A Proposal for Electromagnetic Performance in Cementitious Systems: Carbon Fiber and Copper Slag

Abstract

1. Introduction

2. Experimental Program

2.1. Materials

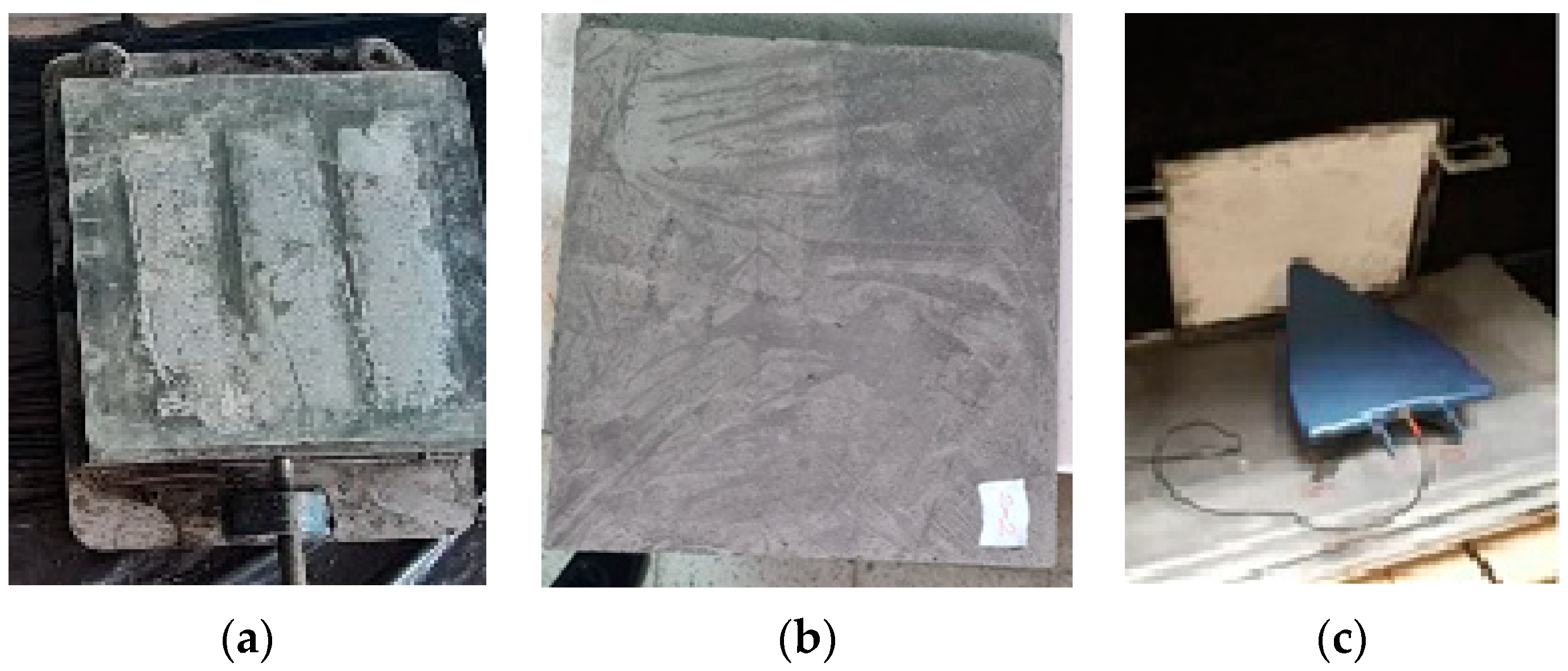

2.2. Sample Preparation

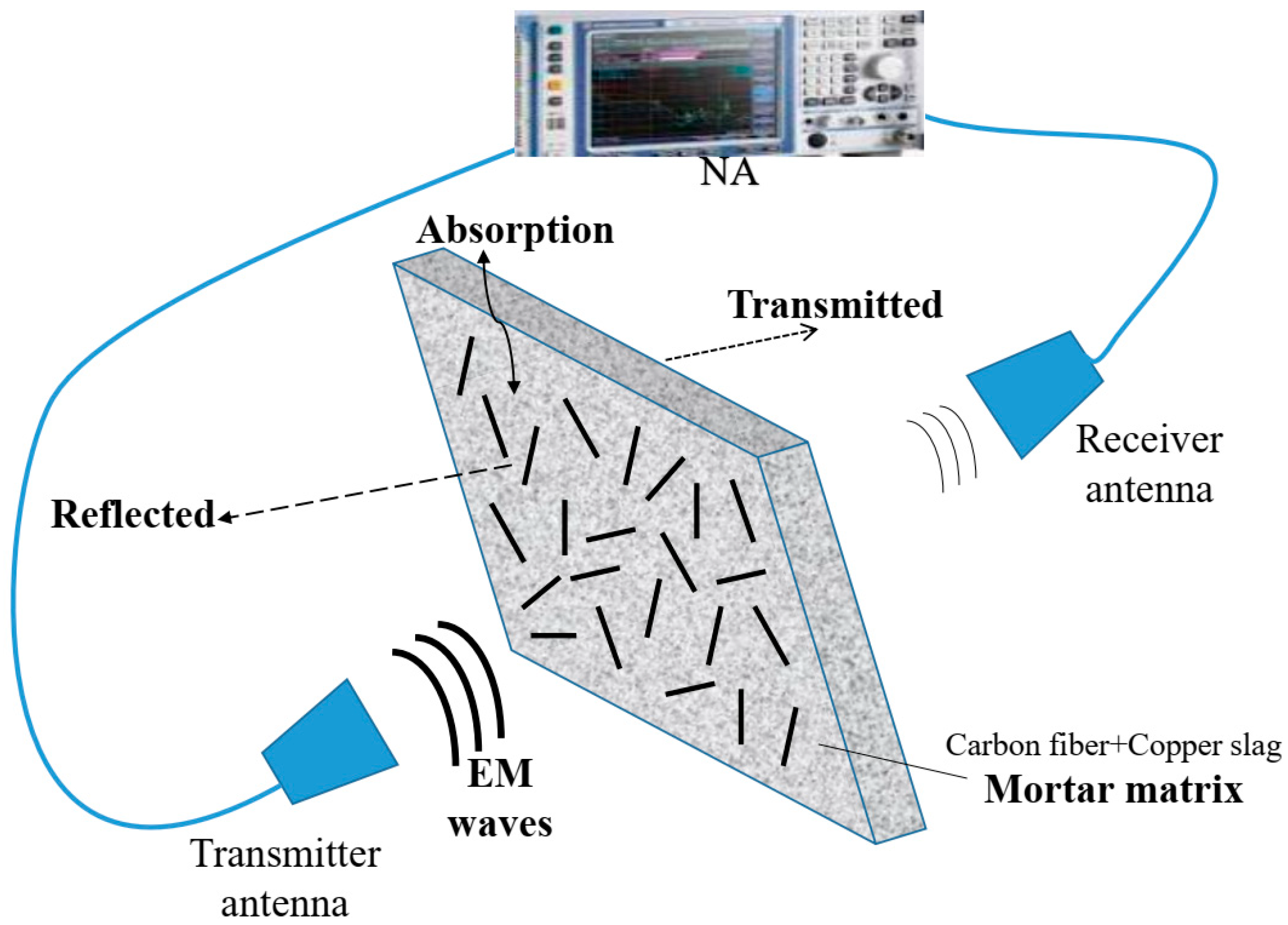

2.3. Test Methods

Electromagnetic Wave Shielding

3. Result and Discussion

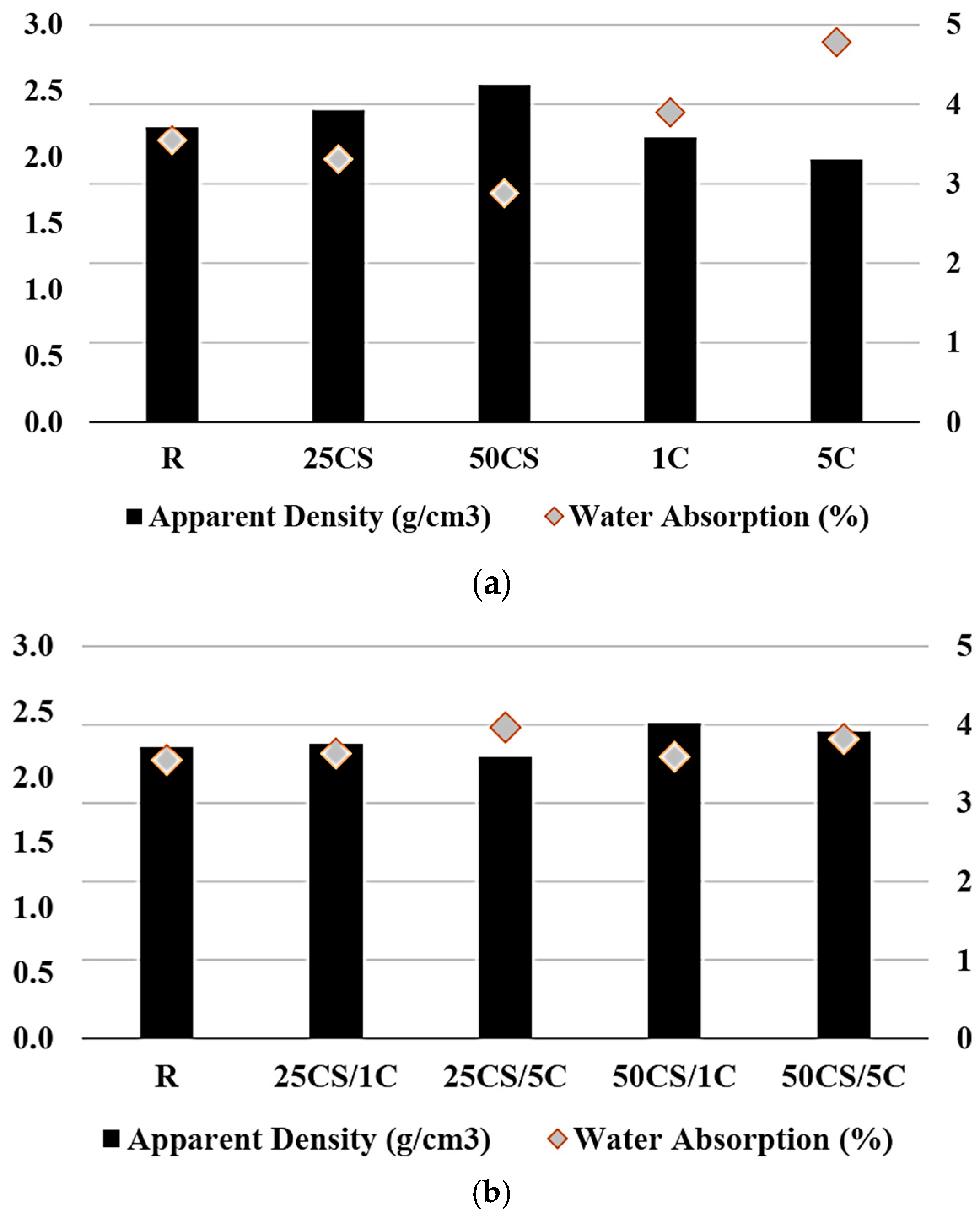

3.1. Measurement Results of Physical and Mechanical Properties of Mortar Samples

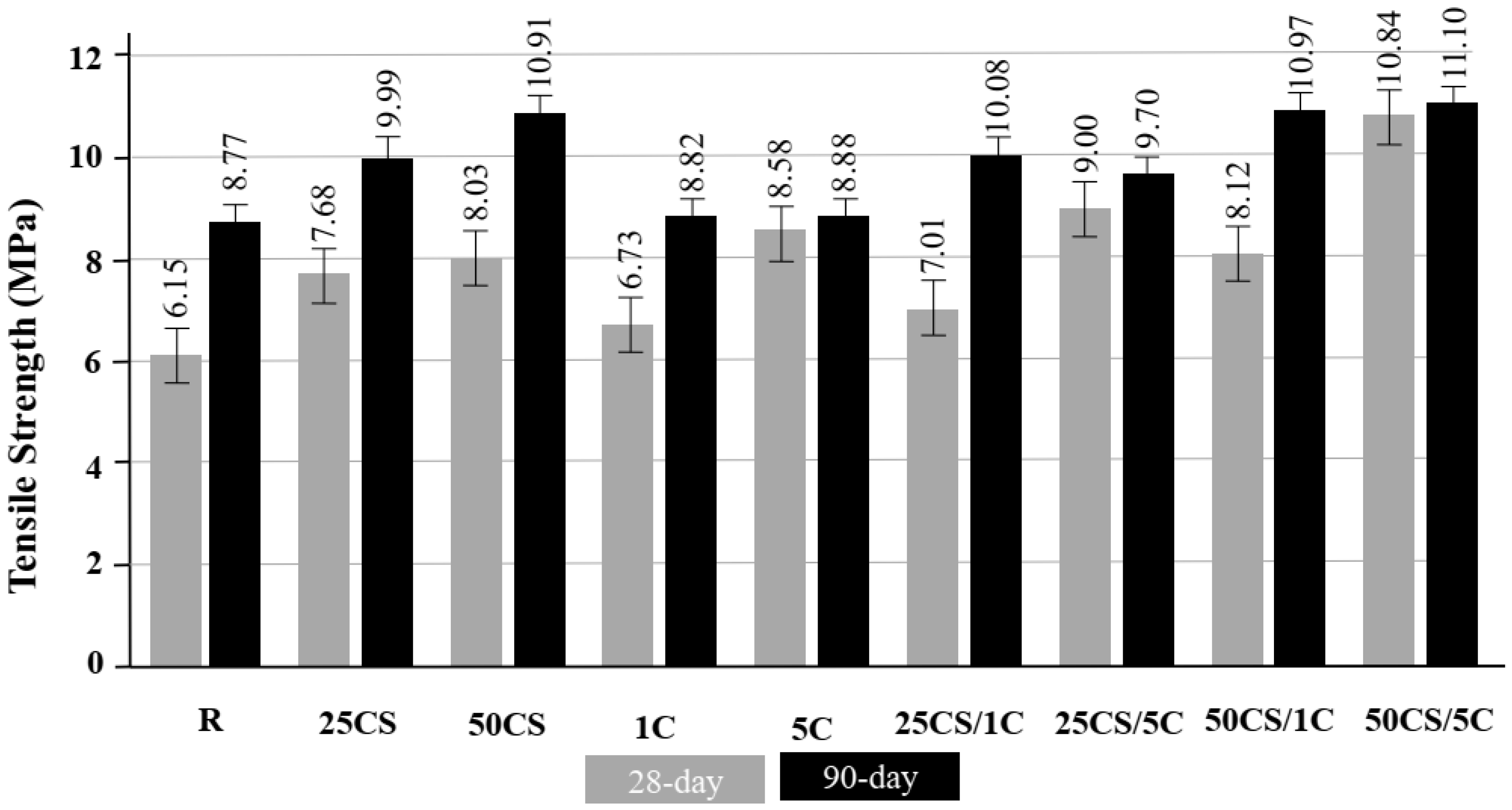

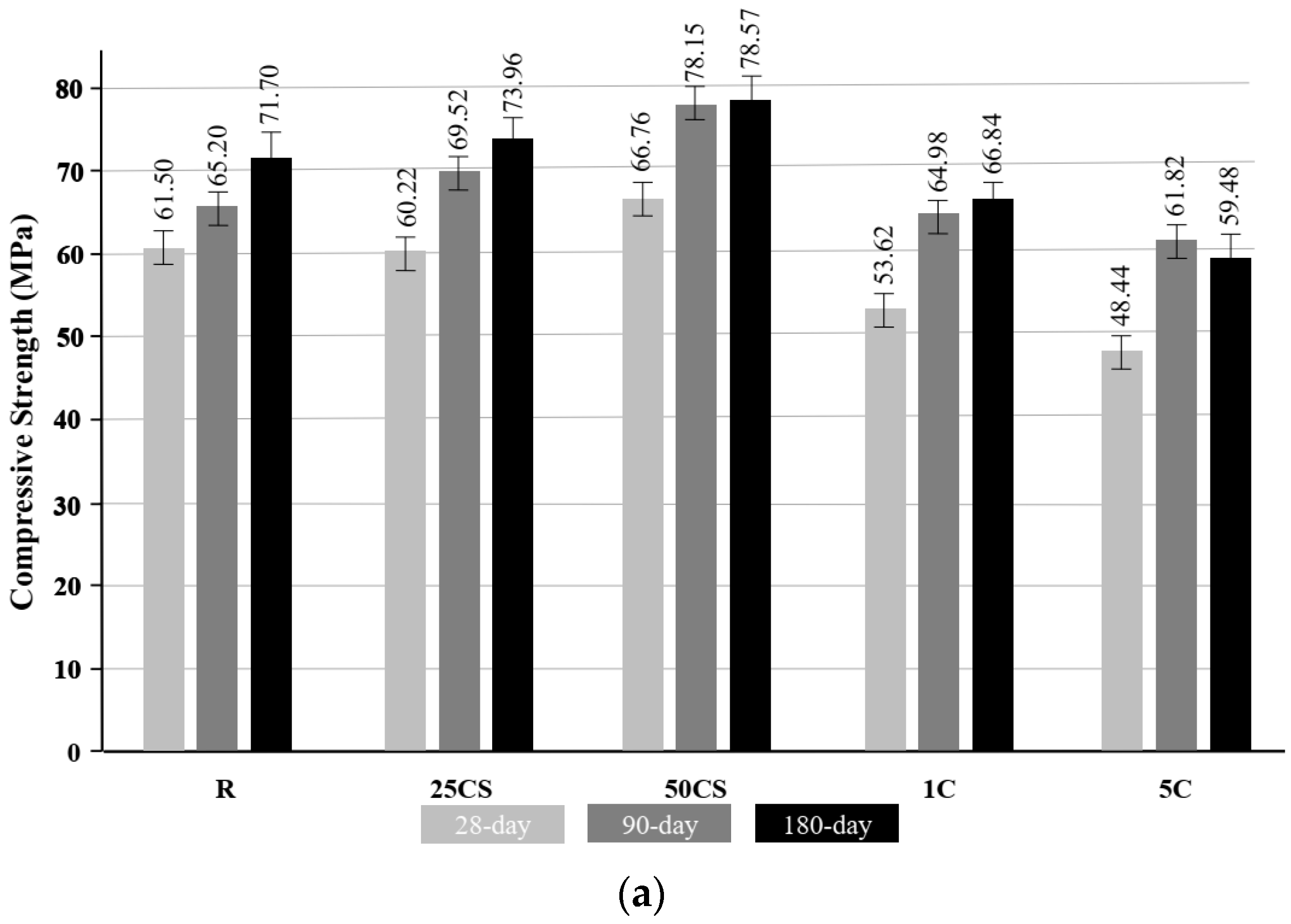

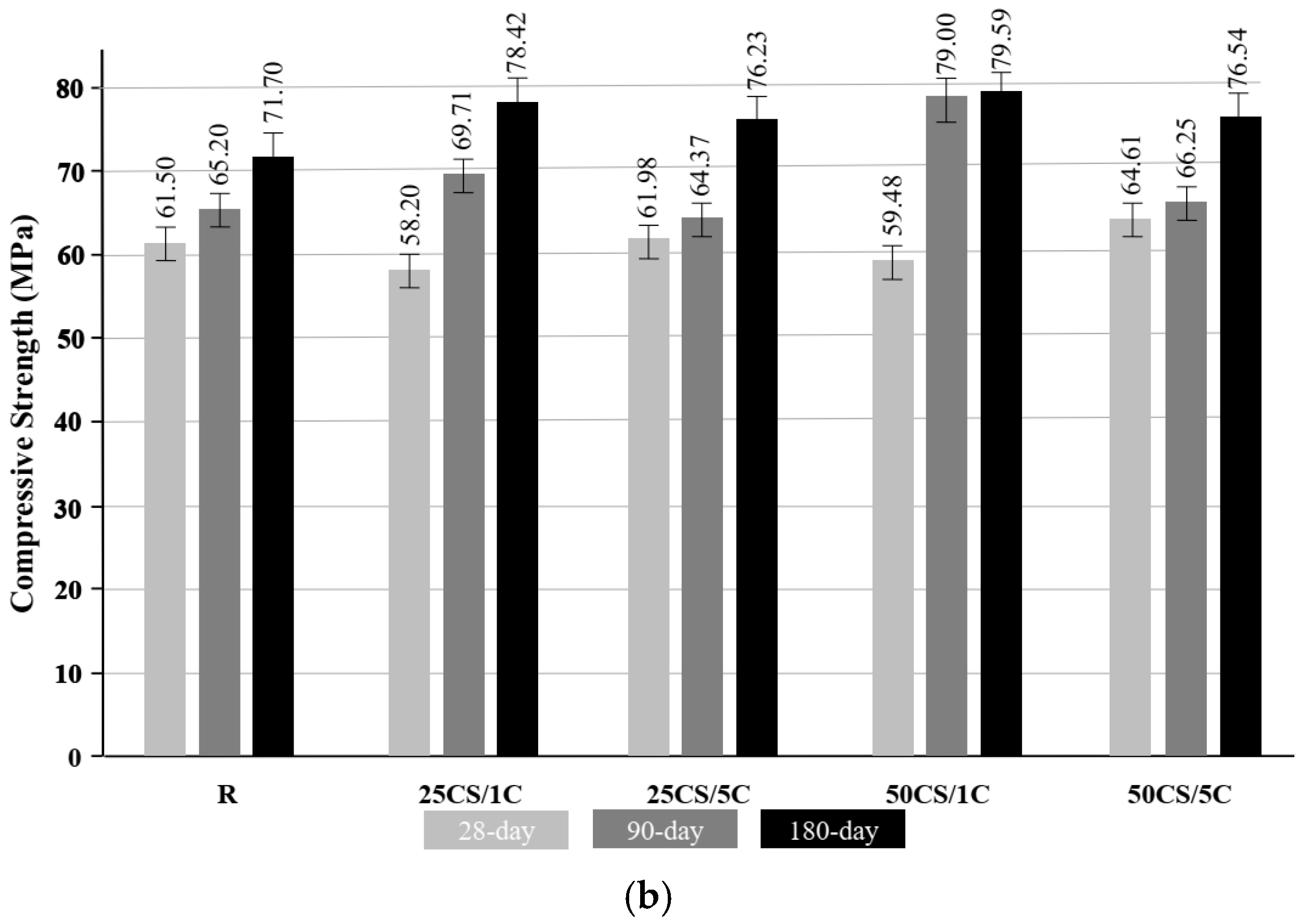

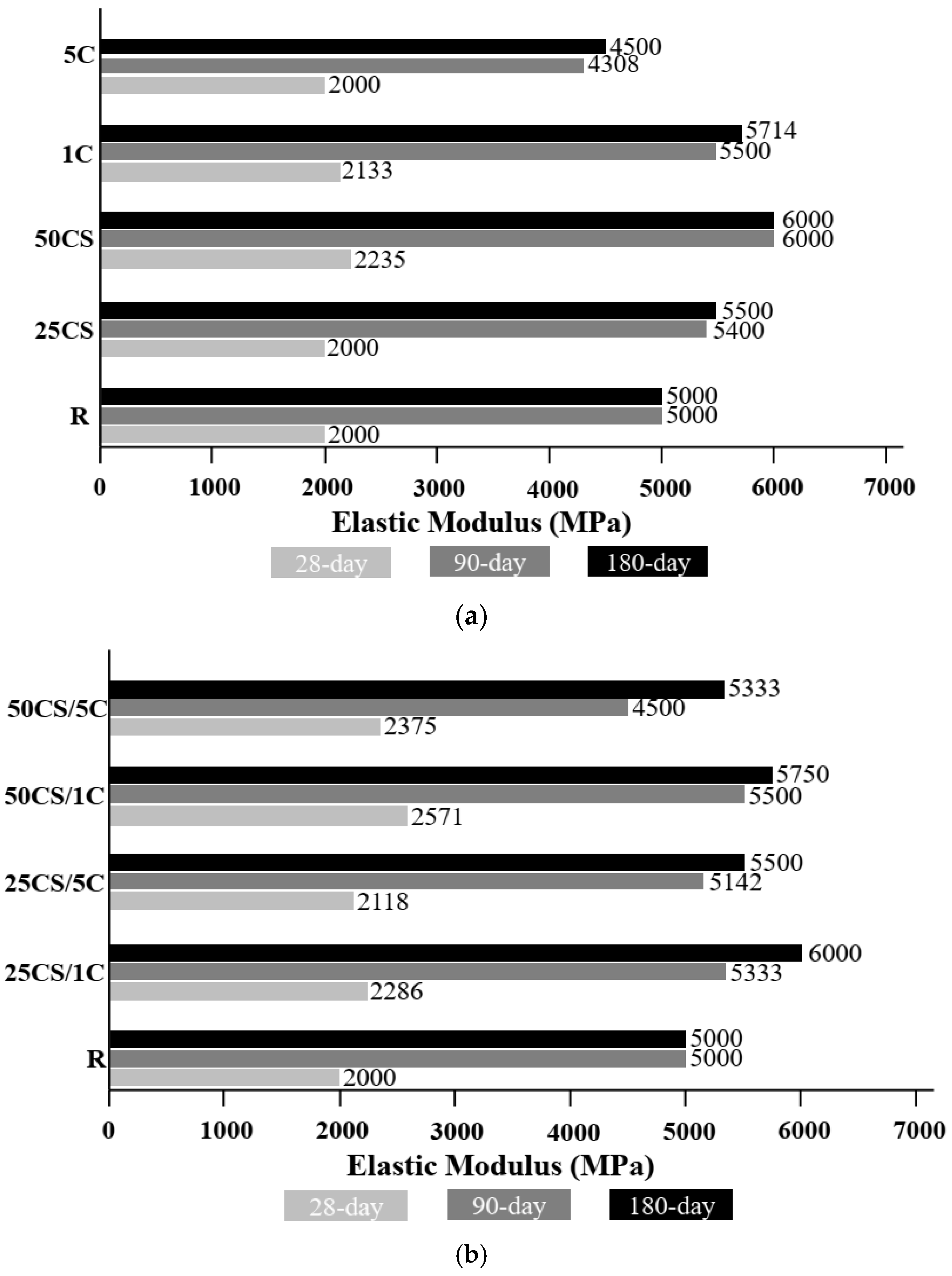

3.2. Measurement Results of Mechanical Strength

3.3. Measurement Results of EMI Shielding Effectiveness

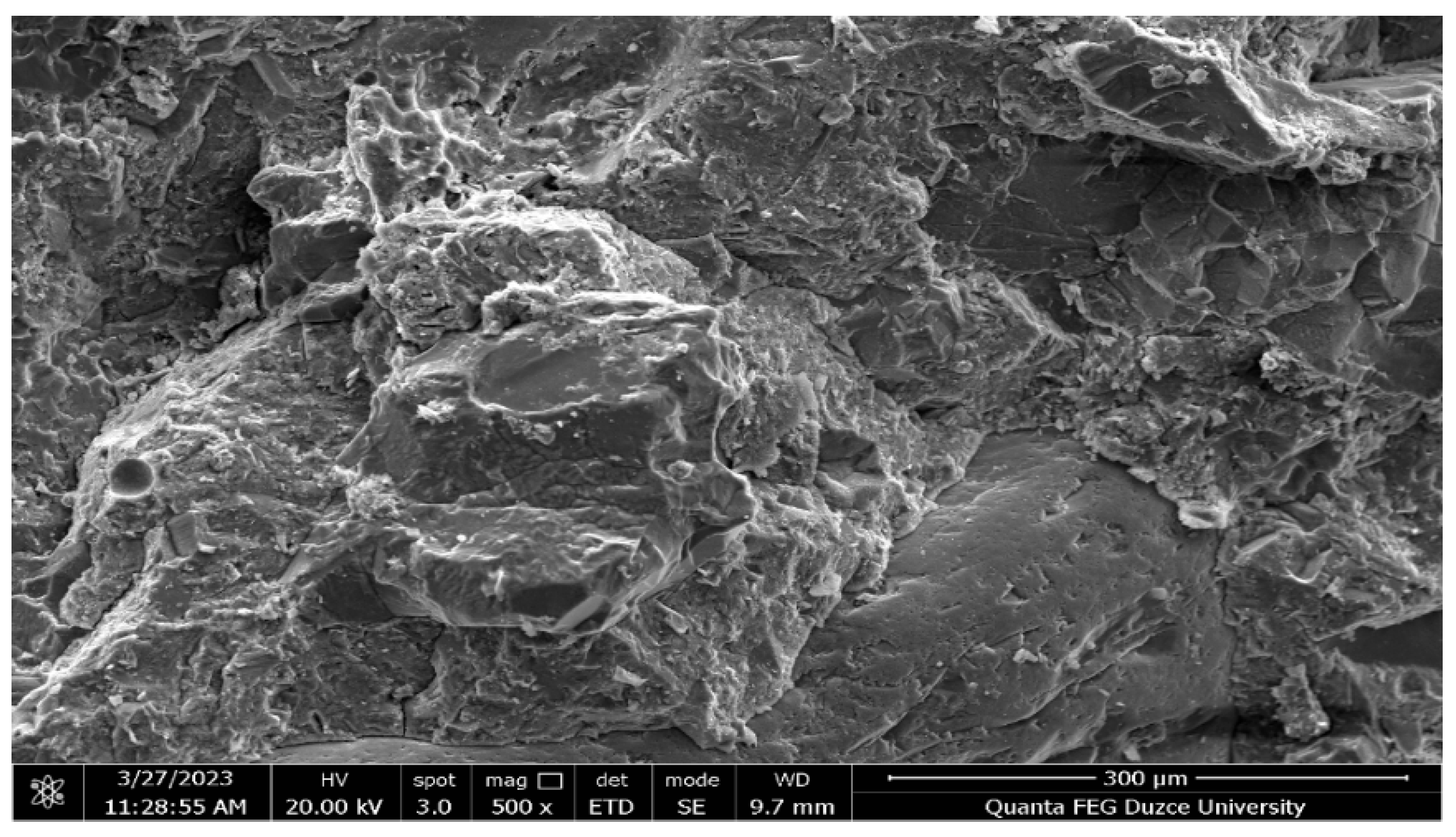

