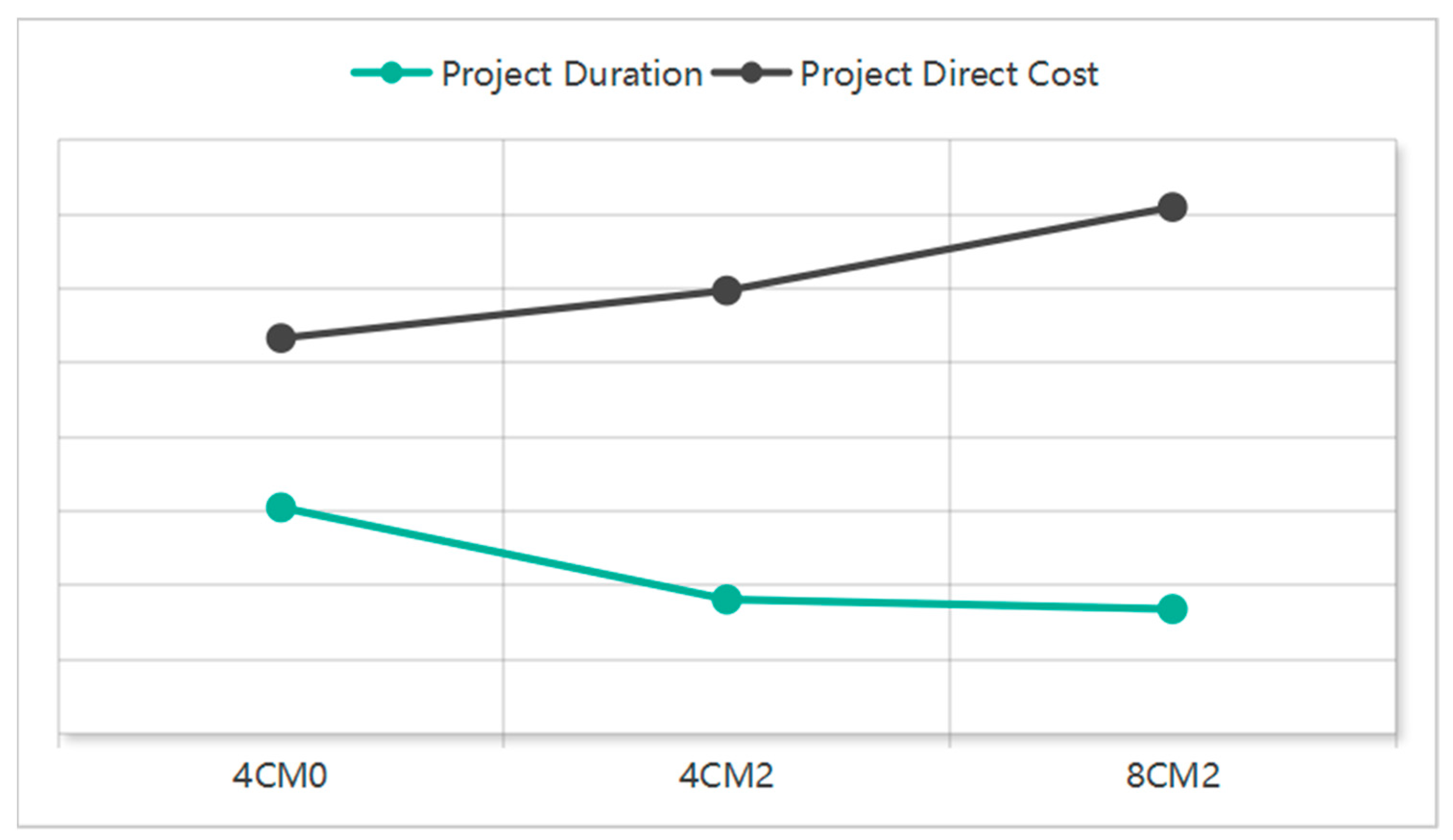

5.1. Simulation Results from Various Resource Allocation Schemes

- (1)

- Scheme 1 (4C0M): The first scheme deploys 4 tower cranes, each with the capacity to serve two building units simultaneously. This scheme involves no mobile cranes and is hereafter referred to as the 4C0M scheme.

