Ground Improvement Using Recycled Concrete Columns: A Case Study of Wind Turbine Foundation

Abstract

1. Introduction

2. Materials

2.1. Recycled Concrete Aggregate

- The particle density of RCA ranges from 2.0 to 2.65 t/m3.

- The cement paste adhering to the aggregate surface significantly affects particle density and porosity.

- Highly porous RCA may undergo considerable deformation.

- Water absorption ranges from 3% to 10%, compared to less than 3% for natural aggregates.

- RCA exhibits higher porosity and hydraulic conductivity (3.83 × 10−6 m/s), approximately two orders of magnitude greater than that of natural aggregates.

- RCA has an abrasion resistance of up to 25%.

- As an unbound granular material (UGM), RCA shows lower CBR values and higher optimum moisture content with lower dry density compared to natural aggregates.

- M1–M4: air-dry mixtures with 0.2 mm grain size and fine fraction (FF) content of 0%, 10%, 20%, and 30%, respectively;

- M5–M6: moistened mixtures with 0.2 mm grain size and FF content of 5% and 15%, respectively.

- Poorly graded fine sands (M1, M2, and M5 blends; FF ≤ 10%);

- Poorly graded sands with silt (M6 blend; FF = 15%; M3, M4 blends; FF > 15%) [29].

- M1_0%FF: G0 = 177 MPa, E0 = 442.5 Mpa;

- M4_30%FF: G0 = 126.27 MPa, E0 = 315.68 MPa (assuming Poisson’s ratio ν = 0.25).

2.2. Reference Materials

3. Methods

3.1. Numerical Modeling Approach

- Recycled aggregate (fRCA) with fine fraction (FF) contents of 0% (M1_0%FF);

- Recycled aggregate (fRCA) with fine fraction (FF) contents of 30% (M4_30%FF);

- Concrete containing recycled aggregate;

- Conventional concrete of class C25/30.

- Column stiffness, compressibility, and strength (from laboratory testing and literature);

- Foundation load cases reflecting typical turbine operating conditions;

- Settlement, stress distribution, tensile force, and bending moment in columns as output values.

3.2. Subsoil Data

4. Results and Discussion

5. Conclusions

- From a technical perspective (bearing capacity, ground settlement, structural behavior):

- Concrete recycled aggregate derived from demolition waste is a viable alternative to natural aggregate concrete for soil reinforcement beneath wind turbine foundations, particularly in low to moderate load ranges.

- Settlements with concrete recycled aggregate derived from demolition waste are up to 20% higher than conventional concrete but remain within acceptable limits. Reinforcement significantly improves performance.

- Recycled concrete can be considered a fully functional engineering material, particularly in infrastructure and energy-related projects where durability and efficiency are essential.

- In the environmental domain (CO2 emission reduction, resource efficiency):

- The environmental benefits of concrete recycled aggregate derived from demolition waste are considerable, including reduced CO2 emissions, lower energy consumption, and diversion of waste from landfills.

- Recycled aggregate and concrete containing recycled components support the principles of a circular economy, reduce construction waste, and limit emissions associated with transportation.

- Their application contributes to achieving the EU’s climate objectives and promotes environmental responsibility in construction.

- From a research perspective (material limitations, necessity of in situ testing, behavior under cyclic and dynamic loads):

- Concrete recycled aggregate derived from demolition waste may be suitable for projects that prioritize sustainability, where ultimate stiffness is not the primary design criterion.

- Further research should focus on the long-term performance of concrete recycled aggregate derived from demolition waste under cyclic and dynamic loading conditions, its behavior under freeze–thaw cycles, and the potential for improving its mechanical properties through biocementation.

- There is a need for continued field studies to assess concrete recycled aggregate derived from demolition waste behavior under realistic operational scenarios and to refine design methodologies.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pikoń, K.; Bogacka, M.; Landrat, M.; Piecha-Sobota, K. A Guide to Circularity in Construction. Available online: https://circon.plgbc.org.pl/ (accessed on 31 August 2025).

- Soto-Paz, J.; Arroyo, O.; Torres-Guevara, L.E.; Parra-Orobio, B.A.; Casallas-Ojeda, M. The circular economy in the construction and demolition waste management: A comparative analysis in emerging and developed countries. J. Build. Eng. 2023, 78, 107724. [Google Scholar] [CrossRef]

- Eurostat. Waste Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics#Total_waste_generation (accessed on 31 August 2025).

- Statista Construction Waste as a Share of All Waste Generated in the E.U. Available online: https://www.statista.com/statistics/1399099/construction-waste-as-a-share-of-all-wastegenerated-in-the-eu/ (accessed on 31 August 2025).

- Fronczyk, J.; Markowska-Lech, K. Solid Waste and Recycling. In Lecture Notes in Civil Engineering; Koda, E., Vaverková, M.D., Reddy, K.R., Agnihotri, A.K., Eds.; Springer: Singapore, 2025; Volume 119, pp. 119–130. ISBN 9789819619443. [Google Scholar] [CrossRef]

- Ustawa z Dnia 14 Grudnia 2012 R o Odpadach (Dz, U. z 2023 R. Poz. 1587. z Późn. Zm.). Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=wdu20130000021 (accessed on 31 August 2025).

- Rytlewska, M.; Bukowski, H.; Niedziółka, K. Report: Recovery of Building Materials—Opportunities and Challenges. Available online: www.saint-gobain.pl/raport-saint-gobain-odzysk-materialow-budowlanych (accessed on 31 August 2025).

