1. Introduction

Infrared (IR) radiation, spanning wavelengths from 700 nm to 1 mm, offers substantial potential for both passive and active thermal management in architectural design. Its application is particularly relevant in energy-efficient shading and insulation systems, where it contributes to reducing heat transfer and improving indoor climate control.

Roofs, being among the most exposed components of a building envelope, present particular challenges for thermal protection. Minimizing heat gain through the roof can significantly reduce cooling energy demand [

1]. The use of IR-absorbing ETFE foil (e.g., Nowoflon ET 6235 Z-IR) has been shown to improve summer thermal comfort by reducing the number of hours above 26 °C by up to 14% and lowering cooling energy demand by 1–8%, depending on the roof system. However, this foil increases surface temperatures due to higher solar IR absorption, which has to be considered in design decisions. In winter, it raises heating demand by 6–7% due to reduced solar gains. The foil is most effective in moderate and warm climates and has limited benefit in extremely hot regions such as New Delhi. It slightly alters the roof’s appearance with a blue-gray tint but maintains high light transmission [

2].

Roof solar reflectance is a critical factor in hot climates. Light-colored or reflective roofs can reduce heat gain by approximately 30% compared to dark roofs, thereby lowering cooling loads and improving indoor comfort. A study introduced a method to quantify this effect using an effective R-value, demonstrating that reflective roofs can substitute part of traditional insulation. The study also accounted for the impact of aging and dirt on reflectivity, proposing a model to estimate long-term performance. These findings support the inclusion of roof color in energy efficiency standards for buildings in warm regions [

3].

Roofs with both high solar reflectivity and infrared emissivity coatings significantly reduce surface temperatures and indoor heat flux, enhancing both thermal comfort and energy efficiency. While mass-insulated roofs further reduce indoor heat gain, they may increase external surface temperatures, contributing to the urban heat island effect. Applying white or selective coatings to both insulated and non-insulated roofs improves performance, with the best results achieved when insulation is combined with reflective coatings. These strategies are particularly effective in hot climates and offer a practical, cost-efficient approach to passive cooling in nonresidential buildings [

4].

The combination of reflective exterior coatings with low-emittance interior coatings (e.g., aluminum) yields optimal results [

5], although external measures have been shown to be more effective in reducing cooling loads than internal ones [

6]. Low-emissivity reflective materials on a roofs inner side, known as radiant barriers, effectively reduce heat transfer by radiation when installed under roof tiles, over attic floor slabs, or beneath roof slopes. To function properly, they must face an air space [

7]. They do not eliminate radiative heat transfer but significantly reduce it. By the presence of radiant barriers the radiative heat exchange is minimized, making the convective heat transfer dominant [

8]. The performance depends on factors such as emissivity, installation method, climate and ventilation. A key factor for long-term effectiveness is to maintain low-emittance surfaces as dust, moisture and corrosion can degrade performance [

9]. Radiant barriers can be mounted beneath the truss or can be applied as horizontal radiant barriers. Both systems perform similarly in terms of heat flux reduction, though truss radiant barriers show better attic air temperature reduction. A negative aspect may be that radiant barriers reduce winter heat gains, especially in sunny climates [

10]. Dynamic radiant barriers, made from layered sheet materials that can switch between insulating and conducting states might be a solution to this problem [

11].

Laboratory testing methods such as the Heat Flow Meter and the Guarded Hot Box have been shown to be valid and reliable for characterizing the thermal resistance of radiant barriers. The radiant barriers can be accurately characterized using this laboratory methods, if material properties like emissivity are well defined [

12].

In heritage-protected buildings, where the exterior appearance cannot be altered, rising roof temperatures can lead to significant heat transfer to the interior, potentially damaging valuable furnishings [

13]. In such cases, installing an IR shield on the interior side of the roof structure may be a viable solution. The effectiveness of this method depends heavily on proper ventilation of the IR shield to dissipate absorbed heat. This approach is also attractive from a low-tech perspective, as it requires minimal investment while offering measurable benefits [

14].

Roof ventilation is another effective strategy to reduce thermal accumulation and cooling loads. Studies show that steeper roof slopes result in lower cavity temperatures [

15,

16]. Numerical simulations suggest that in regions with high solar radiation, roof ventilation can significantly improve the summer energy performance of buildings [

17].

