Design Strategies for Modular Demountable Building Products Oriented to Design for Manufacturing and Assembly: A Case Study of M-Box1.0

Abstract

1. Introduction

1.1. Research Background

1.2. Literature Review

1.2.1. Building Products Design for DFMA

1.2.2. Modular Demountable Buildings

1.3. Research Purpose and Structure

2. Methods

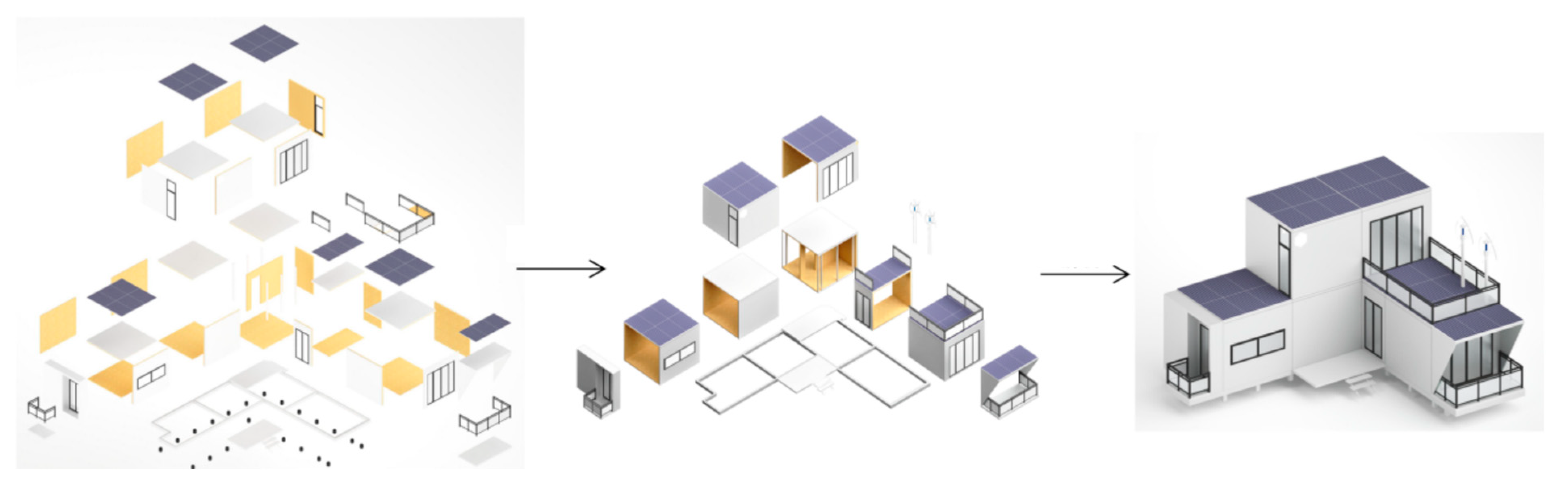

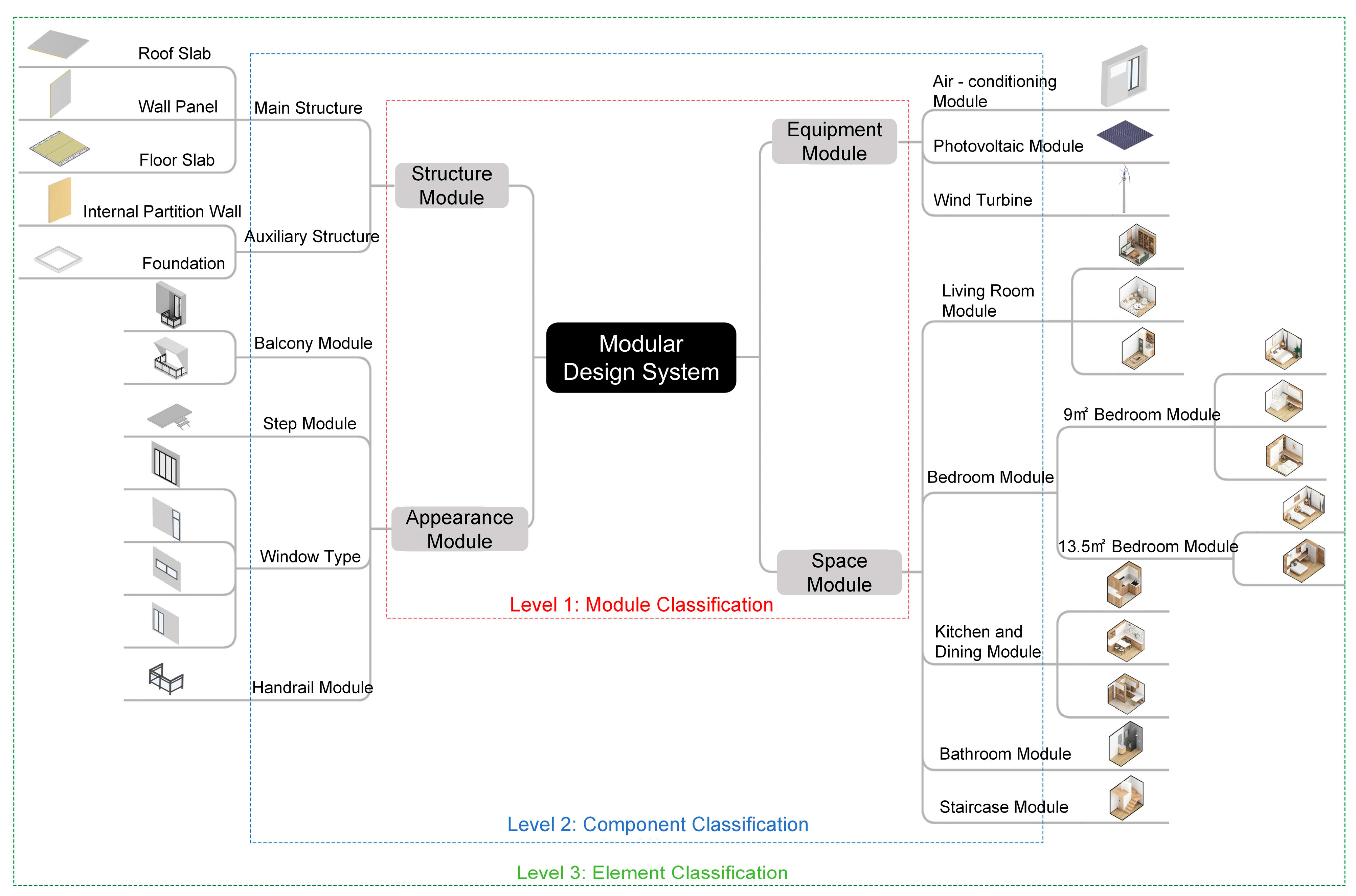

2.1. Product System Modularization

2.2. Rationalization of Assembly Methods

2.3. Optimized Design of Logistics and Transportation

2.4. Component Integration

3. DFMA-Oriented Design Practice of M-Box1.0

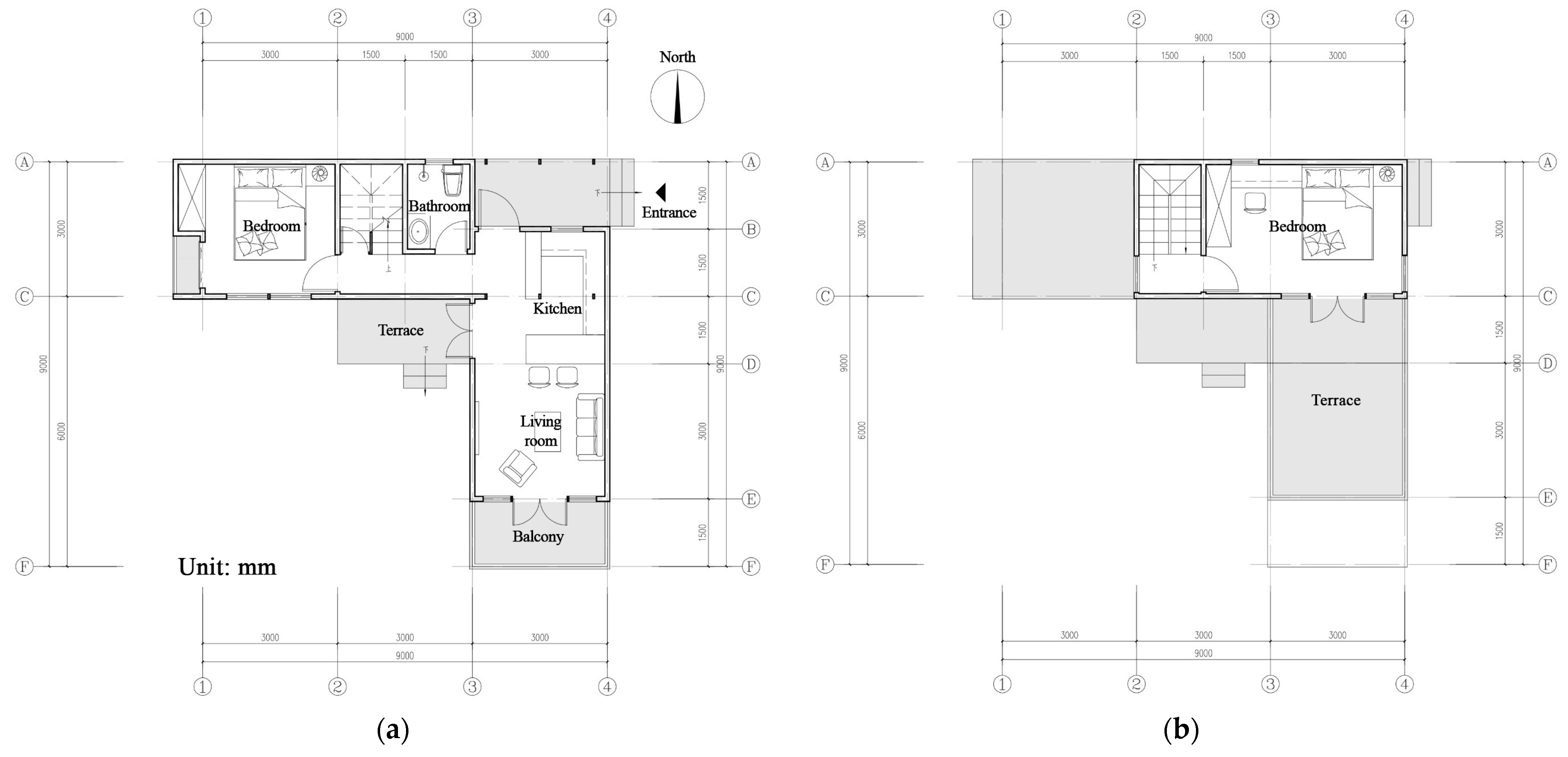

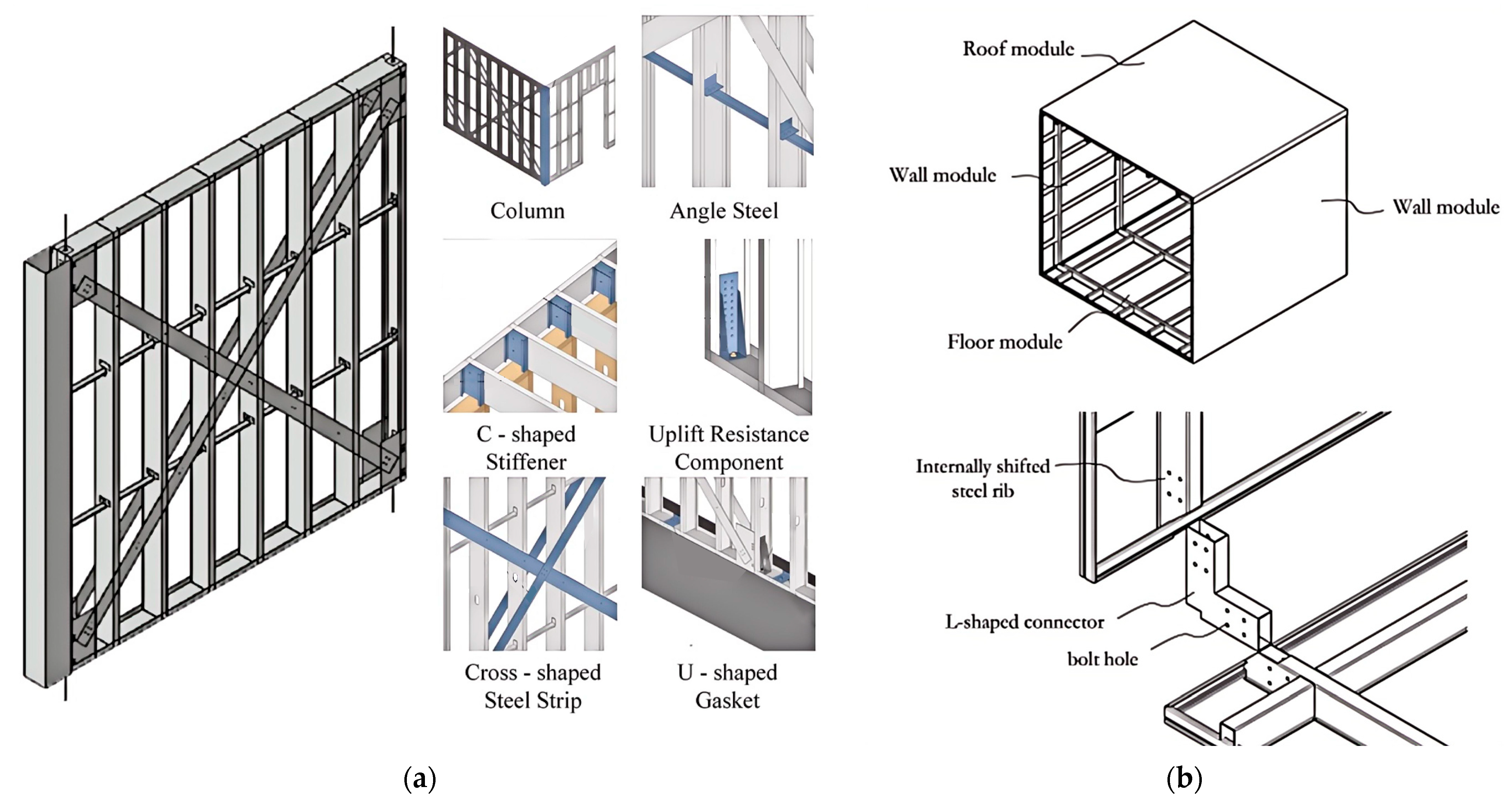

3.1. Modular Design of the Product System

3.2. Rationalized Design of Assembly Methods

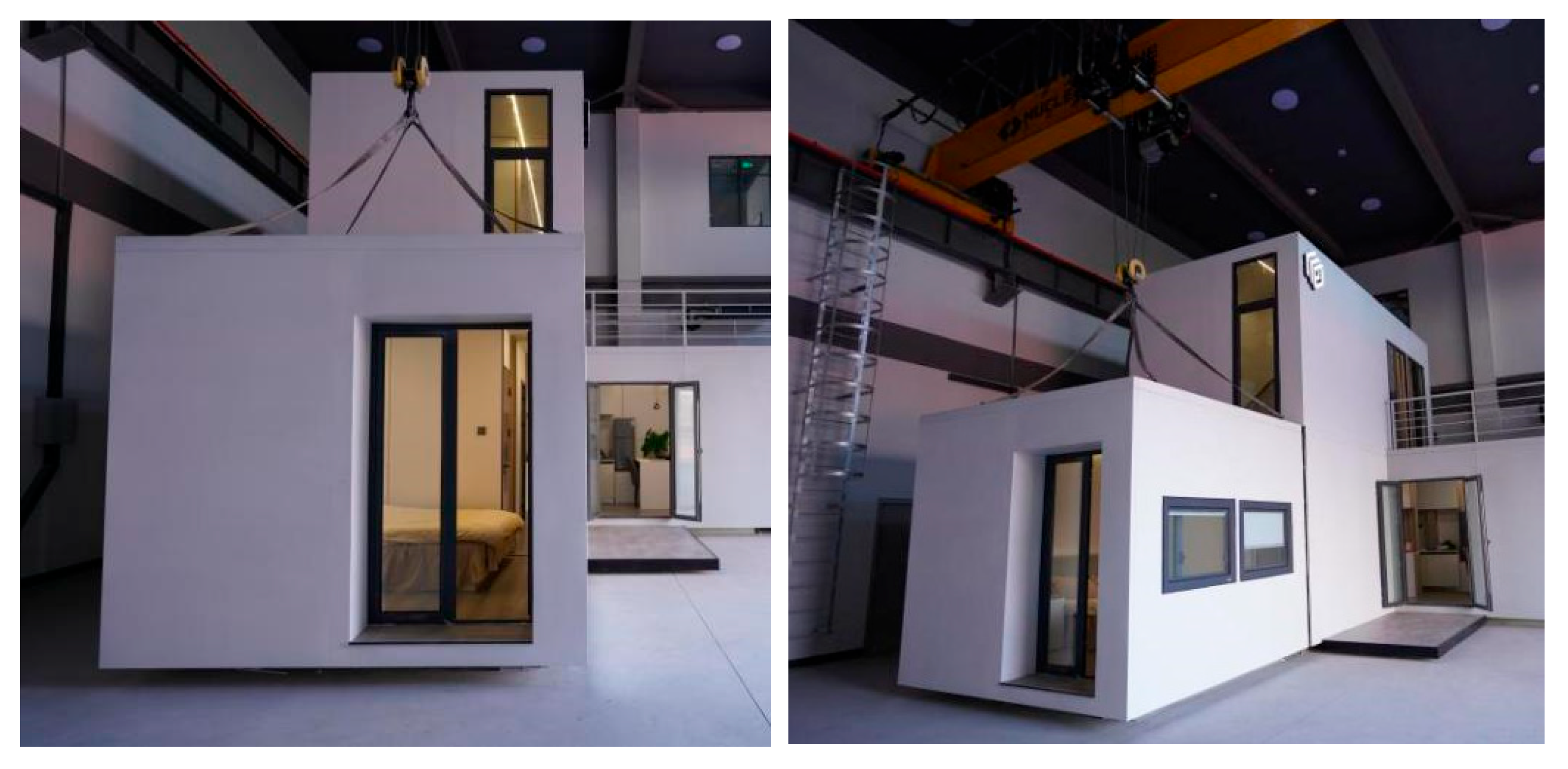

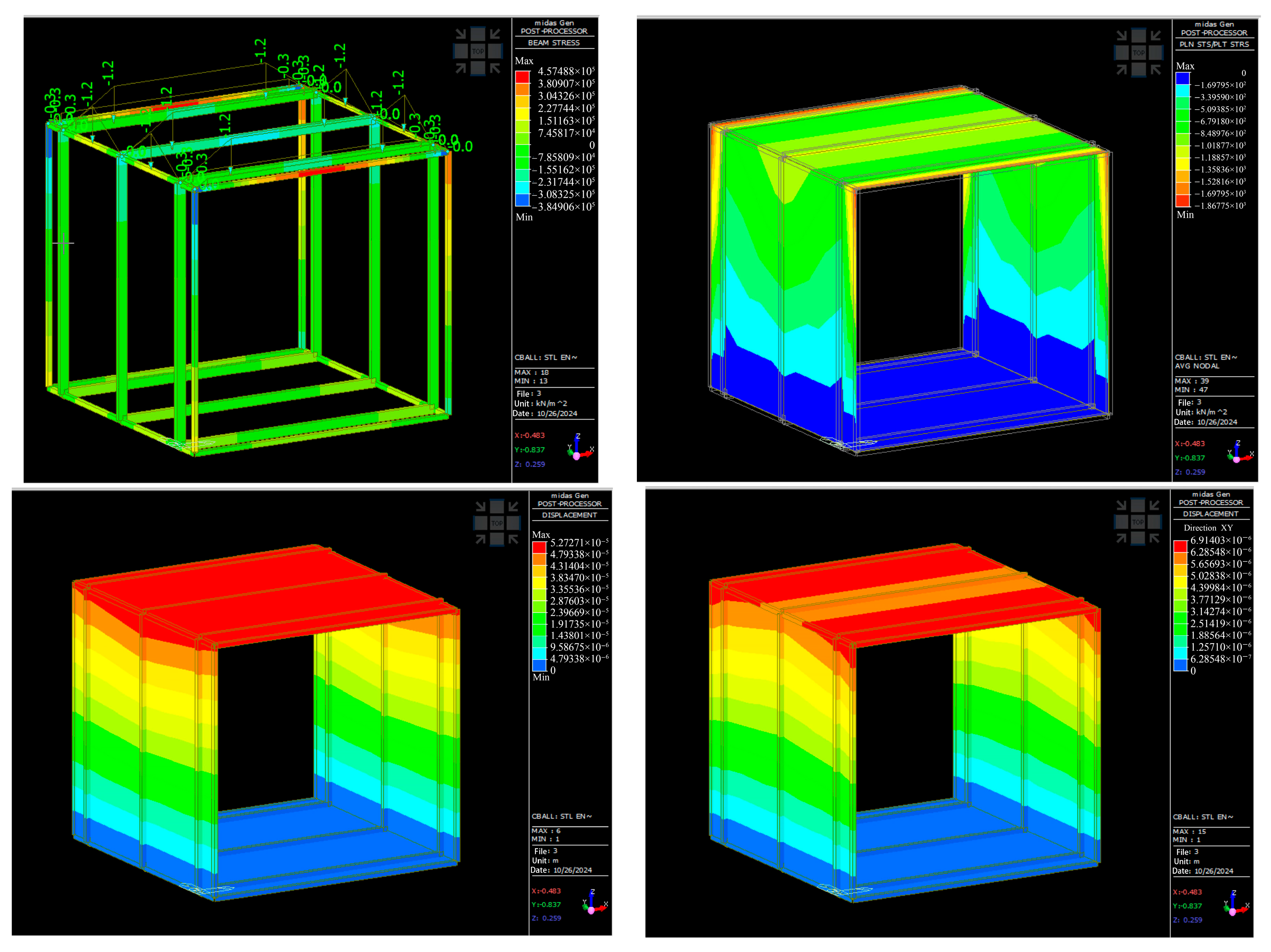

