Effect of Recycled Powder from Construction and Demolition Waste on the Macroscopic Properties and Microstructure of Foamed Concrete with Different Dry Density Grades

Abstract

1. Introduction

2. Materials and Experiments

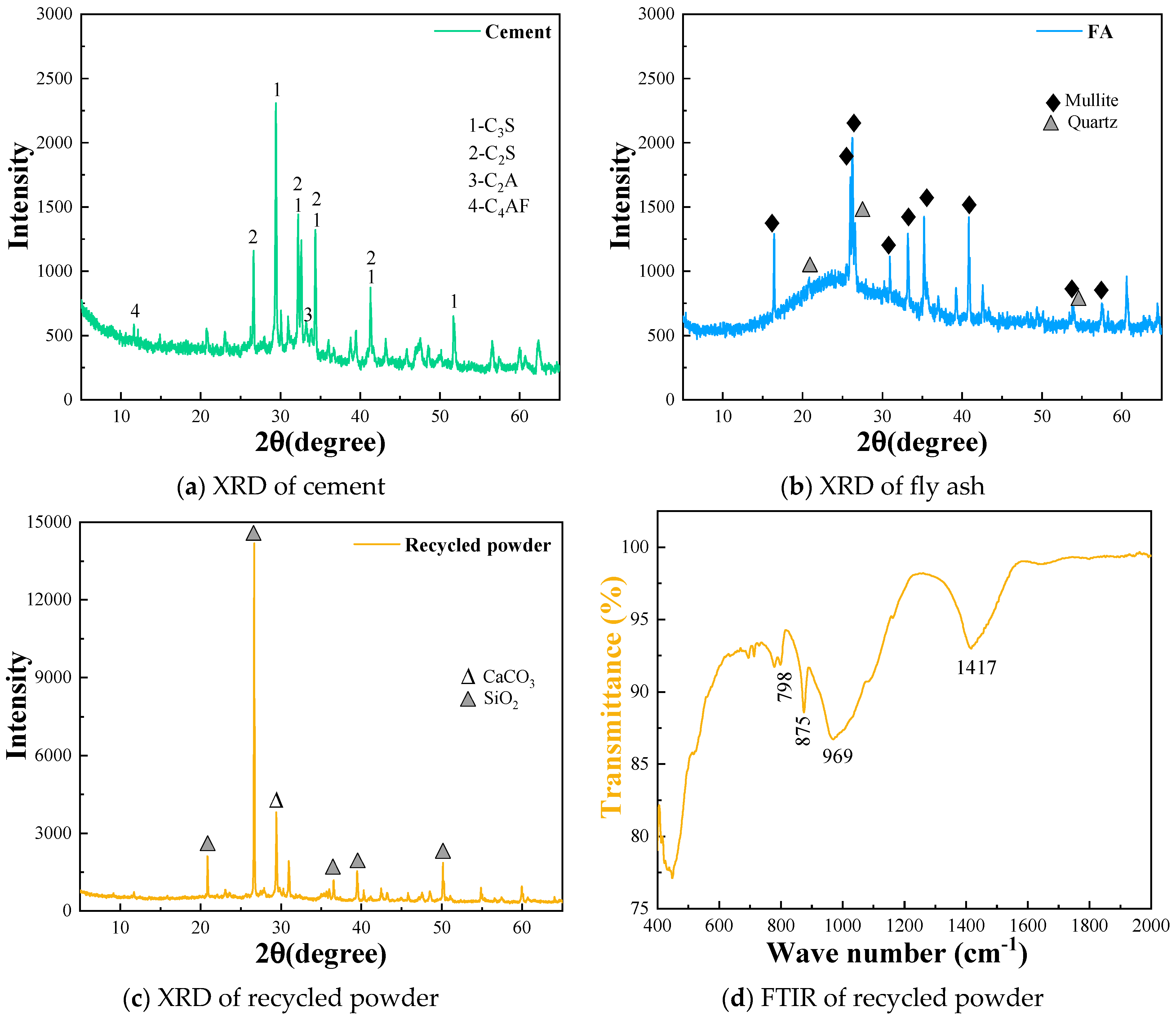

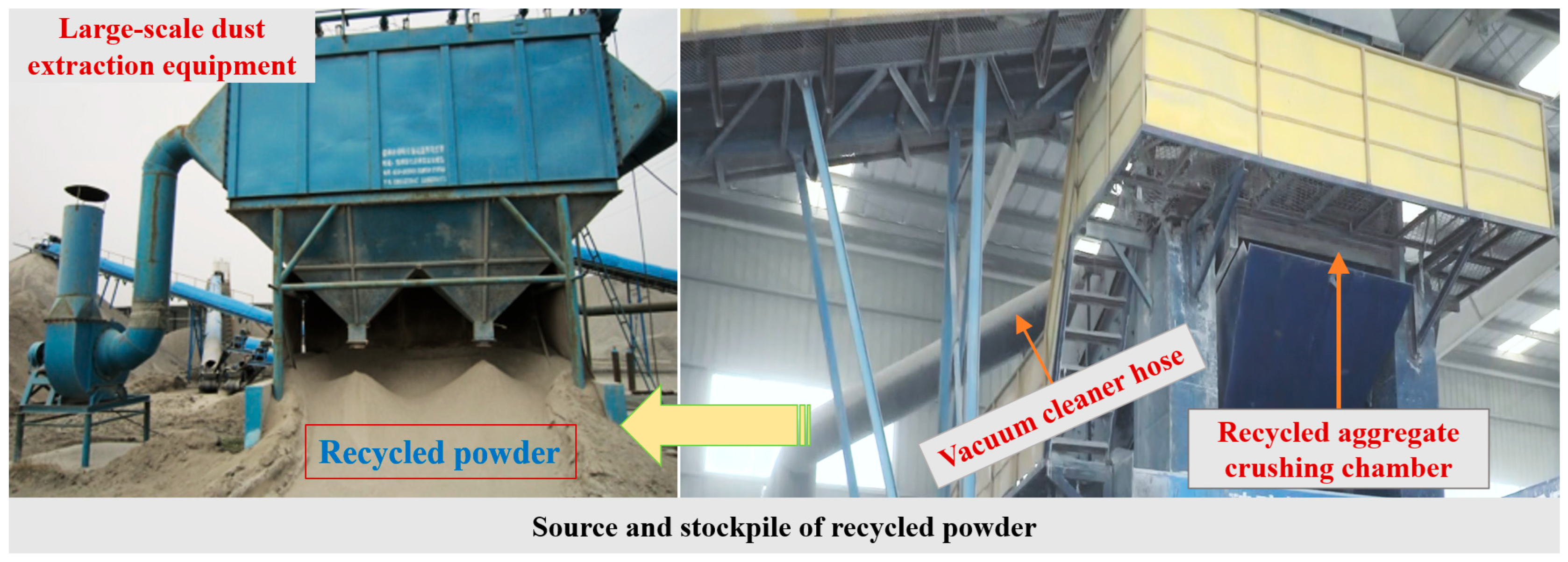

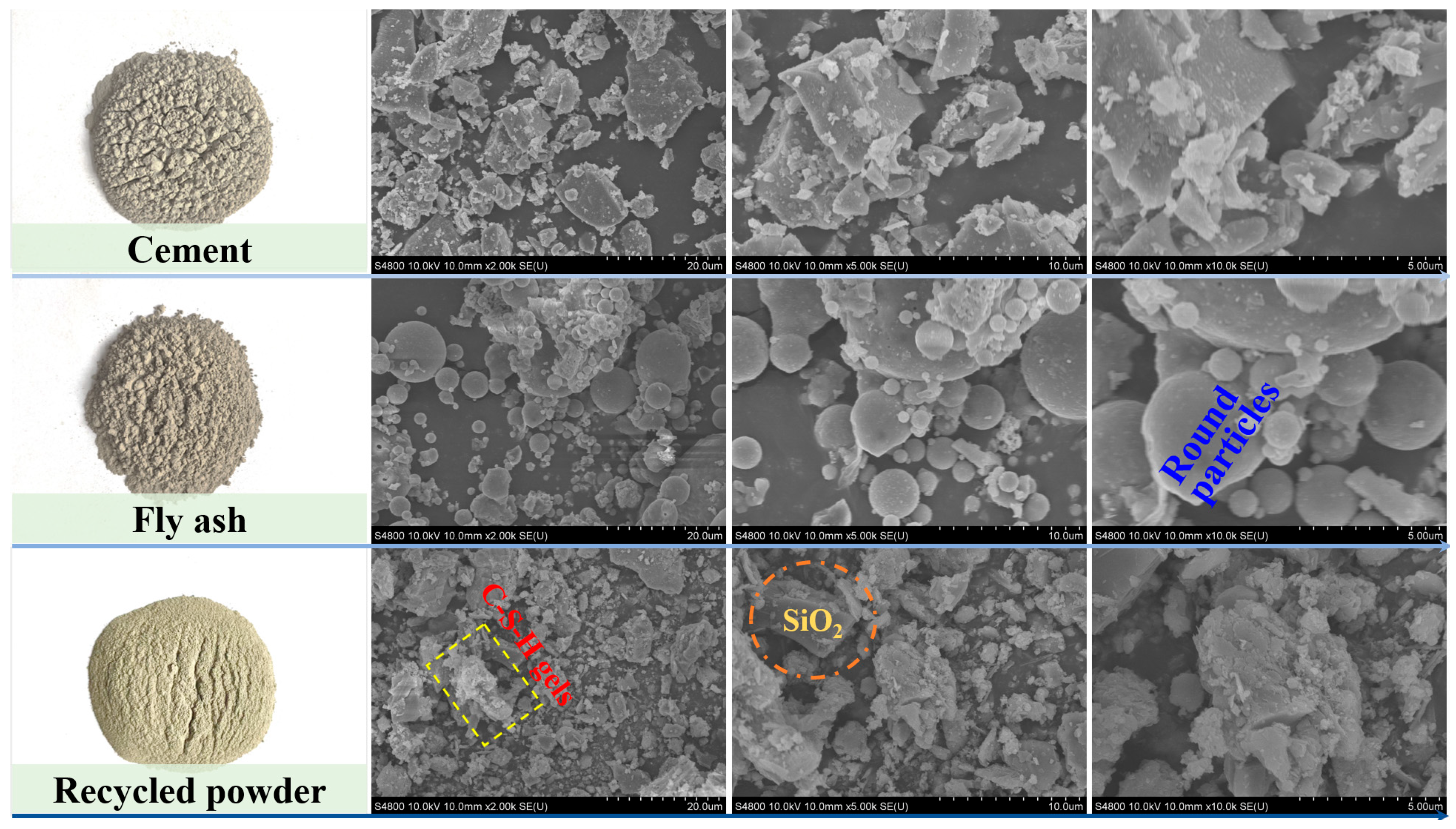

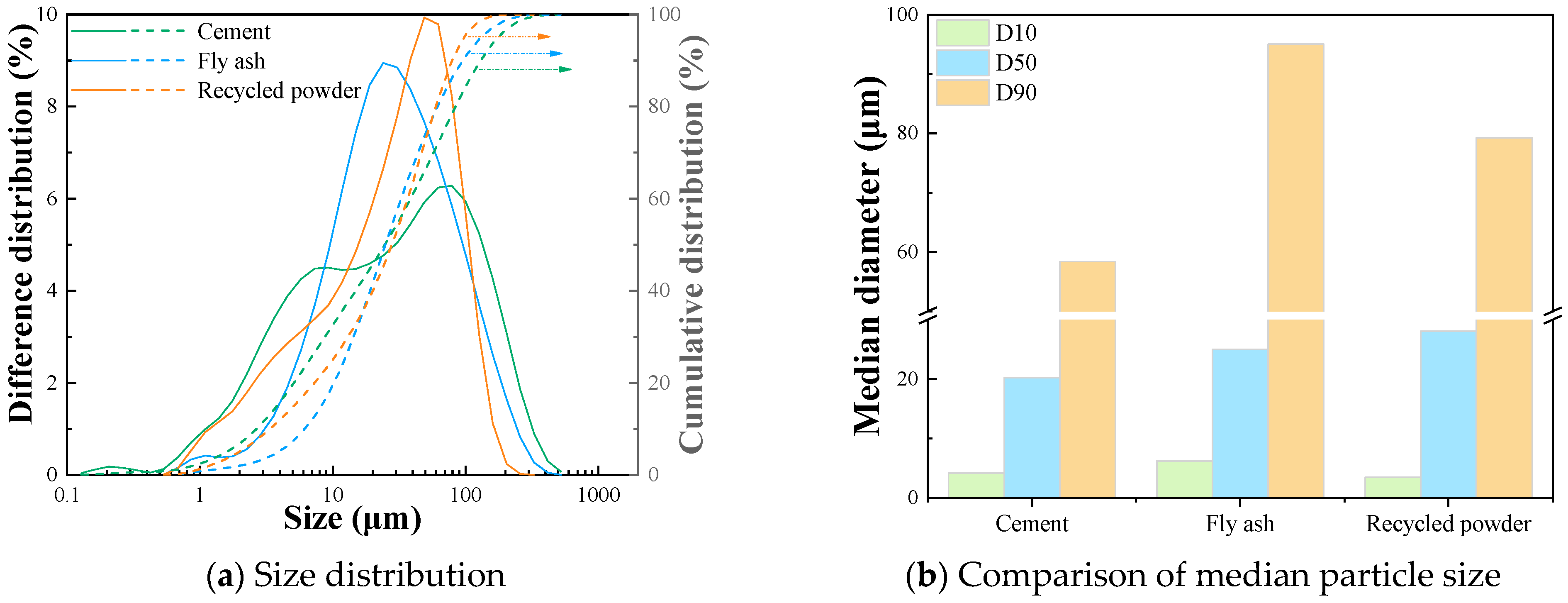

2.1. Raw Materials

2.2. Mix Proportion and Preparation

2.3. Compressive Strength, Softening Coefficient, and Carbonation Coefficient

2.4. Thermal Conductivity, Porosity, and Drying Shrinkage

2.5. Micro-Characteristics Determination

3. Results and Discussions

