1. Introduction

The core task of engineering structure design is to analyze the various effects that structures endure alongside their resistance capabilities. This aims to find an optimal approach for balancing safety and economy [

1]. The goal is to design structures that provide sufficient reliability using the most economical methods, ensuring they meet necessary functionalities throughout their intended lifespan [

2]. The theoretical research on structural reliability has been booming with the transition from the allowable stress design method to probability-based limit state design method [

3,

4,

5]. Freudenthal [

6,

7] first studied the intrinsic relationship between the safety factor and the failure probability of the results in the traditional design method. Cornell [

8] studied the reliability analysis method based on probability theory and gave the definition of the first-order second-moment theory of structural reliability. Lind and Hasofer [

9,

10] gave a geometric interpretation of the reliability index and introduced the concept of the design checking point to ensure that the same reliability index value can be obtained by dealing with different equivalent equations of the same failure surface. Shinozuka [

11] further proved that the design checking point is the maximum possible failure point. According to the geometric meaning of the reliability index, the iterative calculation formula of the reliability index is established using the optimization algorithm. The expression of transforming the reliability index into structural failure probability is based on the assumption that the comprehensive state variables obey a normal distribution. If the probability distribution of random variables is not considered, the accuracy of the structural reliability analysis will be insufficient. Therefore, a series of algorithms for equivalently transforming the arbitrary probability distribution of basic random variables into a normal distribution have been developed [

12,

13,

14,

15], and the first-order second-moment method is used for reliability analysis.

The first-order second-moment method is to make the first-order Taylor expansion of the structural performance function at the checking point, which does not reflect the convexity of the limit state surface and only uses the low-order statistical information of the random variable. When the degree of nonlinearity of the limit state equation is high, the reliability calculation error is large. The high-order direct moment method [

16,

17,

18] makes up for the defects of the first-order second-moment method. Many scholars consider the nonlinear characteristics of the limit state equation by means of a Taylor series high-order expansion of the performance function. In the process of calculating the failure probability, the influence of the curvature change of the performance function surface near the checking point is considered, and the reliability analysis is carried out using the high-order statistical information of the random variable. In general, it has a better calculation accuracy than the first-order second-moment method. At present, the second-order second-moment method [

19,

20,

21] and the second-order fourth-moment method [

22,

23,

24] are mainly used. The first-order second-moment method and the high-order direct moment method weaken the random propagation relationship between the structural load effect and the load action, and it is difficult to comprehensively solve the overall reliability analysis problem of the structure. Later, the response surface method was developed in the reliability analysis of the structural system [

25,

26]. However, in the analysis, it is necessary to list the surrogate model that approximates the nonlinear performance function for each key section of the structure, identify the surrogate model parameters, and combine it with the first-order second-moment method to calculate the reliability, and the analysis workload is large.

In recent years, the international community has shifted towards using probabilistic limit state design methods in structural engineering [

27]. Reliability-based probabilistic design effectively addresses engineering uncertainties, extending its application from structural to geotechnical engineering. Movahedi’s work on the reliability analysis and design optimization of laterally loaded piles demonstrates the efficacy of incorporating reliability theory into practical design contexts [

28]. The first-order second-moment method enables engineers to calculate the average resistance

of structural components

based on the statistical characteristics and distribution types of basic variables, while considering a target reliability index

. This allows for dimensioning of structural components to ensure that the failure probability

remains within an acceptable threshold

over a specified time period. This approach is termed the direct probabilistic design method [

29]. In order to facilitate the calculation of structural designs, Lind [

30] proposed the concept of the partial safety factor and introduced the root linearization coefficient to derive the partial safety factor of structural resistance and the action effect. The international structural reliability design standard ISO2394 [

31] and the European structural reliability design code EN1990 [

32] are based on this idea to determine the partial safety factor for structural design. Many scholars have established various expressions for probabilistic limit state design in different engineering structures based on reliability theory [

33,

34,

35,

36]. However, most formulations rely on the Taylor series expansion of the performance function up to the linear term at verification points, neglecting the nonlinear characteristics such as curvature of the performance function. Recent studies on enhancing the reliability design of structural components have introduced a simplified modeling strategy based on equivalent yield strength [

37]. This approach provides the essential material constitutive and mechanical models necessary to determine the load effect and resistance statistical parameters required by the second-order second-moment theory. It also aids in constructing the limit state equation. This paper addresses the current state of research on structural reliability theory and its applications. It emphasizes safety and economic considerations in engineering design. Building on the direct probabilistic design method, this study proposes a design approach that incorporates the curvature and nonlinear features of limit state surfaces near design verification points, thereby enhancing the application of approximate probabilistic design methods and providing a framework that ensures structural reliability in practical engineering designs.

2. Consider the Approximate Probability Design Theory of Limit State Surface Curvature

2.1. Mapping Transformation Method

The principle of the mapping transformation method is to utilize the mapping where the values of the cumulative distribution functions are equal. This transforms non-normally distributed random variables into normally distributed random variables. Then, the reliability index is solved using the first-order second-moment method [

38]. Assume that each component of the basic variable

of the structure is an independent non-normally distributed variable, while the probability density function of

is

, and the cumulative distribution function is

.