- Al-Hamrani, A.; Kucukvar, M.; Alnahhal, W.; Mahdi, E.; Onat, N.C. Green Concrete for a Circular Economy: A Review on Sustainability. Durability and Structural Properties. Materials 2021, 14, 351. [Google Scholar] [CrossRef]

- Pacheco, J.; de Brito, J.; Lamperti Tornaghi, M. Use of Recycled Aggregates in Concrete: Opportunities for Upscaling in Europe; Publications Office of the European Union: Luxembourg, 2023. [Google Scholar] [CrossRef]

- Knoeri, C.; Sanyé-Mengual, E.; Althaus, H.-J. Comparative LCA of recycled and conventional concrete for structural applications. Int. J. Life Cycle Assess. 2013, 18, 909–918. [Google Scholar] [CrossRef]

- Turk, J.; Cotič, Z.; Mladenovič, A.; Šajna, A. Environmental evaluation of green concrete versus conventional concrete by means of LCA. J. Clean. Prod. 2015, 87, 613–619. [Google Scholar] [CrossRef] [PubMed]

- Almusaed, A.; Yitmen, I.; Myhren, J.A.; Almssad, A. Assessing the Impact of Recycled Building Materials on Environmental Sustainability and Energy Efficiency: A Comprehensive Framework for Reducing Greenhouse Gas Emissions. Buildings 2024, 14, 1566. [Google Scholar] [CrossRef]

- Kumar, B.N.; Vineela, P.S.; Bhat, D.K. Revolutionizing concrete through sustainable Practices: A performance study on strength variation under acidic environments. Discov. Sustain. 2025, 6, 418. [Google Scholar] [CrossRef]

- Chamasemani, N.F.; Kelishadi, M.; Mostafaei, H.; Najvani, M.A.D.; Mashayekhi, M. Environmental Impacts of Reinforced Concrete Buildings: Comparing Common and Sustainable Materials: A Case Study. Constr. Mater. 2024, 4, 1–15. [Google Scholar] [CrossRef]

- Attri, G.; Gupta, R.C.; Shrivastava, S. Comparative Environmental Impacts of Recycled Concrete Aggregate and Manufactured Sand Production. Process Integr. Optim. Sustain. 2022, 6, 737–749. [Google Scholar] [CrossRef]

- Luo, J.; Huang, R.; Wang, J.; Zhang, Y. Carbon Sequestration by Preparing Recycled Cement. Recycled Aggregates. and Recycled Concrete from Construction and Demolition (C&D) Wastes. Materials 2024, 17, 5020. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B.; Adak, D.; Kapoor, K.; Tabish, M. Low carbon concrete: Advancements. challenges and future directions in sustainable construction. Discov. Concr. Cem. 2025, 1, 3. [Google Scholar] [CrossRef]

- Singh, S.; Singh, S.K.; Mahgoub, M.; Mir, S.A.; Kanga, S.; Kumar, S.; Kumar, P.; Meraj, G. Evaluating Recycled Concrete Aggregate and Sand for Sustainable Construction Performance and Environmental Benefits. CivilEng 2024, 5, 461–481. [Google Scholar] [CrossRef]

- Badiger, M.; Mamatha, K.H.; Dinesh, S.V. Mechanical Evaluation of Granular Sub-base Reinforced with Recycled Tyres: A Way Towards Sustainability. Geotech. Geol. Eng. 2025, 43, 189. [Google Scholar] [CrossRef]

- Prasittisopin, L.; Tuvayanond, W.; Kang, T.H.-K.; Kaewunruen, S. Concrete Mix Design of Recycled Concrete Aggregate (RCA): Analysis of Review Papers. Characteristics. Research Trends. and Underexplored Topics. Resources 2025, 14, 21. [Google Scholar] [CrossRef]

- Arulrajah, A.; Piratheepan, J.; Disfani, M.M.; Bo, W. Geotechnical and Geoenvironmental Properties of Recycled Construction and Demolition Materials in Pavement Subbase Applications. J. Mater. Civ. Eng. 2013, 25, 1077–1088. [Google Scholar] [CrossRef]

- Vieira, C.S.; Pereira, P.M. Use of recycled construction and demolition materials in geotechnical applications: A review. Resour. Conserv. Recycl. 2015, 103, 192–204. [Google Scholar] [CrossRef]

- Han, S.; Zhao, S.; Lu, D.; Wang, D. Performance Improvement of Recycled Concrete Aggregates and Their Potential Applications in Infrastructure: A Review. Buildings 2023, 13, 1411. [Google Scholar] [CrossRef]

- Shah, S.K.H.; Uchimura, T.; Kawamoto, K. Permanent Deformation and Breakage Response of Recycled Concrete Aggregates under Cyclic Loading Subject to Moisture Change. Sustainability 2022, 14, 5427. [Google Scholar] [CrossRef]

- Santos, C.N.; Cetin, B. Saturated and unsaturated properties of recycled concrete aggregate for sustainable pavement design. Transp. Geotech. 2025, 52, 101578. [Google Scholar] [CrossRef]

- Alibeigibeni, A.; Stochino, F.; Zucca, M.; Gayarre, F.L. Enhancing Concrete Sustainability: A Critical Review of the Performance of Recycled Concrete Aggregates (RCAs) in Structural Concrete. Buildings 2025, 15, 1361. [Google Scholar] [CrossRef]

- Gabryś, K. Shear modulus and damping ratio of recycled concrete aggregate from cyclic torsional shear test. Roads Bridges 2023, 22, 387–398. [Google Scholar] [CrossRef]

