Damage and Deterioration Characteristics of Sandstone Under Multi-Stage Equal-Amplitude Intermittent Cyclic Loading and Unloading

Abstract

1. Introduction

2. Test Materials, Equipment, and Methods

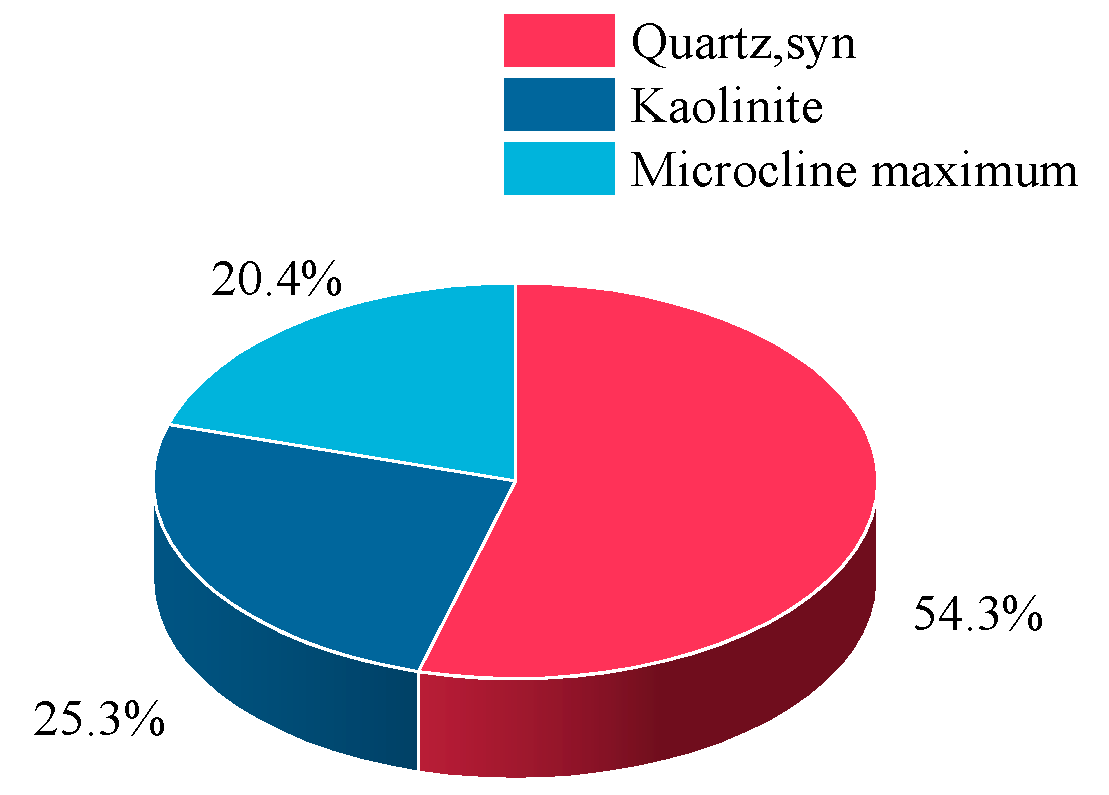

2.1. Test Materials

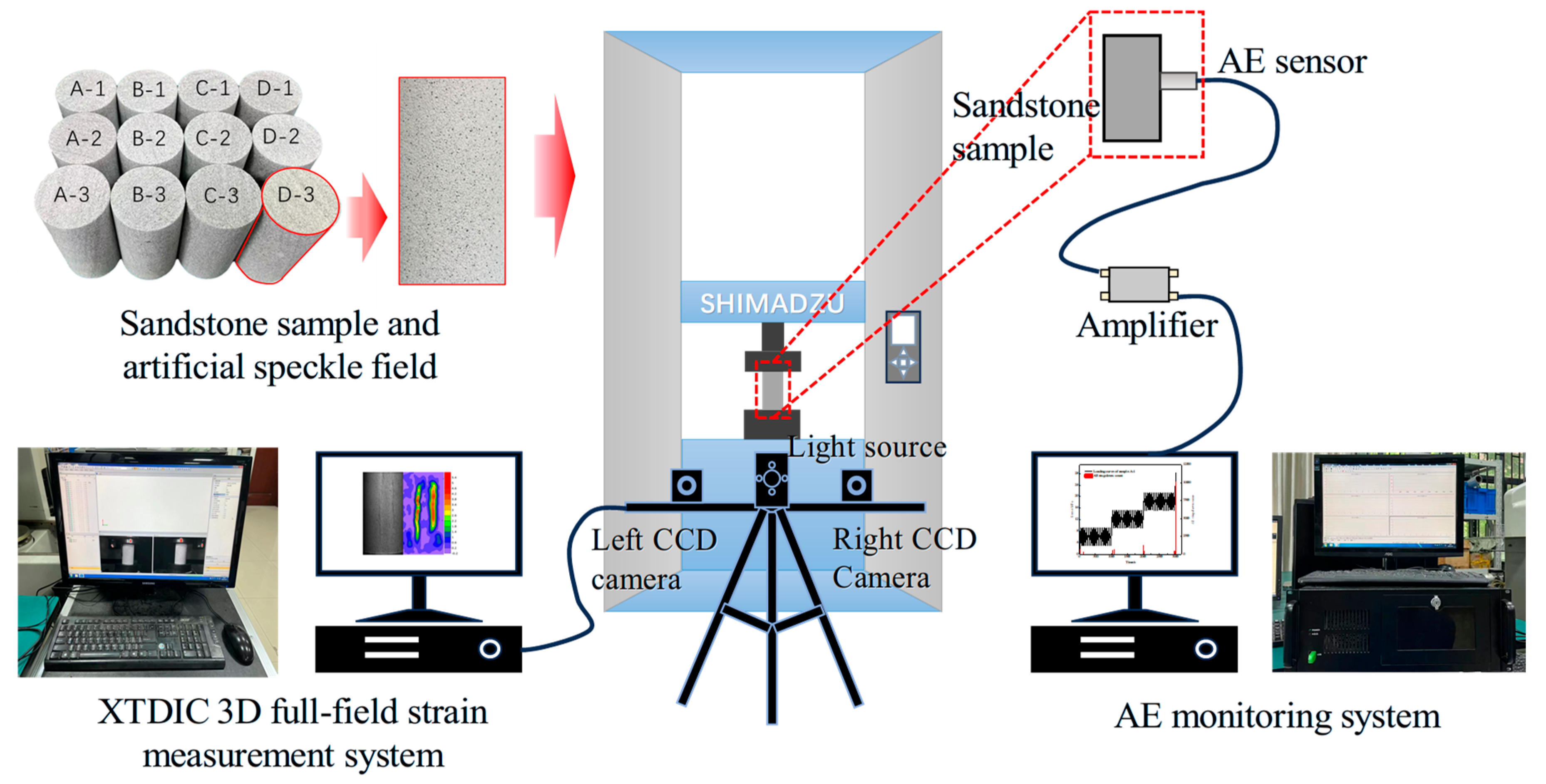

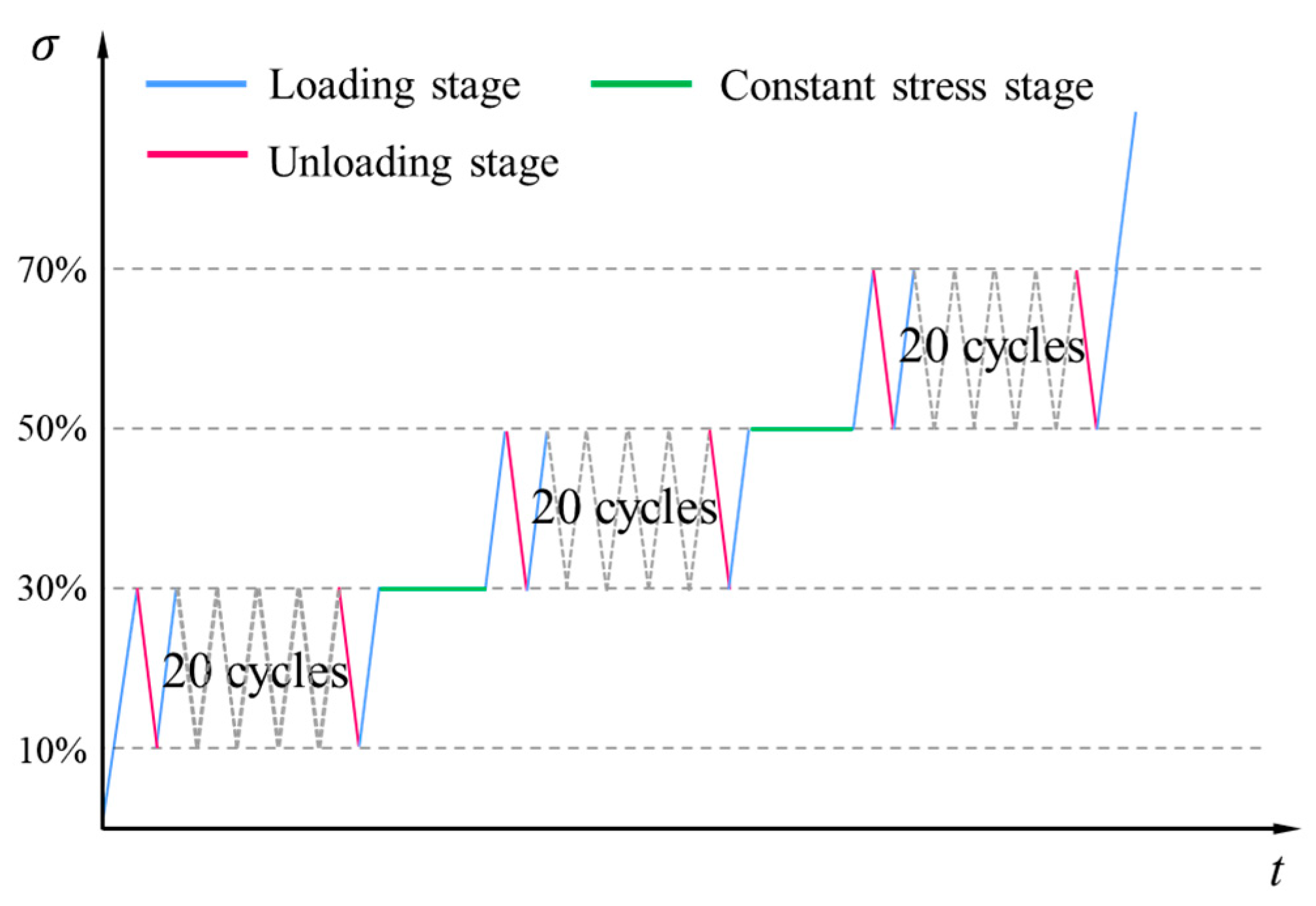

