A Case Study on the Energy Efficiency of Windows in Institutional and Residential Buildings

Abstract

1. Introduction

2. Methods

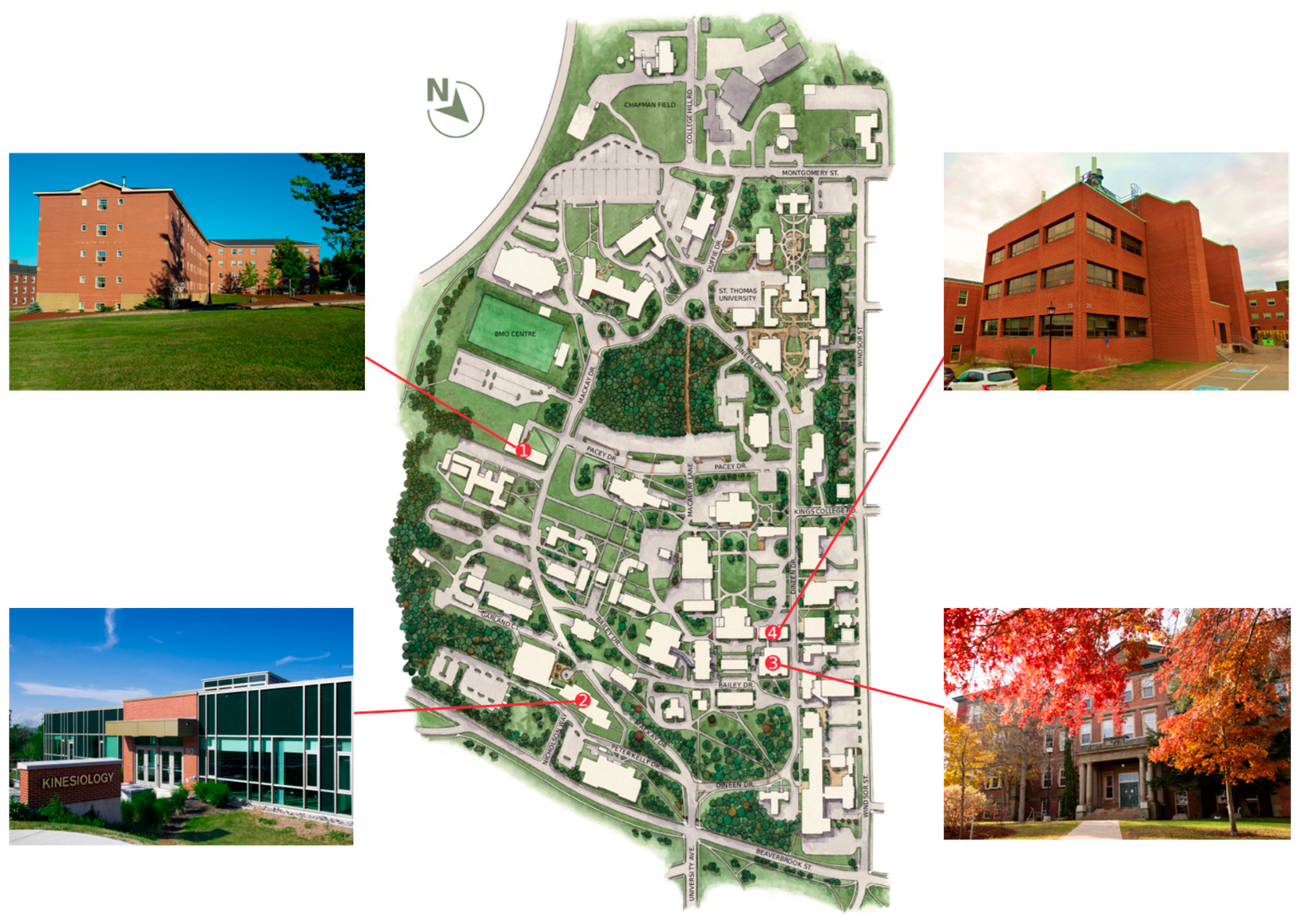

2.1. Study Buildings

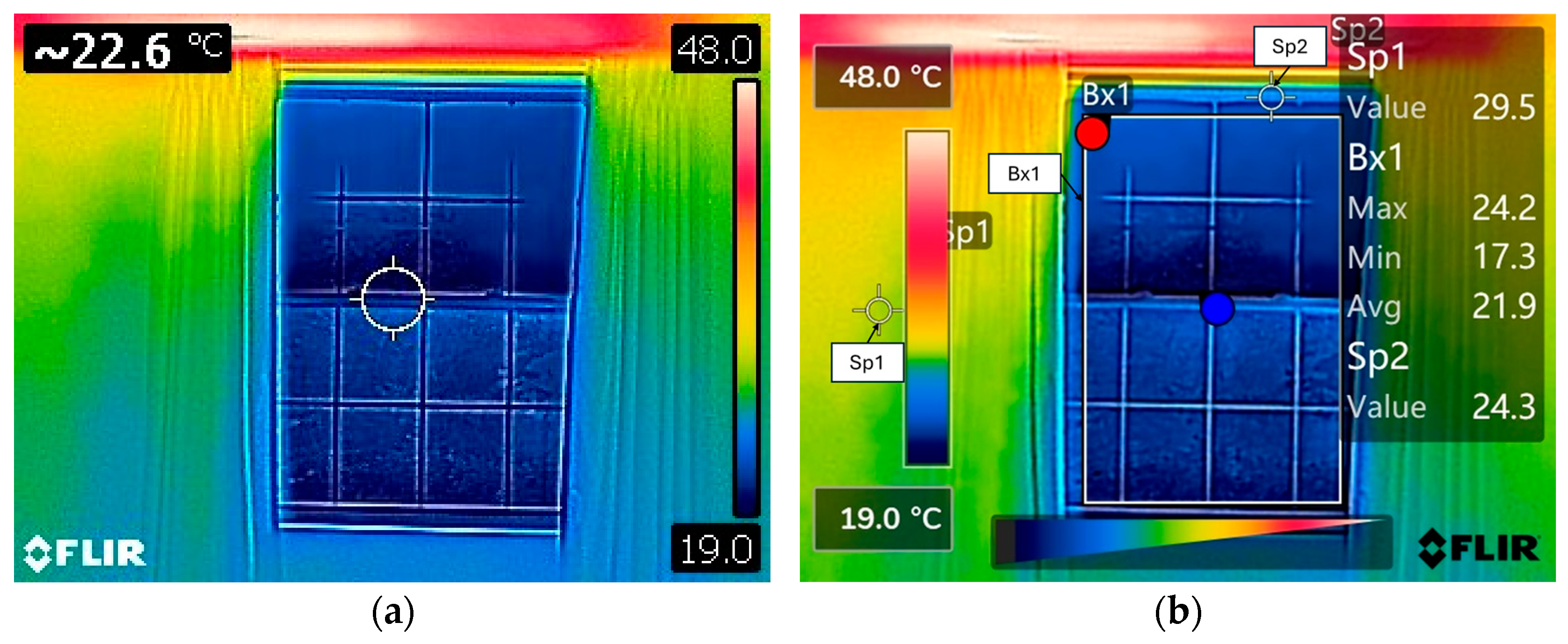

2.2. Instruments and Software

2.3. Collection and Analysis of Data

2.4. Evaluation of Energy Efficiency

3. Results