- Gabryś, K.; Šadzeviĉius, R.; Dapkienė, M.; Ramukeviĉius, D.; Sas, W. Effect of a Fine Fraction on Dynamic Properties of Recycled Concrete Aggregate as a Special Anthropogenic Soil. Materials 2023, 16, 4986. [Google Scholar] [CrossRef]

- Gabryś, K.; Markowska-Lech, K.; Sas, W. Small-strain stiffness of selected anthropogenic aggregates from bender element tests. Stud. Geotech. Mech. 2024, 46, 193–206. [Google Scholar] [CrossRef]

- Arola, A. Use Recycled Concrete Aggregate in Concrete Manufacturing. Master’s Thesis, Aalto University, Espoo, Finland, 2022. Available online: https://aaltodoc.aalto.fi/server/api/core/bitstreams/5571d9b6-e937-4c9c-b8e3-4accb3b24a18/content (accessed on 31 August 2025).

- Klabacha, A. Zastosowanie Cementów z Dodatkiem Popiołu Lotnego do Produkcji Betonów Posadzkowych, Holcim Polska S.A. Available online: https://www.holcim.pl/blog/zastosowanie-cementow-z-dodatkiem-popiolu-lotnego-v-do-produkcji-betonow-posadzkowych (accessed on 31 August 2025).

- PN-EN ISO 14688-2:2018-05; Geotechnical Investigation and Testing—Identification and Classification of Soil—Part 2: Principles for a Classification (ISO 14688-2:2017). Polish Committee for Standardization: Warsaw, Poland, 2018.

- Geotechnical Software GEO5, ver. 2025.61 Educational Version; Fine Software: Prague, Czech Republic, 2025; Available online: https://www.finesoftware.eu/geotechnical-software/ (accessed on 31 August 2025).

- GEO5: Analysis of Vertical Load Bearing Capacity and Settlement of a Pile Group; Fine Software: Prague, Czech Republic; Available online: https://www.finesoftware.eu/geo5/pile-group/ (accessed on 31 August 2025).

- GEO5: Analysis of Deformation and Pile Group Dimensioning; Fine Software: Prague, Czech Republic; Available online: https://www.finesoftware.eu/geo5/pile-group/ (accessed on 31 August 2025).

- EN 1997; Eurocode 7—Geotechnical Design, European Standard. European Committee for Standardization: Brussels, Belgium, 2007.

- Dlubal Software. Wind Load Zones According to PN-EN 1991-1-4. Available online: https://www.dlubal.com/pl/strefy-obciazenia-sniegiem-wiatrem-trzesieniem-ziemi/wiatr-pn-en-1991-1-4.html#¢er=52.01193653675363.19.138183593750004&marker=52.231782.21.021438 (accessed on 31 August 2025).

- Elektrownie Vestas—Parametry. Elektroonline.pl. Available online: http://elektroonline.pl/a/1339.Elektrownie-Vestas-parametry (accessed on 31 August 2025).

- Turbiny Wiatrowe o Pionowej Osi Obrotu. Available online: https://www.rms.com.pl/oferta/turbiny-i-silownie-wiatrowe/turbiny-wiatrowe-o-pionowej-osi-obrotu/ (accessed on 31 August 2025).

- Cavalieri, F.; Bellotti, D.; Caruso, M.; Nascimbene, R. Comparative evaluation of seismic performance and environmental impact of traditional and dissipation-based retrofitting solutions for precast structures. J. Build. Eng. 2023, 79, 107918. [Google Scholar] [CrossRef]

- Jiménez, L.F.; Domínguez, J.A.; Vega-Azamar, R.E. Carbon Footprint of Recycled Aggregate Concrete. Adv. Civ. Eng. 2018, 2018, 7949741. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, Z.; Zhu, Z.; Yang, S.; Wei, J. Research progress of the recycled aggregate concrete in life cycle assessment. J. Build. Des. Environ. 2024, 2, 32570. [Google Scholar] [CrossRef]

- Sabau, M.; Bompa, D.V.; Silva, L.F.O. Comparative carbon emission assessments of recycled and natural aggregate concrete: Environmental influence of cement content. Geosci. Front. 2021, 12, 101235. [Google Scholar] [CrossRef]

- Estévez, B.G.; Aguado, A.; Josa, A. Environmental Impact of Concrete Recycling. Coming from Construction and Demolition Waste (C&DW). Available online: https://www.irbnet.de/daten/iconda/CIB865.pdf (accessed on 31 August 2025).

- Zhu, W.; Li, J.; Wang, L.; Li, X. Sustainable design of recycled concrete using shape optimization and carbon dioxide emission based on LCA. J. Civ. Eng. Manag. 2025, 31, 631–645. [Google Scholar] [CrossRef]

- Jeon, M.-K.; Kim, J.; Ham, S.-M.; Kim, S.; Han, A.T.; Kim, H.; Kwon, T.-H. CO2 treatment of recycled concrete aggregates with high mortar contents: From finding optimal treatment condition. quality enhancement. to life cycle assessment. Constr. Build. Mater. 2024, 447, 137953. [Google Scholar] [CrossRef]

- OEKOBAUDAT 2024-I. Available online: https://www.climatiq.io/data/emission-factor/7f5c9dbe-2259-4bea-8236-cefc18e83365 (accessed on 31 August 2025).

