Research on BIM Modeling of Steel Bridges Based on IFC Extensions

Abstract

1. Introduction

- (1)

- Proposes an IFC-based information modeling framework for the full lifecycle of steel bridges. By integrating static entity extensions with dynamic property set customization, a structured data system encompassing four hierarchical levels—spatial units, assemblies, components, and parts—is established. Corresponding property sets are also defined for both design and manufacturing stages, thereby addressing the current gap in component classification systems and semantic attribute representation.

- (2)

- Implements the extended model on the 3DEXPERIENCE platform. A parameterized BIM modeling workflow for steel bridges is developed, underpinned by the IFC extension. The enriched models are exported in IFC standard format using the IfcOpenShell toolkit, enabling cross-platform and cross-stage data exchange.

- (3)

- Validates the proposed framework through a real-world case study of the Chengdu Q7 North Pedestrian Bridge. The evaluation considers multiple dimensions, including semantic completeness, cross-platform readability, and engineering applicability. The results confirm the practical value of the proposed IFC extension and modeling methodology in enhancing the information integrity of steel bridge BIM models and improving the reliability of design-to-manufacturing information transfer.

2. Literature Review

2.1. Methods for Extending the IFC Model

- Static extension involves introducing new domain-specific entities to augment the original IFC schema, thereby accommodating modeling requirements for structural elements initially absent from the standard (e.g., components in bridges and railways). These newly defined entities are organized through object-oriented inheritance and ultimately exported as EXPRESS schema files, ensuring seamless recognition and parsing by compliant software platforms. The IFC data schema supports multiple representation formats, including HTML, EXPRESS, XSD/XML, and OWL. In bridge engineering, model development is primarily implemented using EXPRESS or XML representations [17].

- Dynamic extension refers to enhancing the existing IFC schema by adding user-defined Property Sets (Psets), which supplement domain-specific information without altering the original schema [18]. This approach provides high compatibility and flexibility, making it particularly suitable for strengthening and refining information requirements in the design and fabrication stages of steel bridges.