This study evaluated the effectiveness of an interior radiant barrier, as defined by Ferreira et al. [

7], enhanced by a ventilation system designed to cool the cladding. This combined approach is referred to as an infrared (IR) shading system, as it creates a zone beneath the cladding that is less affected by thermal radiation [

13]. This research investigated the extent to which this system can reduce heat transmission into the attic of a gable-roofed building. Additionally, it examined the influence of ventilation and the choice of planking material on the system’s overall thermal performance.

2. Materials and Methods

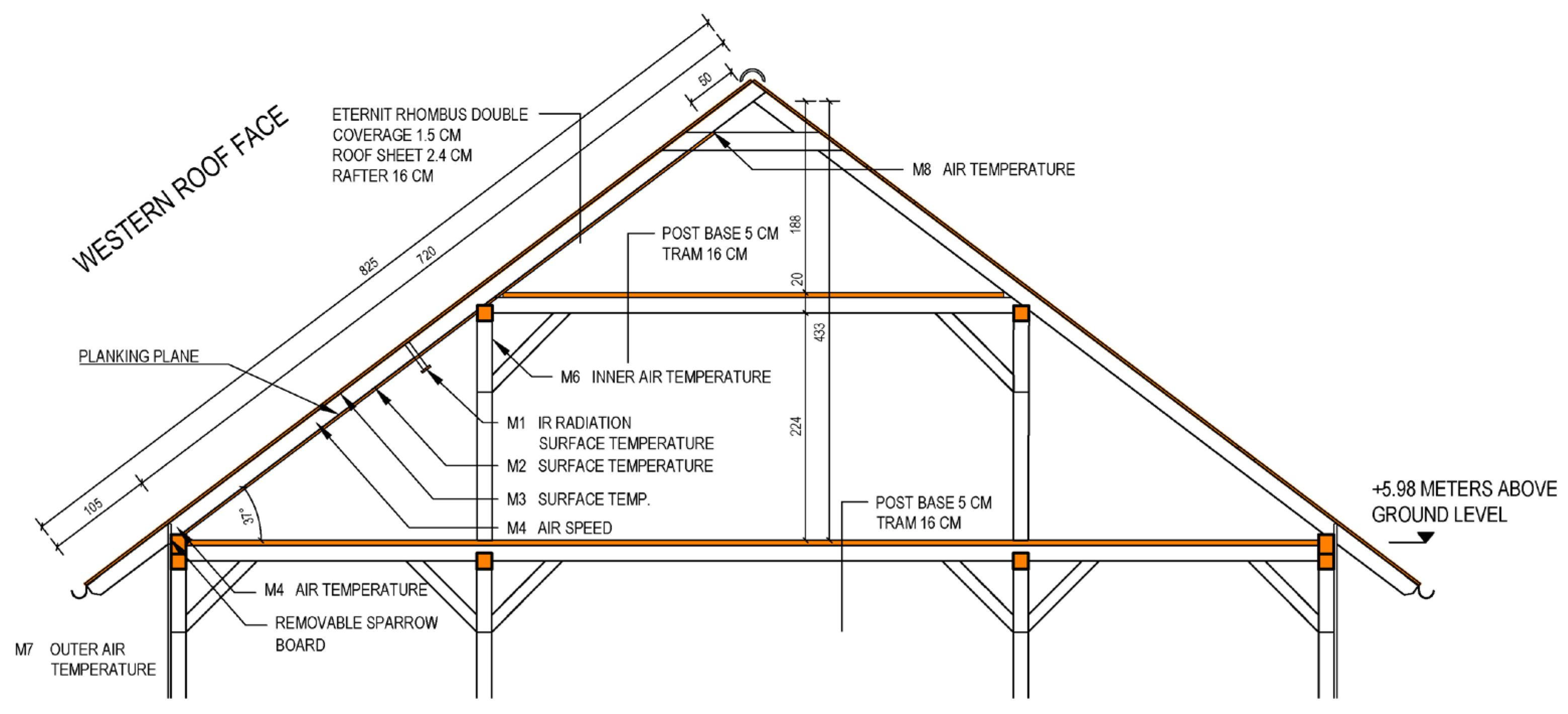

The present measurement campaign was carried out between July and September 2021 in a barn constructed in the 1950s, located in Bad Goisern, Upper Austria. The barn features a gable roof oriented north–south, with a 37° pitch. It is part of a wooden skeleton structure. The roof is sheathed with a 24 mm thick solid wood formwork and externally clad with a double-layer rhombus pattern of Eternit panels (Eternit Austria, Vöcklabruck, Austria) (fiber-reinforced concrete). The structural system comprises a double standing purlin roof truss configuration, notably lacking a ridge purlin. The ridge is sealed using U-shaped ridge tiles, without the integration of an effective ridge ventilation system. As the two levels of the buildings attic are only boarded up without cover strip (ventilation was important as originally the attic was used as a hay storage) and there are two ventilation gaps at the highest point of the gable wall, the air flow resulting from natural thermal boost may escape via cross ventilation (

Figure 1 and

Figure 2).

