Towards Sustainable Mortar: Optimising Sika-Fibre Dosage in Ground Granulated Blast Furnace Slag (GGBS) and Silica Fume Blends for 3D Concrete Printing

Abstract

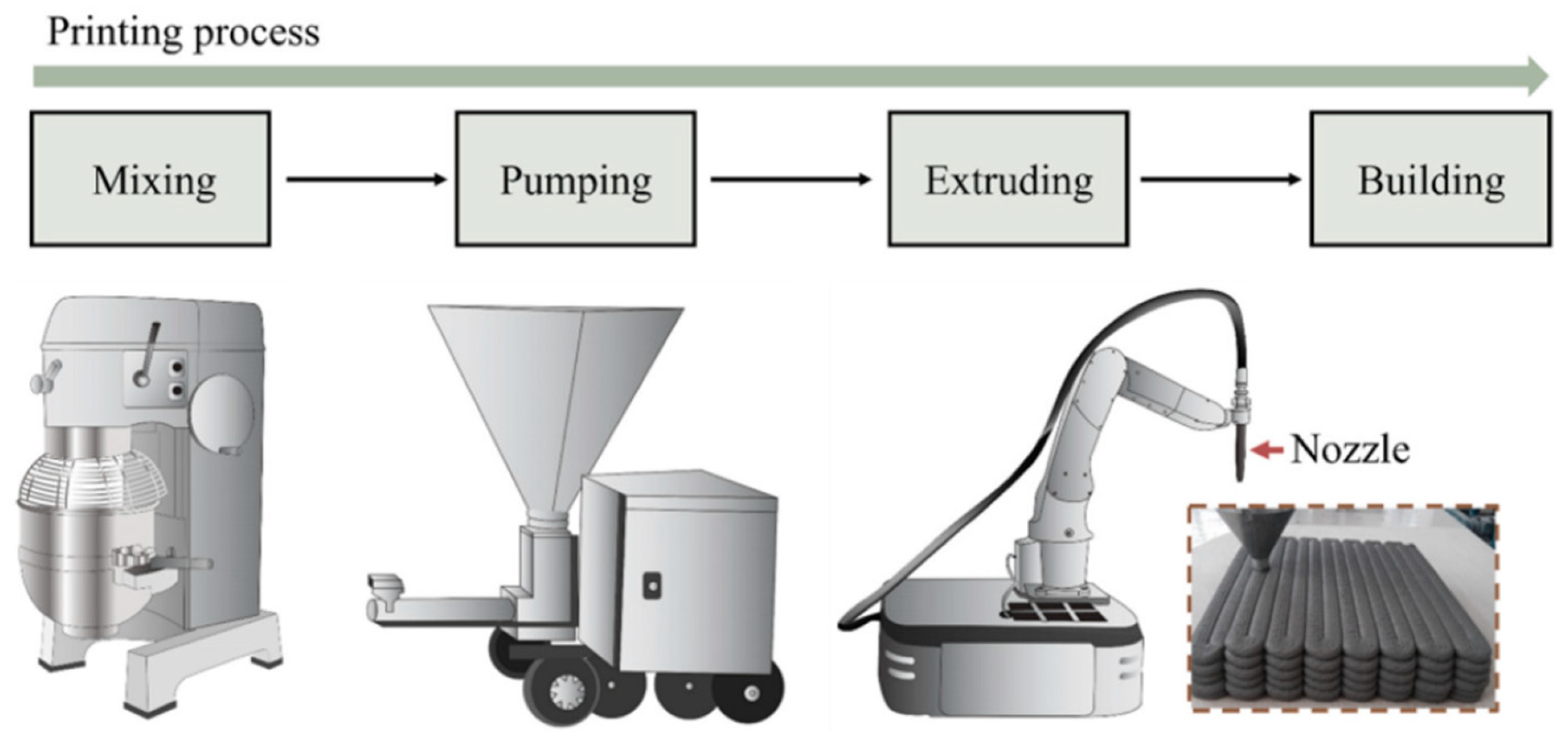

1. Introduction

2. Material and Mix Design

2.1. Materials

2.2. Mixing and Casting Procedures

3. Testing Methods

3.1. Fresh State Testing

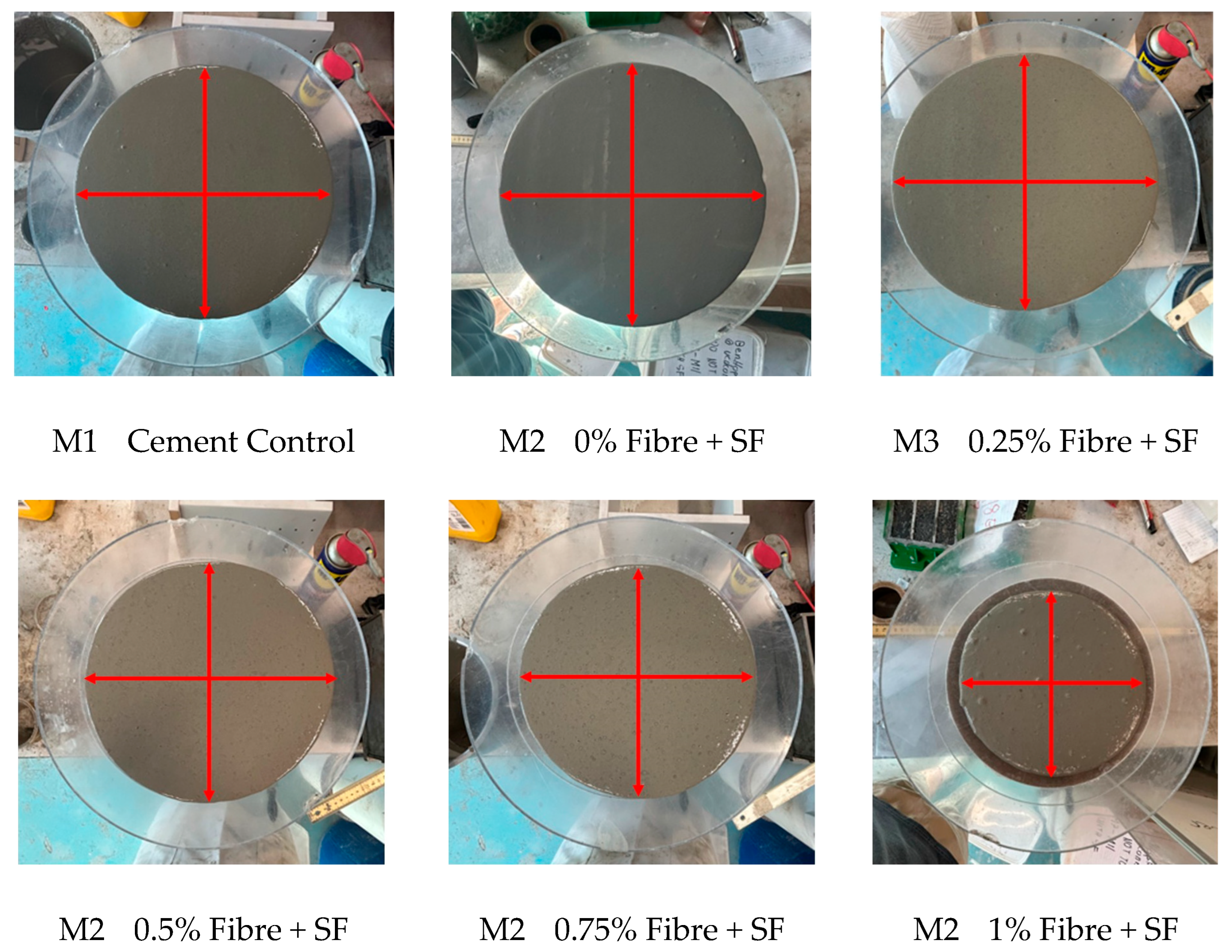

3.1.1. Flow Table Test

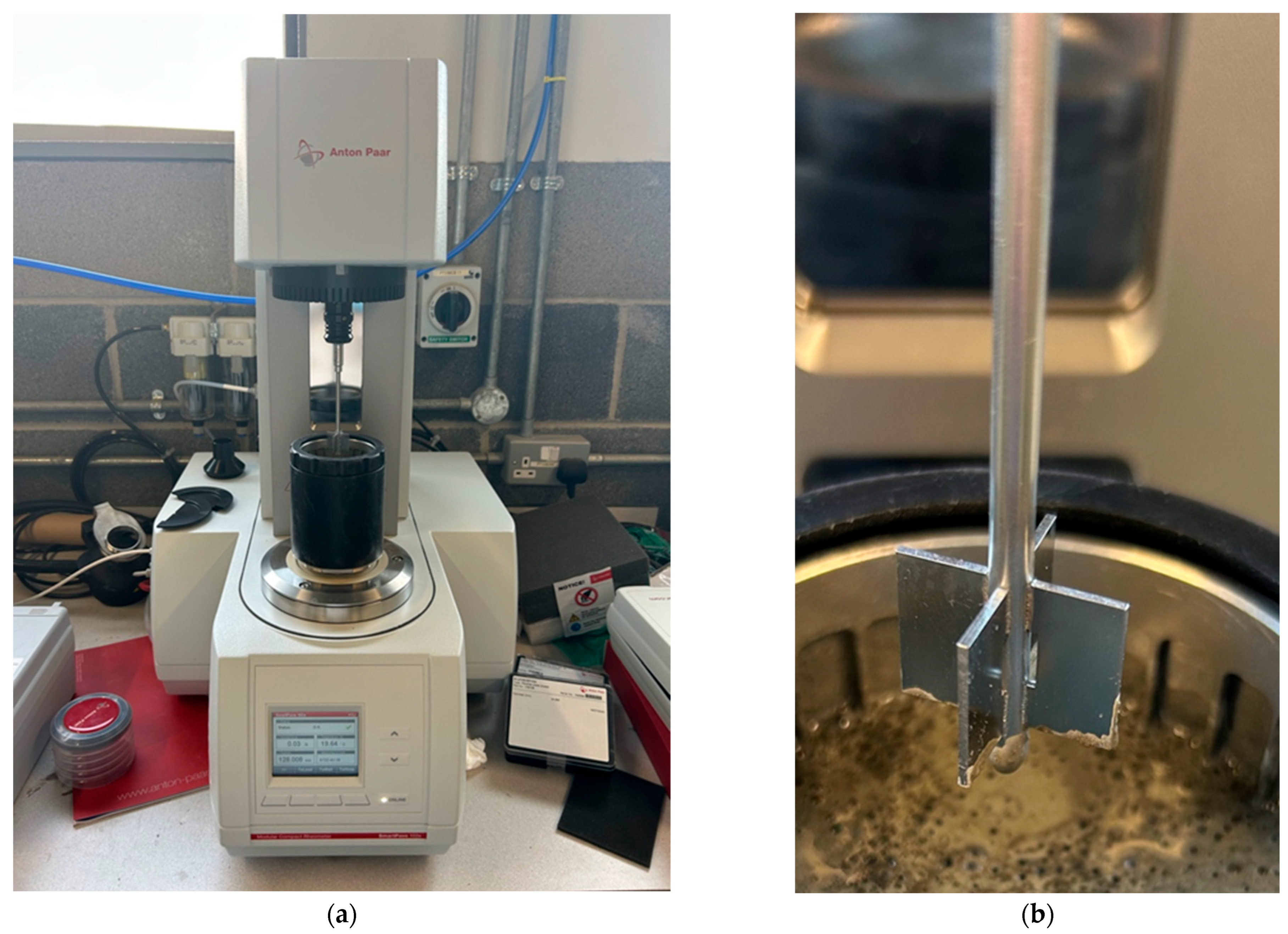

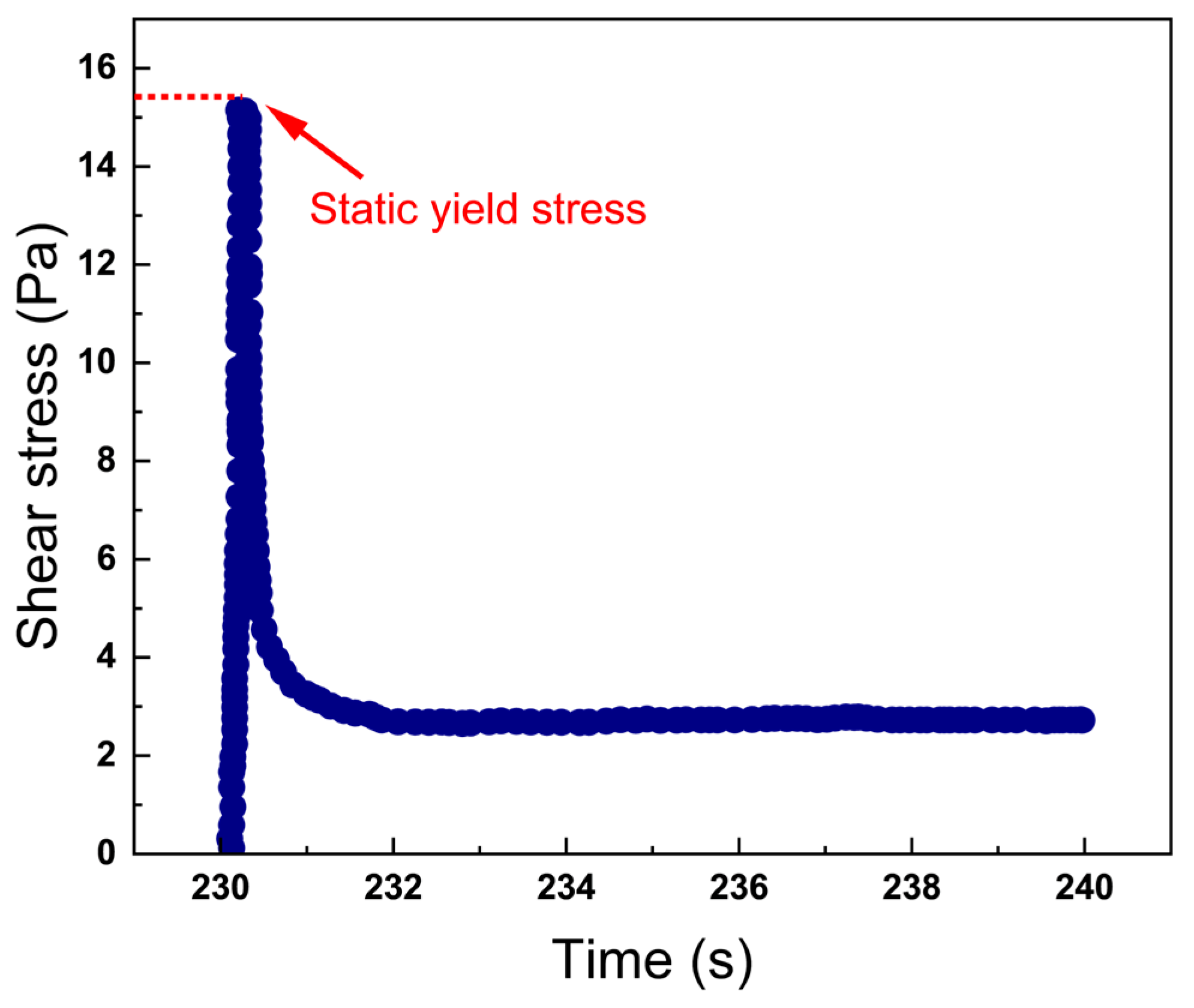

3.1.2. Rheological Test

3.2. Hardened State Testing

3.2.1. Compressive Strength Test

