Proposing an Affordable Real-Time Camera-Based Safety and Quality Management Framework for Construction Industries in Developing Countries

Abstract

1. Introduction

2. Literature Review

2.1. Traditional Quality Management Systems in Construction

2.2. Evolution of Technological Integration in Construction Management

2.3. Camera-Based Safety and Quality Management Systems for Developing Countries

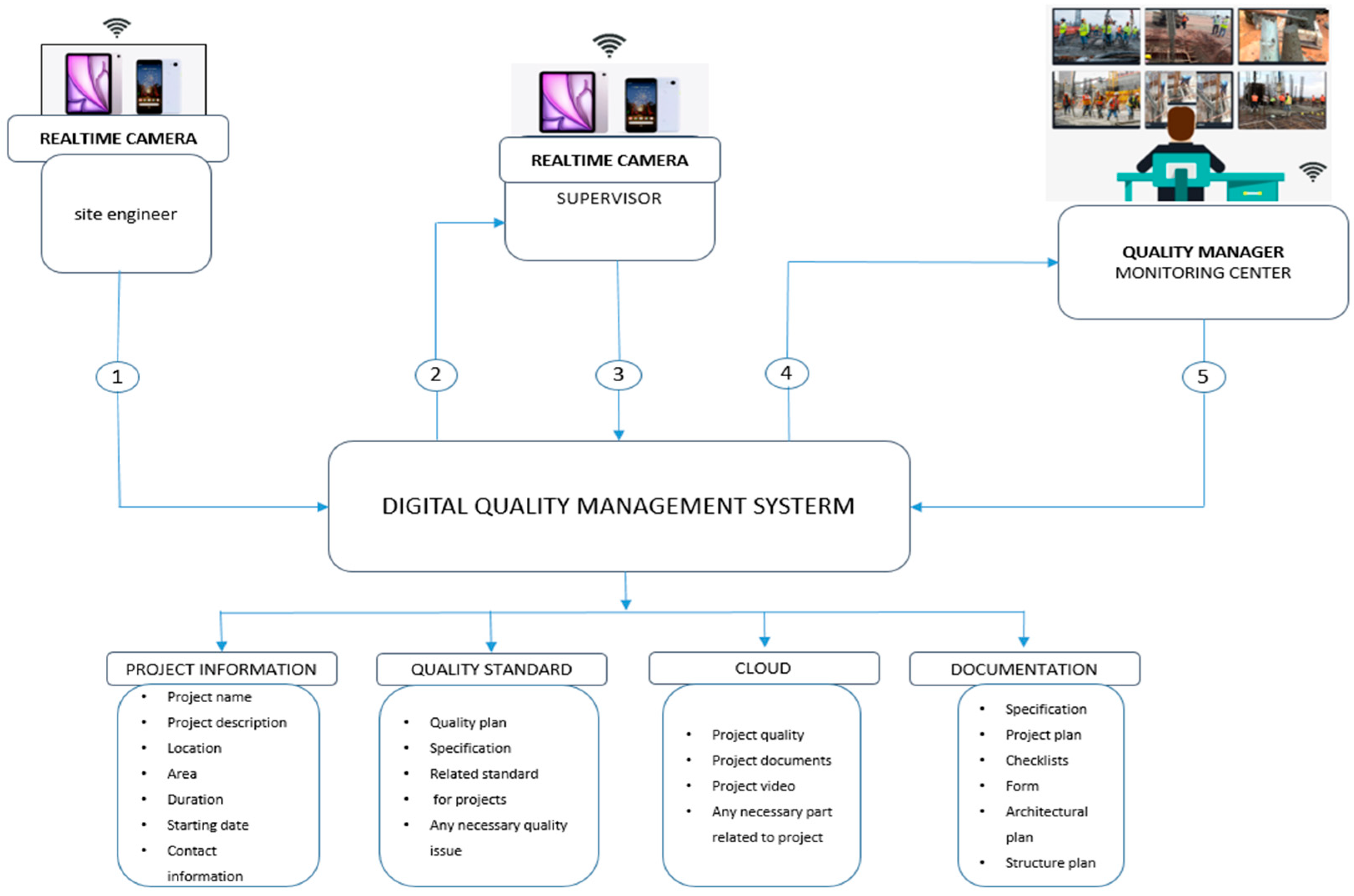

3. Developed Framework

- Small-to-Medium-Sized Enterprises: Small-to-medium-sized enterprises in the construction sector often operate under budget constraints and may find the affordable nature of this framework advantageous.

- Specific Use Cases: Projects requiring rapid deployment, temporary setups, or supplemental quality control mechanisms could benefit from this system’s simplicity and real-time monitoring capabilities.

- Remote Sites: Construction in remote or challenging terrains may find value in the framework’s lightweight and portable nature.

