Study on Creep Behavior of Wenzhou Remolded Coastal Silt Under One-Dimensional and Triaxial Tests

Abstract

1. Introduction

2. Experimental Methodology

2.1. Preparation of Wenzhou Remolded Silt Specimens

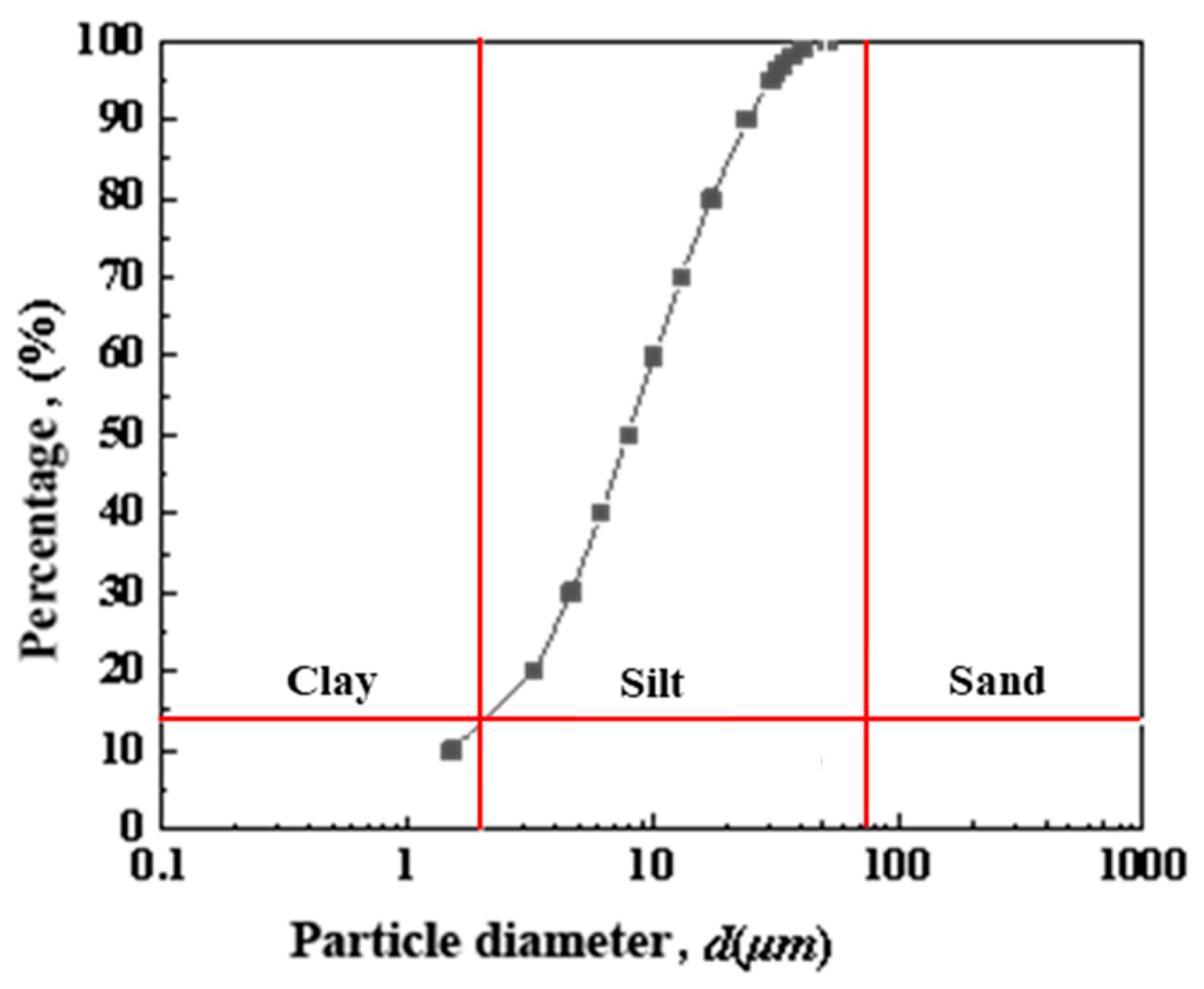

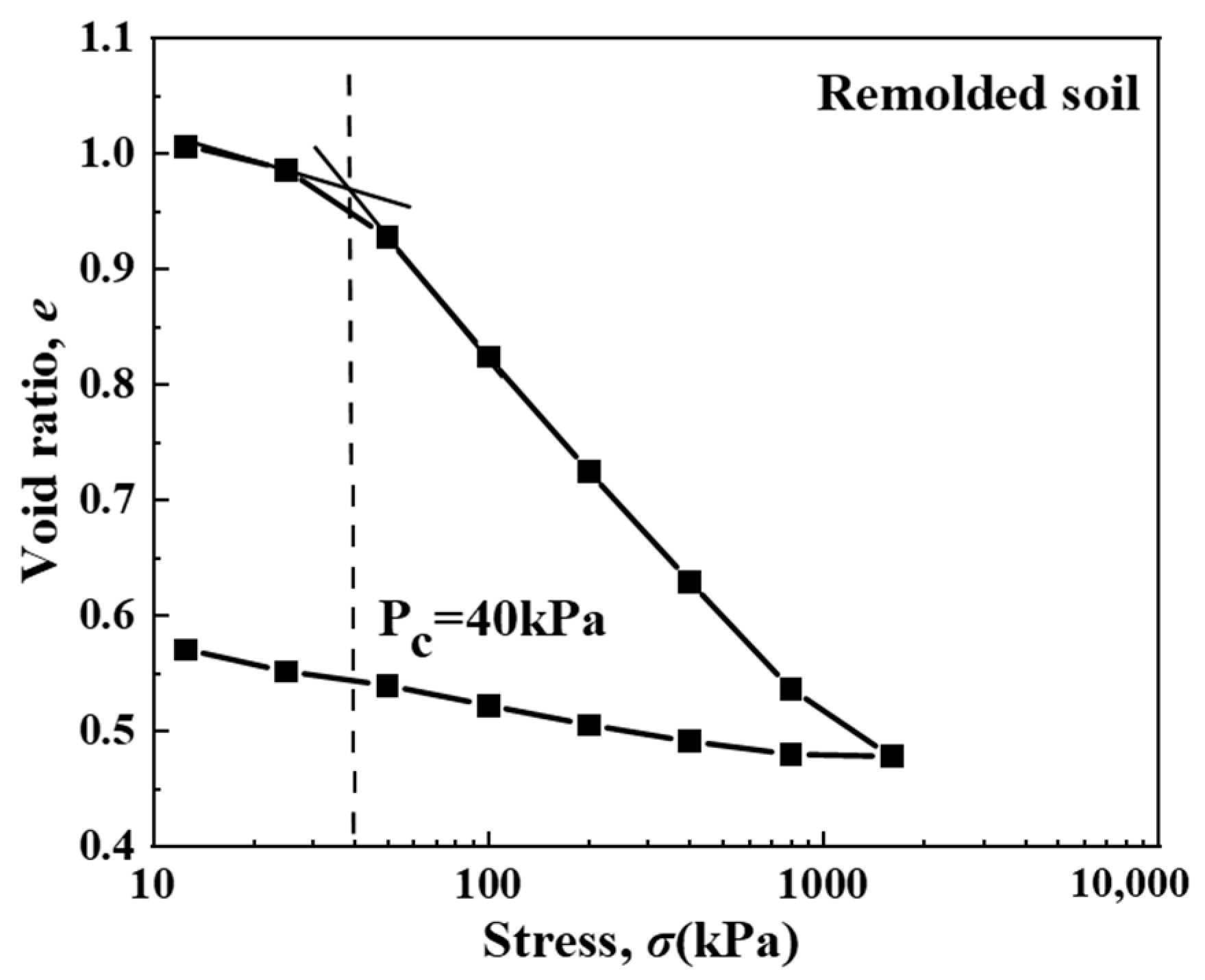

2.1.1. The Basic Physical Properties of Wenzhou Remolded Silt

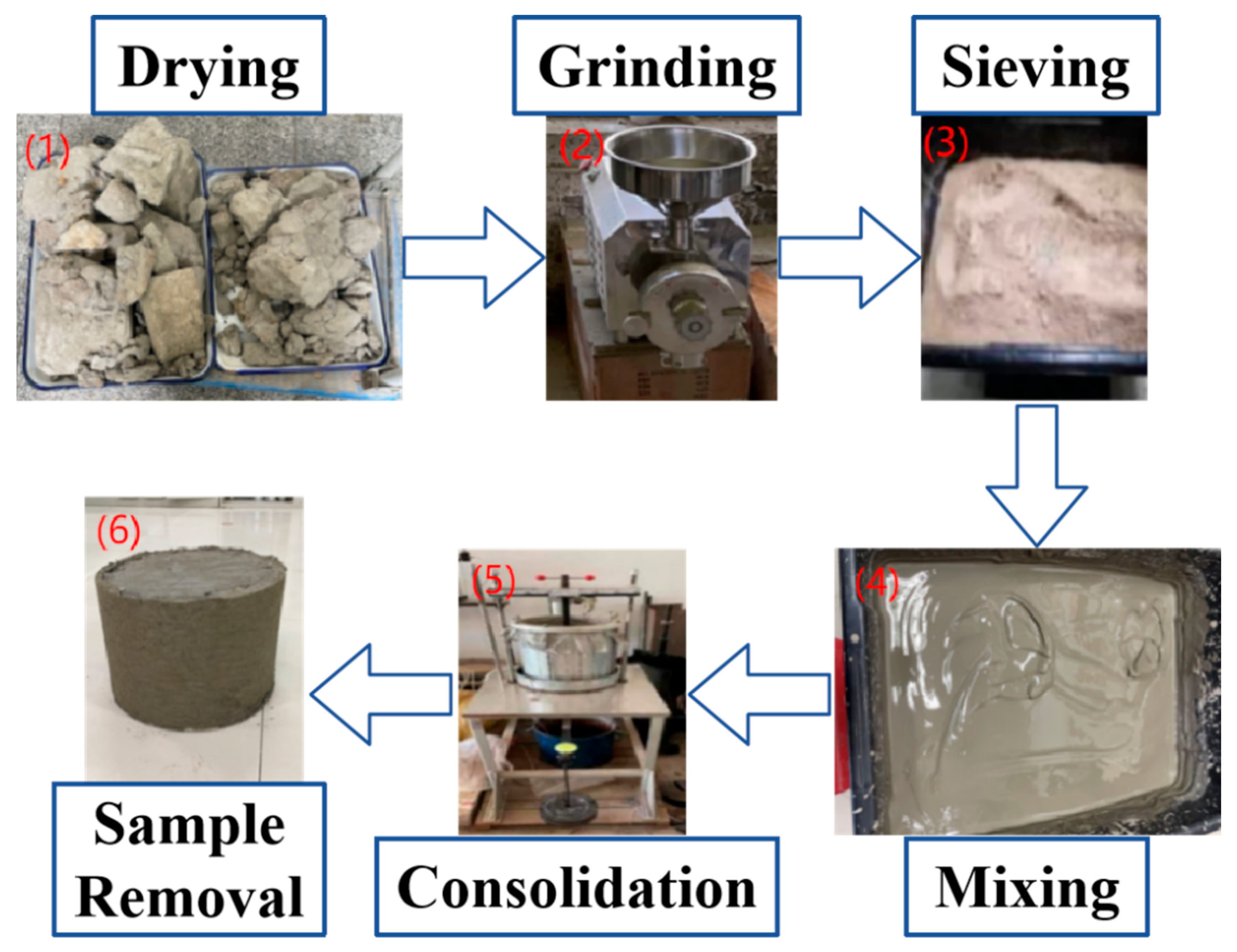

2.1.2. Sample Preparation Process

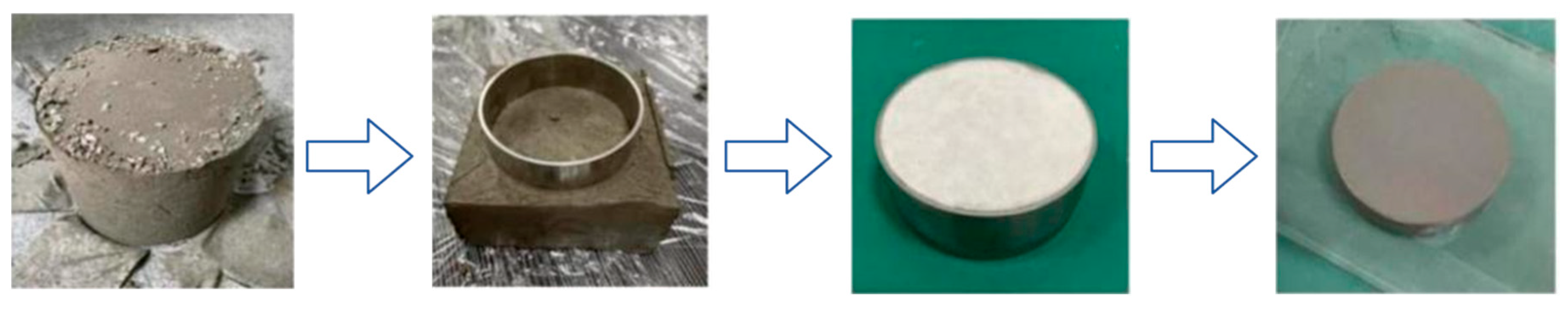

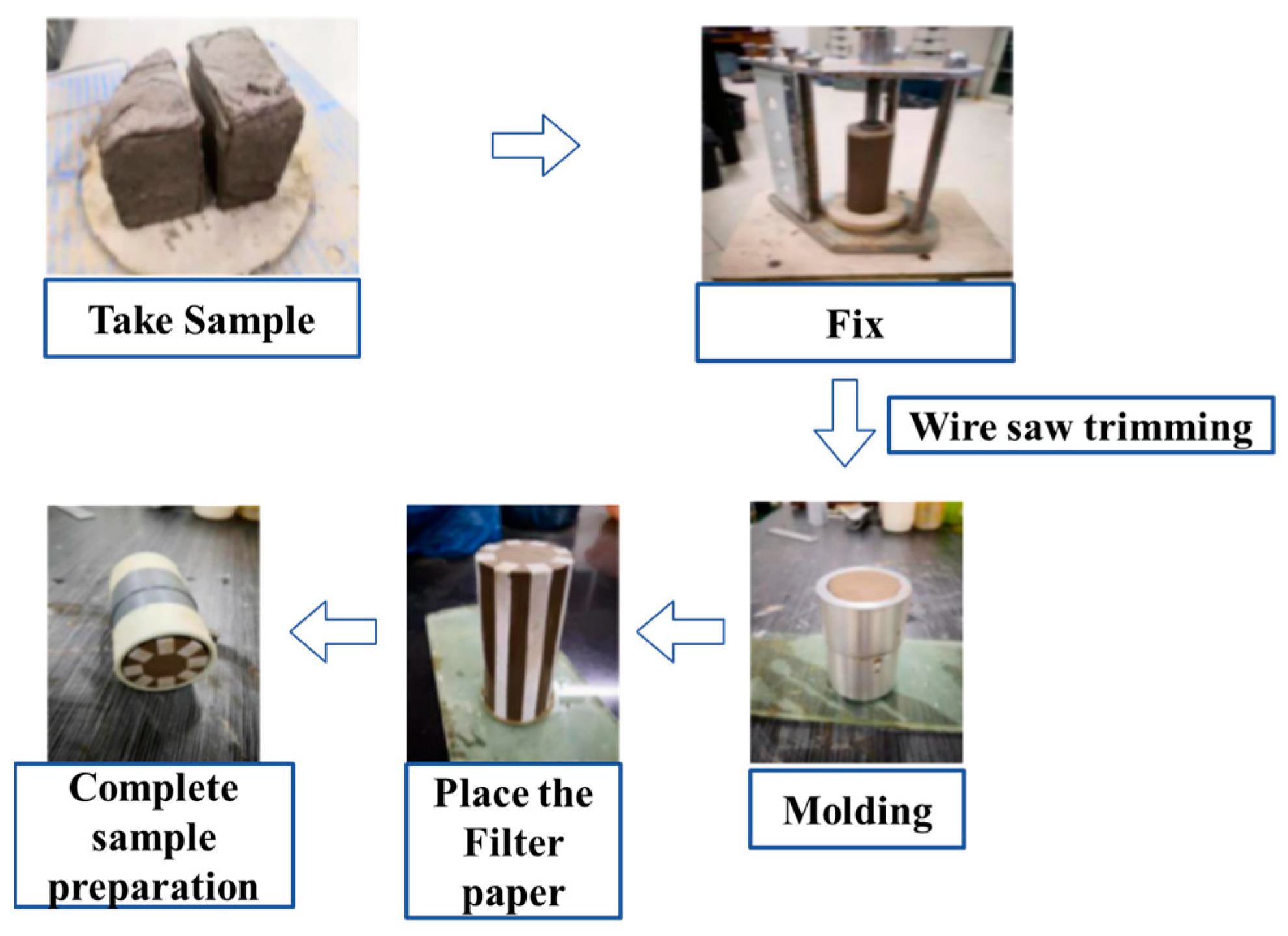

2.1.3. One-Dimensional Creep Sample Preparation Procedure

