Optimisation of 3D Printable Cement- and Lime-Based Mortars for Built Heritage Rehabilitation

Abstract

1. Introduction

2. Experimental Methods

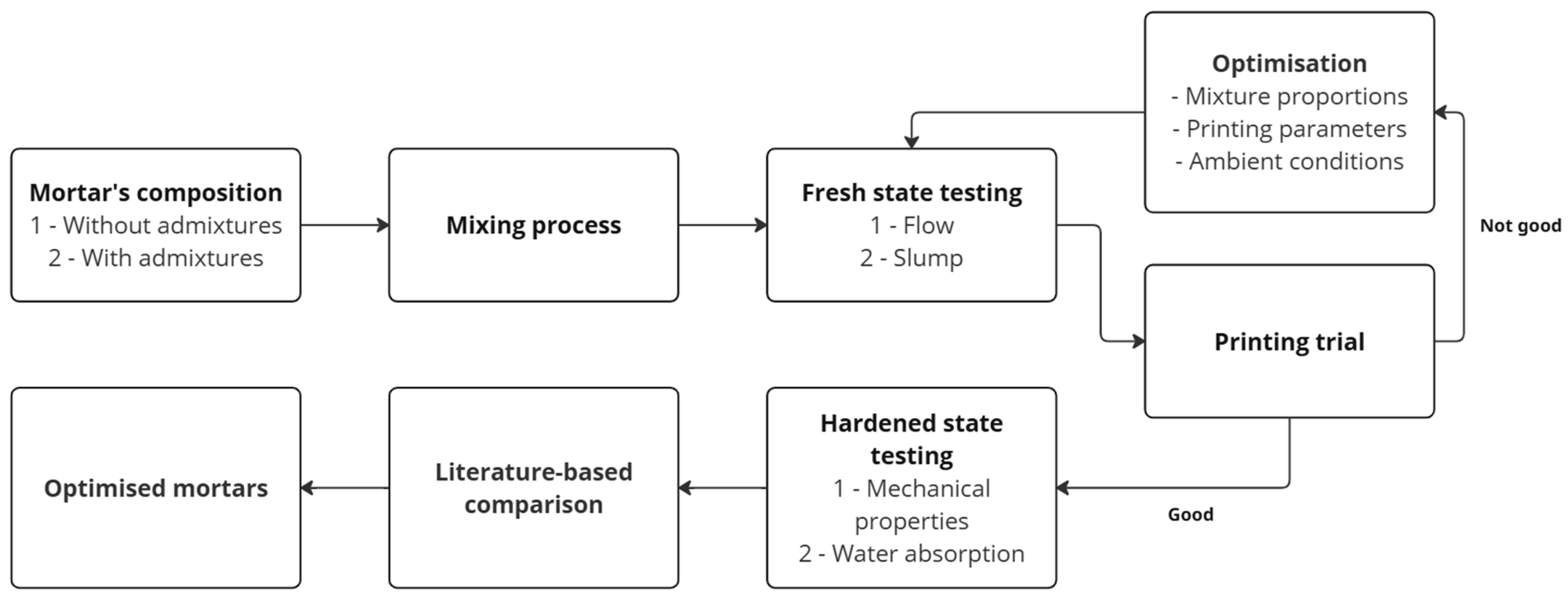

2.1. Work Plan

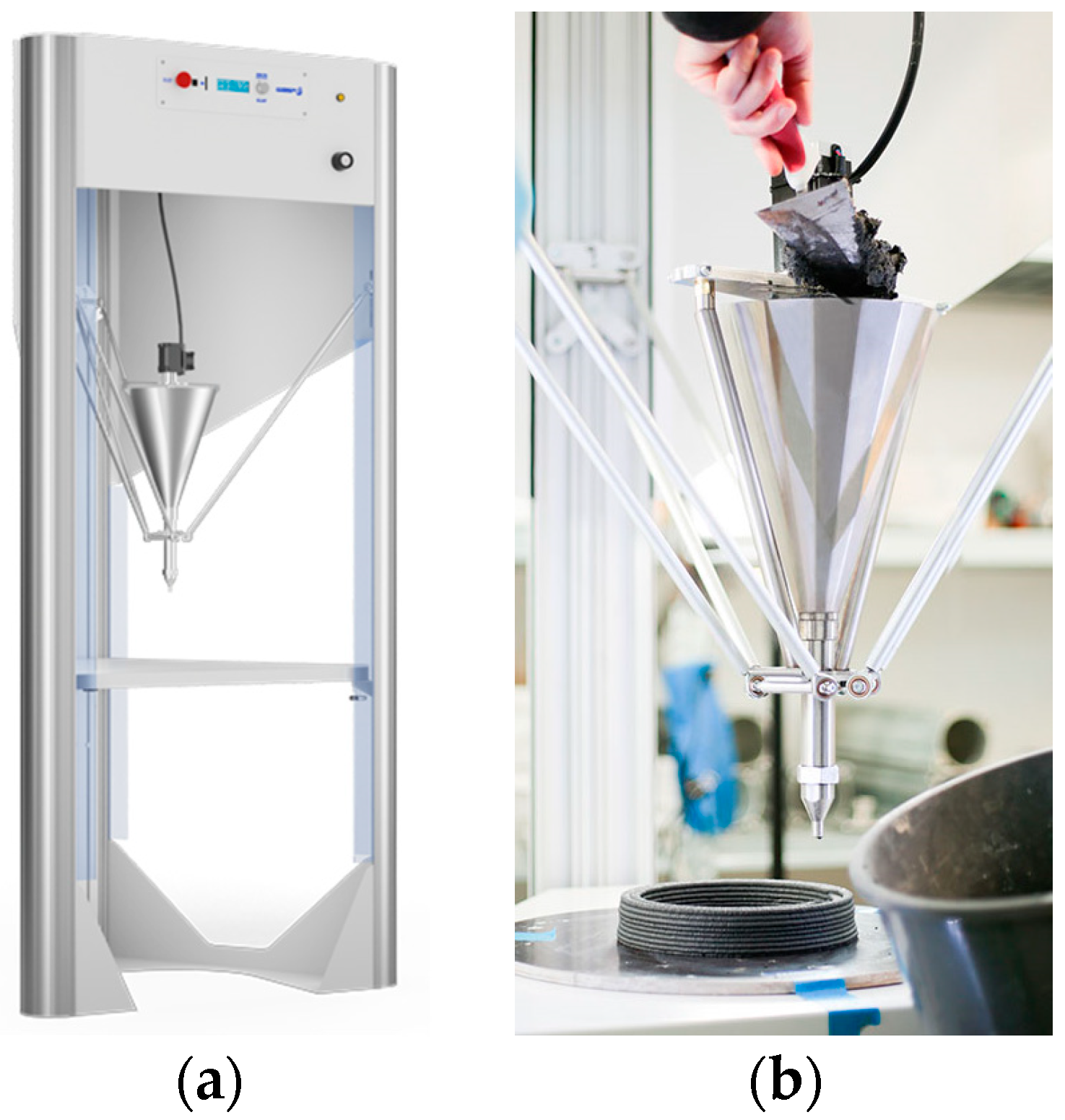

2.2. Equipment

2.3. Mortars’ Preparation

2.3.1. Materials and Formulations

- Binders: Hydraulic lime HL5 and white Portland cement CEM I 52.5R (BR), both from Secil;

- Aggregate: River sand with controlled particle size below 1 mm, ensuring a homogeneous distribution;

- Water: Regular tap water;

- Admixture: A superplasticiser (SP) (Chryso Optima 206, polycarboxylate-based) was used to reduce the water content in the mixes.