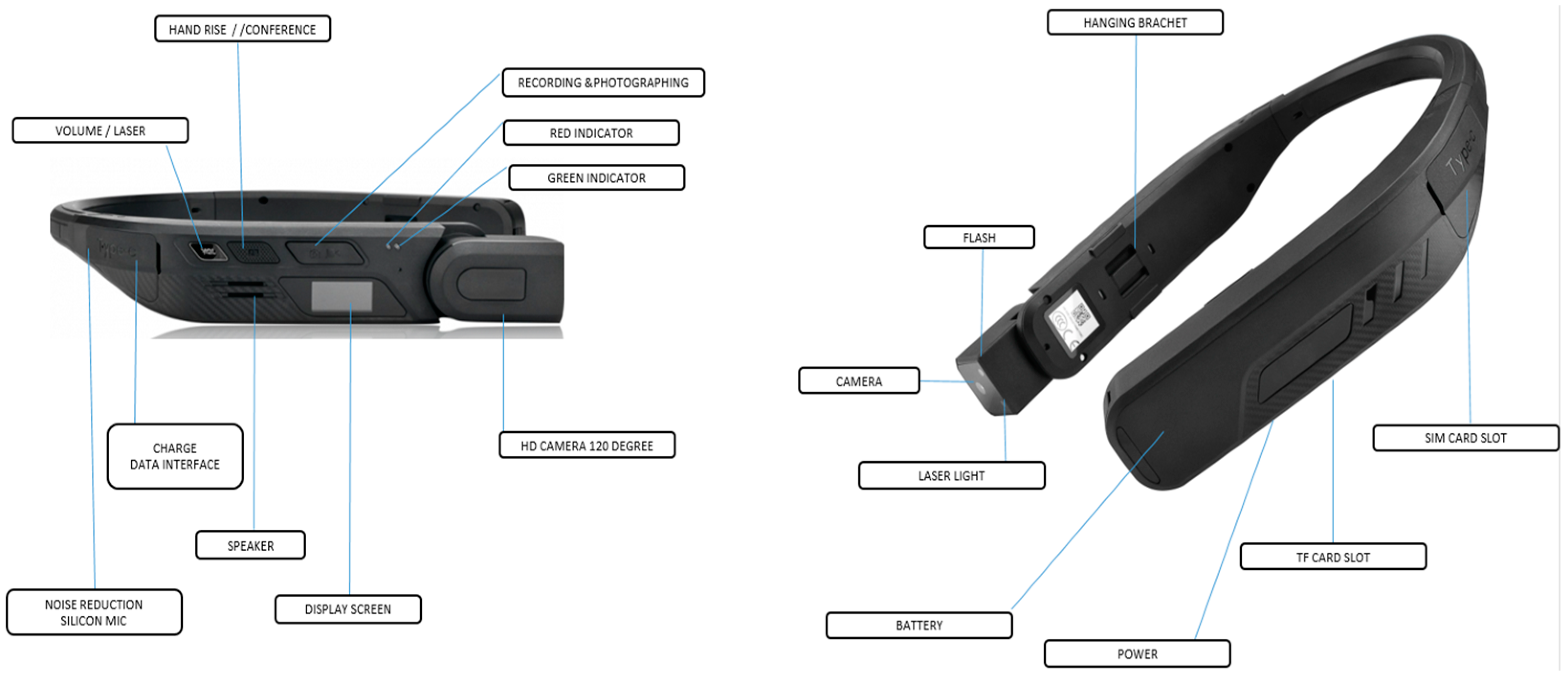

3.1. Camera-Based System

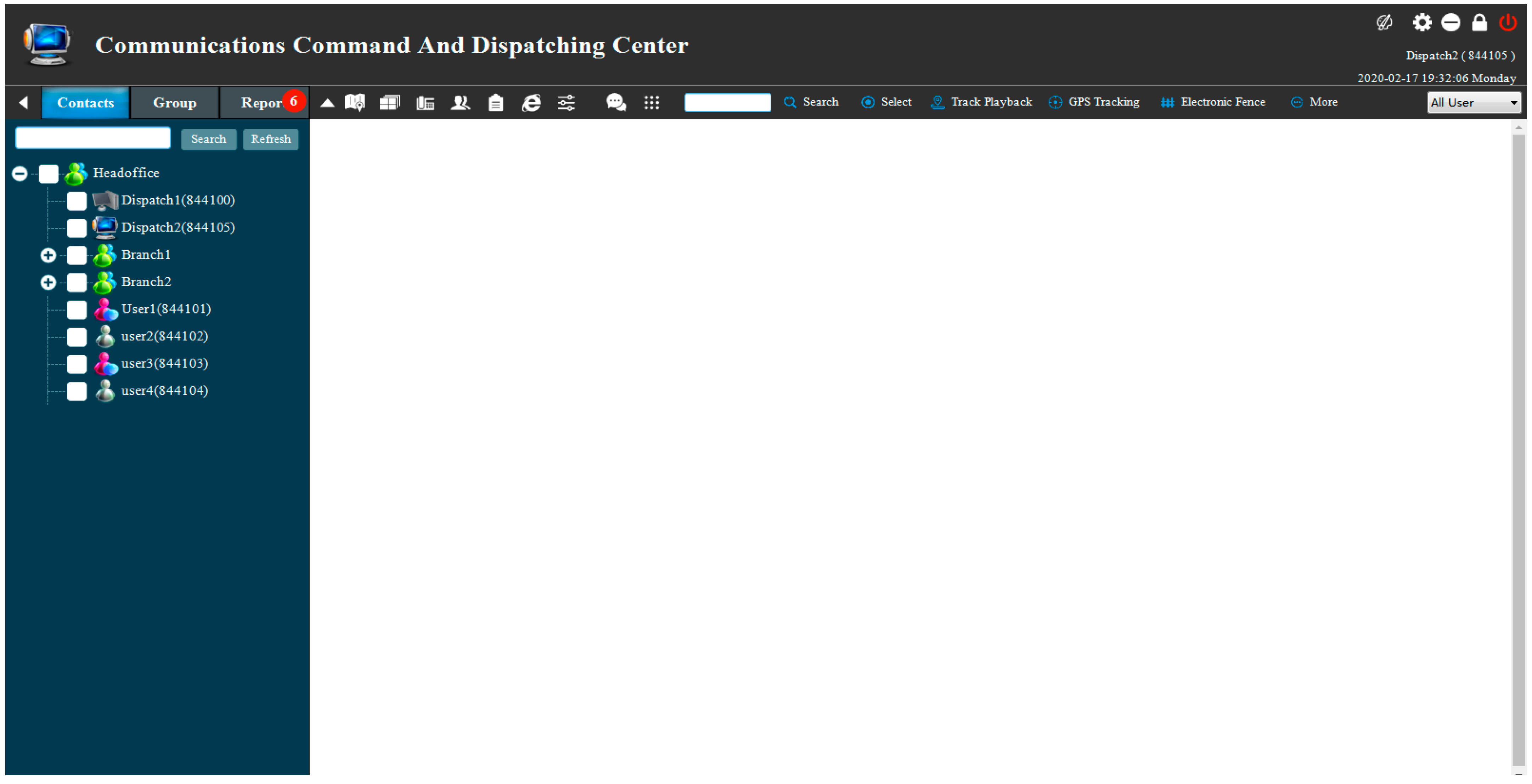

3.2. Centralized Construction Management Platform

3.3. Practical Implementation: Step-by-Step Procedure

- Initial Assessment and Planning:

- Conduct a detailed assessment of the construction site to identify safety and quality risks.