Three rafter bays on the western roof slope were selected for detailed investigation. One centrally located rafter bay was sheathed with a 12 mm oriented strand board (OSB) panel (Egger, St. Johann, Austria), extending from the foot purlin to 50 cm below the first purlin. An adjacent rafter bay remained unsheathed, serving as a reference system, while a third bay was covered with a conventional under-roof membrane (Ampatop, Ampack, Götzis, Austria). A 35 × 70 cm area on the OSB panel was coated with aluminum foil (Carl Roth GmbH, Karlsruhe, Germany) to study the effects of low-emissivity surfaces. Both the OSB panel and the under-roof membrane (hereafter referred to as the foil) function as an infrared (IR) shield between the heated roof and the attic space. Each shielded rafter bay constitutes a cuboid volume (cross section 14 × 88 cm

2), enclosed at the base and open toward the ridge. At set intervals, the sparrow board was removed to allow air ingress and study ventilation effects. (

Figure 2 and

Table 1).

The total thermal radiation emitted by an object across all wavelengths can be quantified using the Stefan–Boltzmann law (Equation (1)). For objects with temperatures below 100 °C (373.15 K), at least 97.5% of the emitted thermal radiation falls within the IR-C band (3–1000 µm), corresponding to long-wave infrared radiation. The thermal load coming from the roof construction adding to the heating of the interior room was estimated according to Equation (1) following the method of Aguilar-Castro et al. [

5] considering convective and radiative transfer between the interior roof surface and interior ambient.

: energy transfer to the interior by convective and radiative effects in W/m2

: interior convective heat transfer coefficient, estimated with 5.0 W/m

2K [

18]

: surface temperature of the roof inside in K

: temperature of the ambient interior air in K

: Stefan-Boltzmann constant W/m2K4

: emissivity (dimensionless between 0 and 1)

: temperature of construction elements in the attic in K.

Thermal images for the current study were taken using a thermal camera Testo 975 (Testo, Hochschwarzwald, Germany) with an IR resolution of 320 × 240 pixels and a spectral range of 7.5–14 micrometers. Image processing was performed using the software IR Soft v5.2 (Testo, Hochschwarzwald, Germany).

Air temperature, surface temperature and air speed were measured at positions according to

Figure 2 and

Table 2.

3. Results

Measurements were strongly influenced by ambient temperature and solar radiation. The following analysis focused on a specific time interval—7 September to 11 September 2021—during which the eaves of the investigated rafter fields were initially open and subsequently closed at 4:00 p.m. on 8 September. The presented results pertained to a single building during the summer of 2021. Therefore, the findings should be interpreted within this constrained context and are not necessarily generalizable. Further research involving broader experimental conditions is recommended to validate and extend these insights, also considering transient conditions like suggested in work focusing on long-term modeling of heat transfer [

19].

