The Effect of Critical Factors on Team Performance of Human–Robot Collaboration in Construction Projects: A PLS-SEM Approach

Abstract

1. Introduction

2. Literature Review

2.1. Development of HRC in Construction

2.2. Factors of HRC Team Performance in Construction

2.2.1. Human-Level Factors

2.2.2. Robot-Level Factors

2.2.3. Task-Level Factors

2.2.4. Interactive Effects

2.3. PLS-SEM Modeling in Construction

2.4. Knowledge Gap in the Literature

3. Research Methodology

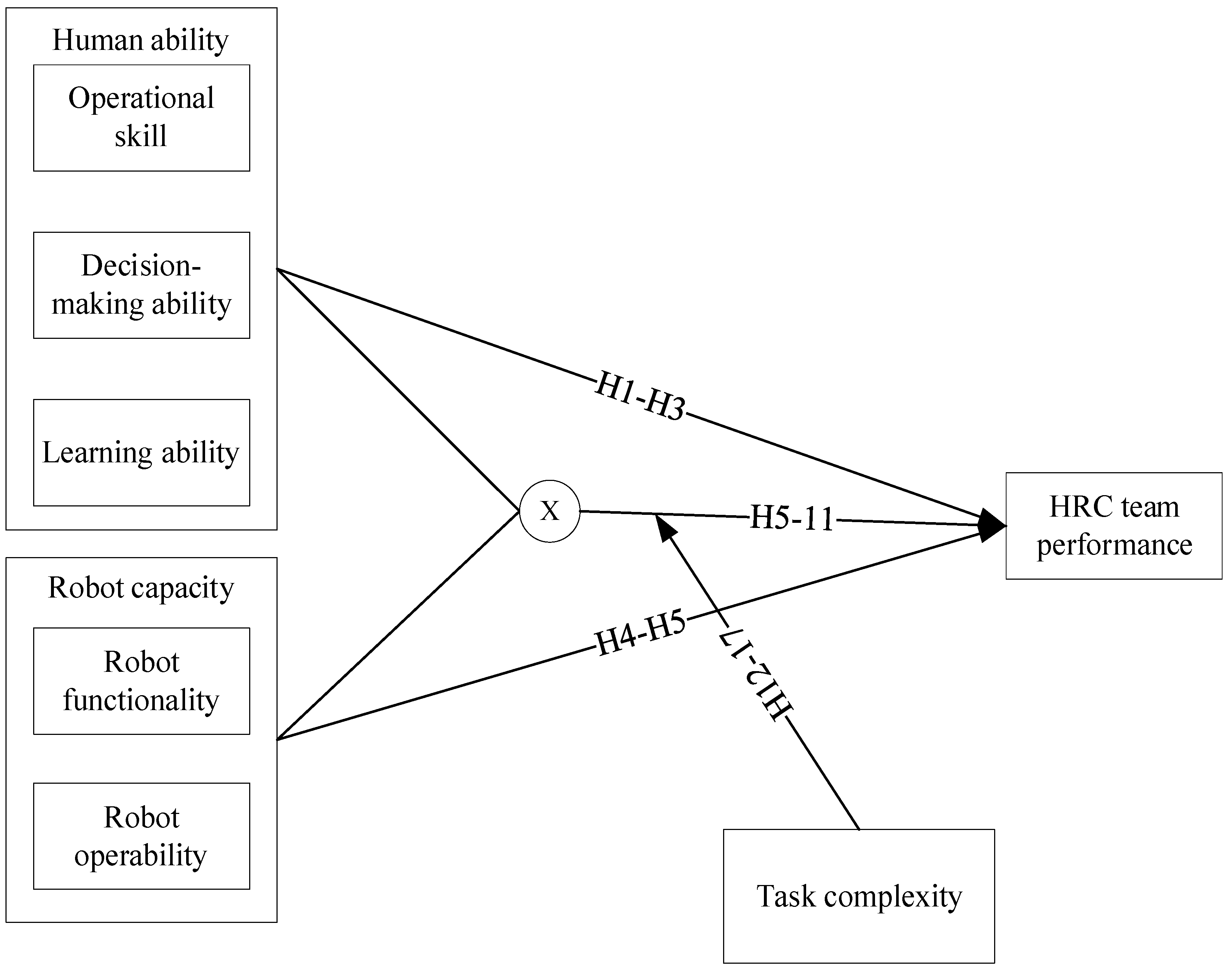

4. Conceptual Framework and Hypotheses Development

4.1. Related Theory Foundations

4.2. Identification of Related Factors

4.3. Hypotheses Development

4.4. Robot Technology Scope

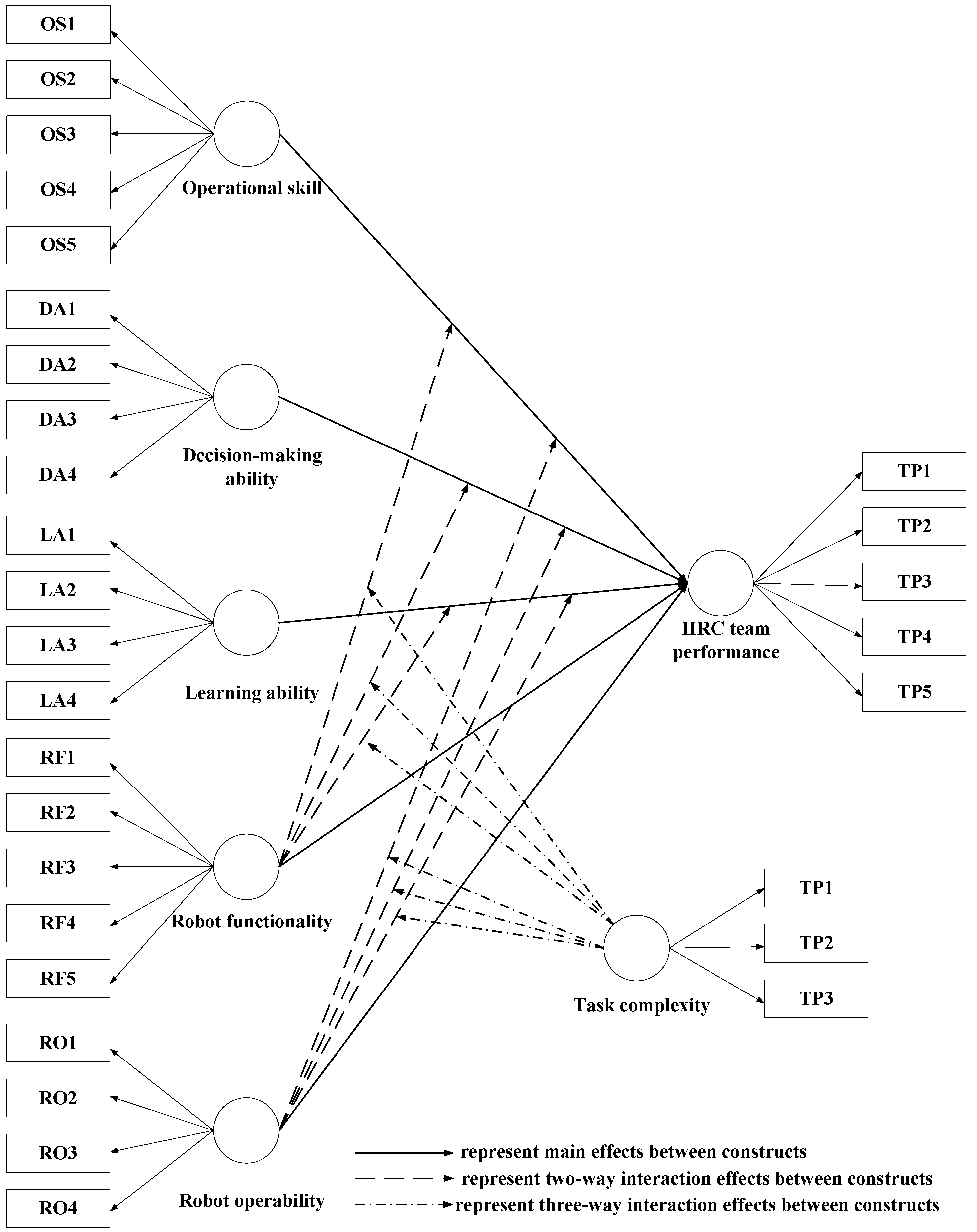

5. Developing PLS-SEM Model

5.1. Pilot Study and Pre-Survey Analysis

5.2. Questionnaire Sampling

5.3. Sample Demographics

5.4. Survey Instrument

5.5. Data Analysis Techniques

6. Results

6.1. Reliability and Validity of Measures

6.2. Structural Model and Hypothesis Testing

6.2.1. Main Effects

6.2.2. Two-Way Interaction Effects

6.2.3. Three-Way Interaction Effects

6.2.4. Summary of Hypothesis Testing

6.3. Interpretation of Interaction Effects

7. Discussion

7.1. Positioning the Findings Within HRC and Socio-Technical Literature

7.2. Theoretical Implications

7.3. Practical Implications for Construction Management and Robotics Implementation

7.3.1. Implications of Significant Interactions for Managers and Project Teams

7.3.2. Investment in Both Human Abilities and Robot Capabilities

7.3.3. Prioritization of Robot Operability

7.3.4. Context-Specific Guidance for HRC Deployment

7.3.5. Cost–Benefit Considerations for HRC Deployment

7.4. Limitations and Future Research Directions

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HRC | Human–Robot Collaboration |

| STCR | Single-Task Construction Robot |

| HRT | Human–Robot Team |

| TTF | Task–Technology Fit |

| TAM | Technology Acceptance Model |

| TPC | Technology-to-Performance Chain |

| HRI | Human–Robot Interaction |

| PLS-SEM | Partial Least Squares Structural Equation Modeling |

| OS | Operational skill |

| DA | Decision-making ability |

| LA | Learning ability |

| RF | Robot functionality |

| RO | Robot Operability |

| TC | Task complexity |

| HTP | HRC Team Performance |

| CR | Composite Reliability |

| AVE | Average Variance Extracted |

| HTMT | Heterotrait–Monotrait |

| R2 | Coefficient of Determination |

| β | Standardized Path Coefficient |

| Δ | Difference |

References

- Odeh, I.; Tsai, O. Is Construction Future-ready? 3 Key Insights on the Sector’s Digital Transformation. Available online: https://www.weforum.org/stories/2025/07/construction-sector-digital-transformation/ (accessed on 6 July 2025).