2.1.4. Preparation Procedure for Three-Dimensional Specimens

2.1.5. Preparation Process of Mesoscopic Test Specimens

2.2. Test Equipment

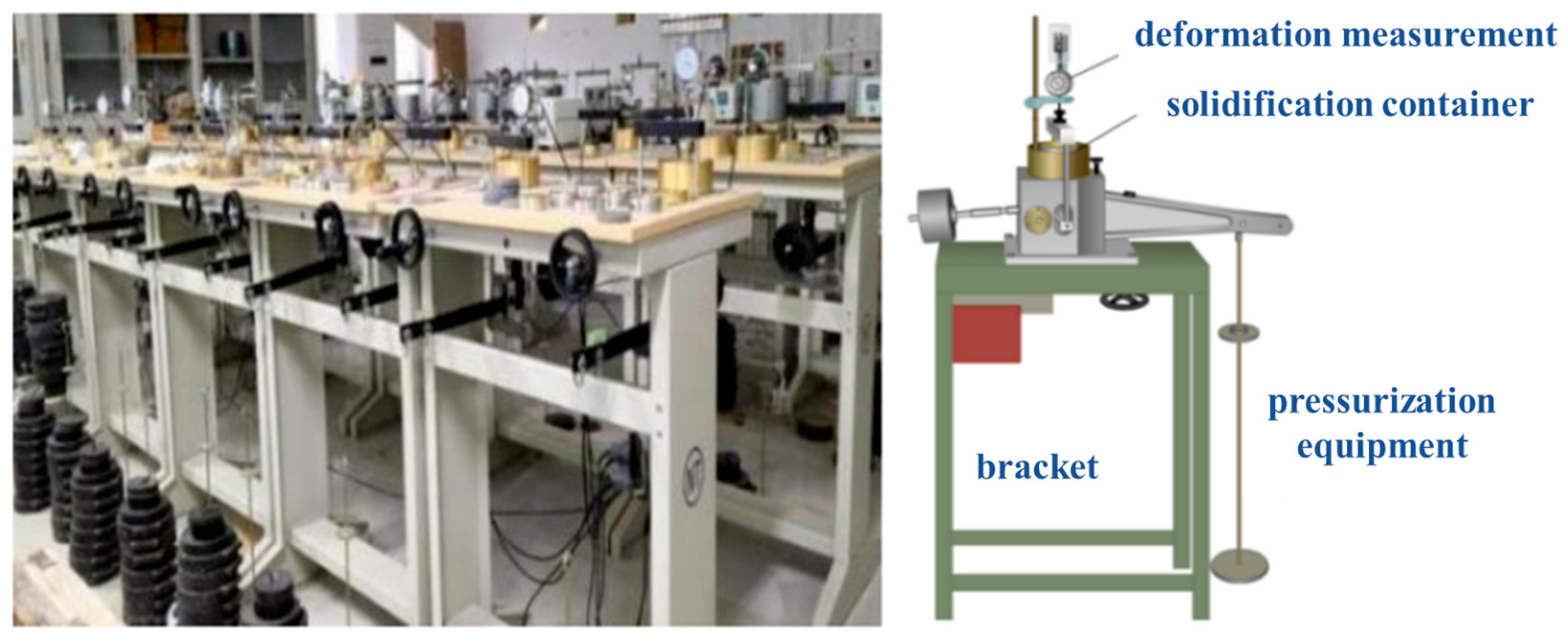

2.2.1. One-Dimensional Consolidometer

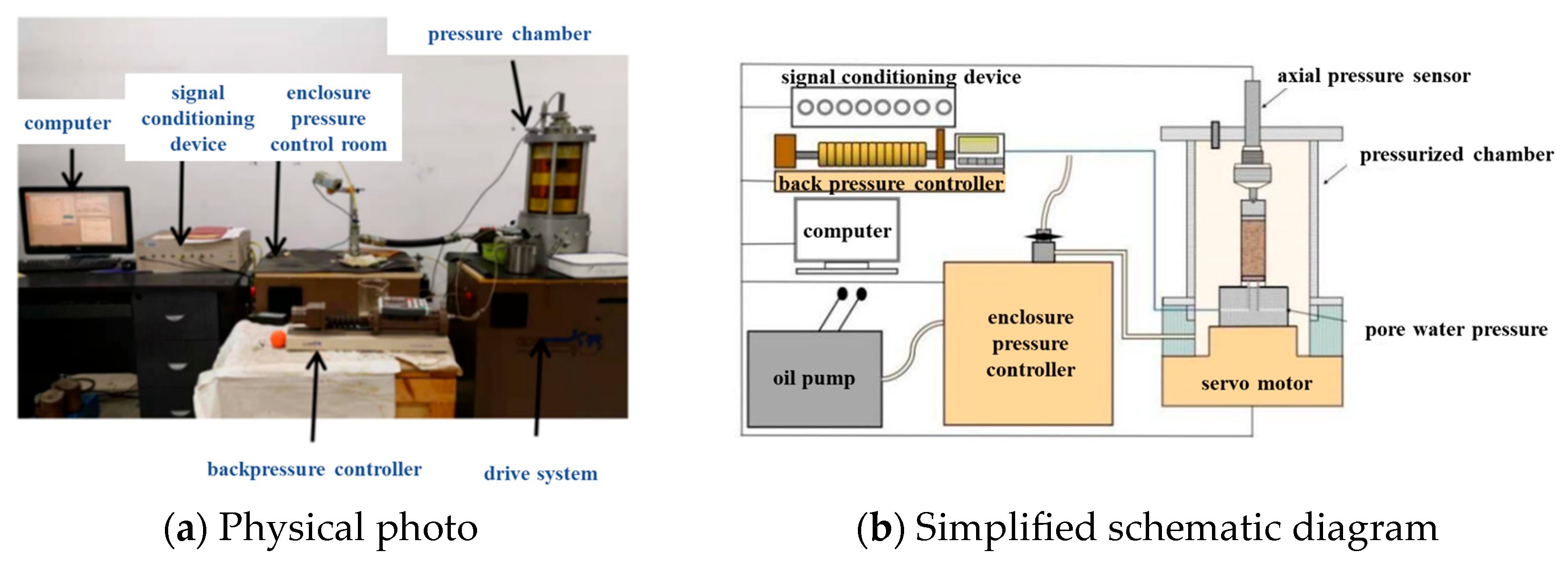

2.2.2. Triaxial Apparatus

2.2.3. Mesostructural Test Equipment

2.3. Test Plan and Procedures

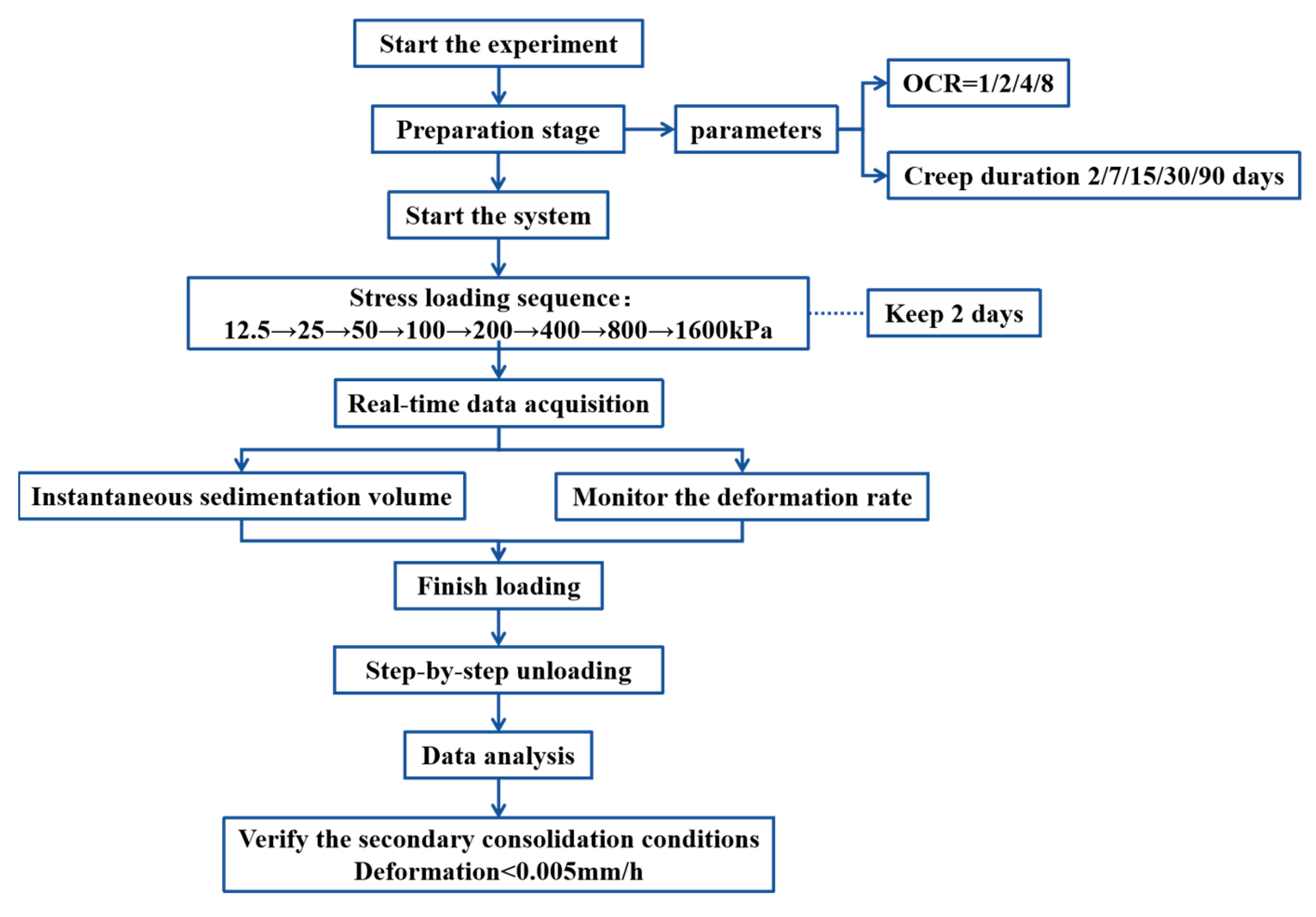

2.3.1. One-Dimensional Creep Test Plan

2.3.2. Three-Dimensional (Triaxial) Creep Test Plan

2.3.3. Mesostructural Test

3. One-Dimensional Creep Characteristics of Remolded Soft Soil

3.1. Influence of Stress Level