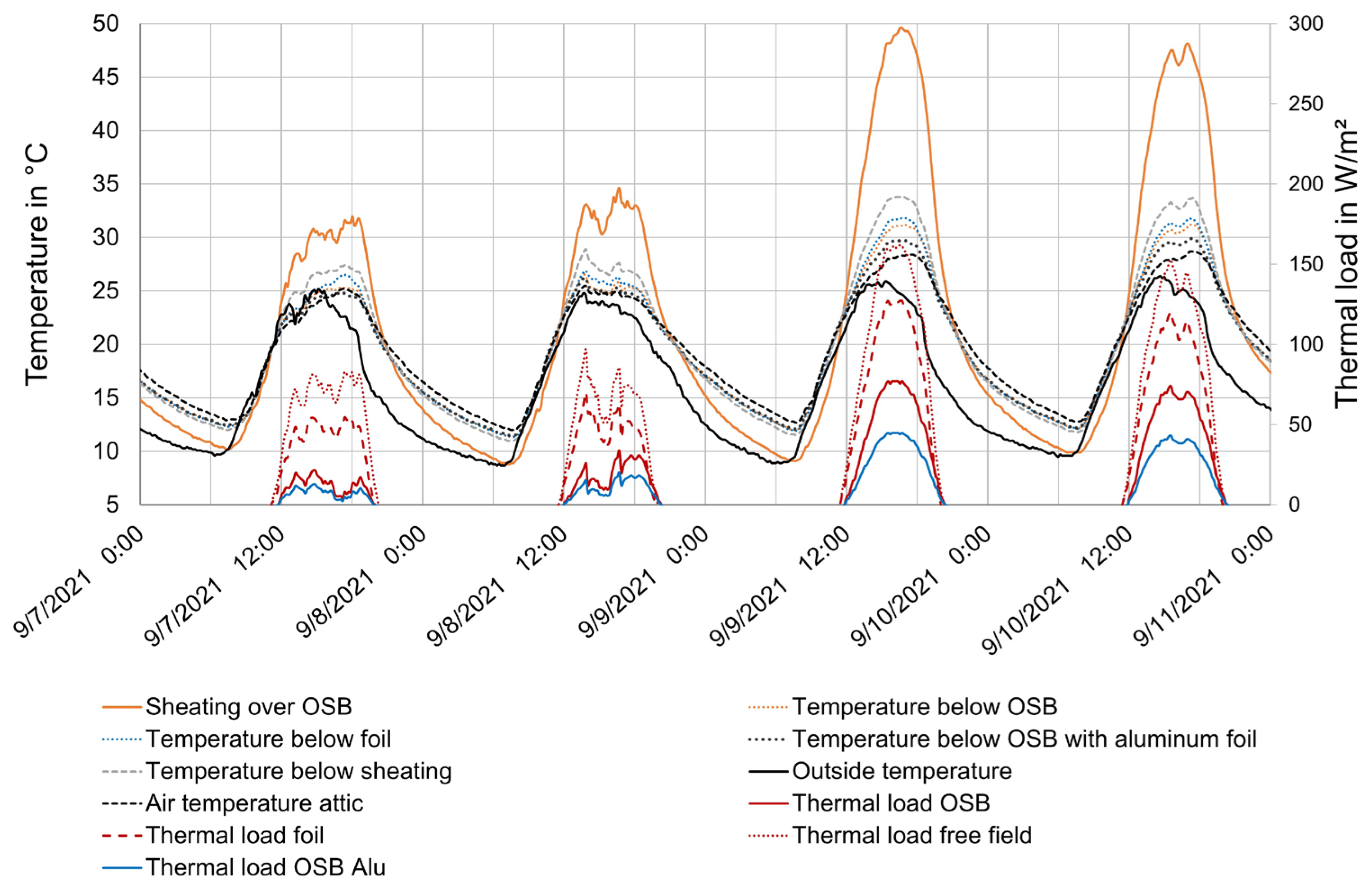

3.1. Air Temperature and Air Speed

When the eaves are open, the air temperature measured directly above the foot purlin closely aligns with the ambient outside air temperature. In contrast, at the ridge, the air temperature originating from the cladded rafter field is notably higher—for example, 29 °C compared to 24 °C on 7 September at 6:00 p.m. (

Figure 3).

Under closed-eave conditions on 10 September, the highest air temperature was recorded at the foot purlin of the OSB-cladded field (40 °C), while the foil-cladded field exhibited a slightly lower temperature (34 °C) at the same location. At the ridge, the outgoing air reached 45 °C and 42.5 °C, respectively.

The configuration of the eaves significantly influences air velocity within the rafter fields. With open eaves, a maximum air speed of 2 m/s was observed on September 8, coinciding with the peak outside temperature. Both the OSB- and foil-cladded fields exhibited comparable air velocity profiles. However, in the unplanked rafter field, the air speed remained substantially lower, reaching only 0.4 m/s under the same conditions.

When the eaves were closed, air velocities across all three fields were similarly low, with a maximum of 0.4 m/s. Overall, air velocity within the rafter fields appears to correlate approximately with the outside air temperature.