3.2.1. Optimization of Connection Nodes and Hoisting Design for Assembly Convenience

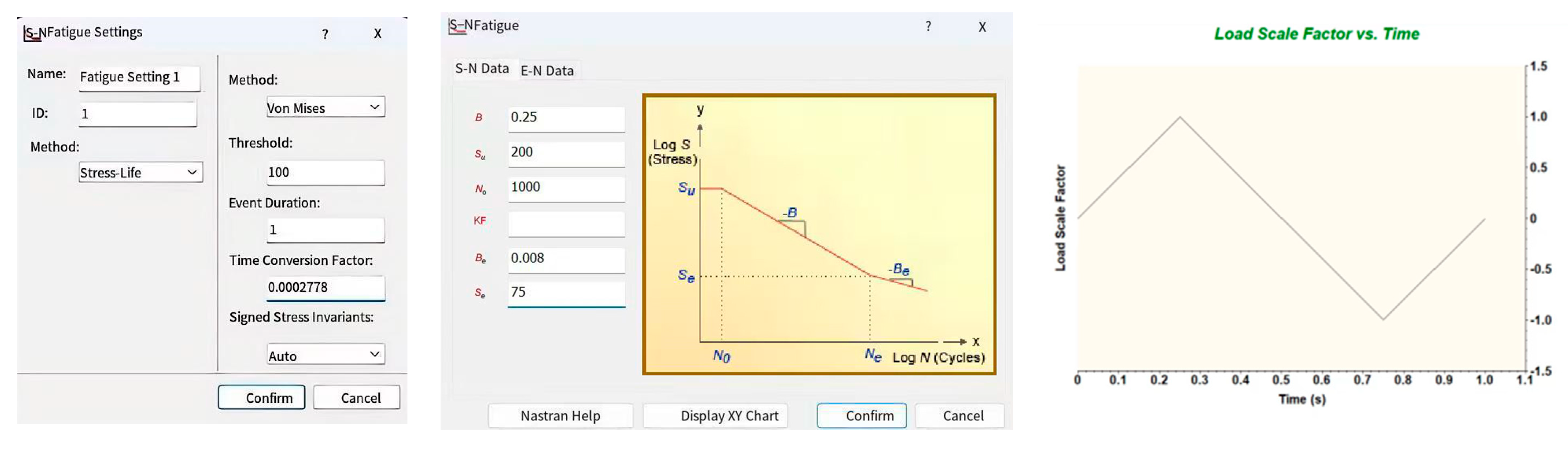

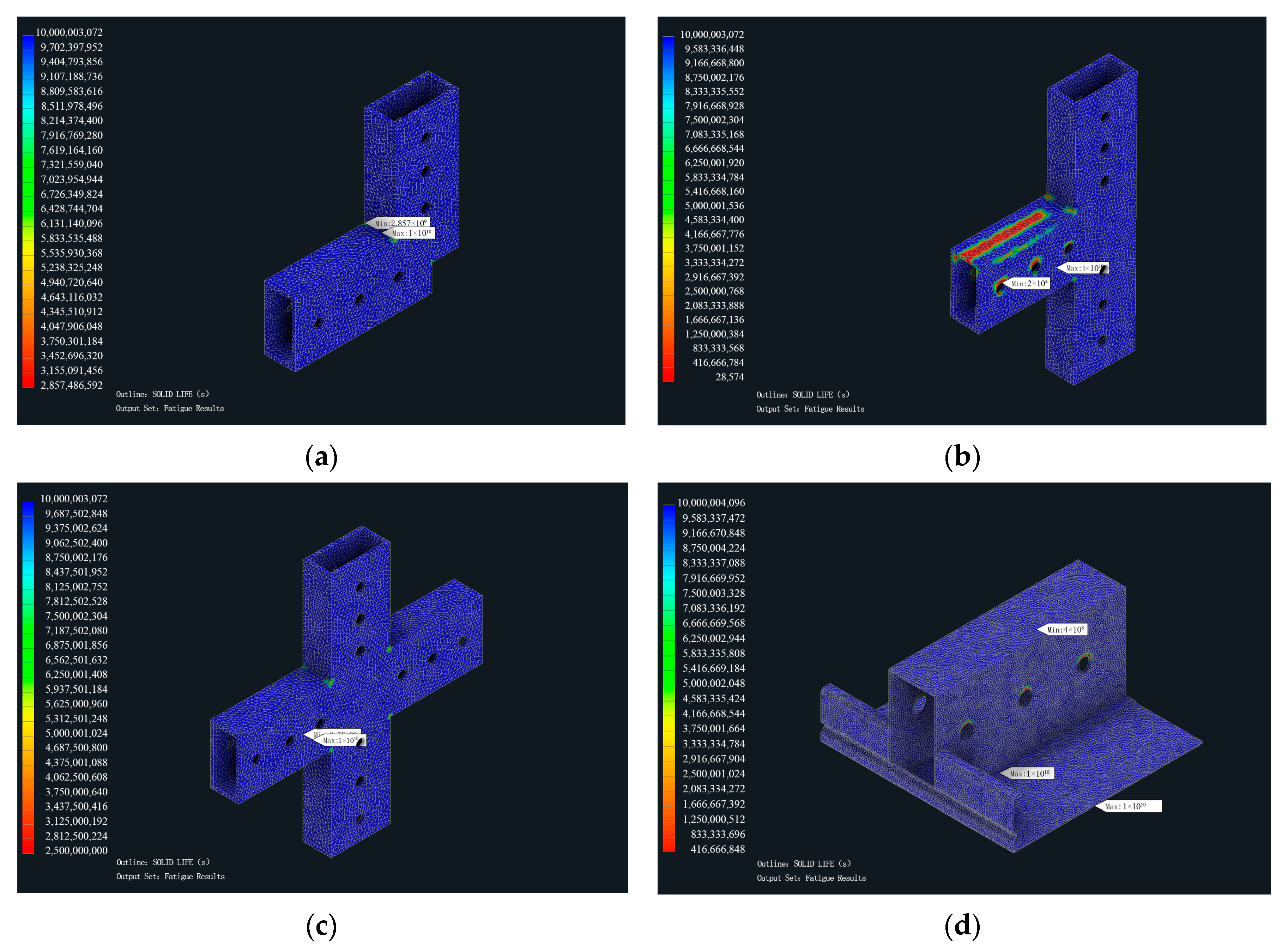

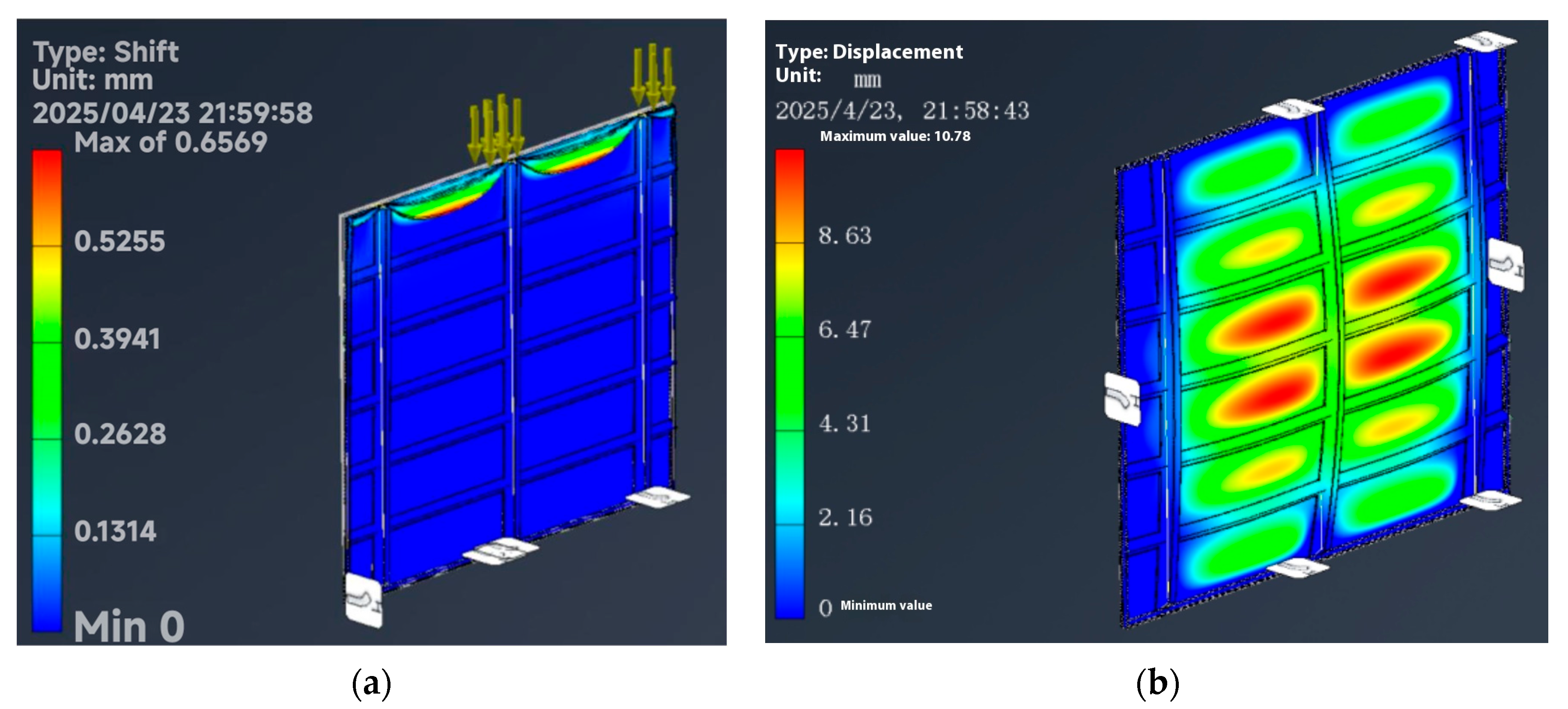

3.2.2. Fatigue Analysis of Demountable Parts to Ensure Structural Durability

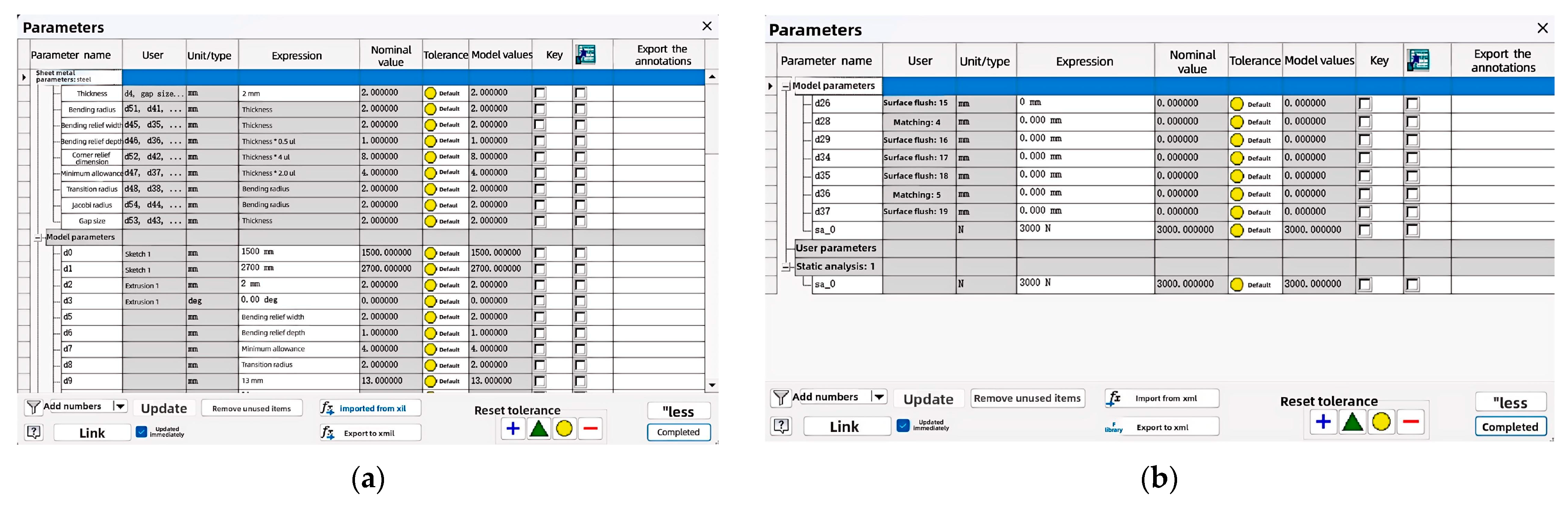

3.2.3. Inventor Modeling for Accurate Control of Design Errors

3.3. Logistics and Transportation Optimization

3.3.1. Design of Disassembled Sheet Transportation to Improve Loading Efficiency

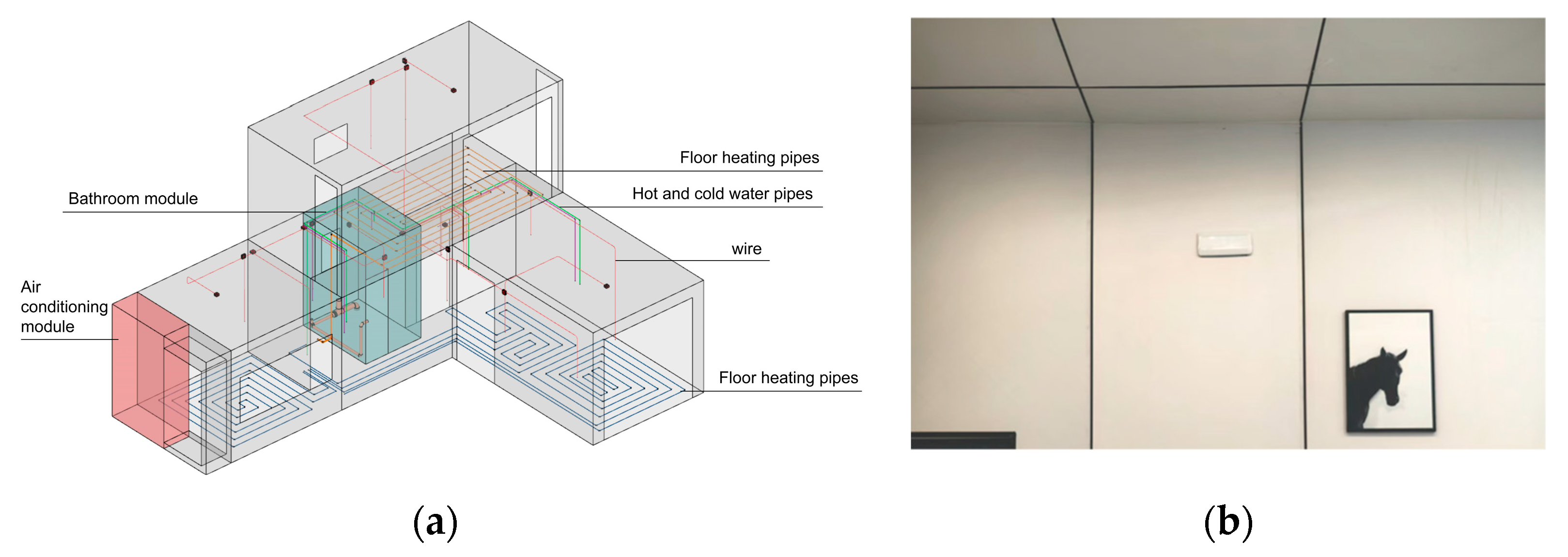

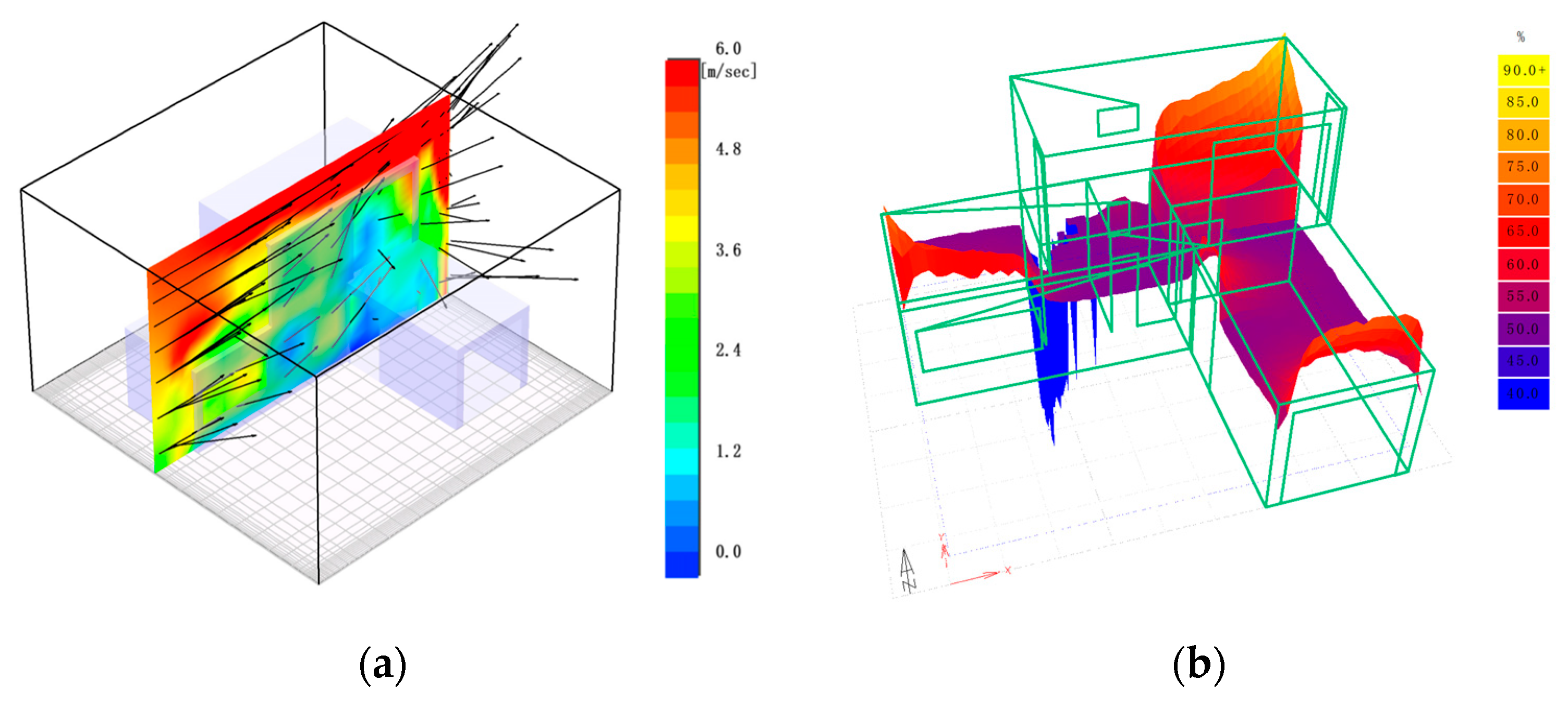

3.3.2. Integrated Design of Plumbing, Electrical, and HVAC

3.4. Integrated Design of Components

3.4.1. Design of “Exoskeleton” Structure for Function Integration

3.4.2. Performance Verification of the “Exoskeleton” Structure

4. Discussion

4.1. Performance Analysis