For each variable

, perform the following transformation to map any random variable

X to the standard normal variable

Y:

The functional expression represented by

Y is

As shown in

Figure 1, Y is established in the standard normal space; for the variable

that follows the standard normal distribution, according to the first-order Taylor series expansion of the functional function at the verification point, the expression for the structural reliability index

β can be obtained as

Define the sensitivity coefficient of the random variable

as follows:

The coordinates of the design acceptance point

in the space of standardised normal variables

Y are

The analytical expressions of some basic distributional probabilities checking point

can be found directly through Equation (2), and differentiating both sides of Equation (1) yields

It can be seen that the mapping transformation is an equal probability transformation, which ensures that the probabilities before and after the transformation are equal, and it also satisfies probability micronutrient equality. According to Equation (8) can be obtained

The mapping transformation method to solve the reliability index can be used as an iterative process of the checkpoint method for independent normally distributed variables, and the iterative calculation steps are as follows:

(1) Select the initial value of the coordinates of the check point ; in general ;

(2) Calculate the initial value of according to Equation (1);

(3) Calculate the value of the direction cosine according to Equations (5), (7) and (9);

(4) Calculate the reliability index based on Equations (4), (7) and (9);

(5) Calculate the new value according to Equation (6);

(6) Calculate the new value according to Equation (2);

(7) Repeat calculation steps (3) to (6) with the new , when , for the required allowable error value, then stop the calculation; the solution of the reliability index value for the required reliability index can be obtained; if , then take = , repeat the calculation steps (3) to (6), and the result is in line with the requirements.

The mapping transformation method is essentially a first-order second-moment method, which is simple to compute and only uses the mean and variance of the basic variables, and it can be better applied to the problem of solving the reliability of the function with a low degree of nonlinearity. However, it does not consider the local nature of the function in the vicinity of the design acceptance point, which will produce a large error when the degree of nonlinearity of the function is high. The nonlinear effect can be assessed by examining the higher-order terms in the Taylor expansion of a function. When the contribution of second-order terms is significantly smaller than that of first-order terms, specifically when the proportion of second-order terms is less than 5% (), the function is considered weakly nonlinear.

2.2. Direct Probabilistic Design Method

For the structural performance function

,

S represents the effect, and

R is the resistance, where the random variables

and

obey normal distribution. Because

Z is a linear function of

R and

S, according to the linear combination of normal random variables’ correlation properties, it can be obtained that

Z also obeys the normal distribution, and its mean value

and standard deviation

. The structural reliability index is

When the target reliability index

is given, the average value

of the resistance

can be obtained by substituting the statistical parameters of the resistance

R and the load effect

S into Equation (10). The standard value of resistance

can be obtained from Equation (11), where

is the mean value factor of

R. Then, the cross-section design is based on the standard value of resistance

.

In practical engineering, the probability distribution of most random variables does not obey the normal distribution, and it is usually necessary to convert the non-normally distributed underlying variables by equivalent normalization. The criterion for equivalent normalization is that the values of the probability distribution function and the probability density function of the equivalent normal variable

(with mean

and standard deviation

) are equal to the values of the probability distribution function and the probability density function of the original non-normal variable

(with mean

and standard deviation

) at the design acceptance point

[

11].

Find the mean of the equivalent normal distribution

for

The standard deviation of the equivalent normal distribution

is

Consider a simple case; assume that the structural limit state equation is

;

is the permanent load effect, which follows normal distribution;

is the variable load effect, which follows an extreme value type I distribution; and

is the structural resistance, which follows a lognormal distribution [

17]. The coefficient

of variation of

, the mean

and standard deviation

of

, the mean

and standard deviation

of

, and the target reliability index

are known, and the steps for solving the standard value of resistance

are as follows:

(1) List the limit state equations and the known probability models for the distribution of the underlying variables and statistical parameters;

(2) Select the initial value of the coordinates of the design check point so that , , ;

(3) Performa an equivalent normalization of and using Equations (14) and (15);

(4) Calculate the direction cosine , ;

(5) Calculate the coordinates

of the checkpoint for the next iteration according to Equation (16);

(6) Repeat the calculation from step (2) to step (5) with the coordinates of the design check point of the new round, and when the difference between the coordinates of the check point obtained this time and the previous one is less than the specified error, take the value of of the current round as the coordinates of the check point sought;

(7) Solve for the equivalent normal mean value

of the resistance

R, which can be obtained as follows:

The average value

of resistance

R can be obtained by substituting the equivalent normal mean

obtained from Equation (17) into Equations (14) and (15). When

R obeys a lognormal distribution, it can be obtained that

The standard value of the resistance

is then calculated from Equation (11) for the section design. The flowchart of this method is shown in

Figure 2.