3.2. Surface Temperatures

The temperature of roof construction elements is strongly influenced by surrounding climatic conditions, particularly solar irradiation and ambient air temperature (

Figure 4). In the free-field configuration, the temperature of the sheathing is 84% explained by the variation in outside air temperature, based on a linear regression model. On average, the sheathing temperature is 36% higher than the ambient temperature. Similarly, the temperatures of the OSB and foil claddings are 86% explained by outside temperature, with average increases of 8% and 12%, respectively.

Statistical analysis (t-test, α = 0.000) confirms that the temperature of the free-field sheathing is significantly higher than that of both the OSB and foil claddings. However, the temperature difference between the OSB and foil claddings is not statistically significant.

Focusing on the period from 7 September to 11, during which daily outside temperatures ranged consistently between 9 °C (night minimum) and 26 °C (day maximum), the impact of ventilation becomes evident. On the ventilated days (7–8 September), the maximum temperature on the lower side of the roof planking reached 34 °C, while the inner side of the IR shield planking peaked at 27 °C (foil) and 26 °C (OSB). In contrast, under non-ventilated conditions (9–10 September), the roof cladding reached maximum temperatures of 49 °C (OSB) and 40 °C (free field). The claddings beneath the rafters recorded peak temperatures of 35 °C (foil) and 34 °C (OSB).

Notably, the temperature peaks of the planking surface were temporally delayed relative to the outside temperature curve—by approximately 2 h for the foil and 3 h for the OSB panels. Low thermal inertia allows the structure to cool overnight and match ambient temperature by morning.

3.3. Temperature Below Inner Roof Surfaces

In addressing the research question of this study, particular emphasis is placed on the thermal energy radiated from the heated roof cladding into the attic space and the top-floor ceiling. A direct indicator of this energy transfer is the surface temperature measured immediately beneath the planking elements (

Figure 5).

During ventilated conditions (7–8 September), the maximum temperatures recorded beneath the roof elements were as follows: 29 °C under the uncladded roof, 27 °C beneath the foil cladding, and 26 °C beneath the OSB panel. The addition of an aluminum foil layer on the OSB panel resulted in a further temperature reduction of 0.5 °C compared to the uncladded OSB.

Under non-ventilated conditions (10–11 September), the temperature differences became more pronounced. The maximum temperature beneath the uncladded sheathing reached 34 °C, while temperatures beneath the foil and OSB panels were 32 °C and 31 °C, respectively. The OSB panel with aluminum foil exhibited a reduced temperature of 29.7 °C beneath the cladding (

Figure 5).

These findings underscore the significant impact of both ventilation and material composition on the thermal behavior of roof assemblies and their potential influence on indoor heat loads.

3.4. Radiation Power

According to the Stefan–Boltzmann law, any object with a temperature above absolute zero (−273.15 °C) emits thermal radiation. The emitted energy is proportional to the emissivity of the material and to the fourth power of its absolute temperature [

20]. The following values are derived from calculations based on measured surface temperatures and should be considered theoretical estimates, requiring metrological verification.

Both the OSB panel and the underlayment foil were considered to have high emissivity values of 0.9 [

21], whereas the aluminum foil was characterized by a low emissivity of 0.05 (specifically 0.049, as reported in [

9]).

Under ventilated conditions on 8 September, the calculated average thermal load (convective and radiative) between 10:00 a.m. and 8:00 p.m. was 47 W/m

2 for the free-field sheathing, 28 W/m

2 for the foil-cladded field, 11 W/m

2 for the OSB panel, and 5 W/m

2 for the OSB panel coated with a low-emissivity aluminum foil (

Table 3).

When ventilation was closed on 9 September, the thermal loads increased significantly. The free-field sheathing reached 68 W/m2, the foil-cladded field 55 W/m2, the OSB panel 30 W/m2, and the OSB panel with aluminum coating 15 W/m2.