3.1. Energy Performance

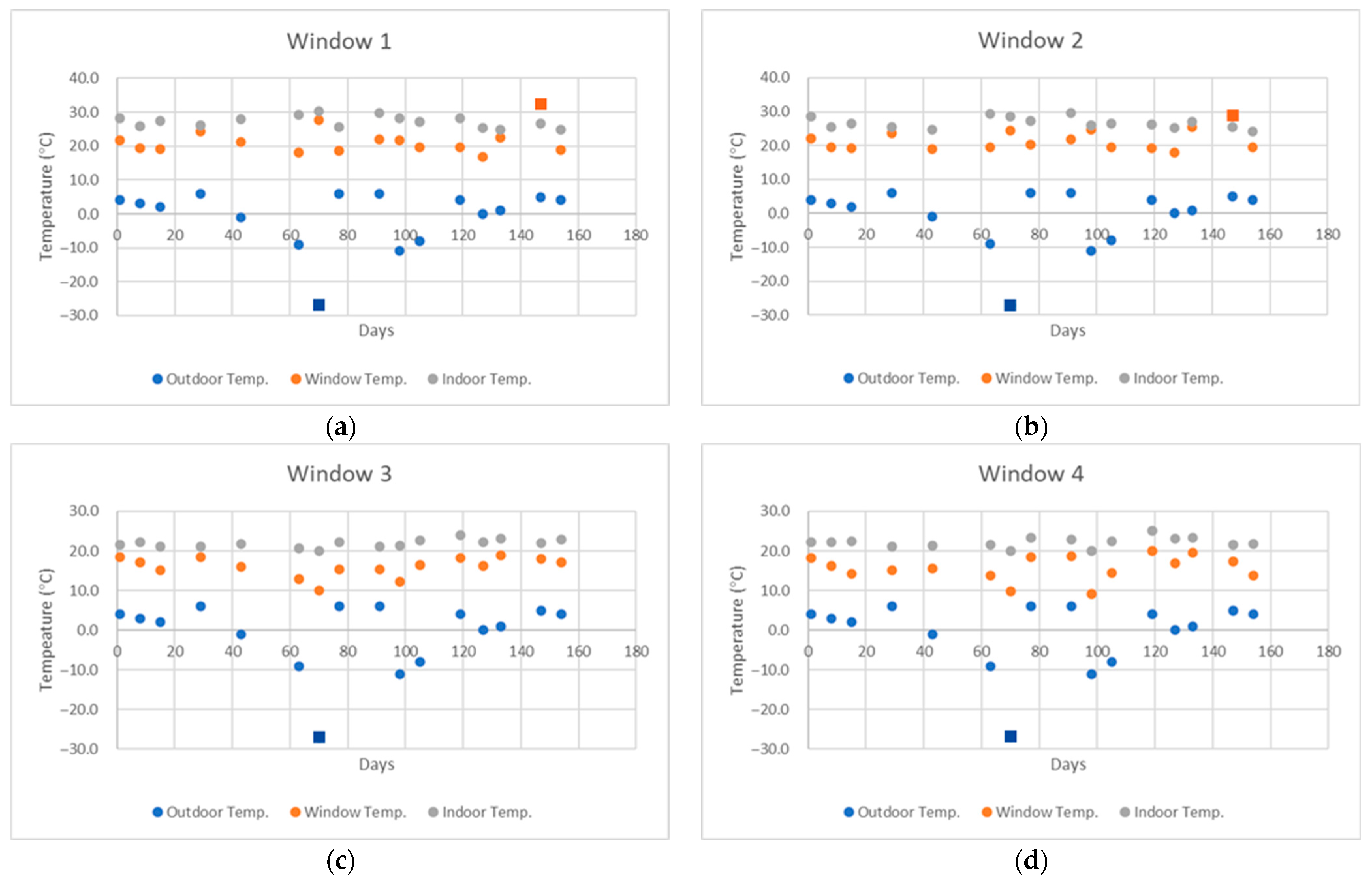

3.1.1. Timeline Analysis

3.1.2. Heat Loss

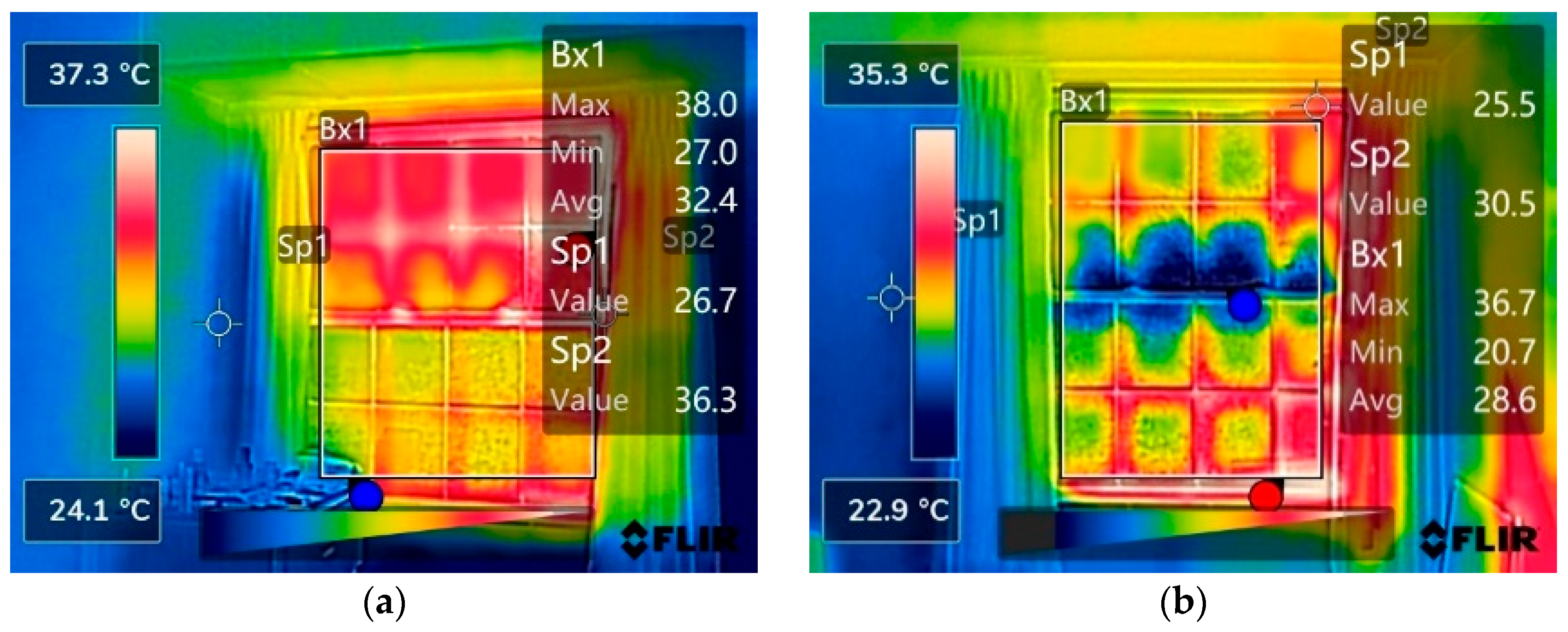

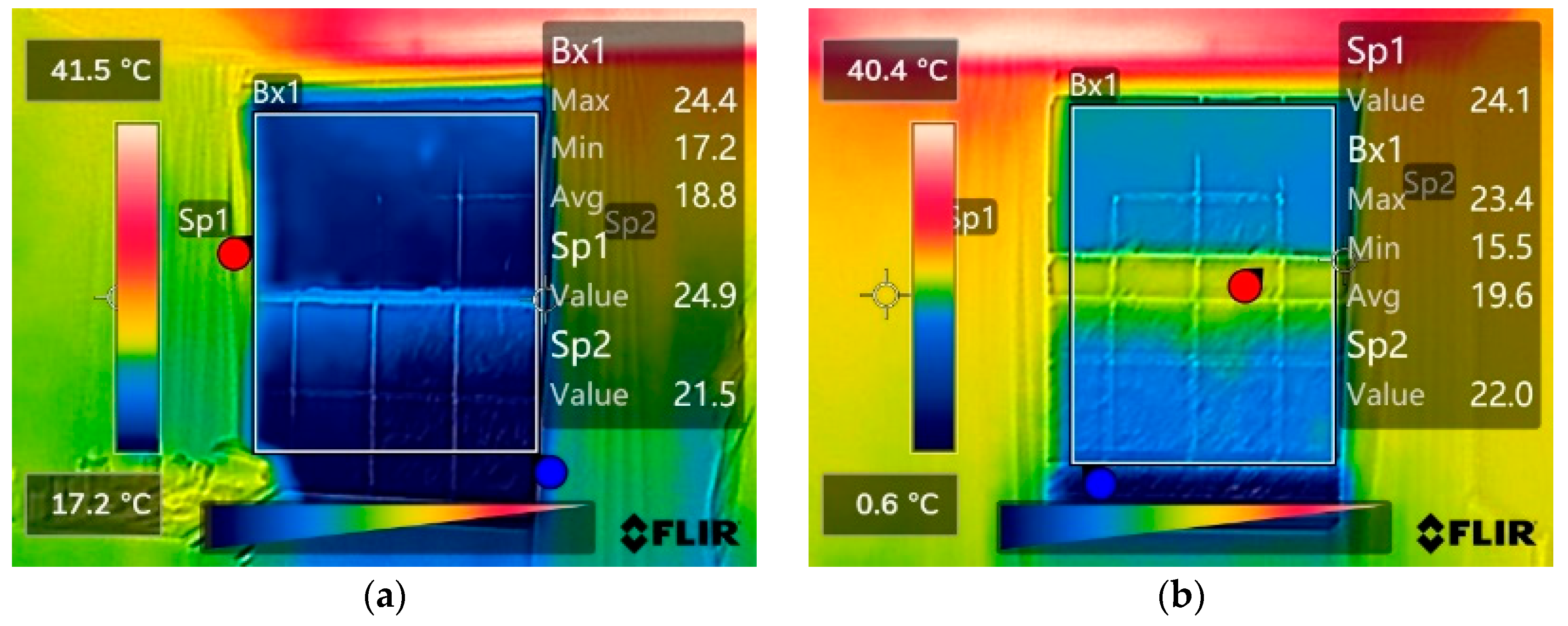

3.1.3. Other Findings

3.2. Implications

4. Conclusions

- The temperature distribution of a window was influenced by the indoor and outdoor temperature of a room, which affected the heat consumption of a window. The larger the temperature difference was, the higher the heat loss was. Setting an appropriate room heating temperature could reduce the heat loss of the window.

- The performance of wooden-framed windows in older buildings generally exceeds that of metal-framed windows in newer buildings with regard to thermal insulation.