2.2. Test Scheme and Setup

3. Test Results and Analysis

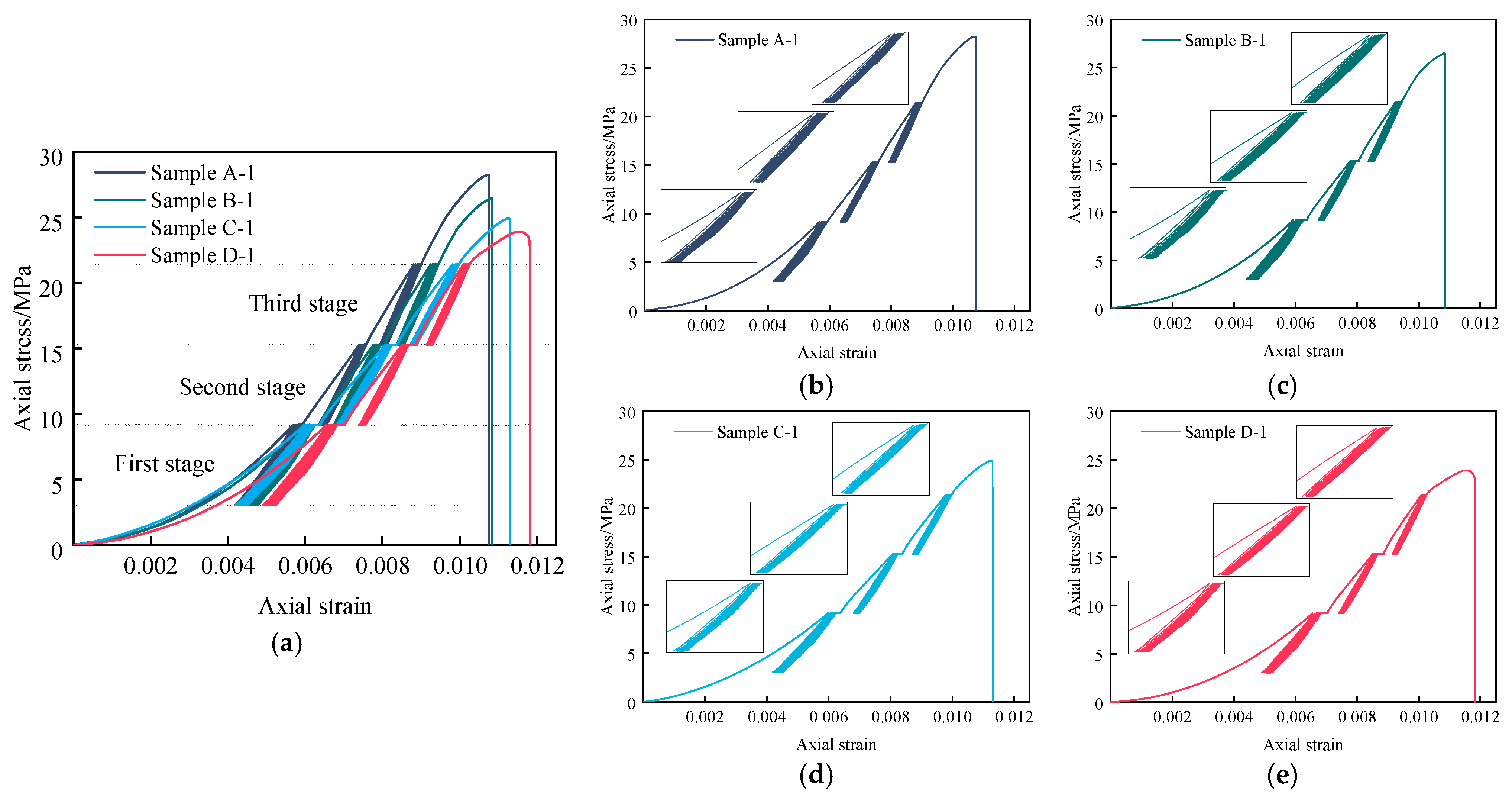

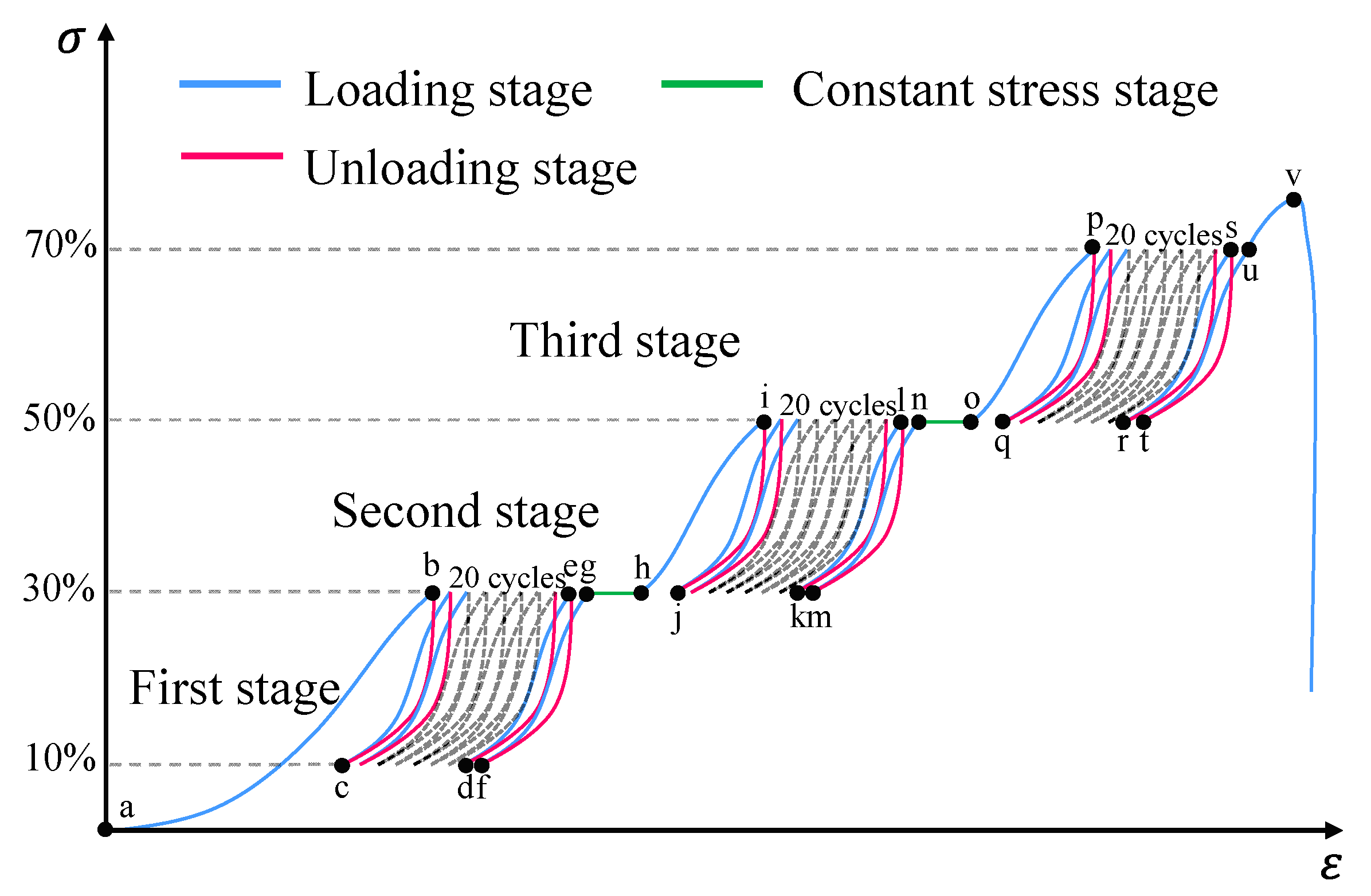

3.1. Characteristics of Stress–Strain Curves

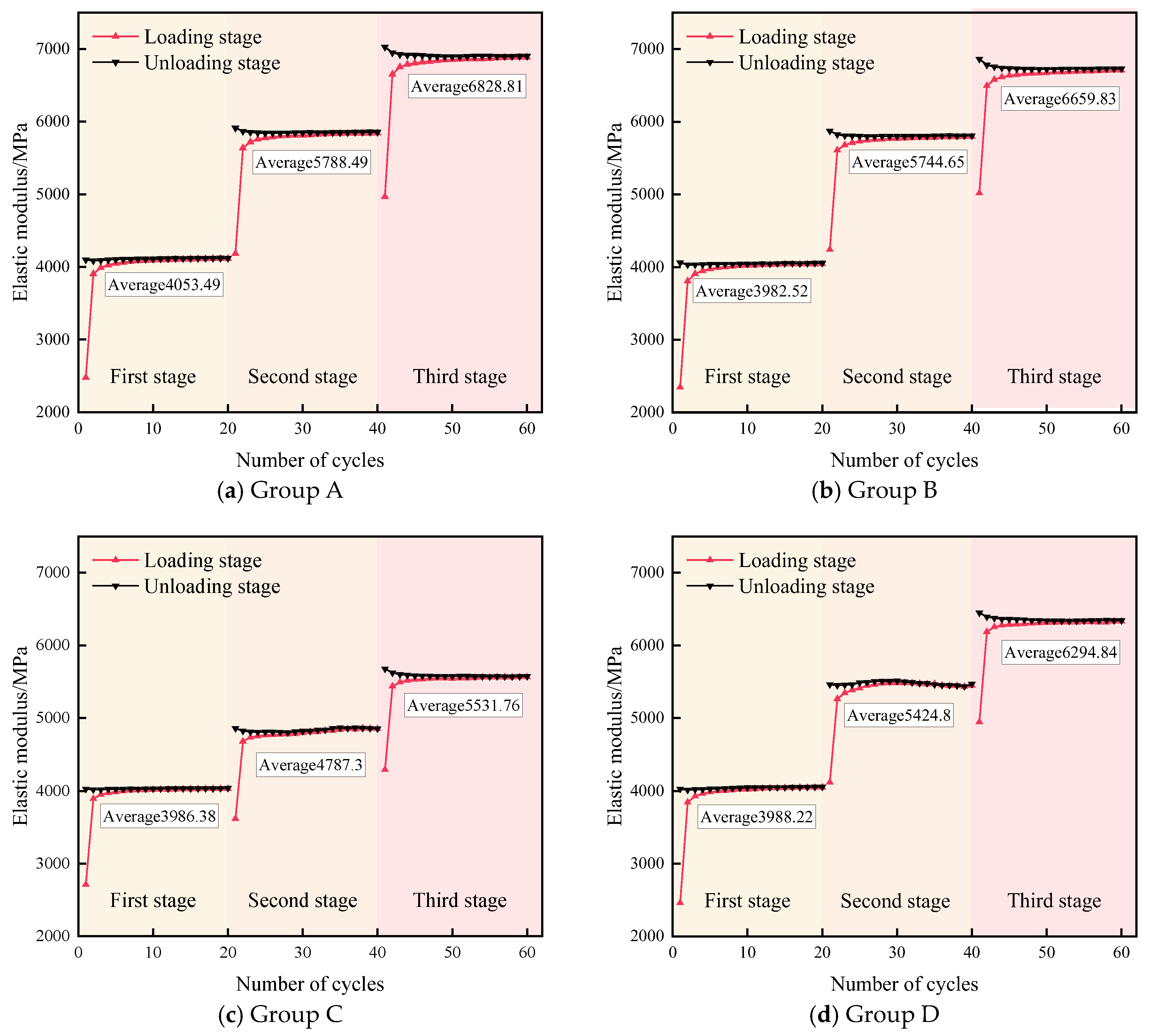

3.2. Elastic Modulus

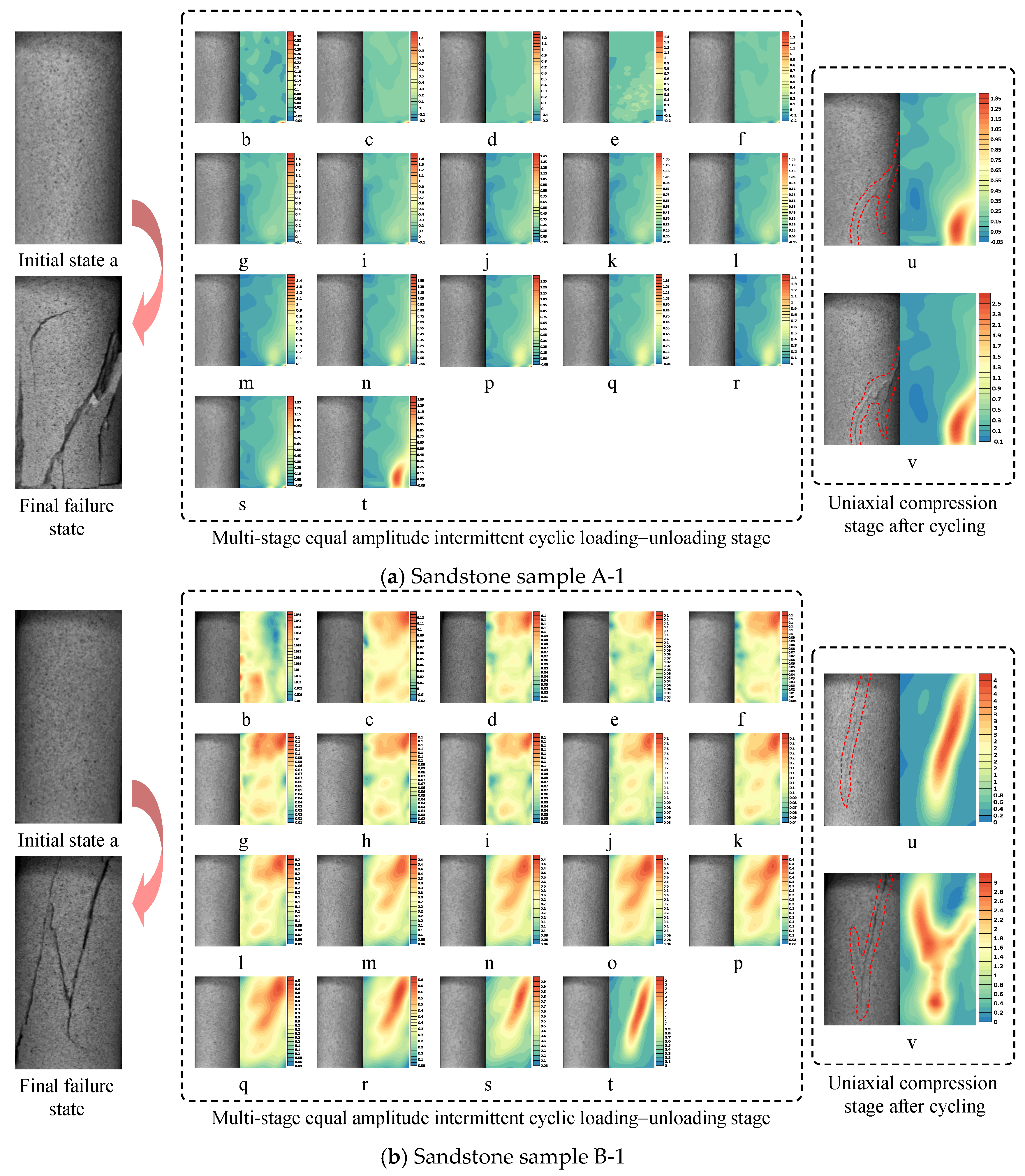

3.3. Deformation and Failure Characteristics