- Lingard, H. Occupational health and safety in the construction industry. Constr. Manag. Econ. 2013, 31, 505–514. [Google Scholar] [CrossRef]

- Wanberg, J.; Harper, C.; Hallowell Matthew, R.; Rajendran, S. Relationship between Construction Safety and Quality Performance. J. Constr. Eng. Manag. 2013, 139, 04013003. [Google Scholar] [CrossRef]

- Hasan, A.; Baroudi, B.; Elmualim, A.; Rameezdeen, R. Factors affecting construction productivity: A 30 year systematic review. Eng. Constr. Archit. Manag. 2018, 25, 916–937. [Google Scholar] [CrossRef]

- Xiao, B.; Chen, C.; Yin, X. Recent advancements of robotics in construction. Autom. Constr. 2022, 144, 104591. [Google Scholar] [CrossRef]

- Kumar, S.; Savur, C.; Sahin, F. Survey of human–robot collaboration in industrial settings: Awareness, intelligence, and compliance. IEEE Trans. Syst. Man Cybern. Syst. 2020, 51, 280–297. [Google Scholar] [CrossRef]

- Liang, X.; Rasheed, U.; Cai, J.; Wibranek, B.; Awolusi, I. Impacts of Collaborative Robots on Construction Work Performance and Worker Perception: Experimental Analysis of Human–Robot Collaborative Wood Assembly. J. Constr. Eng. Manag. 2024, 150, 04024087. [Google Scholar] [CrossRef]

- Xu, J.; Sun, Q.; Han, Q.-L.; Tang, Y. When embodied AI meets Industry 5.0: Human-centered smart manufacturing. IEEE/CAA J. Autom. Sin. 2025, 12, 485–501. [Google Scholar] [CrossRef]

- Asadi, K.; Suresh, A.K.; Ender, A.; Gotad, S.; Maniyar, S.; Anand, S.; Noghabaei, M.; Han, K.; Lobaton, E.; Wu, T. An integrated UGV-UAV system for construction site data collection. Autom. Constr. 2020, 112, 103068. [Google Scholar] [CrossRef]

- Robotics, A.C. Rebar Tools: TyBot and IronBot. Available online: https://www.constructionrobots.com (accessed on 6 July 2025).

- Robotics, C. SAM: Semi-Automated Mason. Available online: https://www.construction-robotics.com (accessed on 6 July 2025).

- Delgado, J.M.D.; Oyedele, L.; Ajayi, A.; Akanbi, L.; Akinade, O.; Bilal, M.; Owolabi, H. Robotics and automated systems in construction: Understanding industry-specific challenges for adoption. J. Build. Eng. 2019, 26, 100868. [Google Scholar] [CrossRef]

- Hopko, S.; Wang, J.; Mehta, R. Human factors considerations and metrics in shared space human-robot collaboration: A systematic review. Front. Robot. AI 2022, 9, 799522. [Google Scholar] [CrossRef]

- Yan, Y.; Jia, Y. A review on human comfort factors, measurements, and improvements in human–robot collaboration. Sensors 2022, 22, 7431. [Google Scholar] [CrossRef]

- Charalambous, G.; Fletcher, S.; Webb, P. Identifying the key organisational human factors for introducing human-robot collaboration in industry: An exploratory study. Int. J. Adv. Manuf. Technol. 2015, 81, 2143–2155. [Google Scholar] [CrossRef]

- Liu, Y.; Caldwell, G.; Rittenbruch, M.; Belek Fialho Teixeira, M.; Burden, A.; Guertler, M. What Affects Human Decision Making in Human–Robot Collaboration?: A Scoping Review. Robotics 2024, 13, 30. [Google Scholar] [CrossRef]

- Ramirez-Amaro, K.; Torre, I.; Diehl, M.; Dean, E. The Importance of Human Factors for Trusted Human-Robot Collaborations. In Proceedings of the 11th International Conference on Human-Agent Interaction, Gothenburg, Sweden, 4–7 December 2023; pp. 502–503. [Google Scholar]

- Ekyalimpa, R.; Okello, E.; Siraj, N.B.; Lei, Z.; Liu, H. Towards human–robot collaboration in construction: Understanding brickwork production rate factors. Buildings 2023, 13, 3087. [Google Scholar] [CrossRef]

- Di Pasquale, V.; De Simone, V.; Giubileo, V.; Miranda, S. A taxonomy of factors influencing worker’s performance in human–robot collaboration. IET Collab. Intell. Manuf. 2023, 5, e12069. [Google Scholar] [CrossRef]

- Pietrantoni, L.; Favilla, M.; Fraboni, F.; Mazzoni, E.; Morandini, S.; Benvenuti, M.; De Angelis, M. Integrating collaborative robots in manufacturing, logistics, and agriculture: Expert perspectives on technical, safety, and human factors. Front. Robot. AI 2024, 11, 1342130. [Google Scholar] [CrossRef]

- Liang, C.-J.; Wang, X.; Kamat Vineet, R.; Menassa Carol, C. Human–Robot Collaboration in Construction: Classification and Research Trends. J. Constr. Eng. Manag. 2021, 147, 03121006. [Google Scholar] [CrossRef]

- Li, S.; Zheng, P.; Liu, S.; Wang, Z.; Wang, X.V.; Zheng, L.; Wang, L. Proactive human–robot collaboration: Mutual-cognitive, predictable, and self-organising perspectives. Robot. Comput.-Integr. Manuf. 2023, 81, 102510. [Google Scholar] [CrossRef]

- Xia, P.; Xu, F.; Zhou, T.; Du, J. Benchmarking Human versus Robot Performance in Emergency Structural Inspection. J. Constr. Eng. Manag. 2022, 148, 04022070. [Google Scholar] [CrossRef]

- Malik, A.A.; Bilberg, A. Complexity-based task allocation in human-robot collaborative assembly. Ind. Robot. Int. J. Robot. Res. Appl. 2019, 46, 471–480. [Google Scholar] [CrossRef]

- Zeng, N.; Liu, Y.; Gong, P.; Hertogh, M.; König, M. Do right PLS and do PLS right: A critical review of the application of PLS-SEM in construction management research. Front. Eng. Manag. 2021, 8, 356–369. [Google Scholar] [CrossRef]

- Liu, J.; Luo, H.; Wu, D. Human–Robot collaboration in construction: Robot design, perception and Interaction, and task allocation and execution. Adv. Eng. Inform. 2025, 65, 103109. [Google Scholar] [CrossRef]

- Wu, Z.; Liao, Q.; Chen, K.; Antwi-Afari, M.F.; Chen, Y.; Bao, Z. A systematic review of digital auxiliary technologies enabling human–robot collaboration in construction. Eng. Constr. Archit. Manag. 2025. [Google Scholar] [CrossRef]

- Bock, T.; Linner, T. Construction Robots: Elementary Technologies and Single-Task Construction Robots; Cambridge University Press: Cambridge, UK, 2016. [Google Scholar]

- Salmi, T.; Ahola, J.M.; Heikkilä, T.; Kilpeläinen, P.; Malm, T. Human-Robot Collaboration and Sensor-Based Robots in Industrial Applications and Construction. In Robotic Building; Bier, H., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 25–52. [Google Scholar]

- Liu, Y.; A.H., A.; Haron, N.A.; N.A., B.; Wang, H. Robotics in the Construction Sector: Trends, Advances, and Challenges. J. Intell. Robot. Syst. 2024, 110, 72. [Google Scholar] [CrossRef]

- Zeng, L.; Guo, S.; Wu, J.; Markert, B. Autonomous mobile construction robots in built environment: A comprehensive review. Dev. Built Environ. 2024, 19, 100484. [Google Scholar] [CrossRef]

- Ghodsian, N.; Benfriha, K.; Olabi, A.; Gopinath, V.; Talhi, E.; Hof, L.A.; Arnou, A. A framework to integrate mobile manipulators as cyber–physical systems into existing production systems in the context of industry 4.0. Robot. Auton. Syst. 2023, 169, 104526. [Google Scholar] [CrossRef]

- Halder, S.; Afsari, K.; Chiou, E.; Patrick, R.; Hamed, K.A. Construction inspection & monitoring with quadruped robots in future human-robot teaming: A preliminary study. J. Build. Eng. 2023, 65, 105814. [Google Scholar] [CrossRef]

- Halder, S.; Afsari, K.; Serdakowski, J.; DeVito, S.; Ensafi, M.; Thabet, W. Real-Time and Remote Construction Progress Monitoring with a Quadruped Robot Using Augmented Reality. Buildings 2022, 12, 2027. [Google Scholar] [CrossRef]

- Jin, J.; Zhang, W.; Li, F.; Li, M.; Shi, Y.; Guo, Z.; Huang, Q. Robotic binding of rebar based on active perception and planning. Autom. Constr. 2021, 132, 103939. [Google Scholar] [CrossRef]

- Momeni, M.; Relefors, J.; Khatry, A.; Pettersson, L.; Papadopoulos, A.V.; Nolte, T. Automated fabrication of reinforcement cages using a robotized production cell. Autom. Constr. 2022, 133, 103990. [Google Scholar] [CrossRef]

- Tan, X.; Xiong, L.; Zhang, W.; Zuo, Z.; He, X.; Xu, Y.; Li, F. Rebar-tying Robot based on machine vision and coverage path planning. Robot. Auton. Syst. 2024, 182, 104826. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, B.; Dong, B.; Wen, Y.; Duan, M. Dynamic robotic bricklaying force-position control considering mortar dynamics for enhanced consistency. Autom. Constr. 2025, 174, 106090. [Google Scholar] [CrossRef]

- Ercan Jenny, S.; Pietrasik, L.L.; Sounigo, E.; Tsai, P.-H.; Gramazio, F.; Kohler, M.; Lloret-Fritschi, E.; Hutter, M. Continuous Mobile Thin-Layer On-Site Printing. Autom. Constr. 2023, 146, 104634. [Google Scholar] [CrossRef]

- Wang, Y.; Xie, L.; Wang, H.; Zeng, W.; Ding, Y.; Hu, T.; Zheng, T.; Liao, H.; Hu, J. Intelligent spraying robot for building walls with mobility and perception. Autom. Constr. 2022, 139, 104270. [Google Scholar] [CrossRef]

- Fascetti, A.; Latteur, P.; Lim, S.H. Ground-based automated construction of droxel structures: An experimental approach. Autom. Constr. 2021, 131, 103899. [Google Scholar] [CrossRef]

- Jud, D.; Kerscher, S.; Wermelinger, M.; Jelavic, E.; Egli, P.; Leemann, P.; Hottiger, G.; Hutter, M. HEAP–The autonomous walking excavator. Autom. Constr. 2021, 129, 103783. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, J.; Feng, C.; Wang, Q. Hybrid-driven autonomous excavator trajectory generation combining empirical driver skills and optimization. Autom. Constr. 2024, 165, 105523. [Google Scholar] [CrossRef]