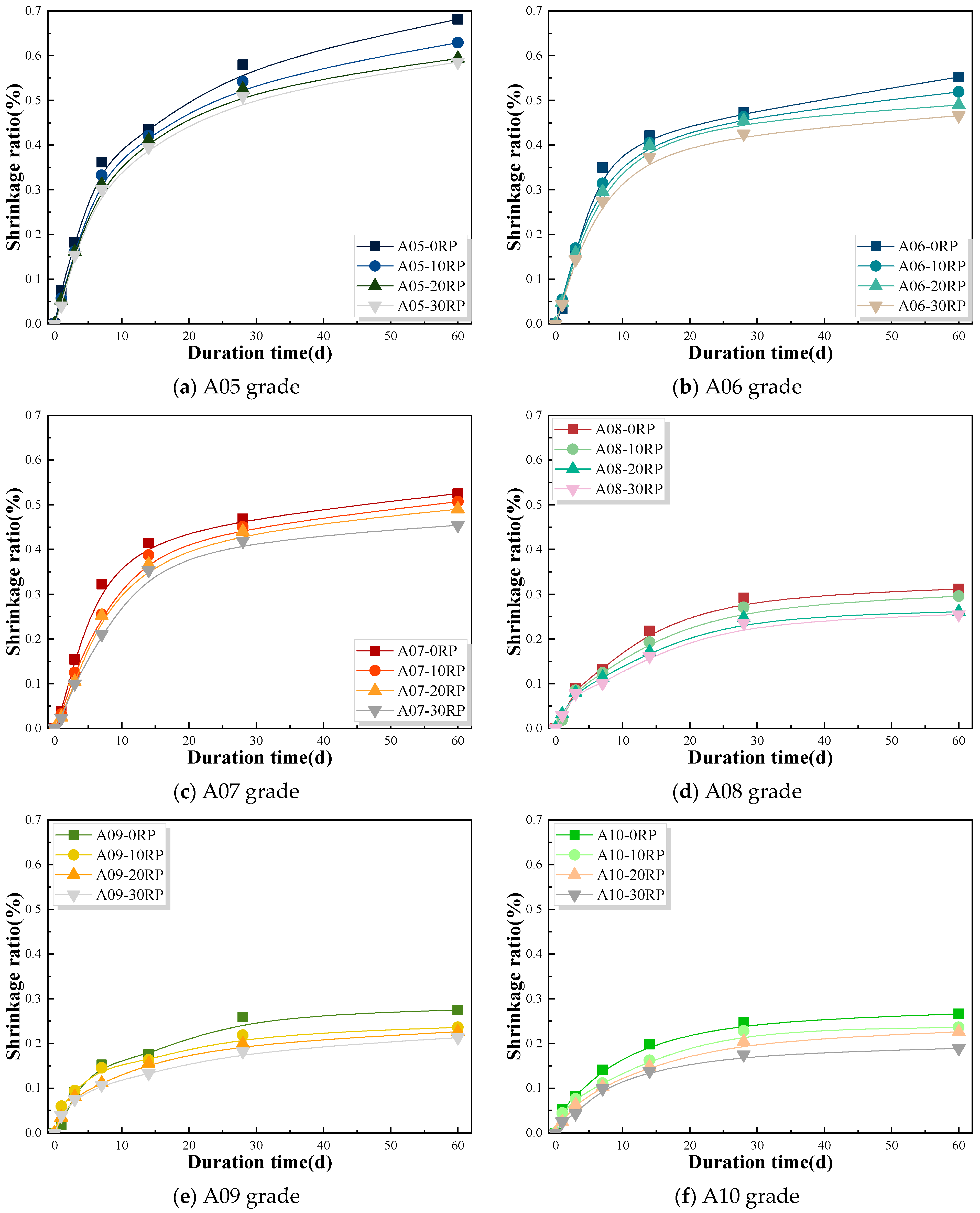

3.1. Drying Shrinkage of Recycled Powder Foamed Concrete

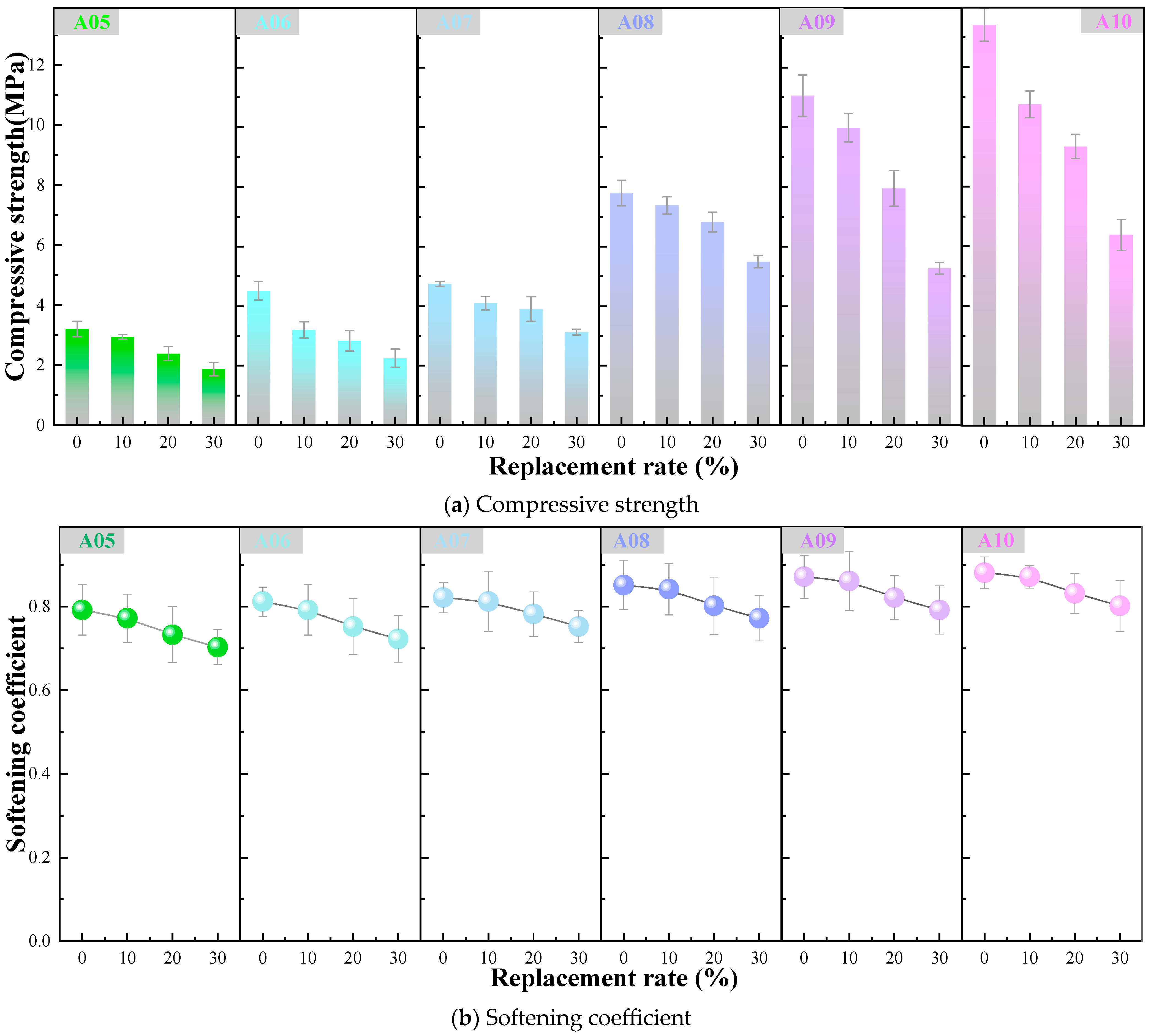

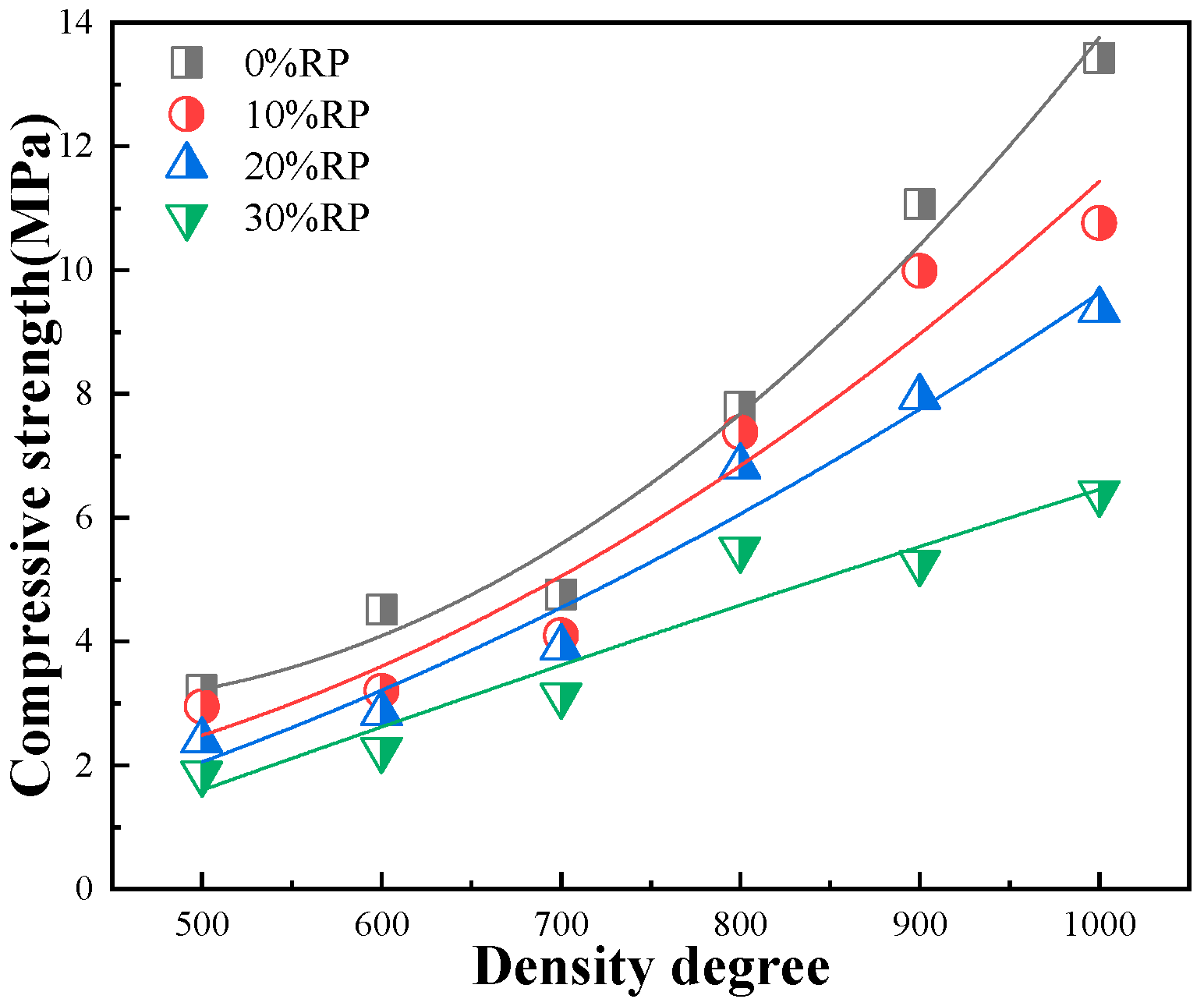

3.2. Compressive Strength and Softening Coefficient of Recycled Powder Foamed Concrete

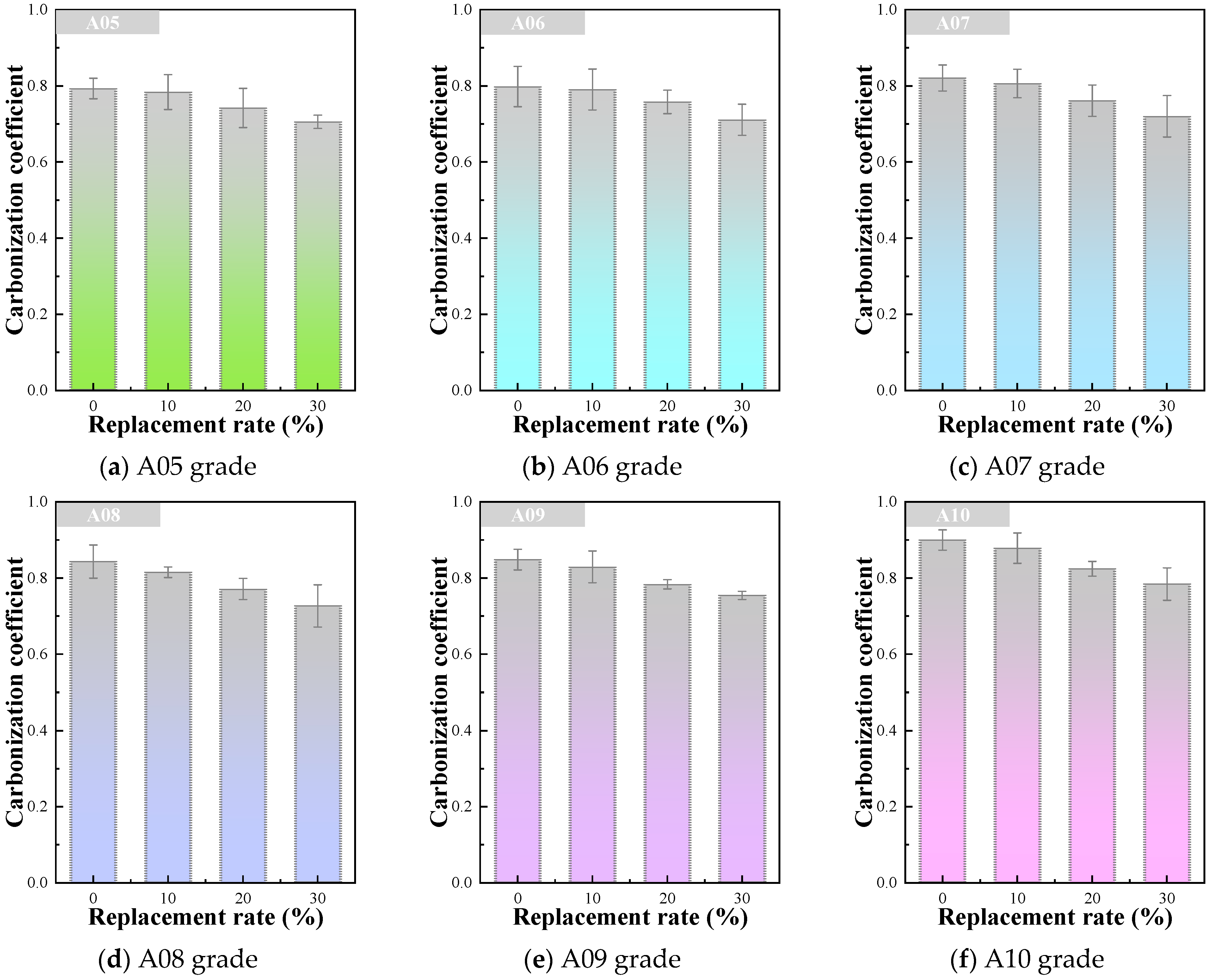

3.3. Carbonation Coefficient of Recycled Powder Foamed Concrete

3.4. Thermal Conductivity and Porosity of Recycled Powder Foamed Concrete

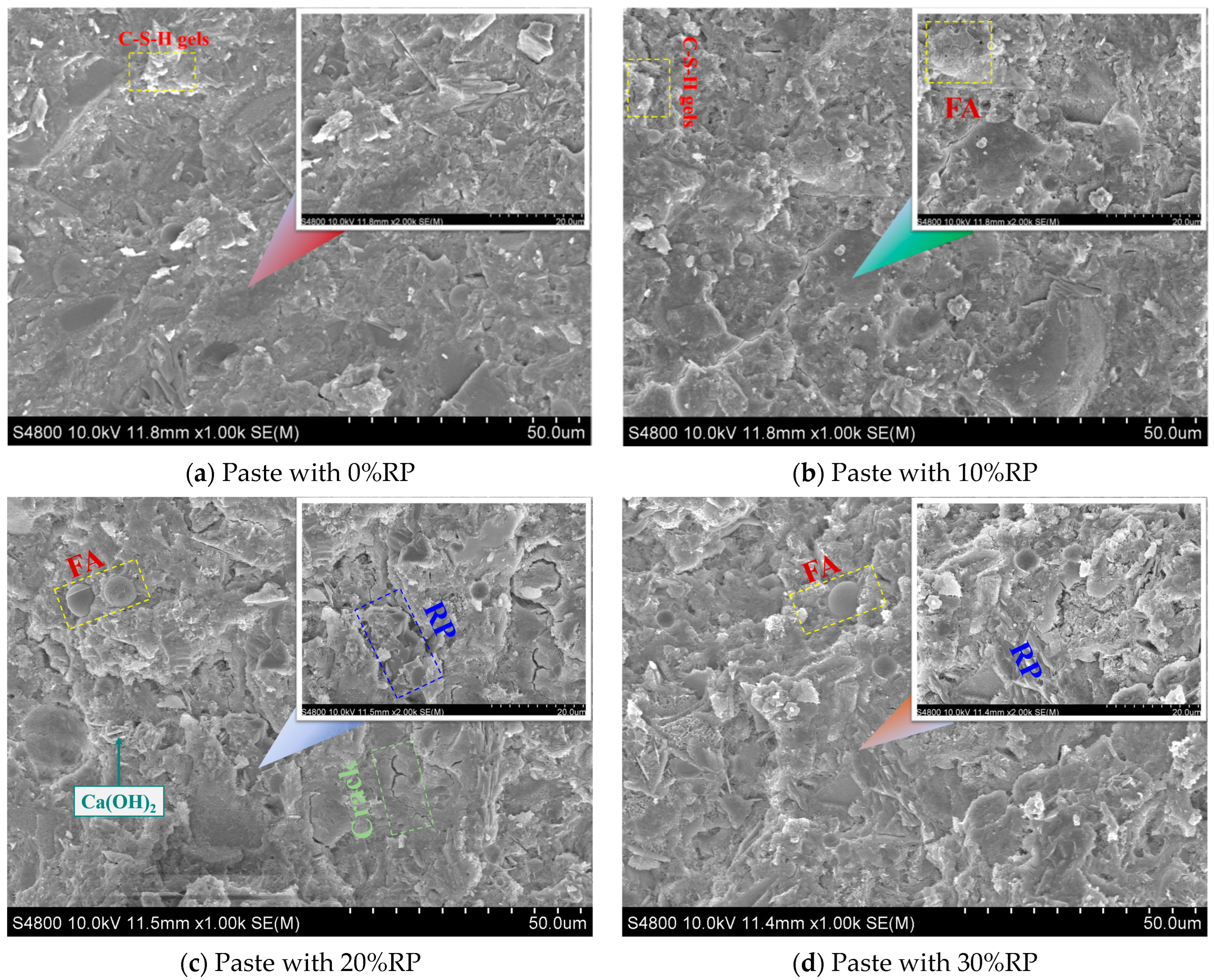

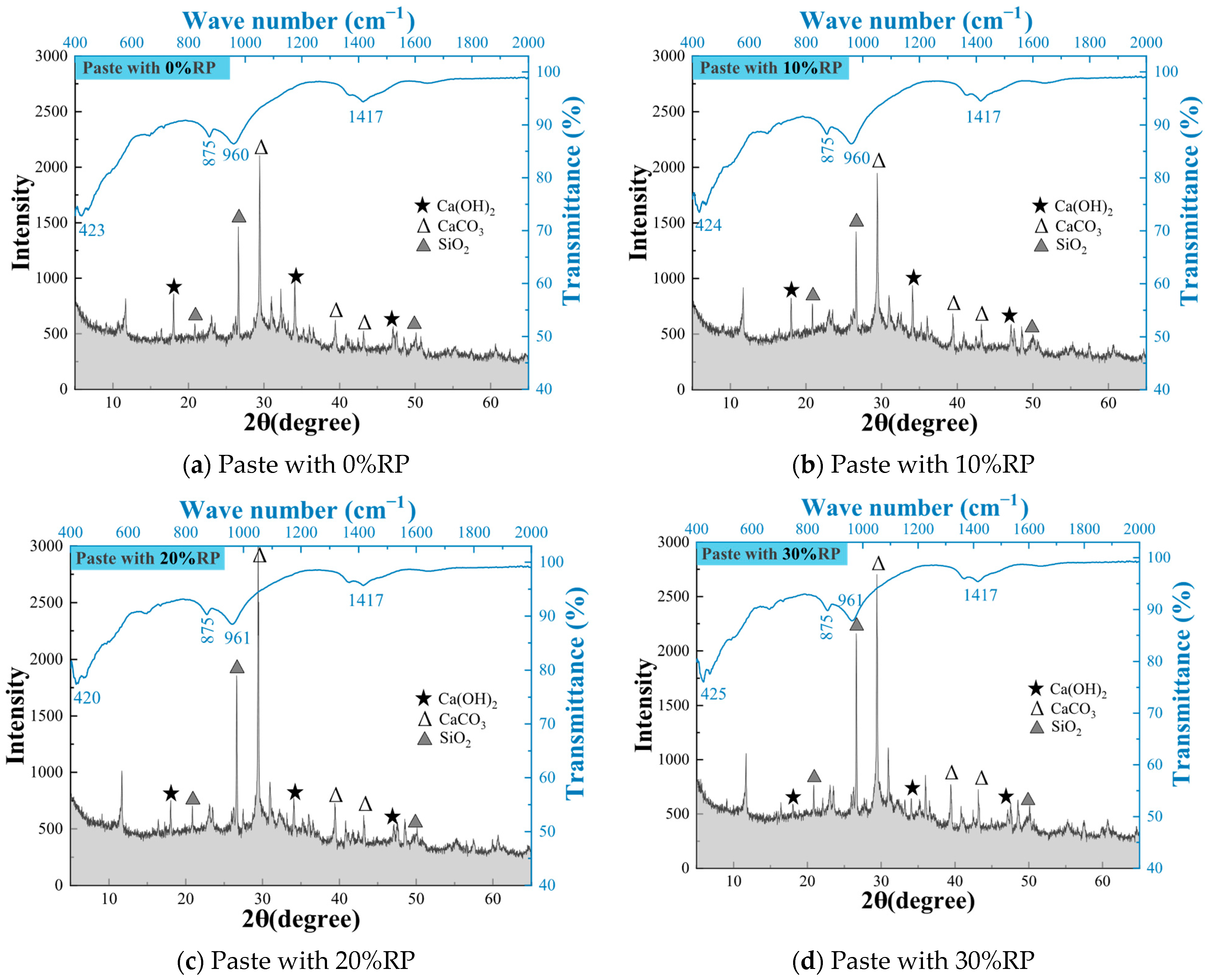

3.5. Micro-Properties of Cementitious Composites with Recycled Powder

4. Conclusions

- (1)

