Identification and Prioritization of Critical Barriers to the Adoption of Robots in the Construction Phase with Interpretive Structural Modeling (ISM) and MICMAC Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Interpretive Structural Modeling (ISM)

- Factor identification: Based on an extensive literature review, 22 barrier factors to construction robot adoption were identified.

- Defining relationships: A panel of 17 experts, consisting of 9 academics and 8 industry professionals (contractors, and robot developers), was invited to independently assess pairwise relationships among the factors. All experts were based in South Korea, with an average of 12 years of professional experience, ensuring that both theoretical perspectives and practical insights were represented. Each expert provided written judgments, and the initial SSIM was constructed using a threshold-based majority aggregation, applying a tie-breaking rule (X > V > A > O). In cases of disagreement, the aggregated results were shared with all experts and agreement was confirmed, thereby combining systematic aggregation with a consensus confirmation step. The finalized relationships among the factors were represented using four directional symbols: V for “i influences j,” A for “j influences i,” X for “mutual influence,” and O for “no relation.”. The subsequent ISM and MICMAC calculations were implemented using custom Python 3.11.9 scripts, ensuring transparency and reproducibility.

- Development of SSIM: Based on expert evaluations, a Structural Self-Interaction Matrix (SSIM) was formulated to represent pairwise relationships among barriers.

- Initial reachability matrix: The SSIM outcomes were then translated into binary indicators (1 and 0) to produce the initial reachability matrix used for subsequent analysis.

- Application of transitivity: Indirect influences were incorporated by applying the transitivity principle of ISM. For example, if F1 influences F2 and F2 influences F3, then F1 is assumed to indirectly influence F3. This step ensures that hidden or secondary relationships are captured, thereby clarifying the complete hierarchical structure of barriers and strengthening the robustness of the model.

- Level partitioning: Hierarchical levels for all factors were identified by comparing the reachability and antecedent sets and examining their common elements.

- ISM model construction: Based on these results, a hierarchical structural model of the interrelationships among the factors was developed.

2.2. MICMAC Analysis

- Autonomous factors: These exhibit both low driving influence and low dependency, remaining largely detached from the overall system dynamics.

- Dependent factors: These possess limited driving capacity but strong reliance on other factors, making them outcome-oriented and symptomatic of deeper causes.

- Linkage factors: With high driving and dependency power, these factors are highly interactive and can amplify system fluctuations.

- Independent (driving) factors: These exert strong driving influence with little dependency, acting as core drivers that shape the system and require focused attention.

3. Results

3.1. Identification of Critical Barrier Factors for the Adoption of Construction Robots

3.1.1. Economic Factors

3.1.2. Industrial Factors

3.1.3. Institutional and Policy Factors

3.1.4. Socio-Cultural Factors

3.1.5. Technological Factors

3.2. Prioritization of Critical Barrier Factors for Adoption and Activation of Construction Robots

3.2.1. Structural Self-Interaction Matrix (SSIM)

- V: Factor i influences factor j → (i, j) = 1, (j, i) = 0.

- A: Factor j influences factor i → (i, j) = 0, (j, i) = 1.

- X: Factors i and j influence each other → (i, j) = 1, (j, i) = 1.

- O: Factors i and j are unrelated → (i, j) = 0, (j, i) = 0.

3.2.2. Reachability Matrix

3.2.3. Level Partitions

- Reachability Set (factors influenced by a given element): Includes a specific factor together with all other factors it can directly or indirectly affect.

- Antecedent Set (influencing factors): Comprises a specific factor and all other factors that can exert influence upon it.

- Intersection Set (common factors between reachability and antecedent sets): Represents the overlap between the reachability and antecedent sets—those factors that both influence and are influenced by others.