2.3. Approximate Probabilistic Design Method Based on Second-Order Second-Moment Theory

Using the first-order second-moment method to solve the reliability index ignores the various nonlinear properties of the structural limit state equation surface. The method of improving the accuracy of reliability calculation and analysis by considering the influence of the quadratic nonlinearity of the structural limit state equation is called the second-order second-moment method [

39]. All input random variables, including various loads, component sizes, and material information, are statistically independent in the original space. For general independent random variables, it is always possible to transform them into random variables obeying a standard normal distribution by means of an equal probability transformation. Assuming that

is already a transformed random variable obeying a standard normal distribution, the structure function thus expressed is

The expression of structural failure probability is

After Taylor series expansion of the limit state surface equation at the design checking point

to the quadratic term, the calculation expression is as follows:

where

is the gradient vector of the limit state surface equation at the design acceptance point. The unit vector expression corresponding to this vector is

In the standardized state space, the relationship between the design checkpoint

, the unit vector

, and the reliability indicator

is given by

By substituting Equations (22) and (23) into Equation (21) and considering that

is satisfied at the design acceptance point

, then it is obtained that

Using the unit vector

as the

nth column element of the matrix, the orthogonal matrix generated by the Gram–Schmidt method is

Using the orthogonal matrix

H, an orthogonal transformation of the random vector

Y is obtained.

The corresponding structure function becomes

The value of the Jacobian determinant transformed from

Y to

U is

. In the

U spatial coordinate system, the expression for the failure probability can be obtained through Equation (20) as

Substituting Equation (27) into Equation (24) results in

Among others, .

In Equation (30), omitting the quadratic term related to

, we can get

where

,

denotes the matrix

of order

after crossing out its

nth row and

nth column. Substituting

into Equation (31) yields

Thus the structural failure probability expressed by Equation (29) is

If an orthogonal transformation is applied to the

order random vector

where

is an orthogonal matrix whose elements are composed of the eigenvectors of the

order matrix

. Thus Equation (31) can be further expressed as

where

is the eigenvalue of the order matrix of

and represents the principal curvature of the limit state surface in the

ith direction.

Figure 3 illustrates the relationship between the reliability index and the principal curvature of the limit state surface. The calculation leads to

The numerator term of Equation (36) is obtained based on the linearization of the limit state equation of the structure, which essentially represents the solution value of the first-order second-moment method, while the denominator term is a correction term based on the calculated value of the numerator term, which is capable of reflecting the quadratic nonlinear characteristic parameters of the limit state equation of the structure.

The direct probability design method is based on the first-order second-moment method to calculate the average value and standard value of the resistance according to the structural target reliability index, and then the cross-section design is carried out. When dealing with the nonlinear performance function problem, the nonlinear characteristics of the performance function are ignored, resulting in an insufficient calculation accuracy. Based on the direct probability design method and the second-order second-moment theory, this paper establishes a second-order second-moment approximate probability design method for structural members, considering the curvature of the limit state surface, so as to improve the reliability control accuracy when dealing with nonlinear performance function problems. The core innovation addresses the inherent limitations of traditional approximate probability design methods when applied to highly nonlinear problems. Unlike the direct probability design method, which is based on the first-order second-moment (FOSM) theory, the proposed method significantly enhances design accuracy by incorporating the second-order term of the Taylor expansion at the design check point. In contrast to the classical second-order second-moment (SORM) theory, which is typically confined to reliability analysis, this paper systematically integrates it into the direct probabilistic design framework. This integration establishes a comprehensive and high-precision probabilistic design system that shifts from ‘analysis’ to ‘design’. It facilitates reverse design with target reliability as the direct input, effectively overcoming the conservatism of traditional design methods while ensuring structural safety.

