Flexural Behavior and Sustainability of Dual-Waste Fiber-Reinforced Concrete Designed for Pavement Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Aggregates

2.1.2. Cement

2.1.3. Steel Fibers (SFs) from Recycled Tires

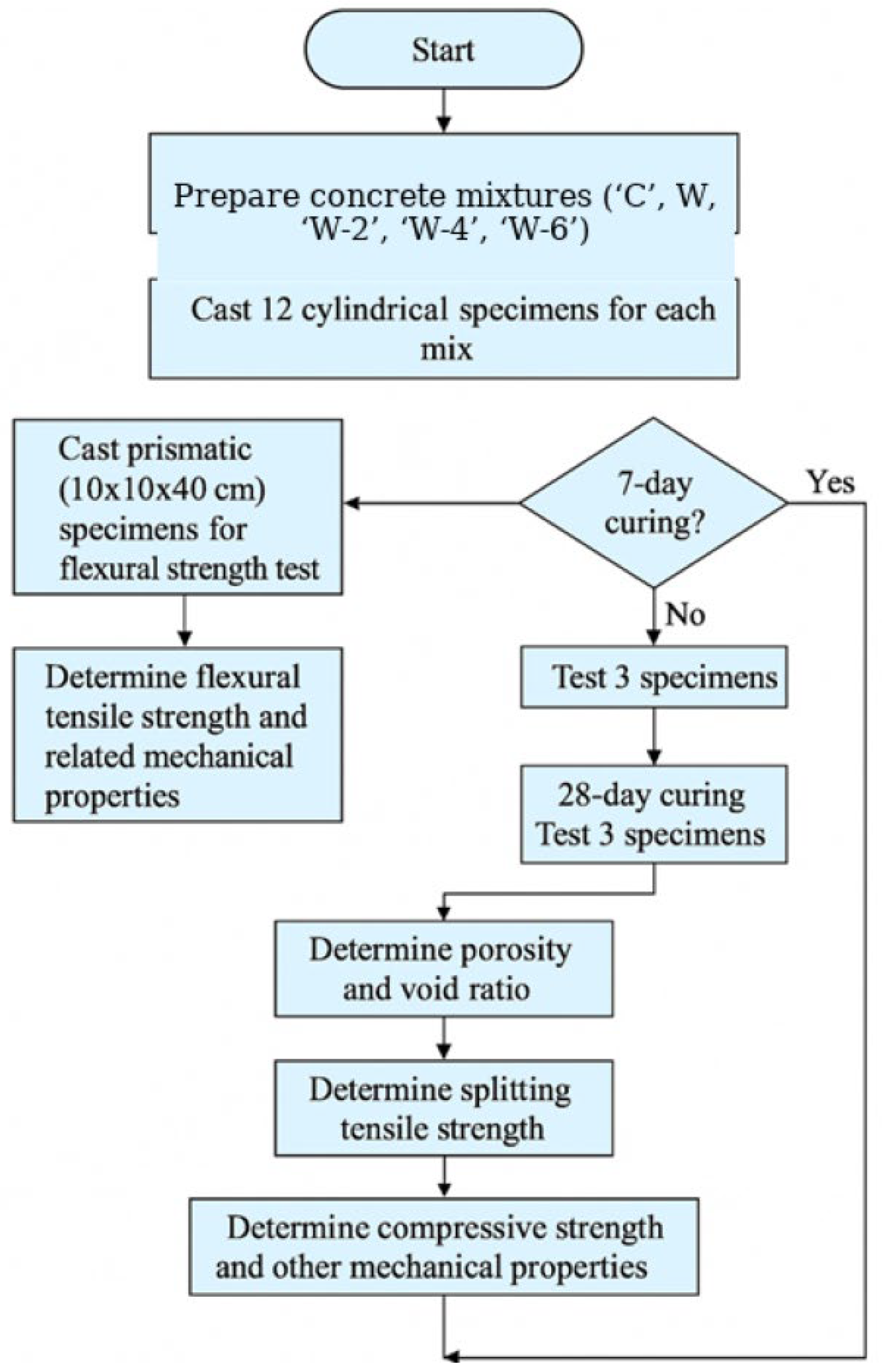

2.2. Methods

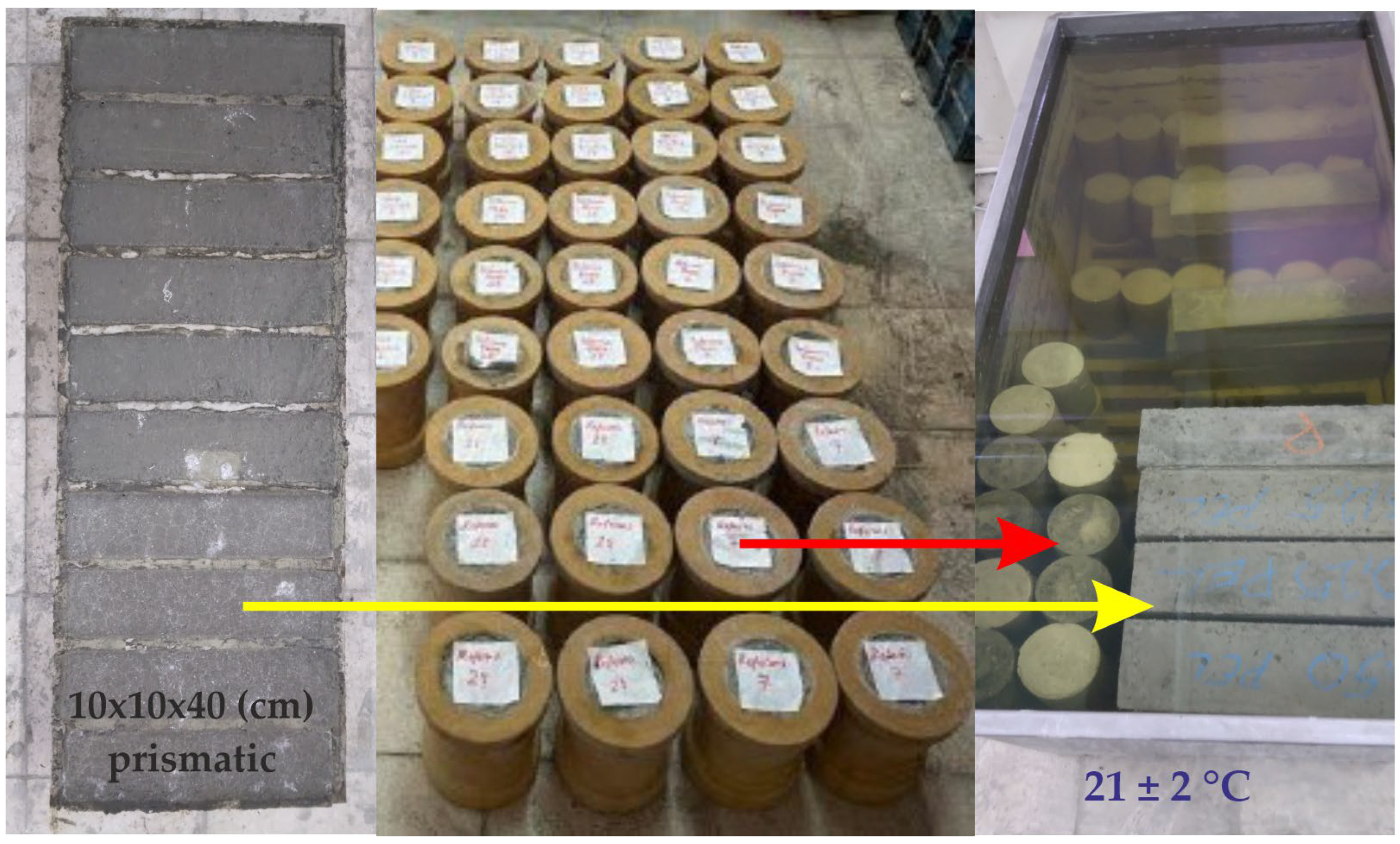

Concrete Mix and Sample Preparation

2.3. Test Procedures

2.3.1. Physical Characteristics

2.3.2. Mechanical Characteristics

3. Results and Discussion

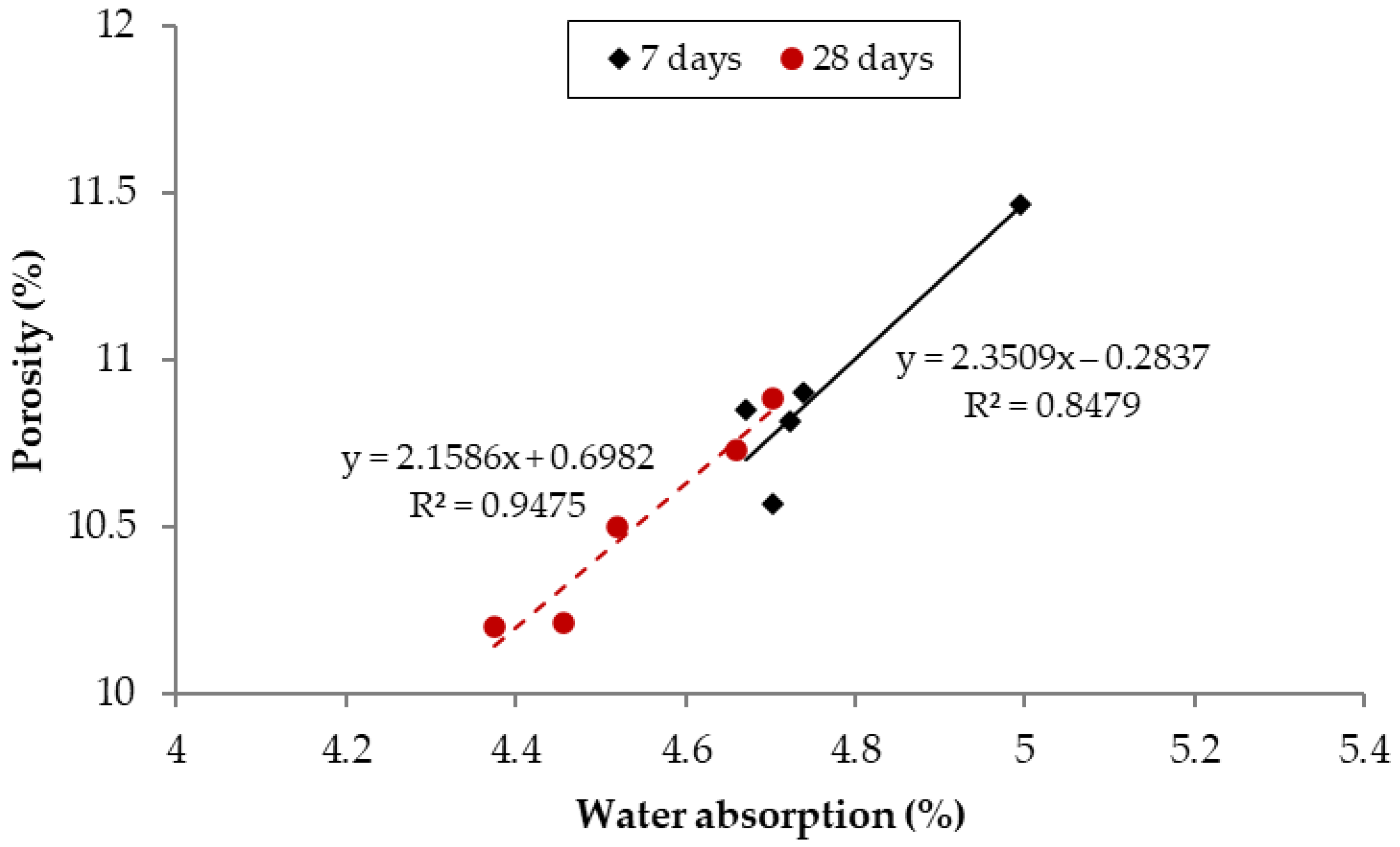

3.1. Physical Properties

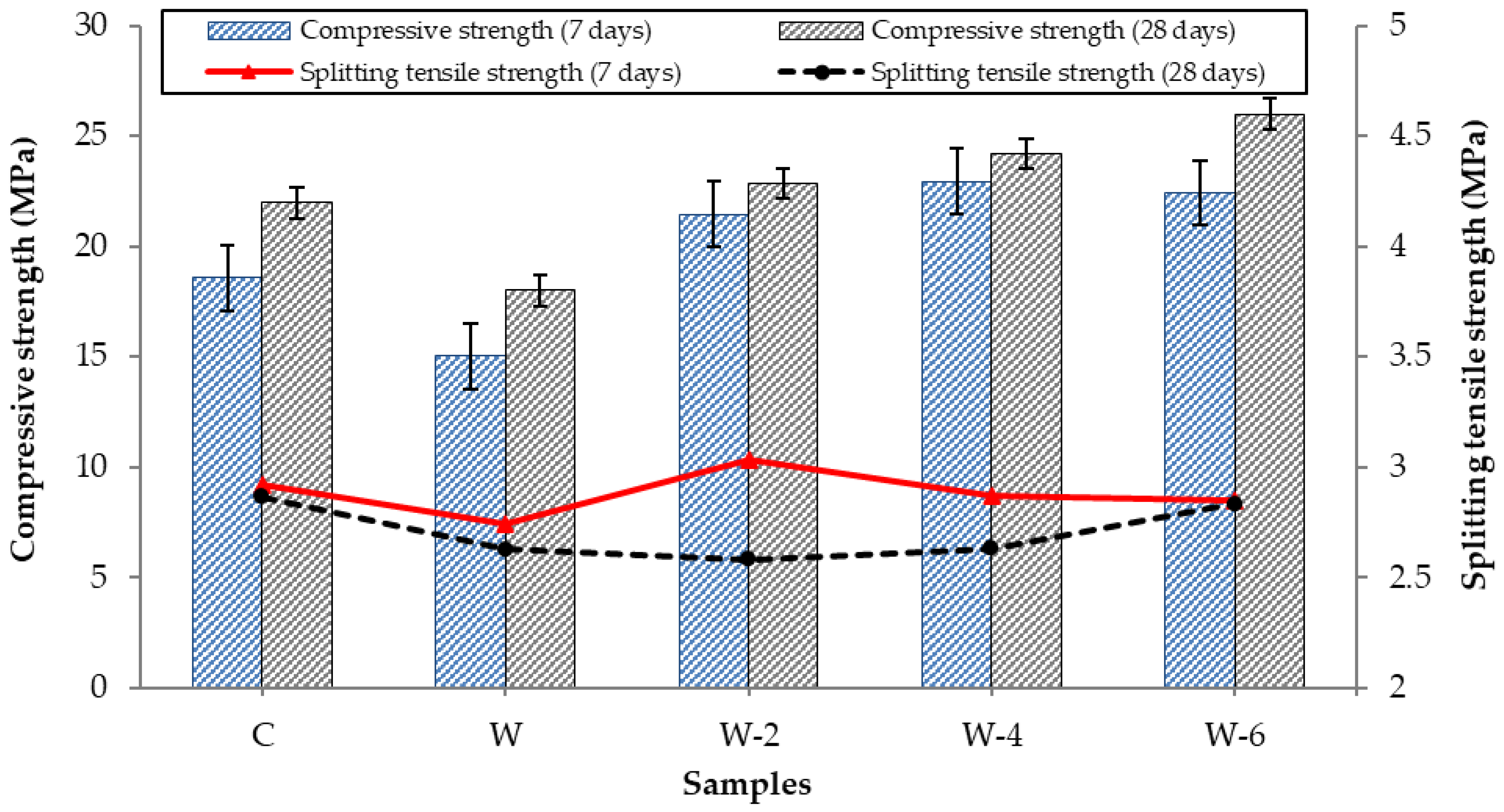

3.2. Compressive Strength, Modulus of Elasticity, and Poisson’s Ratio