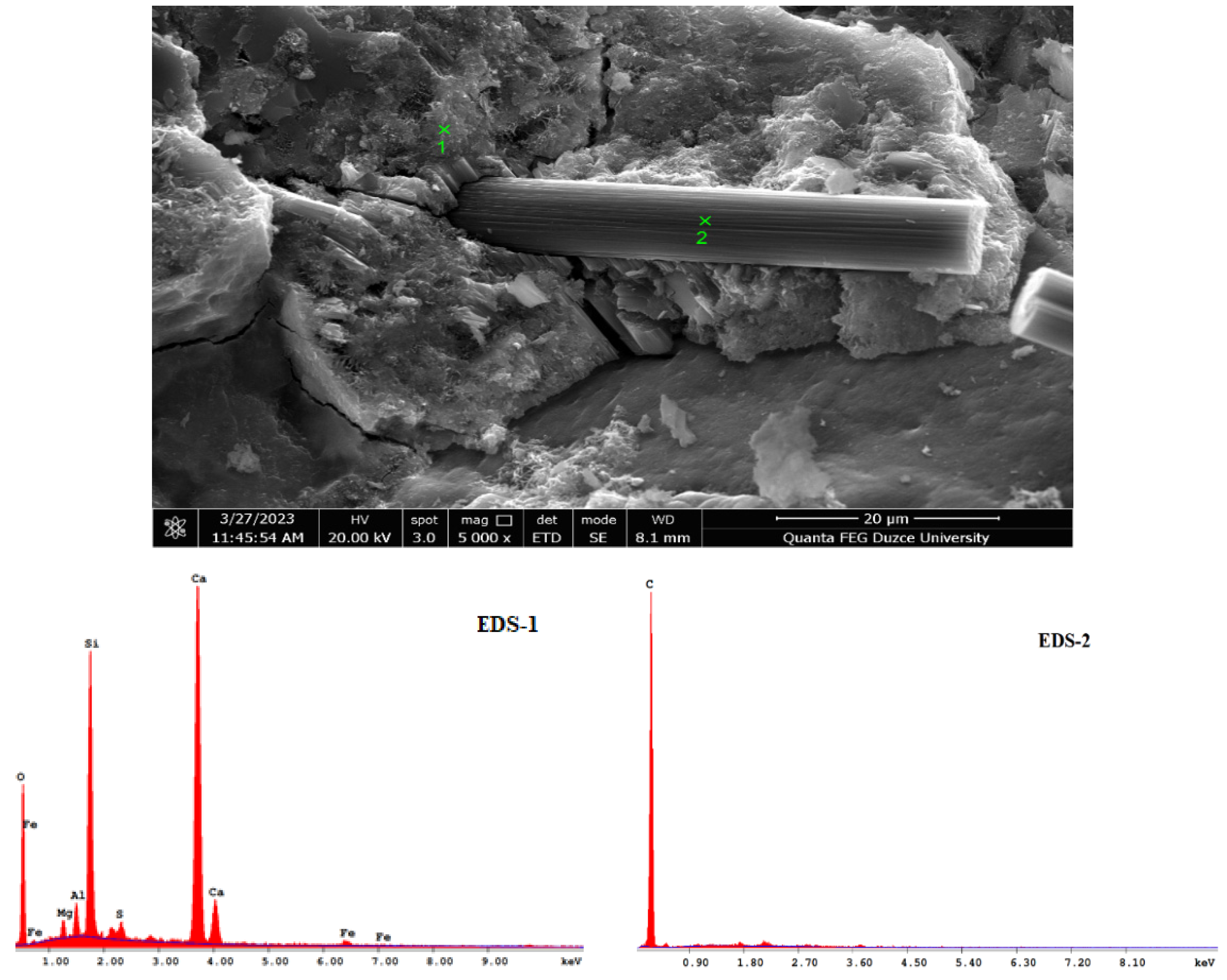

3.4. Microstructural Characterization with SEM

4. Conclusions

- In mortar series, an increase in unit volume weight was observed with the replacement of copper slag, while a decrease in unit volume weight was observed in mortar series with carbon fiber reinforcement. This increase and decrease in the series can be explained by the higher density of copper slag and the relatively low density of carbon fiber.

- Static elasticity modulus values have decreased with carbon fiber substitution and have shown a significant increase with copper slag substitution. As the curing time increases, the elasticity modulus values increase due to the hydration process. Carbon fibers increase the porosity rate and