- Map out key areas where monitoring is required and establish priorities.

- Develop an implementation plan that includes hardware setup, software configuration, and training schedules.

- Hardware Deployment:

- Install wearable devices, such as helmet-mounted cameras, for on-site personnel.

- Set up connectivity infrastructure, including WiFi hotspots or mobile data solutions, to ensure stable real-time communication.

- Ensure backup power supplies are in place to address potential power disruptions.

- Software Configuration:

- Customize the centralized project management platform to reflect the project’s unique requirements, including specific BIM parameters, task lists, and performance indicators.

- Integrate real-time video streaming features and set up data storage for archiving video feeds and communications.

- Configure user access permissions to protect sensitive data while enabling collaboration.

- Team Training:

- Train on-site personnel to use wearable devices and adhere to safety protocols.

- Provide virtual training sessions for off-site experts on the platform’s functionalities, including real-time monitoring and feedback capabilities.

- Conduct trial runs to familiarize teams with the system and identify potential issues.

- Live Deployment:

- Launch the system during actual construction activities, starting with a pilot phase to refine processes.

- Monitor live feeds to ensure safety compliance and address quality concerns in real time.

- Use the platform’s interactive dashboard to track progress and identify emerging risks.

- Performance Monitoring and Feedback:

- Regularly review performance metrics captured by the platform, such as incident rates, task completion times, and quality scores.

- Conduct weekly meetings to discuss findings and implement improvements.

- Archive data and feedback for future analysis and continuous improvement.

- Post-Project Evaluation:

- Evaluate the overall impact of the system on project outcomes, including safety, quality, and financial performance.

- Document lessons learned and create the best practice guide for future projects.

3.4. Implementation Difficulties and Potential Resolutions

3.5. Contribution to Sustainability and Alignment with UN Sustainable Development Goals

4. Case Study

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mostafa, K.; Hegazy, T. Review of image-based analysis and applications in construction. Autom. Constr. 2021, 122, 103516. [Google Scholar] [CrossRef]

- Irfan, M.; Thaheem, M.J.; Khel, S.S.U.H.K.; Haq, M.F.U.; Zafar, M.S.; Ehtsham, M. Development of comprehensive coursework of quality management in universities pertinent to the construction industry: A case of Pakistan. TQM J. 2021, 33, 1100–1122. [Google Scholar] [CrossRef]

- Ofori, G. Challenges of construction industries in developing countries: Lessons from various countries. Gaborone 2000, 5, 15–17. [Google Scholar]

- Sezer, A.A.; Fredriksson, A. Environmental impact of construction transport and the effects of building certification schemes. Resour. Conserv. Recycl. 2021, 172, 105688. [Google Scholar] [CrossRef]

- Hong, J.; Shen, Q.; Xue, F. A multi-regional structural path analysis of the energy supply chain in China’s construction industry. Energy Policy 2016, 92, 56–68. [Google Scholar] [CrossRef]

- Ahn, Y.H.; Kwon, H.; Pearce, A.R.; Shin, H. Key competencies for US construction graduates: An exploratory factor analysis. In Proceedings of the 46th ASC Annual International Conference, Boston, MA, USA, 7–10 April 2010. [Google Scholar]

- Hashim, N.; Chileshe, N.; Baroudi, B. Management challenges within multiple project environments: Lessons for developing countries. Australas. J. Constr. Econ. Build. Conf. Ser. 2012, 1, 21–31. [Google Scholar] [CrossRef][Green Version]

- Okoye, P.U.; Ngwu, C.; Ugochukwu, S.C. Evaluation of management challenges facing construction practice in Nigeria. Int. J. Appl. Innov. Eng. Manag. 2015, 4, 19–28. [Google Scholar]

- Kar, D.; Basak, S.; Bhattacharya, A.K. Implementation of Construction Projects on Schedule—A Challenge to the Developing World. J. Econ. Int. Financ. 2009, 1, 088–092. [Google Scholar]

- Al-Kharashi, A.; Skitmore, M. Causes of delays in Saudi Arabian public sector construction projects. Constr. Manag. Econ. 2009, 27, 3–23. [Google Scholar] [CrossRef]

- Abdullah, A.A.; Mukmin, M.N.; Samad, Z.A. Application of project management methods in the construction of bungalow house project: A case study in Kuala Terengganu, Malaysia. Int. J. Econ. Manag. Sci. 2011, 1, 42–58. [Google Scholar]

- Dudgikar, C.S.; Kumthekar, M.B.; Khot, S.R. Development of ERP module for quality management in construction industry. Int. J. Electron. Commun. (IJEC) 2012, 1, 29–40. [Google Scholar]

- Ugochukwu, S.C.; Onyekwena, T. Participation of indigenous contractors in Nigerian public sector construction projects and their challenges in managing working capital. Int. J. Civ. Eng. Constr. Estate Manag. 2014, 1, 1–21. [Google Scholar]

- Vanegas, J.A.; DuBose, J.R.; Pearce, A.R. Sustainable technologies for the building construction industry. In Proceedings of the Proceedings, Symposium on Design for the Global Environment, Atlanta, GA, USA, 2–4 November 1996. [Google Scholar]

- Ali, A.S.; Wen, K.H. Building defects: Possible solution for poor construction workmanship. J. Build. Perform. 2011, 2, 59–69. [Google Scholar]