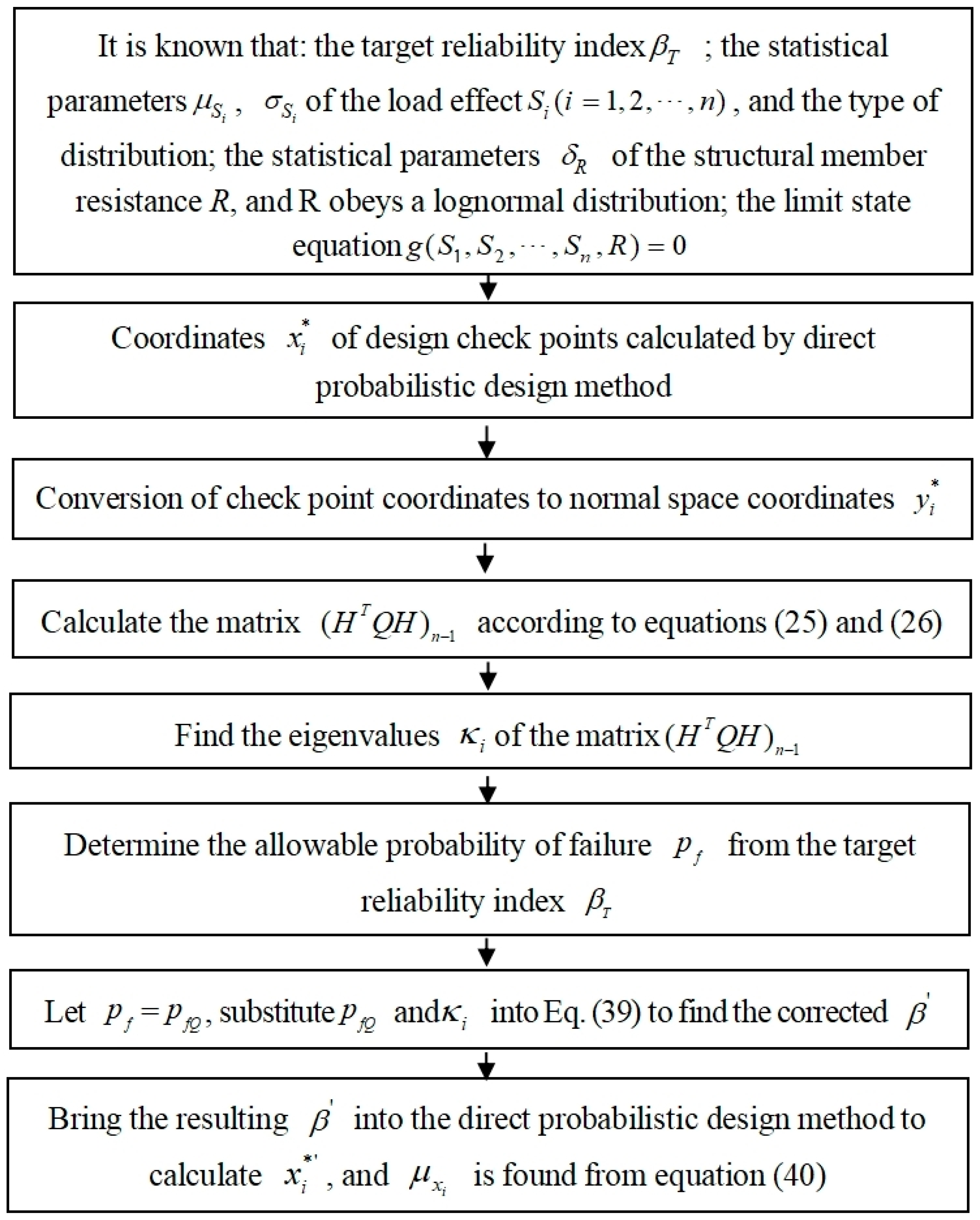

The second-order second-moment approximate probability design method for structural members considering the curvature of the limit state surface consists of the following. Firstly, the direct probability design method introduced in

Section 2.2 is used to calculate the coordinate value of the design checking point of the performance function, and the random variable is transformed into a random variable that obeys the standard normal distribution by equal probability transformation at the design checking point. Then, the allowable failure probability

is calculated according to the structural target reliability index

, and the allowable failure probability

is substituted into the above second-order second-moment method to solve the structural failure probability theory to calculate the modified structural reliability index

. Finally, the direct probability design method is used to calculate the average value

and standard value

of the resistance

according to the modified structural reliability index

, and the section design is carried out. The specific calculation steps are as follows.

(1) Calculate the checkpoint by direct probabilistic design method;

(2)Transform the checkpoints

into standard normal space

by performing an equal probability transformation;

(3) Calculate the matrix according to Equations (25) and (26);

(4) Calculate the eigenvalues of the matrix ;

(5) Calculate the allowable failure probability

from the target reliability index

;

(6) Let

=

, and substitute

and

into Equation (39) to obtain the corrected reliability index

;

(7) Substitute the modified reliability index

into the direct probabilistic design method to find the check point

, and from Equation (40) to find

.

The flowchart of the approximate probabilistic design method based on second-order second-moment theory is shown in

Figure 4. This engineering design method is rooted in probability theory and statistical methods. It involves quantifying the variability of uncertain factors, such as loads and material performance, to establish a target reliability index (e.g.,

βT = 3.2) as the basis for design. This approach mitigates the inherent overconservatism of conventional partial coefficient methods, achieving a balance between safety and cost-effectiveness. It is particularly well-suited for precision-critical engineering projects with stringent safety requirements. Nevertheless, this method exhibits a strong reliance on data, presents challenges in modeling, necessitates a substantial number of samples to determine the probability distribution of random variables, and involves a high computational complexity. In cases where variables exhibit nonlinearity or a non-normal distribution, it becomes essential to perform a second-order expansion of the function at the design verification point and employ iterative methods for resolution, resulting in exponential increases in computational complexity.

The computational cost of the proposed design method is approximately three times that of the direct probability design method based on the first-order second-moment method (FORM). This increased cost stems from three primary calculation stages: initially, determining the design check point through direct probability design iteration; next, adjusting the reliability index using second-order second-moment (SORM) theory; finally, incorporating the updated reliability index into the direct probability design framework for a second iteration, thereby significantly enhancing the accuracy of the final design results. This method offers strong integrability and can be seamlessly embedded into existing specification systems. It manifests in two primary applications: first, by determining optimal partial coefficients under specific load and resistance conditions through reverse calibration, constrained by a target reliability index, thereby updating the coefficient tables in current specifications; second, as a recommended advanced design method, it is included in the specification appendix to offer standardized design options for critical projects requiring high precision or dealing with complex nonlinear characteristics.