reduce the mechanical properties Copper slag, an industrial waste, reduces porosity and increases mechanical strength. When carbon fiber and copper slag are used together, the increase in copper slag contributes to the increase in compressive strength, while keeping the slag ratio constant and increasing the carbon fiber ratio has led to a decrease in compressive strength.

- Shielding effectiveness increased with the use of carbon fiber in the mortar at a volumetric rate of 5%. An average shielding effectiveness of 35 dB was achieved at low frequencies and 30 dB at high frequencies. Substituting copper slag at 25% and 50% resulted in a relative increase in shielding effectiveness. This increase was particularly effective at low frequencies. Substituting 50% copper slag and 5% carbon fiber can significantly increase shielding effectiveness, particularly at high frequencies.

- Considering its contribution to sustainability, the utilization of copper slag in the construction sector, which has a wide scope, will benefit the environment. Additionally, it should be noted that due to the dense structure of copper slag, it can also be evaluated as a substitute for aggregate in heavy mass concrete.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guan, H.; Liu, S.; Duan, Y.; Cheng, J. Cement based electromagnetic shielding and absorbing building materials. Cem. Concr. Compos. 2006, 28, 468–474. [Google Scholar] [CrossRef]

- Jia, Z.; Kou, K.; Yin, S.; Feng, A.; Zhang, C.; Liu, X.; Cao, H.; Wu, G. Magnetic Fe nanoparticle to decorate N dotted C as an exceptionally absorption-dominate electromagnetic shielding material. Compos. Part B Eng. 2020, 189, 107895. [Google Scholar] [CrossRef]

- Ocaktan, M.E.; Akdur, R. Cellular phone technology and health: Review. J. Med. Sci. 2008, 28, 58–65. [Google Scholar]

- Kılıç, G.; Örtlek, H.G.; Saraçoğlu, Ö.G. Electromagnetic pollution and textile barriers for protection from electromagnetic pollution. J. Text. Eng. 2014, 14, 22–35. [Google Scholar]

- Vizi, G.N.; Vandenbosch, G.A.E. Building materials and electromagnetic radiation: The role of material and shape. J. Build. Eng. 2016, 5, 96–103. [Google Scholar] [CrossRef]

- Belpomme, D.; Hardell, L.; Belyaev, I.; Burgio, E.; Carpenter, D.O. Thermal and non-thermal health effects of low intensity non-ionizing radiation: An international perspective. Environ. Pollut. 2018, 242, 643–658. [Google Scholar] [CrossRef]

- Karadağ, T.; Özdemir, A.R.; Abbasov, T. Longterm electromagnetic field measurements and pollution maps in a university campus. Pamukkale Univ. J. Eng. Sci. 2014, 20, 314–318. [Google Scholar] [CrossRef]

- Genuis, S.J. Fielding a current idea: Exploring the public health impact of electromagnetic radiation. Public Health 2008, 122, 113–124. [Google Scholar] [CrossRef] [PubMed]

- Lei, D.; Liu, J.; Liu, C.; Dong, C.; Yang, D.; Li, Y.; Zhang, J.; Han, F.; Guo, Z. Metal–Organic frameworks-derived FeCo/C–CNT nanocomposites modified epoxy resin for electromagnetic protection coatings for buildings. Buildings 2024, 14, 1096. [Google Scholar]