- Mohammed, T.; Haron, N.; Alias, A.; Muhammad, I.B.; Baba, D. Improving cost and time control in construction using building information model (BIM): A review. TQM J. 2018, 26, 21–36. [Google Scholar]

- Ofori, G. Construction industry development: Role of technology transfer. Constr. Manag. Econ. 1994, 12, 379–392. [Google Scholar] [CrossRef]

- Raftery, J.; Pasadilla, B.; Chiang, Y.H.; Hui, E.C.; Tang, B.S. Globalization and construction industry development: Implications of recent developments in the construction sector in Asia. Constr. Manag. Econ. 1998, 16, 729–737. [Google Scholar] [CrossRef]

- Harris, F.; McCaffer, R.; Baldwin, A.; Edum-Fotwe, F. Modern Construction Management; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Ashokkumar, D. Study of quality management in construction industry. Int. J. Innov. Res. Sci. Eng. Technol. 2014, 3, 36–43. [Google Scholar]

- Burati, J.L., Jr.; Matthews, M.F.; Kalidindi, S.N. Quality management in construction industry. J. Constr. Eng. Manag. 1991, 117, 341–359. [Google Scholar] [CrossRef]

- Kozlovska, M.; Mackova, D.; Spisakova, M. Survey of construction management documentation usage in planning and construction of building project. Procedia Eng. 2016, 161, 711–715. [Google Scholar] [CrossRef][Green Version]

- Yan, R.J.; Kayacan, E.; Chen, I.M.; Tiong, L.K.; Wu, J. QuicaBot: Quality inspection and assessment robot. IEEE Trans. Autom. Sci. Eng. 2018, 16, 506–517. [Google Scholar] [CrossRef]

- Akinyemi, A.; Dare, G.; Anthony, A.; Dabara, D.I. Building collapse in Nigeria: Issues and challenges. Int. J. Arts Sci. 2016, 9, 99–108. [Google Scholar]

- Loushine, T.W.; Hoonakker, P.L.; Carayon, P.; Smith, M.J. Quality and safety management in construction. Total Qual. Manag. Bus. Excell. 2006, 17, 1171–1212. [Google Scholar] [CrossRef]

- Petersen, D. Safety Management: A Human Approach, 3rd ed.; American Society of Safety Engineers: New York, NY, USA, 1988. [Google Scholar]

- Vallas, S.P. Why teamwork fails: Obstacles to workplace change in four manufacturing plants. Am. Sociol. Rev. 2003, 68, 223–250. [Google Scholar] [CrossRef]

- Occupational Safety and Health Administration. Safety and health program management guidelines: Issuance of voluntary guidelines. Fed. Regist. 1989, 54, 3904–3916. [Google Scholar]

- Krause, T.R. Safety and quality: Two sides of the same coin. Qual. Prog. 1997, 27, 47–50. [Google Scholar]

- Petersen, D. Accountability, culture & behavior. Prof. Saf. 1997, 42, 45. [Google Scholar]

- Zohar, D. Safety climate in industrial organizations: Theoretical and applied implications. J. Appl. Psychol. 1980, 65, 96. [Google Scholar] [CrossRef] [PubMed]

- Reason, J. Human Error; Cambridge University Press: Cambridge, UK, 1980. [Google Scholar]

- Li, H.; Lu, M.; Hsu, S.-C.; Gray, M.; Huang, T. Proactive behavior-based safety management for construction safety improvement. Saf. Sci. 2015, 75, 107–111. [Google Scholar] [CrossRef]

- IEEE Std 802.15.4-2006; Part 15.4: Wireless Medium Access Control (MAC) and Physical Layer (PHY) Specifications for Low-Rate Wireless Personal Area Networks (LR-WPANs). IEEE Standards Association: Piscataway, NJ, USA, 2006.

- Aleksandrova, S.V.; Vasiliev, V.A.; Alexandrov, M.N. Integration of quality management and digital technologies. In Proceedings of the 2019 International Conference “Quality Management, Transport and Information Security, Information Technologies” (IT&QM&IS), Sochi, Russia, 23–27 September 2019; pp. 20–22. [Google Scholar]

- Björk, B.C. Electronic Document Management in Construction—Research Issue and Results. ITcon V 2003, 8, 101–113. [Google Scholar]

- Lu, W.; Peng, Y.; Shen, Q.; Li, H. Generic model for measuring benefits of BIM as a learning tool in construction tasks. J. Constr. Eng. Manag. 2013, 139, 195–203. [Google Scholar] [CrossRef]

- Aladag, H.; Demirdögen, G.; Isık, Z. Building information modeling (BIM) use in Turkish construction industry. Procedia Eng. 2016, 161, 174–179. [Google Scholar] [CrossRef]

- Woo, J.; Wilsmann, J.; Kang, D. Use of as-built building information modeling. In Construction Research Congress 2010: Innovation for Reshaping Construction Practice; Construction Institute of ASCE: Banff, AB, Canada, 2010; pp. 538–548. [Google Scholar]

- Barlish, K.; Sullivan, K. How to measure the benefits of BIM—A case study approach. Autom. Constr. 2012, 24, 149–159. [Google Scholar] [CrossRef]

- Chen, X.; Zhu, Y.; Chen, H.; Ouyang, Y.; Luo, X.; Wu, X. BIM-based optimization of camera placement for indoor construction monitoring considering the construction schedule. Autom. Constr. 2021, 130, 103825. [Google Scholar] [CrossRef]

- Veras, P.R.; Suresh, S.; Renukappa, S. The adoption of big data concepts for sustainable practices implementation in the construction industry. In Proceedings of the 2018 IEEE/ACM International Conference on Utility and Cloud Computing Companion (UCC Companion), Zurich, Switzerland, 17–20 December 2018; pp. 349–352. [Google Scholar]

- Woodhead, R.; Stephenson, P.; Morrey, D. Digital construction: From point solutions to IoT ecosystem. Autom. Constr. 2018, 93, 35–46. [Google Scholar] [CrossRef]