2.3.2. Mixing Process

2.4. Test Procedures

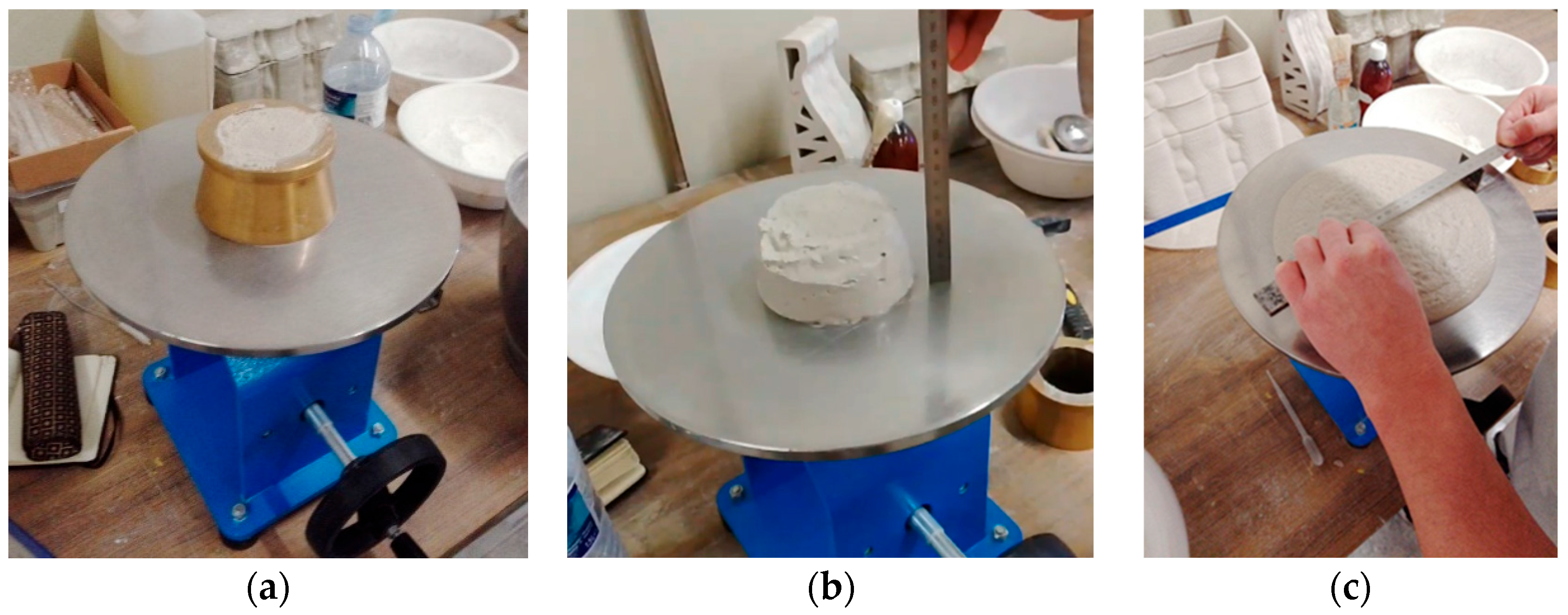

2.4.1. Fresh State Tests

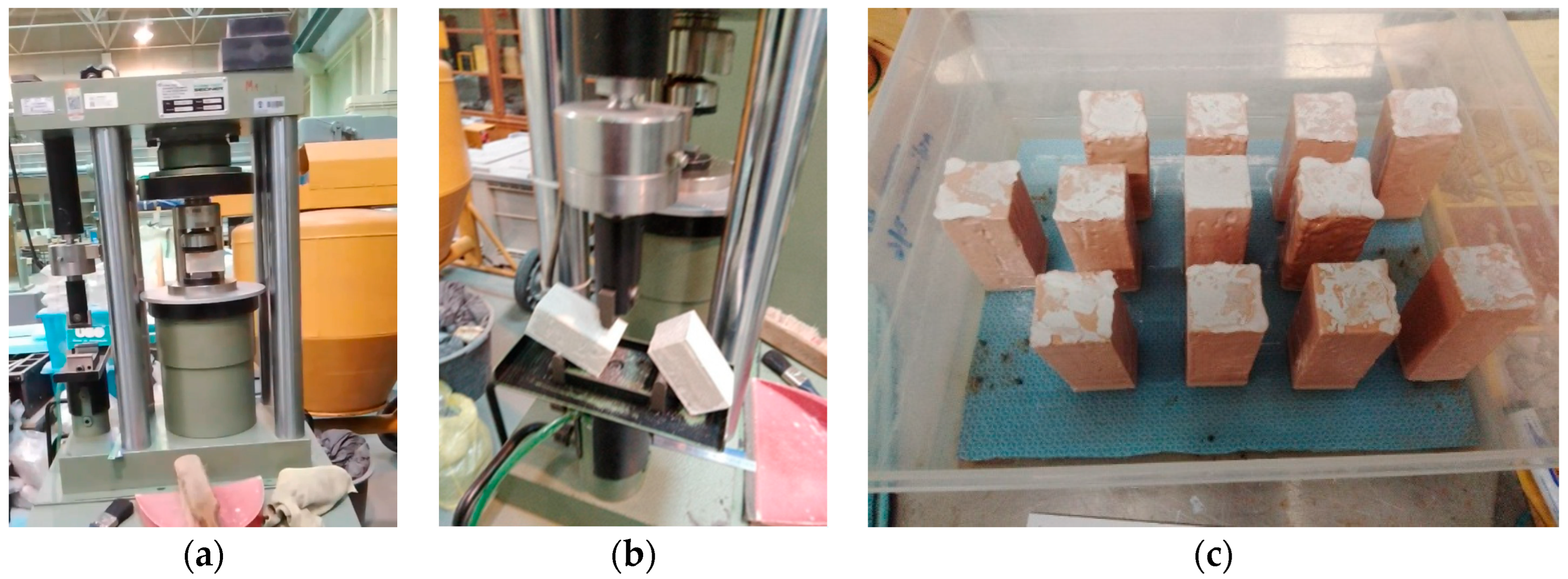

2.4.2. Hardened State Tests

3. Data Analysis

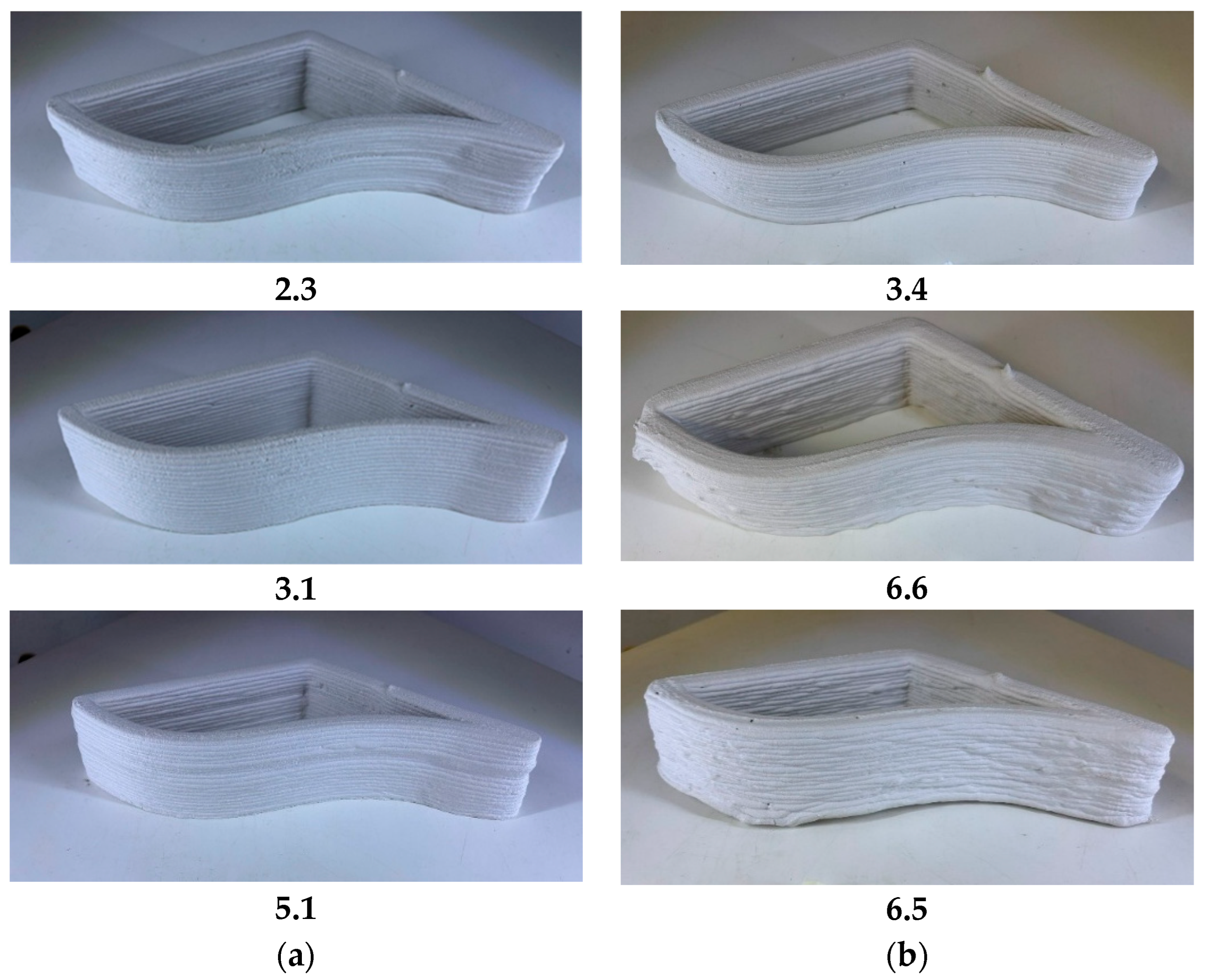

3.1. Printing Validation

3.2. Test Results

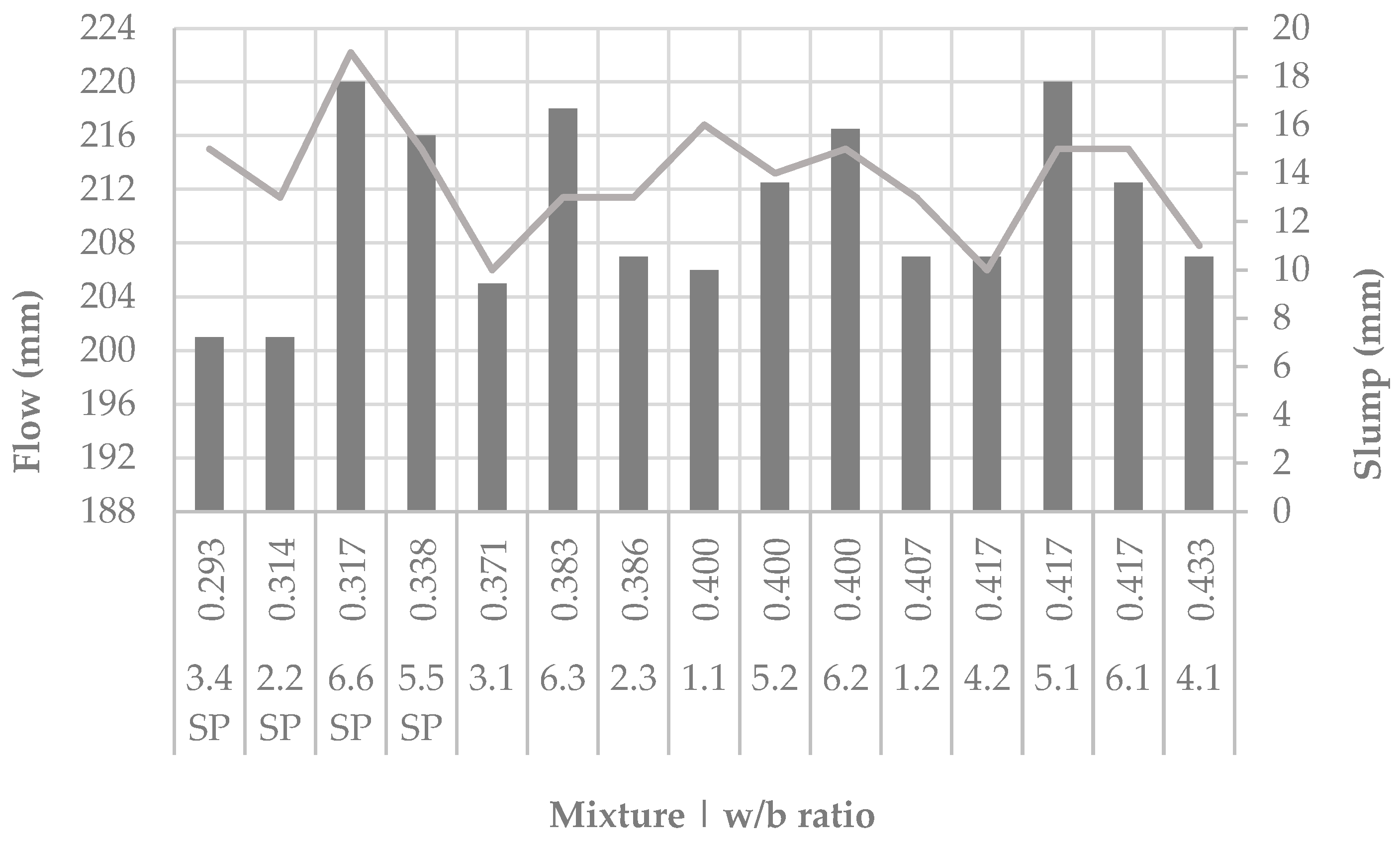

3.2.1. Fresh State Tests

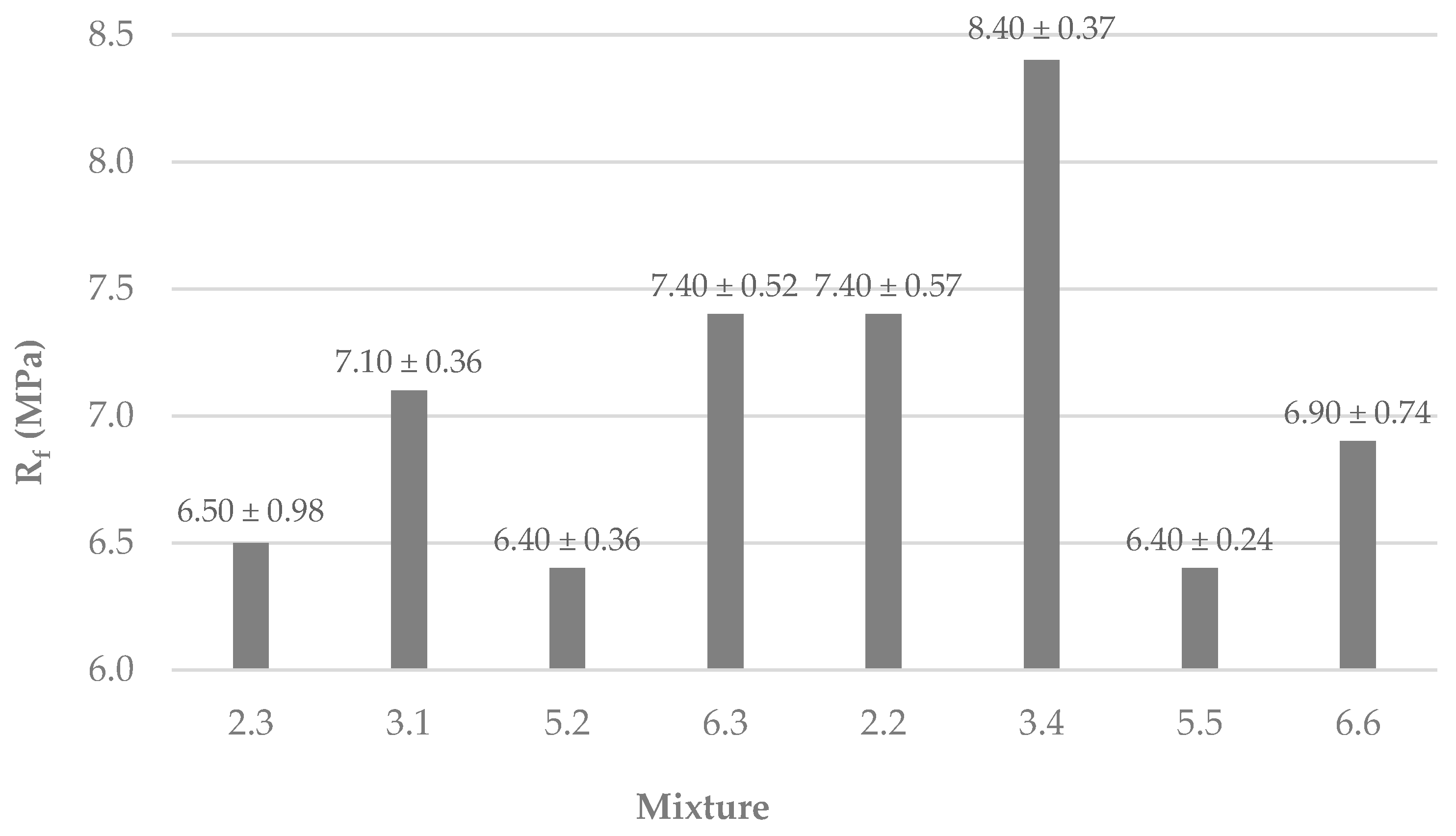

3.2.2. Hardened State Tests

4. Discussion of Test Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jesus, M.; Teixeira, J.; Alves, J.L.; Pessoa, S.; Guimarães, A.S.; Rangel, B. Potential Use of Sugarcane Bagasse Ash in Cementitious Mortars for 3D Printing. In Materials Design and Applications IV; da Silva, L.F.M., Ed.; Springer International Publishing: Cham, Switzerland, 2023; pp. 89–103. [Google Scholar]

- Teixeira, J.; Schaefer, C.O.; Maia, L.; Rangel, B.; Neto, R.; Alves, J.L. Influence of Supplementary Cementitious Materials on Fresh Properties of 3D Printable Materials. Sustainability 2022, 14, 3970. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, C.; Liu, Z.; Wang, H.; Ren, Q. Mechanical Anisotropy of Ultra-High Performance Fibre-Reinforced Concrete for 3D Printing. Cem. Concr. Compos. 2022, 125, 104310. [Google Scholar] [CrossRef]

- Xu, J.; Ding, L.; Love, P.E.D. Digital Reproduction of Historical Building Ornamental Components: From 3D Scanning to 3D Printing. Autom. Constr. 2017, 76, 85–96. [Google Scholar] [CrossRef]