4.2. Analysis of Module Part Count

4.3. Cost Analysis

4.4. Sustainability

- 1.

- The carbon emission formula for material preparation is:

- 2.

- The carbon emission formula for component production is:

- 3.

- The carbon emission formula for transportation is:

- 4.

- The carbon emission formula for component assembly is:

- 5.

- The carbon emission reduction formula for clean energy is:

- 6.

- The carbon emission formula for building system energy consumption is:

5. Conclusions

- Expanding application scenarios to high-rise buildings, public buildings, and buildings in extreme environments, and testing the adaptability of DFMA strategies in complex structures;

- Establish a long-term performance monitoring system to track the structural performance, thermal insulation, and waterproof durability throughout the life cycle;

- Optimize recycling technology, develop intelligent disassembly equipment and component health assessment tools, and improve material reuse efficiency;

- Deepen digital integration, explore the combination of DFMA, parametric design, and machine learning, and realize the automatic optimization of modular systems.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DFMA | Design for Manufacturing and Assembly |

| IEA | International Energy Agency |

References

- Maiorino, A.; Petruzziello, F.; Grilletto, A.; Aprea, C. Kinetic energy harvesting for enhancing sustainability of refrigerated transportation. Appl. Energy 2024, 364, 123145. [Google Scholar] [CrossRef]

- Ma, X.; Wang, C.; Dong, B.; Gu, G.; Chen, R.; Li, Y.; Zou, H.; Zhang, W.; Li, Q. Carbon emissions from energy consumption in China: Its measurement and driving factors. Sci. Total Environ. 2018, 648, 1411–1420. [Google Scholar] [CrossRef]