- Okada, T.; Yamamoto, T.; Doi, T.; Koiwai, K.; Yamashita, K. Database-driven model predictive control system for online adaptation of an autonomous excavator to environmental conditions. Control. Eng. Pract. 2024, 145, 105843. [Google Scholar] [CrossRef]

- Okpala, I.; Nnaji, C.; Gambatese, J. Assessment Tool for Human–Robot Interaction Safety Risks during Construction Operations. J. Constr. Eng. Manag. 2023, 149, 04022145. [Google Scholar] [CrossRef]

- Menendez, E.; Victores, J.G.; Montero, R.; Martínez, S.; Balaguer, C. Tunnel structural inspection and assessment using an autonomous robotic system. Autom. Constr. 2018, 87, 117–126. [Google Scholar] [CrossRef]

- Lattanzi, D.; Miller, G. Review of Robotic Infrastructure Inspection Systems. J. Infrastruct. Syst. 2017, 23, 04017004. [Google Scholar] [CrossRef]

- Ge, L.; Sadhu, A. Deep learning-enhanced smart ground robotic system for automated structural damage inspection and mapping. Autom. Constr. 2025, 170, 105951. [Google Scholar] [CrossRef]

- Mirzaei, K.; Arashpour, M.; Asadi, E.; Feng, H.; Mohandes, S.R.; Bazli, M. Automatic compliance inspection and monitoring of building structural members using multi-temporal point clouds. J. Build. Eng. 2023, 72, 106570. [Google Scholar] [CrossRef]

- Zhao, Y.; Lu, B.; Alipour, M. Optimized structural inspection path planning for automated unmanned aerial systems. Autom. Constr. 2024, 168, 105764. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, Y.; Han, S.; Li, H.; Han, D.; Yang, X.; Guo, N. LiDAR-Based Framework for Accurate Positioning and Robust Tracking of Multiple Construction Workers. J. Comput. Civ. Eng. 2025, 39, 04025027. [Google Scholar] [CrossRef]

- Guo, J.; Wang, Q.; Park, J.-H. Geometric quality inspection of prefabricated MEP modules with 3D laser scanning. Autom. Constr. 2020, 111, 103053. [Google Scholar] [CrossRef]

- Wang, Q.; Li, J.; Tang, X.; Zhang, X. How data quality affects model quality in scan-to-BIM: A case study of MEP scenes. Autom. Constr. 2022, 144, 104598. [Google Scholar] [CrossRef]

- Yue, H.; Wang, Q.; Zhao, Z.; Lai, S.; Huang, G. Interactions between BIM and robotics: Towards intelligent construction engineering and management. Comput. Ind. 2025, 169, 104299. [Google Scholar] [CrossRef]

- Ren, Z.; Kim, J.I. The Role of AI in On-Site Construction Robotics: A State-of-the-Art Review Using the Sense–Think–Act Framework. Buildings 2025, 15, 2374. [Google Scholar] [CrossRef]

- Park, S.; Yoon, S.; Ju, S.; Heo, J. BIM-based scan planning for scanning with a quadruped walking robot. Autom. Constr. 2023, 152, 104911. [Google Scholar] [CrossRef]

- Halder, S.; Afsari, K.; Serdakowski, J.; DeVito, S.; King, R. Accuracy Estimation for Autonomous Navigation of a Quadruped Robot in Construction Progress Monitoring. In Computing in Civil Engineering 2021; Proceedings; American Society of Civil Engineers: Reston, VA, USA, 2022; pp. 1092–1100. [Google Scholar]

- Asadi, K.; Haritsa Varun, R.; Han, K.; Ore, J.-P. Automated Object Manipulation Using Vision-Based Mobile Robotic System for Construction Applications. J. Comput. Civ. Eng. 2021, 35, 04020058. [Google Scholar] [CrossRef]

- Zhang, G.; Luo, X.; Zhang, L.; Li, W.; Wang, W.; Li, Q. A Framework of Indicators for Assessing Team Performance of Human–Robot Collaboration in Construction Projects. Buildings 2025, 15, 2734. [Google Scholar] [CrossRef]

- Wu, M.; Lin, J.-R.; Zhang, X.-H. How human-robot collaboration impacts construction productivity: An agent-based multi-fidelity modeling approach. Adv. Eng. Inform. 2022, 52, 101589. [Google Scholar] [CrossRef]

- Chen, C.; Li, X.; Yao, W.; Wang, Z.; Zhu, H. Analysis of the impact of construction robots on workers’ health. Build. Environ. 2022, 225, 109595. [Google Scholar] [CrossRef]

- You, S.; Kim, J.-H.; Lee, S.; Kamat, V.; Robert, L.P. Enhancing perceived safety in human–robot collaborative construction using immersive virtual environments. Autom. Constr. 2018, 96, 161–170. [Google Scholar] [CrossRef]

- Matheson, E.; Minto, R.; Zampieri, E.G.; Faccio, M.; Rosati, G. Human–robot collaboration in manufacturing applications: A review. Robotics 2019, 8, 100. [Google Scholar] [CrossRef]

- Baltrusch, S.J.; Krause, F.; de Vries, A.W.; van Dijk, W.; de Looze, M.P. What about the human in human robot collaboration? Ergonomics 2022, 65, 719–740. [Google Scholar] [CrossRef] [PubMed]

- Hinds, P.J.; Roberts, T.L.; Jones, H. Whose job is it anyway? A study of human-robot interaction in a collaborative task. Hum.–Comput. Interact. 2004, 19, 151–181. [Google Scholar] [CrossRef]

- Kopp, T.; Baumgartner, M.; Kinkel, S. Success factors for introducing industrial human-robot interaction in practice: An empirically driven framework. Int. J. Adv. Manuf. Technol. 2021, 112, 685–704. [Google Scholar] [CrossRef]

- Molitor, M.; Renkema, M. Human-Robot Collaboration in a Smart Industry Context: Does HRM Matter? Smart Ind.—Better Manag. 2022, 28, 105–123. [Google Scholar] [CrossRef]

- Zamboni, M.; Valente, A. Collaborative robots: Overview and future trends. In Industrial Robots: Design, Applications and Technology; Nova Science Publishers: Hauppauge, NY, USA, 2020; pp. 171–199. [Google Scholar]

- Robla-Gómez, S.; Becerra, V.M.; Llata, J.R.; Gonzalez-Sarabia, E.; Torre-Ferrero, C.; Perez-Oria, J. Working together: A review on safe human-robot collaboration in industrial environments. IEEE Access 2017, 5, 26754–26773. [Google Scholar] [CrossRef]

- Menekse, M.; Higashi, R.; Schunn, C.D.; Baehr, E. The Role of Robotics Teams’ Collaboration Quality on Team Performance in a Robotics Tournament. J. Eng. Educ. 2017, 106, 564–584. [Google Scholar] [CrossRef]

- Taheri, A.; Khatiri, S.; Seyyedzadeh, A.; Ghorbandaei Pour, A.; Siamy, A.; Meghdari, A.F. Investigating the Impact of Human-Robot Collaboration on Creativity and Team Efficiency: A Case Study on Brainstorming in Presence of Robots. In Proceedings of the International Conference on Social Robotics, Doha, Qatar, 3–7 December 2023; pp. 94–103. [Google Scholar]

- Lin, C.J.; Lukodono, R.P. Learning performance and physiological feedback-based evaluation for human–robot collaboration. Appl. Ergon. 2025, 124, 104425. [Google Scholar] [CrossRef]

- Noormohammadi-Asl, A.; Fan, K.; Smith, S.L.; Dautenhahn, K. Human leading or following preferences: Effects on human perception of the robot and the human–robot collaboration. Robot. Auton. Syst. 2025, 183, 104821. [Google Scholar] [CrossRef]

- Simone, V.D.; Pasquale, V.D.; Giubileo, V.; Miranda, S. Human-Robot Collaboration: An analysis of worker’s performance. Procedia Comput. Sci. 2022, 200, 1540–1549. [Google Scholar] [CrossRef]

- Giallanza, A.; La Scalia, G.; Micale, R.; La Fata, C.M. Occupational health and safety issues in human-robot collaboration: State of the art and open challenges. Saf. Sci. 2024, 169, 106313. [Google Scholar] [CrossRef]

- Maurtua, I.; Ibarguren, A.; Kildal, J.; Susperregi, L.; Sierra, B. Human-robot collaboration in industrial applications: Safety, interaction and trust. Int. J. Adv. Robot. Syst. 2017, 7, 1–10. [Google Scholar] [CrossRef]

- Cheng, Z.; Niu, Z.; Wei, P. Operational skill training needs analysis for manufacturing industry. In Proceedings of the 2011 International Conference of Information Technology, Computer Engineering and Management Sciences, ICM 2011, Nanjing, China, 24–25 September 2011; pp. 394–397. [Google Scholar]

- Jang, Y.; Jeong, I.; Chauhan, H.; Pakbaz, A. Workers? Physiological/Psychological Responses during Human-Robot Collaboration in an Immersive Virtual Reality Environment. In Computing in Civil Engineering 2023; Proceedings; American Society of Civil Engineers: Reston, VA, USA, 2024; pp. 461–469. [Google Scholar]

- Őrsi, B.; Kovács, J.; Csukonyi, C. Accepting a robot request contradicting a human instruction in the function of robot attitudes and level of interdependency. Comput. Hum. Behav. Rep. 2024, 14, 100385. [Google Scholar] [CrossRef]

- Çiğdem, Ş.; Meidute-Kavaliauskiene, I.; Yıldız, B. Industry 4.0 and Industrial Robots: A Study from the Perspective of Manufacturing Company Employees. Logistics 2023, 7, 17. [Google Scholar] [CrossRef]

- Messeri, C.; Zanchettin, A.M.; Rocco, P.; Gianotti, E.; Chirico, A.; Magoni, S.; Gaggioli, A. On the Effects of Leader-Follower Roles in Dyadic Human-Robot Synchronization. IEEE Trans. Cogn. Dev. Syst. 2023, 15, 434–443. [Google Scholar] [CrossRef]

- Kaupp, T.; Makarenko, A.; Durrant-Whyte, H. Human–robot communication for collaborative decision making—A probabilistic approach. Robot. Auton. Syst. 2010, 58, 444–456. [Google Scholar] [CrossRef]

- Adami, P.; Rodrigues, P.B.; Woods, P.J.; Becerik-Gerber, B.; Soibelman, L.; Copur-Gencturk, Y.; Lucas, G. Impact of VR-Based Training on Human–Robot Interaction for Remote Operating Construction Robots. J. Comput. Civ. Eng. 2022, 36, 04022006. [Google Scholar] [CrossRef]