- Jianli, S. Design and implementation of IOT-based logistics management system. In Proceedings of the 2012 IEEE Symposium on Electrical & Electronics Engineering (EEESYM), Kuala Lumpur, Malaysia, 24–27 June 2012; pp. 603–606. [Google Scholar]

- Attia, M.; Haidar, N.; Senouci, S.M.; Aglzim, E.H. Towards an efficient energy management to reduce CO2 emissions and billing cost in smart buildings. In Proceedings of the 2018 15th IEEE Annual Consumer Communications & Networking Conference (CCNC), Las Vegas, NV, USA, 12–15 January 2018; pp. 1–6. [Google Scholar]

- Bibri, S.E. The IoT for smart sustainable cities of the future: An analytical framework for sensor-based big data applications for environmental sustainability. Sustain. Cities Soc. 2018, 38, 230–253. [Google Scholar] [CrossRef]

- Arabshahi, M.; Wang, D.; Sun, J.; Rahnamayiezekavat, P.; Tang, W.; Wang, Y.; Wang, X. Review on sensing technology adoption in the construction industry. Sensors 2021, 21, 8307. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Irizarry, J.; Li, Q. Applying advanced technology to improve safety management in the construction industry: A literature review. Constr. Manag. Econ. 2013, 31, 606–622. [Google Scholar] [CrossRef]

- Patel, T.; Patel, V. Data privacy in construction industry by privacy-preserving data mining (PPDM) approach. Asian J. Civ. Eng. 2020, 21, 505–515. [Google Scholar] [CrossRef]

- Shojaei, P.; Haeri, S.A.S. Development of supply chain risk management approaches for construction projects: A grounded theory approach. Comput. Ind. Eng. 2019, 128, 837–850. [Google Scholar] [CrossRef]

- Strauss, A.; Corbin, J. Basics of Qualitative Research; Sage Publications: Thousand Oaks, CA, USA, 1990. [Google Scholar]

- Rodriguez-Repiso, L.; Setchi, R.; Salmeron, J.L. Modelling IT projects success with fuzzy cognitive maps. Expert Syst. Appl. 2007, 32, 543–559. [Google Scholar] [CrossRef]

- Tran SV, T.; Lee, D.; Pham, H.C.; Dang, L.H.; Park, C.; Lee, U.K. Leveraging BIM for Enhanced Camera Allocation Planning at Construction Job Sites: A Voxel-Based Site Coverage and Overlapping Analysis. Buildings 2024, 14, 1880. [Google Scholar] [CrossRef]

- Ray, S.J.; Teizer, J. Real-time construction worker posture analysis for ergonomics training. Adv. Eng. Informatics 2012, 26, 439–455. [Google Scholar] [CrossRef]

- Papageorgiou, E.I.; Salmeron, J.L. A review of fuzzy cognitive maps research during the last decade. IEEE Trans. Fuzzy Syst. 2012, 21, 66–79. [Google Scholar] [CrossRef]

- Seo, J.; Han, S.; Lee, S.; Kim, H. Computer vision techniques for construction safety and health monitoring. Adv. Eng. Informatics 2015, 29, 239–251. [Google Scholar] [CrossRef]

- Guo, S.; Li, J.; Liang, K.; Tang, B. Improved safety checklist analysis approach using intelligent video surveillance in the construction industry: A case study. Int. J. Occup. Saf. Ergon. 2021, 27, 1064–1075. [Google Scholar] [CrossRef]

- Guo, S.Y.; Ding, L.Y.; Luo, H.B.; Jiang, X.Y. A Big-Data-based platform of workers’ behavior: Observations from the field. Accid. Anal. Prev. 2016, 93, 299–309. [Google Scholar] [CrossRef] [PubMed]

- Mabrouk, A.B.; Zagrouba, E. Abnormal behavior recognition for intelligent video surveillance systems: A review. Expert Syst. Appl. 2018, 91, 480–491. [Google Scholar] [CrossRef]

- Guan, S.; Zhu, Z.; Wang, G. A review on UAV-based remote sensing technologies for construction and civil applications. Drones 2022, 6, 117. [Google Scholar] [CrossRef]

- Park, M.W.; Brilakis, I. Construction worker detection in video frames for initializing vision trackers. Autom. Constr. 2012, 28, 15–25. [Google Scholar] [CrossRef]

- Torres, H.N.; Ruiz, J.M.; Chang, G.K.; Anderson, J.L.; Garber, S.I. Automation in Highway Construction Part I: Implementation Challenges at State Transportation Departments and Success Stories (No. FHWA-HRT-16-030); United States. Federal Highway Administration; Office of Infrastructure Research and Development: Washington, DC, USA, 2018.

- Mohamed, M.; Tran, D.Q. Content analysis of e-inspection implementation for highway infrastructure construction projects. Constr. Arch. Manag. 2022, 30, 2621–2644. [Google Scholar] [CrossRef]

- Kamaruddin, S.S.; Mohammad, M.F.; Mahbub, R. Barriers and impact of mechanisation and automation in construction to achieve better quality products. Procedia-Soc. Behav. Sci. 2016, 222, 111–120. [Google Scholar] [CrossRef]

- Yap, J.B.H.; Chow, I.N.; Shavarebi, K. Criticality of construction industry problems in developing countries: Analyzing Malaysian projects. J. Manag. Eng. 2019, 35, 04019020. [Google Scholar] [CrossRef]

- Hinze, J.; Godfrey, R. An evaluation of safety performance measures for construction projects. J. Constr. Res. 2003, 4, 5–15. [Google Scholar] [CrossRef]

- Choe, S.; Leite, F.; Seedah, D.; Caldas, C. Application of sensing technology in the prevention of backing accidents in construction work zones. In Computing in Civil Engineering; SACE Library: Reston, VA, USA, 2013; pp. 557–564. [Google Scholar]