3.2.2. Flexural Strength Test

4. Results and Analysis

4.1. Fresh State Results

4.1.1. Slump Flow

4.1.2. Rheology

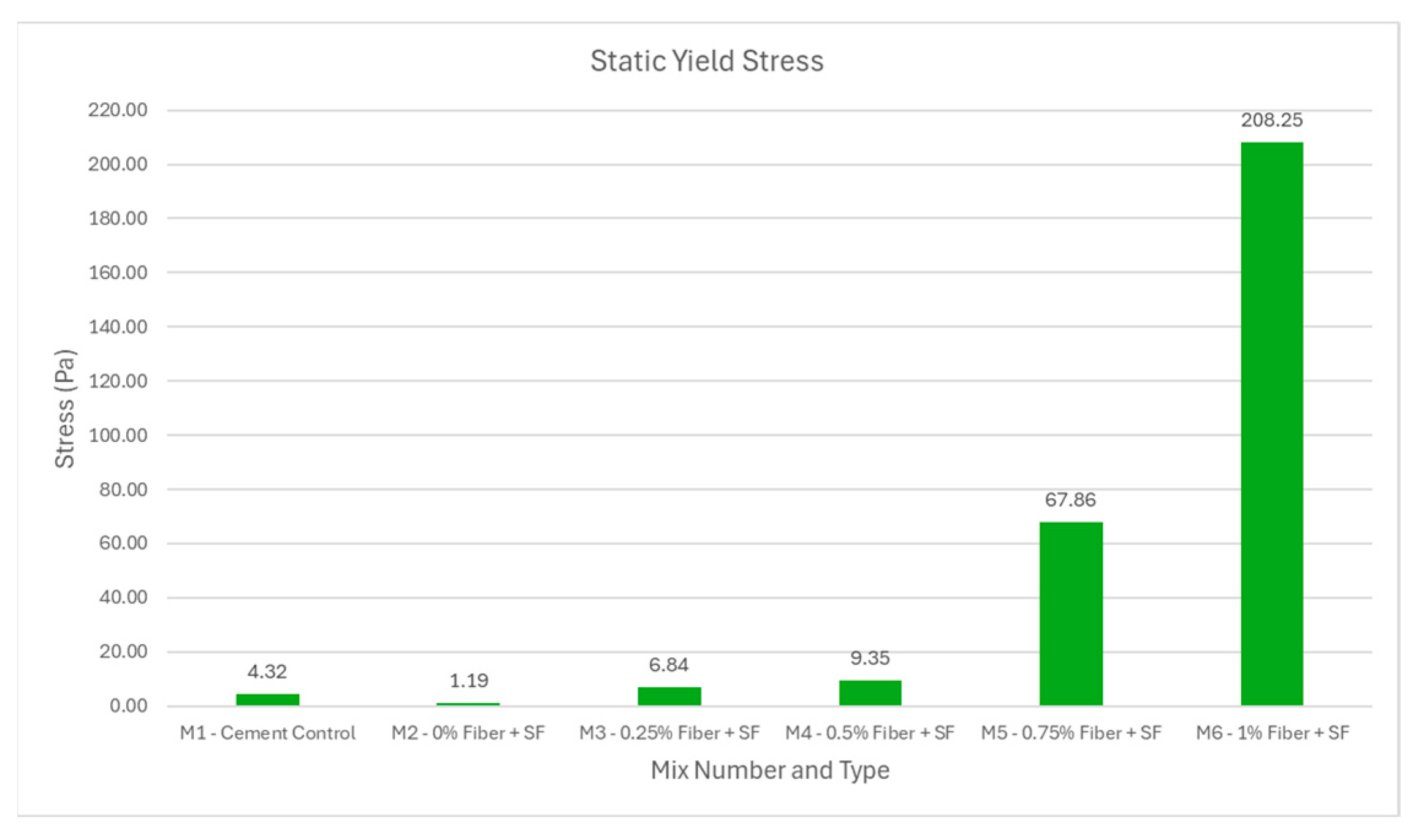

Static Yield Stress

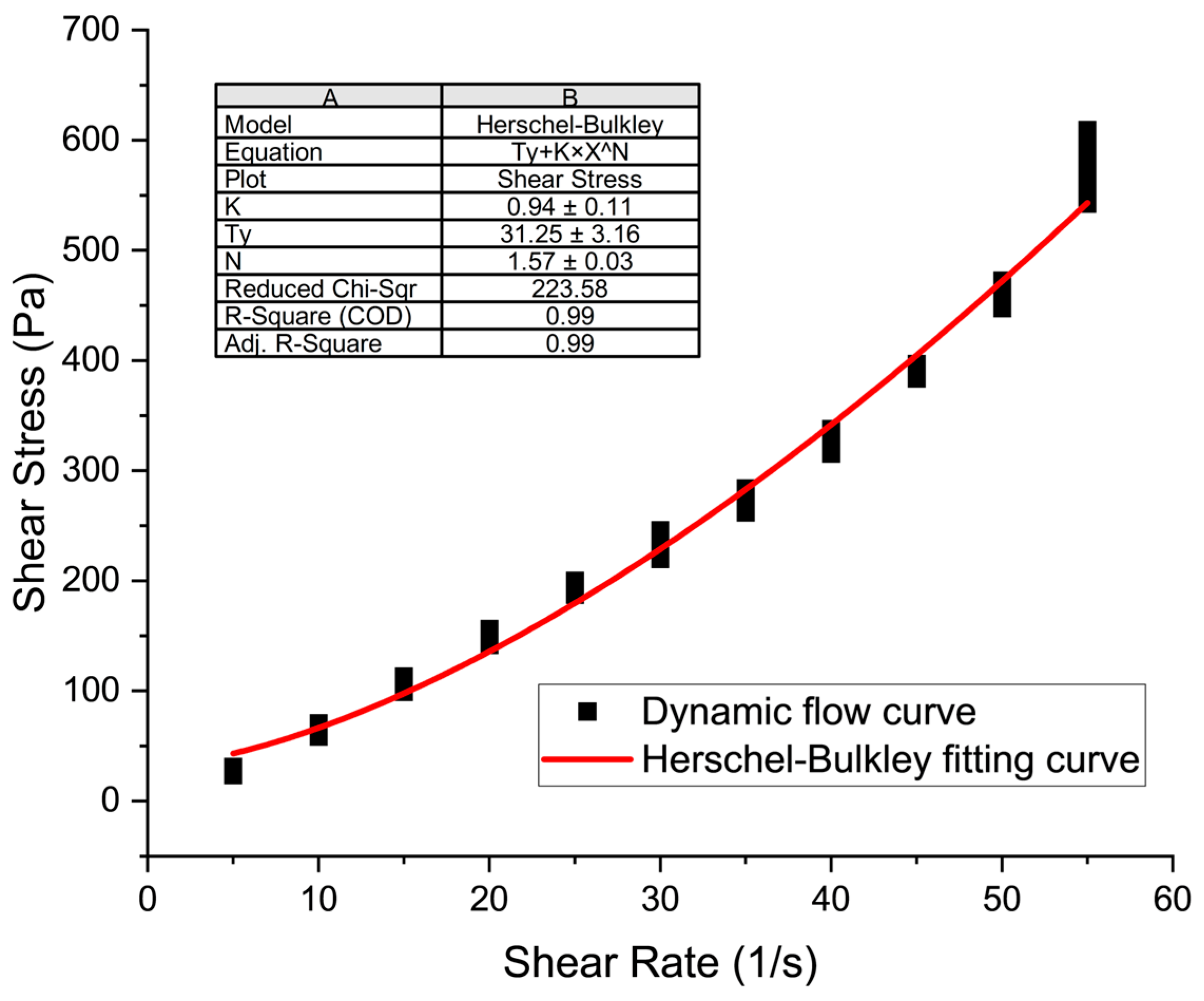

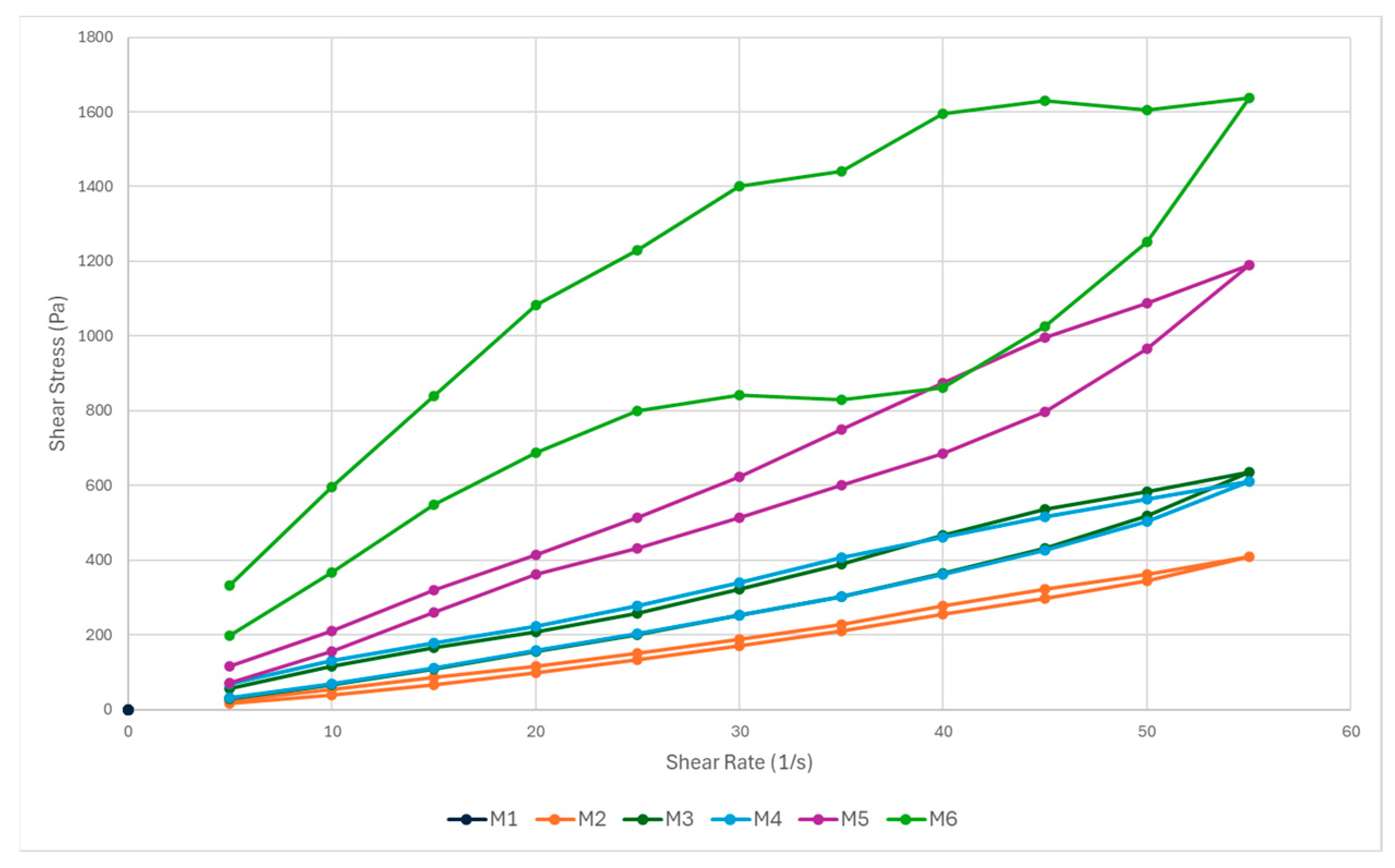

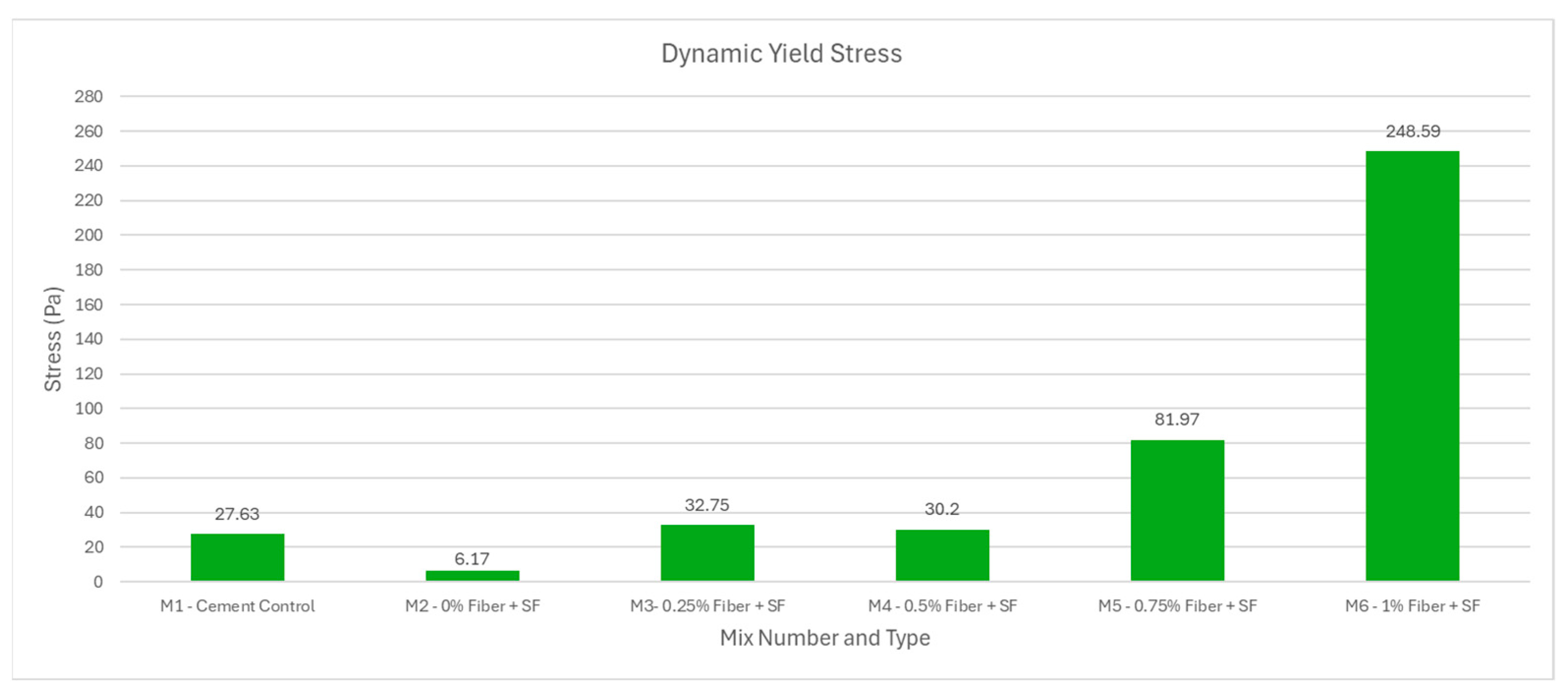

Dynamic Yield Stress and Shear Thickening

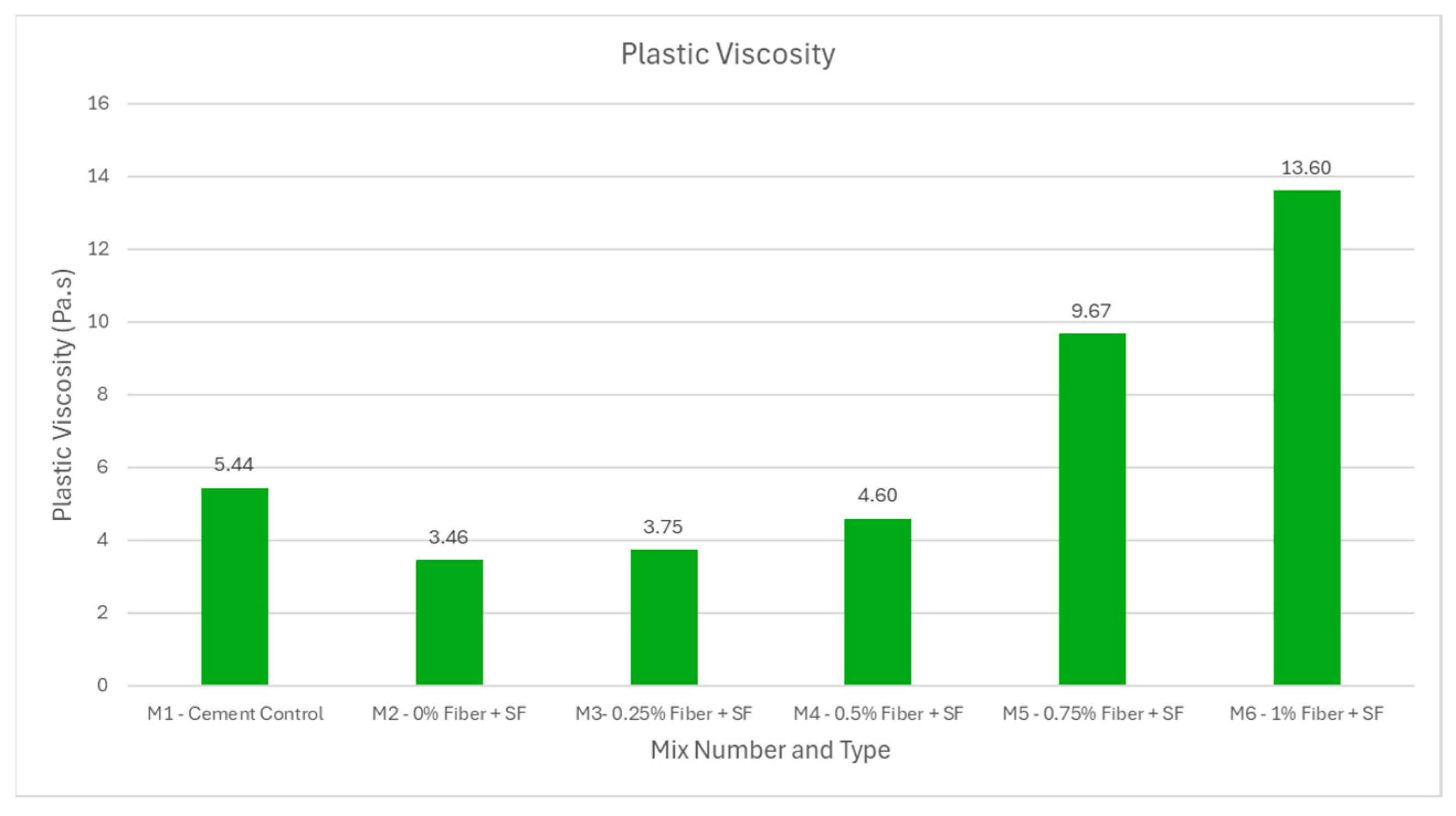

Plastic Viscosity

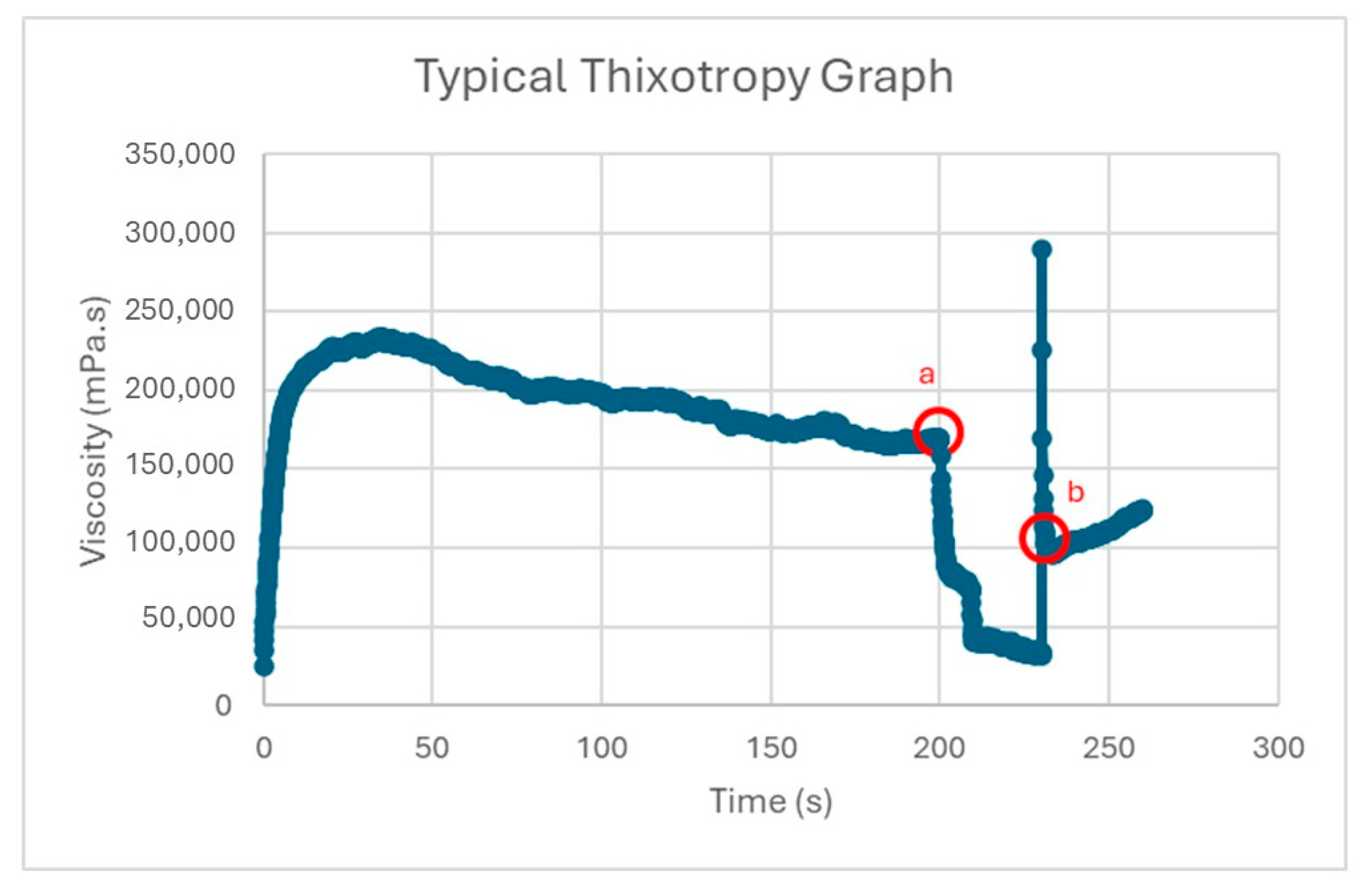

Thixotropy

4.2. Hardened State Results

4.2.1. Compressive Strength

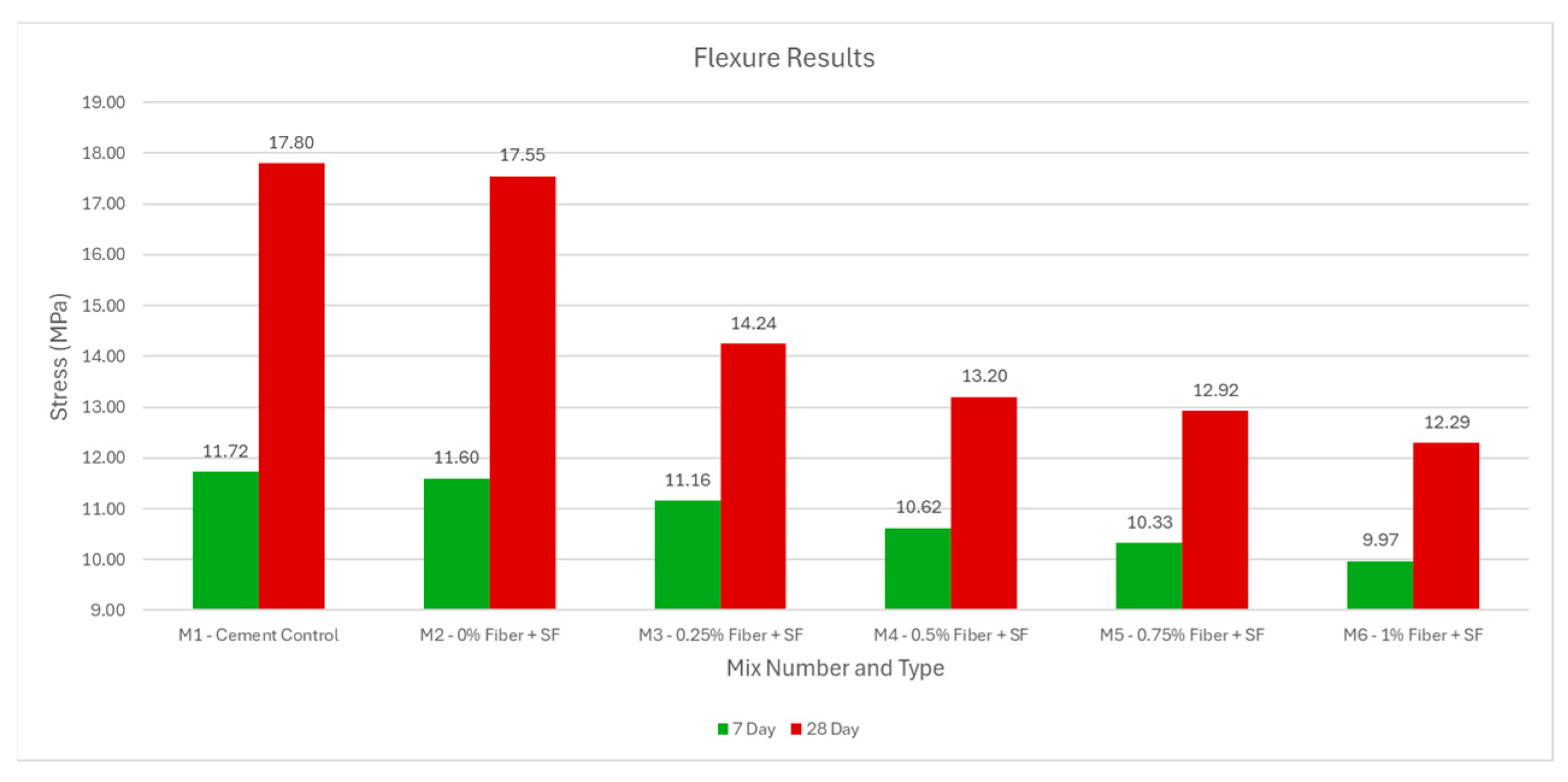

4.2.2. Flexural Strength