- The recycled powder exhibits an irregular microstructure, with large particles frequently covered by smaller adhered particles. Its median particle size is larger than that of both cement and fly ash, indicating a coarser particle size distribution. Mineralogical analysis reveals the presence of C-S-H gel along with a significant amount of inert components such as SiO2 and CaCO3. When used as a partial replacement for cement, the microstructure of the cementitious matrix gradually deteriorates.

- (2)

- With the increase in recycled powder replacement ratio, the compressive strength of foamed concrete gradually decreases, with a particularly pronounced reduction observed at a 30% replacement level. In addition, the incorporation of recycled powder also leads to a decline in both the softening coefficient and carbonation resistance of foamed concrete.

- (3)

- The incorporation of recycled powder effectively mitigates the drying shrinkage of foamed concrete, with shrinkage progressively decreasing as the replacement ratio increases. Notably, high-density recycled powder foamed concrete demonstrates enhanced resistance to shrinkage. Furthermore, the addition of recycled powder exerts a limited influence on both the porosity and thermal conductivity of foamed concrete, indicating good compatibility regarding thermal performance and pore structure stability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, W.; Lin, Q.; Chen, J.; Li, X.; Sun, Y.; Xu, X. Urban building energy prediction at neighborhood scale. Energy Build. 2021, 251, 111307. [Google Scholar] [CrossRef]

- Asdrubali, F.; Baldassarri, C.; Fthenakis, V. Life cycle analysis in the construction sector: Guiding the optimization of conventional Italian buildings. Energy Build. 2013, 64, 73–89. [Google Scholar] [CrossRef]

- Zhou, G.; Su, R.K.L. A review on durability of foam concrete. Buildings 2023, 13, 1880. [Google Scholar] [CrossRef]

- Dong, Y.; Wang, Y.; Zhou, Z.; Fan, H. Study on the preparation and performance of lightweight wallboards from MSWIBA foam concrete. Materials 2024, 17, 4402. [Google Scholar] [CrossRef]

- Mohamed, A.M.; Tayeh, B.A.; Majeed, S.S.; Aisheh, Y.I.A.; Salih, M.N.A. Ultra-light foamed concrete mechanical properties and thermal insulation perspective: A comprehensive review. J. CO2 Util. 2024, 83, 102827. [Google Scholar] [CrossRef]

- Gökçe, H.S.; Hatungimana, D.; Ramyar, K. Effect of fly ash and silica fume on hardened properties of foam concrete. Constr. Build. Mater. 2019, 194, 1–11. [Google Scholar] [CrossRef]

- Summerbell, D.L.; Barlow, C.Y.; Cullen, J.M. Potential reduction of carbon emissions by performance improvement: A cement industry case study. J. Clean. Prod. 2016, 135, 1327–1339. [Google Scholar] [CrossRef]