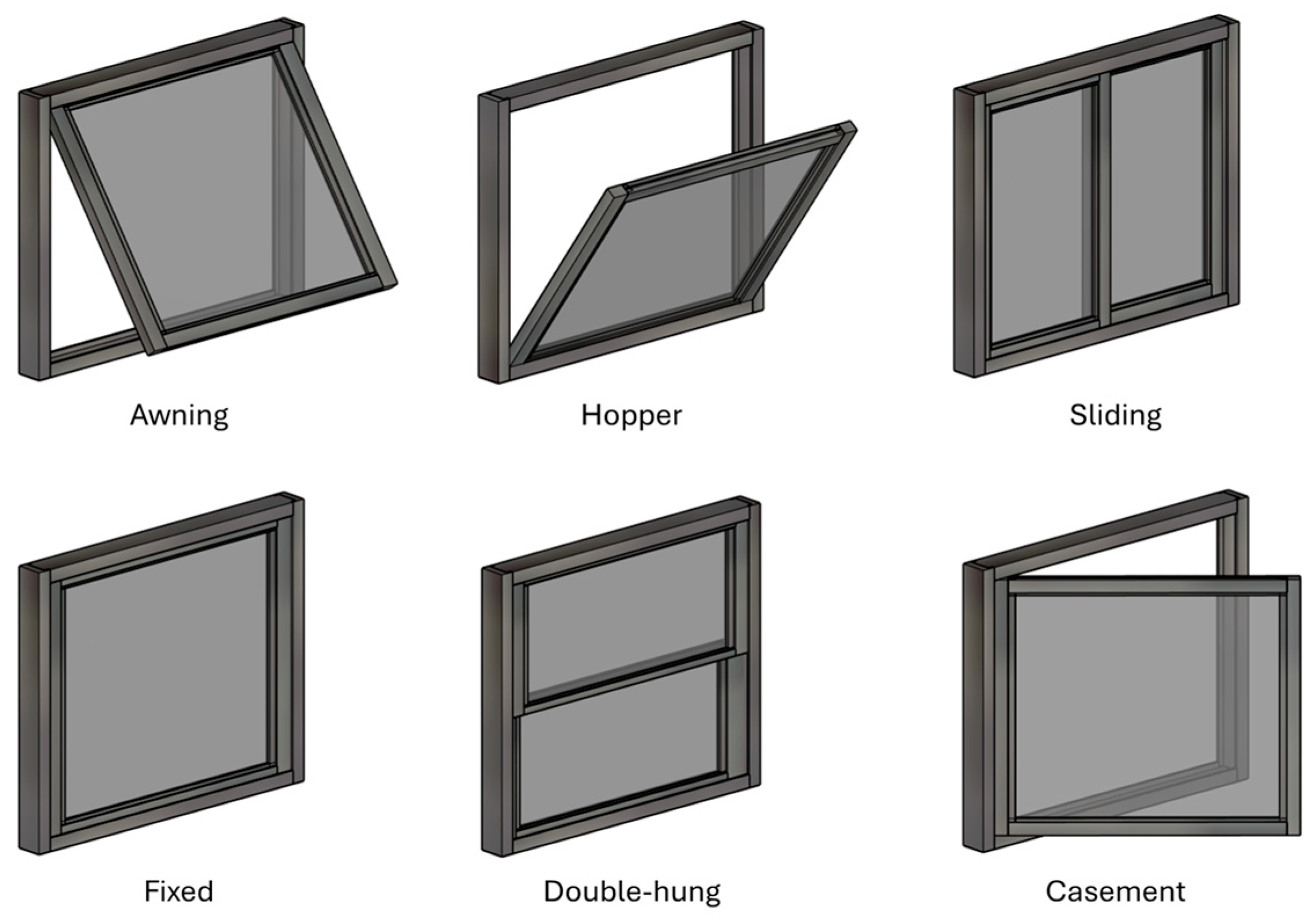

- Fixed windows had a better energy performance than sliding windows and single-hung windows, controlling the air leakage well.

- In winter, the windows which face east had a significantly better energy efficiency than other directions in the morning in a cold climate.

- Increasing the WWR was not good for saving the winter heating load in a cold climate, which was different from the results from a hot climate.

- Using Low-E glazing could greatly improve the energy efficiency of a window. In cold areas like Fredericton, Canada, it was necessary to use Low-E glazing for the window.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AR | Anti-Reflection |