4.2.3. Porosity

5. Discussion

5.1. Comparison of Fibre-Induced Mixes Against Reference Mix

- Buildability improved at all fibre dosages, as static yield stress increased with higher fibre content.

- Plastic viscosity increased significantly at higher fibre dosages, particularly in mixes without silica fume. This behaviour indicates poor fibre dispersion and clustering, which was partially mitigated by the lubrication effect of silica fume [48].

- Thixotropic behaviour increased significantly at high fibre dosages, particularly in mixes without silica fume. This indicates that high fibre content promoted structuration and clustering, which were partially mitigated by silica fume and consistent with findings by Mao et al. [55], who reported that silica fume reduces excessive thickening.

- Each mix exhibited shear thickening behaviour (n > 1), followed by a decrease as fibre content increased. This trend is likely attributed to fibre clustering, which distributes shear more uniformly and aligns with the findings of Jiao et al. [10], indicating that excessive fibre addition reduces shear thickening capacity.

- The compressive strength decreased with increasing fibre dosage at the 7-day age, possibly due to increased porosity and the samples not reaching sufficient hydration development compared to 28-day curing. The highest compressive strength 119.04 MPa was observed in Mix 2, which incorporated silica fume without fibre. The addition of 0.25% fibre unexpectedly reduced strength, followed by a slight improvement at 0.5%, after which the strength declined again with higher dosages. This early increase may be attributed to the formation of an effective fibre network and improved dispersion at lower fibre contents.