- Park, J.; Marks, E.; Cho, Y.K.; Suryanto, W. Performance test of wireless technologies for personnel and equipment proximity sensing in work zones. J. Constr. Eng. Manag. 2016, 142, 04015049. [Google Scholar] [CrossRef]

- Zhu, Z.; Park, M.-W.; Koch, C.; Soltani, M.; Hammad, A.; Davari, K. Predicting movements of on-site workers and mobile equipment for enhancing construction site safety. Autom. Constr. 2016, 68, 95–101. [Google Scholar] [CrossRef]

- Akinci, B.; Boukamp, F.; Gordon, C.; Huber, D.; Lyons, C.; Park, K. A formalism for utilization of sensor systems and integrated project models for active construction quality control. Autom. Constr. 2006, 15, 124–138. [Google Scholar] [CrossRef]

- Kim, C.; Son, H.; Kim, C. Automated construction progress measurement using a 4D building information model and 3D data. Autom. Constr. 2013, 31, 75–82. [Google Scholar] [CrossRef]

- Golparvar-Fard, M.; Pena-Mora, F.; Savarese, S. Automated progress monitoring using unordered daily construction photographs and IFC-based building information models. J. Comput. Civ. Eng. 2015, 29, 04014025. [Google Scholar] [CrossRef]

- Chi, H.L.; Kang, S.C.; Wang, X. Research trends and opportunities of augmented reality applications in architecture, engineering, and construction. Autom. Constr. 2013, 33, 116–122. [Google Scholar] [CrossRef]

- Fang, W.; Ding, L.; Zhong, B.; Love, P.E.; Luo, H. Automated detection of workers and heavy equipment on construction sites: A convolutional neural network approach. Adv. Eng. Inform. 2018, 37, 139–149. [Google Scholar] [CrossRef]

- Fang, W.; Zhong, B.; Zhao, N.; Love, P.E.; Luo, H.; Xue, J.; Xu, S. A deep learning-based approach for mitigating falls from height with computer vision: Convolutional neural network. Adv. Eng. Inform. 2019, 39, 170–177. [Google Scholar] [CrossRef]

| Study | System Features | Context/Application | Limitations of the Study | Advantageous of Proposed System |

|---|---|---|---|---|

| Akinci et al. [70] | Utilizes laser scanners and photogrammetry for quality control in construction. | Applied in construction projects for detecting dimensional discrepancies. | High costs of laser scanners and photogrammetry limit accessibility, especially in developing regions or small-scale projects. | The proposed system offers a more cost-effective solution by using affordable cameras and open source software, reducing initial and operational expenses. |

| Kim et al. [71] | Implements automated progress tracking using 4D BIM and image processing techniques. | Used in monitoring construction progress and comparing it with planned schedules. | Requires integration with 4D BIM, which has a steep learning curve and high software costs, limiting widespread adoption. | The proposed system provides real-time monitoring capabilities with lower hardware costs, making it accessible for small-to-medium-sized projects. |

| Golparvar-Fard et al. [72] | Integrates photogrammetry and BIM for automated construction progress monitoring and quality control. | Focuses on enhancing accuracy in progress tracking and defect detection in construction projects. | Relies heavily on photogrammetry, which is computationally intensive and unsuitable for real-time analysis in resource-constrained settings. | The proposed system combines real-time defect detection and safety monitoring. |

| Chi et al. [73] | Uses computer vision techniques for automated detection of construction defects from site images. | Focuses on improving the efficiency of quality inspections in construction projects. | The system is limited by its dependence on high-quality data and may fail to perform adequately in low-light or noisy environments. | The proposed system integrates customizable privacy features, ensuring compliance with data protection regulations across various regions. |

| Fang et al. [74] | Uses convolutional neural networks for detecting workers and heavy equipment on construction sites. | Focused on ensuring safety by monitoring worker–equipment interaction zones to prevent accidents. | Requires substantial computational resources for neural network operations, limiting deployment in resource-constrained environments. | Proposed system offers similar safety monitoring capabilities at a fraction of the cost, making it accessible to smaller-scale projects. |

| Fang et al. [75] | Implements a real-time construction safety monitoring system using computer vision and deep learning algorithms. | Applied in construction sites to detect and prevent safety hazards in real time. | Requires significant computational resources for deep learning algorithms, making it expensive for smaller projects or developing regions. | The proposed system’s real-time monitoring capabilities enhance both safety and quality management, streamlining processes and reducing costs. |

| Feature | Wearable Tech Interface | Centralized Project Management Platform |

|---|---|---|

| Display | 2-inch LCD screen | On-Screen Display (OSD) |

| Resolution | Up to 1512 p | N/A |

| Frame Rate | Up to 30 fps | N/A |

| Recording Modes | On-demand or continuous | Supports playback |

| Compression | H.264/H.265 | N/A |

| Audio | Supports audio recording | Supports two-way intercom |

| Light source | Flashlight, Laser, IR (up to 10 m) | N/A |

| Storage | Embedded (32~128 GB) | N/A |

| Network | TCP/IP, 3G/4G, WiFi, Bluetooth BT4.1 | TCP/IP, 3G/4G, WiFi, Bluetooth BT 4.1 |

| GPS | Embedded | N/A |

| Additional Features | Push-to-talk radio, snapshot during recording, record time display, device ID and location, overwrite, play speed, pre-post recording, recording encryption | Radio communication, pre-post recording, recording encryption |

| Environment | Temperature: −40–−60°, Humidity: 40~80% | Temperature: −20–+55°, Humidity: 5% RH–95% RH non-condensing |

| Battery Capacity | 4000 mAh non-replaceable battery, up to 12 h recording time | 2500 mAh X2 (interchangeable) +280 mAh, up to 8 h recording time |

| Dimensions | 83.254.829.8 mm | 230.0200.5036.40 mm |

| Weight | Approx. 145 g | 300 ± 5 g |

| IP Rating | IP68 | IP66 |

| Other Features | Dual bit stream, indicator lights | Dual bit stream, indicator lights, SOS and Man Down functionality, GeoFence, five configurable buttons |