3.3. Splitting Tensile Strength

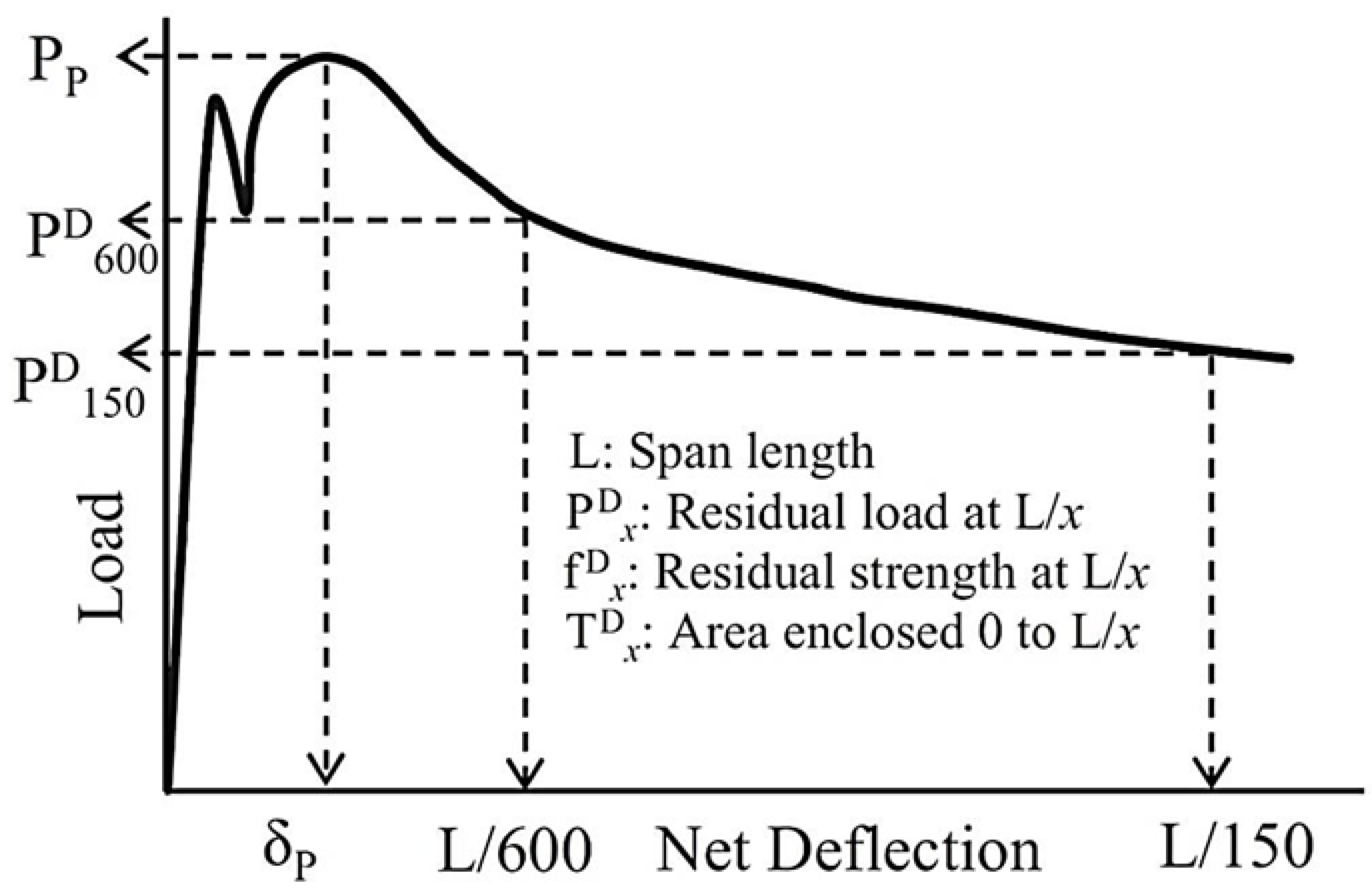

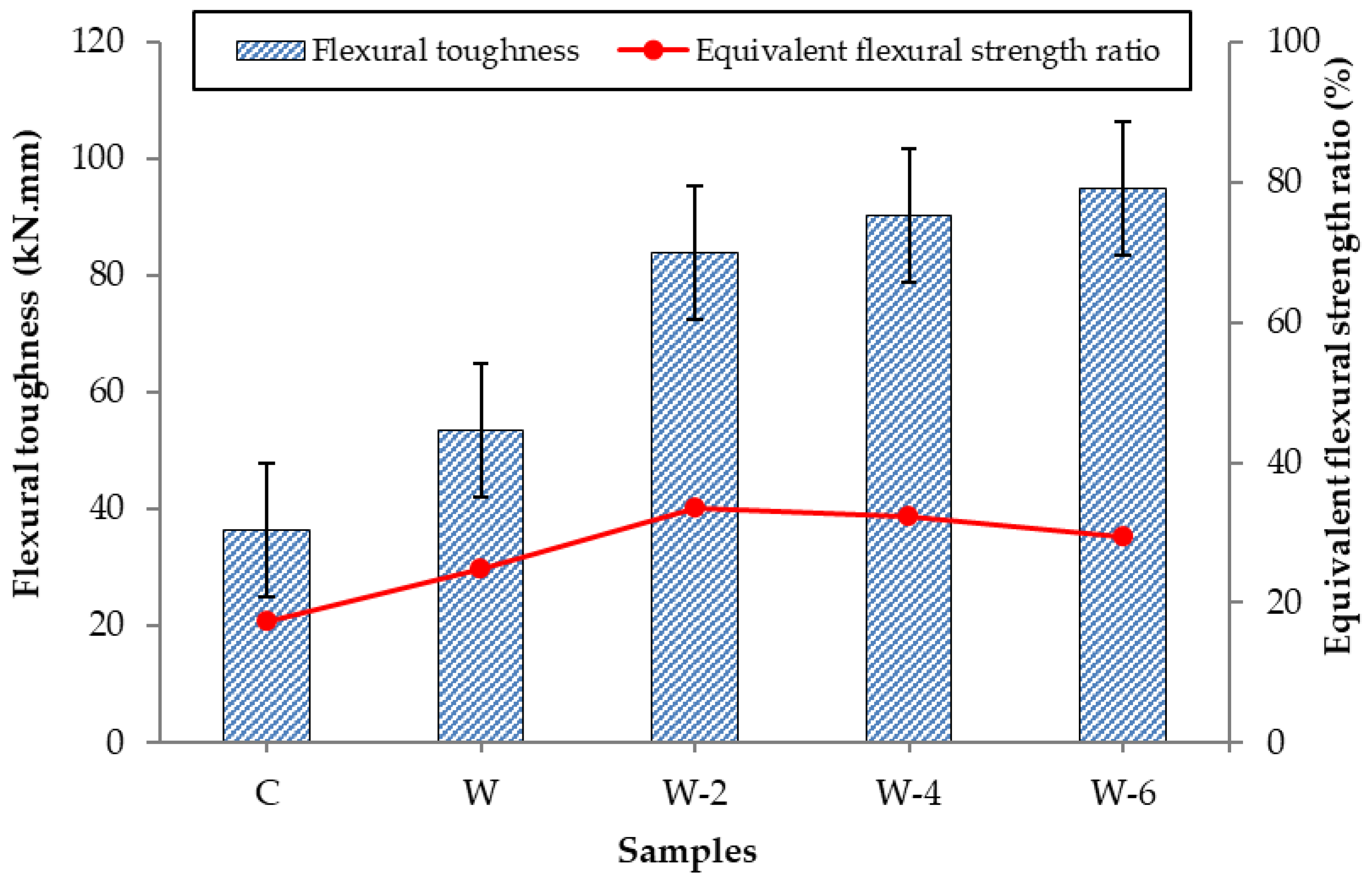

3.4. Flexural Strength, Toughness, and Modulus of Rupture

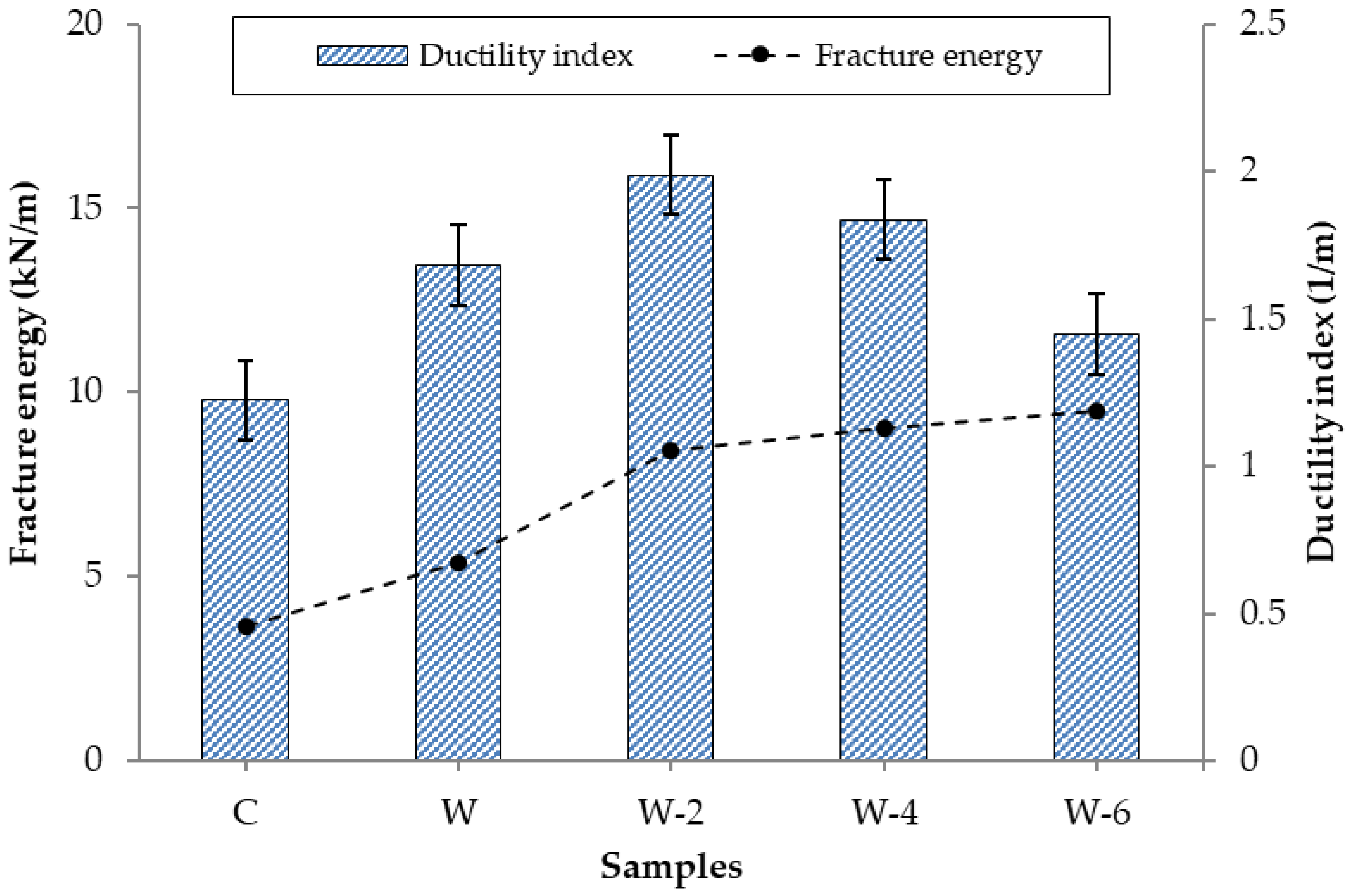

3.5. Fracture Energy and Ductility Index

4. Conclusions

- (1)

- The partial replacement of natural sand with mine tailings slightly increased the porosity and water absorption at early ages. However, the inclusion of waste tire wire at dosages of 0.4% and 0.6% significantly reduced these values at 28 days, indicating enhanced reduced permeability. This improvement supports the development of more durable concrete composites.

- (2)

- The compressive strength of the mixtures progressively improved with increasing fiber content, reaching up to 26.0 MPa with the W-6 mix, an 18.2% increase compared to the control mix. Likewise, the splitting tensile strength improved by up to 7.1%, especially in the higher fiber content mixes due to effective fiber reinforcement by the tire wires.

- (3)

- The waste tire wire significantly enhanced the flexural performance and toughness of the concrete. The modulus of rupture in the W-6 sample increased by 104% and the flexural toughness improved by 161% compared to the control mix. The load drop percentage decreased with higher fiber contents, indicating superior post-cracking behavior.

- (4)

- The concrete specimens incorporating waste tire wire, particularly the W-6 sample with a 0.6% fiber content, exhibited significantly superior performance in terms of flexural load and deflection capacity, enhancing the concrete’s ductility and energy absorption capability.

- (5)

- The fracture energy steadily increased from 3.6 to 9.4 kN/m with rising fiber dosage. The ductility index peaked at a fiber content of 0.2% and declined slightly at higher dosages. This behavior emphasizes the importance of optimizing the fiber dosage to balance toughness and deformability as excessive fiber addition may lead to agglomeration and stiffness loss.