- Chung, D.D.L. Materials for electromagnetic interference shielding. Mater. Chem. Phys. 2020, 255, 123587. [Google Scholar] [CrossRef]

- Hong, X.; Chung, D.D.L. Carbon nanofiber mats for electromagnetic interference shielding. Carbon 2017, 111, 529–537. [Google Scholar] [CrossRef]

- Türk, T. Investigation of arsenic leaching from copper slag by using central composite design. Yerbilimleri 2016, 37, 193–202. [Google Scholar]

- Nazer, A.S.; PavezI, O.; Rojas, F. Use of copper slag in cement mortar. Rem Rev. Esc. Minas 2012, 65, 8791. [Google Scholar] [CrossRef]

- Hwang, C.L.; Laiw, J.C. Properties of concrete using copper slag as a substitute for fine aggregate. In Proceedings of the 3rd International Conference on Fly Ash, Silica Fume, Slag, and Natural Pozzolans in Concrete, Trondheim, Norway, 18–23 June 1989; Volume 114, pp. 1677–1696. [Google Scholar]

- Zhang, Q.; Zhang, B.; Feng, Y.; Qi, C.; Chen, Q.; Xiao, C. Hydration development of blended cement paste with granulated copper slag modified with CaO and Al2O3. J. Mater. Res. Technol. 2022, 18, 909–920. [Google Scholar] [CrossRef]

- Opara, A.F.; Obasi, C.H.; Eke, C.B.; Eze, U.W. Progress in polymer-based composites as efficient materials for electromagnetic interference shielding applications: A review. Curr. Mater. Sci. 2023, 16, 235–261. [Google Scholar] [CrossRef]

- Luo, B.; Su, Y.; Ding, X.; Chen, Y.; Liu, C. Modulation of initial CaO/Al2O3 and SiO2/Al2O3 ratios on the properties of slag/fly ash-based geopolymer stabilized clay: Synergistic effects and stabilization mechanism. Mater. Today Commun. 2025, 47, 113295. [Google Scholar] [CrossRef]

- Brandt, A.M. Fibre reinforced cement-based (FRC) composites after over 40 years of development in building and civil engineering. Compos. Struct. 2008, 86, 3–9. [Google Scholar] [CrossRef]

- Ates, K.; Kocaer, T.Z.; Özen, Ş.; Koçkal, N.U. Electromagnetic interference shielding effectiveness and microwave absorption performance of plaster mortars containing metal waste chips in X-band frequency range. J. Microw. Power Electromagn. Energy 2023, 57, 230–244. [Google Scholar] [CrossRef]

- Jusoh, M.A.; Yeow, K.Y.; Nazlan, R.; Esa, F. Electromagnetic shielding effectiveness of gypsum-magnetite composite at X-band frequency. Prog. Electromagn. Res. Lett. 2019, 86, 21–26. [Google Scholar] [CrossRef]

- Liu, Z.; Song, M.; Liang, W.; Gao, X.; Zhu, B. Effect of carbon fiber paper with thickness gradient on electromagnetic shielding performance of X-Band. Materials 2024, 17, 2767. [Google Scholar] [CrossRef]

- Fu, X.; Chung, D.D.L. Submicron carbon filament cement-matrix composites for electromagnetic interference shielding. Cem. Concr. Res. 1996, 26, 1467–1472. [Google Scholar] [CrossRef]

- Zornoza, E.; Catalá, G.; Jiménez, F.; Andión, L.G.; Garcés, P. Electromagnetic interference shielding with Portland cement paste containing carbon materials and processed fly ash. Mater. Construc. 2010, 60, 21–32. [Google Scholar] [CrossRef]

- Micheli, D.; Pastore, R.; Vricella, A.; Morles, R.B.; Marchetti, M.; Delfini, A.; Mogile, F.; Primiani, V.M. Electromagnetic characterization and shielding effectiveness of concrete composite reinforced with carbon nanotubes in the mobile phones frequency band. Mater. Sci. Eng. B 2014, 188, 119–129. [Google Scholar] [CrossRef]

- Tekin, İ.; Pekgöz, M. The effects of ZnO powder and different fiber types used in tuff/calcite-based geopolymers on electromagnetic shielding effectiveness. J. Build. Eng. 2024, 89, 109343. [Google Scholar]

- Li, Z.; Li, Y.; Shi, B.; Tang, D.; Wang, Y.; Hao, L. Dual gradient direct ink writing of functional geopolymer-based carbonyl-iron/graphene composites for adjustable broadband microwave absorption. Ceram. Int. 2022, 48, 9277–9285. [Google Scholar]

- Wanasinghe, D.; Aslani, F.; Ma, G. Electromagnetic shielding properties of cementitious composites containing carbon nanofibers, zinc oxide, and activated carbon powder. Constr. Build. Mater. 2021, 285, 122842. [Google Scholar] [CrossRef]

- TS EN 196-1; Methods of Testing Cement—Part 1: Determination of Strength. Turkish Standard. Turkish Standards Institute: Ankara, Turkey, 2016.

- TS EN 197-1; Cement—Part 1: Composition, Specification and Conformity Criteria for Common Cements. Turkish Standard. Turkish Standards Institute: Ankara, Turkey, 2012.

- TS EN 1015-3/A2; Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). Turkish Standard. Turkish Standards Institute: Ankara, Turkey, 2007.

- TS EN 1015-10/A1; Methods of Test for Mortar for Masonry—Part 10: Determination of Dry Bulk Density of Hardened Mortar. Turkish Standard. Turkish Standards Institute: Ankara, Turkey, 2007.