| Component | Description |

|---|---|

| Login | Secure login with account number, password, local address selection, and language options. |

| Settings | Configuration of server address, data and signaling ports, video call parameters, and transport protocols. |

| Contacts | Organized display of contact lists and group configurations. |

| Groups | Management of various groups such as conference, intercom, and broadcast groups. |

| Report | Display and management of photos, videos, and audio recordings uploaded by users. |

| Map | Real-time online maps showing member locations and enabling various monitoring functions. |

| Video Monitor | Interface for real-time video surveillance of construction sites. |

| Call Monitor | Real-time audio surveillance and management of voice communications. |

| Member List | Real-time display of member lists in a user-friendly format. |

| Record List | Management of local photos and videos. |

| Web Page | Integration with third-party systems and access to additional online resources. |

| Backstage Management | Tools for task management and administrative functions. |

| Message | Interface for sending and receiving multimedia messages between users and dispatchers. |

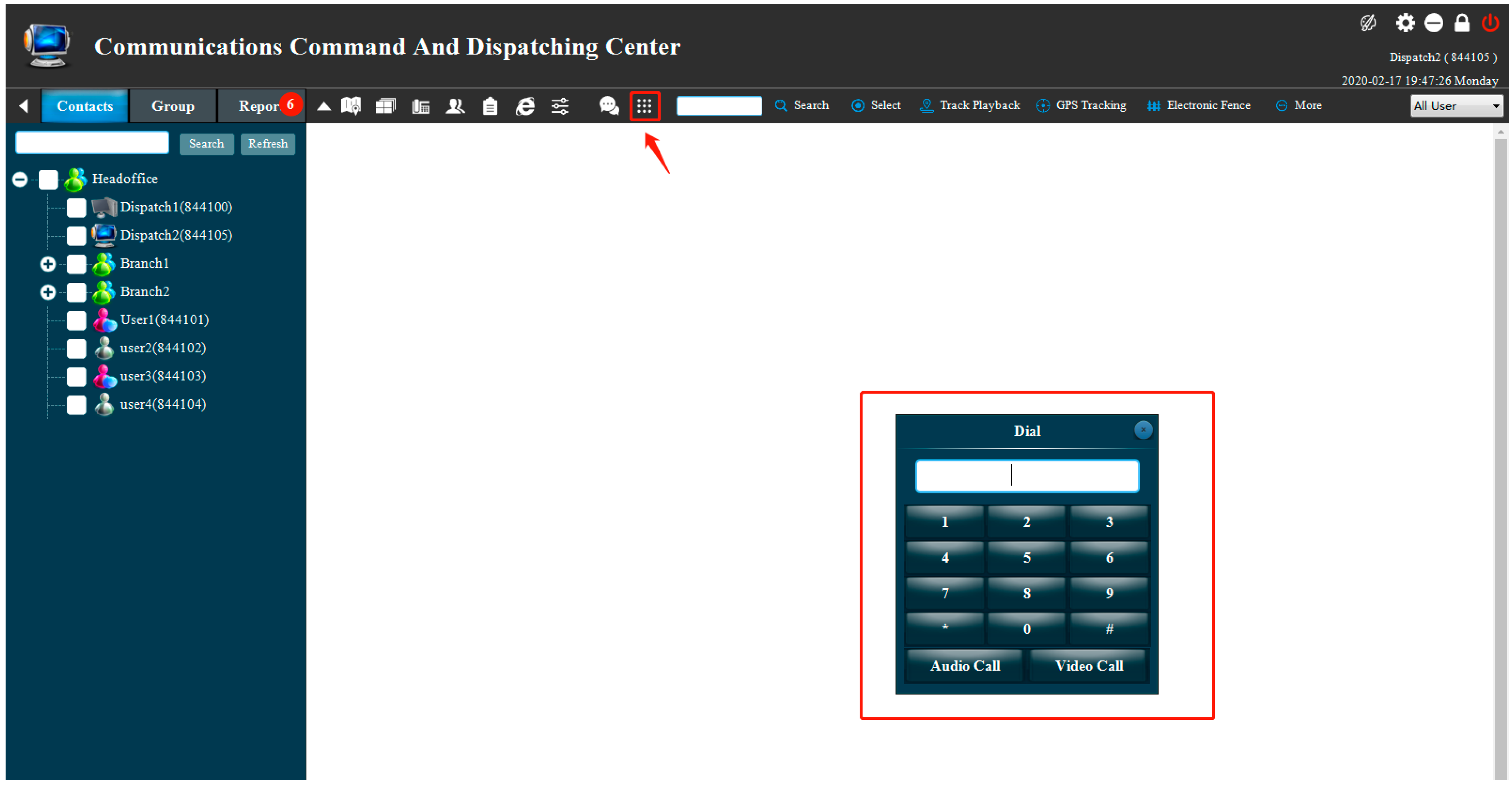

| Dial | Dial pad for initiating and managing calls. |

| Voice Dispatching | Functions for point-to-point calls, group conferencing, monitoring, and emergency call handling. |

| Electronic Fence | Creation and management of electronic fences with alerts for boundary crossings. |

| GPS Tracking | Real-time tracking of member locations and movement. |

| Track Playback | Playback of member movement history over specified timeframes. |

| System Settings | Comprehensive settings for automatic call handling, offline maps, video recording, and log management. |