- Vanzo, A.; Riccio, F.; Sharf, M.; Mirabella, V.; Catarci, T.; Nardi, D. Who is Willing to Help Robots? A User Study on Collaboration Attitude. Int. J. Soc. Robot. 2020, 12, 589–598. [Google Scholar] [CrossRef]

- Wu, T.-J.; Zhang, R.-X. Exploring the impacts of intention towards human-robot collaboration on frontline hotel employees’ positive behavior: An integrative model. Int. J. Hosp. Manag. 2024, 123, 103912. [Google Scholar] [CrossRef]

- Boch, A.; Thomas, B.R. Human-robot dynamics: A psychological insight into the ethics of social robotics. Int. J. Ethics Syst. 2024, 41, 101–141. [Google Scholar] [CrossRef]

- Chauhan, H.; Pakbaz, A.; Jang, Y.; Jeong, I. Analyzing Trust Dynamics in Human–Robot Collaboration through Psychophysiological Responses in an Immersive Virtual Construction Environment. J. Comput. Civ. Eng. 2024, 38, 04024017. [Google Scholar] [CrossRef]

- Kumar, J.D.; Bansal, N.; Kaushik, A.; Sethi, A. Human-Robot Interaction: Designing Effective Interfaces for Collaborative Tasks. In Proceedings of the 2024 1st International Conference on Advances in Computing, Communication and Networking (ICAC2N), Greater Noida, India, 16–17 December 2024; pp. 356–360. [Google Scholar]

- Salehzadeh, R.; Gong, J.; Jalili, N. Purposeful Communication in Human–Robot Collaboration: A Review of Modern Approaches in Manufacturing. IEEE Access 2022, 10, 129344–129361. [Google Scholar] [CrossRef]

- Rabby, M.K.M.; Karimoddini, A.; Khan, M.A.; Jiang, S. A Learning-Based Adjustable Autonomy Framework for Human–Robot Collaboration. IEEE Trans. Ind. Inform. 2022, 18, 6171–6180. [Google Scholar] [CrossRef]

- Lohrmann, C.; Stull, M.; Roncone, A.; Hayes, B. Generating Pattern-Based Conventions for Predictable Planning in Human–Robot Collaboration. J. Hum.-Robot Interact. 2024, 13, 1–23. [Google Scholar] [CrossRef]

- Zeitlhofer, I.; Zumbach, J.; Schweppe, J. Complexity affects performance, cognitive load, and awareness. Learn. Instr. 2024, 94, 102001. [Google Scholar] [CrossRef]

- Liau, Y.Y.; Ryu, K. Task Allocation in Human-Robot Collaboration (HRC) Based on Task Characteristics and Agent Capability for Mold Assembly. Procedia Manuf. 2020, 51, 179–186. [Google Scholar] [CrossRef]

- Wang, P.; Bai, X.; Billinghurst, M.; Zhang, S.; Zhang, X.; Wang, S.; He, W.; Yan, Y.; Ji, H. AR/MR Remote Collaboration on Physical Tasks: A Review. Robot. Comput.-Integr. Manuf. 2021, 72, 102071. [Google Scholar] [CrossRef]

- Sun, Y.; Jeelani, I.; Gheisari, M. Safe human-robot collaboration in construction: A conceptual perspective. J. Saf. Res. 2023, 86, 39–51. [Google Scholar] [CrossRef] [PubMed]

- Gervasi, R.; Mastrogiacomo, L.; Franceschini, F. A conceptual framework to evaluate human-robot collaboration. Int. J. Adv. Manuf. Technol. 2020, 108, 841–865. [Google Scholar] [CrossRef]

- Ullrich, D.; Butz, A.; Diefenbach, S. The Development of Overtrust: An Empirical Simulation and Psychological Analysis in the Context of Human–Robot Interaction. Front. Robot. AI 2021, 8, 554578. [Google Scholar] [CrossRef]

- Kopp, T. Facets of Trust and Distrust in Collaborative Robots at the Workplace: Towards a Multidimensional and Relational Conceptualisation. Int. J. Soc. Robot. 2024, 16, 1445–1462. [Google Scholar] [CrossRef]

- Lima Junior, W.T.; Welter, R.A.; Ferreira, W.P.; Souza, R.F.; Eduardo, T. Human robot interaction (HRI): An artificial cognitive autonomy approach to enhance Decision-Making. Cogn. Syst. Res. 2025, 91, 101336. [Google Scholar] [CrossRef]

- Guo, X.; Liu, Y.; Ma, X.; Fu, H. Human trust effect in remote human–robot collaboration construction task for different level of automation. Adv. Eng. Inform. 2025, 68, 103647. [Google Scholar] [CrossRef]

- Hair, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M.; Danks, N.P.; Ray, S. An Introduction to Structural Equation Modeling. In Partial Least Squares Structural Equation Modeling (PLS-SEM) Using R: A Workbook; Springer International Publishing: Cham, Switzerland, 2021; pp. 1–29. [Google Scholar]

- Batra, S. Exploring the application of PLS-SEM in construction management research: A bibliometric and meta-analysis approach. Eng. Constr. Archit. Manag. 2024, 32, 2697–2727. [Google Scholar] [CrossRef]

- Aibinu, A.A.; Al-Lawati, A.M. Using PLS-SEM technique to model construction organizations’ willingness to participate in e-bidding. Autom. Constr. 2010, 19, 714–724. [Google Scholar] [CrossRef]

- Bajpai, A.; Misra, S.C. A framework for continuation of digitalization in construction: A PLS-SEM approach. Eng. Constr. Archit. Manag. 2022, 30, 4715–4734. [Google Scholar] [CrossRef]

- Okanlawon, T.T.; Oyewobi, L.O.; Dauda, J.A.; Ogunjimi, O.S.; Bello, A.O.; Jimoh, R.A. Modelling the effect of integrating augmented reality on construction lifecycle using partial least squares structural equation modelling (PLS-SEM). Smart Sustain. Built Environ. 2025, 1–30. [Google Scholar] [CrossRef]

- Pan, M.; Pan, W. Understanding the Determinants of Construction Robot Adoption: Perspective of Building Contractors. J. Constr. Eng. Manag. 2020, 146, 04020040. [Google Scholar] [CrossRef]

- Daoud, A.O.; Kineber, A.F.; Chileshe, N.; Elmansoury, A.; Abdel Aziz, K.M. Investigating barriers to drones implementation in sustainable construction using PLS-SEM. Sci. Rep. 2025, 15, 19623. [Google Scholar] [CrossRef]

- Parvez, M.O.; Arasli, H.; Ozturen, A.; Lodhi, R.N.; Ongsakul, V. Antecedents of human-robot collaboration: Theoretical extension of the technology acceptance model. J. Hosp. Tour. Technol. 2022, 13, 240–263. [Google Scholar] [CrossRef]

- Zhang, M.; Xu, R.; Wu, H.; Pan, J.; Luo, X. Human–robot collaboration for on-site construction. Autom. Constr. 2023, 150, 104812. [Google Scholar] [CrossRef]

- Chauhan, H.; Jang, Y.; Jeong, I. Predicting human trust in human-robot collaborations using machine learning and psychophysiological responses. Adv. Eng. Inform. 2024, 62, 102720. [Google Scholar] [CrossRef]

- Beer, J.M.; Fisk, A.D.; Rogers, W.A. Toward a framework for levels of robot autonomy in human-robot interaction. J. Hum.-Robot Interact. 2014, 3, 74–99. [Google Scholar] [CrossRef]

- Berx, N.; Decré, W.; Morag, I.; Chemweno, P.; Pintelon, L. Identification and classification of risk factors for human-robot collaboration from a system-wide perspective. Comput. Ind. Eng. 2022, 163, 107827. [Google Scholar] [CrossRef]

- Marvel, J.A.; Bagchi, S.; Zimmerman, M.; Antonishek, B. Towards Effective Interface Designs for Collaborative HRI in Manufacturing: Metrics and Measures. J. Hum.-Robot Interact. 2020, 9, 1–55. [Google Scholar] [CrossRef]

- Liu, Y.; Habibnezhad, M.; Jebelli, H. Brainwave-driven human-robot collaboration in construction. Autom. Constr. 2021, 124, 103556. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Zuo, J.; Chileshe, N.; Baroudi, B. Evaluating virtuality in teams: A conceptual model. Technol. Anal. Strateg. Manag. 2015, 27, 385–404. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Changxin Wang, C.; Tam, V.W.Y. Effective construction and demolition waste management assessment through waste management hierarchy; a case of Australian large construction companies. J. Clean. Prod. 2021, 312, 127790. [Google Scholar] [CrossRef]

- Fu, Y.; Chen, J.; Lu, W. Human-robot collaboration for modular construction manufacturing: Review of academic research. Autom. Constr. 2024, 158, 105196. [Google Scholar] [CrossRef]

- Goodhue, D.L.; Thompson, R.L. Task-technology fit and individual performance. MIS Q. 1995, 19, 213–236. [Google Scholar] [CrossRef]

- Luo, Z. Interactive Model Fitting for Human Robot Collaboration. In Proceedings of the 2014 IEEE 11th International Conference on e-Business Engineering, Guangzhou, China, 5–7 November 2014; pp. 151–156. [Google Scholar]

- Olukanni, E.; Akanmu, A.; Jebelli, H. Systematic Literature Review of Competencies for Human–Robot Collaboration in Construction: A Task-Technology Fit Perspective. J. Comput. Civ. Eng. 2026, 40, 03125001. [Google Scholar] [CrossRef]

- Asif, S.; Callari, T.C.; Khan, F.; Eimontaite, I.; Hubbard, E.-M.; Bahraini, M.S.; Webb, P.; Lohse, N. Exploring tasks and challenges in human-robot collaborative systems: A review. Robot. Comput.-Integr. Manuf. 2026, 97, 103102. [Google Scholar] [CrossRef]

- Garcés, G. Human-robot synergy in building construction: Advances, challenges, and future horizons for construction 5.0. Discov. Civ. Eng. 2025, 2, 135. [Google Scholar] [CrossRef]

- Shafei, H.; Radzi, A.R.; Algahtany, M.; Rahman, R.A. Construction 4.0 Technologies and Decision-Making: A Systematic Review and Gap Analysis. Buildings 2022, 12, 2206. [Google Scholar] [CrossRef]

- Dhanda, M.; Rogers, B.A.; Hall, S.; Dekoninck, E.; Dhokia, V. Reviewing human-robot collaboration in manufacturing: Opportunities and challenges in the context of industry 5.0. Robot. Comput.-Integr. Manuf. 2025, 93, 102937. [Google Scholar] [CrossRef]

- Petzoldt, C.; Harms, M.; Freitag, M. Review of task allocation for human-robot collaboration in assembly. Int. J. Comput. Integr. Manuf. 2023, 36, 1675–1715. [Google Scholar] [CrossRef]