- Armesto-González, J.; Riveiro-Rodríguez, B.; González-Aguilera, D.; Rivas-Brea, M.T. Terrestrial Laser Scanning Intensity Data Applied to Damage Detection for Historical Buildings. J. Archaeol. Sci. 2010, 37, 3037–3047. [Google Scholar] [CrossRef]

- Döndüren, M.S.; Sişik, O. Materials, Used in Historical Buildings, Analysis Methods and Solutions Puroposals. E3S Web Conf. 2017, 19, 03019. [Google Scholar] [CrossRef]

- Matero, F.G. Ethics and Policy in Conservation; Getty Conservation Institute Newsletter: Los Angeles, CA, USA, 2000; Volume 15. [Google Scholar]

- Higueras, M.; Calero, A.I.; Collado-Montero, F.J. Digital 3D Modeling Using Photogrammetry and 3D Printing Applied to the Restoration of a Hispano-Roman Architectural Ornament. Digit. Appl. Archaeol. Cult. Herit. 2021, 20, e00179. [Google Scholar] [CrossRef]

- Maurenbrecher, A.H.P. Mortars for Repair of Tradicional Masonry. Pract. Period. Struct. Des. Constr. 2004, 9, 62–65. [Google Scholar] [CrossRef]

- Doğruyol, M. Characterization of Historic Mortars and the Effect of Rice Husk Ash (RHA) on Quicklime. Case Stud. Constr. Mater. 2024, 21, e03542. [Google Scholar] [CrossRef]

- Silva, D.A.; Wenk, H.R.; Monteiro, P.J.M. Comparative Investigation of Mortars from Roman Colosseum and Cistern. Thermochim. Acta 2005, 438, 35–40. [Google Scholar] [CrossRef]

- Pavlík, Z.; Vyšvařil, M.; Pavlíková, M.; Bayer, P.; Pivák, A.; Rovnaníková, P.; Záleská, M. Lightweight Pumice Mortars for Repair of Historic Buildings—Assessment of Physical Parameters, Engineering Properties and Durability. Constr. Build. Mater. 2023, 404, 133275. [Google Scholar] [CrossRef]

- Bayat, H.; Kashani, A. Analysis of Rheological Properties and Printability of a 3D-Printing Mortar Containing Silica Fume, Hydrated Lime, and Blast Furnace Slag. Mater. Today Commun. 2023, 37, 107128. [Google Scholar] [CrossRef]

- Panda, B.; Tan, M.J. Experimental Study on Mix Proportion and Fresh Properties of Fly Ash Based Geopolymer for 3D Concrete Printing. Ceram. Int. 2018, 44, 10258–10265. [Google Scholar] [CrossRef]

- Jesus, M.; Ribeiro, E.; Teixeira, J.; Rangel, B.; Guimarães, A.S.; Alves, J.L. 3D-Printed Mortars with Marble Powder Towards Sustainable Construction. In 3D Printing for Construction in the Transformation of the Building Industry; Taylor & Francis Group: Abingdon, UK, 2024; ISBN 9781003403890. [Google Scholar]

- Dulaj, A.; Salet, T.A.M.; Lucas, S.S. Mechanical Properties and Self-Sensing Ability of Graphene-Mortar Compositions with Different Water Content for 3D Printing Applications. Mater. Today Proc. 2022, 70, 412–417. [Google Scholar] [CrossRef]

- Dias, B.D.; Rocha, D.; Faria, P.; Lucas, S.S.; Silva, V.A.; Lobo, B.; Reaes Pinto, A. Limes with Hydraulic Properties for 3D Printing Mortars. In Sustainable and Digital Building; Springer International Publishing: Cham, Switzerland, 2023; pp. 41–50. [Google Scholar]

- Jesus, M.; Teixeira, J.; Guimarães, A.S.; Rangel, B.; Alves, J.L. From 3D Survey Data of Cultural Heritage Artefacts to 3D-Printed Prototypes Based on Cement and Lime-Based Mortars. Digit. Appl. Archaeol. Cult. Herit. 2025, 37, e00412. [Google Scholar] [CrossRef]

- Kenwood Titanium Chef Baker XL KVL65.001WH. Available online: https://www.kenwoodworld.com/pt-pt/titanium-chef-baker-xl-kvl65-001wh/p/KVL65.001WH (accessed on 4 September 2025).

- WASP. WASP 40100 LDM. Available online: https://www.3dwasp.com/en/ceramic-3d-printer-wasp-40100-ldm/ (accessed on 22 July 2024).

- WASP. Geopolymer Extruder—WASP Manual Feeding Extruder. Available online: https://www.3dwasp.com/en/wasp-manual-feeding-extruder/ (accessed on 9 July 2024).

- CEN EN 1015-3:1999; Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). CEN: Brussels, Belgium, 1999.

- CEN EN 196-1:2016; Methods of Testing Cement—Part 1: Determination of Strength. CEN: Brussels, Belgium, 2016.

- ISO 15148:2002; Hygrothermal Performance of Building Materials and Products—Determination of Water Absorption Coefficient by Partial Immersion. ISO: Geneva, Switzerland, 2002.

- Marra, A.; Gerbino, S.; Greco, A.; Fabbrocino, G. Combining Integrated Informative System and Historical Digital Twin for Maintenance and Preservation of Artistic Assets. Sensors 2021, 21, 5956. [Google Scholar] [CrossRef] [PubMed]

- Rehman, A.U.; Kim, J.-H. 3D Concrete Printing: A Systematic Review of Rheology, Mix Designs, Mechanical, Microstructural, and Durability Characteristics. Materials 2021, 14, 3800. [Google Scholar] [CrossRef]

- Gurunandan, M.; Jeet Malla, H.; Nanthagopalan, P. Effect of Water to Binder, Aggregate to Binder Ratio and Admixtures on Printability and Mechanical Properties of 3D Printable Mortar Mixtures. J. Build. Eng. 2025, 99, 111649. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.F.; Thorpe, T. Mix Design and Fresh Properties for High-Performance Printing Concrete. Mater. Struct. 2012, 45, 1221–1232. [Google Scholar] [CrossRef]

- Zhang, M.-H.; Sisomphon, K.; Ng, T.S.; Sun, D.J. Effect of Superplasticizers on Workability Retention and Initial Setting Time of Cement Pastes. Constr. Build. Mater. 2010, 24, 1700–1707. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L. Printable Properties of Cementitious Material Containing Copper Tailings for Extrusion Based 3D Printing. Constr. Build. Mater. 2018, 162, 613–627. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Qian, Y.; Tan, M.J. Printability Region for 3D Concrete Printing Using Slump and Slump Flow Test. Compos. B Eng. 2019, 174, 106968. [Google Scholar] [CrossRef]