| ASHRAE | American Society of Heating, Refrigerating and Air-conditioning Engineers |

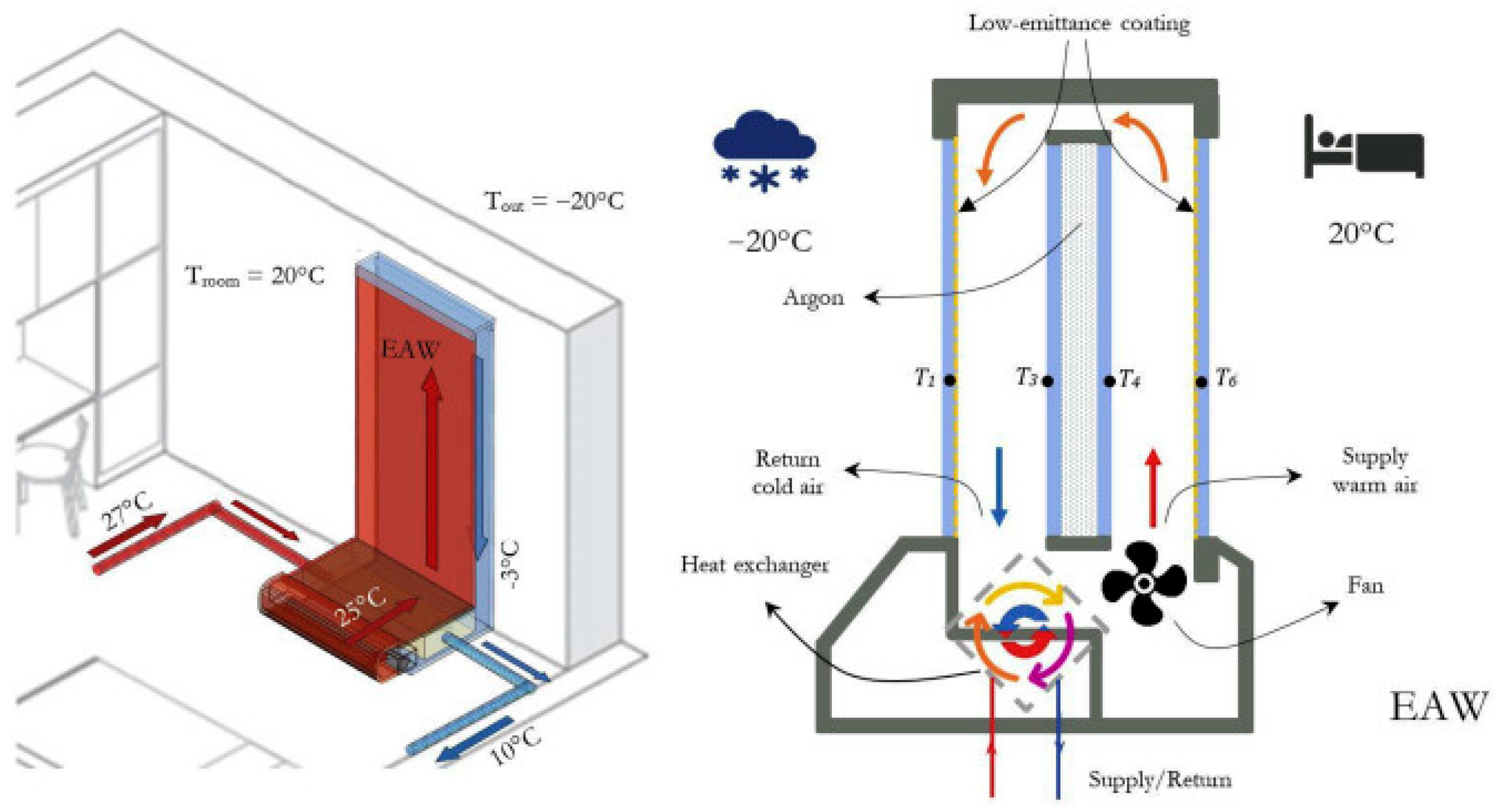

| EAW | Energy-Active Window |

| ED | Electric-Driven |

| HL | Heat Loss, W |

| LFA | Laser Flash Apparatus |

| NFRC | National Fenestration Rating Council |

| OGI | Optical Gas Imaging |

| PVC | Polyvinyl Chloride |

| R | Thermal Resistance, (m2·K)/W |

| RANS | Reynolds Averaged Navier–Stokes |

| T | Temperature, °C |

| U | U-value, W/(m2·K) |

| UAS | Unmanned Aircraft Systems |

References

- International Energy Agency. Global Energy Review 2020. Available online: https://www.iea.org/reports/global-energy-review-2020 (accessed on 1 July 2023).