- Lin, B.; Zhang, Z. Carbon emissions in China׳s cement industry: A sector and policy analysis. Renew. Sustain. Energy Rev. 2016, 58, 1387–1394. [Google Scholar] [CrossRef]

- Luo, J.; Huang, R.; Wang, J.; Zhang, Y. Carbon sequestration by preparing recycled cement, recycled aggregates, and recycled concrete from construction and demolition (C&D) wastes. Materials 2024, 17, 5020. [Google Scholar] [CrossRef]

- Bai, J.; Ge, C.; Liang, J.; Xu, J. Recycled aggregate: A solution to sustainable concrete. Materials 2025, 18, 2706. [Google Scholar] [CrossRef]

- Li, M.; Han, C.; Shao, Z.; Meng, L. Exploring the evolutionary mechanism of the cross-regional cooperation of construction waste recycling enterprises: A perspective of complex network evolutionary game. J. Clean. Prod. 2024, 434, 139972. [Google Scholar] [CrossRef]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Wu, L.; Sun, Z.; Cao, Y. Modification of recycled aggregate and conservation and application of recycled aggregate concrete: A review. Constr. Build. Mater. 2024, 431, 136567. [Google Scholar] [CrossRef]

- ElNemr, A.; Shaltout, R. Rheological and mechanical characterization of self-compacting concrete using recycled aggregate. Materials 2025, 18, 1519. [Google Scholar] [CrossRef]

- Zhang, H.; Xiao, J.; Tang, Y.; Duan, Z.; Poon, C. Long-term shrinkage and mechanical properties of fully recycled aggregate concrete: Testing and modelling. Cem. Concr. Compos. 2022, 130, 104527. [Google Scholar] [CrossRef]

- Liang, C.; Pan, B.; Ma, Z.; He, Z.; Duan, Z. Utilization of CO2 curing to enhance the properties of recycled aggregate and prepared concrete: A review. Cem. Concr. Compos. 2020, 105, 103446. [Google Scholar] [CrossRef]

- Yang, J.; Du, Q.; Bao, Y. Concrete with recycled concrete aggregate and crushed clay bricks. Constr. Build. Mater. 2011, 25, 1935–1945. [Google Scholar] [CrossRef]

- Ma, Z.; Li, W.; Wu, H.; Cao, C. Chloride permeability of concrete mixed with activity recycled powder obtained from C&D waste. Constr. Build. Mater. 2019, 199, 652–663. [Google Scholar] [CrossRef]

- Fořt, J.; Vejmelková, E.; Koňáková, D.; Alblová, N.; Čáchová, M.; Keppert, M.; Rovnaníková, P.; Černý, R. Application of waste brick powder in alkali activated aluminosilicates: Functional and environmental aspects. J. Clean. Prod. 2018, 194, 714–725. [Google Scholar] [CrossRef]

- Mehmood, N.; Zhu, P.; Liu, H.; Li, H.; Zhu, X. Influence of accelerated carbonation conditions on the physical properties improvement of recycled coarse aggregate. Materials 2025, 18, 901. [Google Scholar] [CrossRef]

- Tang, Q.; Ma, Z.; Wu, H.; Wang, W. The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: A critical review. Cem. Concr. Compos. 2020, 114, 103807. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, X.; Peng, Y. Recycled clay brick powder as a dual-function additive: Mitigating the alkali–silica reaction (ASR) and enhancing strength in eco-friendly mortar with hybrid waste glass and clay brick aggregates. Materials 2025, 18, 2838. [Google Scholar] [CrossRef]

- Song, R.; Yang, Q.; Song, H. Performance optimization and synergistic mechanism of ternary blended cementitious system composed of fly ash, slag, and recycled micro-powder. Buildings 2025, 15, 2780. [Google Scholar] [CrossRef]

- Wu, H.; Yang, D.; Xu, J.; Liang, C.; Ma, Z. Water transport and resistance improvement for the cementitious composites with eco-friendly powder from various concrete wastes. Constr. Build. Mater. 2021, 290, 123247. [Google Scholar] [CrossRef]

- Yao, P.; Yang, D.; Wang, C.; Ma, Z. Upcycling of construction waste powder for sustainable ultra-high performance engineered cementitious composites: Effects of waste powder source and content. Constr. Build. Mater. 2022, 349, 128789. [Google Scholar] [CrossRef]

- Chen, D.; Chen, M.; Zhang, Y.; Yang, X.; Zhang, J.; Zhao, Y.; Wu, Y. Development of an environmental foamed concrete incorporating recycled cement concrete powder with carbonation. Constr. Build. Mater. 2024, 422, 135833. [Google Scholar] [CrossRef]

- Yang, D.; Liu, M.; Ma, Z. Properties of the foam concrete containing waste brick powder derived from construction and demolition waste. J. Build. Eng. 2020, 32, 101509. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rattanasak, U. Shrinkage behavior of structural foam lightweight concrete containing glycol compounds and fly ash. Mater. Des. 2011, 32, 723–727. [Google Scholar] [CrossRef]

- Wang, T.; Gao, X.; Li, Y.; Liu, Y. An orthogonal experimental study on the influence of steam-curing on mechanical properties of foam concrete with fly ash. Case Stud. Constr. Mater. 2024, 20, e02665. [Google Scholar] [CrossRef]

- Cho, Y.K.; Jung, S.H.; Choi, Y.C. Effects of chemical composition of fly ash on compressive strength of fly ash cement mortar. Constr. Build. Mater. 2019, 204, 255–264. [Google Scholar] [CrossRef]

- Liu, M.; Wang, C.; Wu, H.; Yang, D.; Ma, Z. Reusing recycled powder as eco-friendly binder for sustainable GGBS-based geopolymer considering the effects of recycled powder type and replacement rate. J. Clean. Prod. 2022, 364, 132656. [Google Scholar] [CrossRef]

- Ellerbrock, R.; Stein, M.; Schaller, J. Comparing amorphous silica, short-range-ordered silicates and silicic acid species by FTIR. Sci. Rep. 2022, 12, 11708. [Google Scholar] [CrossRef] [PubMed]

- Ding, S.; Chen, L.; Wan, X.; Wang, P.; Zhang, J.; Zhang, D.W.; Wang, J. Structure characterization of carbon and fluorine-doped silicon oxide films with low dielectric constant. Mater. Chem. Phys. 2001, 71, 125–130. [Google Scholar] [CrossRef]

- Mollah, M.; Lu, F.; Cocke, D.L. An X-ray diffraction (XRD) and Fourier transform infrared spectroscopic (FT-IR) characterization of the speciation of arsenic (V) in Portland cement type -V. Sci. Total Environ. 1998, 224, 57–68. [Google Scholar] [CrossRef]

- Yang, D.; Liu, M.; Zhang, Z.; Yao, P.; Ma, Z. Properties and modification of sustainable foam concrete including eco-friendly recycled powder from concrete waste. Case Stud. Constr. Mater. 2022, 16, e00826. [Google Scholar] [CrossRef]