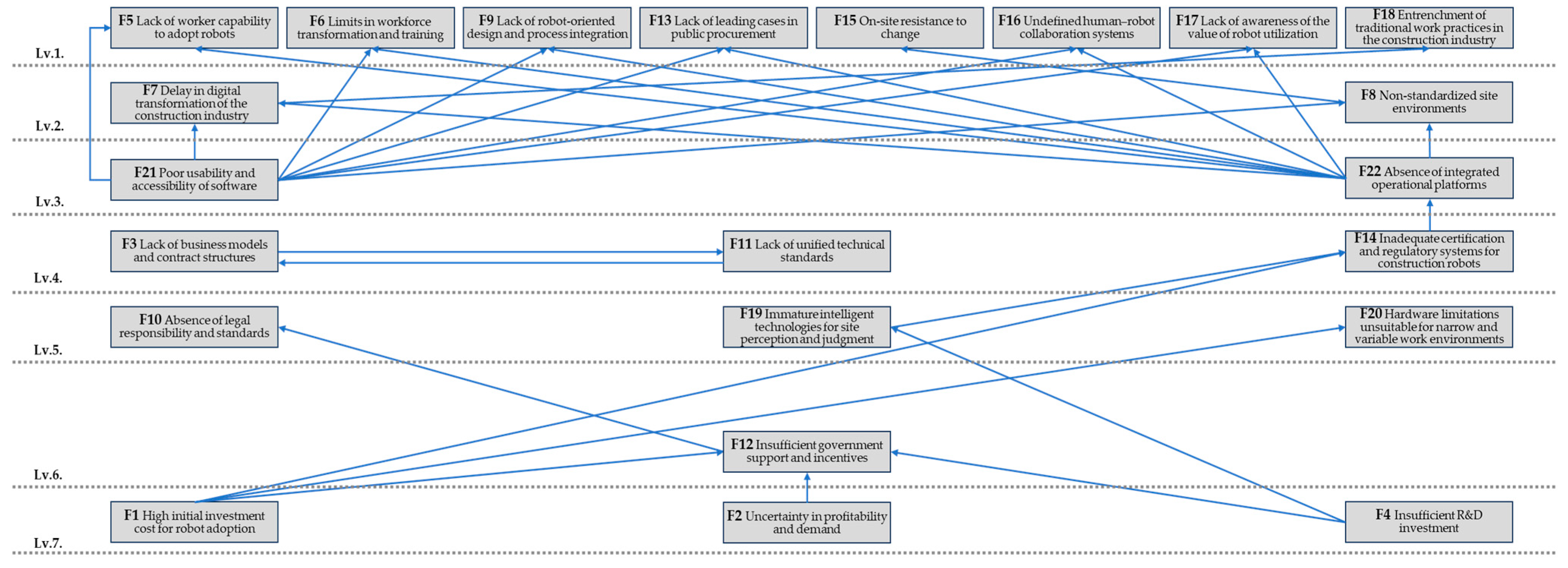

3.2.4. ISM Model

- F5: Lack of worker capability to adopt robots.

- F6: Limits in workforce transformation and training.

- F9: Lack of robot-oriented design and process integration.

- F13: Lack of leading cases in public procurement.

- F15: On-site resistance to change.

- F16: Undefined human–robot collaboration systems.

- F17: Lack of awareness of the value of robot utilization.

- F18: Entrenchment of traditional work practices in the construction industry.

- F1: High initial investment cost for robot adoption.

- F2: Uncertainty in profitability and demand.

- F4: Insufficient R&D investment.

3.2.5. Results of MICMAC Analysis

4. Discussion

- Mitigating economic burdens through subsidies, tax incentives, and investment support to reduce initial entry barriers.

- Strengthening institutional foundations by clarifying safety certification procedures, establishing legal responsibility, and developing unified technical standards.

- Accelerating technological maturity through expanded R&D investment and pilot projects, with particular emphasis on software usability and platform development.

- Enhancing social acceptance by implementing training and awareness programs for contractors and workers, alongside expanding pilot projects to demonstrate benefits.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Law, K.K.; Chang, S.; Siu, M.F.F. Factors influencing adoption of construction robotics in Hong Kong’s industry: A multistakeholder perspective. J. Manag. Eng. 2022, 38, 04021096. [Google Scholar] [CrossRef]

- Bademosi, F.; Issa, R.R. Factors influencing adoption and integration of construction robotics and automation technology in the US. J. Constr. Eng. Manag. 2021, 147, 04021075. [Google Scholar] [CrossRef]

- Energy Daily. Case of Introducing Autonomous Inspection Robots at Power Plants: Effects on Accident Prevention. 2025. Available online: https://www.energydaily.co.kr/news/articleView.html?idxno=160572 (accessed on 30 September 2025).

- Hankook, I. Korean Manufacturers Report Productivity Growth and New Job Creation After Adopting Robots. 2022. Available online: https://www.hankookilbo.com/News/Read/A2022082414340000496 (accessed on 24 August 2022).

- The Robot News. Korea Institute of Robot Convergence] 2024 Advanced Manufacturing Robot Demonstration Project Success Cases. 2025. Available online: https://www.irobotnews.com/news/articleView.html?idxno=37209 (accessed on 9 January 2025).

- The Robot News. Yujin Robot Introduces 1.5-Ton AMR to JeongSik Foods’ Manufacturing Plant. 2025. Available online: https://www.irobotnews.com/news/articleView.html?idxno=37518 (accessed on 10 February 2025).