3. Algorithm Validation

Two examples are solved using both widely adopted design methods and those proposed in this paper. The results are verified through Monte Carlo simulations. These findings are compared to demonstrate the efficacy of the approximate probability design method based on second-order second-moment theory.

Case 1: A simply supported reinforced concrete slab with cross-sectional dimensions

b h = 1000 mm

500 mm, calculated span

3 m, subjected to a uniform variable load

40 kN/m,

(excluding the deadweight of the slab), concrete grade C30,

20.1 N/mm

2, reinforcing bars of HRB335, yield strength

335 N/mm

2. The limit state equation of the slab is [

40]

The random variables are independent of each other, and the physical meanings and statistical information of the random variables are shown in

Table 1. The target reliability index for the slab design is 3.2, and the mean value of the required area of reinforcement is determined to be

.

Method 1: Direct probabilistic design method

(1) List the limit state equations and known conditions

The variable

obeys a lognormal distribution with a coefficient of variation

0.05; then

, and the standard deviation of the equivalent normal variable

is

The variable follows a normal distribution with mean 38 kN/cm2 and standard deviation 2.66 kN/cm2; the variable obeys an extreme value type I distribution with mean kN/cm and standard deviation kN/cm.

Equivalent normalization is performed to obtain the mean and standard deviation of the equivalent normal random variable

corresponding to the original variable

X3.

(2) Assigning initial values to the coordinates of the basic variable checkpoints

(3) Equivalent normalization treatment

(4) Calculate the direction cosine

According to the formula for the direction cosine, it can be obtained that

(5) Calculate the coordinates of the new checkpoints

(6) Repeat the calculation steps (3)~(5) until the relative error of the coordinates of the check points obtained from the two iterations before and after meets the accuracy requirements, and the iteration stops.

Table 2 gives the check point coordinates of the iterative calculation process.

(7) Calculate the equivalent normal mean

and mean

of the variable

Method 2: Second-order second-moment approximation probabilistic design method

(1) List the coordinates of the design acceptance points obtained by the iterative calculation of the direct probabilistic design method: cm2, kN/cm2, kN/m;

(2) Transform the coordinates of the checkpoints to the standard normal space by means of an equal probability transformation

where,

,

,

,

,

,

; substituting the above equation gives

,

,

;

(4) Using

as a column vector, the Schmidt orthogonalization method is used to determine

H(5) Calculate the matrix

QThe remaining second-order mixed partial derivatives are all zero.

(6) Calculate the eigenvalues and eigenvectors of the matrix

The matrix after removing the last row and the last column of the matrix is

(7) The eigenvalues of the matrix , i.e., the principal curvatures of the limit state surfaces, are calculated by the procedure of MATLAB (R2024b) software programming as 0.0240, 0.0023;

(8) Take the target reliability index 3.2, according to the relationship between the reliability index and the probability of failure equation, to get the probability of failure , so that , substituting into the Equation (39), to find the reliability index 3.2130;

(9) Take the reliability index 3.2130 by the direct probabilistic design method and solve it to get the mean value of the area of reinforcement, 541.9891 mm2.

Method 3: Partial coefficient method

Mid-span bending moment due to self-weight of the slab:

Mid-span bending moment from variable loads on the slab:

The design value for the role of the plate is

For C30 concrete, = 1.0. Taking the effective height of the slab as = 485 mm, substituting = 1000 mm, 20.1 N/mm2, 335 N/mm2, = 1.15 into the above equation yields = 608.2427 mm2.

Method 4: Design value method

Taking the structural design base period as

= 50 a,

,

,

,

,

,

, then

The design value for the role of the plate is

Substituting the substitution coefficients into the practical expression gives = 520.9275 mm2.