- Green, M. Why We Should Build Wooden Skyscrapers. Available online: https://www.youtube.com/watch?v=Xi_PD5aZT7Q (accessed on 1 July 2023).

- Building Technologies Program (U.S.). Window Selection: Modern Windows Provide Energy Savings, Durability, and Comfort; Technology Fact Sheet; Building Technologies Program, Office of Energy Efficiency and Renewable Energy, U.S. Department of Energy: Washington, DC, USA, 2003. [Google Scholar]

- American Window Company. What Is a Thermal Break in Windows? Available online: https://www.americanwindowcompany.com/what-is-a-thermal-break-in-a-window/ (accessed on 10 September 2025).

- Kowalczyk, Z.; Tomasik, M. Economic and Energy Analysis of the Operation of Windows in Residential Buildings in Poland. Energies 2023, 16, 6810. [Google Scholar] [CrossRef]

- Shen, X.; Wang, W.; Chen, L.; Zhang, Y. Influences of Glass Layers on Thermal Performance of Windows. Build. Energy Effic. 2017, 2, 61–65. [Google Scholar] [CrossRef]

- Gasparella, A.; Pernigotto, G.; Cappelletti, F.; Romagnoni, P.; Baggio, P. Analysis and modelling of window and glazing systems energy performance for a well-insulated residential building. Energy Build. 2011, 43, 1030–1037. [Google Scholar] [CrossRef]

- Carpenter Stephen, C.; Elmahdy, A.H. Thermal performance of complex fenestration systems. ASHRAE Trans. 1994, 100, 1179–1186. [Google Scholar]

- Gorgolis, G.; Karamanis, D. Solar energy materials for glazing technologies. Sol. Energy Mater. Sol. Cells 2016, 144, 559–578. [Google Scholar] [CrossRef]

- Roos, A. Visual and energy performance of switchable windows with antireflection coatings. Sol. Energy 2010, 84, 1370–1375. [Google Scholar] [CrossRef]

- Nourozi, B.; Ploskić, A.; Chen, Y.; Chui, N.W.; Wang, J.; Wang, Q. Heat transfer model for energy-active windows—An evaluation of efficient reuse of waste heat in buildings. Renew. Energy 2020, 162, 2318–2329. [Google Scholar] [CrossRef]

- Arıcı, M.; Karabay, H.; Kan, M. Flow and heat transfer in double, triple and quadruple pane windows. Energy Build. 2015, 86, 394–402. [Google Scholar] [CrossRef]

- Arıcı, M.; Kan, M. An investigation of flow and conjugate heat transfer in multiple pane windows with respect to gap width, emissivity and gas filling. Renew. Energy 2015, 75, 249–256. [Google Scholar] [CrossRef]

- Elghamry, R.; Hassan, H. Impact of window parameters on the building envelope on the thermal comfort, energy consumption and cost and environment. Int. J. Vent. 2020, 19, 233–259. [Google Scholar] [CrossRef]

- Timeanddate. Past Weather in Fredericton. Available online: www.timeanddate.com/weather/canada/fredericton/historic (accessed on 1 July 2023).

- Government of Canada. Historical Data. Available online: https://climate.weather.gc.ca/historical_data/search_historic_data_e.html (accessed on 1 September 2025).

- University of New Brunswick. University Tour. Available online: https://unb.university-tour.com/fredericton-campus# (accessed on 1 September 2025).

- UNB Department of Facilities Management (The University of New Brunswick (UNB), Fredericton, NB, Canada). Personal communication, 2022.

- FLIR C2 Description. FLIR. Available online: www.flir.com (accessed on 1 July 2023).

- Lechner, N. Heating, Cooling, Lighting: Sustainable Design Methods for Architects, 4th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Rubin, M. Calculating heat transfer through windows. Energy Res. 1982, 6, 341–349. [Google Scholar] [CrossRef]

- Building Material R-Values. Available online: https://efficiencymatrix.com/building-material-r-values/ (accessed on 1 July 2023).

- ASHRAE. ASHRAE Handbook—Fundamentals; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2017. [Google Scholar]

- Șerban, S.E.; Catalina, T.; Popescu, R.; Popescu, L. The Intersection of Architectural Conservation and Energy Efficiency: A Case Study of Romanian Heritage Buildings. Appl. Sci. 2024, 14, 4835. [Google Scholar] [CrossRef]

- Timeanddate. December 2021 Weather in Fredericton. Available online: https://www.timeanddate.com/weather/canada/fredericton/historic?month=12&year=2021 (accessed on 1 July 2023).