- Shin, Y.; Seo, S.; Koo, C. Synthetic Video Generation Process Model for Enhancing the Activity Recognition Performance of Heavy Construction Equipment-Utilizing 3D Simulations in Unreal Engine Environment. Korean J. Constr. Eng. Manag. 2025, 26, 74–82. [Google Scholar]

- Park, J.; Kim, K. Reviewing the Applicability of 3D Printing Technology in the Construction Industry. Korean J. Constr. Eng. Manag. 2022, 23, 119–124. [Google Scholar] [CrossRef]

- Delgado, J.M.D.; Oyedele, L.; Ajayi, A.; Akanbi, L.; Akinade, O.; Bilal, M.; Owolabi, H. Robotics and automated systems in construction: Understanding industry-specific challenges for adoption. J. Build. Eng. 2019, 26, 100868. [Google Scholar] [CrossRef]

- Wei, H.H.; Zhang, Y.; Sun, X.; Chen, J.; Li, S. Intelligent robots and human-robot collaboration in the construction industry: A review. J. Intell. Constr. 2023, 1, 1–12. [Google Scholar] [CrossRef]

- Qu, Y.; Liu, W. Construction Robot Application Barrier Factor Analysis. In Proceedings of the 2023 IEEE 6th International Conference on Knowledge Innovation and Invention (ICKII), Sapporo, Japan, 11–13 August 2023; IEEE: New York, NY, USA, 2023; pp. 312–314. [Google Scholar]

- Bock, T. The future of construction automation: Technological disruption and the upcoming ubiquity of robotics. Autom. Constr. 2015, 59, 113–121. [Google Scholar] [CrossRef]

- Sawhney, A.; Riley, M.; Irizarry, J. Construction 4.0: An Innovation Platform for the Built Environment; Routledge: Oxfordshire, UK, 2018; Available online: https://www.arataumodular.com/app/wp-content/uploads/2022/07/Construction-4.0-An-Innovation-Platform-For-The-Built-Environment.pdf (accessed on 6 February 2020).

- Barbosa, F.; Woetzel, J.; Mischke, J.; Ribeirinho, M.J.; Sridhar, M.; Parsons, M.; Bertram, N.; Brown, S. Reinventing Construction: A Route to Higher Productivity. McKinsey Global Institute. 2017. Available online: https://www.mckinsey.com/industries/private-equity-and-principal-investors/our-insights/reinventing-construction-through-a-productivity-revolution (accessed on 27 February 2017).

- Tan, T.; Chen, K.; Xue, F.; Lu, W. Barriers to Building Information Modeling (BIM) implementation in China’s prefabricated construction: An interpretive structural modeling (ISM) approach. J. Clean. Prod. 2019, 219, 949–959. [Google Scholar] [CrossRef]

- World Economic Forum. Shaping the Future of Construction: A Breakthrough in Mindset and Technology. Geneva: World Economic Forum. 2018. Available online: https://www.weforum.org/publications/shaping-the-future-of-construction-a-breakthrough-in-mindset-and-technology/ (accessed on 4 May 2016).

- Lee, J.; Won, J.; Han, S.H. Challenges for implementing smart construction in Korean construction industry using MICMAC-ISM approach. In International Conference on Construction Engineering and Project Management; Korea Institute of Construction Engineering and Management: Seoul, Republic of Korea, 2024; pp. 917–924. [Google Scholar]

- Attri, R.; Dev, N.; Sharma, V. Interpretive structural modelling (ISM) approach: An overview. Res. J. Manag. Sci. 2013, 2319, 1171. [Google Scholar]

- Sage, A.P. Interpretive Structural Modeling: Methodology for Large-Scale Systems; Estados Unidos: New York, NY, USA, 1977. [Google Scholar]

- Warfield, J.W. Developing interconnected matrices in structural modelling. IEEE Trans. Syst. Men Cybern. 1974, 4, 51–81. [Google Scholar]

- Khaba, S.; Bhar, C. Analysing the barriers of lean in Indian coal mining industry using integrated ISM-MICMAC and SEM. Benchmarking An Int. J. 2018, 25, 2145–2168. [Google Scholar] [CrossRef]

- Shen, L.; Govindan, K.; Shankar, M. Evaluation of barriers of cor-porate social responsibility using an analytical hierarchy process undera fuzzy environment—A textile case. Sustainability 2015, 7, 3493–3514. [Google Scholar] [CrossRef]

- Pan, M.; Linner, T.; Pan, W.; Cheng, H.M.; Bock, T. Influencing factors of the future utilisation of construction robots for buildings: A Hong Kong perspective. J. Build. Eng. 2020, 30, 101220. [Google Scholar] [CrossRef]

- Pan, M.; Pan, W. Determinants of adoption of robotics in precast concrete production for buildings. J. Manag. Eng. 2019, 35, 05019007. [Google Scholar] [CrossRef]

- Bock, T.; Linner, T. Construction Robots: Elementary Technologies and Single-Task Construction Robots; Cambridge University Press: Cambridge, UK, 2016. [Google Scholar]

- Li, R.Y.M. Robots for the construction industry. In An Economic Analysis on Automated Construction Safety: Internet of Things, Artificial Intelligence and 3D Printing; Springer: Singapore, 2017; pp. 23–46. [Google Scholar]

- Yang, Y.; Pan, M.; Pan, W. Co-evolution through interaction’of innovative building technologies: The case of modular integrated construction and robotics. Autom. Constr. 2019, 107, 102932. [Google Scholar] [CrossRef]

- Castro-Lacouture, D. Construction automation. In Springer Handbook of Automation; Springer: Berlin/Heidelberg, Germany, 2009; pp. 1063–1078. [Google Scholar]