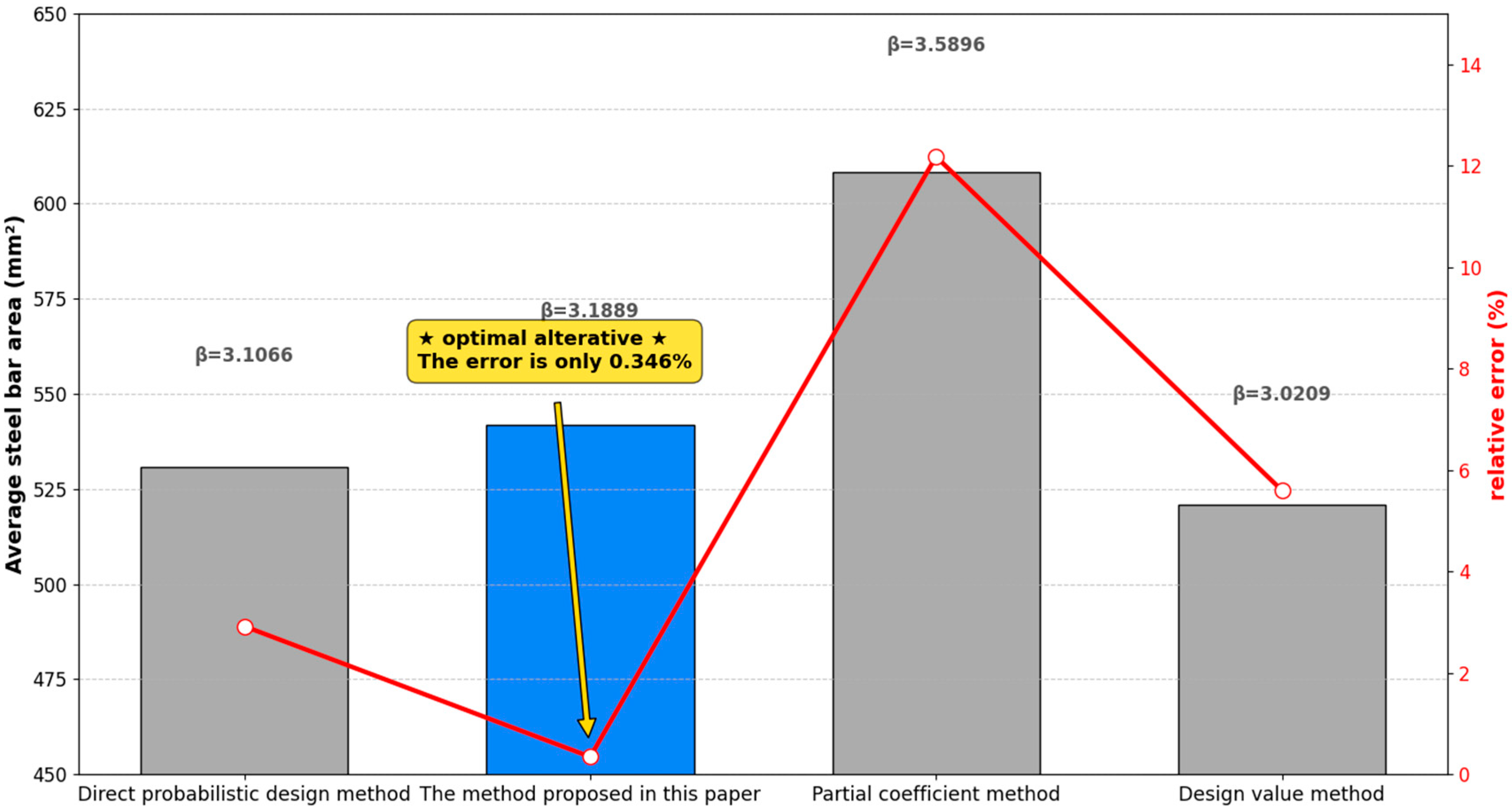

MATLAB software is utilized to implement a Monte Carlo method program for computing the reliability index. By considering the actual distribution of reinforcement area, reinforcement yield strength, and uniform load as outlined in

Table 1, a set of 1 × 10

7 samples is generated. These samples are then inserted into the limit state equation to conduct 1 × 10

7 simulation calculations. The failure probability of the structure is determined by dividing the instances where the function

is less than 0 by the total number of simulations. Subsequently, the reliability index is computed using Formula (38). The mean value of the longitudinal rib area, determined through four design methods, is substituted into the Monte Carlo method program. The resulting relative error between the reliability index obtained from the four design methods and the target reliability index is presented in

Table 3. Utilizing the partial coefficient method yielded a reinforcement consumption of 608.3437 mm

2, with a Monte Carlo program output of

β = 3.5896, exhibiting a relative error of 12.175%. Employing the design value method resulted in a reinforcement consumption of 520.9279 mm

2, with a Monte Carlo program output of

β = 3.0209, and a relative error of 5.597%. The direct probability design method led to a reinforcement consumption of 530.8092 mm

2, with a Monte Carlo program output of

β = 3.1066, demonstrating a relative error of 2.919%. Conversely, applying the design method proposed in this study resulted in a reinforcement consumption of 541.9891 mm

2, with a Monte Carlo program output of

β = 3.1889 and a relative error of 0.346%.

Figure 5 and

Figure 6 present the performance comparison results of the four design methods, along with the Monte Carlo reliability index comparisons for each method. The partial coefficient method yields the highest structural reliability (quantified by the reliability index) but necessitates a notably larger reinforcement area, leading to suboptimal cost-effectiveness. In contrast, the direct probability design method and design value method result in relatively lower reinforcement quantities and correspondingly diminished structural reliability indices. In comparison to these approaches, the proposed method demonstrates superior calculation precision and strikes a more favorable equilibrium between reinforcement usage and structural reliability. These quantitative findings robustly validate the efficacy and superiority of the design method introduced in this study.