- Zagaroli, A.; Kubica, J.; Galman, I.; Falkjar, K. Study on the Mechanical Properties of Two General-Purpose Cement–Lime Mortars Prepared Based on Air Lime. Materials 2024, 17, 1001. [Google Scholar] [CrossRef]

- Li, Y.-F.; Tsai, P.-J.; Syu, J.-Y.; Lok, M.-H.; Chen, H.-S. Mechanical Properties of 3D-Printed Carbon Fiber-Reinforced Cement Mortar. Fibers 2023, 11, 109. [Google Scholar] [CrossRef]

- Lee, H.; Kim, J.-H.J.; Moon, J.-H.; Kim, W.-W.; Seo, E.-A. Evaluation of the Mechanical Properties of a 3D-Printed Mortar. Materials 2019, 12, 4104. [Google Scholar] [CrossRef] [PubMed]

- Mindness, S. (Ed.) Developments in the Formulation and Reinforcement of Concrete; Elsevier: Vancouver, BC, Canada, 2019; ISBN 9780081026168. [Google Scholar]

- Mortar Industry Association. Technical Data Sheet No. 19: Mortar for Masonry—Properties and Performance; Mortar Industry Association: London, UK, 2019. [Google Scholar]

- Van Der Putten, J.; Snoeck, D.; De Coensel, R.; De Schutter, G.; Van Tittelboom, K. Early Age Shrinkage Phenomena of 3D Printed Cementitious Materials with Superabsorbent Polymers. J. Build. Eng. 2021, 35, 102059. [Google Scholar] [CrossRef]

- Soares, A.C.M.; Costa, H.; do Carmo, R.; Rodrigues, A.; Gaspar, F.; Júlio, E. Comprehensive Design Methodology for 3D Printing Mortars. Constr. Build. Mater. 2023, 401, 132804. [Google Scholar] [CrossRef]

- Joh, C.; Lee, J.; Bui, T.Q.; Park, J.; Yang, I.-H. Buildability and Mechanical Properties of 3D Printed Concrete. Materials 2020, 13, 4919. [Google Scholar] [CrossRef] [PubMed]

- Matos, A.M.; Emiroğlu, M.; Subasi, S.; Marasli, M.; Guimrães, A.S.; Delgado, J. Architectonic Cement-Based Composites 3D Printing. In 3D Printing for Construction with Alternative Materials; Springer Nature: Berlin/Heidelberg, Germany, 2023; pp. 67–89. [Google Scholar]

- Yedra, E.; Ferrández, D.; Morón, C.; Saiz, P. New Test Methods to Determine Water Absorption by Capillarity. Experimental Study in Masonry Mortars. Constr. Build. Mater. 2022, 319, 125988. [Google Scholar] [CrossRef]

- Ka, M.; Hoffmann, D.; Molez, L.; Lanos, C. Alkali-Activated Mortars: Porosity and Capillary Absorption. Eur. J. Environ. Civ. Eng. 2023, 27, 1715–1729. [Google Scholar] [CrossRef]

- Pessoa, S.; Jesus, M.; Guimarães, A.S.; Lucas, S.S.; Simões, N. Experimental Characterisation of Hygrothermal Properties of a 3D Printed Cementitious Mortar. Case Stud. Constr. Mater. 2023, 19, e02355. [Google Scholar] [CrossRef]

- Borges, A.; Flores-Colen, I.; de Brito, J. Physical and Mechanical Performance of Cement-Based Renders with Different Contents of Fly Ash, Expanded Cork Granules and Expanded Clay. Constr. Build. Mater. 2018, 191, 535–543. [Google Scholar] [CrossRef]

- Teixeira, J.; Schaefer, C.O.; Rangel, B.; Maia, L.; Alves, J.L. A Road Map to Find in 3D Printing a New Design Plasticity for Construction—The State of Art. Front. Archit. Res. 2023, 12, 337–360. [Google Scholar] [CrossRef]

- Mohammad, M.; Masad, E.; Al-Ghamdi, S.G. 3D Concrete Printing Sustainability: A Comparative Life Cycle Assessment of Four Construction Method Scenarios. Buildings 2020, 10, 245. [Google Scholar] [CrossRef]

- Han, Y.; Yang, Z.; Ding, T.; Xiao, J. Environmental and Economic Assessment on 3D Printed Buildings with Recycled Concrete. J. Clean. Prod. 2021, 278, 123884. [Google Scholar] [CrossRef]

- Long, W.-J.; Lin, C.; Tao, J.-L.; Ye, T.-H.; Fang, Y. Printability and Particle Packing of 3D-Printable Limestone Calcined Clay Cement Composites. Constr. Build. Mater. 2021, 282, 122647. [Google Scholar] [CrossRef]

- Asadoullahtabar, S.R.; Asgari, A.; Mohammad Rezapour Tabari, M. Assessment, Identifying, and Presenting a Plan for the Stabilization of Loessic Soils Exposed to Scouring in the Path of Gas Pipelines, Case Study: Maraveh-Tappeh City. Eng. Geol. 2024, 342, 107747. [Google Scholar] [CrossRef]

- Fonseca, M.; Matos, A.M. 3D Construction Printing Standing for Sustainability and Circularity: Material-Level Opportunities. Materials 2023, 16, 2458. [Google Scholar] [CrossRef]

| Criteria | 1 (Very Poor) | 2 (Poor) | 3 (Acceptable) | 4 (Good) | 5 (Very Good) | Evaluation Method |

|---|---|---|---|---|---|---|

| Finish | Surface with flaws and visible defects | Irregular surface with occasional flaws | Ok surface with small flaws | Smooth surface, few visual defects | Smooth and uniform surface with no defects | Visual inspection |

| Layer dimensions (thickness) | <80% or >200% of nozzle diameter (8 mm) | 80–99% or 171–200% of nozzle diameter | 100–110% or 160–170% of nozzle diameter | 111–159% of nozzle diameter | 120–150% of nozzle diameter | Visual inspection + calliper measurement |

| Structural integrity | Cracks, layer displacements | Some cracks or misalignments | Good bond between layers | Stable structure, no visible cracks | Fully cohesive and intact structure | Visual inspection |

| Printability | Impossible to print | Printing with frequent interruptions | Continuous printing with minor defects | Smooth and continuous printing | Perfect printing, no interruptions | Visual inspection |

| Collapse | Specimen collapses completely | Partial collapse evident | Deformed but printable structure | Stable piece with good geometry | No collapse, complete stability | Visual inspection |