- (6)

- The joint incorporation of mine tailings and recycled tire wire offers an effective, resource-efficient solution, simultaneously reducing virgin resource input and converting industrial waste into valuable materials, which align with circular economy and low-carbon goals.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Al-Kheetan, M.J. Properties of lightweight pedestrian paving blocks incorporating wheat straw: Micro-to macro-scale investigation. Results Eng. 2022, 16, 100758. [Google Scholar] [CrossRef]

- Koucham, M.; Khalil, A.; Mouhagir, L.; Zouhri, L.; El Adnani, M. Comprehensive assessment of environmental behavior of mine tailings for sustainable waste management and mitigation of pollution risks. Water 2025, 17, 43. [Google Scholar] [CrossRef]

- Akaryalı, E. Geochemical, fluid inclusion and isotopic (O, H and S) constraints on the origin of Pb–Zn±Au vein-type mineralizations in the Eastern Pontides Orogenic Belt (NE Turkey). Ore Geol. Rev. 2016, 74, 1–14. [Google Scholar] [CrossRef]

- Çullu, M. Investigation of the mechanical and physical properties of concrete produced with lead–zinc mine waste rock. Polytech. J. 2018, 21, 427–435. [Google Scholar] [CrossRef]

- El Machi, A.; El Berdai, Y.; Mabroum, S.; Safhi, A.e.M.; Taha, Y.; Benzaazoua, M.; Hakkou, R. Recycling of mine wastes in the concrete industry: A review. Buildings 2024, 14, 1508. [Google Scholar] [CrossRef]

- Nandi, S.; Ransinchung, G.; Rana, G.B. A sustainable approach towards reducing cement consumption in the road sector using zinc industry waste. Int. J. Pavement Res. Technol. 2022, 15, 1463–1483. [Google Scholar] [CrossRef]

- Amrani, M.; Taha, Y.; El Haloui, Y.; Benzaazoua, M.; Hakkou, R. Sustainable reuse of coal mine waste: Experimental and economic assessments for embankments and pavement layer applications in Morocco. Minerals 2020, 10, 851. [Google Scholar] [CrossRef]

- Kotan, T.; Ardahanlı, M.; Özbey, Ö.F. Investigation of the fresh and mechanical properties of self-compacting concrete incorporating waste zinc slag powder. Konya J. Eng. Sci. 2023, 11, 518–529. [Google Scholar] [CrossRef]

- Soutsos, M.N.; Le, T.T.; Lampropoulos, A.P. Flexural performance of fibre reinforced concrete made with steel and synthetic fibres. Constr. Build. Mater. 2012, 36, 704–710. [Google Scholar] [CrossRef]

- Su, P.; Li, M.; Dai, Q.; Wang, J. Mechanical and durability performance of concrete with recycled tire steel fibers. Constr. Build. Mater. 2023, 394, 132287. [Google Scholar] [CrossRef]

- Samindi, S.M.; Samarakoon, M.K.; Ruben, P.; Pedersen, J.W.; Evangelista, L. Mechanical performance of concrete made of steel fibers from tire waste. Case Stud. Constr. Mater. 2019, 11, e00259. [Google Scholar] [CrossRef]

- Centonze, G.; Leone, M.; Aiello, M.A. Steel fibers from waste tires as reinforcement in concrete: A mechanical characterization. Constr. Build. Mater. 2012, 36, 46–52. [Google Scholar] [CrossRef]

- Zeybek, Ö.; Özkılıç, Y.O.; Çelik, A.İ.; Deifalla, A.F.; Ahmad, M.; Sabri, M.M. Performance evaluation of fiber-reinforced concrete produced with steel fibers extracted from waste tire. Front. Mater. 2022, 9, 1057128. [Google Scholar] [CrossRef]

- Mindess, S.; Young, J.F.; Darwin, D. Concrete, 2nd ed.; Pearson Education Inc., Prentice Hall: Saddle River, NJ, USA, 2002; p. 629. [Google Scholar]

- Ige, O.E.; Olanrewaju, O.A.; Duffy, K.J.; Collins, O.C. Environmental Impact Analysis of Portland Cement (CEM1) Using the Midpoint Method. Energies 2022, 15, 2708. [Google Scholar] [CrossRef]

- Neupane, R.P.; Devi, N.R.; Imjai, T.; Rajput, A.; Noguchi, T. Cutting-edge techniques and environmental insights in recycled concrete aggregate production: A comprehensive review. Resour. Conserv. Recycl. Adv. 2025, 25, 200241. [Google Scholar] [CrossRef]

- Rahman, Z.; Khan, M.; Hussain, M. A study on concrete with waste rubber tyre as partial replacement to coarse aggregate. Int. J. Eng. Res. Technol. (IJERT) 2017, 6, 234–237. [Google Scholar]

- Xiaoyan, H.; Li, W.; Aijiu, C.; Lingyun, F.; Yanting, J.; Zhihao, W.; Zhenzan, G.; Keliang, L.; Qun, Y.; Xiaozhou, X.; et al. Experimental and analytical evaluation of mechanical properties of rubberized concrete incorporating waste tire crumb rubber. Case Stud. Constr. Mater. 2025, 23, e04970. [Google Scholar] [CrossRef]

- Tate, S.M.; Hamid, H.F.; Durham, S.A.; Chorzepa, M.G. Investigation into recycled rubber aggregates and steel wire fiber for use in concrete subjected to impact loading. Infrastructures 2020, 5, 82. [Google Scholar] [CrossRef]

- Liu, H.; Duan, H.; Gao, H.; Wang, Z.; Zhang, J. Graphite tailings’ effects on mechanical and physical properties of eco-efficient steel fiber-reinforced concrete. Buildings 2022, 12, 509. [Google Scholar] [CrossRef]

- Gayana, B.C.; Chandar, K.R. Sustainable use of mine waste and tailings with suitable admixture as aggregates in concrete pavements-A review. Adv. Concr. Constr. 2018, 6, 221–243. [Google Scholar] [CrossRef]

- Amjad, H.; Abd-Elaal, E.S.; Ma, X.; Benn, T.; Fisher, M. A critical review of iron ore tailings as cement and aggregate substitutes for robust infrastructure: Mechanical, durability, eco-economic, and social impacts. J. Clean. Prod. 2025, 492, 144853. [Google Scholar] [CrossRef]

- Karthikeyan, B.; Kathyayini, R.; Kumar, V.A.; Uthra, V.; Kumaran, S.S. Effect of dumped iron ore tailing waste as fine aggregate with steel and basalt fibre in improving the performance of concrete. Mater. Today Proc. 2021, 46, 7624–7632. [Google Scholar] [CrossRef]

- Gao, H.; An, B.; Dai, Y.; Fan, K.; Ding, J.; Liu, H. Utilizing of graphite tailings as fine aggregates in asphalt mixture: Road performance and economic environment assessments. Case Stud. Constr. Mater. 2025, 22, e04807. [Google Scholar] [CrossRef]

- Indian Institute of Technology Bombay (IITB). Understanding RubCrete: How Waste Tyres Are Making Concrete Tougher and Greener; IITB Research Highlights; Indian Institute of Technology Bombay (IITB): Mumbai, India, 2025. [Google Scholar]

- Adıgüzel, D.; Tüylü, S.; Eker, H. Utilization of tailings in concrete products: A review. Constr. Build. Mater. 2022, 360, 129574. [Google Scholar] [CrossRef]

- Zia, A.; Zhang, P.; Holly, I. Experimental investigation of raw steel fibers derived from waste tires for sustainable concrete. Constr. Build. Mater. 2023, 368, 130410. [Google Scholar] [CrossRef]

- Fares, G.; Alsaif, A.; Alhozaimy, A. Hybridization and cost-performance analysis of waste tire steel fibers into high-volume powdered scoria rocks-based ultra-high performance concrete. J. Build. Eng. 2023, 72, 106568. [Google Scholar] [CrossRef]

- Mobasher, B.; Cheng, Y.L. Effect of interfacial properties on the crack propagation in cementitious composites. Adv. Cem. Based Mater. 1996, 4, 93–105. [Google Scholar] [CrossRef]

- Gao, J.; Sun, W.; Morino, K. Mechanical properties of steel fiber-reinforced, high-strength, lightweight concrete. Cem. Concr. Compos. 1997, 19, 307–313. [Google Scholar] [CrossRef]

- Yazıcı, Ş.; İnan, G.; Tabak, V. Effect of aspect ratio and volume fraction of steel fiber on the mechanical properties of SFRC. Constr. Build. Mater. 2007, 21, 1250–1253. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- ASTM C642; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2004.