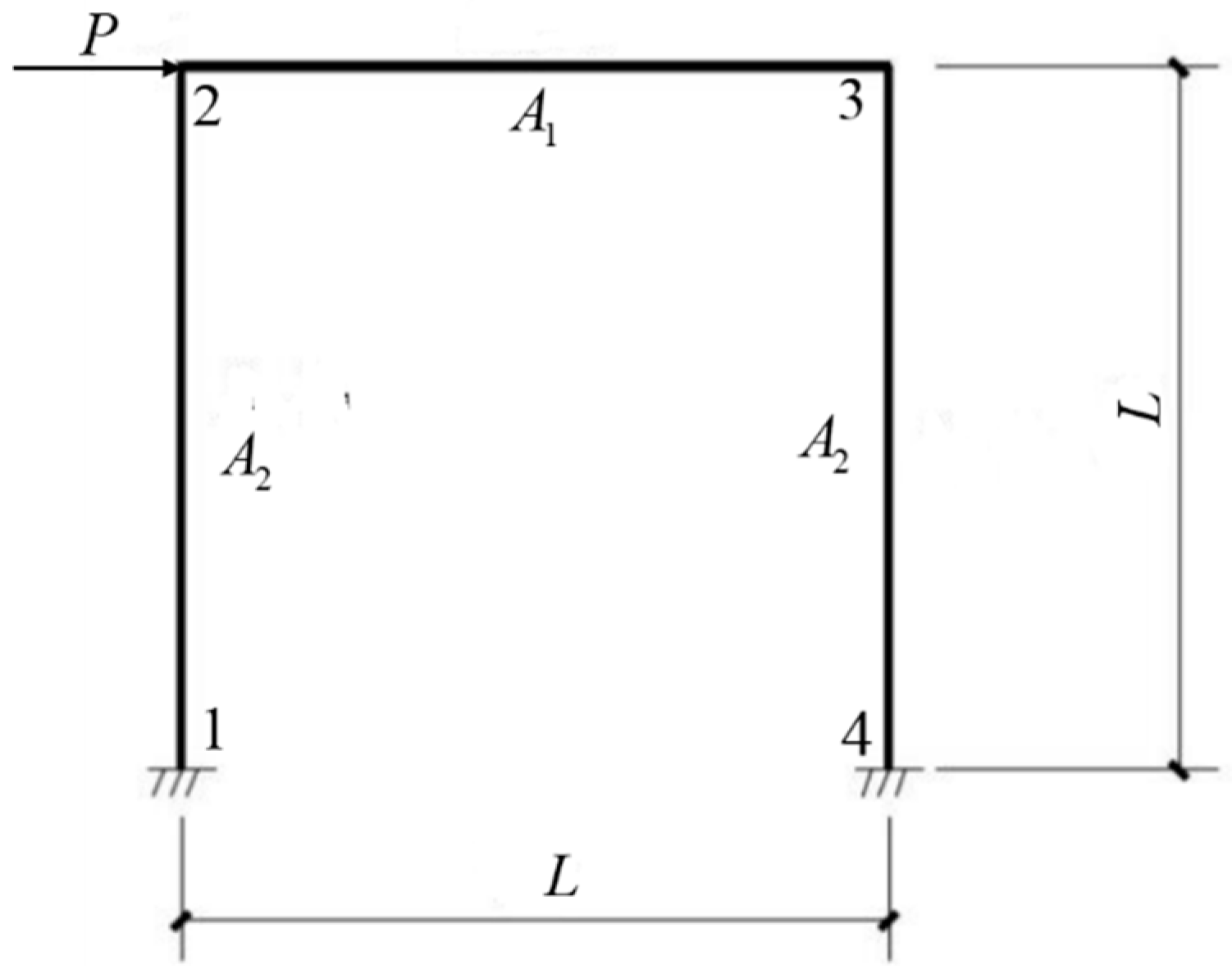

Case 2: Design of the cross-sectional area of the frame beam to satisfy the lateral limit state. The limit state equation for the structure depicted in

Figure 7 is

Among them,

u3 represents the horizontal displacement of vertex 3. The span length of the structure is

L = 4 m, and the cross-sectional area of the column is

A2 = 0.4 m

2. These values remain constant regardless of variations in span length or cross-sectional area. The physical meaning and statistical information of the random variables are detailed in

Table 4, and the mean value

of the cross-sectional area

A1 is determined.

Method 1: Direct probabilistic design method

(1) The variable

P follows an extreme type I distribution with

kN/m and

; The parameters of its probability distribution function are

Let

. Then the probability density function and probability distribution function of P at the checking point are

(2) Assigning initial values to the coordinates of the basic variable checkpoints

(3) Equivalent normalization treatment

(4) Calculate the direction cosine

According to the formula for the direction cosine, it can be gotten that

(5) Calculate the coordinates of the new checkpoints

(6) Repeat calculation steps (3)~(5) until the relative error of the coordinates of the check points obtained from the two iterations before and after meets the accuracy requirements, and the iteration stops.

Table 5 gives the check point coordinates of the iterative calculation process.