- The flexural strength showed a steady reduction at both 7-day and 28-day curing ages, possibly due to the combined presence of fibres and silica fume causing excessive matrix densification, which subsequently affected strength at higher fibre dosages.

5.2. 3D-Printing Implications

5.2.1. Extrudability and Shape Retention

5.2.2. Buildability

5.2.3. Mechanical Performance

5.2.4. Sustainability

5.2.5. Practical Recommendations and Limitations

- For 3D printing applications, the dosage of cellulose microfibres should be limited to a maximum of 0.5%, as this level ensures sufficient extrudability, buildability and compressive strength, while avoiding excessive rheological resistance, fibre clustering, and porosity formation observed at higher dosages.

- The silica fume content should be controlled below 5%, since lower dosages may interact more favourably with fibres by reducing matrix overpacking. However, additional studies are required to confirm the potential benefits of reduced silica fume levels.

- The present study primarily investigated rheological and mechanical performance using mould-cast specimens, without direct validation under real 3D printing conditions. The absence of layered stacking tests means that the influence of interlayer bonding and anisotropy on structural performance has not yet been evaluated.

- The micro-level mechanisms of fibre–matrix interaction remain insufficiently explored. While macro-level results show that fibre clustering and porosity affect strength, further work using microstructural analysis techniques (e.g., CT scanning, SEM, or fibre orientation mapping) is necessary to clarify how cellulose microfibres influence hydration, pore refinement, and crack bridging.

- Future research should focus on full printing trials to validate the printability of these mortars, including filament formation, layer adhesion, and dimensional stability, as well as advanced microscopic investigations to better explain the role of natural microfibres in both rheological response and mechanical behaviour.

6. Conclusions

- Slump flow reduced from 285 mm (0% fibre dosage) to 255 mm at 0.5% fibre dosage (−11%) and 202.5 mm at 1% fibre dosage (−29%), consistent with the increase in yield stress and viscosity.

- Static yield stress increased 7 times at 0.5% fibre dosage and 174 times at 1% fibre, dosage, while thixotropy increased from 1150.6 Pa·s (0% fibre dosage) to 8623 Pa·s (0.5% fibre dosage) and peaked at 135,342 Pa·s (1% fibre dosage). Dynamic yield stress and plastic viscosity remained within printable ranges at 0.25–0.5% fibre dosage (≈30 Pa, 3–5 Pa·s) but increased excessively at higher dosages.

- At 0.5% fibre, compressive strength reached 109.10 MPa, while flexural strength decreased from 17.55 MPa (0% fibre dosage) to 13.20 MPa (0.5% fibre dosage) and 12.29 MPa (1% fibre dosage) due to fibre clustering and weak fibre–matrix bonding. Porosity increased from 4.60 mm2 (0% fibre dosage) to 12.34 mm2 (1% fibre dosage) with larger voids undermining strength.

- The ternary binder (50% GGBS + 5% silica fume) reduced embodied carbon by 49.5%, from 718.4 to 362.9 kg CO2-e/m3, confirming binder composition as the dominant environmental factor.

- A 0.25–0.5% cellulose fibre dosage is identified as optimal, which can provide the best balance of fresh state properties, compressive strength and sustainability. Higher dosages compromise printability through excessive rheological resistance, porosity and flexural strength loss.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jindal, B.B.; Jangra, P. 3D Printed Concrete: A comprehensive review of raw material’s properties, synthesis, performance, and potential field applications. Constr. Build. Mater. 2023, 387, 131614. [Google Scholar] [CrossRef]

- Khan, M.; McNally, C. Recent developments on low carbon 3D printing concrete: Revolutionizing construction through innovative technology. Clean. Mater. 2024, 12, 100251. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Zou, S.; Zhou, X. Anisotropic behavior in bending of 3D printed concrete reinforced with fibers. Compos. Struct. 2020, 254, 112808. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, Q.; Lombois-Burger, H.; Jia, Z.; Zhang, Z.; Niu, G.; Zhang, Y. Pore structure, internal relative humidity, and fiber orientation of 3D printed concrete with polypropylene fiber and their relation with shrinkage. J. Build. Eng. 2022, 61, 105250. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Zou, S.; Yu, J. Flexural properties of 3D printed fibre-reinforced concrete with recycled sand. Constr. Build. Mater. 2021, 288, 123077. [Google Scholar] [CrossRef]

- Bos, F.P.; Bosco, E.; Salet, T.A.M. Ductility of 3D printed concrete reinforced with short straight steel fibers. Virtual Phys. Prototyp. 2018, 14, 160–174. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, C.; Gao, Z.; Wang, F. A review on fracture properties of steel fiber reinforced concrete. J. Build. Eng. 2023, 67, 105975. [Google Scholar] [CrossRef]

- Hopkins, B.; Si, W.; Khan, M.; McNally, C. Recent Advancements in Polypropylene Fibre-Reinforced 3D-Printed Concrete: Insights into Mix Ratios, Testing Procedures, and Material Behaviour. J. Compos. Sci. 2025, 9, 292. [Google Scholar] [CrossRef]

- Liu, X.; Hu, J.; Guo, X. Printability and interlayer bonding property of 3D printed fiber reinforced geopolymer (3DP-FRG). J. Build. Eng. 2024, 87, 109060. [Google Scholar] [CrossRef]

- Jiao, D.; Shi, C.; Yuan, Q.; Zhu, D.; De Schutter, G. Effects of rotational shearing on rheological behavior of fresh mortar with short glass fiber. Constr. Build. Mater. 2019, 203, 314–321. [Google Scholar] [CrossRef]

- Alami, A.H.; Olabi, A.G.; Ayoub, M.; Aljaghoub, H.; Alasad, S.; Abdelkareem, M.A. 3D Concrete Printing: Recent Progress, Applications, Challenges, and Role in Achieving Sustainable Development Goals. Buildings 2023, 13, 924. [Google Scholar] [CrossRef]

- Singh, N.; Colangelo, F.; Farina, I. Sustainable Non-Conventional Concrete 3D Printing—A Review. Sustainability 2023, 15, 10121. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, M. 3D printing geopolymers: A review. Cem. Concr. Compos. 2022, 128, 104455. [Google Scholar] [CrossRef]

- Demont, L.; Ducoulombier, N.; Mesnil, R.; Caron, J.-F. Flow-based pultrusion of continuous fibers for cement-based composite material and additive manufacturing: Rheological and technological requirements. Compos. Struct. 2021, 262, 113564. [Google Scholar] [CrossRef]

- Zhou, W.; Zhang, Y.; Ma, L.; Li, V.C. Influence of printing parameters on 3D printing engineered cementitious composites (3DP-ECC). Cem. Concr. Compos. 2022, 130, 104562. [Google Scholar] [CrossRef]

- Duan, J.; Sun, S.; Chi, S.; Hu, C.; Ling, C.; Fu, H.; Han, Z. Effect of process parameters on forming quality and flexural strength of continuous fiber reinforced cement-based 3D printed composites. Constr. Build. Mater. 2024, 438, 137241. [Google Scholar] [CrossRef]

- Gong, F.; Cheng, X.; Zhang, X.; Fang, B. Equipment design and parameters recommendation of rubber modified 3D printed asphalt in pavement maintenance. Constr. Build. Mater. 2024, 431, 136523. [Google Scholar] [CrossRef]

- Si, W.; Khan, M.; McNally, C. A Comprehensive Review of Rheological Dynamics and Process Parameters in 3D Concrete Printing. J. Compos. Sci. 2025, 9, 299. [Google Scholar] [CrossRef]

- Ahi, O.; Ertunç, Ö.; Bundur, Z.B.; Bebek, Ö. Automated flow rate control of extrusion for 3D concrete printing incorporating rheological parameters. Autom. Constr. 2024, 160, 105319. [Google Scholar] [CrossRef]

- Maroszek, M.; Rudziewicz, M.; Hutyra, A.; Dziura, P.; Hebda, M. Evaluation of 3D Concrete Printing Extrusion Efficiency. Appl. Sci. 2024, 14, 11866. [Google Scholar] [CrossRef]

- Cai, J.; Wang, J.; Zhang, Q.; Du, C.; Meloni, M.; Feng, J. State-of-the-art of mechanical properties of 3D printed concrete. Case Stud. Constr. Mater. 2024, 21, e03847. [Google Scholar] [CrossRef]

- Warsi, S.B.F.; Panda, B.; Biswas, P. Exploring fibre addition methods and mechanical properties of fibre-reinforced 3D printed concrete: A review. Dev. Built Environ. 2023, 16, 100295. [Google Scholar] [CrossRef]

- Ahmad, J.; Burduhos-Nergis, D.D.; Arbili, M.M.; Alogla, S.M.; Majdi, A.; Deifalla, A.F. A Review on Failure Modes and Cracking Behaviors of Polypropylene Fibers Reinforced Concrete. Buildings 2022, 12, 1951. [Google Scholar] [CrossRef]