- Rahhal, V.F.; Trezza, M.A.; Tironi, A.; Castellano, C.C.; Pavlíková, M.; Pokorný, J.; Irassar, E.F.; Jankovský, O.; Pavlík, Z. Complex characterization and behavior of waste fired brick powder-portland cement system. Materials 2019, 12, 1650. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, M.; Duan, Z.; Liang, C.; Wu, H. Effects of active waste powder obtained from C&D waste on the microproperties and water permeability of concrete. J. Clean. Prod. 2020, 257, 120518. [Google Scholar] [CrossRef]

- García Lodeiro, I.; Macphee, D.E.; Palomo, A.; Fernández-Jiménez, A. Effect of alkalis on fresh C-S-H gels. FTIR analysis. Cem. Concr. Res. 2009, 39, 147–153. [Google Scholar] [CrossRef]

- Ylmén, R.; Wadsö, L.; Panas, I. Insights into early hydration of Portland limestone cement from infrared spectroscopy and isothermal calorimetry. Cem. Concr. Res. 2010, 40, 1541–1546. [Google Scholar] [CrossRef]

- Chen, P.; Wang, X.; Zhang, T.; Guo, Y.; Li, K.; Chen, C.; Wu, Z.; Wei, J.; Yu, Q. Effect of ultrafine recycled brick powder on the properties of blended cement: Hydration kinetics, microstructure evolution and properties development. Constr. Build. Mater. 2023, 394, 132239. [Google Scholar] [CrossRef]

- Barbir, D.; Dabić, P.; Jakić, M.; Weber, I. Evaluating the heat of hydration, conductivity, and microstructural properties of cement composites with recycled concrete powder. Buildings 2025, 15, 2613. [Google Scholar] [CrossRef]

- Xiao, J.; Hao, L.; Cao, W.; Ye, T. Influence of recycled powder derived from waste concrete on mechanical and thermal properties of foam concrete. J. Build. Eng. 2022, 61, 105203. [Google Scholar] [CrossRef]

| Cement (kg) | Fly Ash (kg) | Recycled Powder (kg) | Water (kg) | Calcium Stearate (kg) | Foam (m3) | Dry Apparent Density (kg/m3) | |

|---|---|---|---|---|---|---|---|

| A05-0RP | 412.80 | 45.87 | 0 | 229.33 | 3.44 | 0.932 | 525.2 |

| A05-10RP | 371.52 | 45.87 | 41.28 | 229.33 | 3.44 | 0.932 | 518.3 |

| A05-20RP | 330.24 | 45.87 | 82.56 | 229.33 | 3.44 | 0.932 | 520.4 |

| A05-30RP | 288.96 | 45.87 | 123.84 | 229.33 | 3.44 | 0.932 | 515.6 |

| A06-0RP | 483.75 | 53.75 | 0 | 268.75 | 4.03 | 0.834 | 619.3 |

| A06-10RP | 435.37 | 53.75 | 48.38 | 268.75 | 4.03 | 0.834 | 620.8 |

| A06-20RP | 387.00 | 53.75 | 96.75 | 268.75 | 4.03 | 0.834 | 613.8 |

| A06-30RP | 338.62 | 53.75 | 145.13 | 268.75 | 4.03 | 0.834 | 615.3 |

| A07-0RP | 548.85 | 60.98 | 0 | 304.92 | 4.57 | 0.744 | 720.3 |

| A07-10RP | 493.96 | 60.98 | 54.89 | 304.92 | 4.57 | 0.744 | 715.5 |

| A07-20RP | 439.08 | 60.98 | 109.77 | 304.92 | 4.57 | 0.744 | 717.6 |

| A07-30RP | 384.19 | 60.98 | 164.66 | 304.92 | 4.57 | 0.744 | 711.8 |

| A08-0RP | 585.90 | 65.10 | 0 | 325.50 | 4.88 | 0.693 | 820.7 |

| A08-10RP | 527.31 | 65.10 | 58.59 | 325.50 | 4.88 | 0.693 | 819.2 |

| A08-20RP | 468.72 | 65.10 | 117.18 | 325.50 | 4.88 | 0.693 | 813.2 |

| A08-30RP | 410.13 | 65.10 | 175.77 | 325.50 | 4.88 | 0.693 | 809.6 |

| A09-0RP | 659.59 | 73.29 | 0 | 366.44 | 5.50 | 0.592 | 918.4 |

| A09-10RP | 593.63 | 73.29 | 65.96 | 366.44 | 5.50 | 0.592 | 909.8 |

| A09-20RP | 527.67 | 73.29 | 131.92 | 366.44 | 5.50 | 0.592 | 912.6 |

| A09-30RP | 461.71 | 73.29 | 197.88 | 366.44 | 5.50 | 0.592 | 908.4 |

| A10-0RP | 720.45 | 80.05 | 0 | 400.25 | 6.00 | 0.508 | 1008.9 |

| A10-10RP | 648.41 | 80.05 | 72.04 | 400.25 | 6.00 | 0.508 | 1003.2 |

| A10-20RP | 576.36 | 80.05 | 144.09 | 400.25 | 6.00 | 0.508 | 998.3 |

| A10-30RP | 504.31 | 80.05 | 216.14 | 400.25 | 6.00 | 0.508 | 1008.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tong, X.; Yan, Y.; Tang, Y.; Xu, F.; Liu, M.; Gong, Y. Effect of Recycled Powder from Construction and Demolition Waste on the Macroscopic Properties and Microstructure of Foamed Concrete with Different Dry Density Grades. Buildings 2025, 15, 3395. https://doi.org/10.3390/buildings15183395

Tong X, Yan Y, Tang Y, Xu F, Liu M, Gong Y. Effect of Recycled Powder from Construction and Demolition Waste on the Macroscopic Properties and Microstructure of Foamed Concrete with Different Dry Density Grades. Buildings. 2025; 15(18):3395. https://doi.org/10.3390/buildings15183395

Chicago/Turabian StyleTong, Xiaofang, Yurong Yan, Yujuan Tang, Fei Xu, Miao Liu, and Yongfan Gong. 2025. "Effect of Recycled Powder from Construction and Demolition Waste on the Macroscopic Properties and Microstructure of Foamed Concrete with Different Dry Density Grades" Buildings 15, no. 18: 3395. https://doi.org/10.3390/buildings15183395

APA StyleTong, X., Yan, Y., Tang, Y., Xu, F., Liu, M., & Gong, Y. (2025). Effect of Recycled Powder from Construction and Demolition Waste on the Macroscopic Properties and Microstructure of Foamed Concrete with Different Dry Density Grades. Buildings, 15(18), 3395. https://doi.org/10.3390/buildings15183395