- Fan, Y.; Zhang, B.; Song, J.; Volski, V.; Vandenbosch, G.A.E.; Guo, M. An innovated application of reutilize copper smelter slag for cement-based electromagnetic interference Composites. Sci. Rep. 2018, 8, 16155. [Google Scholar] [CrossRef] [PubMed]

- Amaro, A.; Suarez, A.; Torres, J.; Martinez, P.A.; Herraiz, R.; Alcarria, A.; Benedito, A.; Ruiz, R.; Galvez, P.; Penades, A. Shielding effectiveness measurement method for planar nanomaterial samples based on CNT materials up to 18 GHz. Magnetochemistry 2023, 9, 114. [Google Scholar] [CrossRef]

- Boğa, A.R. Effect of using carbon fiber and steel slag on mechanical and electrical conductivity properties of mortars. Afyon Kocatepe Univ. J. Sci. Eng. 2017, 17, 1066–1075. [Google Scholar] [CrossRef]

- Chakrawarthi, V.; Dharmar, B.; Avudaiappan, S.; Amran, M.; Flores, E.S.; Alam, M.A.; Fediuk, R.; Vatin, N.I.; Rashid, R.S.M. Destructive and non-destructive testing of the performance of copper slag fiber-reinforced concrete. Materials 2022, 15, 4536. [Google Scholar]

- Yan, Z.; Sun, Z.; Yang, J.; Yang, H.; Ji, Y.; Hu, K. Mechanical performance and reaction mechanism of copper slag activated with sodium silicate or sodium hydroxide. Constr. Build. Mater. 2021, 266, 120900. [Google Scholar] [CrossRef]

- Wanasinghe, D.; Aslani, F.; Ma, G. Electromagnetic shielding properties of carbon fibre reinforced cementitious composites. Constr. Build. Mater. 2020, 260, 120439. [Google Scholar] [CrossRef]

- Al-Jabri, K.S.; Al-Saidy, A.H.; Taha, R. Effect of copper slag as a fine aggregate on the properties of cement mortars and concrete. Constr. Build. Mater. 2011, 25, 933–938. [Google Scholar] [CrossRef]

- Gorai, B.; Jana, R.K. Characteristics and utilisation of copper slag—A review. Resour. Conserv. Recycl. 2003, 39, 299–313. [Google Scholar] [CrossRef]

- Deng, M.; Dong, Z.; Zhang, C. Experimental investigation on tensile behavior of carbon textile reinforced mortar (TRM) added with short polyvinyl alcohol (PVA) fibers. Constr. Build. Mater. 2020, 235, 117801. [Google Scholar] [CrossRef]

- Safiuddin, M.; Abdel-Sayed, G.; Hearn, N. Absorption and strength properties of short carbon fiber reinforced mortar composite. Buildings 2021, 11, 300. [Google Scholar] [CrossRef]

- Wu, J.; Yang, S.; Williamson, M.; Wong, H.S.; Bhudia, T.; Pu, H.; Yin, Q.; Ma, D.; Chen, W. Microscopic mechanism of cellulose nanofibers modified cemented gangue backfill materials. Adv. Compos. Hybrid Mater. 2025, 8, 177. [Google Scholar] [CrossRef]

- Wang, J.; Yu, Q.; Xiang, Z.; Fu, J.; Wang, L.; Song, W. Influence of basalt fiber on pore structure, mechanical performance and damage evolution of cemented tailings backfill. J. Mater. Res. Technol. 2023, 27, 5227–5242. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A. Use of silica fume and recycled steel fibers in self-compacting concrete (SCC). Constr. Build. Mater. 2016, 125, 196–209. [Google Scholar] [CrossRef]

- Chung, D.D.L. Electromagnetic interference shielding effectiveness of carbon materials. Carbon 2001, 39, 279–285. [Google Scholar] [CrossRef]

- Chiou, J.M.; Zheng, Q.; Chung, D.D.L. Electromagnetic interference shielding by carbon fibre reinforced cement. Composites 1989, 20, 379–381. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, W. Electromagnetic shielding and absorption properties of fiber reinforced cementitious composites. J. Wuhan Univ. Technol. 2012, 27, 172–176. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, T.; Zhou, L. Investigation on electromagnetic and microwave absorption properties of copper slag-filled cement mortar. Cem. Concr. Compos. 2016, 74, 174–181. [Google Scholar] [CrossRef]

| Chemical properties | |||

| Compound (%) | Element (%) | ||

| SiO2 | 35.25 | Cu | 0.76–0.03 |

| Al2O3 | 2.54 | Co | 0.19 |

| Fe2O3 | 59 | S | 0.40–2.31 |

| CaO | 1.58 | Au(mg/lt) | - |

| Na2O | 0.75 | Ag(mg/lt) | 6.44 |

| K2O | 0.33 | SiO2 | 26.89 |

| SO3 | 0.16 | ||

| CuO | 0.53 | ||

| Physical properties | |||

| Density (g/cm3) | 3.69 | ||

| Color | Dark gray | ||

| Sample Code | Cement (g) | Water (mL) | Sand (g) | Carbon Fiber (g) | Copper Slag (g) | ||

|---|---|---|---|---|---|---|---|

| 2–1 (mm) | 1–0.5 (mm) | 0.5–0 (mm) | |||||

| R | 445.07 | 222.48 | 1334.87 | - | - | - | - |

| 25CS | 445.07 | 222.48 | 1001.14 | - | 164.19 | 164.19 | 164.19 |

| 50CS | 445.07 | 222.48 | 667.44 | - | 328.38 | 328.38 | 328.38 |

| 1C | 444.94 | 222.4 | 1334.46 | 1.62 | - | - | - |

| 5C | 444.5 | 222.2 | 1333.2 | 8.1 | - | - | - |

| 25CS/1C | 444.94 | 222.4 | 1000.8 | 1.62 | 164.13 | 164.13 | 164.13 |

| 25CS/5C | 444.52 | 222.2 | 999.9 | 8.1 | 163.98 | 163.98 | 163.98 |

| 50CS/1C | 444.94 | 222.4 | 667.23 | 1.62 | 328.27 | 328.27 | 328.27 |

| 50CS/5C | 444.52 | 222.2 | 666.6 | 8.1 | 327.97 | 327.97 | 327.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Demirtaş, H.; Dayı, M. A Proposal for Electromagnetic Performance in Cementitious Systems: Carbon Fiber and Copper Slag. Buildings 2025, 15, 3634. https://doi.org/10.3390/buildings15193634

Demirtaş H, Dayı M. A Proposal for Electromagnetic Performance in Cementitious Systems: Carbon Fiber and Copper Slag. Buildings. 2025; 15(19):3634. https://doi.org/10.3390/buildings15193634

Chicago/Turabian StyleDemirtaş, Hilal, and Mustafa Dayı. 2025. "A Proposal for Electromagnetic Performance in Cementitious Systems: Carbon Fiber and Copper Slag" Buildings 15, no. 19: 3634. https://doi.org/10.3390/buildings15193634

APA StyleDemirtaş, H., & Dayı, M. (2025). A Proposal for Electromagnetic Performance in Cementitious Systems: Carbon Fiber and Copper Slag. Buildings, 15(19), 3634. https://doi.org/10.3390/buildings15193634