- BS EN 12390-3; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. British Standards Institution: London, UK, 2009.

- ASTM C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C496; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C1609; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2019.

- Noushini, A.; Hastings, M.; Castel, A.; Aslani, F. Mechanical and flexural performance of synthetic fibre reinforced geopolymer concrete. Constr. Build. Mater. 2018, 186, 454–475. [Google Scholar] [CrossRef]

- Aksüt, Y.S.; Çullu, M.; Yetgin, Ş. Optimal ratio of steel and polyester fibers on the mechanical behavior of alkali-activated concrete produced by industrial waste minerals. Iran J. Sci. Technol. Trans. Civ. Eng. 2024, 49, 657–671. [Google Scholar] [CrossRef]

- Johansson, L.; Bahrami, A.; Wallhagen, M.; Cehlin, M. A comprehensive review on properties of tailings-based low-carbon concrete: Mechanical, environmental, and toxicological performances. Dev. Built Environ. 2024, 18, 100428. [Google Scholar] [CrossRef]

- Saedi, A.; Jamshidi-Zanjani, A.; Darban, A.K.; Mohseni, M.; Nejati, H. Utilization of lead–zinc mine tailings as cement substitutes in concrete construction: Effect of sulfide content. J. Build. Eng. 2022, 57, 104865. [Google Scholar] [CrossRef]

- Roshan, N.; Ghalehnovi, M. The effect of recycled-tire steel fiber and engineered steel fiber on rebar corrosion and shear behavior of corroded RC beam. Case Stud. Constr. Mater. 2023, 19, e02251. [Google Scholar] [CrossRef]

- Manan, A.; Zhang, P.; Alattyih, W.; Alzara, M.; Ahmad, J.; Yosri, A.M. Physical properties of recycled concrete powder and waste tyre fibre reinforced concrete. Proc. Inst. Civ. Eng. Eng. Sustain. 2024, 178, 171–184. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, C.; Li, Q.; Song, G.; Hu, Y. The synergistic effect of recycled steel fibers and rubber aggregates from waste tires on the basic properties, drying shrinkage, and pore structures of cement concrete. Constr. Build. Mater. 2025, 470, 140574. [Google Scholar] [CrossRef]

- Soulioti, D.V.; Barkoula, N.M.; Paipetis, A.; Matikas, T.E. Effects of fibre geometry and volume fraction on the flexural behaviour of steel-fibre reinforced concrete. Strain 2011, 47, e535–e541. [Google Scholar] [CrossRef]

- Şimsek, O. Concrete and Concrete Technology, 6th ed.; Seçkin Publishing House: Ankara, Turkey, 2020. [Google Scholar]

- Aswathi, R.; Shahla, C.P. Mechanical properties of hybrid fiber reinforced geopolymer concrete. Int. Res. J. Eng. Technol. 2019, 6, 170–173. Available online: https://www.irjet.net/archives/V6/i8/IRJET-V6I830.pdf (accessed on 16 August 2025).

- Venkateswarlu, M.; Gunneswara Rao, T.D. Effect of steel and PVA fibres as monofibres on strength and cracking properties of fly ash and slag-based alkali-activated concrete. J. Eng. Appl. Sci. 2023, 70, 100. [Google Scholar] [CrossRef]

- Tokyay, M.; Ramyar, K.; Turanlı, L. Behavior of polypropylene and steel fiber high strength concrete under compressive and tensile loads. In Proceedings of the TMMOB Chamber of Civil Engineers 2nd National Concrete Congress Proceedings, Ankara, Turkey, 27–30 May 1991; pp. 303–311. [Google Scholar]

- Kolesnikov, G.; Shekov, V.; Gavrilov, T. Modeling the influence of non-constant Poisson’s ratio on crack formation under uniaxial compression of rocks and concrete. Eng 2025, 6, 130. [Google Scholar] [CrossRef]

- Bankir, Ş.; Bikce, M. Experimental investigation and statistical evaluation of the effects of steel fiber aspect ratio and fiber rate on static and dynamic mechanical properties of concrete. Constr. Build. Mater. 2024, 414, 135064. [Google Scholar] [CrossRef]

- Shadfar, A.; Nani, M.; Shirinabadi, R.; Hosseini, S.A. The feasibility of constructing rubber concrete pavement reinforced with recycled and industrial steel fibers. Results Mater. 2025, 25, 100657. [Google Scholar] [CrossRef]

- Zia, A.; Zhang, P.; Holly, I.; Prokop, J. Sustainability enhancement through high-dose recycled tire steel fibers in concrete: Experimental insights and practical applications. Sustainability 2023, 15, 15760. [Google Scholar] [CrossRef]

- Gong, J.; Ma, Y.; Fu, J.; Hu, J.; Ouyang, X.; Zhang, Z.; Wang, H. Utilization of fibers in ultra high-performance concrete: A review. Compos. Part B Eng. 2022, 241, 109995. [Google Scholar] [CrossRef]

- Dziomdziora, P.; Smarzewski, P. Effect of hybrid fiber compositions on mechanical properties and durability of ultra-high-performance concrete: A comprehensive review. Materials 2025, 18, 2426. [Google Scholar] [CrossRef] [PubMed]

- Oyejobi, D.O.; Firoozi, A.A.; Fernández, D.B.; Avudaiappan, S. Integrating circular economy principles into concrete technology: Enhancing sustainability through industrial waste utilization. Results Eng. 2024, 24, 102846. [Google Scholar] [CrossRef]

- EN 13877-1:2023; Concrete Pavements—Part 1: Materials. CEN—European Committee for Standardization: Brussels, Belgium, 2023.

- ACI 325.9 R; Guide for Construction of Concrete Pavements and Concrete Bases. American Concrete Institute (ACI): Farmington Hills, MI, USA, 2015.