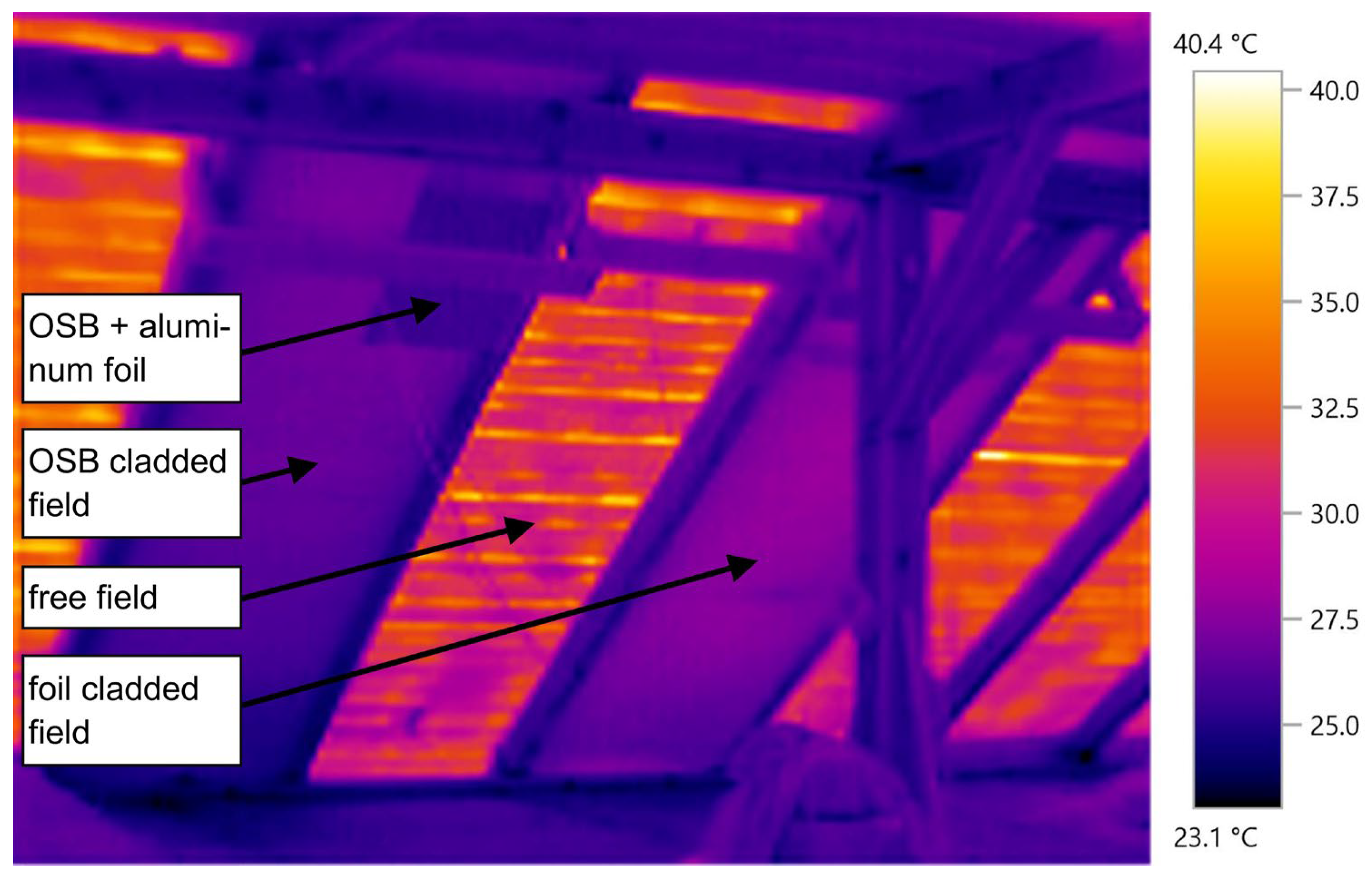

Due to its low emissivity, the OSB panel covered with aluminum foil emits significantly less thermal radiation, averaging only around 5 W/m2 (ventilated). While this effect is consistent with the lower temperatures measured beneath the inner sheathing elements, it is less pronounced than expected. This discrepancy is likely attributable to diffuse thermal radiation from surrounding construction elements, which themselves maintain elevated temperatures—e.g., attic air temperature peaked at 28.4 °C on 9 September.

It should be noted that the appearance of the aluminum foil in the thermographic image (

Figure 6) is most likely a reflection of surrounding diffuse radiation, rather than its own emission. Given the low emissivity of aluminum, its actual thermal radiation is expected to be minimal.

Furthermore, measurements taken with an IR-A sensor (wavelength range: 780–1100 nm) beneath the OSB panel in early September confirm that shortwave infrared radiation is negligible. A maximum value of only 0.1 W/m2 was recorded on 10 September at 11:00 a.m.