- Lin, Z.; Lyu, G.; Fang, K. Carbon emissions assessment of concrete and quantitative calculation of CO2 reduction benefits of SCMs: A case study of C30-C80 ready-mixed concrete in China. Case Stud. Constr. Mater. 2025, 22, e04287. [Google Scholar] [CrossRef]

- Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Agwa, I.S. Effect of ferrosilicon and silica fume on mechanical, durability, and microstructure characteristics of ultra high-performance concrete. Constr. Build. Mater. 2022, 320, 126233. [Google Scholar] [CrossRef]

- Singh, R.P.; Vanapalli, K.R.; Cheela, V.R.S.; Peddireddy, S.R.; Sharma, H.B.; Mohanty, B. Fly ash, GGBS, and silica fume based geopolymer concrete with recycled aggregates: Properties and environmental impacts. Constr. Build. Mater. 2023, 378, 131168. [Google Scholar] [CrossRef]

- Ibrahim, K.A.; van Zijl, G.P.; Babafemi, A.J. Comparative studies of LC3- and fly ash-based blended binders in fibre-reinforced printed concrete (FRPC): Rheological and quasi-static mechanical characteristics. J. Build. Eng. 2023, 80, 108016. [Google Scholar] [CrossRef]

- Si, W.; Carr, L.; Zia, A.; Khan, M.; McNally, C. Advancing 3D Printable Concrete with Nanoclays: Rheological and Mechanical Insights for Construction Applications. J. Compos. Sci. 2025, 9, 449. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Carbonation of concrete made with high amount of fly ash and recycled concrete aggregates for utilization of CO2. J. CO2 Util. 2019, 29, 12–19. [Google Scholar] [CrossRef]

- Si, W.; Khan, M.; McNally, C. Effect of nano silica with high replacement of GGBS on enhancing mechanical properties and rheology of 3D printed concrete. Results Eng. 2025, 27, 106680. [Google Scholar] [CrossRef]

- I.S. EN 197-1:2011; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common. National Standards Authority of Ireland: Dublin, Ireland, 2011.

- I.S. EN 15167-1:2006; Ground Granulated Blast Furnace Slag for Use in Concrete, Mortar and Grout—Part 1: Definitions, Specifications and Conformity Criteria. National Standards Authority of Ireland: Dublin, Ireland, 2016.

- I.S. EN 13263-1:2005+A1:2009; Silica Fume for Concrete—Part 1: Definitions, Requirements and Conformity Criteria. National Standards Authority of Ireland: Dublin, Ireland, 2009.

- I.S. EN 196-1:2016; Methods of Testing Cement—Part 1: Determination of Strength. National Standards Authority of Ireland: Dublin, Ireland, 2016.

- I.S. EN 934-2:2009+A1:2012; Admixtures for Concrete, Mortar and Grout—Part 2: Concrete Admixtures—Definitions, Requirements, Conformity, Marking and Labelling. National Standards Authority of Ireland: Dublin, Ireland, 2012.

- ASTM C230/C230M-20; Standard Specification for Flow Table for Use in Tests of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2020.

- Li, Q.; Fan, Y.; Shah, S.P. Rheological Properties and Structural Build-Up of Cement Based Materials with Addition of Nanoparticles: A Review. Buildings 2022, 12, 2219. [Google Scholar] [CrossRef]

- Mezger, T.G. The Rheology Handbook; No. 9783748600367; Vincentz Network: Hannover, Germany, 2012. [Google Scholar]

- I.S. EN 1015-11:2019; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. National Standards Authority of Ireland: Dublin, Ireland, 2019.

- Ivanova, I.; Mechtcherine, V. Possibilities and challenges of constant shear rate test for evaluation of structural build-up rate of cementitious materials. Cem. Concr. Res. 2020, 130, 105974. [Google Scholar] [CrossRef]

- Yuan, Q.; Zhou, D.; Khayat, K.H.; Feys, D.; Shi, C. On the measurement of evolution of structural build-up of cement paste with time by static yield stress test vs. small amplitude oscillatory shear test. Cem. Concr. Res. 2017, 99, 183–189. [Google Scholar] [CrossRef]

- Rahman, M.; Baluch, M.; Malik, M. Thixotropic behavior of self compacting concrete with different mineral admixtures. Constr. Build. Mater. 2014, 50, 710–717. [Google Scholar] [CrossRef]

- Feys, D.; De Schutter, G.; Verhoeven, R. Parameters influencing pressure during pumping of self-compacting concrete. Mater. Struct. 2013, 46, 533–555. [Google Scholar] [CrossRef]

- Perrot, A.; Lecompte, T.; Khelifi, H.; Brumaud, C.; Hot, J.; Roussel, N. Yield stress and bleeding of fresh cement pastes. Cem. Concr. Res. 2012, 42, 937–944. [Google Scholar] [CrossRef]

- Lee, K.-W.; Lee, H.-J.; Choi, M.-S. Correlation between thixotropic behavior and buildability for 3D concrete printing. Constr. Build. Mater. 2022, 347, 128498. [Google Scholar] [CrossRef]

- Jayathilakage, R.; Rajeev, P.; Sanjayan, J. Rheometry for Concrete 3D Printing: A Review and an Experimental Comparison. Buildings 2022, 12, 1190. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Hussain, A.; Chu, S. Effect of silica-fume content on performance of CaCO3 whisker and basalt fiber at matrix interface in cement-based composites. Constr. Build. Mater. 2021, 300, 124046. [Google Scholar] [CrossRef]

- Wu, Z.; Khayat, K.H.; Shi, C. Changes in rheology and mechanical properties of ultra-high performance concrete with silica fume content. Cem. Concr. Res. 2019, 123, 105786. [Google Scholar] [CrossRef]

- Hanratty, N.; Khan, M.; McNally, C. The Role of Different Clay Types in Achieving Low-Carbon 3D Printed Concretes. Buildings 2024, 14, 2194. [Google Scholar] [CrossRef]

- Mohan, M.K.; Rahul, A.; Van Tittelboom, K.; De Schutter, G. Rheological and pumping behaviour of 3D printable cementitious materials with varying aggregate content. Cem. Concr. Res. 2021, 139, 106258. [Google Scholar] [CrossRef]

- Jiao, D.; Shi, C.; Yuan, Q.; An, X.; Liu, Y.; Li, H. Effect of constituents on rheological properties of fresh concrete—A review. Cem. Concr. Compos. 2017, 83, 146–159. [Google Scholar] [CrossRef]

- Dong, D.; Huang, Y.; Pei, Y.; Zhang, X.; Cui, N.; Zhao, P.; Hou, P.; Lu, L. Effect of spherical silica fume and fly ash on the rheological property, fluidity, setting time, compressive strength, water resistance and drying shrinkage of magnesium ammonium phosphate cement. J. Build. Eng. 2023, 63, 105484. [Google Scholar] [CrossRef]

- Roussel, N.; Ovarlez, G.; Garrault, S.; Brumaud, C. The origins of thixotropy of fresh cement pastes. Cem. Concr. Res. 2012, 42, 148–157. [Google Scholar] [CrossRef]

- Panda, B.; Unluer, C.; Tan, M.J. Investigation of the rheology and strength of geopolymer mixtures for extrusion-based 3D printing. Cem. Concr. Compos. 2018, 94, 307–314. [Google Scholar] [CrossRef]

- Mao, Y.; Jiao, D.; Hu, X.; Jiang, Z.; Shi, C. Effect of dispersion behavior of silica fume on the rheological properties and early hydration characteristics of ultra-high strength mortar. Cem. Concr. Compos. 2024, 152, 105654. [Google Scholar] [CrossRef]

- Peters, S.J.; Rushing, T.S.; Landis, E.N.; Cummins, T.K. Nanocellulose and Microcellulose Fibers for Concrete. Transp. Res. Rec. J. Transp. Res. Board 2010, 2142, 25–28. [Google Scholar] [CrossRef]

- Masoudzadeh, F.; Fasihi, M.; Jamshidi, M. The influence of cellulose pulp and cellulose microfibers on the flexural performance of green-engineered cementitious composites. J. Part. Sci. Technol. 2017, 3, 33–40. [Google Scholar] [CrossRef]

- Hoyos, C.G.; Cristia, E.; Vázquez, A. Effect of cellulose microcrystalline particles on properties of cement based composites. Mater. Des. 2013, 51, 810–818. [Google Scholar] [CrossRef]

- Fasihi, A.; Libre, N.A. Interaction between material and process parameters during 3D concrete extrusion process. Structures 2024, 70, 107678. [Google Scholar] [CrossRef]

- Nerella, V.; Näther, M.; Iqbal, A.; Butler, M.; Mechtcherine, V. Inline quantification of extrudability of cementitious materials for digital construction. Cem. Concr. Compos. 2019, 95, 260–270. [Google Scholar] [CrossRef]