| Specimen Code | Fraction (mm) | Mean Grain Size D50 (mm) | Preparation Method | Initial Void Ratio e0 | Initial Dry Unit Weight γd0 (kN/m3) |

|---|---|---|---|---|---|

| M1_0%FF | 0.063–2.0 | 0.20 | Dry tamping | 0.61 | 16.29 |

| M2_10%FF | 0.02–1.0 | 0.16 | Dry tamping | 0.63 | 16.08 |

| M3_20%FF | 0.015–0.8 | 0.14 | Dry tamping | 0.72 | 15.43 |

| M4_30%FF | 0.015–0.6 | 0.21 | Dry tamping | 0.81 | 14.62 |

| M5_5%FF | 0.02–2.0 | 0.21 | Moist tamping | 0.74 | 14.96 |

| M6_15%FF | 0.02–1.0 | 0.18 | Moist tamping | 0.71 | 15.00 |

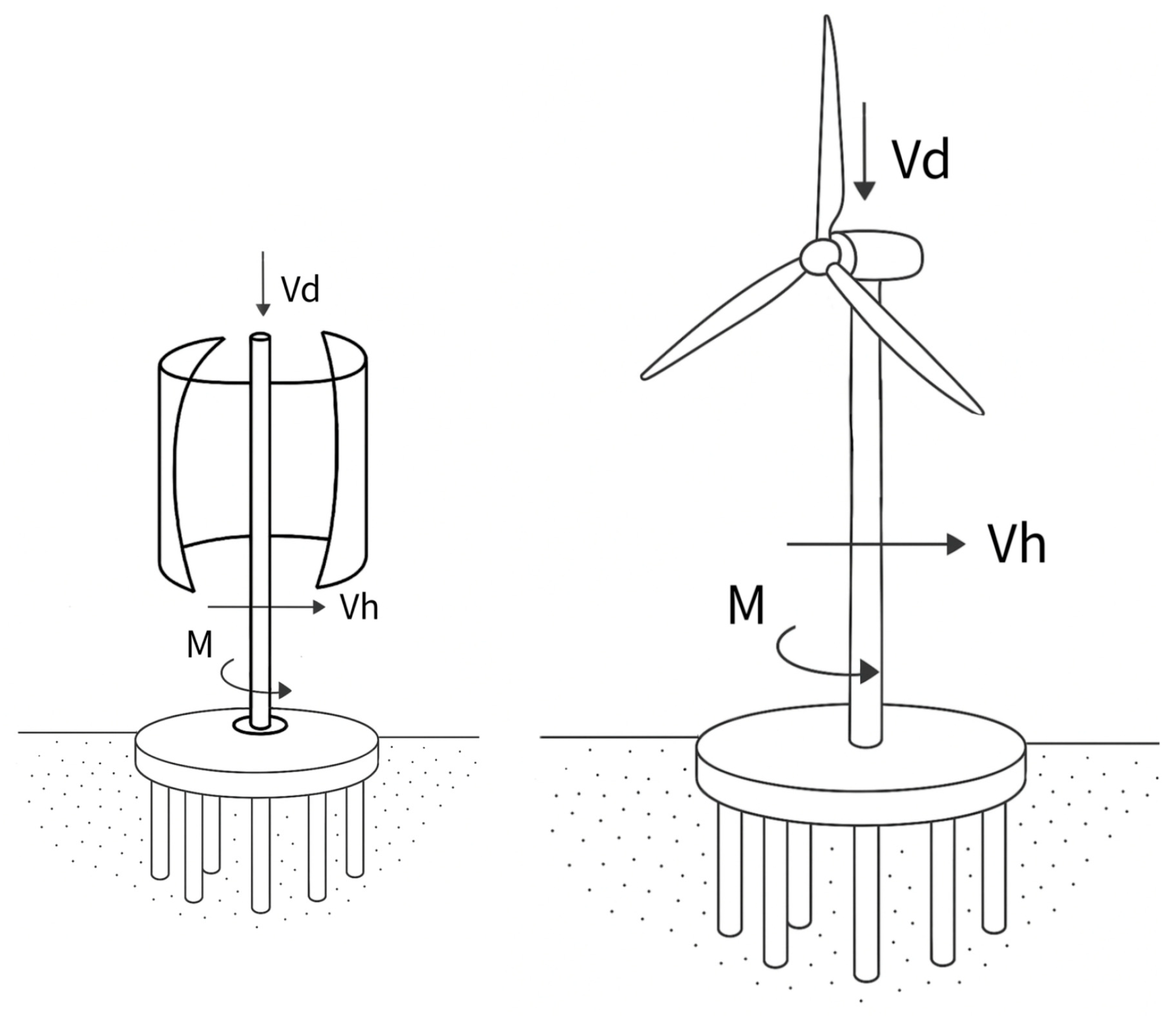

| Turbine/ Rotor Type | Power (kW) | Tower/Mast Height (m) | Rotor (for Horizontal) or Turbine (for Vertical) Diameter (m) | Rotor Weight (t) | Tower (Horizontal) or Mast (Vertical) Weight (t) | Vertical Load (kN) | Horizontal Force (kN) | Bending Moment (kNm) |

|---|---|---|---|---|---|---|---|---|

| HAWT850 | 850 | 55 | 52 | 10 | 137.5 | 1500 | 300 | 16,500 |

| HAWT1000 | 1000 | 60 | 60 | 18 | 150.0 | 1700 | 350 | 21,000 |

| HAWT2000 | 2000 | 80 | 80 | 23 | 200.0 | 2200 | 600 | 48,000 |

| VAWT1 | 1 | 5.5 | 1.8 | 0.18 | 13.75 | 140 | 2 | 11 |

| VAWT5 | 5 | 5.5 | 4 | 0.95 | 13.75 | 150 | 7 | 40 |

| VAWT10 | 10 | 11 | 6 | 1.7 | 27.50 | 300 | 16 | 180 |

| Material Type | Compressive Strength fck (MPa) | Tensile Strength fctm (MPa) | Elastic Modulus Ecm (MPa) | Shear Modulus G (MPa) |