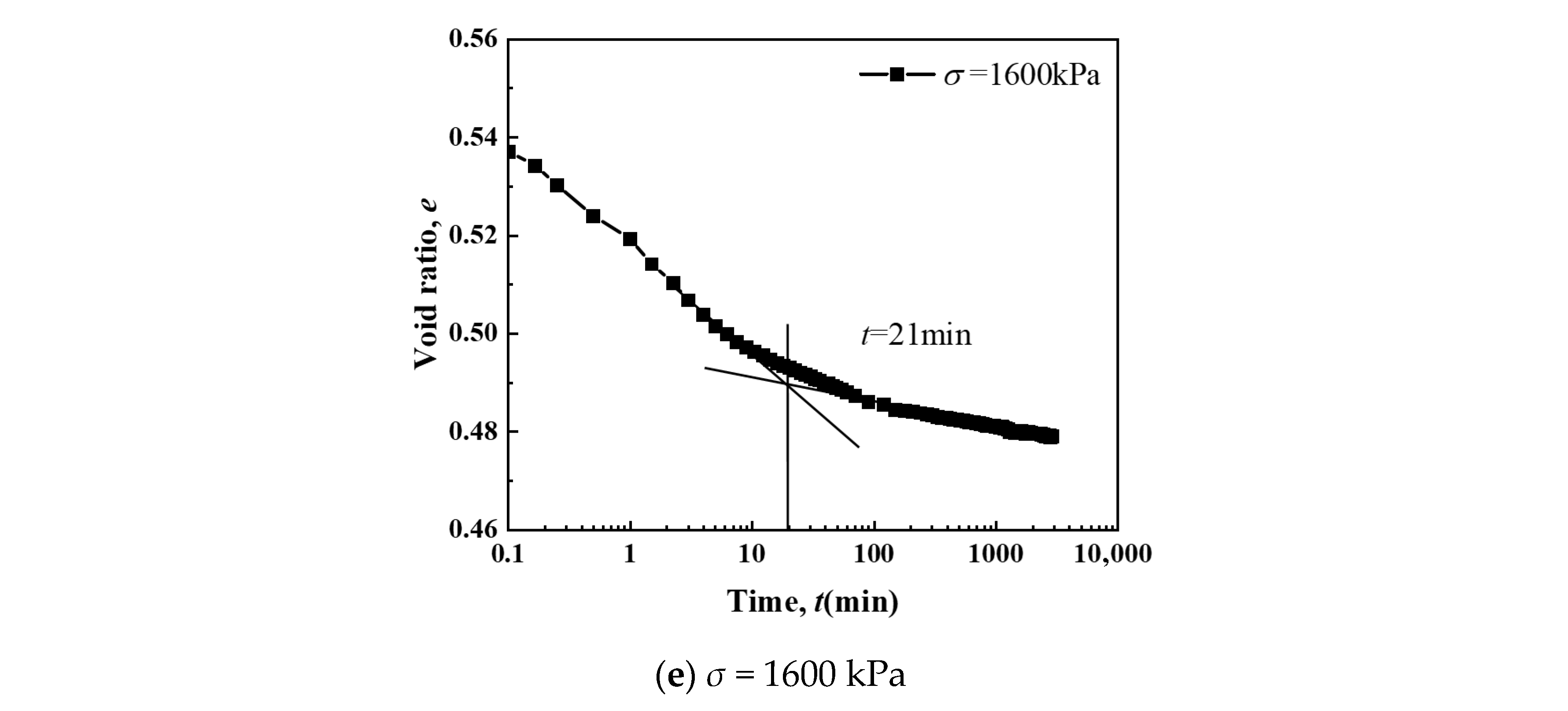

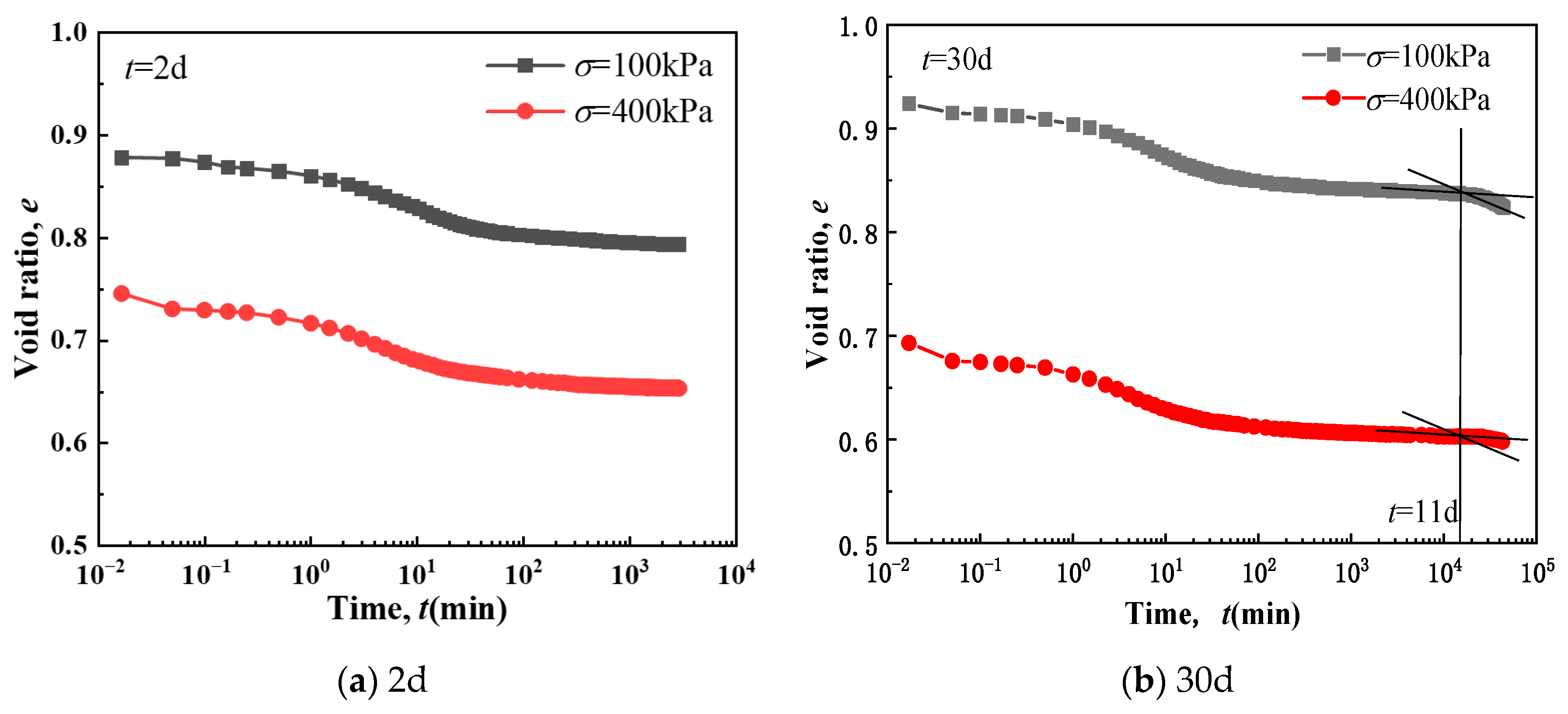

3.1.1. Void Ratio–Time Relationship

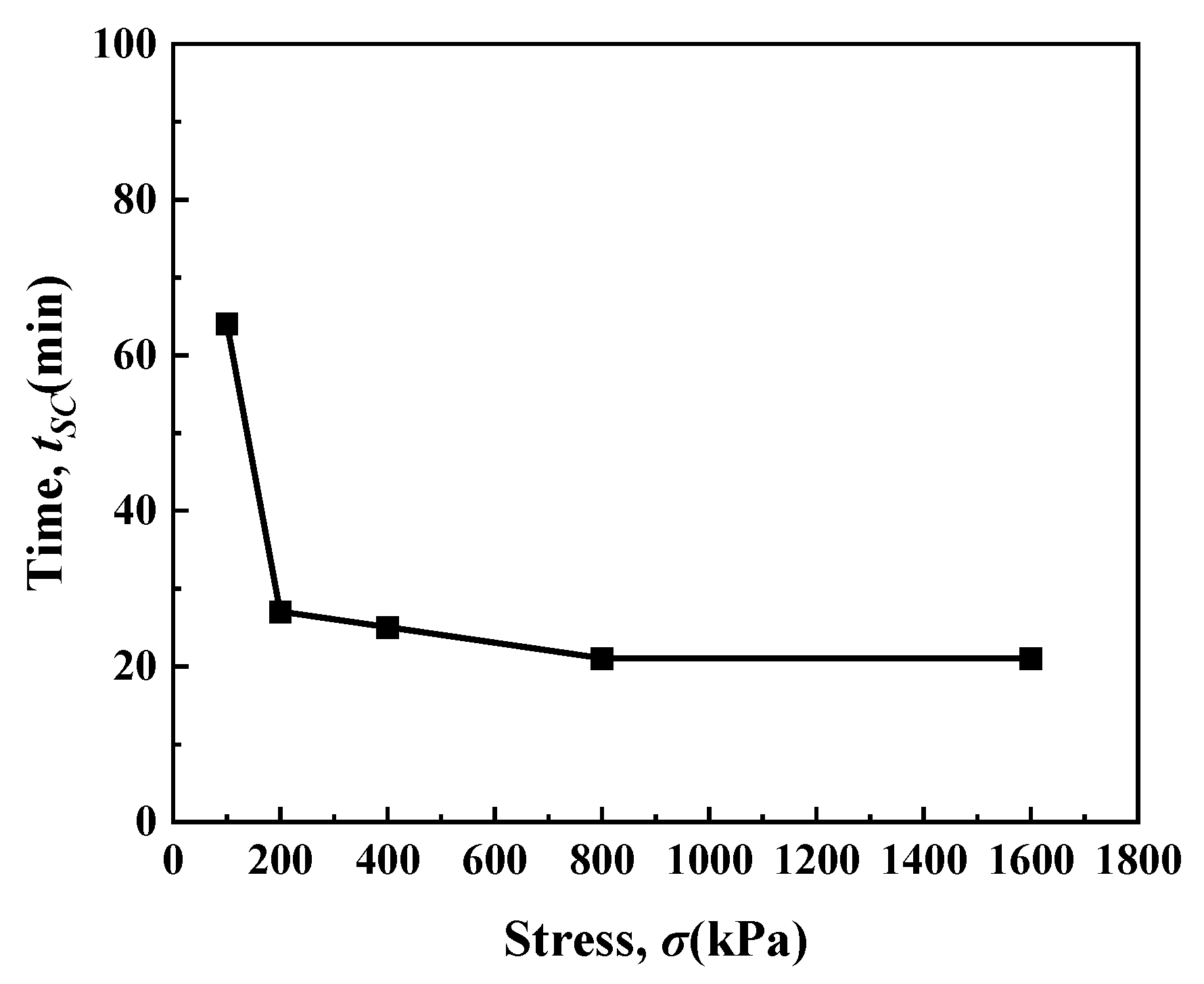

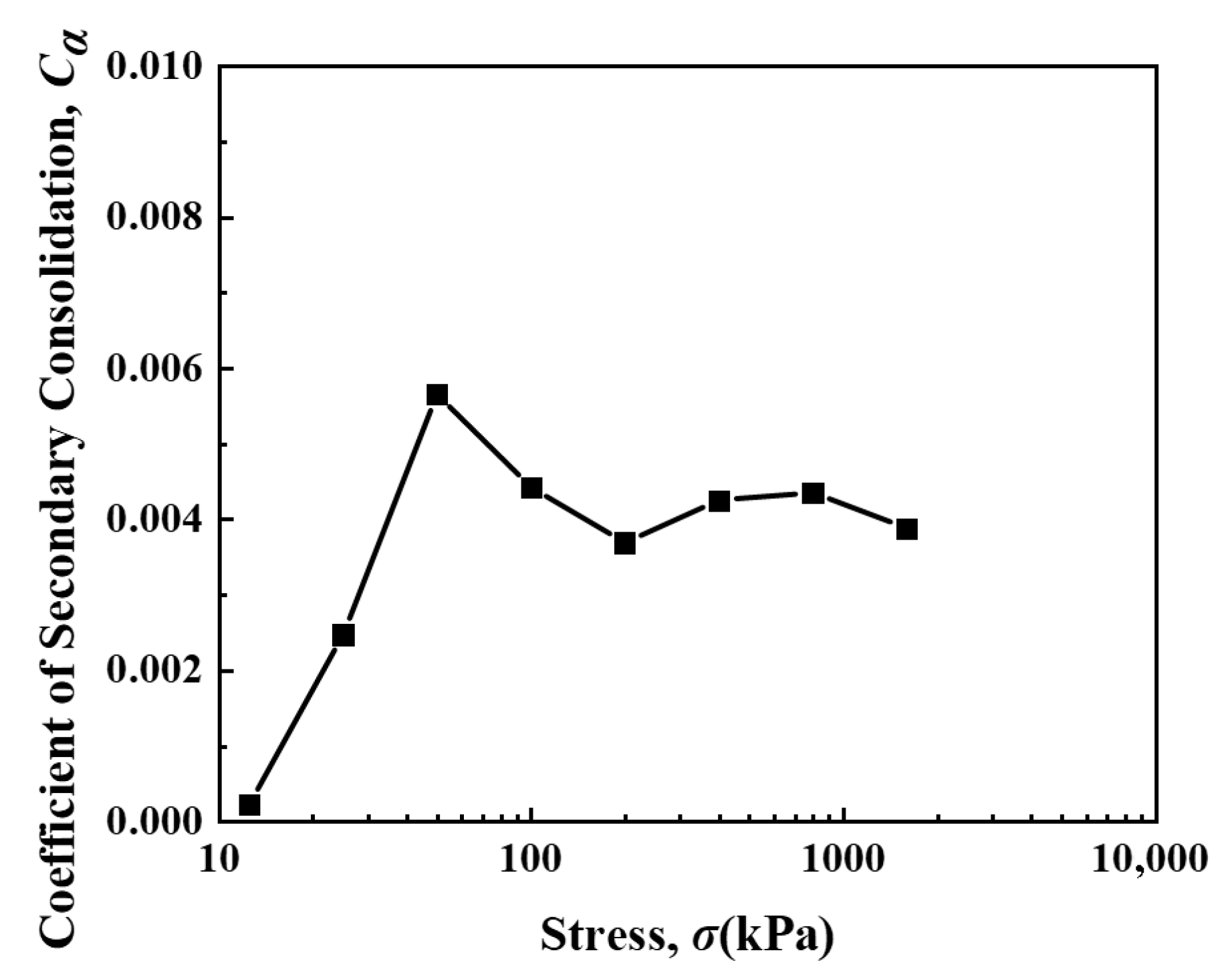

3.1.2. Secondary Consolidation Coefficient

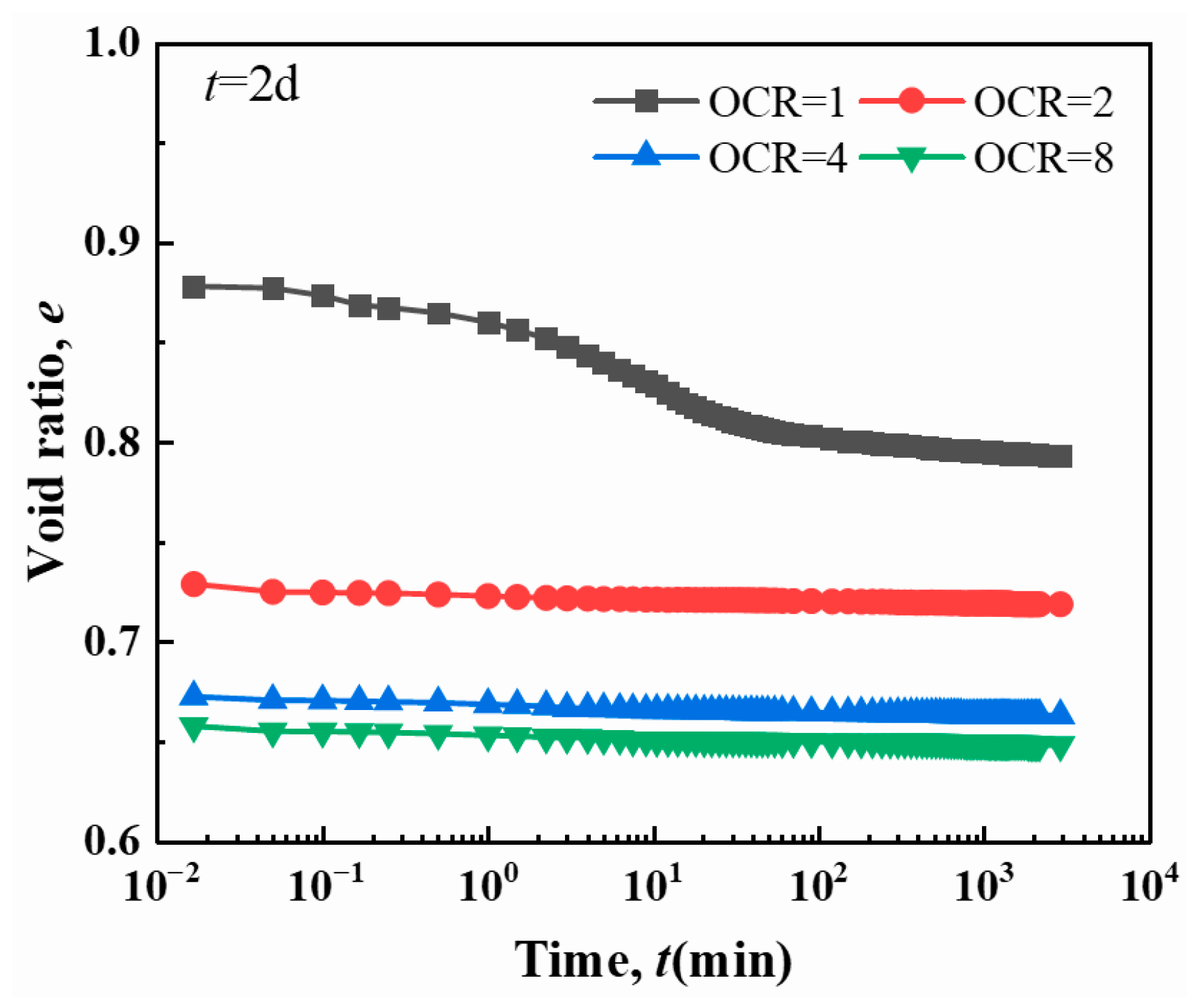

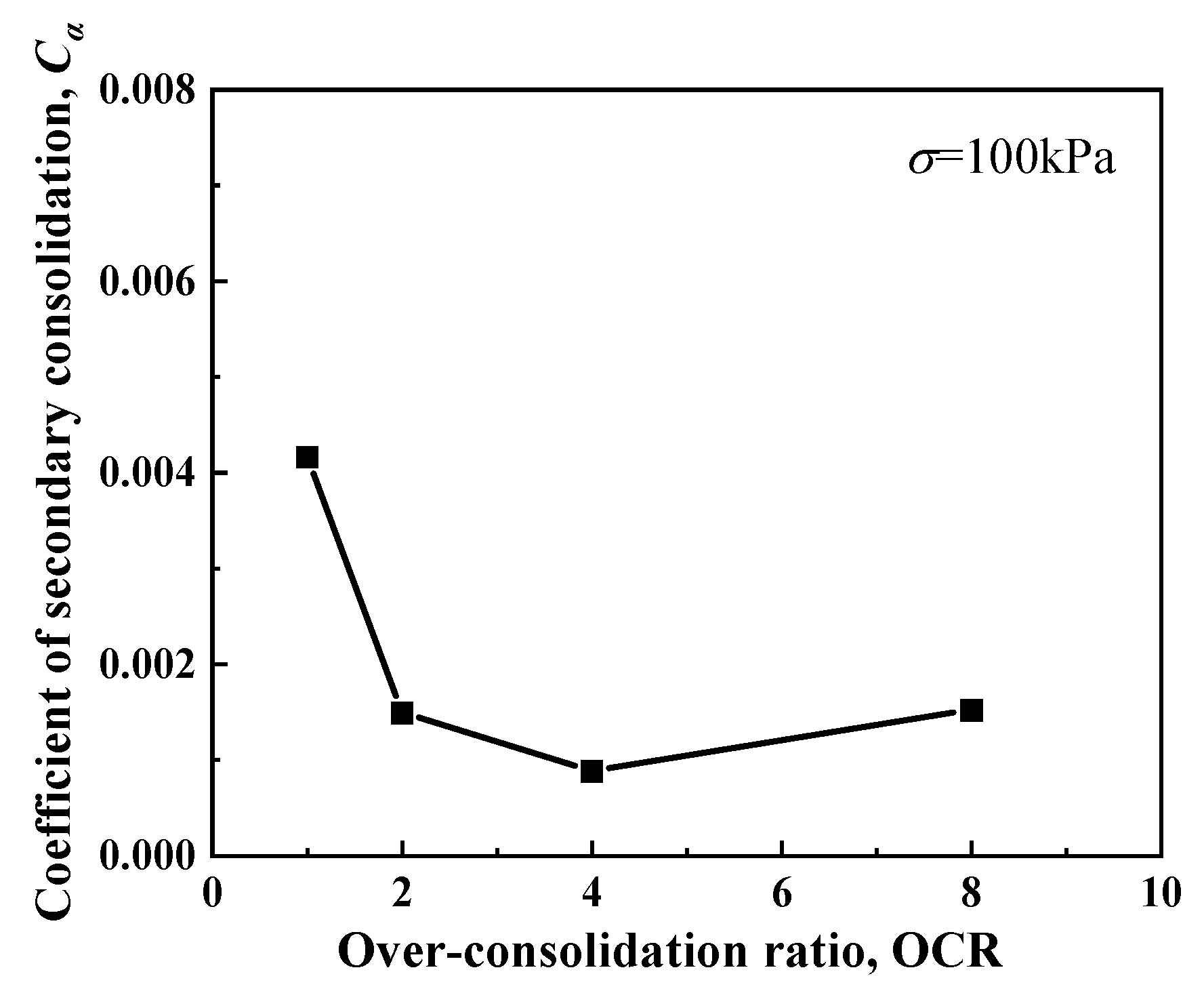

3.2. The Influence of OCR

3.2.1. Porosity-Time Relationship

3.2.2. Secondary Consolidation Coefficient

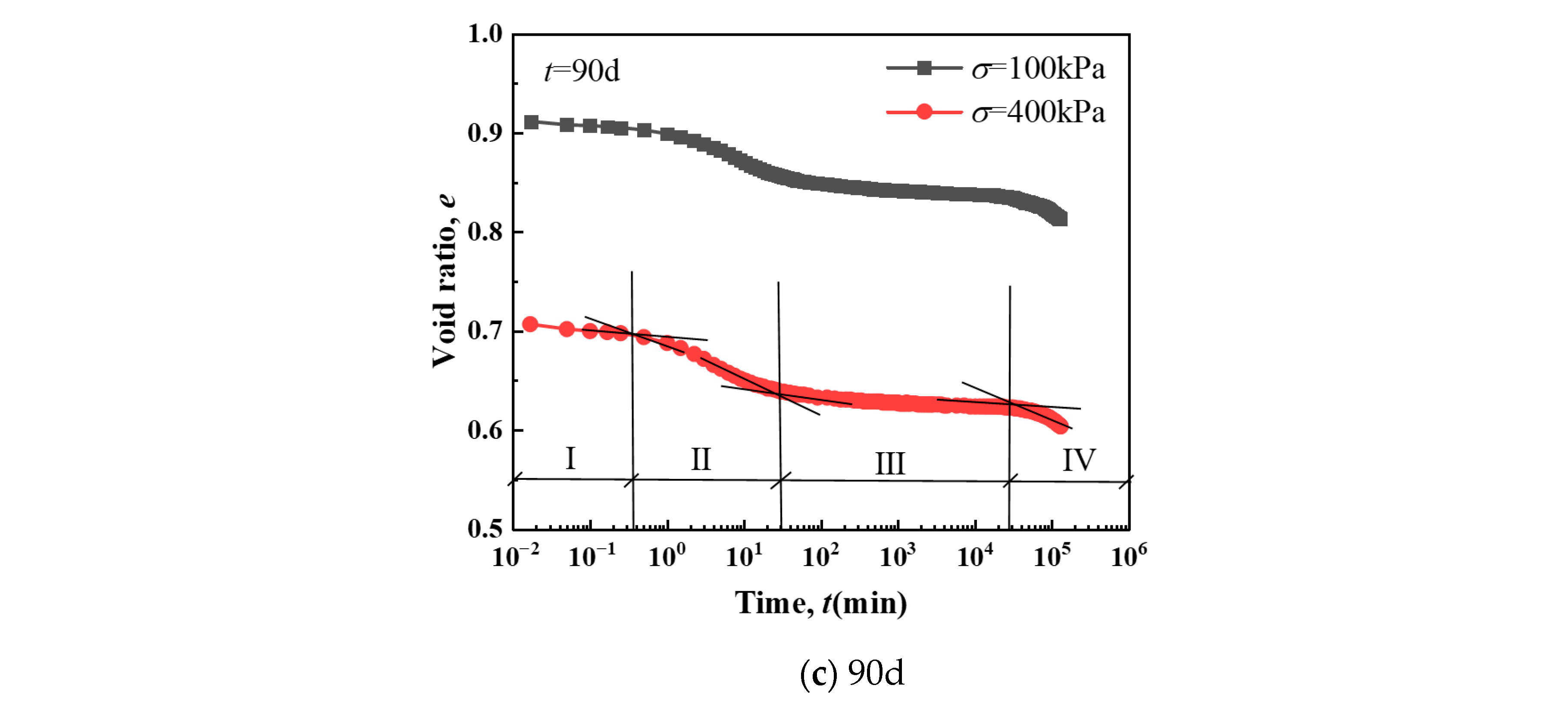

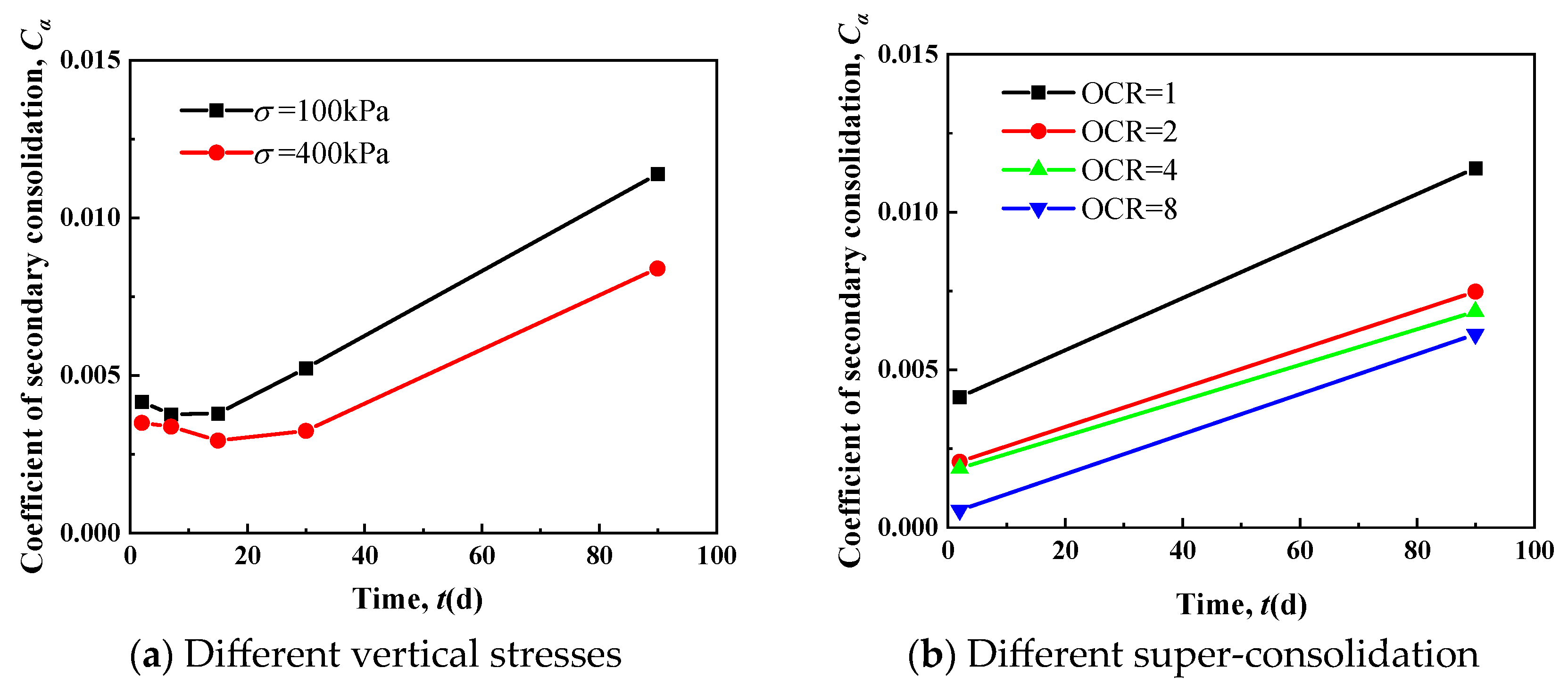

3.3. The Influence of Creep Time

3.3.1. Porosity Ratio–Time Relationship