- Kilic, U.; Ma, J.; Baharlou, E.; Ozbulut, O.E. Effects of viscosity modifying admixture and nanoclay on fresh and rheo-viscoelastic properties and printability characteristics of cementitious composites. J. Build. Eng. 2023, 70, 106355. [Google Scholar] [CrossRef]

- Chen, Y.; Figueiredo, S.C.; Yalçinkaya, Ç.; Çopuroğlu, O.; Veer, F.; Schlangen, E. The Effect of Viscosity-Modifying Admixture on the Extrudability of Limestone and Calcined Clay-Based Cementitious Material for Extrusion-Based 3D Concrete Printing. Materials 2019, 12, 1374. [Google Scholar] [CrossRef]

- Zhang, C.; Deng, Z.; Chen, C.; Zhang, Y.; Mechtcherine, V.; Sun, Z. Predicting the static yield stress of 3D printable concrete based on flowability of paste and thickness of excess paste layer. Cem. Concr. Compos. 2022, 129, 104494. [Google Scholar] [CrossRef]

- De Vlieger, J.; Blaakmeer, J.; Gruyaert, E.; Cizer, Ö. Assessing static and dynamic yield stress of 3D printing mortar with recycled sand: Influence of sand geometry, fineness modulus, and water-to-binder ratio. J. Build. Eng. 2025, 101, 111827. [Google Scholar] [CrossRef]

- Nair, S.A.; Panda, S.; Santhanam, M.; Sant, G.; Neithalath, N. A critical examination of the influence of material characteristics and extruder geometry on 3D printing of cementitious binders. Cem. Concr. Compos. 2020, 112, 103671. [Google Scholar] [CrossRef]

- Jayathilakage, R.; Rajeev, P.; Sanjayan, J. Yield stress criteria to assess the buildability of 3D concrete printing. Constr. Build. Mater. 2020, 240, 117989. [Google Scholar] [CrossRef]

- Chen, M.; Yang, L.; Zheng, Y.; Huang, Y.; Li, L.; Zhao, P.; Wang, S.; Lu, L.; Cheng, X. Yield stress and thixotropy control of 3D-printed calcium sulfoaluminate cement composites with metakaolin related to structural build-up. Constr. Build. Mater. 2020, 252, 119090. [Google Scholar] [CrossRef]

- Moeini, M.A.; Hosseinpoor, M.; Yahia, A. 3D printing of cement-based materials with adapted buildability. Constr. Build. Mater. 2022, 337, 127614. [Google Scholar] [CrossRef]

- Liu, Z.; Li, M.; Weng, Y.; Wong, T.N.; Tan, M.J. Mixture Design Approach to optimize the rheological properties of the material used in 3D cementitious material printing. Constr. Build. Mater. 2019, 198, 245–255. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, Y.; Pan, T.; Yin, K. The Synergistic Effect of Ester-Ether Copolymerization Thixo-Tropic Superplasticizer and Nano-Clay on the Buildability of 3D Printable Cementitious Materials. Materials 2021, 14, 4622. [Google Scholar] [CrossRef] [PubMed]

- EN 15804:2012+A2:2019; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. European Committee for Standardization: Brussels, Belgium, 2019.

- ISO 21930:2017; Sustainability in Buildings and Civil Engineering Works—Core Rules for Environmental Product Declarations of Construction Products and Services. International Organization for Standardization: Geneva, Switzerland, 2017.

| Mix No. | Mix Name | Cement/b | GGBS/b | SF/b | w/b | s/b | SP/b | Micro-Fibre/vol |

|---|---|---|---|---|---|---|---|---|

| 1 | Cement Control | 1 | 0 | 0 | 0.26 | 1 | 0.02 | 0.00% |

| 2 | 0% Microfibre + SF | 0.45 | 0.5 | 0.05 | 0.26 | 1 | 0.02 | 0.00% |

| 3 | 0.25% Microfibre + SF | 0.45 | 0.5 | 0.05 | 0.26 | 1 | 0.02 | 0.25% |

| 4 | 0.5% Microfibre + SF | 0.45 | 0.5 | 0.05 | 0.26 | 1 | 0.02 | 0.50% |

| 5 | 0.75% Microfibre + SF | 0.45 | 0.5 | 0.05 | 0.26 | 1 | 0.02 | 0.75% |

| 6 | 1% Microfibre + SF | 0.45 | 0.5 | 0.05 | 0.26 | 1 | 0.02 | 1.00% |

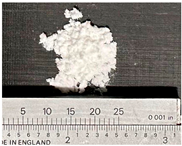

| Fibre Type | Length | Diameter | Aspect Ratio | Density | Chemical Concentration (% w/w) | Appearance |

|---|---|---|---|---|---|---|

| Cellulose fibres | 200 μm | 20 μm | 10 | 1.5 kg/m3 | ≥80 |  |

| Ref. | Mix Design | Dynamic Yield Stress (Pa) | Static Yield Stress (Pa) | Plastic Viscosity (Pa·s) |

|---|---|---|---|---|

| [62] | Adjusted VMA Cement:Limestone:Calcined Clay = 0.4:0.4:0.2 | 400–900 | 1000–3000 (by 25–45 min) | 40–120 |

| [63] | Adjusted Nano silica and sand content | 300–1200 | 500–2500 | 5–20 |

| [59] | Adjusted water to binder ratio and silica fume content | 108–263 | —— | 5.1–16.4 |

| [60] | With microsilica and finer sand replacement | 306/643 | —— | 5.3–5.8 |

| [64] | Adjusted water to binder ratio and recycled sand content | 218–1105 (printable: 400–800) | 298–9000 (printable: 500–2600) | —— |

| [61] | Calcium sulfoaluminate (CSA) cement adjusted VMA and NC contents | 73–935 (printable: 300–900) | 86–4240 (printable: 1000–4200) | 351–2361 (relative scale) |

| [65] | Adjusted admixture type and content (flay ash, limestone and microsilica) | 50–300 | —— | 0.2–1.0 |

| Ref. | Mix Design | Static Yield Stress (Pa) | Plastic Viscosity (Pa·s) | Thixotropy |

|---|---|---|---|---|

| [67] | Adjusted Metakaolin content in CSA cement | 500–1500 at 25 min | 2.41–2.56 Pa·s | Hysteresis area: 15–3.5 × 104 Pa/s; Viscosity recovery degree > 60–70% |

| [68] | Adjusted additives content (NC, fly ash, silica fume) | 1000–2500 | 5–7.5 Pa·s | Structuration rate: 0.54–2.34 kPa/min |

| [45] | Adjusted sand to binder ratio | 1000–2000 | —— | Hysteresis area: 20–30 kPa/s Buildup ratio: 0.77–0.81 |

| [70] | Adjusted NC and admixtures | 1200–1700 | 1.6–2.6 Pa·s | Rate of static yield stress evolution: 1.0–2.0 Pa/s |

| [66] | Time-dependent rheological properties (0–60 min) | 1200–2000 | —— | Structuration rate: 0.02 kPa/min |

| Constituent | Cement | GGBS | Sand | SP | SF |

|---|---|---|---|---|---|

| Carbon factor | 678 | 34 | 33 | 369 | 7.6 |

| Mix | kg CO2-e/m3 | Reduction (%) |

|---|---|---|

| 100% Cement (M1) | 718.4 | - |

| 50% GGBS/45% Cement/5% Silica Fume (M2) | 362.9 | 49.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Si, W.; Hopkins, B.; Khan, M.; McNally, C. Towards Sustainable Mortar: Optimising Sika-Fibre Dosage in Ground Granulated Blast Furnace Slag (GGBS) and Silica Fume Blends for 3D Concrete Printing. Buildings 2025, 15, 3436. https://doi.org/10.3390/buildings15193436

Si W, Hopkins B, Khan M, McNally C. Towards Sustainable Mortar: Optimising Sika-Fibre Dosage in Ground Granulated Blast Furnace Slag (GGBS) and Silica Fume Blends for 3D Concrete Printing. Buildings. 2025; 15(19):3436. https://doi.org/10.3390/buildings15193436

Chicago/Turabian StyleSi, Wen, Ben Hopkins, Mehran Khan, and Ciaran McNally. 2025. "Towards Sustainable Mortar: Optimising Sika-Fibre Dosage in Ground Granulated Blast Furnace Slag (GGBS) and Silica Fume Blends for 3D Concrete Printing" Buildings 15, no. 19: 3436. https://doi.org/10.3390/buildings15193436

APA StyleSi, W., Hopkins, B., Khan, M., & McNally, C. (2025). Towards Sustainable Mortar: Optimising Sika-Fibre Dosage in Ground Granulated Blast Furnace Slag (GGBS) and Silica Fume Blends for 3D Concrete Printing. Buildings, 15(19), 3436. https://doi.org/10.3390/buildings15193436