- Sosa-Ceron, A.D.; Gonzalez-Hernandez, H.G.; Reyes-Avendaño, J.A. Learning from Demonstrations in Human–Robot Collaborative Scenarios: A Survey. Robotics 2022, 11, 126. [Google Scholar] [CrossRef]

- Segura, P.; Lobato-Calleros, O.; Ramírez-Serrano, A.; Soria, I. Human-robot collaborative systems: Structural components for current manufacturing applications. Adv. Ind. Manuf. Eng. 2021, 3, 100060. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Substantial capabilities of robotics in enhancing industry 4.0 implementation. Cogn. Robot. 2021, 1, 58–75. [Google Scholar] [CrossRef]

- Liu, Y.; Alias, A.H.B.; Haron, N.A.; Bakar, N.A.; Wang, H. Exploring three pillars of construction robotics via dual-track quantitative analysis. Autom. Constr. 2024, 162, 105391. [Google Scholar] [CrossRef]

- Chacón, A.; Ponsa, P.; Angulo, C. Usability Study through a Human-Robot Collaborative Workspace Experience. Designs 2021, 5, 35. [Google Scholar] [CrossRef]

- Berg, J.; Lu, S. Review of Interfaces for Industrial Human-Robot Interaction. Curr. Robot. Rep. 2020, 1, 27–34. [Google Scholar] [CrossRef]

- Phaijit, O.; Sammut, C.; Johal, W. User Interface Interventions for Improving Robot Learning from Demonstration. In Proceedings of the 11th International Conference on Human-Agent Interaction, Gothenburg, Sweden, 4–7 December 2023; pp. 152–161. [Google Scholar]

- Baratta, A.; Cimino, A.; Gnoni, M.G.; Longo, F. Human Robot Collaboration in Industry 4.0: A literature review. Procedia Comput. Sci. 2023, 217, 1887–1895. [Google Scholar] [CrossRef]

- Othman, U.; Yang, E. Human–Robot Collaborations in Smart Manufacturing Environments: Review and Outlook. Sensors 2023, 23, 5663. [Google Scholar] [CrossRef]

- Bonarini, A. Communication in Human-Robot Interaction. Curr. Robot. Rep. 2020, 1, 279–285. [Google Scholar] [CrossRef]

- Schoeller, F.; Miller, M.; Salomon, R.; Friston, K.J. Trust as Extended Control: Human-Machine Interactions as Active Inference. Front. Syst. Neurosci. 2021, 15, 669810. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Wang, T.; Wang, C.; Quan, W.; Tang, M. Complexity-Driven Trust Dynamics in Human–Robot Interactions: Insights from AI-Enhanced Collaborative Engagements. Appl. Sci. 2023, 13, 12989. [Google Scholar] [CrossRef]

- Haney, J.M.; Liang, C.-J. A Literature Review on Safety Perception and Trust during Human–Robot Interaction with Autonomous Mobile Robots That Apply to Industrial Environments. IISE Trans. Occup. Ergon. Hum. Factors 2024, 12, 6–27. [Google Scholar] [CrossRef]

- Jin, R.; Zou, P.X.; Piroozfar, P.; Wood, H.; Yang, Y.; Yan, L.; Han, Y. A science mapping approach based review of construction safety research. Saf. Sci. 2019, 113, 285–297. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, H.; Kang, S.-C.; Al-Hussein, M. Virtual reality applications for the built environment: Research trends and opportunities. Autom. Constr. 2020, 118, 103311. [Google Scholar] [CrossRef]

- Mongeon, P.; Paul-Hus, A. The journal coverage of Web of Science and Scopus: A comparative analysis. Scientometrics 2016, 106, 213–228. [Google Scholar] [CrossRef]

- Sun, G.; Sun, J.; Li, F. Influencing Factors of Early Termination for PPP Projects Based on Multicase Grounded Theory. J. Constr. Eng. Manag. 2022, 148, 04022120. [Google Scholar] [CrossRef]

- Lim Huey, W.; Francis, V. A Conceptual Model of Cognitive and Behavioral Processes Affecting Mental Health in the Construction Industry: A Systematic Review. J. Constr. Eng. Manag. 2023, 149, 04023114. [Google Scholar] [CrossRef]

- Xu, Y.; Chi, M.; Lee, C.-Y.; Chong, H.-Y.; Wu, H. Effects of the Blockchain and Artificial Intelligence on Value Cocreation in Construction Projects: A Mixed Methods Study. J. Constr. Eng. Manag. 2025, 151, 04025091. [Google Scholar] [CrossRef]

- Ibrahim, A.; Xu, J.; Cheon, S.; Wang, X.; Nnaji, C. Human–Robot Interaction in Dynamic Work Environment: Implications for Workers’ Situational Awareness. J. Constr. Eng. Manag. 2025, 151, 04025133. [Google Scholar] [CrossRef]

- Jahanmahin, R.; Masoud, S.; Rickli, J.; Djuric, A. Human-robot interactions in manufacturing: A survey of human behavior modeling. Robot. Comput.-Integr. Manuf. 2022, 78, 102404. [Google Scholar] [CrossRef]

- Tomori, M.; Ogunseiju, O.; Nnaji, C. A Review of Human-Robotics Interactions in the Construction Industry. In Construction Research Congress 2024; Proceedings; American Society of Civil Engineers: Reston, VA, USA, 2024; pp. 903–912. [Google Scholar]

- Okishiba, S.; Fukui, R.; Takagi, M.; Azumi, H.; Warisawa, S.i.; Togashi, R.; Kitaoka, H.; Ooi, T. Tablet interface for direct vision teleoperation of an excavator for urban construction work. Autom. Constr. 2019, 102, 17–26. [Google Scholar] [CrossRef]

- Zhou, T.; Zhu, Q.; Ye, Y.; Du, J. Humanlike Inverse Kinematics for Improved Spatial Awareness in Construction Robot Teleoperation: Design and Experiment. J. Constr. Eng. Manag. 2023, 149, 04023044. [Google Scholar] [CrossRef]

- Zhang, Z.; Guo, B.H.W.; Feng, Z.; Goh, Y.M. Investigating situation awareness transition in construction hazard recognition: A multimodal study of cognitive and neural mechanisms. Adv. Eng. Inform. 2025, 68, 103712. [Google Scholar] [CrossRef]

- Rinaldi, M.; Di Pasquale, V.; Farina, P.; Iannone, R.; Macchiaroli, R.; Grosse, E.H. Human–robot interaction in industry: A tertiary study. Procedia Comput. Sci. 2025, 253, 1691–1701. [Google Scholar] [CrossRef]

- Yoon, S.; Park, M.; Ahn Changbum, R. LaserDex: Improvising Spatial Tasks Using Deictic Gestures and Laser Pointing for Human–Robot Collaboration in Construction. J. Comput. Civ. Eng. 2024, 38, 04024012. [Google Scholar] [CrossRef]

- Wang, L.; Huang, Y.; Wang, Y.; Gu, B.; Li, B.; Fang, D. Comprehensive lifecycle safety risk assessment for construction robotics using T-S fault tree analysis and Bayesian network. Autom. Constr. 2025, 172, 106041. [Google Scholar] [CrossRef]

- Goh, J.; Fang, Y.; Ens, B. Embedded visualizations in crane operation user interfaces for real-time assistance. Autom. Constr. 2025, 173, 106078. [Google Scholar] [CrossRef]

- Baccarini, D. The concept of project complexity—A review. Int. J. Proj. Manag. 1996, 14, 201–204. [Google Scholar] [CrossRef]

- Chen, Y. A Preliminary Review of Current Research Studies on Human Robot Collaboration in Construction Industry. In Computing in Civil Engineering 2021; Proceedings; American Society of Civil Engineers: Reston, VA, USA, 2022; pp. 329–333. [Google Scholar]

- Parascho, S. Construction Robotics: From Automation to Collaboration. Annu. Rev. Control. Robot. Auton. Syst. 2023, 6, 183–204. [Google Scholar] [CrossRef]

- Baratta, A.; Cimino, A.; Longo, F.; Mirabelli, G.; Nicoletti, L. Task Allocation in Human-Robot Collaboration: A Simulation-based approach to optimize Operator’s Productivity and Ergonomics. Procedia Comput. Sci. 2024, 232, 688–697. [Google Scholar] [CrossRef]

- Shayesteh, S.; Ojha, A.; Liu, Y.; Jebelli, H. Human-robot teaming in construction: Evaluative safety training through the integration of immersive technologies and wearable physiological sensing. Saf. Sci. 2023, 159, 106019. [Google Scholar] [CrossRef]

- Tehrani, B.M.; Alwisy, A. Optimizing Task Allocation in Human-in-the-Lead Construction Robotics: A Framework for Wood Assembly–Based Robotics in Panelized Construction. J. Comput. Civ. Eng. 2025, 39, 04025097. [Google Scholar] [CrossRef]

- Pradhananga, P.; ElZomor, M.; Kasabdji, G.S. Identifying the Challenges to Adopting Robotics in the US Construction Industry. J. Constr. Eng. Manag. 2021, 147, 05021003. [Google Scholar] [CrossRef]

- He, P.; Qin, L.; Yuan, Y.; Yuan, J. Action Reliability Assessment Framework for Automated Construction Labor Measurements: Case Study on Plastering Operations. J. Constr. Eng. Manag. 2025, 151, 05025006. [Google Scholar] [CrossRef]

- Marangunić, N.; Granić, A. Technology acceptance model: A literature review from 1986 to 2013. Univers. Access Inf. Soc. 2015, 14, 81–95. [Google Scholar] [CrossRef]

- Sheridan, T.B. Human–Robot Interaction: Status and Challenges. Hum. Factors 2016, 58, 525–532. [Google Scholar] [CrossRef]

- Dishaw, M.T.; Strong, D.M. Supporting software maintenance with software engineering tools: A Computed task–technology fit analysis. J. Syst. Softw. 1998, 44, 107–120. [Google Scholar] [CrossRef]

- Hopko, S.K.; Mehta, R.K.; Pagilla, P.R. Physiological and perceptual consequences of trust in collaborative robots: An empirical investigation of human and robot factors. Appl. Ergon. 2023, 106, 103863. [Google Scholar] [CrossRef]

- Ranz, F.; Hummel, V.; Sihn, W. Capability-based Task Allocation in Human-robot Collaboration. Procedia Manuf. 2017, 9, 182–189. [Google Scholar] [CrossRef]

- Musić, S.; Hirche, S. Control sharing in human-robot team interaction. Annu. Rev. Control. 2017, 44, 342–354. [Google Scholar] [CrossRef]