- Pan, M.; Linner, T.; Pan, W.; Cheng, H.; Bock, T. A framework of indicators for assessing construction automation and robotics in the sustainability context. J. Clean. Prod. 2018, 182, 82–95. [Google Scholar] [CrossRef]

- Van Marrewijk, A.; Veenswijk, M.; Clegg, S. Changing collaborative practices through cultural interventions. Build. Res. Inf. 2014, 42, 330–342. [Google Scholar] [CrossRef]

- Newton, P.; Hampson, K. Transforming the built environment through construction innovation. In Technology, Design and Process Innovation in the Built Environment; Spon Press: London, UK, 2009; pp. 29–54. [Google Scholar]

- Hampson, K.D.; Kraatz, J.A.; Sanchez, A.X. The global construction industry and R&D. In R&D Investment and Impact in the Global Construction Industry; Routledge: Oxfordshire, UK, 2014; pp. 4–23. [Google Scholar]

- Blayse, A.M.; Manley, K. Key influences on construction innovation. Constr. Innov. 2004, 4, 143–154. [Google Scholar] [CrossRef]

- Mahbub, R. An Investigation into the Barriers to the Implementation of Automation and Robotics Technologies in the Construction industry. Ph.D. Dissertation, Queensland University of Technology, Brisbane, Australia, 2008. [Google Scholar]

- Recm, D.J.T.M.; Holt, E. Barriers to automation and robotics in construction. EPiC Ser. Built Environ. 2020, 1, 257–265. [Google Scholar]

- Watson, J.; Sharp, G. Barriers to skills development in a local construction labour market. Local Econ. 2007, 22, 123–137. [Google Scholar] [CrossRef]

- Cousineau, L.; Miura, N. Construction Robots: The Search for New Building Technology in Japan; ASCE Publications: Reston, VA, USA, 1998. [Google Scholar]

- Jäkel, J.I.; Rahnama, S.; Klemt-Albert, K. Construction Robotics Excellence Model: A framework to overcome existing barriers for the implementation of robotics in the construction industry. In Proceedings of the International Symposium on Automation and Robotics in Construction (IAARC), Bogotá, Colombia, 12–15 July 2022. [Google Scholar] [CrossRef]

- You, S.; Kim, J.H.; Lee, S.; Kamat, V.; Robert, L.P., Jr. Enhancing perceived safety in human–robot collaborative construction using immersive virtual environments. Autom. Constr. 2018, 96, 161–170. [Google Scholar] [CrossRef]

- Wong, J.; Zhang, J.; Lee, J. A vision of the future construction industry of Hong Kong. In Proceedings of the ISARC, international symposium on automation and robotics in construction (IAARC), Oulu, Finland, 15–18 June 2015; Volume 32, p. 1. [Google Scholar]

- Warszawski, A.; Navon, R. Implementation of robotics in building: Current status and future prospects. J. Constr. Eng. Manag. 1998, 124, 31–41. [Google Scholar] [CrossRef]

- Saidi, K.S.; Bock, T.; Georgoulas, C. Robotics in construction. In Springer Handbook of Robotics; Springer International Publishing: Cham, Switzerland, 2016; pp. 1493–1520. [Google Scholar]

- Quezada, G.; Bratanova, A.; Boughen, N.; Hajkowicz, S. Farsight for Construction: Exploratory Scenarios for Queensland’s Construction Industry to 2036; CSIRO: Canberra, Australia, 2016. [Google Scholar]

- Skibniewski, M.J.; Zavadskas, E.K. Technology development in construction: A continuum from distant past into the future. J. Civil. Eng. Manag. 2013, 19, 136–147. [Google Scholar] [CrossRef]

- Mistri, P.S.; Rathod, H.A. Remedies over barriers of automation and robotics for construction industry. Int. J. Adv. Res. Eng. Sci. Manag. 2015, 1, 1–4. [Google Scholar]

- Carra, G.; Argiolas, A.; Bellissima, A.; Niccolini, M.; Ragaglia, M. Robotics in the construction industry: State of the art and future opportunities. In Proceedings of the ISARC, international symposium on automation and robotics in construction (IAARC), Berlin, Germany, 20–25 July 2018; Volume 35, pp. 1–8. [Google Scholar]

- Stewart, R.A.; Mohamed, S.; Marosszeky, M. An empirical investigation into the link between information technology implementation barriers and coping strategies in the Australian construction industry. Constr. Innov. 2004, 4, 155–171. [Google Scholar] [CrossRef]

- Bae, H.S. A Study on the Legislation for the Promotion of the Robot Industry-With cooperative robots at the center. Law Bus. Stud. 2024, 14, 35–55. [Google Scholar] [CrossRef]

- Kwon, G.H. Impacts of technical innovation and regulatory reform on performance of companies in new industries–focusing on the moderating effect of Korean Regulatory Sandbox. J. Regul. Stud. 2023, 32, 33–71. [Google Scholar]

- Lee, G.P.; Choe, S.I. Legislative Directions for the Promotion of Smart Construction Technologies. Constr. Eng. Manag. 2019, 20, 28–32. Available online: https://kiss.kstudy.com/DetailOa/Ar?key=53691738 (accessed on 30 October 2019).