- Köksal, F.; Beycioğlu, A.; Dobiszewska, M. Optimization based on toughness and splitting tensile strength of steel-fiber-reinforced concrete incorporating silica fume using response surface method. Materials 2022, 15, 6218. [Google Scholar] [CrossRef]

- Cui, D.; Wang, L.; Zhang, C.; Xue, H.; Gao, D.; Chen, F. Dynamic splitting performance and energy dissipation of fiber-reinforced concrete under impact loading. Materials 2024, 17, 421. [Google Scholar] [CrossRef]

- Almohammed, F.; Thakur, M.S.; Lee, D.; Kumar, R.; Singh, T. Flexural and split tensile strength of concrete with basalt fiber: An experimental and computational analysis. Constr. Build. Mater. 2024, 414, 134936. [Google Scholar] [CrossRef]

- Sukontasukkul, P. Tensile behaviour of hybrid fibre reinforced concrete. Adv. Cem. Res. 2004, 16, 115–122. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Pongsopha, P.; Chindaprasirt, P.; Songpiriyakij, S. Flexural performance and toughness of hybrid steel and polypropylene fibre reinforced geopolymer. Constr. Build. Mater. 2018, 161, 37–44. [Google Scholar] [CrossRef]

- Maldar, M.; Kianoush, R.; Siad, H.; Lachemi, M. An experimental investigation on the mechanical performance of engineered cementitious composites with different types of steel fiber. Materials 2025, 18, 2990. [Google Scholar] [CrossRef] [PubMed]

- Mehmandari, T.A.; Shokouhian, M.; Josheghan, M.Z.; Mirjafari, S.A.; Fahimifar, A.; Armaghani, D.J.; Tee, K.F. Flexural properties of fiber-reinforced concrete using hybrid recycled steel fibers and manufactured steel fibers. J. Build. Eng. 2024, 98, 111069. [Google Scholar] [CrossRef]

- Bzeni, D.K. Investigating the influence of fiber content and geometry on the flexural response of fiber-reinforced cementitious composites. J. Compos. Sci. 2024, 8, 347. [Google Scholar] [CrossRef]

- He, J.; Sun, C.; Wang, X. Mechanical properties and microanalytical study of concrete reinforced with blended corn straw and scrap steel fibers. Materials 2024, 17, 3844. [Google Scholar] [CrossRef]

- Aksoylu, C.; Özkılıç, Y.O.; Hadzima-Nyarko, M.; Işık, E.; Arslan, M.H. Investigation on improvement in shear performance of reinforced-concrete beams produced with recycled steel wires from waste tires. Sustainability 2022, 14, 13360. [Google Scholar] [CrossRef]

- Sanok, A.; Domski, J.; Kobaka, J.; Logoń, D. Torsional behavior of waste fiber-reinforced concrete. Materials 2024, 17, 3269. [Google Scholar] [CrossRef]

- Suárez González, J.; Lopez Boadella, I.; López Gayarre, F.; López-Colina Pérez, C.; Serrano López, M.; Stochino, F. Use of mining waste to produce ultra-high-performance fibre-reinforced concrete. Materials 2020, 13, 2457. [Google Scholar] [CrossRef]

- Jiang, M.; Cao, S.; Yilmaz, E. Enhanced strength and fracture features of tailings-based concrete reinforced with fibers and X-shaped rocks. J. Mater. Res. Technol. 2025, 36, 62–71. [Google Scholar] [CrossRef]

- Zaid, O.; Ahmed, M.; Yosri, A.M.; Alshammari, T.O. Evaluating the impact of mine tailings wastes on the development of sustainable ultra-high performance fiber reinforced concrete. Sci. Rep. 2025, 15, 6285. [Google Scholar] [CrossRef]

- Yu, J.; Wu, Q.; Zhao, D.; Jiao, Y. Influence of recycled tire steel fiber content on the mechanical properties and fracture characteristics of ultra-high-performance concrete. Materials 2025, 18, 3300. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Feng, C.; Qiu, J.; Wang, L.; Peng, Y.; Liu, J. Influence of recycled tire steel fibers on the mechanical properties and carbon emissions of high-performance cement-based materials. Materials 2025, 18, 3008. [Google Scholar] [CrossRef] [PubMed]

- Yan, C.; Jiang, C.; Zhang, J.; Li, L.; Li, G. Experimental study on flexural performance of recycled aggregate concrete with recycled tire steel fiber. Buildings 2023, 13, 3046. [Google Scholar] [CrossRef]

- Khan, S.; Qing, L.; Ahmad, I.; Mu, R.; Bi, M. Investigation on fracture behavior of cementitious composites reinforced with aligned hooked-end steel fibers. Materials 2022, 15, 542. [Google Scholar] [CrossRef]

- Wang, Z.; Gou, J.; Gao, D. Experimental study on the fracture parameters of concrete. Materials 2021, 14, 129. [Google Scholar] [CrossRef]

- Hosen, M.A.; Liew, K.M.; Lee, H.K. Ductility enhancement of sustainable fibrous-reinforced high-strength lightweight concrete. Polymers 2022, 14, 727. [Google Scholar] [CrossRef]

- Su, J.Y.; Luo, R.H.; Chen, Z.B.; Lin, J.X.; Huang, P.Y.; Guo, Y.C. Experimental study on the fracture performance of rubberized high strength-high ductility concrete with J-integral method. Constr. Build. Mater. 2024, 421, 135668. [Google Scholar] [CrossRef]

- Jin, A.H.; Woo, J.S.; Yun, H.D.; Kim, S.W.; Park, W.S.; Choi, W.C. Influence of concrete strength and fiber properties on residual flexural strength of steel fiber-reinforced concrete. Constr. Build. Mater. 2025, 489, 142366. [Google Scholar] [CrossRef]

- Xu, W.; Chen, Y.; Miao, H.; Zhang, L. An experimental study on fracture characteristics of high-performance fiber-reinforced cement composites through combined acoustic emission and digital image correlation. J. Build. Eng. 2025, 103, 112110. [Google Scholar] [CrossRef]

- Gao, D.; Gu, Z.; Wei, C.; Wu, C.; Pang, Y. Effects of fiber clustering on fatigue behavior of steel fiber reinforced concrete beams. Constr. Build. Mater. 2021, 301, 124070. [Google Scholar] [CrossRef]

- Al Rifai, M.M.; Sikora, K.S.; Hadi, M.N.S. Effect of micro steel fibers volume fraction on behavior of high-strength self-compacting concrete. Constr. Build. Mater. 2024, 450, 138709. [Google Scholar] [CrossRef]

| Reference | Waste Material(s) Used | Application | Material and Ratios | Key Findings |

|---|---|---|---|---|

| [17] | Waste rubber particles (coarse) | Concrete | 5–30%, optimum: 10% | Strength decreases after 10% |

| [18] | Waste rubber aggregate | Concrete | Between 10 and 35% | Eco-friendly additive for non-structural concrete |

| [19] | Rubber particles + waste tire wire | Concrete | 10% rubber + 0.25% wire | Improved energy absorption and strength |

| [20] | Mine tailings + SF | Concrete | 10–20% | 10% is optimal for strength enhancement |

| [21] | Iron ore tailings (fine aggregate) | Pavement | Between 20 and 50% | Positive effect on performance, sustainable solution |

| [22] | Iron ore tailings | Concrete | 0–25% | Increased strength, decreased workability |

| [23] | Iron tailings + SF/basalt fiber | Concrete | Between 10 and 30% | Performance enhanced with fiber |

| [24] | Graphite tailings | Asphalt | Up to 50% | Improved performance, economic benefits |

| [25] | Tire wire + concrete | Concrete | Applied as “RubCrete” | Tough and eco-friendly concrete |

| Aggregate Type | Aggregate Grade (mm) | Physical Properties | |||

|---|---|---|---|---|---|

| Dry Grain Density (g/cm3) | Saturated Dry Surface Density (g/cm3) | Water Absorption (%) | Porosity (%) | ||

| Mine tailings | 0–5 | 2.68 | 2.72 | 4.01 | 10.72 |

| Limestone | 5–12 12–25 | 2.70 2.71 | 2.81 2.78 | 4.22 1.98 | 10.61 4.88 |

| Aggregate Type | SiO2 | Al2O3 | Fe2O | MgO | CaO | MgCO3 | Zn | Pb | Cu | H2O | Others (CO2, etc.) | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mine tailings | - | - | 4.65 | - | 34.6 | - | 1.11 | 0.98 | >0.01 | 7.96 | 50.68 | 100 |