- (2)

- Scheme 2 (4C2M): The second scheme also utilizes 4 tower cranes (each serving two units), which are supplemented by 2 mobile cranes. This is denoted as the 4C2M scheme.

- (3)

- Scheme 3 (8C2M): The third scheme entails the use of 8 tower cranes, with each crane dedicated to a single building unit, in conjunction with 2 mobile cranes. This is abbreviated as the 8C2M scheme.

5.1.1. Simulation Results Under the 4C0M Resource Allocation Scheme

5.1.2. Simulation Results Under the 4C2M Resource Allocation Scheme

5.1.3. Simulation Results Under the 8C2M Resource Allocation Scheme

5.2. Comparison of Simulation Results from Various Resource Allocation Schemes

5.3. BIM-5D Visualization of Simulation Results

6. Conclusions

6.1. Practical Applications

6.2. Recommendations for Future Research

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- “14th Five-Year” Plan for Prefabricated Buildings in Shanghai. Available online: https://zjw.sh.gov.cn/ghjh/20211109/f5ed3fe865b447b7b064fc695cae1351.html (accessed on 3 November 2021).

- Yin, J.; Huang, R.; Sun, H.; Cai, S. Multi-Objective Optimization for Coordinated Production and Transportation in Prefabricated Construction with on-Site Lifting Requirements. Comput. Ind. Eng. 2024, 189, 110017. [Google Scholar] [CrossRef]

- Xiang, L.; Tan, Y.; Shen, G.; Jin, X. Applications of Multi-Agent Systems from the Perspective of Construction Management: A Literature Review. Eng. Constr. Archit. Manag. 2022, 29, 3288–3310. [Google Scholar] [CrossRef]

- Feng, J.; Liu, B.; Tang, J.; Wang, Q. The Emergence of the Contractor’s Innovation Capability at Project Level: An Agent-Based Modeling Approach. Buildings 2023, 13, 2941. [Google Scholar] [CrossRef]

- Attajer, A.; Mecheri, B. Multi-Agent Simulation Approach for Modular Integrated Construction Supply Chain. Appl. Sci. 2024, 14, 5286. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, F.; Yin, S.; Fu, Y.; Liu, J.; Duan, P. Study on the Optimization of Duration for Repetitive Projects Considering Spatial Interference Effects in Operations. J. Asian Archit. Build. Eng. 2025, 1–26. [Google Scholar] [CrossRef]

- Jiang, S.; Yang, B.; Liu, B. Precast Components On-Site Construction Planning and Scheduling Method Based on a Novel Deep Learning Integrated Multi-Agent System. J. Build. Eng. 2025, 102, 111907. [Google Scholar] [CrossRef]

- Liu, B.; Yang, B.; Zhang, B.; Dong, M.; Jiang, S.; Xiao, J. Spatio-Temporal Deduction of Floor Construction Based on the Agent Modeling of Construction Actors. Autom. Constr. 2022, 142, 104487. [Google Scholar] [CrossRef]

- Liu, B.D.; Yang, B.; Han, Y.; Xiao, J.Z.; Dong, M.S. Establishment and Application of Multi-Agent Simulation System Based on On-Site Construction Performers. In Proceedings of the 17th East Asian-Pacific Conference on Structural Engineering and Construction, 2022, EASEC-17, Singapore, 14 March 2023. [Google Scholar] [CrossRef]

- Kim, K.; Faust, K.M.; Leite, F. Simulation Modeling Efforts in the Construction Industry: Integrated Application of BIM and Agent-Based Modeling. In Proceedings of the Computing in Civil Engineering 2023, Corvallis, OR, USA, 25 January 2024. [Google Scholar] [CrossRef]