- Cui, H.; Cao, Y. Low-carbon city construction, spatial spillovers and greenhouse gas emission performance: Evidence from Chinese cities. Journal of environmental management. J. Environ. Manag. 2024, 355, 120405. [Google Scholar] [CrossRef]

- Yang, Z.; Gao, W.; Han, Q.; Qi, L.; Cui, Y.; Chen, Y. Digitalization and carbon emissions: How does digital city construction affect China’s carbon emission reduction? Sustain. Cities Soc. 2022, 87, 104201. [Google Scholar] [CrossRef]

- Citaristi, I. International Energy Agency—IEA. In The Europa Directory of International Organizations 2022; Routledge: Abingdon, UK, 2022. [Google Scholar] [CrossRef]

- Chen, Y.S.; Wu, J.W. Component circulation: Dismantlable building design from product to thinking. Archit. J. 2024, S01, 172–177. [Google Scholar]

- Tuvayanond, W.; Prasittisopin, L. Design for Manufacture and Assembly of Digital Fabrication and Additive Manufacturing in Construction: A Review. Buildings 2023, 13, 429. [Google Scholar] [CrossRef]

- Montazeri, S.; Odo, N.; Naqvi, S.A.W.; Lei, Z. Integrating Design for Manufacturing and Assembly Principles in Modular Home Construction: A Comprehensive Framework for Enhanced Efficiency and Sustainability. Buildings 2024, 15, 103. [Google Scholar] [CrossRef]

- Gao, S.; Jin, R.Y.; Lu, W.S. Design for manufacture and assembly in construction: A review. Build. Res. Inf. 2019, 48, 538–550. [Google Scholar] [CrossRef]

- Boothroyd, G. Product Design for Manufacture and Assembly. Comput.-Aided Des. 1994, 7, 505–520. [Google Scholar] [CrossRef]

- Cao, J.; Vakaj, E.; Soman, R.K.; Hall, D.M. Ontology-based manufacturability analysis automation for industrialized construction. Autom. Constr. 2022, 139, 104277. [Google Scholar] [CrossRef]