- Wilson, A.G.; Brown, W.P. Thermal Characteristics of Double Windows; Division of Building Research, National Research Council of Canada: Ottawa, ON, Canada, 1964. [Google Scholar] [CrossRef]

- Fasi, M.A.; Budaiwi, I.M. Energy performance of windows in office buildings considering daylight integration and visual comfort in hot climates. Energy Build. 2015, 108, 307–316. [Google Scholar] [CrossRef]

- Taileb, A.; Sherzad, M.F. Energy Audits and Energy Modeling as a Tool towards Reducing Energy Consumption in Buildings: The Cases of Two Multi-Unit Residential Buildings (MURBs) in Toronto. Sustainability 2023, 15, 13983. [Google Scholar] [CrossRef]

| Building | No. | Location | Sizes | Dir. | Materials | Type | ||

|---|---|---|---|---|---|---|---|---|

| Width (m) | Height (m) | Area (m2) | ||||||

| 1. Elizabeth Parr-Johnston Residence | 1 | Bedroom | 1.219 | 1.372 | 1.672 | SE | Vinyl | Single-hung |

| 2 | Living room | 1.219 | 1.372 | 1.672 | SE | Vinyl | Single-hung | |

| 3 | Corridor | 1.219 | 1.372 | 1.672 | SW | Vinyl | Single-hung | |

| 4 | Corridor | 1.219 | 1.372 | 1.672 | NW | Vinyl | Single-hung | |

| 2. Kinesiology Building | 5 | Classroom 201 | 1.500 | 2.200 | 3.300 | E | Al. | Fixed |

| 6 | Classroom 201 | 1.500 | 2.200 | 3.300 | S | Al. | Fixed | |

| 7 | Public area | 1.500 | 2.200 | 3.300 | E | Al. | Fixed | |

| 8 | Public area | 1.500 | 2.200 | 3.300 | N | Al. | Fixed | |

| 3. Forestry and Geology Building | 9 | Office FG307 | 2.083 | 1.981 | 4.126 | SE | Wood | Single-hung |

| 10 | 2nd floor | 1.143 | 2.134 | 2.439 | SE | Wood | Single-hung | |

| 11 | 1st floor | 3.000 | 2.140 | 6.420 | SE | Wood | Single-hung | |

| 4. I.U.C. Forestry Building | 12 | Office 219A | 1.524 | 1.626 | 2.478 | S | Al. | Awning |

| 13 | Office 208 | 1.524 | 1.626 | 2.478 | N | Al. | Awning | |

| 14 | Office 208 | 1.524 | 1.626 | 2.478 | E | Al. | Awning | |

| 15 | Classroom 315 | 1.524 | 1.626 | 2.478 | W | Al. | Sliding | |

| 16 | Bridge | 0.610 | 1.981 | 1.208 | E | Al. | Fixed | |

| 17 | Bridge | 0.610 | 1.981 | 1.208 | W | Al. | Fixed | |

| Aluminum Frame w/o Thermal Break | Aluminum Frame with Thermal Break | Wood or Vinyl Frame | |

|---|---|---|---|

| Single glass | 1.30 | 1.07 | n/a |

| Double glass, ½” air space | 0.81 | 0.62 | 0.48 |

| Double glass, Low-E, (E * = 0.2), and ½” air space | 0.70 | 0.52 | 0.39 |

| Double glass, Low-E, (E * = 0.1), and ½” air space | 0.67 | 0.49 | 0.37 |

| Double glass, Low-E, (E * = 0.2), and ½” space with argon | 0.64 | 0.46 | 0.34 |

| Triple glass, Low-E, on two panes, and ½” paces with argon | 0.53 | 0.36 | 0.23 |

| Quadruple glass, Low-E (E * = 0.1) on two panes, and ¼” spaces with krypton | n/a | n/a | 0.22 |

| Building | No. | Location | Window Temp. (°C) | Indoor Temp. (°C) | Frame Temp. (°C) | ||

|---|---|---|---|---|---|---|---|

| Max. | Min. | Avg. | |||||

| 1. Elizabeth Parr-Johnston Residence | 1 | Bedroom | 21.9 | 15.5 | 19.2 | 27.3 | 20.5 |

| 2 | Living room | 21.9 | 14.6 | 19.3 | 26.6 | 23.6 | |

| 3 | Corridor | 19.3 | 13.3 | 15.1 | 21.1 | 15.2 | |

| 4 | Corridor | 16.9 | 7.8 | 14.3 | 22.4 | 15.4 | |

| 2. Kinesiology Building | 5 | Classroom 201 | 18.4 | 15.2 | 17.5 | 18.5 | 16.7 |

| 6 | Classroom 201 | 18.1 | 14.9 | 16.7 | 20.1 | 15.5 | |

| 7 | Public area | 20.8 | 13.8 | 17.9 | 18.7 | 17.0 | |

| 8 | Public area | 21.0 | 17.9 | 19.8 | 20.9 | 19.0 | |

| 3. Forestry and Geology Building | 9 | Office FG307 | 16.3 | 13.9 | 15.0 | 16.8 | 15.6 |

| 10 | 2nd floor | 18.4 | 16.8 | 17.5 | 19.3 | 18.8 | |

| 11 | 1st floor | 22.4 | 18.1 | 19.9 | 23.1 | 22.5 | |

| 4. I.U.C. Forestry Building | 12 | Office 219A | 14.2 | 5.5 | 12.4 | 20.3 | 13.2 |