- Chan, D.W.; Olawumi, T.O.; Ho, A.M. Perceived benefits of and barriers to Building Information Modelling (BIM) implementation in construction: The case of Hong Kong. J. Build. Eng. 2019, 25, 100764. [Google Scholar] [CrossRef]

- Kangari, R.; Halpin, D.W. Identification of factors influencing implementation of construction robotics. Constr. Manag. Econ. 1990, 8, 89–104. [Google Scholar] [CrossRef]

- Bogue, R. What are the prospects for robots in the construction industry? Ind. Robot. An Int. J. 2018, 45, 1–6. [Google Scholar] [CrossRef]

- Lee, K.; Choi, S.; Son, T.; Choi, S. Current Status and Activation Strategies for Smart Technology Utilization in Korean Construction Companies. 2019. Available online: https://cerik.re.kr/report/research/2330 (accessed on 26 December 2019).

- Jung, S.; Lee, S.; Yu, J. Identification and prioritization of critical success factors for off-site construction using ISM and MICMAC analysis. Sustainability 2021, 13, 8911. [Google Scholar] [CrossRef]

- Kumar, P.; Bhamu, J.; Sangwan, K.S. Analysis of barriers to Industry 4.0 adoption in manufacturing organizations: An ISM approach. Procedia CIRP 2021, 98, 85–90. [Google Scholar] [CrossRef]

- Sun, B.; Mao, C.; Wang, T.; Li, Z. Cost assessment framework for construction robots: Comparative study of robotic and traditional construction. J. Manag. Eng. 2024, 40, 04024064. [Google Scholar] [CrossRef]

- Hu, R.; Iturralde, K.; Linner, T.; Zhao, C.; Pan, W.; Pracucci, A.; Bock, T. A simple framework for the cost–benefit analysis of single-task construction robots based on a case study of a cable-driven façade installation robot. Buildings 2021, 11, 8. [Google Scholar] [CrossRef]

- BuiltWorlds. Construction’s Roadblocks to Robotics: AEC’s Adoption Struggles and What We Can Learn from Industries Leading the Way. 16 July 2024. Available online: https://builtworlds.com/news/constructions-roadblocks-to-robotics (accessed on 16 July 2024).

| Division | No. | Barriers Factors | Refs. |

|---|---|---|---|

| Economic Factors | F1 | High initial investment cost for robot adoption | [9,12,17,23,24,25] |

| F2 | Uncertainty in profitability and demand | [9,17,23,24,25,26,27,28] | |

| F3 | Lack of business models and contract structures | [9,29,30] | |

| F4 | Insufficient R&D investment | [9,12,23,31,32,33] | |

| Industrial Factors | F5 | Lack of worker capability to adopt robots | [9,23,28,32,34,35,36,37] |

| F6 | Limits in workforce transformation and training | [9,12,23,34,35,36,37,38,39] | |

| F7 | Delay in digital transformation of the construction industry | [9,23,27,37,40,41,42] | |

| F8 | Non-standardized site environments | [23,34,37,38,39,40,41,43] | |

| F9 | Lack of robot-oriented design and process integration | [40,41,42] | |

| Institutional and Policy Factors | F10 | Absence of legal responsibility and standards | [12,23,41] |

| F11 | Lack of unified technical standards | [33,41,42,43] | |

| F12 | Insufficient government support and incentives | [9,23,37,42] | |

| F13 | Lack of leading cases in public procurement | [23,42,43] | |

| F14 | Inadequate certification and regulatory systems for construction robots | [44,45] | |

| Socio- Cultural Factors | F15 | On-site resistance to change | [41,42,43,44,45] |

| F16 | Undefined human–robot collaboration systems | [46] | |

| F17 | Lack of awareness of the value of robot utilization | [9,23,33,47] | |

| F18 | Entrenchment of traditional work practices in the construction industry | [12,41,42,48] | |

| Technical Factors | F19 | Immature intelligent technologies for site perception and judgment | [41] |

| F20 | Hardware limitations unsuitable for narrow and variable work environments | [9,23,24,25,38] | |

| F21 | Poor usability and accessibility of software | [9,16,23,33] | |

| F22 | Absence of integrated operational platforms | [9,28,49] |

| - | F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | F10 | F11 | F12 | F13 | F14 | F15 | F16 | F17 | F18 | F19 | F20 | F21 | F22 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F1 | - | O | O | O | V | V | V | V | V | O | O | V | V | V | V | V | V | V | O | V | O | O |