- Han, D.C.; Yin, H.X.; Qu, M.; Zhu, J.; Wang, C. Research on design strategies for manufacturing and assembly oriented to customized prefabricated buildings—A case study of Lotus Residence. J. West. Resid. Environ. 2022, 37, 30–35. [Google Scholar]

- Chen, G.; Dong, D.D.; Jiang, Y.B.; Wang, W. BIM parametric design of components for a metro parking lot oriented to DFMA. Exp. Technol. Manag. 2024, 41, 135–142. [Google Scholar]

- Cong, M.; Zhang, H. Transformation of design and construction—Research and development of movable aluminum alloy building products. Archit. Cult. 2014, 11, 143–144. [Google Scholar]

- Yang, Z.; Lu, W. Facility layout design for modular construction manufacturing: A comparison based on simulation and optimization. Autom. Constr. 2022, 147, 104713. [Google Scholar] [CrossRef]

- China’s Construction Waste Output Is Increasingly Serious but with Low Resource Utilization Rate. Legal Daily, 10 January 2023. Available online: http://www.ce.cn/cysc/stwm/gd/202009/24/t20200924_35806871.shtml (accessed on 10 January 2023).

- Sandagomika, H.; Salehi, S.; Arashpour, M. Hybrid Life Cycle Assessment (LCA) of prefabrication: A comparison of conventional and mixed reality-based solutions. J. Clean. Prod. 2024, 450, 141883. [Google Scholar] [CrossRef]

- Arshad, H.; Zayed, T.; Bakhtawar, B.; Chen, A.; Li, H. Damage assessment of modular integrated construction during transport and assembly using a hybrid CNN–Gated recurrent unit model. Autom. Constr. 2025, 174, 106136. [Google Scholar] [CrossRef]

- Yang, Y.; Pan, M.; Pan, W.; Zhang, Z. Sources of Uncertainties in Offsite Logistics of Modular Construction for High-Rise Building Projects. J. Manag. Eng. 2021, 37, 04021011. [Google Scholar] [CrossRef]

- Yevu, S.K.; Blay, K.B.; Ayinla, K.; Hadjidemetriou, G. Artificial intelligence in offsite and modular construction research. Autom. Constr. 2025, 171, 105994. [Google Scholar] [CrossRef]

- Zhang, Y.; Pan, W.; Teng, Y.; Chen, S. Construction Waste Reduction in Buildings through Modular and Offsite Construction. J. Manag. Eng. 2024, 40, 04024026. [Google Scholar] [CrossRef]

- Zhang, Y.; Lei, Z.; Han, S.; Bouferguene, A.; Al-Hussein, M. Process-Oriented Framework to Improve Modular and Offsite Construction Manufacturing Performance. J. Constr. Eng. Manag. 2020, 146, 04020116. [Google Scholar] [CrossRef]

- Yan, H.L.; Luo, D. Discussion on dismantlable buildings. House Sci. 2015, 35, 24–28. [Google Scholar] [CrossRef]

- Liu, C.; Song, Y.; Li, R.; Ma, W.; Hao, J.L.; Qiang, G. Three-level modular grid system for sustainable construction of industrialized residential buildings: A case study in China. J. Clean. Prod. 2023, 395, 136379. [Google Scholar] [CrossRef]

- Hu, F.P. Application analysis of construction technology for dismantlable dry-hanging stone curtain walls. Res. Hous. 2022, 29–31. [Google Scholar]

- Cao, X.; Li, X.; Zhu, Y.; Zhang, Z. A comparative study of environmental performance between prefabricated and traditional residential buildings in China. J. Clean. Prod. 2015, 109, 131–143. [Google Scholar] [CrossRef]

- Duncheva, T.; Bradley, F.F. Multifaceted Productivity Comparison of Off-Site Timber Manufacturing Strategies in Mainland Europe and the United Kingdom. J. Constr. Eng. Manag. 2019, 145, 04019043. [Google Scholar] [CrossRef]

- Garusinghe, G.D.A.U.; Perera, B.A.K.S.; Weerapperuma, U.S. Integrating Circular Economy Principles in Modular Construction to Enhance Sustainability. Sustainability 2023, 15, 11730. [Google Scholar] [CrossRef]

- Hong, Y. A study on the condition of temporary housing following disasters: Focus on container housing. Front. Arch. Res. 2017, 6, 374–383. [Google Scholar] [CrossRef]

- Huang, B.J.; Gao, X.Y.; Xu, X.Z.; Song, J.; Geng, Y.; Sarkis, J.; Fishman, T.; Kua, H.; Nakatani, J. A Life Cycle Thinking Framework to Mitigate the Environmental Impact of Building Materials. One Earth 2020, 3, 564–573. [Google Scholar] [CrossRef]

- OPEN Architecture Office. The Detachable Space Steel Structure Design of Vanke Sales Office in Guangzhou South Station Using the HEX-SYS Hexagonal System. 2020. Available online: https://www.sohu.com/a/423413508_663589 (accessed on 9 October 2020).

- Galle, W.; Cambier, C.; De Temmerman, N. Dynamic life cycle costing of demountable buildings: A scenario-based approach. Build. Sci. 2017, 33, 12–18. [Google Scholar]

- Luca, A.; Antonio, G.; Giada, L.S.; Manuela, L.F.C.; Rosa, M. Life cycle assessment of a new industrial process for sustainable construction materials. Ecol. Indic. 2023, 148, 110042. [Google Scholar] [CrossRef]

- Labik, O.; Nahmens, I.; Ikuma, L.; Harvey, C. On-Site versus In-Factory Installation of Solar-Plus-Storage in Modular Construction. J. Constr. Eng. Manag. 2023, 149, 05023003. [Google Scholar] [CrossRef]

- Building a Villa Like “Building Blocks”: Minhang’s First “One-Day Construction” Smart Low-Carbon New House. Available online: http://m.toutiao.com/group/7487897057118716479/?upstream_biz=doubao (accessed on 14 July 2025).

- Shandong Provincial Department of Housing and Urban-Rural Development. Notice on Announcing the List of Shandong Province’s New Construction Industrialization (Green Construction) Demonstration Projects in 2023; Shandong Provincial Department of Housing and Urban-Rural Development: Jinan, China, 2023. [Google Scholar]

- PR Newswire. CIMC Modular Building Systems Wins Two International Awards in the United States. Available online: https://www.prnewswire.com/news-releases (accessed on 17 June 2025).

- Brambilla, G.; Lavagna, M.; Vasdravellis, G.; Castiglioni, C.A. Environmental benefits arising from demountable steel-concrete composite floor systems in buildings. Resour. Conserv. Recycl. 2019, 141, 133–142. [Google Scholar] [CrossRef]

- Yang, Y.; Luk, C.; Zheng, B.; Hu, Y.; Chan, A.P.-C. Disassembly and Reuse of Demountable Modular Building Systems. J. Manag. Eng. 2024, 41, 05024012. [Google Scholar] [CrossRef]

- Van Gulck, L.; Steeman, M. Life cycle assessment of demountable building elements: Influential design and use parameters. Build. Environ. 2023, 245, 110876. [Google Scholar] [CrossRef]

- Jeon, J.; Park, J.H.; Wi, S.; Yang, S.; Ok, Y.S.; Kim, S. Latent heat storage biocomposites of phase change material-biochar as feasible eco-friendly building materials. Environ. Res. 2019, 172, 637–648. [Google Scholar] [CrossRef]

- INGKA. BoKlok Comes to Britain. Ingka Group. 2021. Available online: https://www.ingka.com/newsroom/boklok-comes-to-britain/ (accessed on 14 July 2025).