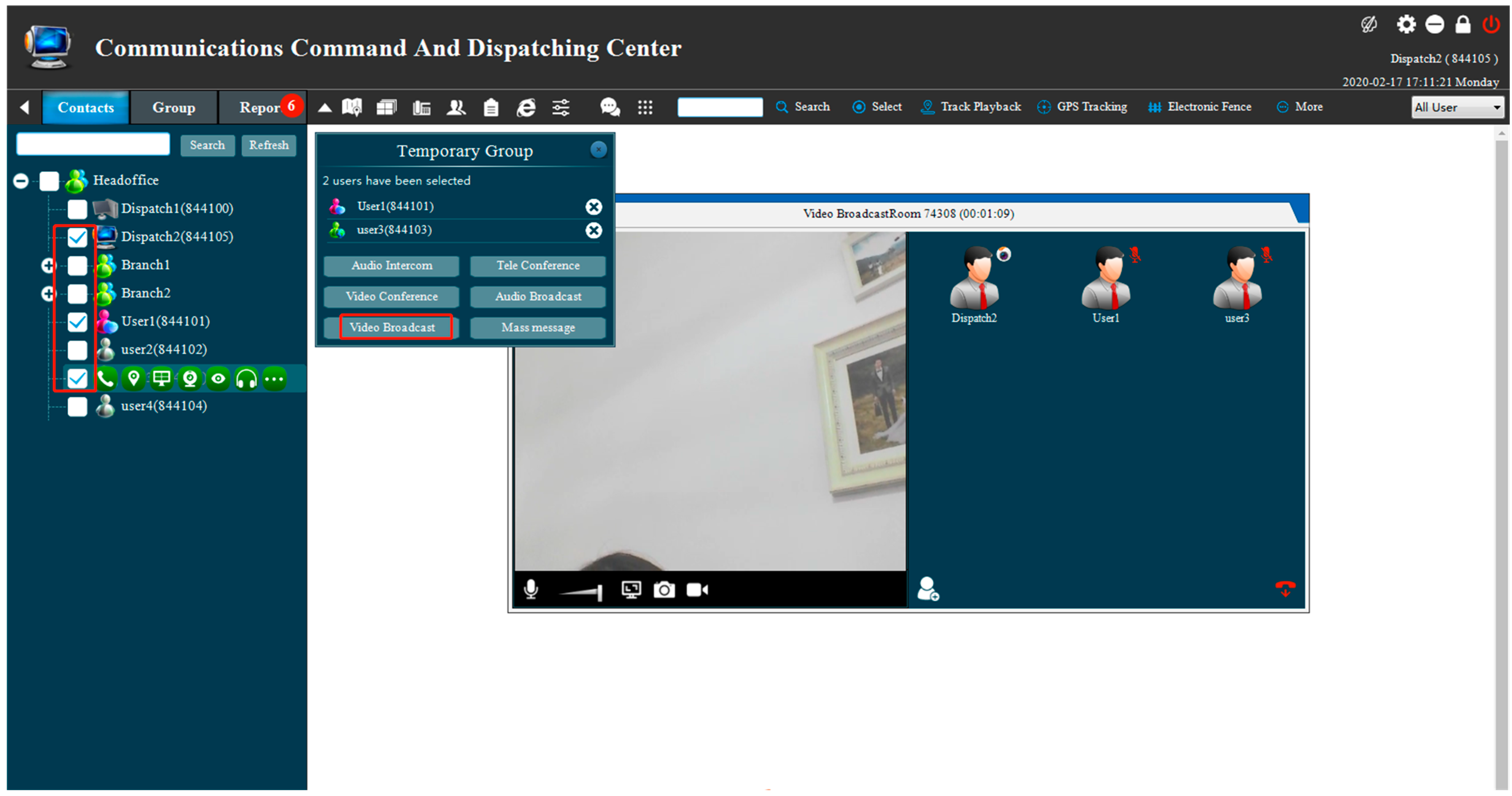

| Temporary Groups | Quick creation of temporary audio, video, and teleconference groups for dynamic communication needs. |

| Challenge | Description | Suggested Solution |

|---|---|---|

| Data Security and Privacy | Vulnerability to unauthorized access or cyberattacks. | Advanced encryption, secure VPNs, multi-factor authentication. |

| System Downtime | Risk of prolonged downtime due to DDoS attacks. | Robust IDPS, redundant server infrastructure. |

| Unauthorized Device Access | Potential access by unauthorized users through stolen devices. | Biometric authentication, remote wipe capability. |

| Network Connectivity Vulnerabilities | Exposure to man-in-the-middle attacks due to weak connections. | Secure protocols (HTTPS, TLS), network traffic monitoring. |

| Compliance with Local Regulations | Need to meet varying data storage and privacy laws. | Collaboration with legal experts, system customization. |

| Feature | Relevant SDGs | Contribution |

|---|---|---|

| Real-Time Monitoring | SDG 9, SDG 11 | Enhances construction efficiency and quality, supports resilient infrastructure development. |

| Waste Reduction | SDG 12 | Minimizes material wastage, promotes responsible resource consumption. |

| Safety Protocols | SDG 8 | Improves workplace safety, ensures decent working conditions. |

| Global Collaboration | SDG 17 | Facilitates international knowledge sharing and best practice adoption. |

| Quality Management Integration | SDG 11 | Supports sustainable urban development by improving construction standards. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdullah, Z.O.; Çelik, T.; Çelik, T. Proposing an Affordable Real-Time Camera-Based Safety and Quality Management Framework for Construction Industries in Developing Countries. Buildings 2025, 15, 156. https://doi.org/10.3390/buildings15020156

Abdullah ZO, Çelik T, Çelik T. Proposing an Affordable Real-Time Camera-Based Safety and Quality Management Framework for Construction Industries in Developing Countries. Buildings. 2025; 15(2):156. https://doi.org/10.3390/buildings15020156

Chicago/Turabian StyleAbdullah, Zanyar Omar, Tahir Çelik, and Tolga Çelik. 2025. "Proposing an Affordable Real-Time Camera-Based Safety and Quality Management Framework for Construction Industries in Developing Countries" Buildings 15, no. 2: 156. https://doi.org/10.3390/buildings15020156

APA StyleAbdullah, Z. O., Çelik, T., & Çelik, T. (2025). Proposing an Affordable Real-Time Camera-Based Safety and Quality Management Framework for Construction Industries in Developing Countries. Buildings, 15(2), 156. https://doi.org/10.3390/buildings15020156