|---|---|---|---|---|

| Recycled aggregate with 0% fine fraction content (M1_0%FF) | 8 | 1.2 | 442.5 | 177.0 |

| Recycled aggregate with 30% fine fraction content (M4_30%FF) | 8 | 1.2 | 315.5 | 126.27 |

| Concrete containing recycled aggregate | 15 | 1.5 | 15,000 | 6250 |

| Conventional concrete C25/30 | 25 | 2.6 | 31,000 | 12,917 |

| Layer No. | Layer Thickness (m) | Soil Type | Liquidity Index LI/Relative Density Dr | Bulk Density γ (kN/m3) | Effective Internal Friction Angle φ′ (°) | Cohesion c′ (kPa) | Poisson’s Ratio ν (–) |

|---|---|---|---|---|---|---|---|

| 1 | 1.20 | saCl | LI = 0.20 | 19.5 | 27.0 | 10 | 0.35 |

| 2 | 1.20 | FSa/siSa | Dr = 0.45 | 17.5 | 29.5 | - | 0.30 |

| 3 | 1.00 | grSa | Dr = 0.50 | 20.0 | 35.5 | - | 0.20 |

| 4 | 1.80 | saCl | LI = 0.20 | 18.5 | 24.5 | 14 | 0.35 |

| 5 | 4.00 | Si | LI = 0.30 | 20.0 | 21.0 | 12 | 0.40 |

| 6 | 5.90 | saCl | LI = 0.15 | 21.0 | 19.0 | 12 | 0.40 |

| 7 | 7.90 | saCl | LI = 0.10 | 21.0 | 19.0 | 12 | 0.40 |

| Turbine/ Rotor Type | Number of Piles | Pile Diameter (m) | Pile Length (m) | Foundation Radius (m) |