- Kedir, N.S.; Somi, S.; Fayek, A.R.; Nguyen, P.H.D. Hybridization of Reinforcement Learning and Agent-Based Modeling to Optimize Construction Planning and Scheduling. Autom. Constr. 2022, 142, 104498. [Google Scholar] [CrossRef]

- Pourrahimian, E.; Salhab, D.; Hamzeh, F.; AbouRizk, S. A Decision Support System for Evaluating Construction Project Recovery Plans. Can. J. Civ. Eng. 2025, 52, 1336–1354. [Google Scholar] [CrossRef]

- Hu, Y.; Wu, L.; Li, N.; Zhao, T. Multi-Agent Decision-Making in Construction Engineering and Management: A Systematic Review. Sustainability 2024, 16, 7132. [Google Scholar] [CrossRef]

- Zohourian, M.; Pamidimukkala, A.; Kermanshachi, S.; Almaskati, D. Modular Construction: A Comprehensive Review. Buildings 2025, 15, 2020. [Google Scholar] [CrossRef]

- Abdul Nabi, M.; El-adaway, I.H. Risk-based approach to predict the cost performance of modularization in construction projects. J. Constr. Eng. Manag. 2021, 147, 04021133. [Google Scholar] [CrossRef]

- Mehdipoor, A.; Iordanova, I.; Al-Hussein, M. Enhancing the Manufacturing Process in Light-Gauge Steel Off-Site Construction Using Semiautomation. J. Constr. Eng. Manag. 2025, 151, 04025055. [Google Scholar] [CrossRef]

- Yuan, Z.; Man, Q.; Guan, Z.; Yi, C.; Zheng, M.; Chang, Y.; Li, H.X. Simulation and Optimization of Prefabricated Building Construction Considering Multiple Objectives and Uncertain Factors. J. Build. Eng. 2024, 86, 108830. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Gong, J.; Ma, X. Synchronizing Production Scheduling with Resources Allocation for Precast Components in a Multi-Agent System Environment. J. Manuf. Syst. 2018, 49, 131–142. [Google Scholar] [CrossRef]

- Attajer, A.; Mecheri, B.; Hadbi, I.; Amoo, S.N.; Bouchnita, A. Sustainable Supply Chain Strategies for Modular-Integrated Construction Using a Hybrid Multi-Agent-Deep Learning Approach. Sustainability 2025, 17, 5434. [Google Scholar] [CrossRef]

- Jang, D.-H.; Roh, G.-T.; Jeon, C.-H. Simulation-Based Optimization of Crane Lifting Position and Capacity Using a Construction Digital Twin for Prefabricated Bridge Deck Assembly. Buildings 2025, 15, 475. [Google Scholar] [CrossRef]

- Tak, A.N.; Taghaddos, H.; Mousaei, A.; Bolourani, A.; Hermann, U. BIM-Based 4D Mobile Crane Simulation and Onsite Operation Management. Autom. Constr. 2021, 128, 103766. [Google Scholar] [CrossRef]

- Khodabandelu, A.; Park, J.; Arteaga, C. Improving Multitower Crane Layout Planning by Leveraging Operational Flexibility Related to Motion Paths. J. Manag. Eng. 2023, 39, 04023035. [Google Scholar] [CrossRef]

- Huang, C.; Wang, Z.K.; Li, B.; Wang, C.; Xu, L.S.; Jiang, K.; Liu, M.; Guo, C.X.; Zhao, X.F.; Yang, H. Discretized Cell Modeling for Optimal Layout of Multiple Tower Cranes. J. Constr. Eng. Manag. 2023, 149, 04023068. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, H.; Yu, L. Collaborative Planning for Stacking and Installation of Prefabricated Building Components Regarding Crane-Collision Avoidance. J. Constr. Eng. Manag. 2023, 149, 04023029. [Google Scholar] [CrossRef]

- Younes, A.; Marzouk, M. Tower Cranes Layout Planning Using Agent-Based Simulation Considering Activity Conflicts. Autom. Constr. 2018, 93, 348–360. [Google Scholar] [CrossRef]