| Mixture | Cement (g) | Lime (g) | Sand (g) | Water (g) | w/b | a/b | |

|---|---|---|---|---|---|---|---|

| 1 | 1.1 | 350 | 350 | 300 | 280 | 0.400 | 0.429 |

| 1.2 | 350 | 350 | 300 | 285 | 0.407 | 0.429 | |

| 2 | 2.1 | 420 | 280 | 300 | 260 | 0.371 | 0.429 |

| 2.2 | 420 | 280 | 300 | 265 | 0.379 | 0.429 | |

| 2.3 | 420 | 280 | 300 | 270 | 0.386 | 0.429 | |

| 3 | 3.1 | 525 | 175 | 300 | 260 | 0.371 | 0.429 |

| 4 | 4.1 | 300 | 300 | 400 | 260 | 0.433 | 0.667 |

| 4.2 | 300 | 300 | 400 | 250 | 0.417 | 0.667 | |

| 5 | 5.1 | 360 | 240 | 400 | 250 | 0.417 | 0.667 |

| 5.2 | 360 | 240 | 400 | 240 | 0.400 | 0.667 | |

| 6 | 6.1 | 450 | 150 | 400 | 250 | 0.417 | 0.667 |

| 6.2 | 450 | 150 | 400 | 240 | 0.400 | 0.667 | |

| 6.3 | 450 | 150 | 400 | 230 | 0.383 | 0.667 | |

| Mixture | F | LD | SI | C | P | Observations | FE [1,2,3,4,5] |

|---|---|---|---|---|---|---|---|

| 1.1 | 3 | 3 | 3 | 3 | 3 | Acceptable result; some deformations; layers not fully uniform; exudation observed | 3 |

| 1.2 | 2 | 3 | 2 | 1 | 3 | Uniform layers; lack of buildability; collapse due to excess water | 2.2 |

| 2.1 | 1 | 2 | 3 | 2 | 2 | Poor extrudability; visible mortar gaps and defects | 2.0 |

| 2.2 | 3 | 3.5 | 3.5 | 3 | 3 | Still showing flaws and imperfections compared to mix 2.1 | 3.2 |

| 2.3 | 4 | 4 | 4.5 | 4.5 | 4 | Uniform layers and minimal deformation; almost perfect | 4.2 |

| 3.1 | 5 | 5 | 5 | 5 | 5 | Perfect result; uniform layers; good buildability; no deformation; no excess water | 5 |

| 4.1 | 3 | 3 | 3.5 | 3.5 | 3.5 | Acceptable; visible exudation and some deformations | 3.3 |

| 4.2 | 4 | 3 | 3 | 4 | 4 | Good final surface finish | 3.6 |

| 5.1 | 3 | 4 | 4 | 4 | 4 | Uniform layers; good printability; some deformations | 3.8 |

| 5.2 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | Uniform layers; good surface finish | 4.5 |

| 6.1 | 3 | 2 | 3 | 3 | 3 | Good printability; exudation observed | 2.8 |

| 6.2 | 3 | 3 | 3 | 3 | 3 | Some imperfections and deformations | 3 |

| 6.3 | 3.5 | 4 | 4 | 4 | 3.5 | Good finish; good printability; good flowability | 3.8 |

| Mixture | Cement (g) | Lime (g) | Sand (g) | Water (g) | SP (g) | w/b | a/b | |

|---|---|---|---|---|---|---|---|---|

| 2 | 2.1 | 420 | 280 | 300 | 210 | 3.50 | 0.300 | 0.429 |

| 2.2 | 420 | 280 | 300 | 220 | 3.50 | 0.314 | 0.429 | |

| 3 | 3.1 | 525 | 175 | 300 | 225 | 3.50 | 0.321 | 0.429 |

| 3.2 | 525 | 175 | 300 | 220 | 3.50 | 0.314 | 0.429 | |

| 3.3 | 525 | 175 | 300 | 215 | 3.50 | 0.307 | 0.429 | |

| 3.4 | 525 | 175 | 300 | 205 | 3.50 | 0.293 | 0.429 | |

| 5 | 5.1 | 360 | 240 | 400 | 180 | 3 | 0.300 | 0.667 |

| 5.2 | 360 | 240 | 400 | 200 | 3 | 0.333 | 0.667 | |

| 5.3 | 360 | 240 | 400 | 205 | 3 | 0.342 | 0.667 | |

| 5.4 | 360 | 240 | 400 | 204 | 3 | 0.340 | 0.667 | |

| 5.5 | 360 | 240 | 400 | 202.50 | 3 | 0.338 | 0.667 | |

| 6 | 6.1 | 450 | 150 | 400 | 180 | 3 | 0.300 | 0.667 |

| 6.2 | 450 | 150 | 400 | 185 | 3 | 0.308 | 0.667 | |

| 6.3 | 450 | 150 | 400 | 187.50 | 3 | 0.313 | 0.667 | |

| 6.4 | 450 | 150 | 400 | 195 | 3 | 0.325 | 0.667 | |

| 6.5 | 450 | 150 | 400 | 192.50 | 3 | 0.321 | 0.667 | |

| 6.6 | 450 | 150 | 400 | 190 | 3 | 0.317 | 0.667 | |

| Mixture | F | LD | SI | C | P | Observations | FE [1,2,3,4,5] |

|---|---|---|---|---|---|---|---|

| 2.2 | 3 | 3 | 4 | 4 | 4 | Extrudable mortar with no clogging; flow adjustment noticeable in layer thickness | 3.6 |

| 3.4 | 4 | 4 | 4 | 4 | 5 | Very uniform and nearly perfect finish; some variation in layer thickness observed | 4.2 |

| 5.2 | 2.5 | 3 | 3 | 4 | 3.5 | Moderately consistent layers with preserved geometry; rough finish, but structurally solid and with good strength—suitable for functional use where aesthetics are not a priority | 3.2 |

| 5.3 | 2 | 3 | 3.5 | 4 | 3.5 | Structurally robust; poor finish with thick and irregular layers; noticeable roughness on the top surface | 3.2 |

| 5.4 | 1.5 | 2 | 2.5 | 2 | 2 | Highly inadequate mix | 2 |

| 5.5 | 3 | 3.5 | 3 | 4 | 3.5 | Some surface roughness; consistent texture; uniform layers; increased flowability | 3.4 |

| 6.2 | 2 | 2.5 | 3 | 3 | 3 | Some irregularities; lack of water | 2.7 |

| 6.3 | 3 | 2 | 3 | 3 | 3 | Acceptable finish despite clogging at the end; some layer thickness variation | 2.8 |

| 6.5 | 3 | 4 | 4 | 4 | 4 | Easy extrusion; consistent flow; acceptable finish | 3.8 |