3.3.2. Secondary Consolidation Coefficient

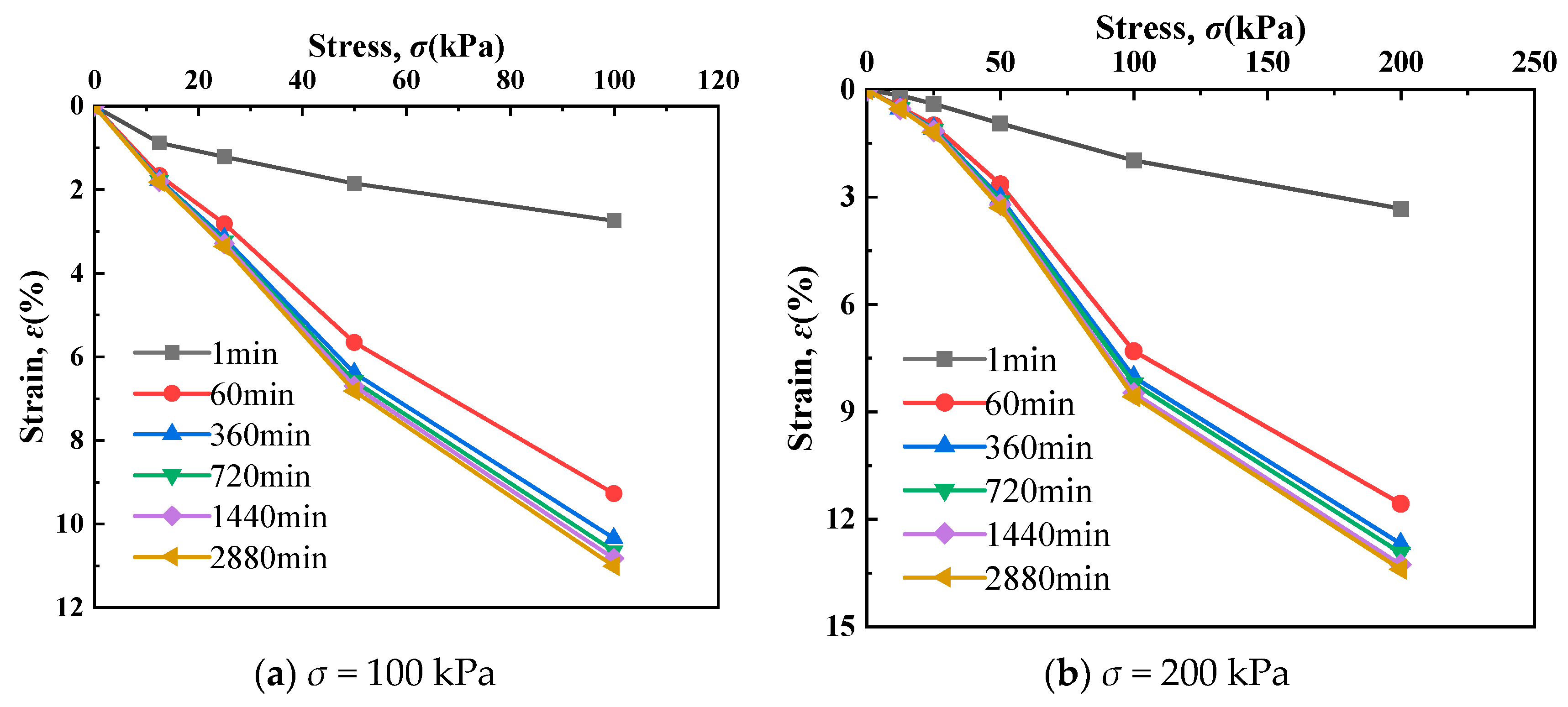

3.4. Stress–Strain Isochronous Relationship Curve

4. Triaxial Creep Characteristics of Remolded Soft Soil

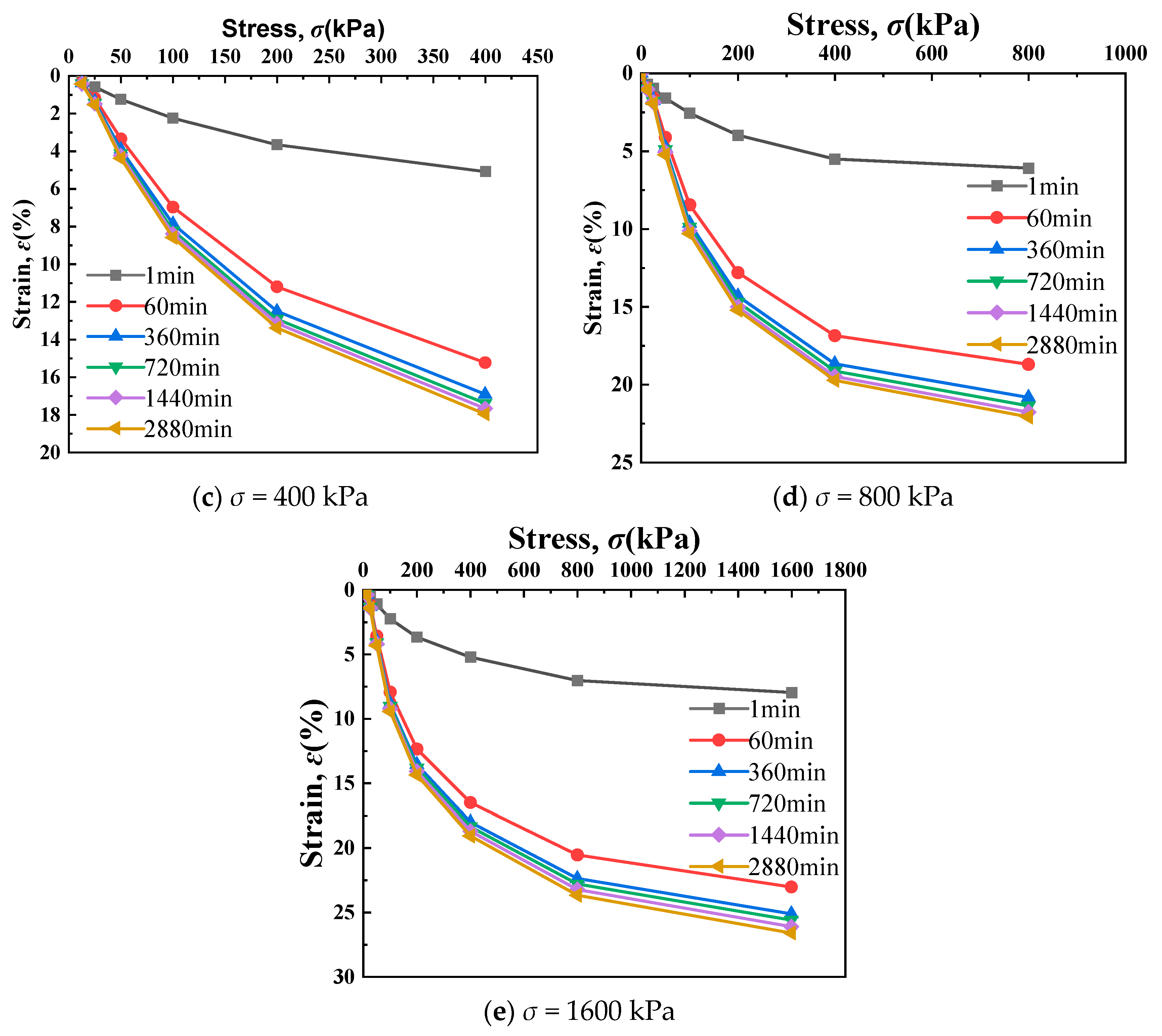

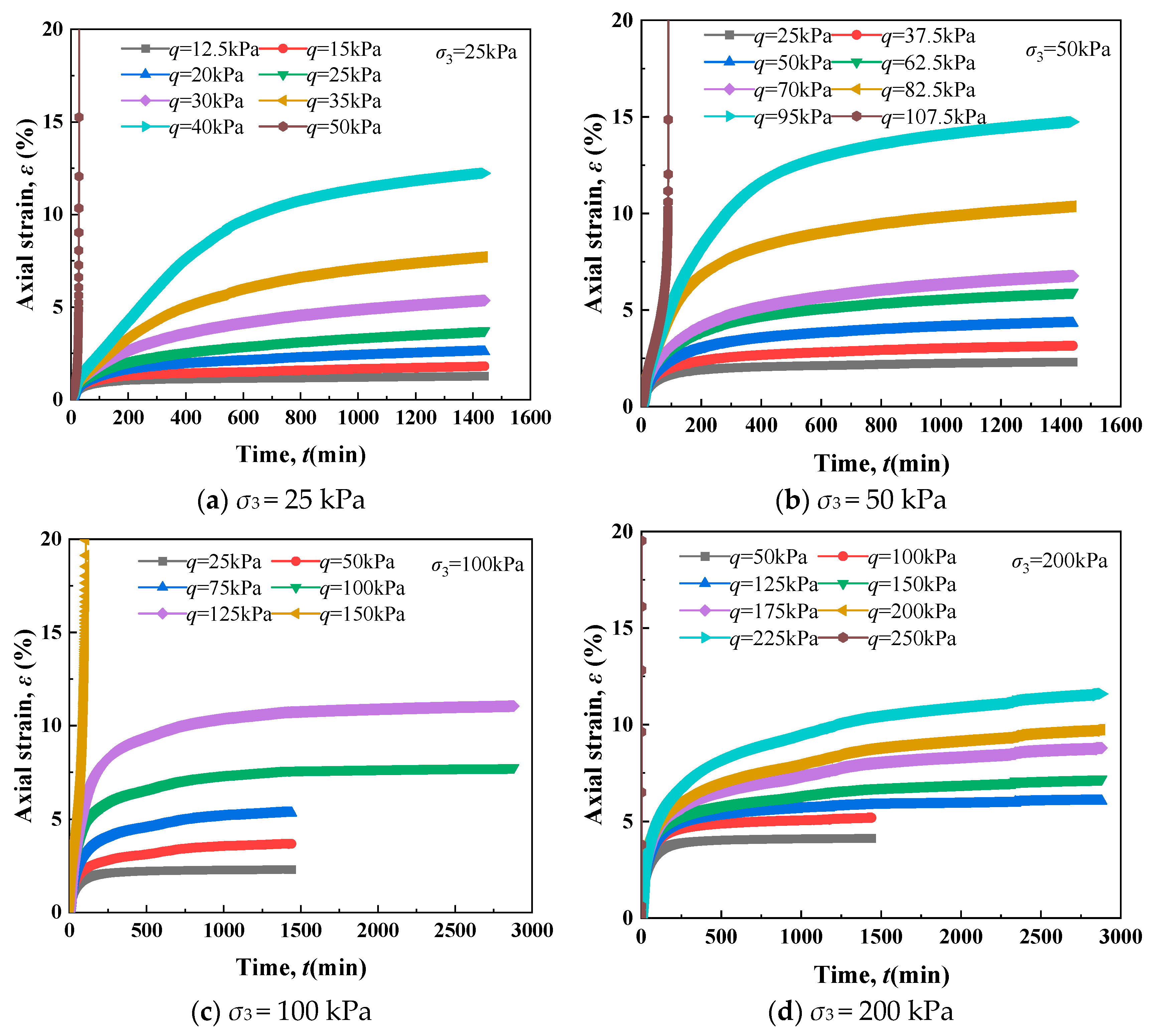

4.1. Axial Strain—Time Relationship

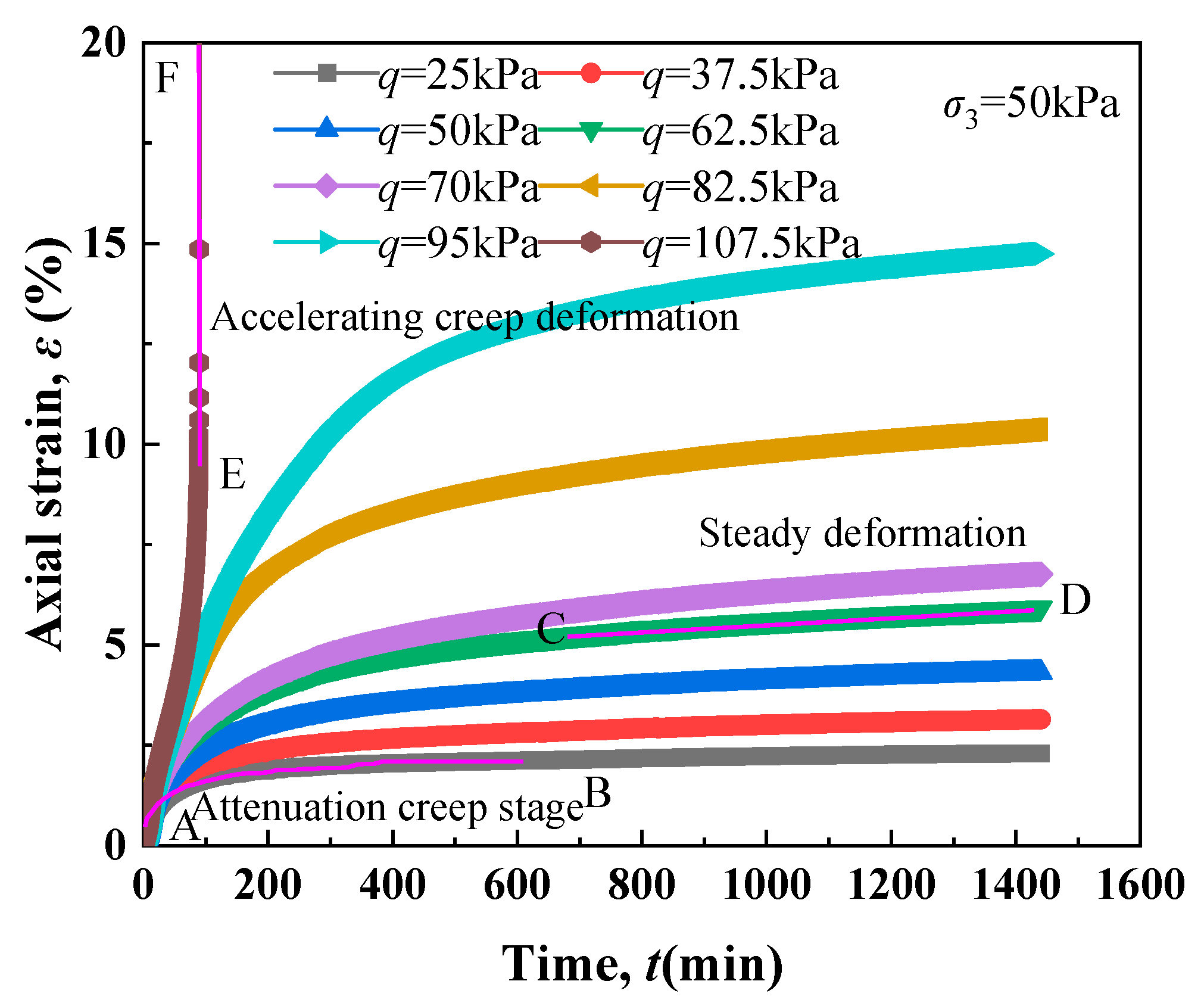

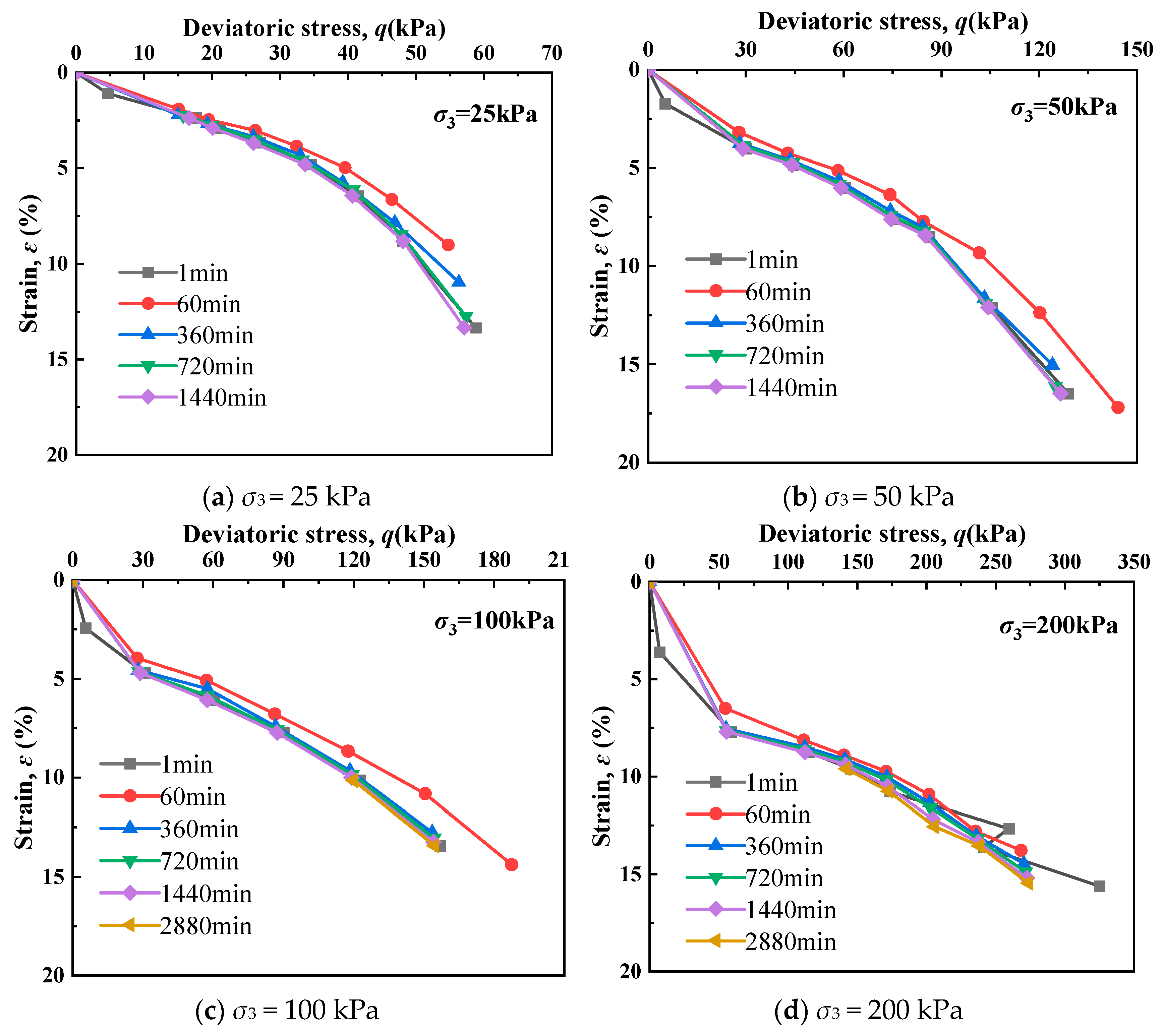

4.2. Partial Stress—Strain Isochronous Relationship Curve

5. Reconstruct the Evolution Characteristics of the Mesoscopic Creep Structure of Soft Soil

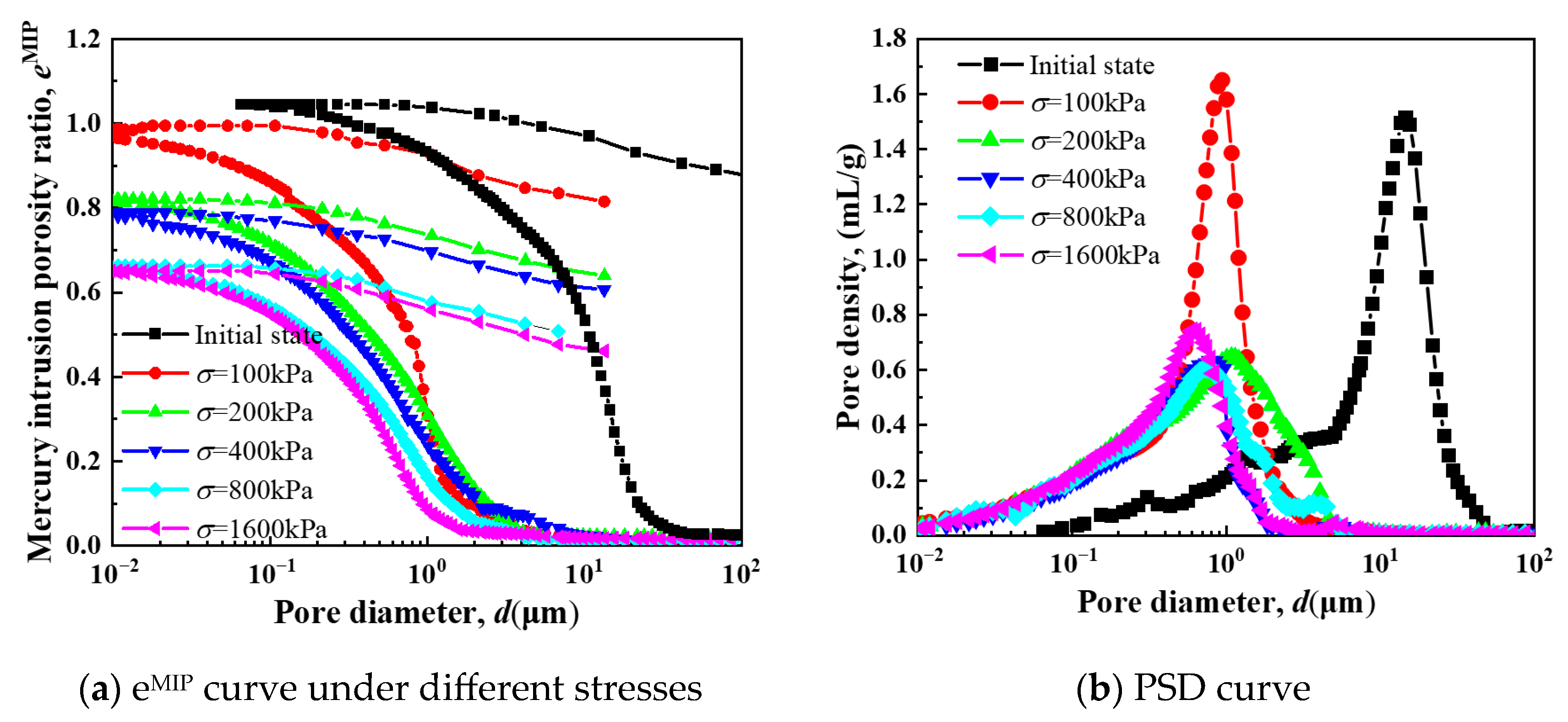