| Limestone | 2.95 | 0.43 | 0.46 | - | 73.93 | 22.23 | - | - | - | - | - | 100 |

| Chemical Characteristics | Physical Characteristics | ||

|---|---|---|---|

| Mass Percentage in Cement (%) | Mass Percentage in Cement (%) | ||

| SiO2 | 18.51 | Insoluble residue | 0.86 |

| Al2O3 | 4.23 | 45 micron sieve residue | 2 |

| Fe2O3 | 3.38 | 90 micron sieve residue | 0 |

| CaO | 60.46 | Consistency water quantity | 30.7 |

| MgO | 2.79 | Initial setting time (min) | 195 min |

| SO3 | 3.11 | Final setting time (min) | 240 min |

| Loss of ignition | 3.53 | Specific mass | 3.10 g/cm3 |

| Na2O | 0.33 | Expansion (Le Chatelier) | 1 mm |

| K2O | 0.74 | Specific surface (Blaine) | 3627 cm2/g |

| Cl | 0.0106 | Mechanical properties | |

| Time (day) | Strength (N/mm2) | ||

| Total | 97.42 | 1 | 13.1 |

| Unmeasurable | 2.58 | 2 | 28 |

| Free lime | 0.68 | 28 | 57.8 |

| SF | Diameter (mm) | Length (mm) | Aspect Ratio (%) | Weight Ratio (%) |

| 0.10–0.15 | 15–35 | 110–180 | 40–60 |

| Mix code | Cement (kg/m3) | Water (L/m3) | Aggregate (kg/m3) | SP (kg/m3) | Pb-Zn-Cu Tailings (0–5 mm) (kg/m3) | SFs | |

|---|---|---|---|---|---|---|---|

| (%) | (kg/m3) | ||||||

| C | 350 | 175 | 1744.03 | 5.25 | - | - | - |

| W | 350 | 175 | 1744.03 | 5.25 | 784.81 | - | - |

| W-2 | 350 | 175 | 1744.03 | 5.25 | 784.81 | 0.2 | 15.7 |

| W-4 | 350 | 175 | 1744.03 | 5.25 | 784.81 | 0.4 | 31.4 |

| W-6 | 350 | 175 | 1744.03 | 5.25 | 784.81 | 0.6 | 47.1 |

| Sample | Density (kg/m3) | Porosity (%) | Water Absorption (%) | |||

|---|---|---|---|---|---|---|

| 7 Days | 28 Days | 7 Days | 28 Days | 7 Days | 28 Days | |

| C | 2392.97 | 2398.68 | 10.82 | 10.21 | 4.72 | 4.46 |

| W | 2409.51 | 2410.99 | 11.47 | 10.73 | 4.99 | 4.66 |

| W-2 | 2405.49 | 2426.97 | 10.90 | 10.88 | 4.74 | 4.70 |

| W-4 | 2427.72 | 2431.02 | 10.85 | 10.50 | 4.67 | 4.52 |

| W-6 | 2434.27 | 2352.71 | 10.57 | 10.20 | 4.70 | 4.37 |

| Sample | Compressive Strength (MPa) | Modulus of Elasticity (GPa) | Poisson’s Ratio | |||

|---|---|---|---|---|---|---|

| 7 Days | 28 Days | 7 Days | 28 Days | 7 Days | 28 Days | |

| C | 18.58 | 21.99 | 27.49 | 47.80 | 0.29 | 0.30 |

| W | 15.03 | 18.00 | 31.02 | 44.50 | 0.31 | 0.33 |

| W-2 | 21.47 | 22.87 | 37.44 | 72.80 | 0.31 | 0.34 |

| W-4 | 22.96 | 24.21 | 30.84 | 33.30 | 0.33 | 0.37 |

| W-6 | 22.44 | 26.00 | 26.64 | 29.69 | 0.34 | 0.41 |

| Sample | First Peak, P1 | Valley After First Peak, Pval | Second Peak, Pp | Load Drop, ΔPdrop | Modulus of Rupture (MPa) | |||

|---|---|---|---|---|---|---|---|---|

| kN | kN | % | kN | % | kN | % | ||

| C | 6.09 | - | - | - | - | 6.09 | 0 | 2.13 |

| W | 6.67 | - | - | - | - | 6.67 | 0 | 2.33 |

| W-2 | 8.70 | 7.82 | 10.14 | 8.25 | 5.50 | 0.88 | 10.11 | 3.05 |

| W-4 | 9.48 | 8.72 | 8.01 | 9.07 | 4.01 | 0.76 | 8.02 | 3.32 |

| W-6 | 12.45 | 11.69 | 6.07 | 12.06 | 3.17 | 0.76 | 6.10 | 4.36 |

| Sample | P1 (kN) | f1 (MPa) | Δ1 (mm) | Pp (kN) | fp (MPa) | Δp (mm) | (kN) | (MPa) | (kN) | (MPa) | (J) | (%) | DI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | 6.09 | 2.13 | 0.9 | 6.09 | 2.13 | 1.1 | 3.96 | 1.39 | 1.86 | 0.65 | 36.36 | 17.31 | 1.22 |

| W | 6.67 | 2.33 | 1.03 | 6.67 | 2.33 | 1.08 | 5.27 | 1.84 | 3.59 | 1.26 | 53.65 | 24.73 | 1.68 |

| W-2 | 8.7 | 3.05 | 1.18 | 8.25 | 2.89 | 1.35 | 7.41 | 2.59 | 5.88 | 2.06 | 84.05 | 33.62 | 1.99 |

| W-4 | 9.48 | 3.32 | 1.4 | 9.07 | 3.17 | 1.77 | 8.36 | 2.93 | 7.4 | 2.59 | 90.33 | 32.26 | 1.84 |

| W-6 | 12.45 | 4.36 | 1.85 | 12.06 | 4.22 | 2.26 | 11.02 | 3.86 | 9.84 | 3.44 | 94.99 | 29.41 | 1.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seferoğlu, M.T.; Aksüt, Y.S.; Seferoğlu, A.G. Flexural Behavior and Sustainability of Dual-Waste Fiber-Reinforced Concrete Designed for Pavement Applications. Buildings 2025, 15, 3454. https://doi.org/10.3390/buildings15193454

Seferoğlu MT, Aksüt YS, Seferoğlu AG. Flexural Behavior and Sustainability of Dual-Waste Fiber-Reinforced Concrete Designed for Pavement Applications. Buildings. 2025; 15(19):3454. https://doi.org/10.3390/buildings15193454

Chicago/Turabian StyleSeferoğlu, Mehmet Tevfik, Yavuz Selim Aksüt, and Ayşegül Güneş Seferoğlu. 2025. "Flexural Behavior and Sustainability of Dual-Waste Fiber-Reinforced Concrete Designed for Pavement Applications" Buildings 15, no. 19: 3454. https://doi.org/10.3390/buildings15193454

APA StyleSeferoğlu, M. T., Aksüt, Y. S., & Seferoğlu, A. G. (2025). Flexural Behavior and Sustainability of Dual-Waste Fiber-Reinforced Concrete Designed for Pavement Applications. Buildings, 15(19), 3454. https://doi.org/10.3390/buildings15193454