- Khodabandelu, A.; Park, J.; Arteaga, C. Crane Operation Planning in Overlapping Areas Through Dynamic Supply Selection. Autom. Constr. 2020, 117, 103253. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, F.; Han, X.; Ye, H.; Shi, Z.; Zhang, J.; Wang, T.; She, J.; Zhang, T. Intelligent Optimization of Tower Crane Location and Layout Based on Firefly Algorithm. Comput. Intell. Neurosci. 2022, 2022, 6810649. [Google Scholar] [CrossRef] [PubMed]

- He, C.; Liu, M.; Zhang, Y.; Wang, Z.; Hsiang, S.M.; Chen, G.; Li, W.; Dai, G. Space–Time–Workforce Visualization and Conditional Capacity Synthesis in Uncertainty. J. Manag. Eng. 2023, 39, 15. [Google Scholar] [CrossRef]

| Demographic Profile | Category | Number of Respondents | Percentage |

|---|---|---|---|

| Work Experience | Below 5 years | 27 | 45% |

| 5–10 years | 18 | 30% | |

| Over 10 years | 15 | 25% | |

| Work Role | Design | 6 | 10% |

| Production | 3 | 5% | |

| Construction | 15 | 25% | |

| Consulting | 21 | 35% | |

| Supervision | 6 | 10% | |

| Client | 9 | 15% |

| Family Name | PC Unit ID | Length (m) | Width (m) | Height (m) | Volume (m3) | Coordinate X (m) | Coordinate Y (m) | Coordinate Z (m) |

|---|---|---|---|---|---|---|---|---|

| PCJQ-01 | 010-01-003-0001 | 1.950 | 0.250 | 2.602 | 1.261 | 119.885 | 233.310 | 10.490 |

| PCQ-01 | 010-01-002-0001 | 1.250 | 0.200 | 2.110 | 0.203 | 118.435 | 233.710 | 4.490 |

| PCB-01 | 010-01-001-0001 | 3.095 | 1.270 | 0.060 | 0.239 | 123.070 | 233.900 | 4.265 |

| PCLT-01 | 010-01-004-0001 | 3.080 | 1.245 | 0.180 | 0.842 | 117.195 | 226.830 | 2.770 |

| …… |

| Family Type * | Vertical/Horizontal | Installation Priority Weight | Installation Operation Time (Per PC) | PC Material Cost (Per Cubic Meter) |

|---|---|---|---|---|

| PCJQ | Vertical | 1 | 30 min | ¥4647 |

| PCQ | Vertical | 2 | 35 min | ¥4414 |

| PCB | Horizontal | 3 | 35 min | ¥4292 |

| PCLT | Vertical | 4 | 35 min | ¥4051 |

| Tower Crane ID | Max Boom Length * (m) | Coordinate X (m) | Coordinate Y (m) | Coordinate Z (m) | Rotation Angle | Corresponding Building ID |

|---|---|---|---|---|---|---|

| C1 | 50 | 33.295 | 11.911 | 0.000 | 76.5 | 7# |

| C2 | 50 | 106.232 | −8.827 | 0.000 | 346.2 | 8# |

| C3 | 50 | 124.486 | 39.609 | 0.000 | 346.2 | 6# |

| C4 | 50 | 56.595 | 74.867 | 0.000 | 346.2 | 5# |

| C5 | 50 | 116.537 | 93.193 | 0.000 | 346.2 | 4# |

| C6 | 50 | 121.809 | 139.953 | 0.000 | 356.1 | 3# |

| C7 | 50 | 61.992 | 135.092 | 0.000 | 346.2 | 2# |

| C8 | 50 | 49.565 | 212.552 | 0.000 | 346.2 | 1# |

| Yard ID | Yard Type | Coordinate X (m) | Coordinate Y (m) | Coordinate Z (m) | Yard Area (m2) | Yard Height Limit (m) |