4. Discussion

Surface temperature measurements of roof cladding with OSB panels revealed peak values of up to 50 °C on 19 July at 5:00 p.m. This is consistent with previous studies on the thermal behavior of decking materials [

22]. Using Equation (1), which applies the Stefan–Boltzmann law for radiative heat transfer, this corresponds to a thermal load of 314 W/m

2, demonstrating the significant radiative contribution from the roof surface under peak conditions.

As shown in

Table 3, these extreme loads can be reduced to 5–37 W/m

2, depending on material and ventilation. These values are consistent with those reported by Aguilar-Castro et al. [

5], who observed slightly lower loads under cooler ambient conditions.

From mid-July to early September, the roof planking surface exceeded attic air temperature during 16% of the monitored time between 9:00 a.m. and 8:00 p.m. in mid-July, and between 10:00 a.m. and 8:00 p.m. in early September, with an average temperature difference of 5.7 °C (SD: 5.4 °C). This positive gradient indicates net heat flux into the attic, reinforcing the importance of reducing the roof’s surface temperature. This observation is consistent with studies on lightweight timber structures, which suggest that cooling energy demand may outweigh ecological benefits [

23].

Ventilation proved effective in reducing the temperature of the inner-facing planking. This corroborates the findings of Lee et al. [

15] and Gagliano et al. [

17], where natural convection—driven by open eaves—enhanced heat dissipation.

On ventilated days in early September, the inner surface temperature of OSB panels was 4 °C lower on average compared to non-ventilated conditions. Given that radiative heat transfer scales with the fourth power of temperature, even small temperature reductions yield significant energy savings. This is further supported by research on roof ventilation in historic buildings [

16]. Depending on the cladding material the thermal load was reduced between 46 and 64% by ventilation. When applied to the 85 m

2 western roof section of the building under study, this results in a total daily energy reduction of approximately 26 to 53 kWh compared with a non-shielded system.

If cool air is available—e.g., from an air well [

24] or air conditioning systems powered by photovoltaic overproduction—its introduction into the rear ventilation layer of IR shading elements could offer substantial efficiency gains. Conversely, closing ventilation layers during winter could enhance solar heat gains [

16], demonstrating the value of seasonally adaptive systems.

A comparison of ridge outlet air temperatures (measurement point M8, see

Figure 2) and inlet temperature on 7 September shows that the outgoing air was on average 4.9 (OSB) and 4.6 (foil) °C warmer at the ridge outlet on the ventilated day, with an average air speed of 0.15 (OSB) and 0.10 (foil) indicating heat absorption from the interior planking elements and supporting the calculations for thermal load.

Comparing IR shading materials, OSB panels showed 38% lower thermal loads than foil, suggesting that higher thermal mass and surface emissivity play critical roles. OSB sheathing is preferable when structural conditions allow, due to its thermal performance and energy buffering capacity.

Temperatures measured directly beneath the planking layers serve as indirect indicators of radiative exposure from the roof interior, though they are also influenced by thermal radiation from surrounding structural elements [

25]. Future studies should consider sensor shielding to isolate radiative effects [

26]. On September 8, which featured a sinusoidal outside temperature profile, peak temperatures beneath the planking were: 25.9 °C (OSB with aluminum foil), 26.5 °C (OSB), 26.9 °C (foil), and 28.7 °C (uncladded roof) confirming the effectiveness of shading elements. Without ventilation, the same ranking was observed, but with more pronounced differences (

Figure 4). These results suggest that shading elements are effective, particularly when ventilated. There is also clear indication that higher thermal mass (e.g., OSB vs. foil or fabric) offers a thermal advantage, because it absorbs and stores heat which reduces the rate at which heat enters the building. Additionally thermal mass delays heat transmission. This delay helps align heat gain with off-peak energy hours [

27].

The temperature measured beneath the OSB panel coated with aluminum foil was measurably lower, but not as significantly as expected given the low emissivity of 0.05 compared to 0.91 for OSB [

21]. This is likely due to the limited surface area and interference from surrounding elements, which predominantly radiate in the IR-C spectrum [

25] and may cause reflections, as discussed by Kim et al. [

28]. A related study on interior aluminum roof coatings demonstrated that such treatments can reduce radiative heat transfer to 6 W/m

2 compared with 111 W/m

2 with a white interior coating [

9]. The current study suggests a thermal load of 5 to 15 W/m

2 with the low-emission coated OSB panel and is in the range of the cited study.