| F2 | O | - | O | O | V | V | V | V | V | O | O | V | V | O | V | V | V | V | O | O | O | O |

| F3 | O | O | - | O | V | V | V | V | V | O | V | O | V | O | V | V | V | V | O | O | V | O |

| F4 | O | O | O | - | V | V | V | V | V | O | O | V | V | O | V | V | V | V | V | O | O | O |

| F5 | A | A | A | A | - | O | O | O | O | A | A | A | O | A | O | O | O | O | A | A | A | A |

| F6 | A | A | A | A | O | - | O | O | O | A | A | A | O | A | O | O | O | O | A | A | A | A |

| F7 | A | A | A | A | O | O | - | O | O | A | A | A | O | A | O | O | O | V | A | A | A | A |

| F8 | A | A | A | A | O | O | O | - | O | A | A | A | O | A | O | O | O | O | A | A | A | A |

| F9 | A | A | A | A | O | O | O | O | - | A | A | A | O | A | O | O | O | O | A | A | A | A |

| F10 | O | O | V | O | V | V | V | V | V | - | O | O | V | O | V | V | V | V | O | O | O | O |

| F11 | O | O | V | O | V | V | V | V | V | O | - | O | V | O | V | V | V | V | O | O | O | O |

| F12 | O | O | O | O | V | V | V | V | V | V | V | - | V | O | V | V | V | V | O | O | O | O |

| F13 | A | A | A | A | O | O | O | O | O | A | A | A | - | A | O | O | O | O | A | A | A | A |

| F14 | O | O | O | O | V | V | V | V | V | O | O | O | V | - | V | V | V | V | O | O | O | V |

| F15 | A | A | A | A | O | O | O | A | O | A | A | A | O | A | - | O | O | O | A | A | A | A |

| F16 | A | A | A | A | O | O | O | O | O | A | A | A | O | A | O | - | O | O | A | A | A | A |

| F17 | A | A | A | A | O | O | O | O | O | A | A | A | O | A | O | O | - | O | A | A | A | A |

| F18 | A | A | A | A | O | O | O | O | O | A | A | A | O | A | O | O | O | - | A | A | A | A |

| F19 | O | O | O | O | V | V | V | V | V | O | V | O | V | V | V | V | V | V | - | O | O | V |

| F20 | O | O | V | O | V | V | V | V | V | O | V | O | V | O | V | V | V | V | O | - | O | O |

| F21 | O | O | O | O | V | V | V | V | V | O | O | O | V | O | V | V | V | V | O | O | - | O |

| F22 | O | O | O | O | V | V | V | V | V | O | O | O | V | O | V | V | V | V | O | O | O | - |

| - | F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | F10 | F11 | F12 | F13 | F14 | F15 | F16 | F17 | F18 | F19 | F20 | F21 | F22 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F1 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 |

| F2 | 0 | 1 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 |

| F3 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 |

| F4 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 |

| F5 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F6 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F7 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 |

| F8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F9 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F10 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 |

| F11 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 |

| F12 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 |

| F13 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F14 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 |

| F15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F16 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| F17 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 |

| F18 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 |

| F19 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 |

| F20 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 |

| F21 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 |

| F22 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 |

| - | F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | F10 | F11 | F12 | F13 | F14 | F15 | F16 | F17 | F18 | F19 | F20 | F21 | F22 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F1 | 1 | 0 | 1 * | 0 | 1 | 1 | 1 | 1 | 1 | 1 * | 1 * | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 * | 1 * |

| F2 | 0 | 1 | 1 * | 0 | 1 | 1 | 1 | 1 | 1 | 1 * | 1 * | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 * | 0 |

| F3 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 |

| F4 | 0 | 0 | 1 * | 1 | 1 | 1 | 1 | 1 | 1 | 1 * | 1 * | 1 | 1 | 1 * | 1 | 1 | 1 | 1 | 1 | 0 | 1 * | 1 * |

| F5 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F6 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F7 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 |

| F8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F9 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F10 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 * | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 * | 0 |

| F11 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 * | 0 |

| F12 | 0 | 0 | 1 * | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 * | 0 |

| F13 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F14 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 |

| F15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F16 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| F17 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 |

| F18 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 |

| F19 | 0 | 0 | 1 * | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 * | 1 |