2.2. Applications and Limitations of IFC in Bridge Engineering

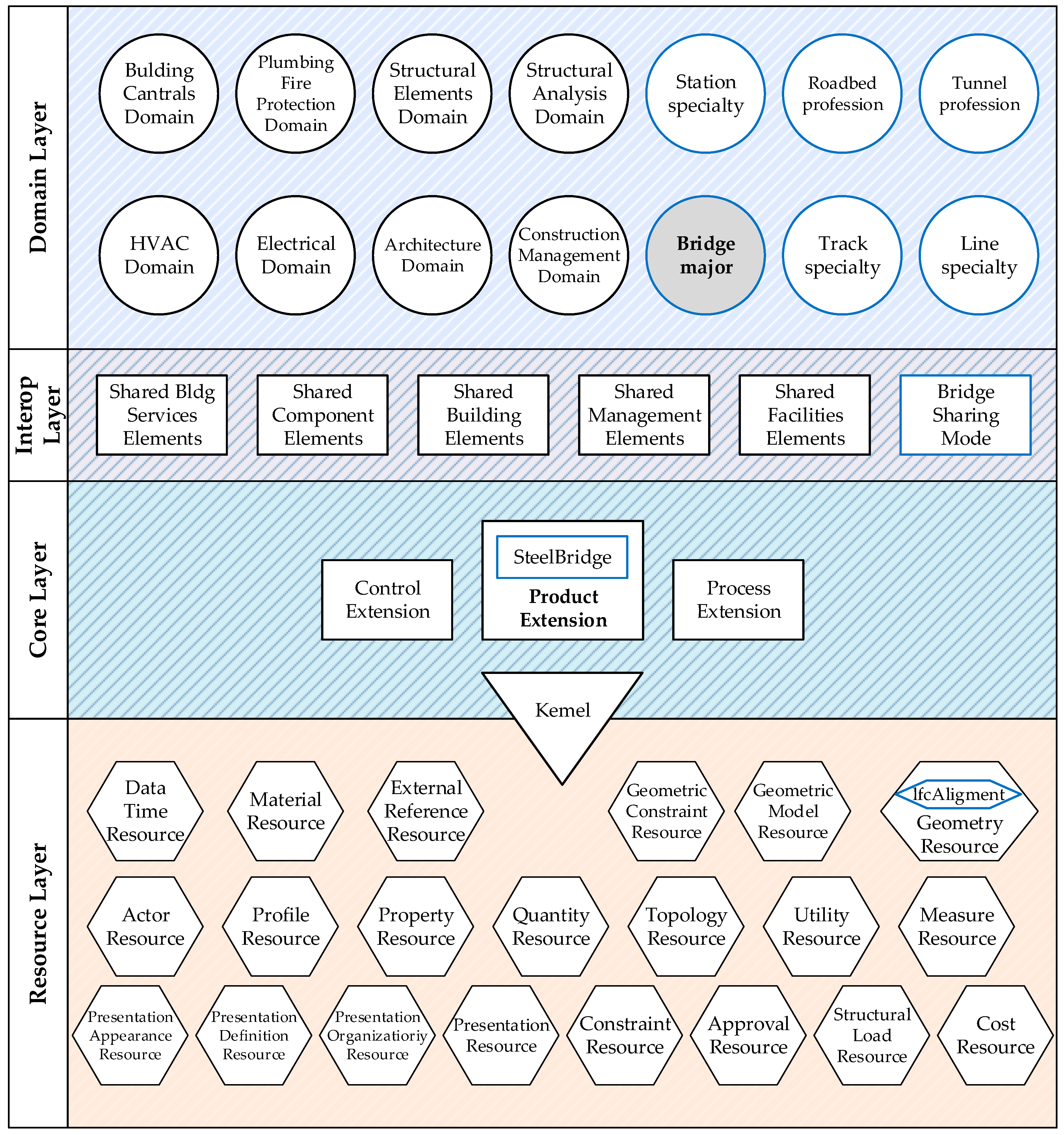

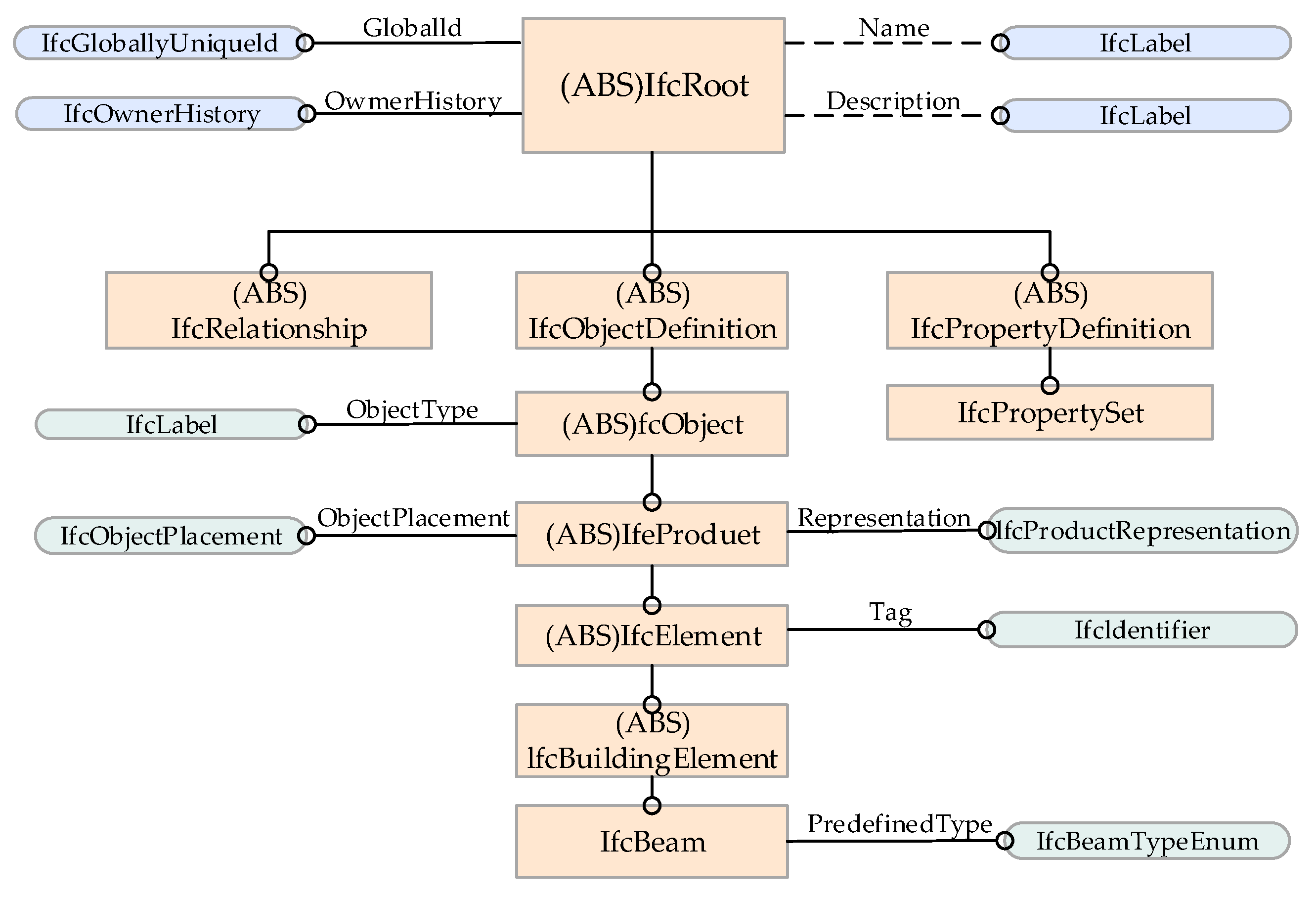

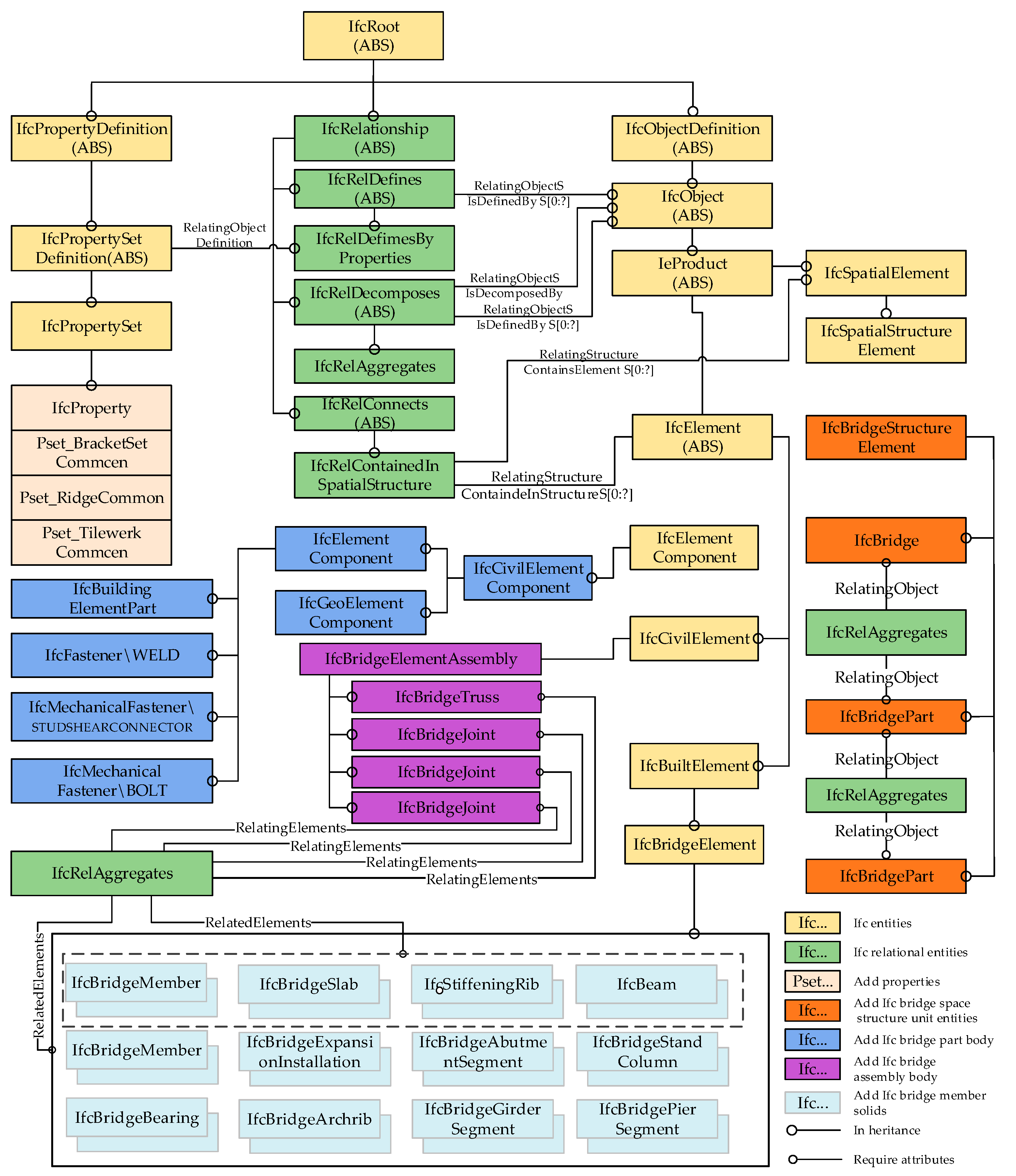

3. Extension and Analysis of the IFC Standard Data Architecture

3.1. The Data Architecture of the IFC Standard

- Core Layer: Introduction of core semantic concepts related to steel bridges, such as STEELBRIDGE.

- Interoperability Layer: Addition of general-purpose entities for steel bridge modeling, including IfcBridgeElement.

- Domain Layer: Definition of multiple domain-specific entities and property sets tailored to the steel bridge engineering context, with a focus on enhancing the expression of fabrication-related attributes.

- Resource Layer: Extension of material resources and geometric representations, including the reuse of IfcAlignment to describe alignment and spatial positioning of steel bridge components.

3.2. Mechanisms for Extending the IFC Schema

- (1)

- Extension Based on Newly Defined Entities

- (2)

- Extension via Property Set Definitions

- (3)