- Kohlbrecher, S.; Romay, A.; Stumpf, A.; Gupta, A.; von Stryk, O.; Bacim, F.; Bowman, D.A.; Goins, A.; Balasubramanian, R.; Conner, D.C. Human-robot Teaming for Rescue Missions: Team ViGIR’s Approach to the 2013 DARPA Robotics Challenge Trials. J. Field Robot. 2015, 32, 352–377. [Google Scholar] [CrossRef]

- Liu, P.; Li, Z. Task complexity: A review and conceptualization framework. Int. J. Ind. Ergon. 2012, 42, 553–568. [Google Scholar] [CrossRef]

- Li, P.-c.; Wang, Y.-x.; Chen, J.-h.; Luo, Z.-h.; Dai, L.-c. An experimental study on the effects of task complexity and knowledge and experience level on SA, TSA and workload. Nucl. Eng. Des. 2021, 376, 111112. [Google Scholar] [CrossRef]

- Wohleber, R.W.; Stowers, K.; Barnes, M.; Chen, J.Y.C. Agent transparency in mixed-initiative multi-UxV control: How should intelligent agent collaborators speak their minds? Comput. Hum. Behav. 2023, 148, 107866. [Google Scholar] [CrossRef]

- Tatasciore, M.; Bowden, V.; Loft, S. Do concurrent task demands impact the benefit of automation transparency? Appl. Ergon. 2023, 110, 104022. [Google Scholar] [CrossRef]

- Liu, T.; Wang, J.; Wong, S.; Razjigaev, A.; Beier, S.; Peng, S.; Do, T.N.; Song, S.; Chu, D.; Wang, C.H.; et al. A Review on the Form and Complexity of Human–Robot Interaction in the Evolution of Autonomous Surgery. Adv. Intell. Syst. 2024, 6, 2400197. [Google Scholar] [CrossRef]

- Beijing Municipal Commission of Housing and Urban-Rural Development. Beijing Technical Catalogue for Intelligent Construction Technologies. Available online: https://www.beijing.gov.cn/zhengce/zhengcefagui/202307/t20230706_3156390.html (accessed on 28 September 2025).

- Guangdong Provincial Department of Housing and Urban-Rural Development. Policies to Promote the Coordinated Development of Intelligent Construction and Industrialized Building. Available online: https://gdee.gd.gov.cn/attachment/0/481/481758/3816698.pdf (accessed on 28 September 2025).

- Ministry of Housing and Urban-Rural Development of the P.R.C. Several Opinions on Promoting the Coordinated Development of Intelligent Construction and Building Industrialization. Available online: https://www.gov.cn/zhengce/zhengceku/2020-07/28/content_5530762.htm (accessed on 28 September 2025).

- Ministry of Housing and Urban-Rural Development of the P.R.C. Notice on the Work of Pilot Cities for Intelligent Construction. Available online: https://www.gov.cn/zhengce/zhengceku/202406/content_6958371.htm (accessed on 28 September 2025).

- Shenzhen Municipal Housing and Construction Bureau. Shenzhen Intelligent Construction Pilot City Implementation Plan. Available online: https://www.sz.gov.cn/zfgb/2023/gb1285/content/post_10594580.html (accessed on 28 September 2025).

- Shenzhen Municipal Housing and Construction Bureau. Shenzhen Construction Robot Product Catalogue (First Batch). Available online: https://zjj.sz.gov.cn/xxgk/tzgg/content/post_12403517.html (accessed on 28 September 2025).

- Hair, J.F.; Ringle, C.M.; Sarstedt, M. PLS-SEM: Indeed a Silver Bullet. J. Mark. Theory Pract. 2011, 19, 139–152. [Google Scholar] [CrossRef]

- Salih, F.; El-adaway Islam, H. Exploring the Adoption of Construction Technologies in Infrastructure Projects: Bridging Perceptions of Experts with Real Project Data. J. Infrastruct. Syst. 2025, 31, 04025013. [Google Scholar] [CrossRef]

- Wu, M.-J.; Zhao, K.; Fils-Aime, F. Response rates of online surveys in published research: A meta-analysis. Comput. Hum. Behav. Rep. 2022, 7, 100206. [Google Scholar] [CrossRef]

- He, C.; Hu, Z.; Shen, Y.; Wu, C. Effects of Demographic Characteristics on Safety Climate and Construction Worker Safety Behavior. Sustainability 2023, 15, 10985. [Google Scholar] [CrossRef]

- Wang, X.; Du, M.; Li, H.X.; Hasan, A.; Ahmadian Fard Fini, A. Gender inequality and challenges of women in the construction industry: An evidenced-based analysis from China. Eng. Constr. Archit. Manag. 2025, 32, 213–233. [Google Scholar] [CrossRef]

- Abdullah, F.; Ward, R.; Ahmed, E. Investigating the influence of the most commonly used external variables of TAM on students’ Perceived Ease of Use (PEOU) and Perceived Usefulness (PU) of e-portfolios. Comput. Hum. Behav. 2016, 63, 75–90. [Google Scholar] [CrossRef]

- Hair, J.F.; Howard, M.C.; Nitzl, C. Assessing measurement model quality in PLS-SEM using confirmatory composite analysis. J. Bus. Res. 2020, 109, 101–110. [Google Scholar] [CrossRef]

- Chin, W.W. How to Write Up and Report PLS Analyses. In Handbook of Partial Least Squares: Concepts, Methods and Applications; Esposito Vinzi, V., Chin, W.W., Henseler, J., Wang, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 655–690. [Google Scholar]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A new criterion for assessing discriminant validity in variance-based structural equation modeling. J. Acad. Mark. Sci. 2015, 43, 115–135. [Google Scholar] [CrossRef]

- Naji Khalid, K.; Gunduz, M.; Naser Ayman, F. The Effect of Change-Order Management Factors on Construction Project Success: A Structural Equation Modeling Approach. J. Constr. Eng. Manag. 2022, 148, 04022085. [Google Scholar] [CrossRef]

- Conway, J.M.; Lance, C.E. What Reviewers Should Expect from Authors Regarding Common Method Bias in Organizational Research. J. Bus. Psychol. 2010, 25, 325–334. [Google Scholar] [CrossRef]

- Howard, M.C.; Boudreaux, M.; Oglesby, M. Can Harman’s single-factor test reliably distinguish between research designs? Not in published management studies. Eur. J. Work. Organ. Psychol. 2024, 33, 790–804. [Google Scholar] [CrossRef]

- Dormann, C.F.; Elith, J.; Bacher, S.; Buchmann, C.; Carl, G.; Carré, G.; Marquéz, J.R.G.; Gruber, B.; Lafourcade, B.; Leitão, P.J.; et al. Collinearity: A review of methods to deal with it and a simulation study evaluating their performance. Ecography 2013, 36, 27–46. [Google Scholar] [CrossRef]

- Chin, W.W. The partial least squares approach to structural equation modeling. In Modern methods for Business Research; Psychology Press: Hove, UK, 1998; pp. 295–336. [Google Scholar]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences; Routledge: London, UK, 2013. [Google Scholar]

- Fournier, É.; Kilgus, D.; Landry, A.; Hmedan, B.; Pellier, D.; Fiorino, H.; Jeoffrion, C. The Impacts of Human-Cobot Collaboration on Perceived Cognitive Load and Usability during an Industrial Task: An Exploratory Experiment. IISE Trans. Occup. Ergon. Hum. Factors 2022, 10, 83–90. [Google Scholar] [CrossRef]

- Segura, P.; Lobato-Calleros, O.; Soria-Arguello, I.; Hernández-Martínez, E.G. Work Roles in Human–Robot Collaborative Systems: Effects on Cognitive Ergonomics for the Manufacturing Industry. Appl. Sci. 2025, 15, 744. [Google Scholar] [CrossRef]

- Dijk, W.; Baltrusch, S.; Dessers, E.; Looze, M. The effect of human autonomy and robot work pace on perceived workload in human-robot collaborative assembly work. Front. Robot. AI 2023, 10, 1244656. [Google Scholar] [CrossRef] [PubMed]

- Pasmore, W.; Winby, S.; Mohrman, S.A.; Vanasse, R. Reflections: Sociotechnical Systems Design and Organization Change. J. Change Manag. 2019, 19, 67–85. [Google Scholar] [CrossRef]

- Zafar, M.H.; Langås, E.F.; Sanfilippo, F. Exploring the synergies between collaborative robotics, digital twins, augmentation, and industry 5.0 for smart manufacturing: A state-of-the-art review. Robot. Comput.-Integr. Manuf. 2024, 89, 102769. [Google Scholar] [CrossRef]

- Zhou, T.; Xia, P.; Ye, Y.; Du, J. Embodied Robot Teleoperation Based on High-Fidelity Visual-Haptic Simulator: Pipe-Fitting Example. J. Constr. Eng. Manag. 2023, 149, 04023129. [Google Scholar] [CrossRef]

- Brosque, C.; Fischer, M. A robot evaluation framework comparing on-site robots with traditional construction methods. Constr. Robot. 2022, 6, 187–206. [Google Scholar] [CrossRef]

- Apraiz, A.; Lasa, G.; Mazmela, M. Evaluation of User Experience in Human–Robot Interaction: A Systematic Literature Review. Int. J. Soc. Robot. 2023, 15, 187–210. [Google Scholar] [CrossRef]

- Campana, J.R.; Quaresma, M. The Importance of Specific Usability Guidelines for Robot User Interfaces. In Proceedings of the Design, User Experience, and Usability: Designing Pleasurable Experiences, Vancouver, BC, Canada, 9–14 July 2017; pp. 471–483. [Google Scholar]

- Morandini, S.; Currò, F.; Parlangeli, O.; Pietrantoni, L. Collaborative Robots Adapting Their Behavior Based on Workers’ Psychological States: A Systematic Scoping Review. Hum. Behav. Emerg. Technol. 2025, 2025, 6361777. [Google Scholar] [CrossRef]

- Pereira, E.; Sigcha, L.; Silva, E.; Sampaio, A.; Costa, N.; Costa, N. Capturing Mental Workload Through Physiological Sensors in Human–Robot Collaboration: A Systematic Literature Review. Appl. Sci. 2025, 15, 3317. [Google Scholar] [CrossRef]

- Makulavičius, M.; Petronienė, J.J.; Šutinys, E.; Bučinskas, V.; Dzedzickis, A. Industrial Robotic Setups: Tools and Technologies for Tracking and Analysis in Industrial Processes. Appl. Sci. 2025, 15, 10249. [Google Scholar] [CrossRef]

- Sarvghadi, H.; Reinhardt, A.; Semmelhack, E.A. A survey of wearable devices to capture human factors for human-robot collaboration. Pervasive Mob. Comput. 2025, 110, 102048. [Google Scholar] [CrossRef]