(7) Calculate the mean value

of the cross-sectional area

A1Method 2: Second-order second-moment approximation probabilistic design method

(1) List the coordinates of the design acceptance points obtained by the iterative calculation of the direct probabilistic design method: kN, kN/m2, m2;

(2) Transform the coordinates of the checkpoints to the standard normal space by means of an equal probability transformation

where

,

,

,

,

,

; substituting the above equation gives

,

,

;

(4) Using

as a column vector, the Schmidt orthogonalization method is used to determine

H(5) Calculate the matrix

Q(6) Calculate the eigenvalues and eigenvectors of the matrix

The matrix after removing the last row and the last column of the matrix is

(7) The eigenvalues of the matrix , i.e., the principal curvatures of the limit state surfaces, are calculated by the procedure of MATLAB software programming as , ;

(8) Take the target reliability index , according to the relationship between the reliability index and the probability of failure equation, to get the probability of failure , so that substituting into the Equation (39) to find the reliability index ;

(9) Take the reliability index by the direct probabilistic design method and solve it to get the mean value of the area of reinforcement .

Using MATLAB software to implement the Monte Carlo method, the mean value

of the cross-sectional area

A1 of the beam, as calculated by the two design methods, is substituted. This yields the relative error between the reliability indices of the two design methods and the target reliability index, as presented in

Table 6.

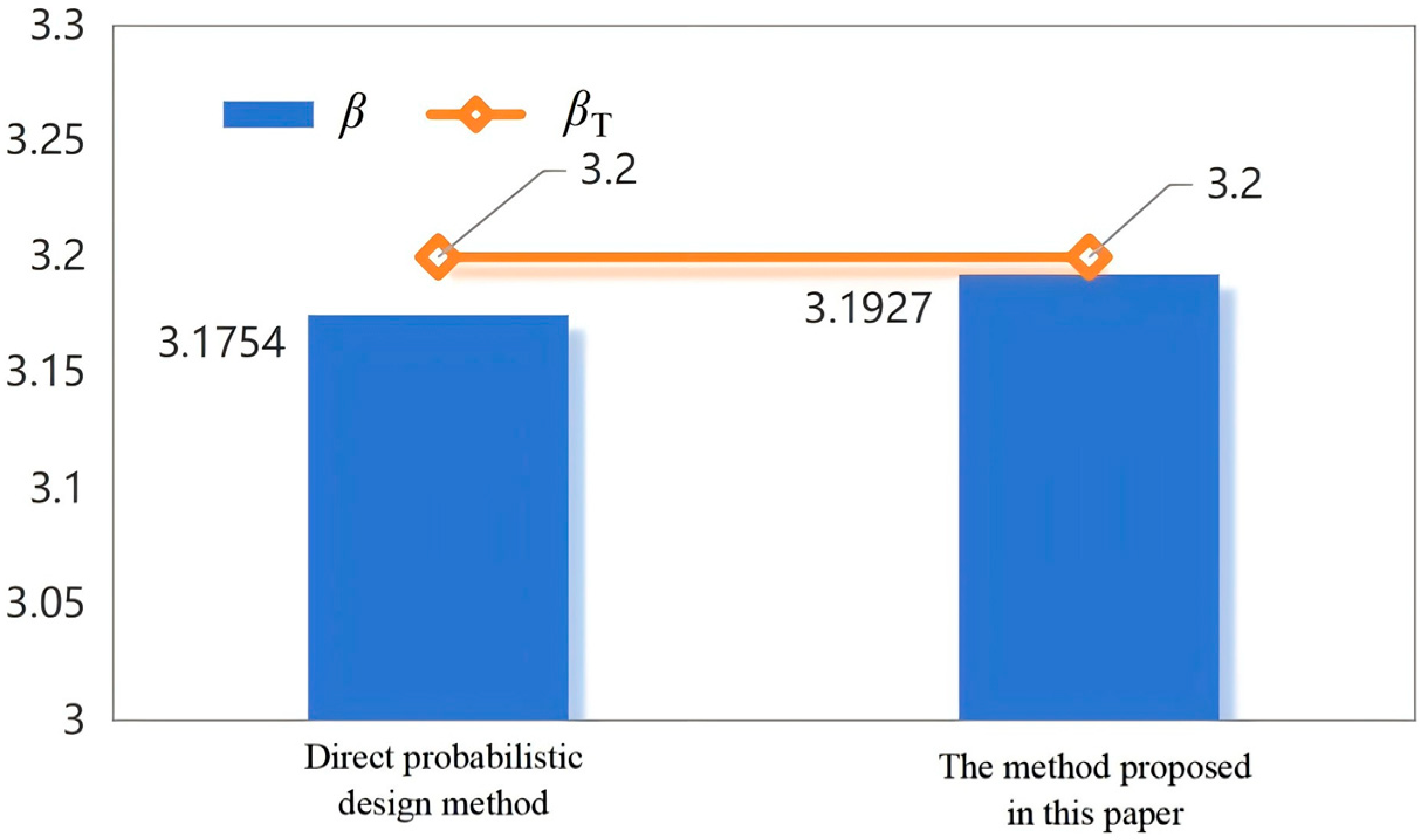

Figure 8 presents a comparison of Monte Carlo reliability indices for various design methods. The Monte Carlo method program’s output for the direct probability design method is

β = 3.1754, with a relative error of 0.769% compared to the target reliability index. For the design method introduced in this paper, the Monte Carlo method program yields

β = 3.1927, with a relative error of just 0.228% against the target reliability index. These quantitative comparison results further validate the efficacy of the design method proposed in this paper.