| 6.6 | 4 | 4 | 4 | 4 | 4 | Good mortar; uniform layer thickness; best among the 6.3 formulations | 4 |

| SP? | Mixture | Absorption Coefficient, Aw, 24h (kg/m2s0.5) | Mean Absorption Coefficient, Aw, 24h (kg/m2s0.5) | BS EN 998-1 Classification [36] | |

|---|---|---|---|---|---|

| No | 2.3 | 1 | 0.00099 | 0.00109 ± 0.00007 | W2 |

| 2 | 0.00118 | ||||

| 3 | 0.00109 | ||||

| 3.1 | 1 | 0.00050 | 0.00072 ± 0.00021 | W2 | |

| 2 | 0.00065 | ||||

| 3 | 0.00100 | ||||

| 5.2 | 1 | 0.00111 | 0.00139 ± 0.00028 | W2 | |

| 2 | 0.00778 | ||||

| 3 | 0.00167 | ||||

| 6.3 | 1 | 0.00112 | 0.00117 ± 0.00015 | W2 | |

| 2 | 0.00101 | ||||

| 3 | 0.00137 | ||||

| Yes | 2.2 | 1 | 0.00043 | 0.00047 ± 0.00003 | W2 |

| 2 | 0.00048 | ||||

| 3 | 0.00050 | ||||

| 3.4 | 1 | 0.00045 | 0.00039 ± 0.00010 | W2 | |

| 2 | 0.00025 | ||||

| 3 | 0.00048 | ||||

| 5.5 | 1 | 0.00069 | 0.00063 ± 0.00004 | W2 | |

| 2 | 0.00061 | ||||

| 3 | 0.00059 | ||||

| 6.6 | 1 | 0.00042 | 0.00039 ± 0.00003 | W2 | |

| 2 | 0.00039 | ||||

| 3 | 0.00035 | ||||

| Mixture | Coefficient Without SP (kg/m2s0.5) | Mixture | Coefficient with SP (kg/m2s0.5) | Coefficient Variation | Reduction (%) |

|---|---|---|---|---|---|

| 2.3 | 0.00109 | 2.2 | 0.00047 | –0.00062 | 56.88 |

| 3.1 | 0.00072 | 3.4 | 0.00039 | –0.00033 | 45.83 |

| 5.2 | 0.00139 | 5.5 | 0.00063 | –0.00076 | 54.68 |

| 6.3 | 0.00117 | 6.6 | 0.00039 | –0.00078 | 66.67 |

| SP? | Mixture | w/b | a/b | Flow (mm) | Slump (mm) |

|---|---|---|---|---|---|

| No | 1.1 | 0.400 | 0.429 | 206.00 | 16 |

| 2.3 | 0.386 | 0.429 | 207.00 | 13 | |

| 3.1 | 0.371 | 0.429 | 205.00 | 10 | |

| 4.2 | 0.417 | 0.667 | 207.00 | 10 | |

| 5.2 | 0.400 | 0.667 | 212.50 | 14 | |

| 6.3 | 0.383 | 0.667 | 218.00 | 13 | |

| Yes | 2.2 | 0.314 | 0.429 | 201.00 | 13 |

| 3.4 | 0.293 | 0.429 | 201.00 | 15 | |

| 5.5 | 0.338 | 0.667 | 216.00 | 15 | |

| 6.6 | 0.317 | 0.667 | 220.00 | 19 | |

| Without SP | 0.371–0.417 | 0.429/0.667 | 205–218 | 10–16 | |

| With SP | 0.293–0.338 | 0.429/0.667 | 201–220 | 13–19 | |

| Laboratory Test | Mortar Type | Result | Unit | Reference |

|---|---|---|---|---|

| Compressive strength | Traditional mortar * | 4.16–7.91 | MPa | Zagaroli et al. [32] |

| 3DP mortar with fibres | 48–52 | Li et al. [33] | ||

| 3DP concrete | 23.50 | Joh et al. [39] | ||

| 3DP cement mortar | 30.40 | Jesus et al. [1] | ||

| 3DP cement mortar | 55–87 | Matos et al. [40] | ||

| 3DP mortar | 48.90–64.20 | Present study | ||

| 3DP mortar with SP | 52.70–74.00 | Present study | ||

| Flexural strength | Traditional mortar * | 1.23–2.21 | MPa | Zagaroli et al. [32] |

| 3DP mortar with fibres | 6.00–8.30 | Li et al. [33] | ||

| 3DP concrete | 6.50 | Joh et al. [39] | ||

| 3DP cement mortar | 5.30 | Jesus et al. [1] | ||

| 3DP cement mortar | 4.00–7.00 | Matos et al. [40] | ||

| 3DP mortar | 6.40–7.40 | Present study | ||

| 3DP mortar with SP | 6.40–8.40 | Present study | ||

| Water absorption by capillarity | Masonry mortars | 0.05–0.10 | kg/m2s0.5 | Yedra et al. [41] |

| Cement mortar | 0.024 | Ka et al. [42] | ||

| 3DP mortar | 0.00071 | Pessoa et al. [43] | ||

| Traditional coating mortar | 0.13–0.14 | Borges et al. [44] | ||

| 3DP mortar with SP | 0.00039–0.00063 | Present study | ||

| 3DP mortar | 0.00072–0.00139 | Present study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jesus, M.; Dias, R.; Teixeira, J.; Delgado, J.M.P.Q.; Alves, J.L.; Rangel, B.; Guimarães, A.S. Optimisation of 3D Printable Cement- and Lime-Based Mortars for Built Heritage Rehabilitation. Buildings 2025, 15, 3464. https://doi.org/10.3390/buildings15193464

Jesus M, Dias R, Teixeira J, Delgado JMPQ, Alves JL, Rangel B, Guimarães AS. Optimisation of 3D Printable Cement- and Lime-Based Mortars for Built Heritage Rehabilitation. Buildings. 2025; 15(19):3464. https://doi.org/10.3390/buildings15193464

Chicago/Turabian StyleJesus, Manuel, Ricardo Dias, João Teixeira, João M. P. Q. Delgado, Jorge Lino Alves, Bárbara Rangel, and Ana Sofia Guimarães. 2025. "Optimisation of 3D Printable Cement- and Lime-Based Mortars for Built Heritage Rehabilitation" Buildings 15, no. 19: 3464. https://doi.org/10.3390/buildings15193464

APA StyleJesus, M., Dias, R., Teixeira, J., Delgado, J. M. P. Q., Alves, J. L., Rangel, B., & Guimarães, A. S. (2025). Optimisation of 3D Printable Cement- and Lime-Based Mortars for Built Heritage Rehabilitation. Buildings, 15(19), 3464. https://doi.org/10.3390/buildings15193464