- Navaratnam, S.; Satheeskumar, A.; Zhang, G.; Nguyen, K.; Venkatesan, S.; Poologanathan, K. The challenges confronting the growth of sustainable prefabricated building construction in Australia: Construction industry views. J. Build. Eng. 2022, 48, 103935. [Google Scholar] [CrossRef]

- Cong, M.; Zhang, H.; Liu, W.; Luo, S.; Wang, M.; Lyu, Y. Research on productization design method and construction management technology for industrialized rural buildings. Ind. Constr. 2024, 54, 97–109. [Google Scholar] [CrossRef]

- GB/T 228.1-2021; Metallic Materials-Tensile Testing-Part 1: Method of Test at Room Temperature. Standardization Administration of the People’s Republic of China: Beijing, China, 2021.

- GB/T 51232-2016; Technical Standard for Fabricated Steel Structure Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2016.

- GB/T 700-2017; Carbon Structural Steels. Standardization Administration of the People’s Republic of China: Beijing, China, 2017.

- GB 50009-2012; Code for Loads on Building Structures. China Architecture & Building Press: Beijing, China, 2012.

- GB/T 50344-2019; Standard for Inspection Technology of Building Structures. China Architecture & Building Press: Beijing, China, 2019.

- GB 50033-2019; Building Lighting Design Standard. China Architecture & Building Press: Beijing, China, 2019.

- Lou, N.; Qu, K.X.; Peng, M.Y.; Yi, G.H.; Ren, L.M. A Steel Module Building Based on Light Steel Structure and Its Installation Method. CN 119593494 A, 11 March 2025. [Google Scholar]

- Li, Y. Research on Construction Technology and Space Design of Steel Structure Modular Buildings. Master’s Thesis, School of Architecture and Urban Planning, Chongqing University, Chongqing, China, 2017. [Google Scholar]

- Huang, S.Z. Architectural Design of Detachable Prefabricated Steel Structure Temporary Office Buildings for Construction Sites. Master’s Thesis, Chongqing University, Chongqing, China, 2021. [Google Scholar]

- Vaz-Serra, P.; Wasim, M.; Egglestone, S. Design for manufacture and assembly: A case study for a prefabricated bathroom wet wall panel. J. Build. Eng. J. Build. Eng. 2024, 116, 108080. [Google Scholar] [CrossRef]

- Wuhan Liulangcang Architectural Technology Co., Ltd. Liulangcang. Available online: https://llrover.com/ (accessed on 26 August 2025).

- Jiangsu 303 Vessel Technology Co., Ltd. 303 Vessel. Available online: https://www.303vessel.cn/ (accessed on 26 August 2025).

- Huzhou Huji Construction Technology Co., Ltd. Huji House. Available online: http://www.hujihouse.com/ (accessed on 26 August 2025).

- Zhejiang Zhijian Meizhu Technology Co., Ltd. Prefabricated Construction. Available online: https://cn.zcamp.com/prefab-C5.html (accessed on 26 August 2025).

- Guangdong Yinneng Technology Co., Ltd. Guangdong Yinneng Technology. Available online: https://www.gdyinneng.com/ (accessed on 26 August 2025).

- Beijing Pailaisi Architectural Technology Co., Ltd. How Much Profit Is There for Steel Structure Workshops Calculated According to the Quota? (Profit Analysis of Steel Structure Workshops). Beijing Steel Structure Design-Beijing Pailaisi Architectural Technology Co., Ltd. Available online: http://www.bjbrsc.cn/about/post/138083.html (accessed on 11 August 2025).

- GB/T 51366-2019; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard for Calculation of Building Carbon Emissions; China Architecture & Building Press: Beijing, China, 2019.

- Ministry of Transport of the People’s Republic of China. Guidelines for Calculating Carbon Dioxide Emission Intensity of Operating Vehicles in the Highway and Waterway Industry; Ministry of Transport of the People’s Republic of China: Beijing, China.

- National Climate Strategy Center. 2023 Regional Power Grid Baseline Emission Factors for CCER Projects. Available online: http://www.ncsc.org.cn:8080/SY/zywj/202407/W020240709709436742308.pdf (accessed on 9 July 2024).

| Existing Modular Steel Structure Wall Panel Module (Single Unit) | M-Box1.0 Wall Panel Module (Single Unit) | ||||

|---|---|---|---|---|---|

| Detailed Category | Specific Component | Quantity (Piece) | Detailed Category | Specific Component | Quantity (Piece) |

| Structural Components | Longitudinal Main Rib | 6 | Structural Components | “Exoskeleton” Plate | 1 |

| Transverse Main Rib | 2 | Longitudinal Main Rib | 3 | ||

| Transverse Secondary Rib | 2 | Transverse Main Rib | 10 | ||

| Square Steel Gasket | 8 | Transverse Secondary Rib | 10 | ||

| Vertical Steel Column | 2 | ||||

| Connecting Components | Angle Steel | 16 | Connecting Components | Angle Bracket | 3 |

| C-shaped Steel | 16 | ||||

| Uplift Component | 4 | ||||

| Cross Steel Strip | 4 | ||||

| U-shaped Steel | 3 | ||||

| Bolts | Self-tapping Screw | 64 | Bolts | Shear Bolt | 12 |

| Dovetail Screw | 24 | ||||

| Shear Bolt | 32 | ||||

| Prices and Classification | M-Box1.0 | |

|---|---|---|

| material cost | 1-Structure | 10 w (“exoskeleton” structure) |

| 2-Interior finishes | 1 w | |

| 3-Exterior finishes | 0.2 w (painting/filming) | |

| 4-Insulation | 1 w | |

| 5-Plumbing | 1 w | |

| 6-Kitchen and bathroom fixtures | 1.5 w | |

| 7-Photovoltaics and energy storage | 2 w | |

| labor cost | 8-Fabrication | 3 w |

| 9-Packing | 0.1 w | |

| 10-Transportation | 0.1 w | |

| 11-Assembly/building costs | 0.2 w | |

| add up the total | 20.1 w | |

| Carbon emissions during construction | Material preparation (t.CO2) | 16.2 |

| Component production (t.CO2) | 3.44 | |

| Transportation (t.CO2) | 5.08 | |

| Component assembly (t.CO2) | 1.39 | |

| Carbon emissions during operation | Clean energy (t.CO2·y) | −32.11 |

| Building system energy consumption (t.CO2·y) | 3.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Jing, Y.; Wang, J.; Mika, P.; Li, F.; Yan, Y. Design Strategies for Modular Demountable Building Products Oriented to Design for Manufacturing and Assembly: A Case Study of M-Box1.0. Buildings 2025, 15, 3424. https://doi.org/10.3390/buildings15183424

Wang M, Jing Y, Wang J, Mika P, Li F, Yan Y. Design Strategies for Modular Demountable Building Products Oriented to Design for Manufacturing and Assembly: A Case Study of M-Box1.0. Buildings. 2025; 15(18):3424. https://doi.org/10.3390/buildings15183424

Chicago/Turabian StyleWang, Meng, Yifan Jing, Jianghua Wang, Pawel Mika, Feng Li, and Yikang Yan. 2025. "Design Strategies for Modular Demountable Building Products Oriented to Design for Manufacturing and Assembly: A Case Study of M-Box1.0" Buildings 15, no. 18: 3424. https://doi.org/10.3390/buildings15183424

APA StyleWang, M., Jing, Y., Wang, J., Mika, P., Li, F., & Yan, Y. (2025). Design Strategies for Modular Demountable Building Products Oriented to Design for Manufacturing and Assembly: A Case Study of M-Box1.0. Buildings, 15(18), 3424. https://doi.org/10.3390/buildings15183424