|---|---|---|---|---|

| HAWT850 | 20 | 0.8 | 10 | 6 |

| HAWT1000 | 22 | 0.8 | 10 | 6 |

| HAWT2000 | 24 | 1.0 | 12 | 8 |

| VAWT1 | 8 | 0.6 | 5 | 4 |

| VAWT5 | 10 | 0.6 | 6 | 5 |

| VAWT10 | 10 | 0.6 | 10 | 6 |

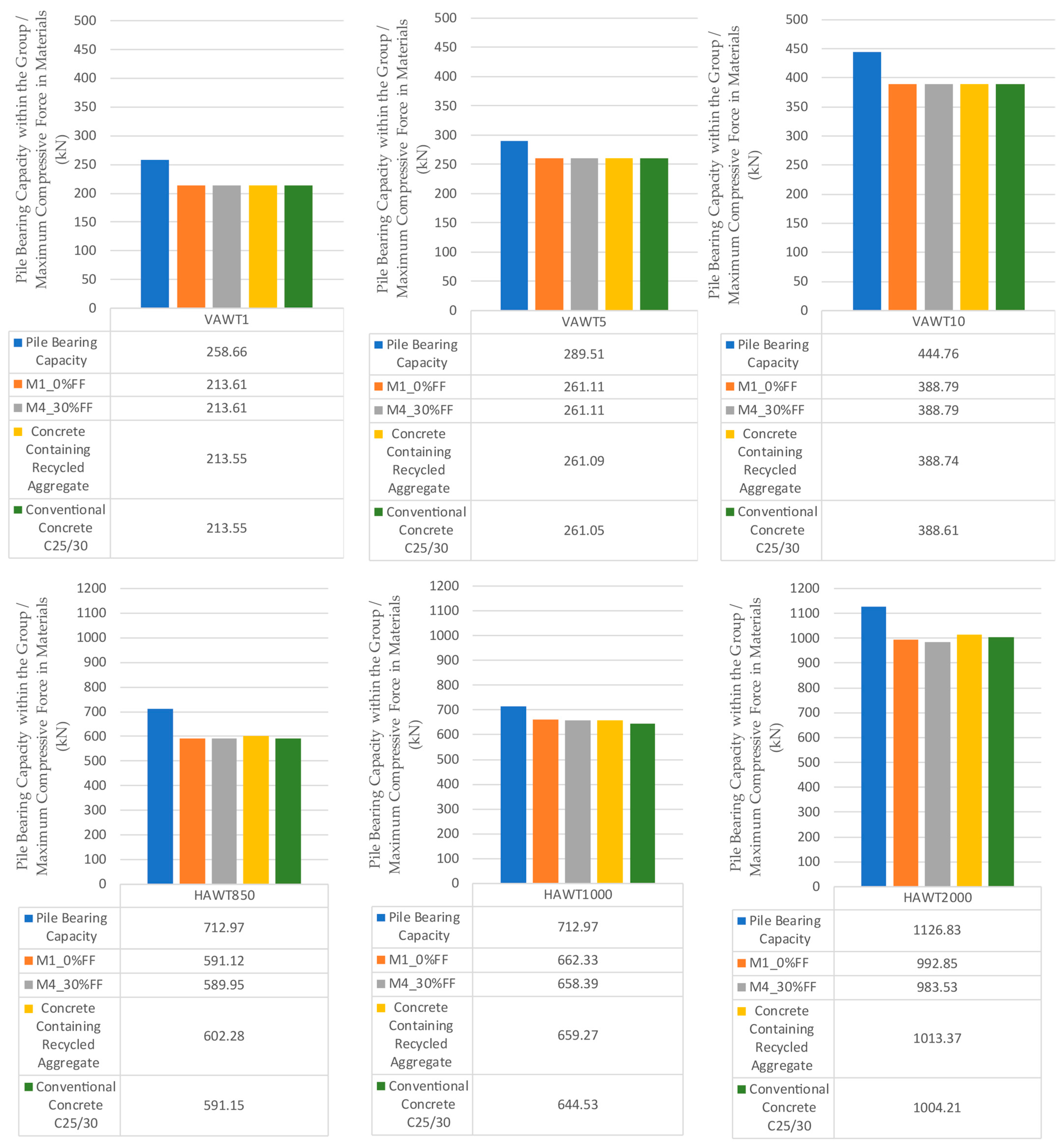

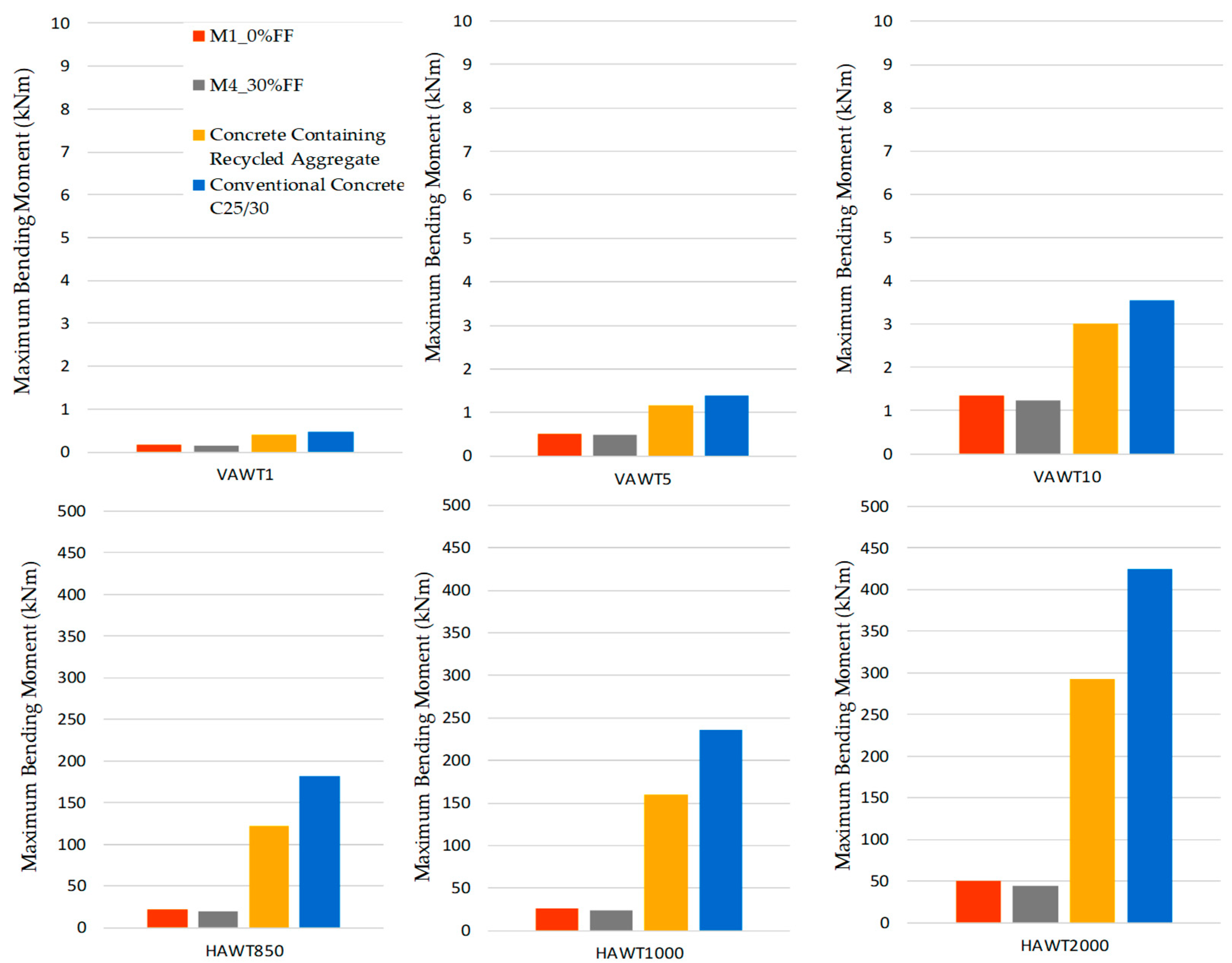

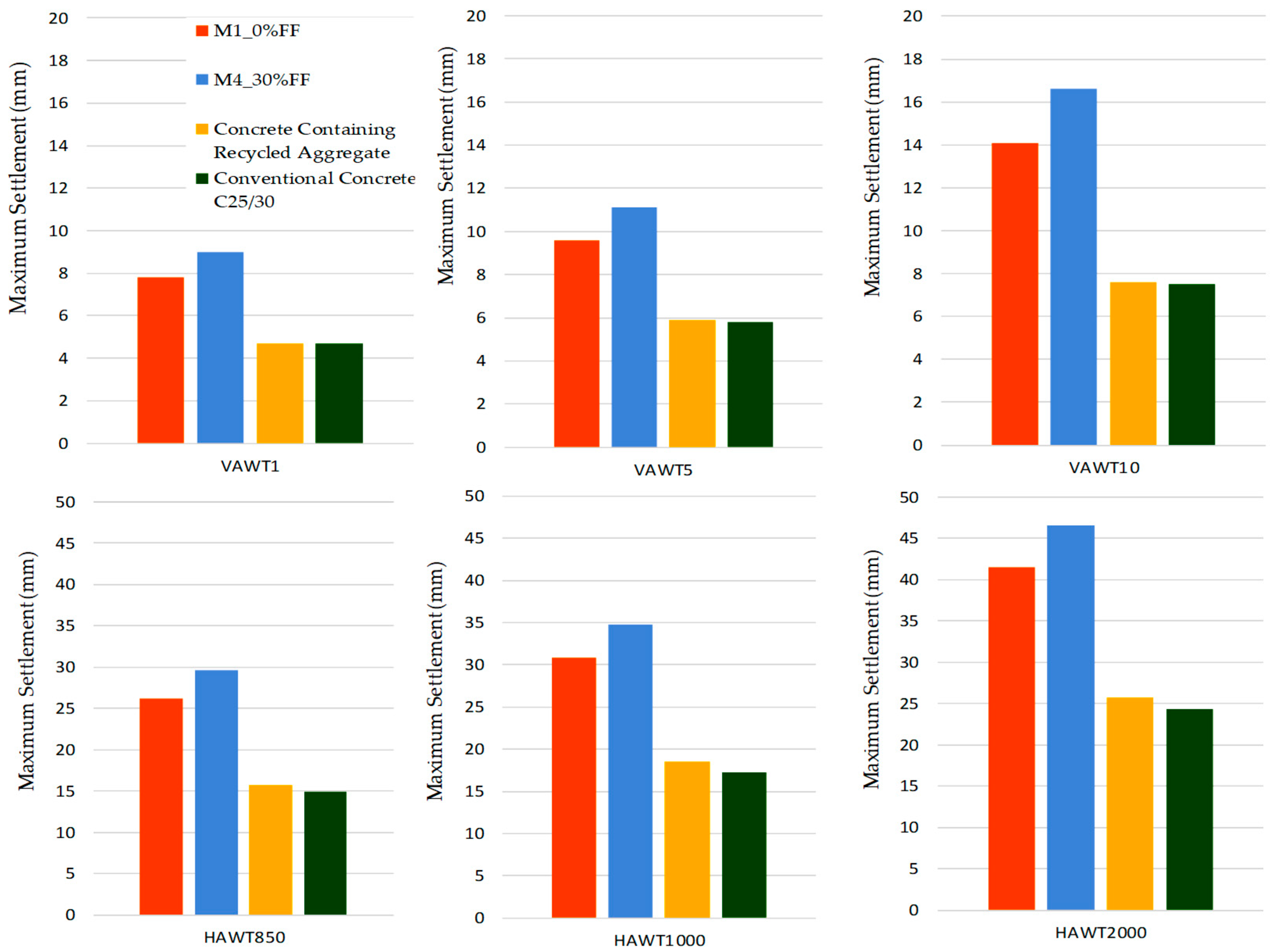

| Turbine Type | VAWT 1 | VAWT 5 | VAWT 10 | HAWT 850 | HAWT 1000 | HAWT 2000 |

|---|---|---|---|---|---|---|

| Maximum Compressive Force Vd (kN) | 213.61 | 261.11 | 388.79 | 591.12 | 662.33 | 992.85 |

| Maximum Tensile Force (kN) | 23.77 | 21.5 | 45.31 | 159.48 | 206.57 | 312.06 |

| Maximum Bending Moment (kNm) | 0.17 | 0.52 | 1.34 | 22.01 | 25.84 | 49.85 |

| Maximum Shear Force (kN) | 0.25 | 0.7 | 1.6 | 15 | 15.91 | 25 |

| Maximum Settlement (mm) | 7.8 | 9.6 | 14.1 | 26.2 | 30.9 | 41.5 |

| Maximum Horizontal Displacement (mm) | 0 | 0.1 | 0.4 | 3.9 | 4.6 | 5.7 |

| Maximum Slab Rotation (°) | 0.00053 | 0.00082 | 0.0023 | 0.14 | 0.18 | 0.17 |