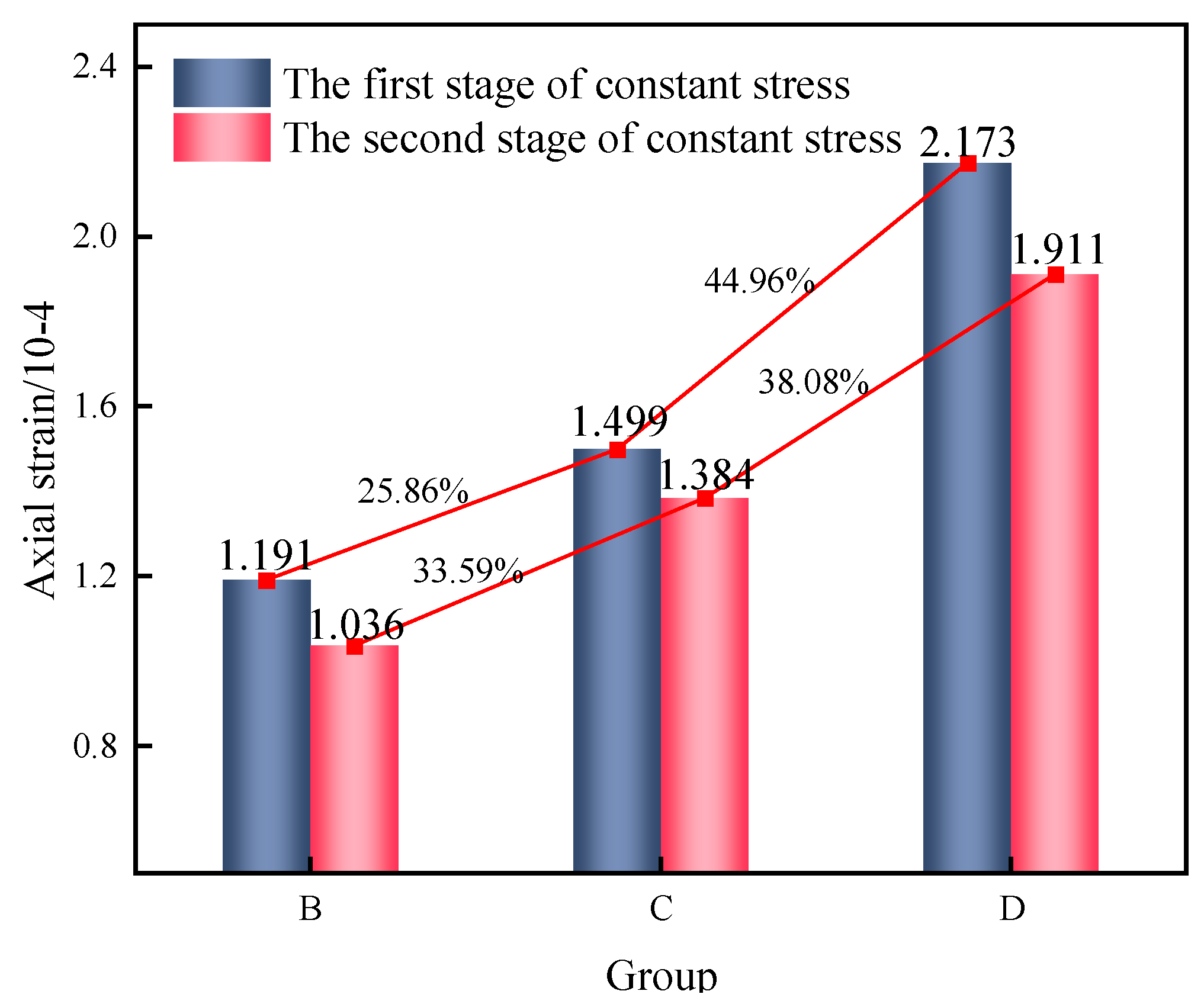

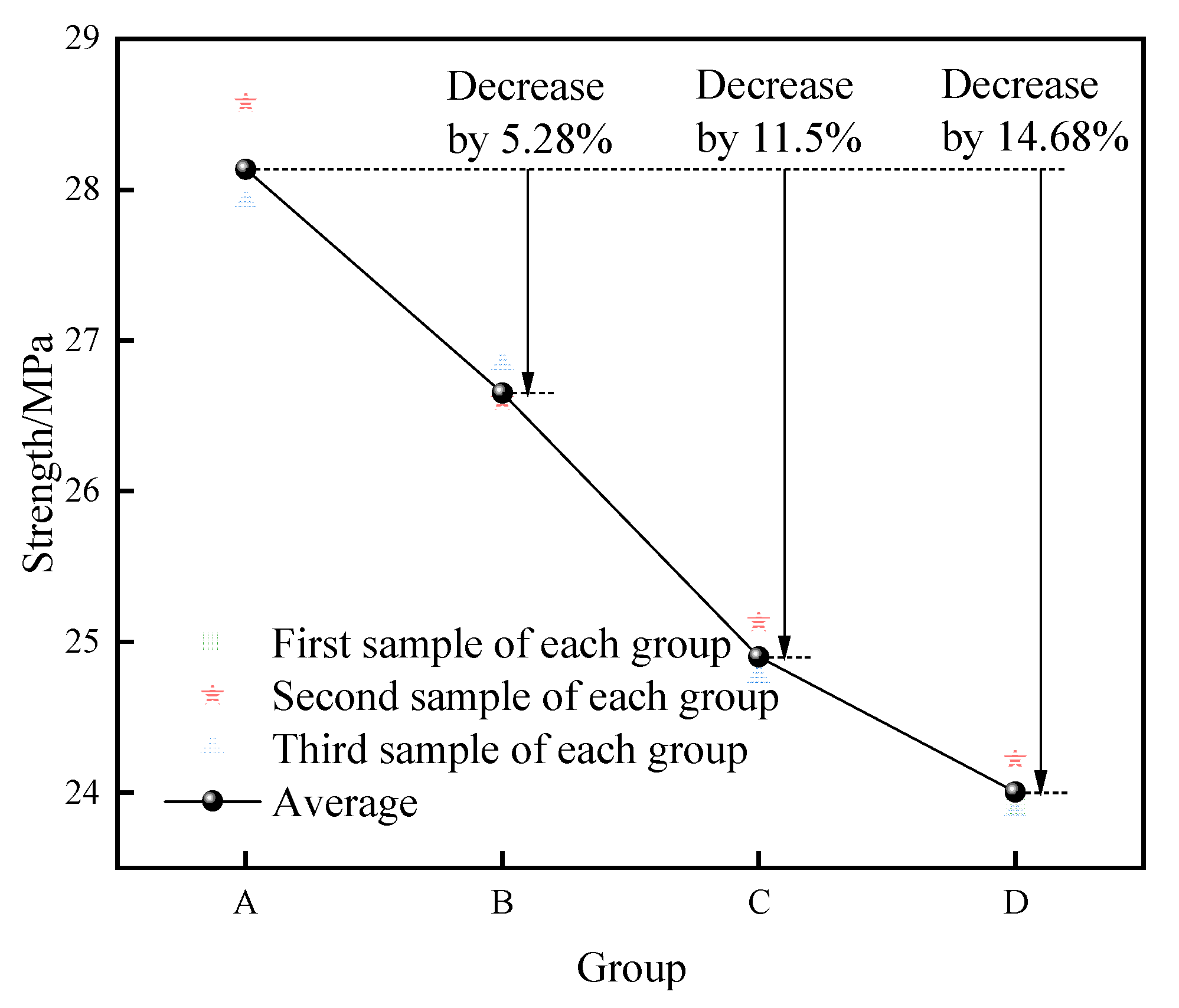

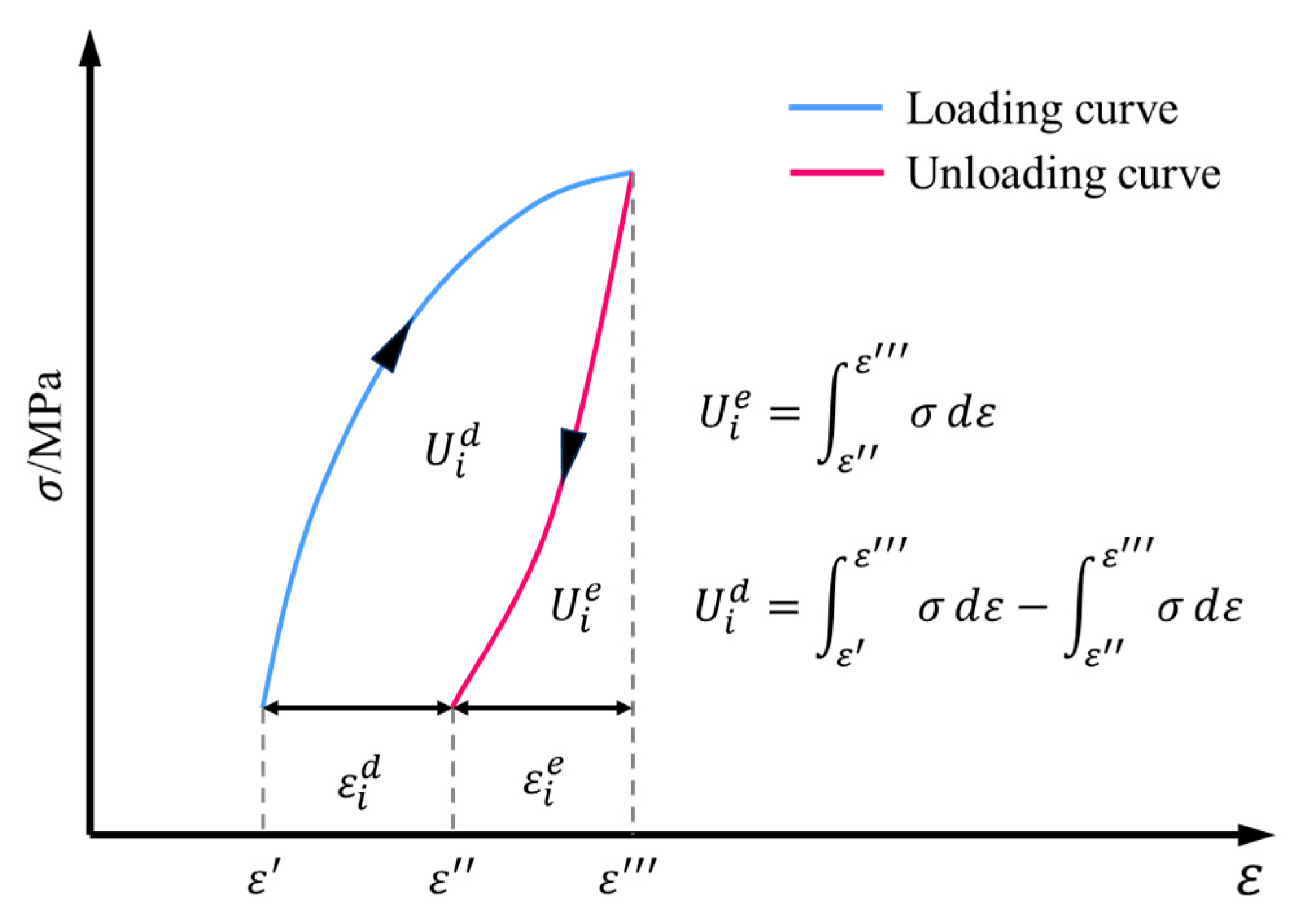

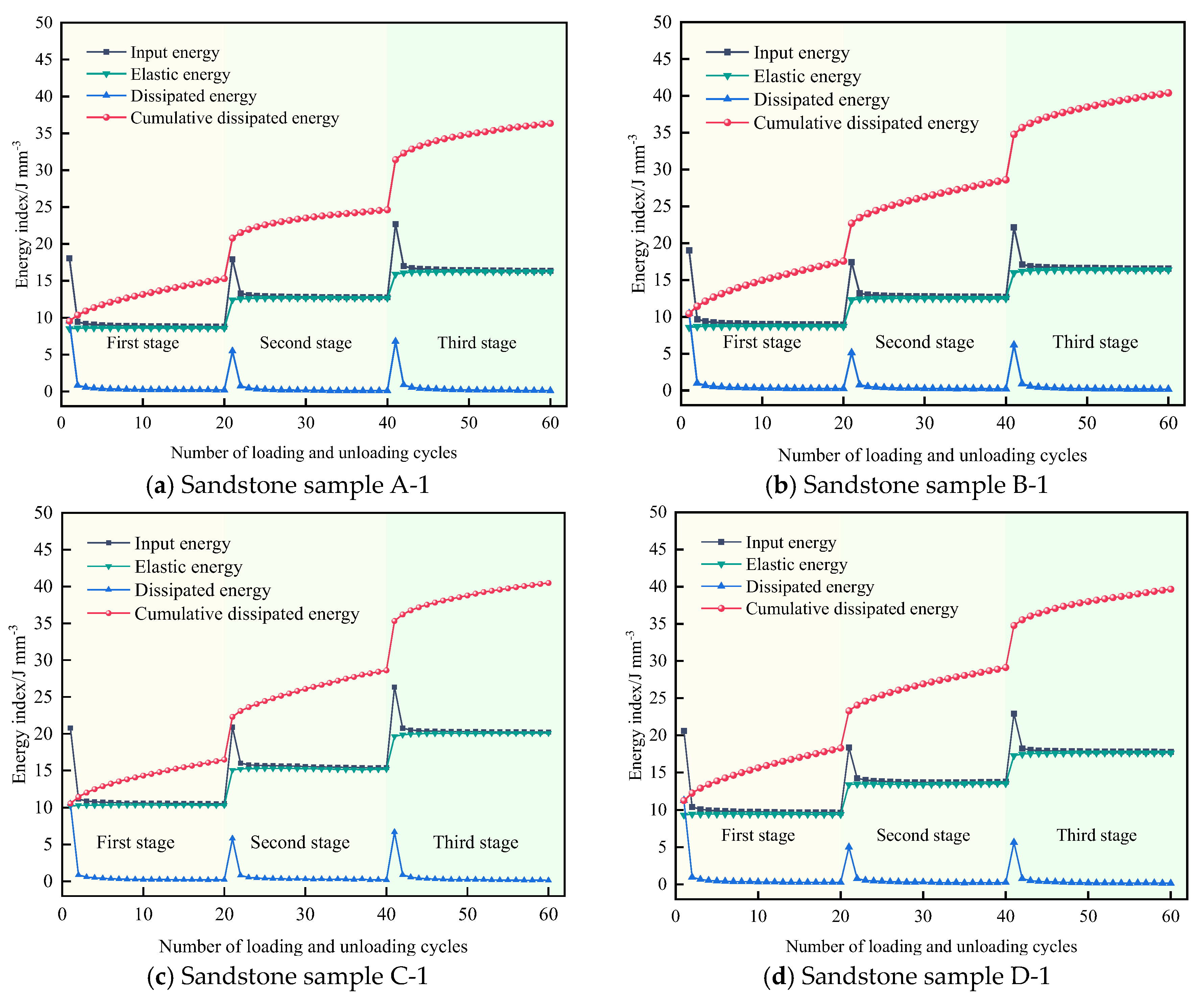

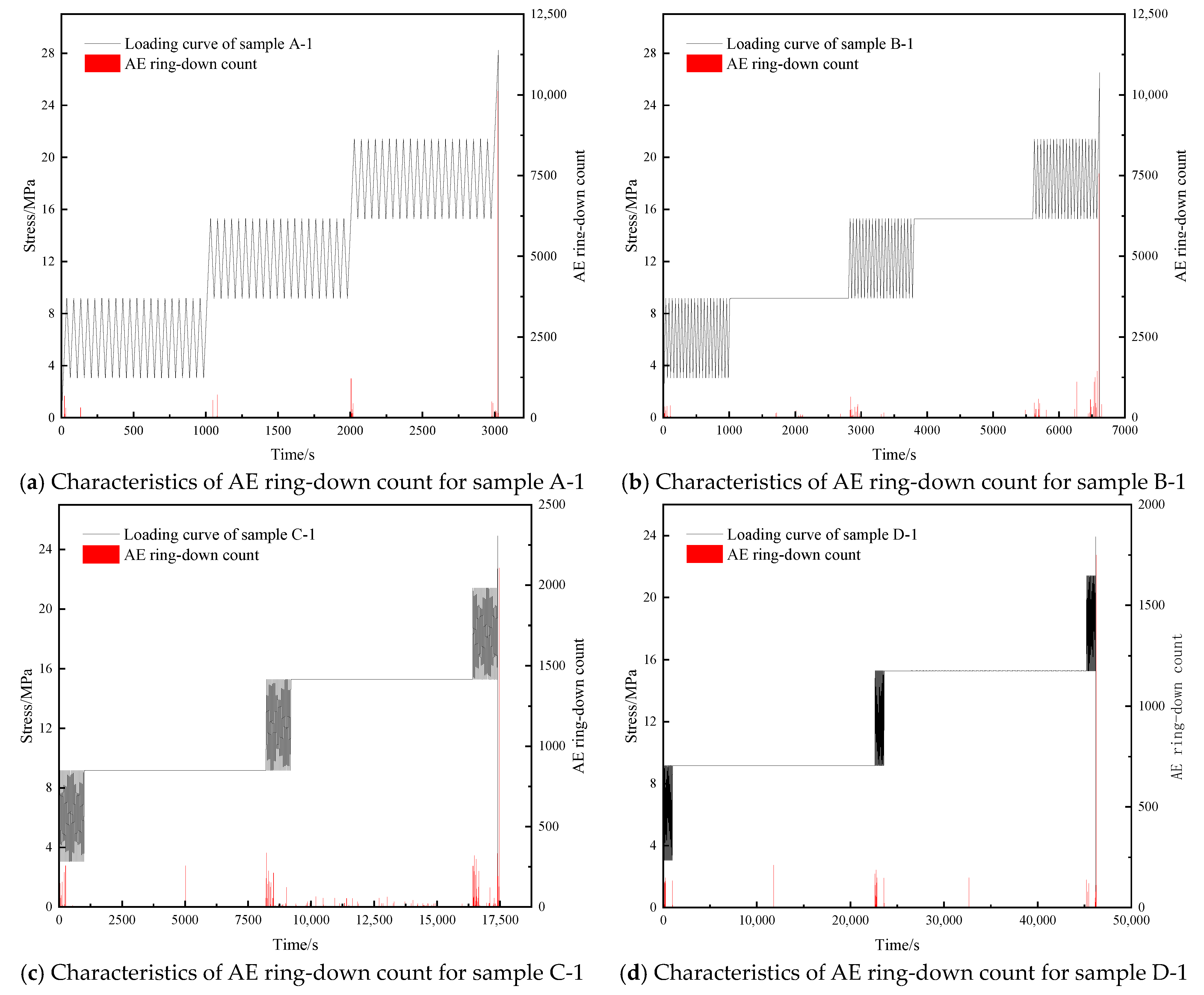

3.4. Evolution Law of Energy and AE in Sandstone

3.5. Sandstone Damage Degradation Mechanism

4. Conclusions

- (1)

- As the duration of constant stress increased, the uniaxial compressive strength of sandstone samples decreased by 5.28, 11.5, and 14.68, respectively, under multi-stage equal-amplitude cyclic loading and unloading and constant stress. Internal micro-crack propagation and particle displacement in sandstone induced during the constant stress phase intensified with the extended constant stress duration. This decreased the stiffness and deformation recovery capacity of sandstone samples, as well as the elastic modulus.

- (2)

- As the duration of constant stress increased, the evolution of deformation localization zones became more pronounced in sandstone samples during multi-stage cyclic loading and unloading. Deformation localization zones covered a broader area during the loading phase, with the maximum principal strain field at failure becoming more active. Stress concentration phenomena at defects in the sandstone samples grew increasingly significant. The samples experienced tensile-shear failure accompanied by spalling damage and increased fragmentation degree.

- (3)