- Cvetkovic, A.; Savolainen, I.; Koike, M.; Oksanen, A. A four-wave longitudinal study on attitudes toward the use of AI in different domains—The self-determination theory and locus of control perspective. Telemat. Inform. Rep. 2025, 18, 100220. [Google Scholar] [CrossRef]

- Jeon, J.; Cai, H. Wearable EEG-based construction hazard identification in virtual and real environments: A comparative study. Saf. Sci. 2023, 165, 106213. [Google Scholar] [CrossRef]

- Hémono, P.; Nait Chabane, A.; Sahnoun, M.h. Multi objective optimization of human–robot collaboration: A case study in aerospace assembly line. Comput. Oper. Res. 2025, 174, 106874. [Google Scholar] [CrossRef]

- Koreis, J. Human–robot vs. human–manual teams: Understanding the dynamics of experience and performance variability in picker-to-parts order picking. Comput. Ind. Eng. 2025, 200, 110750. [Google Scholar] [CrossRef]

| Variable | Category | Frequency | Percentage |

|---|---|---|---|

| Gender | Male | 71 | 88.75% |

| Female | 9 | 11.25% | |

| Age | 18–24 | 2 | 2.50% |

| 25–34 | 21 | 26.25% | |

| 35–44 | 25 | 31.25% | |

| 45–54 | 29 | 36.25% | |

| ≥55 | 3 | 3.75% | |

| Education | Primary school or below | 9 | 11.25% |

| Middle school | 23 | 28.75% | |

| Technical secondary school | 14 | 17.50% | |

| High school | 22 | 27.50% | |

| Junior college and above | 12 | 15.00% | |

| Role | Equipment operator | 2 | 2.50% |

| Concrete worker | 23 | 28.75% | |

| Rebar worker | 18 | 22.50% | |

| Form worker | 4 | 5.00% | |

| Interior decorator | 20 | 25.00% | |

| Other | 13 | 16.25% | |

| Years of experience on construction site | ≤2 | 7 | 8.75% |

| 2–5 | 31 | 38.75% | |

| 5–10 | 23 | 28.75% | |

| 10–15 | 17 | 21.25% | |

| ≥15 | 2 | 2.50% | |

| Type of construction sites | Residential building | 47 | 58.75% |

| Public building | 22 | 27.50% | |

| Office building | 11 | 13.75% | |

| East China | 26 | 32.50% | |

| Region | Central China | 23 | 28.75% |

| West China | 31 | 38.75% |

| Construct | Operational Definition | Boundaries | Label | Item | Cronbach’s Alpha |

|---|---|---|---|---|---|

| Operational skill (OS) | Operators’ procedural proficiency in setting up, operating, and supervising construction robots, minimizing procedural errors and intervention time during HRC. | Focuses on technical handling and standardized procedures; excludes broader decision judgment (DA) and learning pace (LA). | OS1 | I understand how to operate and interact with robots in my work. | 0.862 |

| OS2 | I have the technical knowledge required to collaborate with robots. | ||||

| OS3 | I am capable of understanding the robot’s instructions, signals, or outputs. | ||||

| OS4 | I make few or no mistakes when following standard procedures in using robots. | ||||

| OS5 | I usually need detailed step-by-step instructions to carry out robot operations. | ||||

| OS6 | I can complete tasks efficiently within the given time. | ||||

| Decision-making ability (DA) | Capability to make timely, context-appropriate judgments under uncertainty (e.g., override, re-plan, allocate work between human/robot). | Focuses on judgment under constraints; excludes procedural operation (OS) and learning adaptivity (LA). | DA1 | I can make quick decisions within limited time. | |

| DA2 | I consider multiple possibilities before making a decision. | ||||

| DA3 | I can weigh pros and cons and make reasonable choices when facing complex problems. | ||||

| DA4 | I can make sound decisions even when information is incomplete. | ||||

| DA5 | I take responsibility for my decisions and adjust them when necessary. | ||||

| Learning ability (LA) | Adaptivity and learning pace in acquiring new HRC procedures and features, and updating mental models through experience. | Focuses on rate and depth of learning; distinct from robot ease-of-use (RO) and one-off skill snapshot (OS). | LA1 | I improve my work practices based on my experiences collaborating with robots. | |

| LA2 | I think using the robot requires little mental effort. | ||||

| LA3 | I can quickly learn how to operate new robotic or automated systems introduced in construction projects. | ||||

| LA4 | I quickly learn new robot operations by observing coworkers’ demonstrations. | ||||

| LA5 | I actively seek to understand the latest technologies and human–robot collaboration processes in construction. | ||||

| LA6 | Even without formal training, I can teach myself to use new robot features correctly. | ||||

| Robot functionality (RF) | Robot’s technical performance envelope (autonomy, reliability, responsiveness, accuracy, consistency) to execute construction tasks and adapt sequences. | Focuses on what the robot can do; excludes UI/interaction usability (RO). | RF1 | The robot can operate autonomously for complex tasks and adjust its task sequence without human intervention. | |

| RF2 | The robot’s actions are predictable and transparent. | ||||

| RF3 | The robot responds quickly to commands or changes. | ||||

| RF4 | The robot maintains consistent performance across different tasks and conditions. | ||||

| RF5 | The robot accurately responds to my inputs or instructions in real-time. | ||||

| Robot Operability (RO) | Human-centered usability during collaboration: intuitive interface, controllability, smooth manual/auto switching, low effort to learn. | Focuses on how easily humans can direct the robot; distinct from capability breadth (RF). | RO1 | The construction robot is easy for me to operate, even without specialized training. | |

| RO2 | The robot’s interface is user-friendly and intuitive for construction tasks. | ||||

| RO3 | I can control and adjust the robot’s behavior smoothly during collaboration. | ||||

| RO4 | It does not take much effort to learn how to work with the construction robot effectively. | ||||

| RO5 | I can switch between manual and automatic modes smoothly and confidently. | ||||

| Task complexity (TC) | TC captures the task’s contextual difficulty and structure along cognitive demand, responsibility clarity, and critical impact. The higher TC means more challenging, less structured tasks that place greater demands on HRC. | Task difficulty; not an attitude or capability. | TC1 | My tasks are complex and require high levels of analysis and decision-making. | |

| TC2 | My tasks involve high technical complexity (e.g., specialized tools, calibration, parameter tuning) that requires advanced expertise. | ||||

| TC3 | Task responsibilities are clearly allocated between human and robot. | ||||

| TC4 | My tasks require intensive coordination with other trades/teams and are highly interdependent across steps. | ||||

| TC5 | The tasks have a major impact on construction progress. | ||||

| TC6 | Site conditions (e.g., congestion, noise, dust, weather) frequently increase task difficulty or require on-the-fly adjustments. | ||||

| HRC Team Performance (HTP) | Multidimensional outcomes attributable to HRC on the task/project: productivity, safety, quality, flexibility, creativity. | Performance construct; not an antecedent. | HTP1 | Our team achieves high productivity with the robot. | |

| HTP2 | Robot use contributes to a safe work environment. | ||||

| HTP3 | The quality of our outcomes has improved with the robot. | ||||

| HTP4 | The team is flexible when facing changes during tasks. | ||||

| HTP5 | The HRC brings creativity climate in the task completion. |

| Construct | Label | Component | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | ||

| Operational skill (OS) | OS1 | 0.803 | ||||||||||||||

| OS2 | 0.856 | |||||||||||||||

| OS3 | 0.749 | |||||||||||||||

| OS4 | 0.762 | |||||||||||||||

| OS5 | 0.852 | |||||||||||||||

| OS6 | 0.835 | |||||||||||||||

| Decision-making ability (DA) | DA1 | 0.803 | ||||||||||||||

| DA2 | 0.725 | |||||||||||||||

| DA3 | 0.722 | |||||||||||||||

| DA4 | 0.866 | |||||||||||||||

| DA5 | 0.876 | |||||||||||||||

| Learning ability (LA) | LA1 | 0.766 | ||||||||||||||

| LA2 | 0.839 | |||||||||||||||

| LA3 | 0.841 | |||||||||||||||

| LA4 | 0.849 | |||||||||||||||

| LA5 | 0.863 | |||||||||||||||

| LA6 | 0.819 | |||||||||||||||

| Robot functionality (RF) | RF1 | 0.900 | ||||||||||||||

| RF2 | 0.773 | |||||||||||||||

| RF3 | 0.861 | |||||||||||||||

| RF4 | 0.870 | |||||||||||||||

| RF5 | 0.795 | |||||||||||||||

| Robot Operability (RO) | RO1 | 0.857 | ||||||||||||||

| RO2 | 0.791 | |||||||||||||||

| RO3 | 0.786 | |||||||||||||||

| RO4 | 0.876 | |||||||||||||||

| RO5 | 0.753 | |||||||||||||||

| Task complexity (TC) | TC1 | 0.843 | ||||||||||||||

| TC2 | 0.869 | |||||||||||||||

| TC3 | 0.770 | |||||||||||||||

| TC4 | 0.879 | |||||||||||||||

| TC5 | 0.777 | |||||||||||||||

| TC6 | 0.739 | |||||||||||||||

| HRC Team Performance (HTP) | TP1 | 0.785 | ||||||||||||||

| TP2 | 0.772 | |||||||||||||||

| TP3 | 0.793 | |||||||||||||||

| TP4 | 0.812 | |||||||||||||||

| TP5 | 0.850 | |||||||||||||||

| Variable | Category | Frequency | Percentage |

|---|---|---|---|

| Gender | Male | 472 | 86.13% |

| Female | 76 | 13.87% | |

| Age | 18–24 | 24 | 4.38% |

| 25–34 | 119 | 21.72% | |

| 35–44 | 145 | 26.46% | |

| 45–54 | 217 | 39.60% | |

| ≥55 | 43 | 7.85% | |

| Education | Primary school or below | 42 | 7.66% |

| Middle school | 209 | 38.14% | |

| Technical secondary school | 73 | 13.32% | |

| High school | 126 | 22.99% | |

| Junior college and above | 98 | 17.88% | |

| Role | Equipment operator | 45 | 8.21% |

| Concrete worker | 108 | 19.71% | |

| Rebar worker | 139 | 25.36% | |

| Form worker | 73 | 13.32% | |

| Interior decorator | 87 | 15.88% | |

| Other | 96 | 17.52% | |

| Years of experience on construction site | ≤2 | 47 | 8.58% |

| 2–5 | 153 | 27.92% | |

| 5–10 | 207 | 37.77% | |

| 10–15 | 82 | 14.96% | |

| ≥15 | 59 | 10.77% | |

| Type of construction sites | Residential building | 239 | 43.61% |

| Public building | 173 | 31.56% | |

| Office building | 136 | 24.82% | |

| East China | 178 | 32.48% | |

| Region | Central China | 203 | 37.04% |

| West China | 167 | 30.47% |

| Construct | Label | Item | Loading | Parameter |

|---|---|---|---|---|

| Operational skill (OS) | OS1 | I understand how to operate and interact with robots in my work. | 0.868 *** | Cronbach’s α = 0.901 CR = 0.927 AVE = 0.717 |