| Pile Bearing Capacity within the Group Rc (kN) | 289.51 | 289.51 | 444.76 | 712.97 | 712.97 | 1126.83 |

| Load-Bearing Capacity Criterion | 1.36 Satisfied | 1.11 Satisfied | 1.14 Satisfied | 1.21 Satisfied | 1.08 Satisfied | 1.13 Satisfied |

| Turbine Type | VAWT 1 | VAWT 5 | VAWT 10 | HAWT 850 | HAWT 1000 | HAWT 2000 |

|---|---|---|---|---|---|---|

| Maximum Compressive Force Vd (kN) | 213.61 | 261.11 | 388.79 | 589.95 | 658.39 | 983.57 |

| Maximum Tensile Force (kN) | 21.54 | 19.46 | 37.4 | 160.86 | 209.24 | 317.57 |

| Maximum Bending Moment (kNm) | 0.16 | 0.48 | 1.24 | 19.93 | 23.2 | 44.86 |

| Maximum Shear Force (kN) | 0.25 | 0.7 | 1.6 | 15 | 15.91 | 25 |

| Maximum Settlement (mm) | 9 | 11.1 | 16.6 | 29.6 | 34.8 | 46.6 |

| Maximum Horizontal Displacement (mm) | 0 | 0.1 | 0.4 | 4.2 | 5 | 6.1 |

| Maximum Slab Rotation (°) | 0.00062 | 0.00096 | 0.0027 | 0.16 | 0.21 | 0.19 |

| Pile Bearing Capacity within the Group Rc (kN) | 289.51 | 289.51 | 444.76 | 712.97 | 712.97 | 1126.83 |