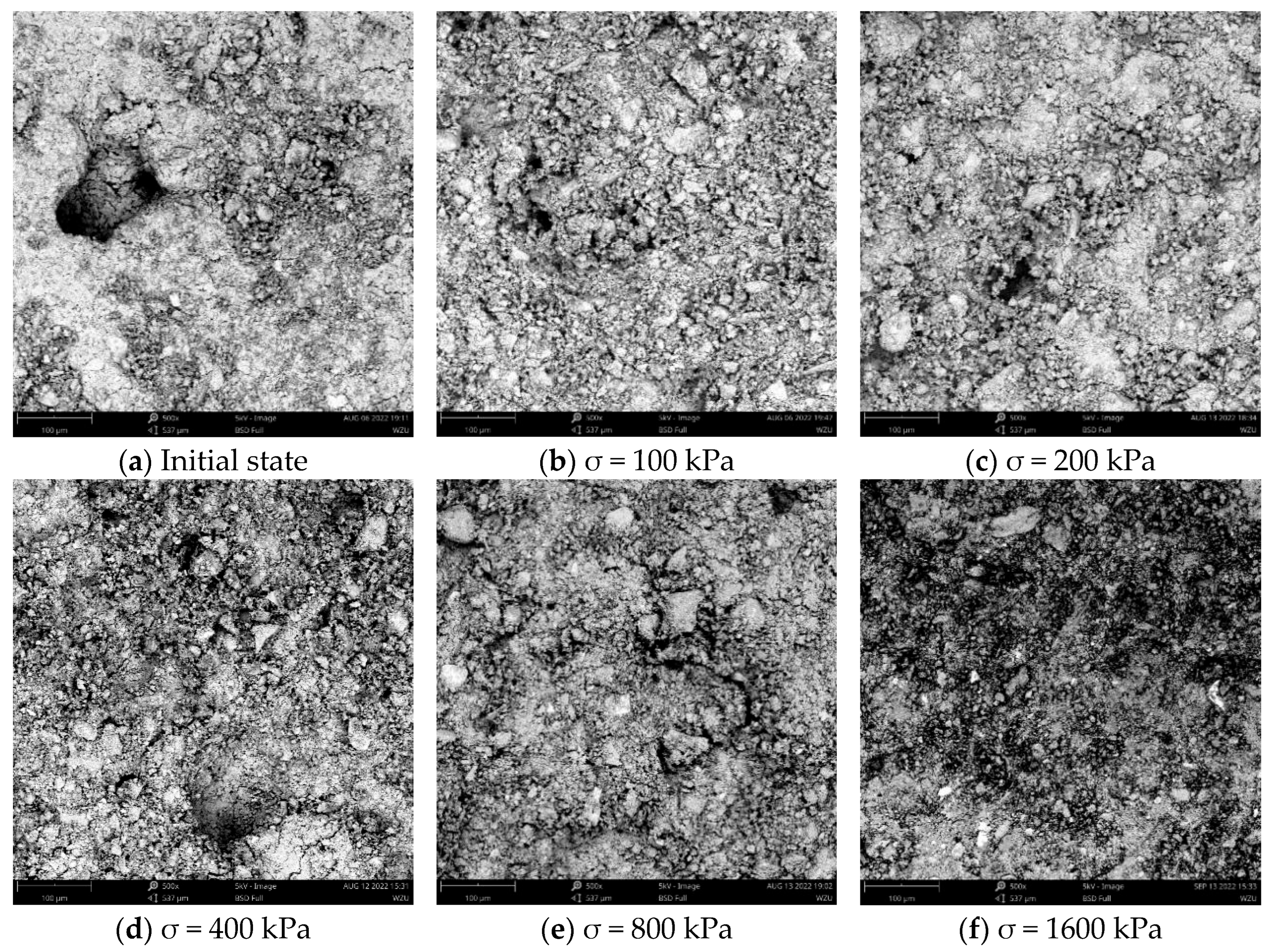

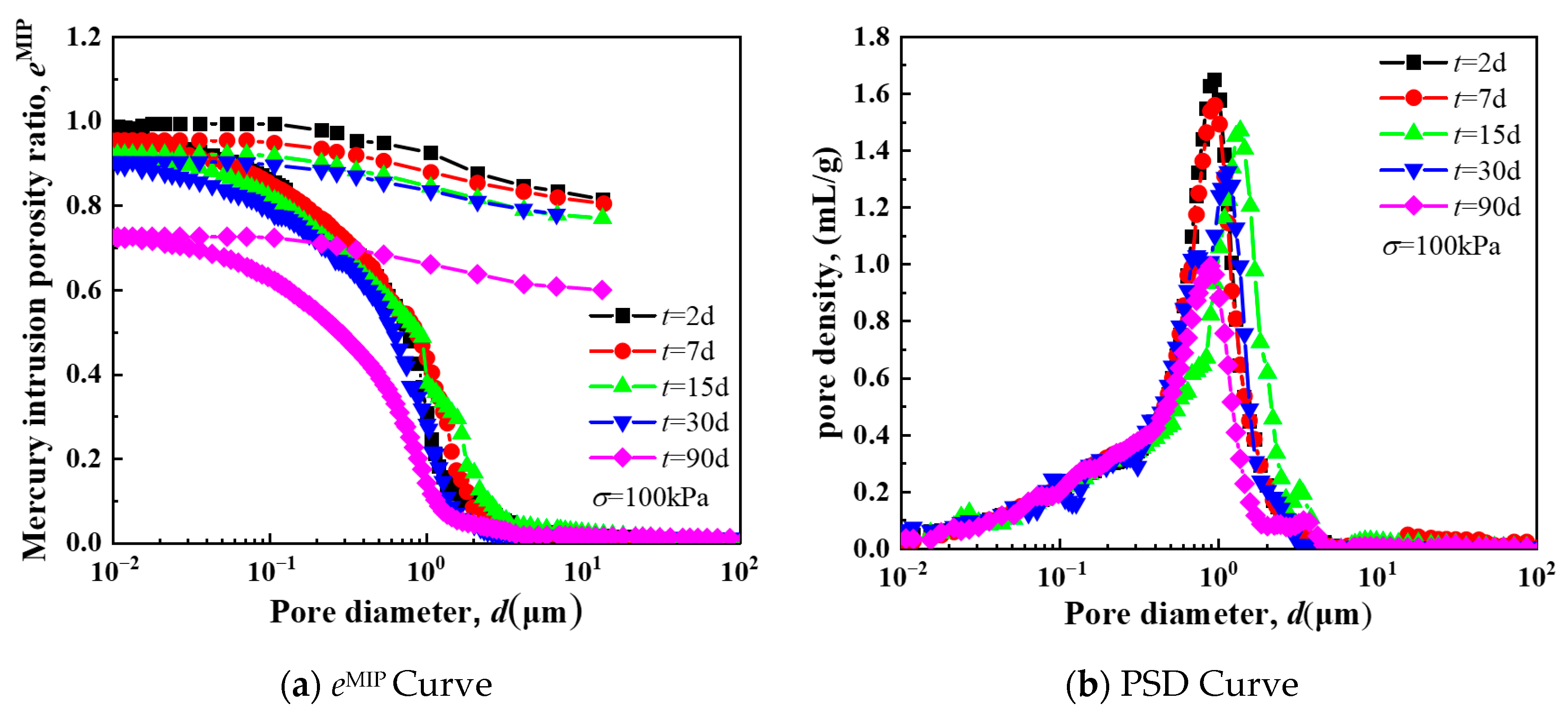

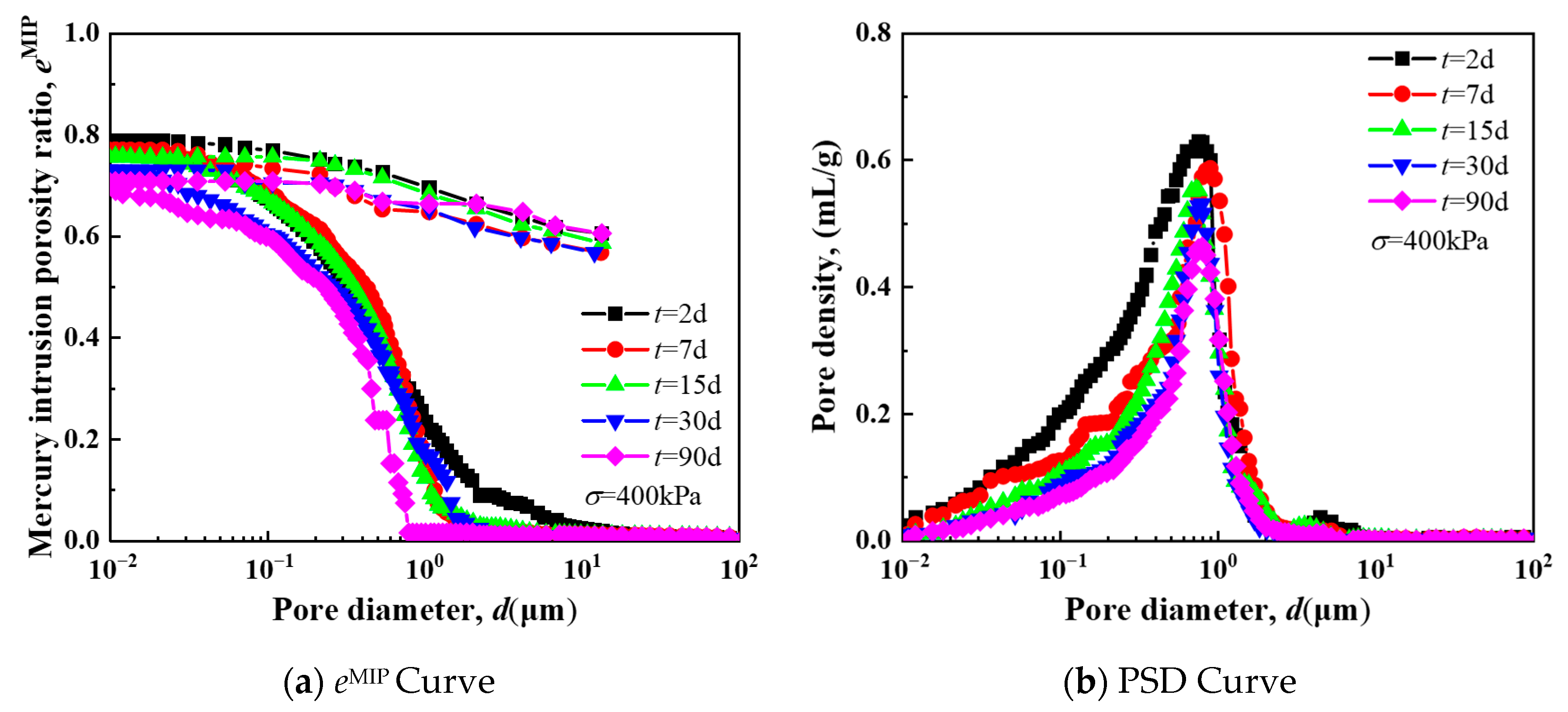

5.1. The Influence of Stress Levels

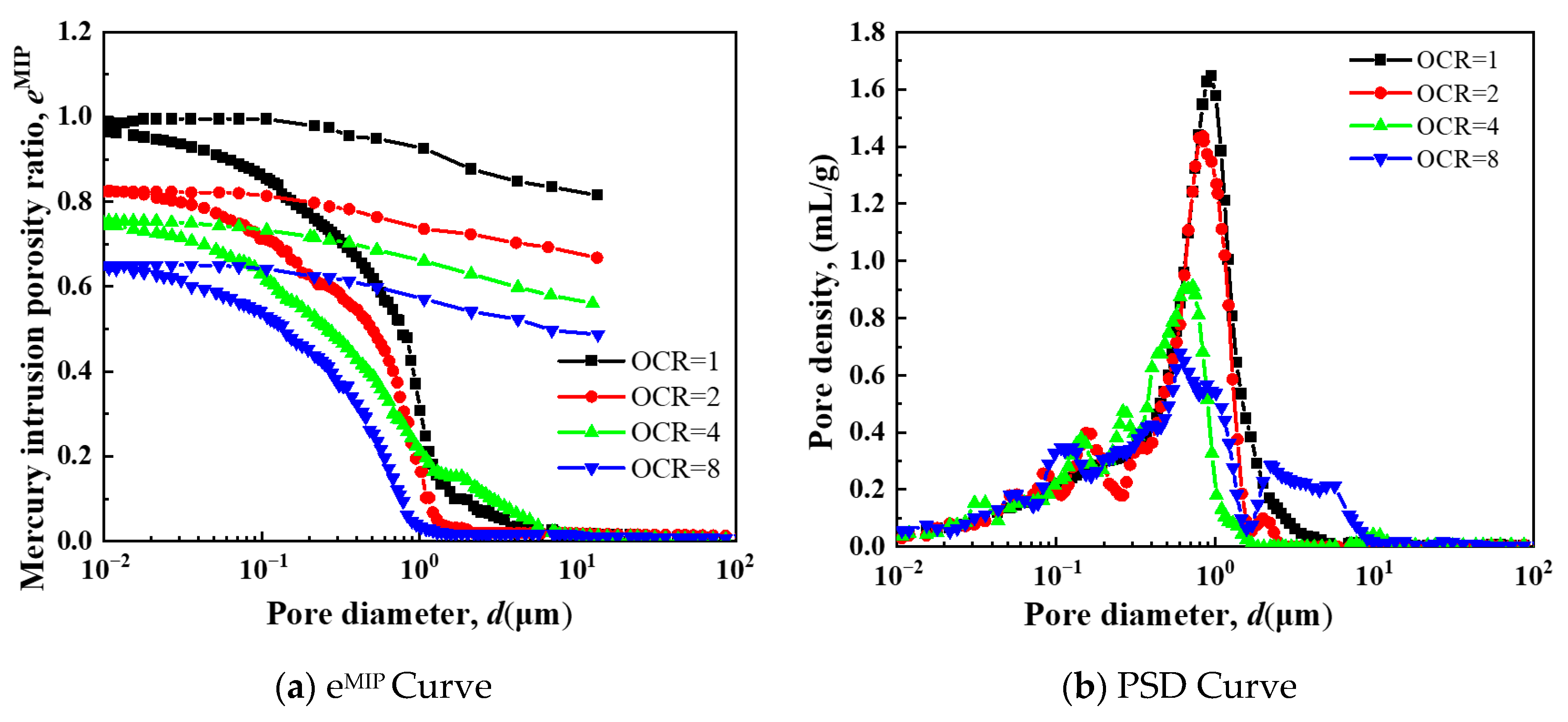

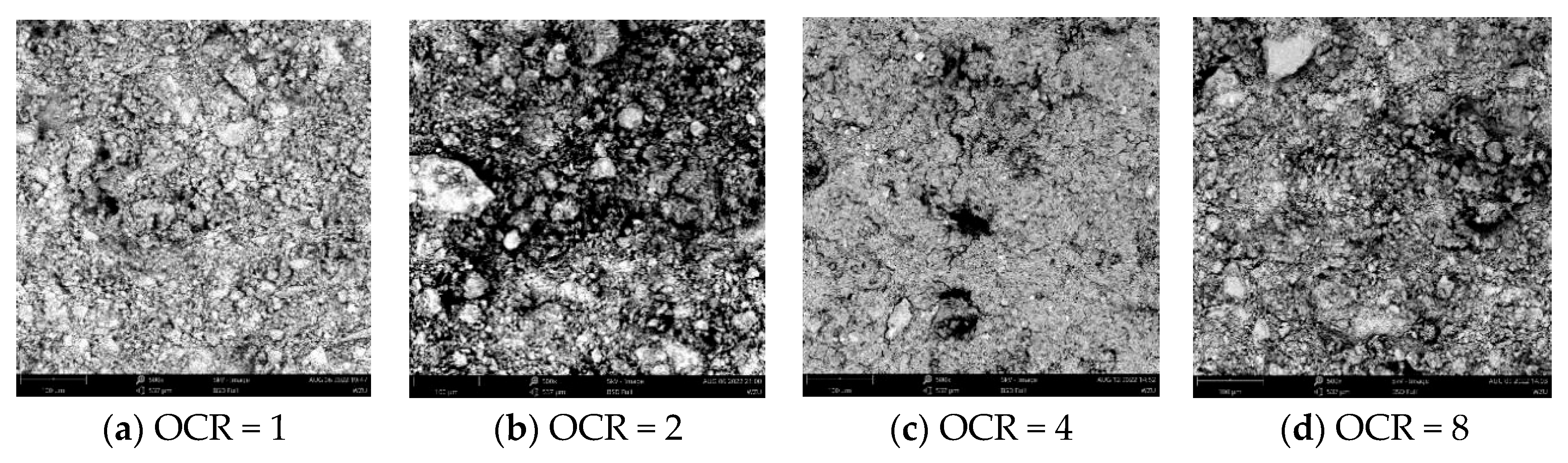

5.2. The Influence of the OCR

5.3. The Influence of Creep Time

6. Conclusions

- The research reveals critical characteristics of remolded silt creep and mesoscopic evolution. First, the secondary consolidation coefficient exhibits distinct stress dependence: it increases rapidly with stress level, peaks at 0.006 under 50 kPa, then decreases and stabilizes. It also shows an inverse relationship with OCR, decreasing as OCR increases, with higher OCR values effectively reducing long-term creep deformation. Second, long-term creep deformation follows four stages (instantaneous, primary consolidation, secondary consolidation, and accelerated secondary consolidation), with the secondary consolidation coefficient increasing over time, confirming time-dependent instability in creep behavior. Third, triaxial creep curves display three stages (attenuation, steady-state, and accelerated creep), with nonlinear attenuation characteristics; higher confining pressures raise the deviatoric stress threshold for entering accelerated creep. Additionally, stress–strain isochronous curves transition from near-linear to nonlinear with increasing stress, exhibiting yield behavior and shifting toward the strain axis as confining pressure increases. Finally, mesoscopic tests show a single-peak pore size distribution (PSD) in remolded silt; with increasing stress, OCR, and creep time, peak pore size and density decrease, and large pores are compressed, indicating that creep deformation is primarily driven by macropore compression.