| F20 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 1 | 1 * | 0 |

| F21 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 |

| F22 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 |

| Label | Factors Influenced | Influencing Factors | Common Factors | Level |

|---|---|---|---|---|

| F1 | F1 F3 F5 F6 F7 F8 F9 F10 F11 F12 F13 F14 F15 F16 F17 F18 F20 F21 F22 | F1 | F1 | 0 |

| F2 | F2 F3 F5 F6 F7 F8 F9 F10 F11 F12 F13 F15 F16 F17 F18 F21 | F2 | F2 | 0 |

| F3 | F3 F5 F6 F7 F8 F9 F11 F13 F15 F16 F17 F18 F21 | F1 F2 F3 F0 F11 F12 F19 F20 | F3 F11 | 0 |

| F4 | F3 F4 F5 F6 F7 F8 F9 F10 F11 F12 F13 F14 F15 F16 F17 F18 F19 F21 F22 | F4 | F4 | 0 |

| F5 | F5 | F1 F2 F3 F4 F5 F10 F11 F12 F14 F19 F20 F21 F22 | F5 | 1 |

| F6 | F6 | F1 F2 F3 F4 F6 F10 F11 F12 F14 F19 F20 F21 F22 | F6 | 1 |

| F7 | F7 F18 | F1 F2 F3 F4 F7 F10 F11 F12 F14 F19 F20 F21 F22 | F7 | 0 |

| F8 | F8 F15 | F1 F2 F3 F4 F8 F10 F11 F12 F14 F19 F20 F21 F22 | F8 | 0 |

| F9 | F9 | F1 F2 F3 F4 F9 F10 F11 F12 F14 F19 F20 F21 F22 | F9 | 1 |

| F10 | F3 F5 F6 F7 F8 F9 F10 F11 F13 F15 F16 F17 F18 F21 | F1 F2 F4 F10 F12 | F10 | 0 |

| F11 | F3 F5 F6 F7 F8 F9 F11 F13 F15 F16 F17 F18 F21 | F1 F2 F3 F4 F10 F11 F12 F19 F20 | F3 F11 | 0 |

| F12 | F3 F5 F6 F7 F8 F9 F10 F11 F12 F13 F15 F16 F17 F18 F21 | F1 F2 F4 F12 | F12 | 0 |

| F13 | F13 | F1 F2 F3 F4 F10 F11 F12 F13 F14 F19 F20 F21 F22 | F13 | 1 |

| F14 | F5 F6 F7 F8 F9 F13 F14 F15 F16 F17 F18 F22 | F1 F4 F14 F19 | F14 | 0 |

| F15 | F15 | F1 F2 F3 F4 F8 F10 F11 F12 F14 F15 F19 F20 F21 F22 | F15 | 1 |

| F16 | F16 | F1 F2 F3 F4 F10 F11 F12 F14 F16 F19 F20 F21 F22 | F16 | 1 |

| F17 | F17 | F1 F2 F3 F4 F10 F11 F12 F14 F17 F19 F20 F21 F22 | F17 | 1 |

| F18 | F18 | F1 F2 F3 F4 F7 F10 F11 F12 F14 F18 F19 F20 F21 F22 | F18 | 1 |

| F19 | F3 F5 F6 F7 F8 F9 F11 F13 F14 F15 F16 F17 F18 F19 F21 F22 | F4 F19 | F19 | 0 |

| F20 | F3 F5 F6 F7 F8 F9 F11 F13 F15 F16 F17 F18 F20 F21 | F1 F20 | F20 | 0 |

| F21 | F5 F6 F7 F8 F9 F13 F15 F16 F17 F18 F21 | F1 F2 F3 F4 F10 F11 F12 F19 F20 F21 | F21 | 0 |

| F22 | F5 F6 F7 F8 F9 F13 F15 F16 F17 F18 F22 | F1 F4 F14 F19 F22 | F22 | 0 |

| Label | Factors Influenced | Influencing Factors | Common Factors | Level |

|---|---|---|---|---|

| F1 | F1 F3 F7 F8 F10 F11 F12 F14 F20 F21 F22 | F1 | F1 | 0 |

| F2 | F2 F3 F7 F8 F10 F11 F12 F21 | F2 | F2 | 0 |

| F3 | F3 F7 F8 F11 F21 | F1 F2 F3 F4 F10 F11 F12 F19 F20 | F3 F11 | 0 |

| F4 | F3 F4 F7 F8 F10 F11 F12 F14 F19 F21 F22 | F4 | F4 | 0 |

| F7 | F7 | F1 F2 F3 F4 F7 F10 F11 F12 F14 F19 F20 F21 F22 | F7 | 2 |

| F8 | F8 | F1 F2 F3 F4 F8 F10 F11 F12 F14 F19 F20 F21 F22 | F8 | 2 |

| F10 | F3 F7 F8 F10 F11 F21 | F1 F2 F4 F10 F12 | F10 | 0 |

| F11 | F3 F7 F8 F11 F21 | F1 F2 F3 F4 F10 F11 F12 F19 F20 | F3 F11 | 0 |

| F12 | F3 F7 F8 F10 F11 F12 F21 | F1 F2 F4 F12 | F12 | 0 |

| F14 | F7 F8 F14 F22 | F1 F4 F14 F19 | F14 | 0 |

| F19 | F3 F7 F8 F11 F14 F19 F21 F22 | F4 F19 | F19 | 0 |

| F20 | F3 F7 F8 F11 F20 F21 | F1 F20 | F20 | 0 |

| F21 | F7 F8 F21 | F1 F2 F3 F4 F10 F11 F12 F19 F20 F21 | F21 | 0 |

| F22 | F7 F8 F22 | F1 F4 F14 F19 F22 | F22 | 0 |

| Label | Factors Influenced | Influencing Factors | Common Factors | Level |

|---|---|---|---|---|