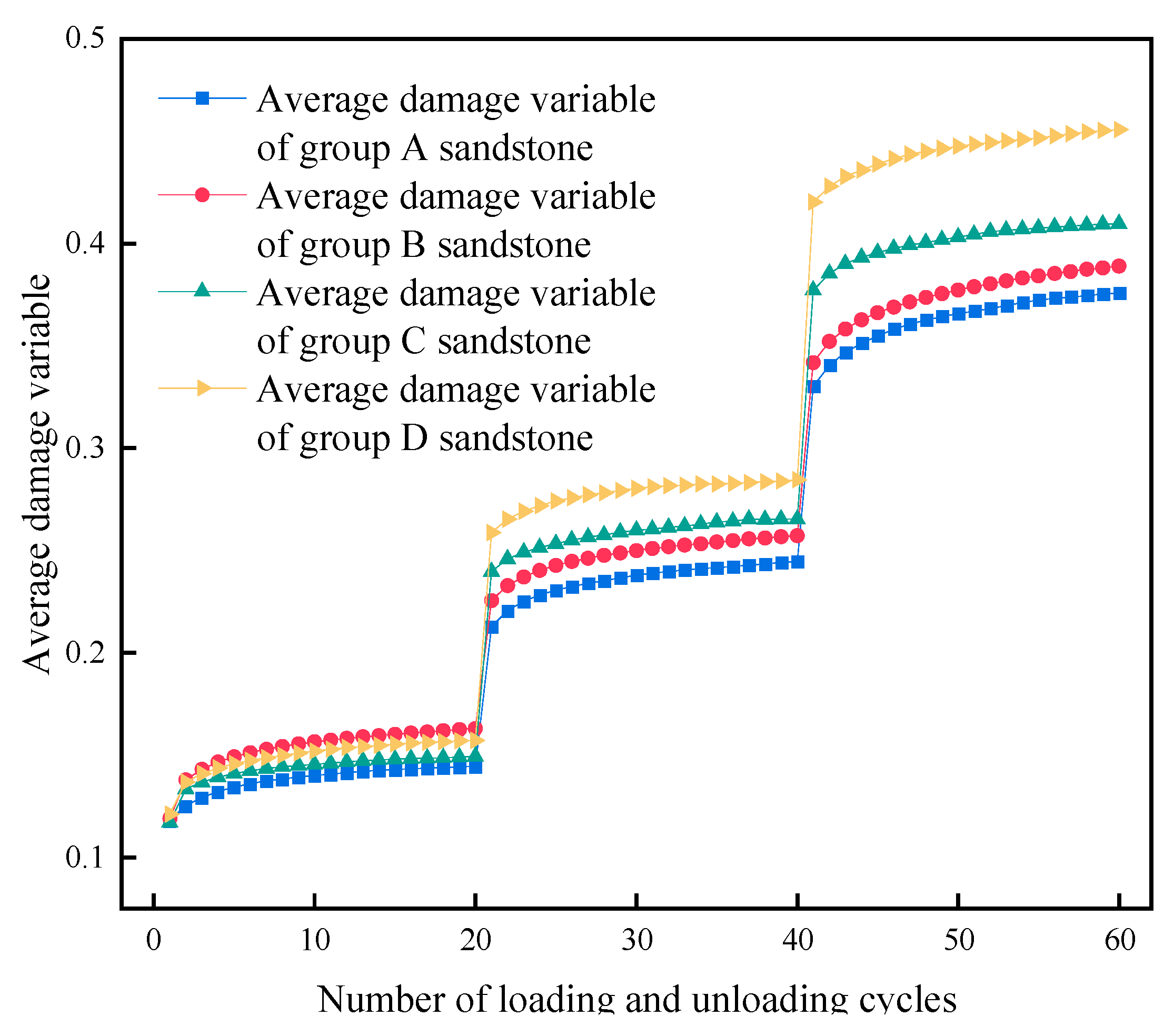

- As the stress level of multi-stage cyclic loading and unloading with equal amplitude increased, the damage rate of sandstone accelerated. Dissipated energy was the maximum during the first cycle and then stabilized in subsequent cycles. The variation in cumulative dissipated energy aligned with the decline of the elastic modulus, reflecting the progressive failure process from dynamic expansion to stabilization of internal defects. AE activity initially intensified with increasing stages before stabilizing during multi-stage cyclic loading and unloading. The damage path depended on prior cumulative effects. As the duration of constant stress increased, the damage variable of sandstone samples increased. The constant stress promoted the deterioration of sandstone samples.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yuan, L.; Wang, E.; Ma, Y.; Liu, Y.; Li, X. Research progress of coal and rock dynamic disasters and scientific and technological problems in China. J. China Coal Soc. 2023, 48, 1825–1845. [Google Scholar] [CrossRef]

- Wei, M.; Liu, C.; Liu, Y.; Man, Z.; Wang, Q.; Niu, H. Evolution of accumulated damage in deep coal roadway with repeated dynamic disturbance. J. Cent. South Univ. (Sci. Technol.) 2021, 52, 2689–2701. [Google Scholar] [CrossRef]

- Xu, Q.; Huang, Q.; Zhang, G. Fracture and instability mechanism and control technology of a narrow coal pillar in an entry in fully mechanized caving mining under intense effect mining. J. Min. Saf. Eng. 2019, 36, 941–948. [Google Scholar] [CrossRef]

- Chen, Y.; Zuo, J.; Song, H.; Feng, L.; Shao, G. Deformation and crack evolution of coal rock combined body under cyclic loading unloading effects. J. Min. Saf. Eng. 2018, 35, 826–833. [Google Scholar] [CrossRef]

- Jiang, N.; Su, Q.; Jiang, X.; Gao, Z.; Guo, Q.; Song, S.; Lyu, T.; Lyu, K. Experimental research on the tensile properties of coal rocks in deep old goafs. Geomech. Eng. 2024, 39, 357–368. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhang, F.; Peng, Q.; Dupla, J.-C.; Canou, J.; Cumunel, G.; Foerster, E. Effect of the loading frequency on the sand liquefaction behaviour in cyclic triaxial tests. Soil Dyn. Earthq. Eng. 2021, 147, 106779. [Google Scholar] [CrossRef]

- Li, D.; Sun, Z.; Xie, T.; Li, X.; Ranjith, P.G. Energy Evolution Characteristics of Hard Rock During Triaxial Failure with Different Loading and Unloading Paths. Eng. Geol. 2017, 228, 270–281. [Google Scholar] [CrossRef]

- Yang, X.; Han, X.; Liu, E.; Zhang, Z.; Wang, X. Experimental study on the acoustic emission characteristics of nonuniform deformation evolution of granite under cyclic loading and unloading test. Rock Soil Mech. 2018, 39, 2732–2739. [Google Scholar] [CrossRef]

- Liu, X.; Chai, Z.; Liu, X.; Yang, Z.; Xin, Z. Pore fracture propagation and unloading failure characteristics of siltite under cyclic loads. J. China Coal Soc. 2022, 47, 77–89. [Google Scholar] [CrossRef]

- Zou, Q.; Chen, Z.; Zhan, J.; Chen, C.; Gao, S.; Kong, F.; Xia, X. Morphological Evolution And flow Conduction Characteristics of Fracture Channels in Fractured sandstone Under Cyclic Loading and Unloading. Int. J. Min. Sci. Technol. 2023, 33, 1527–1540. [Google Scholar] [CrossRef]

- Song, Z.; Cheng, Y.; Yang, T.; Yang, P.; Pan, H. Experimental study on fatigue damage evolution mechanism of hard layered sandstone under cyclic loading. Chin. J. Geotech. Eng. 2024, 46, 490–499. [Google Scholar] [CrossRef]

- Yin, D.; Sun, P.; Hu, H.; Tan, Y.; Qu, X.; Wang, F.; Jiang, N. Characterization of damage deterioration of pressure waterlogged coal rock under cyclic loading and unloading effects. J. China Coal Soc. 2025, 1–17. [Google Scholar] [CrossRef]

- Peng, R.; Ju, Y.; Gao, F.; Xie, H.; Wang, P. Energy analysis on damage of coal under cyclical triaxial loading and unloading conditions. J. China Coal Soc. 2014, 39, 245–252. [Google Scholar] [CrossRef]

- Meng, Q.; Wang, C.; Huang, B.; Pu, H.; Zhang, Z.; Sun, W.; Wang, J. Rock energy evolution and distribution law under triaxial cyclic loading and unloading conditions. Chin. J. Rock Mech. Eng. 2020, 39, 2047–2059. [Google Scholar] [CrossRef]

- Ding, Z.; Jia, J.; Tang, Q.; Li, X. Mechanical Properties and Energy Damage Evolution Characteristics of Coal Under Cyclic Loading and Unloading. Rock Mech. Rock Eng. 2022, 55, 4765–4781. [Google Scholar] [CrossRef]

- Zhao, G.; Cheng, W.; Liu, C.; Liang, W. Failure mechanical behavior and energy evolution of coal and rock under cyclic loading and unloading. Chin. J. Rock Mech. Eng. 2024, 43, 1636–1645. [Google Scholar] [CrossRef]

- Cheng, C.; Xu, T.; Zhou, G.; Qin, T. Experimental Investigation of Influence of Alternating Cyclic Loadings on Creep Behaviors of Sandstone. Mech. Time-Depend. Mater. 2021, 25, 1–19. [Google Scholar] [CrossRef]

- Su, C.; Xiong, Z.; Zhai, X.; Gu, M. Analysis of deformation and strength characteristics of coal samples under the triaxial cyclic loading and unloading stress path. J. Min. Saf. Eng. 2014, 31, 456–461. [Google Scholar] [CrossRef]