- An innovative multi-scale experimental framework linking “macroscopic creep–mesoscopic pore structure” was established for remolded silty clays; using MIP and SEM, this framework quantified for the first time the stress-dependent correlation between macropore collapse and macroscopic creep parameters (e.g., secondary consolidation coefficient Cα, accelerated creep threshold)—filling the gap in previous single-scale studies that overlooked this correlation and offering a universal method for long-term creep prediction of similar soils worldwide. Second, a novel “accelerated secondary consolidation stage” was identified in remolded silt: unlike traditional theory assuming constant Cα in this stage increases continuously over time due to long-term particle sliding and pore structure evolution, revising classical creep stage divisions and avoiding the ~20% underestimation of long-term settlement by traditional methods—a geographically unrestricted conclusion applicable to optimizing settlement calculations in global remolded silt engineering. Third, the critical OCR for suppressing remolded silty clay creep was quantified.

- Despite these insights, the study has limitations. First, the current analysis focuses on mechanistic trends rather than large-scale statistical validation. Additionally, the number of specimens used is not explicitly reported, which limits the detailed assessment of variability. Second, mesoscopic structural analyses remain primarily qualitative, with limited quantitative correlations between pore evolution and macroscopic creep. Third, tests were conducted under controlled laboratory conditions, and extrapolation to complex field environments (e.g., varying temperature, salinity, or soil heterogeneity) requires further validation.

- To build on this work, future studies should: (1) incorporate quantitative statistical analyses of specimen variability to strengthen the reliability of results reliability; (2) develop quantitative models linking mesoscopic parameters (e.g., pore size distribution, particle alignment) to macroscopic creep using advanced techniques like 3D microstructure imaging or synchrotron-based characterization; (3) conduct field monitoring of engineered structures in Wenzhou to validate laboratory findings under real-world conditions; (4) explore extended test conditions, such as temperature effects or additive-based modifications (e.g., cementation), to expand understanding of creep mitigation strategies [28].

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qin, W.; Cai, S.; Dai, G.; Wang, D.; Chang, K. Soil Resistance during Driving of Offshore Large-Diameter Open-Ended Thin-Wall Pipe Piles Driven into Clay by Impact Hammers. Comput. Geotech. 2023, 153, 105085. [Google Scholar] [CrossRef]

- Chen, Z.; Deng, H.; Dai, G.; Zhu, M.; Gong, W.; Azadi, M.R. Study on the influence of unsymmetrical surcharge on adjacent pile foundations in a coastal soft soil area. Soil Dyn. Earthq. Eng. 2025, 194, 109365. [Google Scholar] [CrossRef]

- Wang, L.; Qiao, X.; Li, M.; Zhang, Y. Application and Development of Intelligent Systems in Monitoring and Early Warning of Coastal Soft Soil Foundation. Procedia Comput. Sci. 2024, 243, 577–584. [Google Scholar] [CrossRef]

- Liu, F.; Zheng, G.; Cui, G. Settlement deformation characteristics and control of soft soil through groundwater discharge zone. Desalin. Water Treat. 2021, 241, 282–287. [Google Scholar] [CrossRef]

- Peduto, D.; Giangreco, C.; Venmans, A.A. Differential settlements affecting transition zones between bridges and road embankments on soft soils: Numerical analysis of maintenance scenarios by multi-source monitoring data assimilation. Transp. Geotech. 2020, 24, 100369. [Google Scholar] [CrossRef]

- Qin, W.; Ye, C.; Gao, J.; Dai, G.; Wang, D.; Dong, Y. Pore water pressure of clay soil around large-diameter open-endedthin-walled pile (LOTP) during impact penetration. Comput. Geotech. 2025, 180, 107065. [Google Scholar]

- Qin, W.; Gao, J.; Chang, K.; Dai, G.; Wei, H. Set-up effect of large-diameter open-ended thin-walled pipe piles driven in clay. Comput. GeotechReshapeics 2023, 159, 105459. [Google Scholar]

- Li, P.; Yin, J.-H.; Yin, Z.-Y.; Chen, Z. One–dimensional nonlinear finite strain analysis of self–weight consolidation of soft clay considering creep. Comput. Geotech. 2023, 153, 105081. [Google Scholar] [CrossRef]

- Asgari, A.; Sorkhi, S.F.A. Wind turbine performance under multi-hazard loads: Wave, wind, and earthquake effects on liquefiable soil. Results Eng. 2025, 26, 104647. [Google Scholar] [CrossRef]

- Mendoza, C.; Caicedo, B.; Duque, J. Technical report on the compression, structure, and creep behaviors of lacustrine soil deposits in Bogotá, Colombia. Soils Found. 2022, 62, 101215. [Google Scholar] [CrossRef]

- Oliveira, P.J.V.; Correia, A.A.; Lemos, L.J. Numerical modelling of the effect of curing time on the creep behaviour of a chemically stabilised soft soil. Comput. Geotech. 2017, 91, 117–130. [Google Scholar] [CrossRef]

- Zhi, B.; Wang, S.; Wei, P.; Liu, E.; Han, W. Experimental Study on Creep Characteristics of Loess with Different Compactness. KSCE J. Civ. Eng. 2024, 28, 1702–1714. [Google Scholar] [CrossRef]

- Feng, W.Q.; Yin, J.H.; Chen, W.B.; Tan, D.Y.; Wu, P.C. A new simplified method for calculating consolidation settlement of multi-layer soft soils with creep under multi-stage ramp loading. Eng. Geol. 2020, 264, 105322. [Google Scholar] [CrossRef]

- Shen, Z.; Tian, Z.; Chen, X. Experimental Study on the Compression Creep Characteristics of Soft Soil in the West Area of Nanjing. J. Nanjing Inst. Technol. (Nat. Sci. Ed.) 2015, 13, 12–14. [Google Scholar]

- Sun, H.; Hou, M.; Chen, C.; Ge, X. Microstructure investigation of soft clay subjected to triaxial loading. Eng. Geol. 2020, 274, 105735. [Google Scholar] [CrossRef]

- Burton, G.J.; Pineda, J.A.; Sheng, D.; Airey, D. Microstructural changes of an undisturbed, reconstituted and compacted high plasticity clay subjected to wetting and drying. Eng. Geol. 2015, 193, 363–373. [Google Scholar] [CrossRef]

- Hicher, P.Y.; Wahyudi, H.; Tessier, D. Microstructural analysis of inherent and induced anisotropy in clay. Mech. Cohesive-Frict. Mater. 2000, 5, 341–371. [Google Scholar] [CrossRef]

- Yang, P.; Li, C.; Wu, Z.; He, Z. Study on the microstructure and strength characteristics of marine soft soil under wet-dry cycle condition. Alex. Eng. J. 2024, 102, 240–249. [Google Scholar] [CrossRef]

- Li, J.X.; Wang, C.M.; Zhang, X.W. Creep properties and micropore changes of soft soil under different drainage conditions. Rock Soil Mech 2010, 31, 3493–3498. [Google Scholar]

- Xie, X.; Qi, S.; Zhao, F.; Wang, D. Creep behavior and the microstructural evolution of loess-like soil from Xi’an area, China. Eng. Geol. 2018, 236, 43–59. [Google Scholar] [CrossRef]

- Wang, Z.; Wong, R.C. Strain-dependent creep behavior of Athabasca oil sand in triaxial compression. Int. J. Geomech. 2017, 17, 04016027. [Google Scholar] [CrossRef]

- Wang, Z.; Wong, R.C. Strain-dependent and stress-dependent creep model for a till subject to triaxial compression. Int. J. Geomech. 2016, 16, 04015084. [Google Scholar] [CrossRef]

- ASTM D2487—2017; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2017.

- GB/T 50123-2019; Ministry of Housing and Urban-Rural Development of the People’s Republic of China, and State Administration for Market Regulation. Standard for Soil Test Methods. China Planning Press: Beijing, China, 2019.

- ASTM D2435/D2435M-19; ASTM International Standard Test Methods for Density and Unit Weight of Soil in Place by Nuclear Methods (Shallow Depth). ASTM International: West Conshohocken, PA, USA, 2019.

- Wang, E.L.; Ren, Z.F.; Han, H.W.; Tian, Y. Experimental study on uniaxial compressive strength of ultra-low temperature frozen clay. Chin. J. Geotech. Eng. 2021, 43, 1851–1860. [Google Scholar]

- Ruan, Y.; Zhu, S.; Qiao, W.; Wu, L.; Cai, L. Creep characteristics of lacustrine sedimentary peaty soil. Chin. J. Geotech. Eng. 2022, 44, 166–171. [Google Scholar]

- Asadoullahtabar, S.R.; Asgari, A.; Tabari, M.M.R. Assessment, identifying, and presenting a plan for the stabilization of loessic soils exposed to scouring in the path of gas pipelines, case study: Maraveh-Tappeh city. Eng. Geol. 2024, 342, 107747. [Google Scholar] [CrossRef]

| Remolded Consolidation Pressure (kPa) | Water Content (%) | Initial Void Ratio of Remolded Soil | Density of Remolded Soil (g/cm3) | Specific Gravity of Soil Gs | Plastic Limit WP (%) | Liquid Limit WL (%) | Plasticity Index IP |

|---|---|---|---|---|---|---|---|

| 50 | 35.41 | 0.96–1.07 | 1.805 | 2.68 | 19.7 | 43.7 | 24 |

| Load (Pressure) | Day 1 | Day 2 | Day 3 | Day 4 | Day 5 |

|---|---|---|---|---|---|

| Load (kg) | 0 | 15 | 30 | 60 | 120 |

| Pressure (kPa) | 0 | 6.25 | 12.5 | 25 | 50 |

| Parameter | Range | Accuracy |

|---|---|---|

| Axial Stress | 10 kN | 10 N |

| Axial Displacement | 100 mm | 0.07% |

| Confining Pressure | 2 MPa | 1 kPa |

| Confining Volume | 200 cm3 | 1 mm3 |

| Back Pressure | 2 MPa | 1 kPa |

| Back Volume | 200 cm3 | 1 mm3 |

| Pore Water Pressure | 2 MPa | 1 kPa |

| Servo Motor | 0.1–5 Hz | / |

| Component | Measurement Range | |

|---|---|---|

| Chamber | Low Pressure | Pressure Range: 345 kPa; Pore Size Range: 360–3.6 µm |

| High Pressure | Pressure Range: Atmospheric to 228 MPa; Pore Size Range: 6–0.0055 µm | |

| Porosimeter | Sensor | Accuracy: +/−0.10% of full scale; Hysteresis: 0.05% of full scale |

| Capillary Volume | 0.38, 1.1, 1.7, 3.1, 3.9 cm3 (depending on penetrometer specification) | |

| Max Sample Size | 2.5 cm × 2.5 cm × 2.5 cm | |

| Soil Type | σ (kPa) | OCR | T (d) |

|---|---|---|---|

| Remolded Soft Soil | 100 | 1, 2, 4, 8 | 2, 90 |

| 100, 200, 400, 800, 1600 | 1 | 2 | |

| 100 | 1 | 2, 7, 15, 30, 90 | |

| 400 | 1 | 2, 7, 15, 30, 90 |

| Confining Pressure σ3 (kPa) | Axial Stress σ1 (kPa) | Deviatoric Stress q (kPa) | Each Level of Time (d) |

|---|---|---|---|

| 25 | 37.5 | 12.5 | 1 |

| 40 | 15 | ||

| 45 | 20 | ||

| 50 | 25 | ||

| 55 | 30 | ||

| 60 | 35 | ||

| 50 | 75 | 25 | 1 |

| 87.5 | 37.5 | ||

| 100 | 50 | ||

| 112.5 | 62.5 | ||

| 120 | 70 | ||

| 125 | 75 | ||

| 100 | 125 | 25 | 1 |

| 150 | 50 | ||

| 175 | 75 | ||

| 200 | 100 | 2 | |

| 225 | 125 | ||

| 250 | 150 | ||

| 200 | 250 | 50 | 1 |

| 300 | 100 | ||

| 325 | 125 | 2 | |

| 350 | 150 | ||

| 375 | 175 | ||

| 400 | 200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Y.; Chen, Y.; Yi, X.; Qin, W.; Zhou, Z.; Peng, G.; Lou, K.; Liu, Y. Study on Creep Behavior of Wenzhou Remolded Coastal Silt Under One-Dimensional and Triaxial Tests. Buildings 2025, 15, 3378. https://doi.org/10.3390/buildings15183378

Shi Y, Chen Y, Yi X, Qin W, Zhou Z, Peng G, Lou K, Liu Y. Study on Creep Behavior of Wenzhou Remolded Coastal Silt Under One-Dimensional and Triaxial Tests. Buildings. 2025; 15(18):3378. https://doi.org/10.3390/buildings15183378

Chicago/Turabian StyleShi, Yi, Yongwei Chen, Xiaohui Yi, Wei Qin, Zhijin Zhou, Guoxiang Peng, Kun Lou, and Yuanyuan Liu. 2025. "Study on Creep Behavior of Wenzhou Remolded Coastal Silt Under One-Dimensional and Triaxial Tests" Buildings 15, no. 18: 3378. https://doi.org/10.3390/buildings15183378

APA StyleShi, Y., Chen, Y., Yi, X., Qin, W., Zhou, Z., Peng, G., Lou, K., & Liu, Y. (2025). Study on Creep Behavior of Wenzhou Remolded Coastal Silt Under One-Dimensional and Triaxial Tests. Buildings, 15(18), 3378. https://doi.org/10.3390/buildings15183378