| Load-Bearing Capacity Criterion | 1.36 Satisfied | 1.11 Satisfied | 1.14 Satisfied | 1.21 Satisfied | 1.08 Satisfied | 1.14 Satisfied |

| Turbine Type | VAWT 1 | VAWT 5 | VAWT 10 | HAWT 850 | HAWT 1000 | HAWT 2000 |

|---|---|---|---|---|---|---|

| Maximum Compressive Force Vd (kN) | 213.55 | 261.09 | 388.74 | 602.28 | 659.27 | 1013.37 |

| Maximum Tensile Force (kN) | 30.47 | 27.8 | 78.6 | 121.86 | 160.93 | 241.14 |

| Maximum Bending Moment (kNm) | 0.4 | 1.16 | 3 | 121.82 | 159.29 | 292.99 |

| Maximum Shear Force (kN) | 0.25 | 0.7 | 1.6 | 18.89 | 24.87 | 37.76 |

| Maximum Settlement (mm) | 4.7 | 5.9 | 7.6 | 15.7 | 18.5 | 25.7 |

| Maximum Horizontal Displacement (mm) | 0 | 0.1 | 0.1 | 3.5 | 4.6 | 5.1 |

| Maximum Slab Rotation (°) | 0.00029 | 0.00047 | 0.0011 | 0.076 | 0.099 | 0.086 |

| Pile Bearing Capacity within the Group Rc (kN) | 258.66 | 289.51 | 444.76 | 712.97 | 712.97 | 1126.83 |

| Load-Bearing Capacity Criterion | 1.21 Satisfied | 1.11 Satisfied | 1.14 Satisfied | 1.18 Satisfied | 1.08 Satisfied | 1.11 Satisfied |

| Turbine Type | VAWT 1 | VAWT 5 | VAWT 10 | HAWT 850 | HAWT 1000 | HAWT 2000 |

|---|---|---|---|---|---|---|

| Maximum Compressive Force Vd (kN) | 213.55 | 261.05 | 388.61 | 591.15 | 644.53 | 1004.21 |

| Maximum Tensile Force (kN) | 30.59 | 27.92 | 79.41 | 103.54 | 140.45 | 213.15 |

| Maximum Bending Moment (kNm) | 0.47 | 1.38 | 3.55 | 181.72 | 235.48 | 424.58 |

| Maximum Shear Force (kN) | 0.25 | 0.7 | 1.6 | 27.73 | 36.18 | 54.5 |

| Maximum Settlement (mm) | 4.7 | 5.8 | 7.5 | 14.9 | 17.3 | 24.3 |

| Maximum Horizontal Displacement (mm) | 0 | 0 | 0.1 | 3.8 | 4.9 | 5.5 |

| Maximum Slab Rotation (°) | 0.00028 | 0.00046 | 0.0011 | 0.068 | 0.088 | 0.076 |

| Pile Bearing Capacity within the Group Rc (kN) | 258.66 | 289.51 | 444.76 | 712.97 | 712.97 | 1126.83 |

| Load-Bearing Capacity Criterion | 1.21 Satisfied | 1.11 Satisfied | 1.14 Satisfied | 1.21 Satisfied | 1.11 Satisfied | 1.12 Satisfied |

| Turbine/ Rotor Type | Concrete Volume per Single Structure (m3) | CO2 Emissions for Single Structure of C25/30 Concrete * (kg CO2) | CO2 Emissions for Wind Farm Foundations (kg CO2) | CO2 Emission Reduction for RCA (kg CO2) | CO2 Emission Reduction for Aggregate (kg CO2) |

|---|---|---|---|---|---|

| HAWT850 | 128.81 | 1148.04 | 22,960.83 | 4592.17 | 6888.25 |

| HAWT1000 | 138.86 | 1237.64 | 24,752.90 | 4950.58 | 7425.87 |

| HAWT2000 | 216.77 | 1932.07 | 38,641.40 | 7728.28 | 11,592.42 |

| VAWT1 | 23.88 | 212.81 | 4256.15 | 851.23 | 1276.85 |

| VAWT5 | 36.60 | 326.21 | 6524.24 | 1304.85 | 1957.27 |

| VAWT10 | 56.55 | 504.02 | 10,080.37 | 2016.07 | 3024.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markowska-Lech, K.; Gabryś, K.; Lech, M. Ground Improvement Using Recycled Concrete Columns: A Case Study of Wind Turbine Foundation. Buildings 2025, 15, 3752. https://doi.org/10.3390/buildings15203752

Markowska-Lech K, Gabryś K, Lech M. Ground Improvement Using Recycled Concrete Columns: A Case Study of Wind Turbine Foundation. Buildings. 2025; 15(20):3752. https://doi.org/10.3390/buildings15203752

Chicago/Turabian StyleMarkowska-Lech, Katarzyna, Katarzyna Gabryś, and Mariusz Lech. 2025. "Ground Improvement Using Recycled Concrete Columns: A Case Study of Wind Turbine Foundation" Buildings 15, no. 20: 3752. https://doi.org/10.3390/buildings15203752

APA StyleMarkowska-Lech, K., Gabryś, K., & Lech, M. (2025). Ground Improvement Using Recycled Concrete Columns: A Case Study of Wind Turbine Foundation. Buildings, 15(20), 3752. https://doi.org/10.3390/buildings15203752