|---|---|---|---|---|---|---|

| S1 | PC | 44.234 | 238.589 | −1.950 | 426.92 | 4 |

| S2 | PC | 124.225 | 238.788 | −1.950 | 211.71 | 4 |

| S3 | PC | 95.904 | 188.420 | −1.950 | 635.12 | 4 |

| S4 | PC | 180.919 | 162.914 | −1.950 | 211.71 | 4 |

| S5 | PC | 214.912 | 244.844 | −1.950 | 211.71 | 4 |

| S6 | PC | 8.176 | 192.013 | −1.950 | 142.10 | 4 |

| S7 | PC | 78.019 | 106.955 | −1.950 | 211.71 | 4 |

| S8 | PC | 42.361 | 66.443 | −1.950 | 211.71 | 4 |

| S9 | PC | 42.746 | 35.028 | −1.950 | 211.71 | 4 |

| S10 | PC | 96.833 | 9.415 | −1.950 | 211.71 | 4 |

| S11 | PC | 111.364 | 35.028 | −1.950 | 379.75 | 4 |

| S12 | PC | 101.459 | 66.398 | −1.950 | 419.66 | 4 |

| S13 | PC | 194.536 | 67.691 | −1.950 | 379.75 | 4 |

| S14 | PC | 189.029 | 35.255 | −1.950 | 378.95 | 4 |

| Machinery Model | Machinery Type | Operational Parameters | Mobilization Cost | Rental Cost (Per Equipment Shift *) |

|---|---|---|---|---|

| QTZ250 | tower crane | Preparation time: 10 min/operation Lowering speed: 40 m/min Lifting speed: 20 m/min | ¥125,000 | ¥1444.89 |

| QY50B | Mobile Crane | Preparation time: 8 min/operation Lowering speed: 30 m/min Lifting speed: 15 m/min | ¥250,000 | ¥1191.33 |

| NL-415 | Grouting Machine | None | ¥0 | ¥30.9 |

| Trade Type | Labor Cost (Per Man-Day *) | Number of Workers Allocated Per Machine |

|---|---|---|

| PC Worker | ¥265 | Tower Crane: 1 Mobile Crane: 1 |

| Surveyor | ¥218 | Tower Crane: 2 |

| Rigger | ¥500 | Tower Crane: 1 Mobile Crane: 1 |

| Helper | ¥218 | Tower Crane: 1 Mobile Crane: 1 Grouting Machine: 4 |

| Building Unit ID | Start Date | End Date | Direct Cost | Crane ID | PC Units Hoisted |

|---|---|---|---|---|---|

| 1# | 1 December 2024 | 22 July 2025 | ¥7,846,820 | C1 | 2092 |

| 2# | 1 December 2024 | 2 October 2025 | ¥12,650,060 | C2 | 2956 |

| 3# | 1 December 2024 | 16 April 2025 | ¥3,456,630 | C3 | 1078 |

| 4# | 1 December 2024 | 22 April 2025 | ¥4,950,630 | C0 | 1472 |

| 5# | 10 December 2024 | 20 August 2025 | ¥8,540,120 | C1 | 2417 |

| 6# | 8 December 2024 | 23 May 2025 | ¥460,772 | C2 | 1324 |

| 7# | 6 December 2024 | 1 May 2025 | ¥4,148,790 | C3 | 1147 |

| 8# | 8 December 2024 | 1 July 2025 | ¥7,111,470 | C0 | 1763 |

| Total | The project duration: 305 days | ¥53,312,240 | 4C0M | 14,249 | |

| Building Unit ID | Start Date | End Date | Direct Cost | Crane ID | PC Units Hoisted |