| OS2 | I have the technical knowledge required to collaborate with robots. | 0.850 *** | ||

| OS3 | I am capable of understanding the robot’s instructions, signals, or outputs. | 0.821 *** | ||

| OS4 | I make few or no mistakes when following standard procedures in using robots. | 0.870 *** | ||

| OS5 | I can complete tasks efficiently within the given time. | 0.823 *** | ||

| Decision-making ability (DA) | DA1 | I can make quick decisions within limited time. | 0.895 *** | Cronbach’s α = 0.888 CR = 0.922 AVE = 0.748 |

| DA2 | I consider multiple possibilities before making a decision. | 0.862 *** | ||

| DA3 | I can weigh pros and cons and make reasonable choices when facing complex problems. | 0.842 *** | ||

| DA4 | I take responsibility for my decisions and adjust them when necessary. | 0.858 *** | ||

| Learning ability (LA) | LA1 | I improve my work practices based on my experiences collaborating with robots. | 0.873 *** | Cronbach’s α = 0.870 CR = 0.911 AVE = 0.720 |

| LA2 | I think using the robot requires little mental effort. | 0.874 *** | ||

| LA3 | I can quickly learn how to operate new robotic or automated systems introduced in construction projects. | 0.815 *** | ||

| LA4 | I actively seek to understand the latest technologies and human–robot collaboration processes in construction. | 0.829 *** | ||

| Robot functionality (RF) | RF1 | The robot can operate autonomously for complex tasks and adjust its task sequence without human intervention. | 0.874 *** | Cronbach’s α = 0.905 CR = 0.929 AVE = 0.725 |

| RF2 | The robot’s actions are predictable and transparent. | 0.872 *** | ||

| RF3 | The robot responds quickly to commands or changes. | 0.841 *** | ||

| RF4 | The robot maintains consistent performance across different tasks and conditions. | 0.844 *** | ||

| RF5 | The robot accurately responds to my inputs or instructions in real-time. | 0.823 *** | ||

| Robot Operability (RO) | RO1 | The construction robot is easy for me to operate, even without specialized training. | 0.886 *** | Cronbach’s α = 0.885 CR = 0.920 AVE = 0.743 |

| RO2 | The robot’s interface is user-friendly and intuitive for construction tasks. | 0.870 *** | ||

| RO3 | I can control and adjust the robot’s behavior smoothly during collaboration. | 0.850 *** | ||

| RO4 | It does not take much effort to learn how to work with the construction robot effectively. | 0.840 *** | ||

| Task complexity (TC) | TC1 | My tasks are complex and require high levels of analysis and decision-making. | 0.874 *** | Cronbach’s α = 0.816 CR = 0.889 AVE = 0.728 |

| TC2 | Task responsibilities are clearly allocated between human and robot. | 0.872 *** | ||

| TC3 | The tasks have a major impact on construction progress. | 0.841 *** | ||

| HRC Team Performance (HTP) | HTP1 | Our team achieves high productivity with the robot. | 0.844 *** | Cronbach’s α = 0.856 CR = 0.897 AVE = 0.634 |

| HTP2 | Robot use contributes to a safe work environment. | 0.823 *** | ||

| HTP3 | The quality of our outcomes has improved with the robot. | 0.886 *** | ||

| HTP4 | The team is flexible when facing changes during tasks. | 0.870 *** | ||

| HTP5 | The HRC brings creativity climate in the task completion. | 0.850 *** |

| Variable | OS | DA | LA | RF | RO | TS | HTP |

|---|---|---|---|---|---|---|---|

| OS | 1 | ||||||

| DA | 0.337 | 1 | |||||

| LA | 0.344 | 0.348 | 1 | ||||

| RF | 0.311 | 0.237 | 0.28 | 1 | |||

| RO | 0.234 | 0.28 | 0.219 | 0.396 | 1 | ||

| TS | 0.209 | 0.151 | 0.149 | 0.195 | 0.177 | 1 | |

| HTP | 0.407 | 0.387 | 0.382 | 0.465 | 0.45 | 0.203 | 1 |

| Component | Initial Eigenvalues | Extraction Sums of Squared Loadings | ||||

|---|---|---|---|---|---|---|

| Total | % of Variance | Cumulative % | Total | % of Variance | Cumulative % | |

| 1 | 8.265 | 27.552 | 27.552 | 8.265 | 27.552 | 27.552 |

| 2 | 2.967 | 9.891 | 37.443 | 2.967 | 9.891 | 37.443 |

| 3 | 2.428 | 8.095 | 45.537 | 2.428 | 8.095 | 45.537 |

| 4 | 2.171 | 7.235 | 52.773 | 2.171 | 7.235 | 52.773 |

| 5 | 2.025 | 6.752 | 59.524 | 2.025 | 6.752 | 59.524 |

| 6 | 1.948 | 6.493 | 66.018 | 1.948 | 6.493 | 66.018 |

| 7 | 1.740 | 5.798 | 71.816 | 1.740 | 5.798 | 71.816 |

| 8 | 0.570 | 1.899 | 73.715 | |||

| 9 | 0.529 | 1.762 | 75.477 | |||

| 10 | 0.518 | 1.728 | 77.205 | |||

| 11 | 0.481 | 1.603 | 78.808 | |||

| 12 | 0.474 | 1.579 | 80.387 | |||

| 13 | 0.446 | 1.485 | 81.872 | |||

| 14 | 0.414 | 1.381 | 83.253 | |||

| 15 | 0.403 | 1.344 | 84.598 | |||

| 16 | 0.398 | 1.325 | 85.923 | |||

| 17 | 0.386 | 1.288 | 87.211 | |||

| 18 | 0.364 | 1.212 | 88.423 | |||

| 19 | 0.350 | 1.168 | 89.591 | |||

| 20 | 0.346 | 1.152 | 90.743 | |||

| 21 | 0.331 | 1.104 | 91.847 | |||

| 22 | 0.322 | 1.073 | 92.921 | |||

| 23 | 0.301 | 1.002 | 93.922 | |||

| 24 | 0.297 | 0.991 | 94.913 | |||

| 25 | 0.282 | 0.942 | 95.855 | |||

| 26 | 0.269 | 0.897 | 96.752 | |||

| 27 | 0.264 | 0.879 | 97.631 | |||

| 28 | 0.247 | 0.824 | 98.455 | |||

| 29 | 0.235 | 0.785 | 99.240 | |||

| 30 | 0.228 | 0.760 | 100.000 | |||

| Hypothesis | Path (Effect) | β (Beta) | 95% CI [LLCI, ULCI] | S.E. | f2 | T-Value | p-Value | Support or Not |

|---|---|---|---|---|---|---|---|---|

| H1 | OS → HTP | 0.147 | [0.096, 0.208] | 0.041 | 0.161 | 4.824 | 0.000 | Yes |

| H2 | DA → HTP | 0.152 | [0.101, 0.218] | 0.029 | 0.165 | 5.285 | 0.000 | Yes |

| H3 | LA → HTP | 0.182 | [0.121, 0.240] | 0.031 | 0.175 | 5.895 | 0.000 | Yes |

| H4 | RF → HTP | 0.158 | [0.095, 0.225] | 0.033 | 0.155 | 4.785 | 0.000 | Yes |

| H5 | RO → HTP | 0.199 | [0.138, 0.262] | 0.032 | 0.181 | 6.195 | 0.000 | Yes |

| H6 | OS × RF → HTP | 0.081 | [0.022, 0.142] | 0.034 | 0.111 | 2.412 | 0.016 | Yes |

| H7 | OS × RO → HTP | 0.122 | [0.064, 0.183] | 0.032 | 0.126 | 3.869 | 0.000 | Yes |

| H8 | DA × RF → HTP | 0.06 | [0.011, 0.122] | 0.028 | 0.107 | 2.139 | 0.032 | Yes |

| H9 | DA × RO → HTP | 0.203 | [0.143, 0.265] | 0.031 | 0.186 | 6.58 | 0.000 | Yes |

| H10 | LA × RF → HTP | 0.134 | [0.075, 0.194] | 0.033 | 0.129 | 4.08 | 0.000 | Yes |

| H11 | LA × RO → HTP | 0.163 | [0.101, 0.229] | 0.033 | 0.148 | 4.966 | 0.000 | Yes |

| H12 | (OS × RF) × TC → HTP | 0.089 | [0.028, 0.153] | 0.035 | 0.110 | 2.563 | 0.010 | Yes |

| H13 | (OS × RO) × TC → HTP | 0.059 | [−0.008, 0.128] | 0.034 | 0.001 | 1.751 | 0.080 | No |

| H14 | (DA × RF) × TC → HTP | 0.071 | [0.012, 0.138] | 0.027 | 0.114 | 2.36 | 0.018 | Yes |

| H15 | (DA × RO) × TC → HTP | −0.010 | [−0.070, 0.053] | 0.033 | 0.001 | 0.304 | 0.761 | No |

| H16 | (LA × RF) × TC → HTP | 0.094 | [0.031, 0.158] | 0.036 | 0.114 | 2.628 | 0.009 | Yes |

| H17 | (LA × RO) × TC → HTP | −0.069 | [−0.145, 0.010] | 0.037 | 0.008 | 1.849 | 0.064 | No |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Luo, X.; Li, W.; Zhang, L.; Li, Q. The Effect of Critical Factors on Team Performance of Human–Robot Collaboration in Construction Projects: A PLS-SEM Approach. Buildings 2025, 15, 3685. https://doi.org/10.3390/buildings15203685

Zhang G, Luo X, Li W, Zhang L, Li Q. The Effect of Critical Factors on Team Performance of Human–Robot Collaboration in Construction Projects: A PLS-SEM Approach. Buildings. 2025; 15(20):3685. https://doi.org/10.3390/buildings15203685

Chicago/Turabian StyleZhang, Guodong, Xiaowei Luo, Wei Li, Lei Zhang, and Qiming Li. 2025. "The Effect of Critical Factors on Team Performance of Human–Robot Collaboration in Construction Projects: A PLS-SEM Approach" Buildings 15, no. 20: 3685. https://doi.org/10.3390/buildings15203685

APA StyleZhang, G., Luo, X., Li, W., Zhang, L., & Li, Q. (2025). The Effect of Critical Factors on Team Performance of Human–Robot Collaboration in Construction Projects: A PLS-SEM Approach. Buildings, 15(20), 3685. https://doi.org/10.3390/buildings15203685