| F1 | F1 F3 F10 F11 F12 F14 F20 F21 F22 | F1 | F1 | 0 |

| F2 | F2 F3 F10 F11 F12 F21 | F2 | F2 | 0 |

| F3 | F3 F11 F21 | F1 F2 F3 F4 F10 F11 F12 F19 F20 | F3 F11 | 0 |

| F4 | F3 F4 F10 F11 F12 F14 F19 F21 F22 | F4 | F4 | 0 |

| F10 | F3 F10 F11 F21 | F1 F2 F4 F10 F12 | F10 | 0 |

| F11 | F3 F11 F21 | F1 F2 F3 F4 F10 F11 F12 F19 F20 | F3 F11 | 0 |

| F12 | F3 F10 F11 F12 F21 | F1 F2 F4 F12 | F12 | 0 |

| F14 | F14 F22 | F1 F4 F14 F19 | F14 | 0 |

| F19 | F3 F11 F14 F19 F21 F22 | F4 F19 | F19 | 0 |

| F20 | F3 F11 F20 F21 | F1 F20 | F20 | 0 |

| F21 | F21 | F1 F2 F3 F4 F10 F11 F12 F19 F20 F21 | F21 | 3 |

| F22 | F22 | F1 F4 F14 F19 F22 | F22 | 3 |

| Label | Factors Influenced | Influencing Factors | Common Factors | Level |

|---|---|---|---|---|

| F1 | F1 F3 F10 F11 F12 F14 F20 | F1 | F1 | 0 |

| F2 | F2 F3 F10 F11 F12 | F2 | F2 | 0 |

| F3 | F3 F11 | F1 F2 F3 F4 F10 F11 F12 F19 F20 | F3 F11 | 4 |

| F4 | F3 F4 F10 F11 F12 F14 F19 | F4 | F4 | 0 |

| F10 | F3 F10 F11 | F1 F2 F4 F10 F12 | F10 | 0 |

| F11 | F3 F11 | F1 F2 F3 F4 F10 F11 F12 F19 F20 | F3 F11 | 4 |

| F12 | F3 F10 F11 F12 | F1 F2 F4 F12 | F12 | 0 |

| F14 | F14 | F1 F4 F14 F19 | F14 | 4 |

| F19 | F3 F11 F14 F19 | F4 F19 | F19 | 0 |

| F20 | F3 F11 F20 | F1 F20 | F20 | 0 |

| Label | Factors Influenced | Influencing Factors | Common Factors | Level |

|---|---|---|---|---|

| F1 | F1 F10 F12 F20 | F1 | F1 | 0 |

| F2 | F2 F10 F12 | F2 | F2 | 0 |

| F4 | F4 F10 F12 F19 | F4 | F4 | 0 |

| F10 | F10 | F1 F2 F4 F10 F12 | F10 | 5 |

| F12 | F10 F12 | F1 F2 F4 F12 | F12 | 0 |

| F19 | F19 | F4 F19 | F19 | 5 |

| F20 | F20 | F1 F20 | F20 | 5 |

| Label | Factors Influenced | Influencing Factors | Common Factors | Level |

|---|---|---|---|---|

| F1 | F1 F12 | F1 | F1 | 0 |

| F2 | F2 F12 | F2 | F2 | 0 |

| F4 | F4 F12 | F4 | F4 | 0 |

| F12 | F12 | F1 F2 F4 F12 | F12 | 6 |

| Label | Factors Influenced | Influencing Factors | Common Factors | Level |

|---|---|---|---|---|

| F1 | F1 | F1 | F1 | 7 |

| F2 | F2 | F2 | F2 | 7 |

| F4 | F4 | F4 | F4 | 7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Lee, S.; Jung, S. Identification and Prioritization of Critical Barriers to the Adoption of Robots in the Construction Phase with Interpretive Structural Modeling (ISM) and MICMAC Analysis. Buildings 2025, 15, 3770. https://doi.org/10.3390/buildings15203770

Kim J, Lee S, Jung S. Identification and Prioritization of Critical Barriers to the Adoption of Robots in the Construction Phase with Interpretive Structural Modeling (ISM) and MICMAC Analysis. Buildings. 2025; 15(20):3770. https://doi.org/10.3390/buildings15203770

Chicago/Turabian StyleKim, Jaemin, Seulki Lee, and Seoyoung Jung. 2025. "Identification and Prioritization of Critical Barriers to the Adoption of Robots in the Construction Phase with Interpretive Structural Modeling (ISM) and MICMAC Analysis" Buildings 15, no. 20: 3770. https://doi.org/10.3390/buildings15203770

APA StyleKim, J., Lee, S., & Jung, S. (2025). Identification and Prioritization of Critical Barriers to the Adoption of Robots in the Construction Phase with Interpretive Structural Modeling (ISM) and MICMAC Analysis. Buildings, 15(20), 3770. https://doi.org/10.3390/buildings15203770