|---|---|---|---|---|---|

| 1# | 1 December 2024 | 27 May 2025 | ¥11,097,810 | C1 | 1392 |

| M0 | 439 | ||||

| M1 | 261 | ||||

| 2# | 1 December 2024 | 6 May 2025 | ¥11,911,350 | C2 | 1307 |

| M0 | 802 | ||||

| M1 | 847 | ||||

| 3# | 1 December 2024 | 11 April 2025 | ¥3,894,440 | C3 | 1073 |

| M0 | 2 | ||||

| M1 | 3 | ||||

| 4# | 1 December 2024 | 6 May 2025 | ¥5,557,370 | C0 | 1297 |

| M0 | 83 | ||||

| M1 | 92 | ||||

| 5# | 3 December 2024 | 6 May 2025 | ¥8,844,580 | C1 | 1308 |

| M0 | 578 | ||||

| M1 | 531 | ||||

| 6# | 3 December 2024 | 15 May 2025 | ¥5,418,280 | C2 | 1291 |

| M0 | 17 | ||||

| M1 | 16 | ||||

| 7# | 6 December 2024 | 1 May 2025 | ¥4,622,270 | C3 | 1147 |

| 8# | 8 December 2024 | 31 May 2025 | ¥8,377,460 | C0 | 1390 |

| M0 | 186 | ||||

| M1 | 187 | ||||

| Total | The project duration: 181 days | ¥59,723,560 | 4C2M | 14,249 | |

| Building Unit ID | Start Date | End Date | Direct Cost | Crane ID | PC Units Hoisted |

|---|---|---|---|---|---|

| 1# | 1 December 2024 | 18 May 2025 | ¥10,827,630 | C1 | 1373 |

| M0 | 311 | ||||

| M1 | 408 | ||||

| 2# | 1 December 2024 | 18 May 2025 | ¥15,047,220 | C2 | 1433 |

| M0 | 797 | ||||

| M1 | 726 | ||||

| 3# | 1 December 2024 | 16 April 2025 | ¥5,048,880 | C3 | 1078 |

| 4# | 1 December 2024 | 17 May 2025 | ¥7,142,030 | C4 | 1415 |

| M0 | 28 | ||||

| M1 | 29 | ||||

| 5# | 1 December 2024 | 18 May 2025 | ¥11,436,920 | C5 | 1484 |

| M0 | 448 | ||||

| M1 | 485 | ||||

| 6# | 1 December 2024 | 14 May 2025 | ¥6,586,830 | C6 | 1311 |

| M0 | 6 | ||||

| M1 | 7 | ||||

| 7# | 1 December 2024 | 25 April 2025 | ¥5,656,560 | C7 | 1147 |

| 8# | 1 December 2024 | 18 May 2025 | ¥9,225,290 | C0 | 1367 |

| M0 | 229 | ||||

| M1 | 167 | ||||

| Total | The project duration: 168 days | ¥70,971,360 | 8C2M | 14,249 | |

| Resource Allocation Scheme | The Project Direct Cost | The Project Duration | Cost Increase | Schedule Reduction |

|---|---|---|---|---|

| 4CM0 | ¥53,312,240 | 305 days | / | / |

| 4CM1 | ¥55,142,440 | 193 days | 3.43% | 36.72% |

| 4CM2 | ¥59,723,560 | 181 days | 12.03% | 40.66% |

| 4CM3 | ¥62,286,190 | 155 days | 16.83% | 49.18% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, Y.; Wang, J.; Jin, G.-H. Integrating PC Splitting Design and Construction Organization Through Multi-Agent Simulation for Prefabricated Buildings. Buildings 2025, 15, 3773. https://doi.org/10.3390/buildings15203773

Shen Y, Wang J, Jin G-H. Integrating PC Splitting Design and Construction Organization Through Multi-Agent Simulation for Prefabricated Buildings. Buildings. 2025; 15(20):3773. https://doi.org/10.3390/buildings15203773

Chicago/Turabian StyleShen, Yi, Jing Wang, and Guan-Hang Jin. 2025. "Integrating PC Splitting Design and Construction Organization Through Multi-Agent Simulation for Prefabricated Buildings" Buildings 15, no. 20: 3773. https://doi.org/10.3390/buildings15203773

APA StyleShen, Y., Wang, J., & Jin, G.-H. (2025). Integrating PC Splitting Design and Construction Organization Through Multi-Agent Simulation for Prefabricated Buildings. Buildings, 15(20), 3773. https://doi.org/10.3390/buildings15203773