| 13 | Office 208 | 19.9 | 15.9 | 18.3 | 21.3 | 18.8 | |

| 14 | Office 208 | 18.4 | 14.9 | 16.0 | 20.7 | 16.7 | |

| 15 | Classroom 315 | 15.4 | 8.4 | 13.1 | 18.6 | 12.1 | |

| 16 | Bridge | 11.4 | 7.4 | 9.0 | 11.6 | 8.7 | |

| 17 | Bridge | 9.7 | 3.2 | 7.5 | 11.7 | 6.2 | |

| Building | No. | Location | Dir. | Materials | Window Configuration | Heat Loss (W) | Heat Loss/Area (W/m2) |

|---|---|---|---|---|---|---|---|

| 1. Elizabeth Parr-Johnston Residence | 1 | Bedroom | SE | Vinyl | Single-hung | 13.81 | 8.26 |

| 2 | Living room | SE | Vinyl | Single-hung | 13.89 | 8.30 | |

| 3 | Corridor | SW | Vinyl | Single-hung | 10.52 | 6.29 | |

| 4 | Corridor | NW | Vinyl | Single-hung | 9.87 | 5.90 | |

| 2. Kinesiology Building | 5 | Classroom 201 | E | Al. | Fixed | 25.06 | 7.60 |

| 6 | Classroom 201 | S | Al. | Fixed | 23.77 | 7.20 | |

| 7 | Public area | E | Al. | Fixed | 25.71 | 7.79 | |

| 8 | Public area | N | Al. | Fixed | 28.78 | 8.72 | |

| 3. Forestry and Geology Building | 9 | Office FG307 | SE | Wood | Single-hung | 25.75 | 6.24 |

| 10 | 2nd floor | SE | Wood | Single-hung | 18.15 | 7.44 | |

| 11 | 1st floor | SE | Wood | Single-hung | 55.16 | 8.59 | |

| 4. I.U.C. Forestry Building | 12 | Office 219A | S | Al. | Awning | 17.27 | 6.97 |

| 13 | Office 208 | N | Al. | Awning | 27.06 | 10.92 | |

| 14 | Office 208 | E | Al. | Awning | 24.24 | 9.78 | |

| 15 | Classroom 315 | W | Al. | Sliding | 18.43 | 7.44 | |

| 16 | Bridge | E | Al. | Fixed | 5.67 | 4.69 | |

| 17 | Bridge | W | Al. | Fixed | 4.45 | 3.69 |

| Building | No. | Location | Dir. | Materials | Window Configuration | Area (m2) | H/W Ratio | φ |

|---|---|---|---|---|---|---|---|---|

| 1. Elizabeth Parr-Johnston Residence | 1 | Bedroom | SE | Vinyl | Single-hung | 1.672 | 1.13 | 32.02% |

| 2 | Living room | SE | Vinyl | Single-hung | 1.672 | 1.13 | 29.67% | |

| 3 | Corridor | SW | Vinyl | Single-hung | 1.672 | 1.13 | 31.41% | |

| 4 | Corridor | NW | Vinyl | Single-hung | 1.672 | 1.13 | 39.71% | |

| 2. Kinesiology Building | 5 | Classroom 201 | E | Al. | Fixed | 3.300 | 1.47 | 6.06% |

| 6 | Classroom 201 | S | Al. | Fixed | 3.300 | 1.47 | 18.78% | |

| 7 | Public area | E | Al. | Fixed | 3.300 | 1.47 | 4.79% | |

| 8 | Public area | N | Al. | Fixed | 3.300 | 1.47 | 5.82% | |

| 3. Forestry and Geology Building | 9 | Office FG307 | SE | Wood | Single-hung | 4.126 | 0.95 | 12.16% |

| 10 | 2nd floor | SE | Wood | Single-hung | 2.439 | 1.87 | 10.40% | |

| 11 | 1st floor | SE | Wood | Single-hung | 6.420 | 0.71 | 15.17% | |

| 4. I.U.C. Forestry Building | 12 | Office 219A | S | Al. | Awning | 2.478 | 1.07 | 43.17% |

| 13 | Office 208 | N | Al. | Awning | 2.478 | 1.07 | 15.54% | |

| 14 | Office 208 | E | Al. | Awning | 2.478 | 1.07 | 25.13% | |

| 15 | Classroom 315 | W | Al. | Sliding | 2.478 | 1.07 | 33.13% | |

| 16 | Bridge | E | Al. | Fixed | 1.208 | 3.25 | 27.08% | |

| 17 | Bridge | W | Al. | Fixed | 1.208 | 3.25 | 43.30% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, X.; Gong, M.; Kaboorani, A. A Case Study on the Energy Efficiency of Windows in Institutional and Residential Buildings. Buildings 2025, 15, 3478. https://doi.org/10.3390/buildings15193478

Qiu X, Gong M, Kaboorani A. A Case Study on the Energy Efficiency of Windows in Institutional and Residential Buildings. Buildings. 2025; 15(19):3478. https://doi.org/10.3390/buildings15193478

Chicago/Turabian StyleQiu, Xinzhi, Meng Gong, and Alireza Kaboorani. 2025. "A Case Study on the Energy Efficiency of Windows in Institutional and Residential Buildings" Buildings 15, no. 19: 3478. https://doi.org/10.3390/buildings15193478

APA StyleQiu, X., Gong, M., & Kaboorani, A. (2025). A Case Study on the Energy Efficiency of Windows in Institutional and Residential Buildings. Buildings, 15(19), 3478. https://doi.org/10.3390/buildings15193478