- Chen, X.; Xiao, Y.; Tang, M.; Jiao, T.; Zhang, F. Experimental study on deformation, permeability and AE characteristics of sandstone under multi stage cyclic loading with a constant amplitude. Chin. J. Rock Mech. Eng. 2024, 43, 1923–1935. [Google Scholar] [CrossRef]

- Xu, P.; Yang, S. Study of Visco Elasto Plastic Constitutive Model of coal Under Cyclic Loading. Chin. J. Rock Mech. Eng. 2015, 34, 537–545. [Google Scholar] [CrossRef]

- Gao, D.; Sang, S.; Liu, S.; Wu, J.; Geng, J.; Tao, W.; Sun, T. Experimental Study on the Deformation Behaviour, Energy Evolution Law and Failure Mechanism of Tectonic Coal Subjected to Cyclic Loads. Int. J. Min. Sci. Technol. 2022, 32, 1301–1313. [Google Scholar] [CrossRef]

- Yuan, H.; Abi, E.; Zhang, J.; Cong, Y.; Liu, M.; Pu, Y.; Li, H. Experimental Study on Deformation and Failure Characteristics of Saturated Sandstone Under Graded Cyclic Loading and Unloading. Chin. J. Rock Mech. Eng. 2023, 42, 3943–3955. [Google Scholar] [CrossRef]

- Fan, X.; Jiang, D.; Wu, F.; Zou, Q.; Chen, J.; Chen, B.; Sun, Z. Effects of Prior cyclic Loading Damage on Failure Characteristics Of sandstone Under True Triaxial Unloading Conditions. Int. J. Rock Mech. Min. Sci. 2020, 132, 104379. [Google Scholar] [CrossRef]

- Xiao, F.; Mo, R.; Shan, L.; Hou, Z.; Iuliia, F.; Qin, F. Study on damage characteristics of rock under multi-level characteristic stress cyclic loading and unloading. J. Min. Saf. Eng. 2025, 42, 430–439. [Google Scholar] [CrossRef]

- Xie, H.; Ju, Y.; Li, L. Criteria for Strength and Structural Failure of Rocks based on Energy Dissipation and Energy Release Principles. Chin. J. Rock Mech. Eng. 2005, 17, 3003–3010. [Google Scholar]

- Meng, Q.; Zhang, M.; Han, L.; Pu, H.; Nie, T. Effects of acoustic Emission and Energy Evolution of Rock specimens under the Uniaxial Cyclic Loading And unloading Compression. Rock Mech. Rock Eng. 2016, 49, 3873–3886. [Google Scholar] [CrossRef]

- Zhao, Z.; Xie, H. Energy Transfer and Energy Dissipation in Rock Deformation and Fracture. J. Sichuan Union Univ. Eng. Sci. Ed 2008, 40, 26–31. [Google Scholar]

- Xu, J.; Zhang, Y.; Yang, H.; Wang, J. Energy Evolution Law of Deformation and Damage of Sandstone Under Cyclic Pore Water Pressures. Chin. J. Rock Mech. Eng. 2011, 30, 141–148. [Google Scholar]

- Lei, R.; Su, L.; He, P.; Hu, C.; Li, J.; Zhou, L. Study on acoustic emission characteristics and energy evolution of Brazilian splitting tests of coal samples with different height diameter ratio. Coal Sci. Technol. 2024, 52, 63–77. [Google Scholar] [CrossRef]

- Huang, P.; Zhang, J.; Damascene, N.J.; Dong, C.; Wang, Z. A fractional order viscoelastic plastic creep model for coal sample considering initial damage accumulation. Alex. Eng. J. 2021, 04, 3921–3930. [Google Scholar] [CrossRef]

- Xi, J.; Wan, X.; Xi, D. Anelastic attenuation and damage of saturated sandstone under cyclic loading. Chin. J. Rock Mech. Eng. 2023, 42, 1214–1224. [Google Scholar] [CrossRef]

- Zhang, L.; Ma, S.; Ren, M.; Jiang, S.; Wang, Z.; Wang, J. Acoustic Emission Frequency and B Value Characteristics in Rock Failure Process Under Various Confining Pressures. Chin. J. Rock Mech. Eng. 2015, 34, 2057–2063. [Google Scholar] [CrossRef]

- Feng, G.; Wen, X.; Guo, J.; Wang, P.; Qian, P.; Yan, Y.; Hao, C. Study on influence of moisture content on coal sample AE properties and fragment distribution characteristics. J. Cent. South Univ. Technol. 2021, 52, 2910–2918. [Google Scholar] [CrossRef]

- Yin, D.; Ding, Y.; Wang, F.; Jiang, N.; Liu, H.; Tan, Y. Experimental study on mechanical properties of coal soaked in pressurized water considering initial damage. J. China Coal Soc. 2023, 48, 4417–4432. [Google Scholar] [CrossRef]

| Sample Number | Loading Method | Diameter/cm | Height/cm | Mass/g | Density g/cm3 | Uniaxial Compressive Strength/MPa |

|---|---|---|---|---|---|---|

| DZ-1 | Convention Uniaxial Compression | 4.86 | 10.12 | 472.6 | 2.5173 | 30.373 |

| DZ-2 | 4.84 | 10.14 | 472.3 | 2.5316 | 30.473 | |

| DZ-3 | 4.82 | 10.08 | 472.6 | 2.5695 | 29.973 | |

| DZ-4 | 4.84 | 10.08 | 472.8 | 2.5493 | 31.173 | |

| DZ-5 | 4.84 | 10.12 | 472.2 | 2.5571 | 30.473 |

| Sample Number | Loading Method | Diameter/cm | Height/cm | Mass/g | Density g/cm3 | Constant Pressure Duration/h |

|---|---|---|---|---|---|---|

| A-1 | Multi-stage equal amplitude intermittent cyclic loading and unloading | 4.82 | 10.2 | 472.4 | 2.5382 | 0 |

| A-2 | 4.84 | 10.12 | 472.8 | 2.5393 | ||

| A-3 | 4.84 | 10.08 | 472.3 | 2.5467 | ||

| B-1 | 4.82 | 10.12 | 470.5 | 2.5480 | 0.5 | |

| B-2 | 4.82 | 10.22 | 469.6 | 2.5182 | ||

| B-3 | 4.82 | 10.36 | 474.3 | 2.5091 | ||

| C-1 | 4.82 | 10.1 | 471.5 | 2.5584 | 2 | |

| C-2 | 4.86 | 10.18 | 472.5 | 2.5020 | ||

| C-3 | 4.8 | 10.12 | 470.9 | 2.5714 | ||

| D-1 | 4.82 | 10.04 | 471.2 | 2.5721 | 6 | |

| D-2 | 4.9 | 10.04 | 471.9 | 2.4925 | ||

| D-3 | 4.86 | 10.26 | 473.2 | 2.4862 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, N.; Zhang, Y.; Gao, Z.; Zhang, G.; Feng, Q.; Gong, C. Damage and Deterioration Characteristics of Sandstone Under Multi-Stage Equal-Amplitude Intermittent Cyclic Loading and Unloading. Buildings 2025, 15, 3459. https://doi.org/10.3390/buildings15193459

Jiang N, Zhang Y, Gao Z, Zhang G, Feng Q, Gong C. Damage and Deterioration Characteristics of Sandstone Under Multi-Stage Equal-Amplitude Intermittent Cyclic Loading and Unloading. Buildings. 2025; 15(19):3459. https://doi.org/10.3390/buildings15193459

Chicago/Turabian StyleJiang, Ning, Yangyang Zhang, Zhiyou Gao, Genwang Zhang, Quanlin Feng, and Chao Gong. 2025. "Damage and Deterioration Characteristics of Sandstone Under Multi-Stage Equal-Amplitude Intermittent Cyclic Loading and Unloading" Buildings 15, no. 19: 3459. https://doi.org/10.3390/buildings15193459

APA StyleJiang, N., Zhang, Y., Gao, Z., Zhang, G., Feng, Q., & Gong, C. (2025). Damage and Deterioration Characteristics of Sandstone Under Multi-Stage Equal-Amplitude Intermittent Cyclic Loading and Unloading. Buildings, 15(19), 3459. https://doi.org/10.3390/buildings15193459