- Extension via IfcProxy Entities

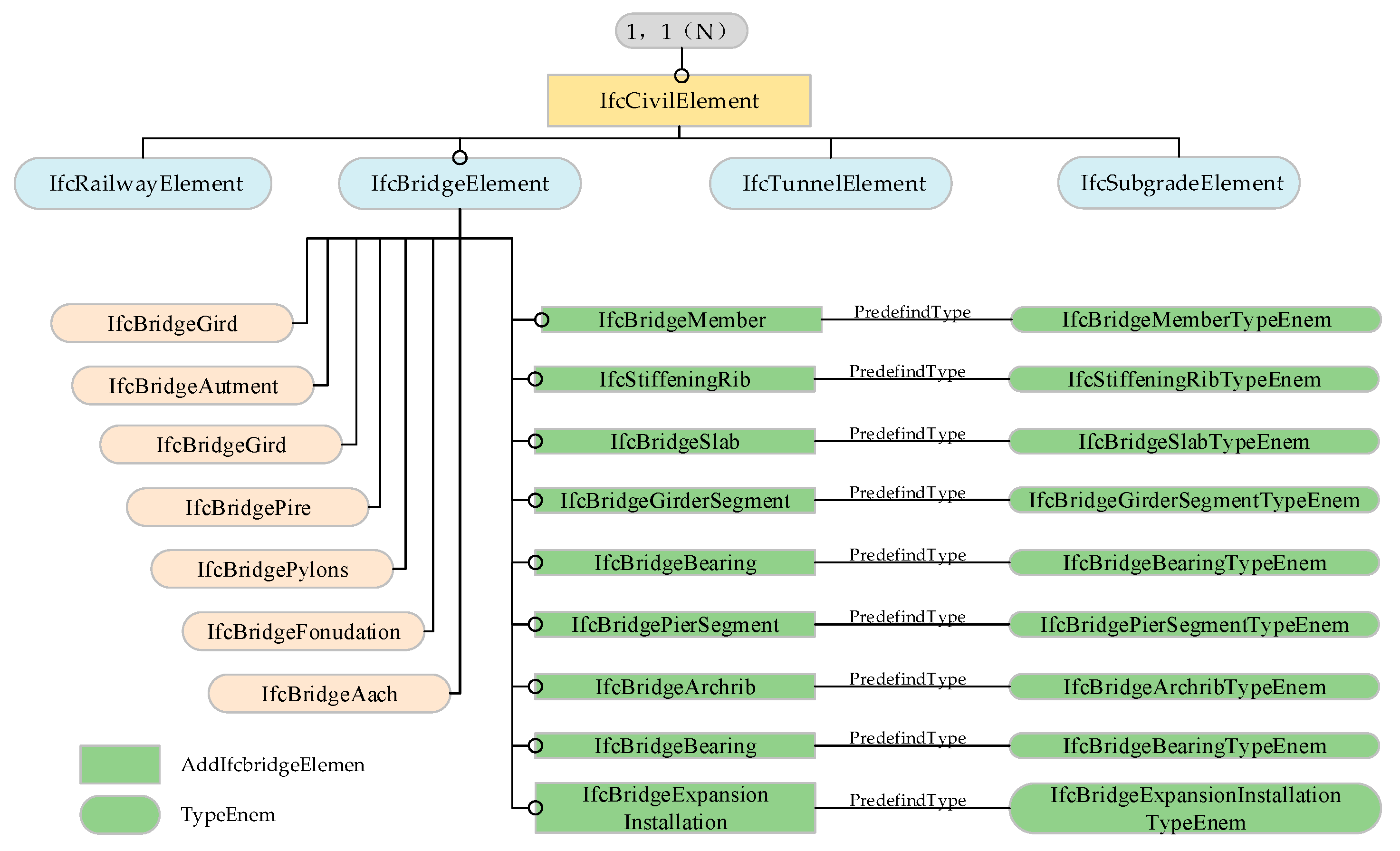

4. Extension and Representation of Bridge Data Models Based on the IFC Standard

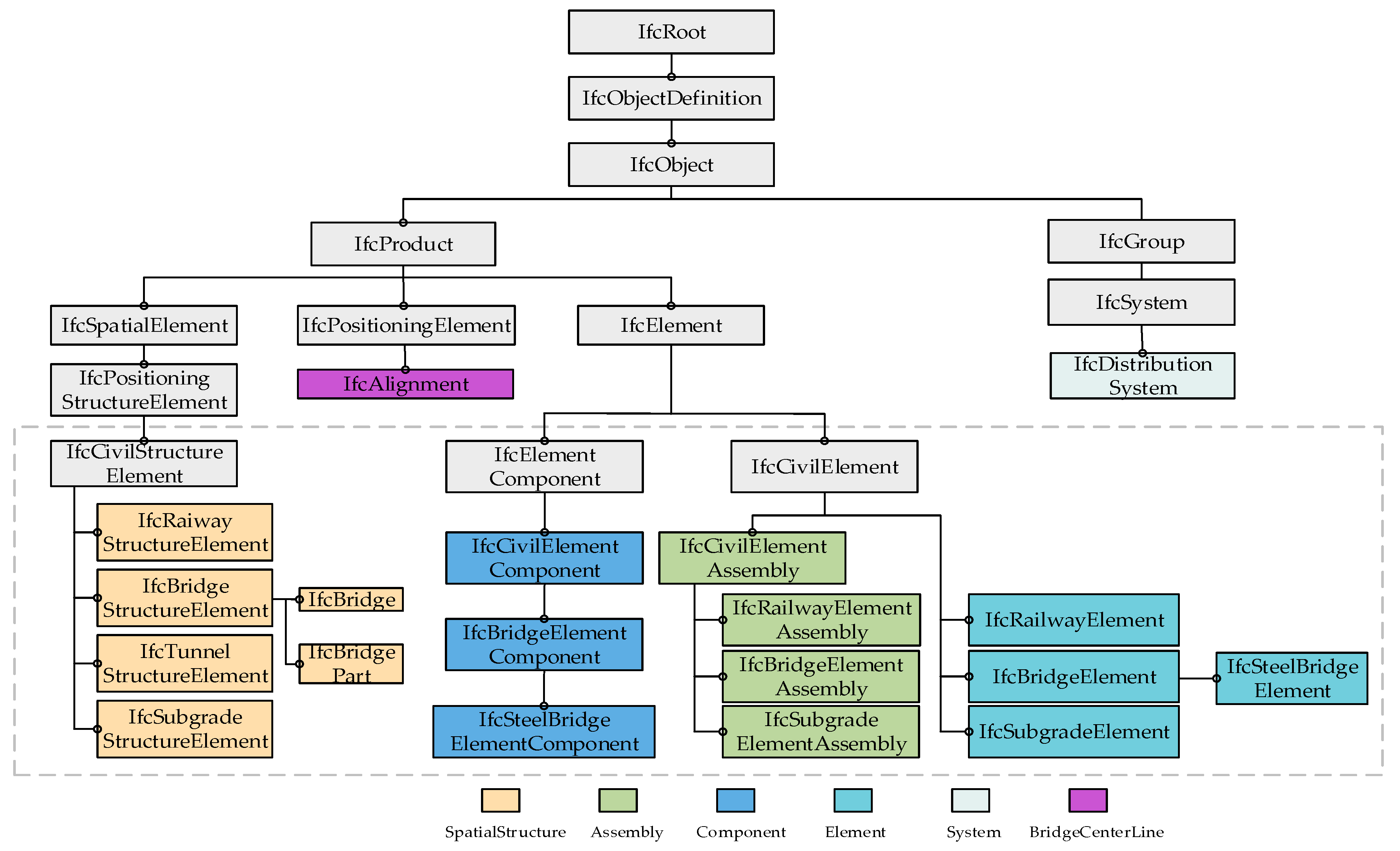

4.1. Data Structure of the Steel Bridge Information Model

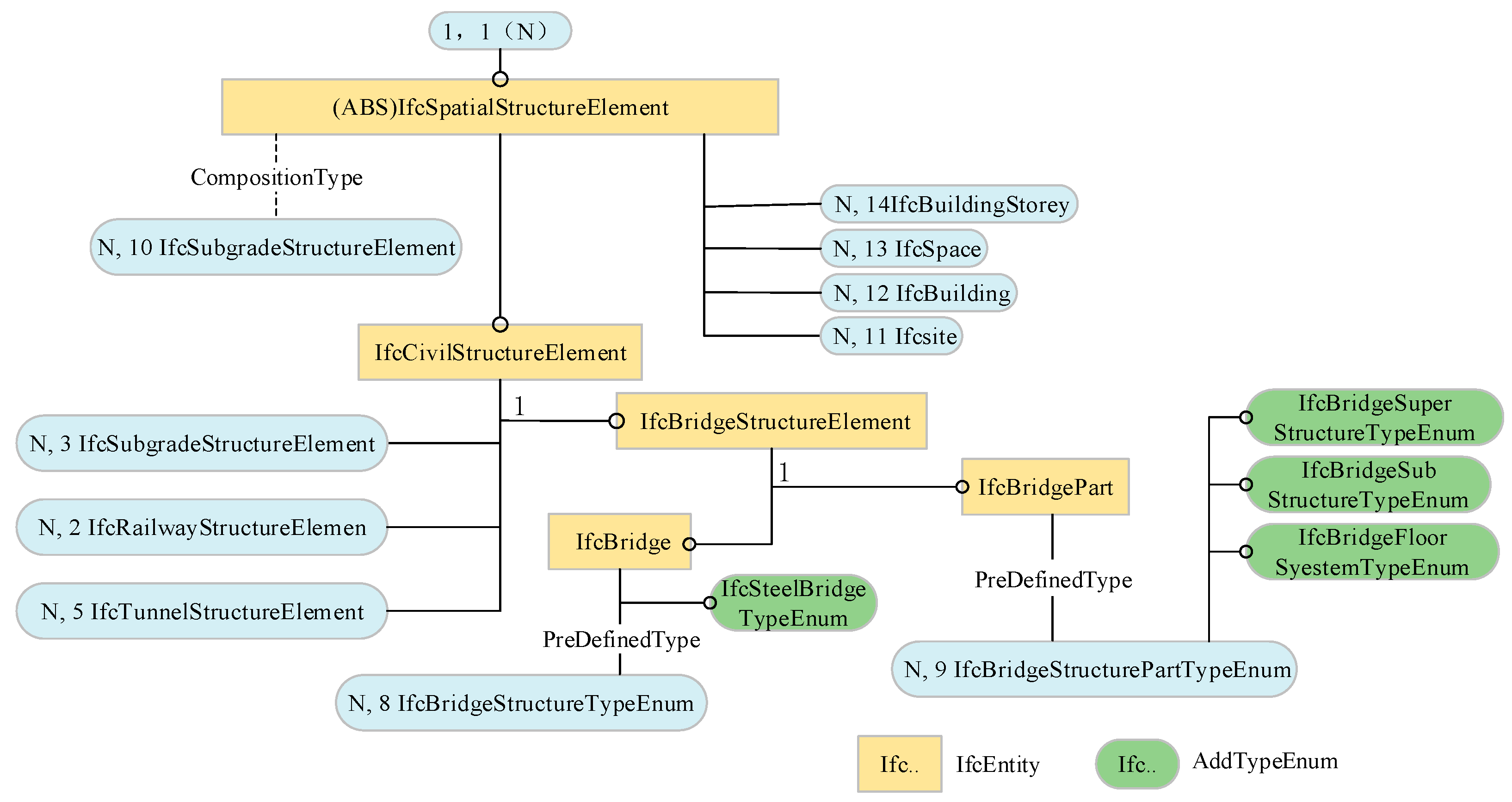

4.1.1. Steel Bridge Spatial Structure Units

4.1.2. Steel Bridge Components

4.1.3. Assembly Units of Steel Bridges

4.1.4. Bridge Part Components

4.2. Steel Bridge Entity Expansion and Representation Based on IFC Standards

4.3. Extension and Expression of Property Sets for Steel Bridge Entities Based on the IFC Standard

- Pset_BridgeElementIdentificationCommon, encompassing general identity attributes such as name, tag, and component code;

- Pset_SteelBridgeComponentDesign, which captures technical design parameters including section type, geometric dimensions, load class, and connection method;

- Pset_SteelBridgeComponentFabrication, describing manufacturing execution data such as fabrication techniques, welding specifications, prefabricated part codes, and installation orientation.

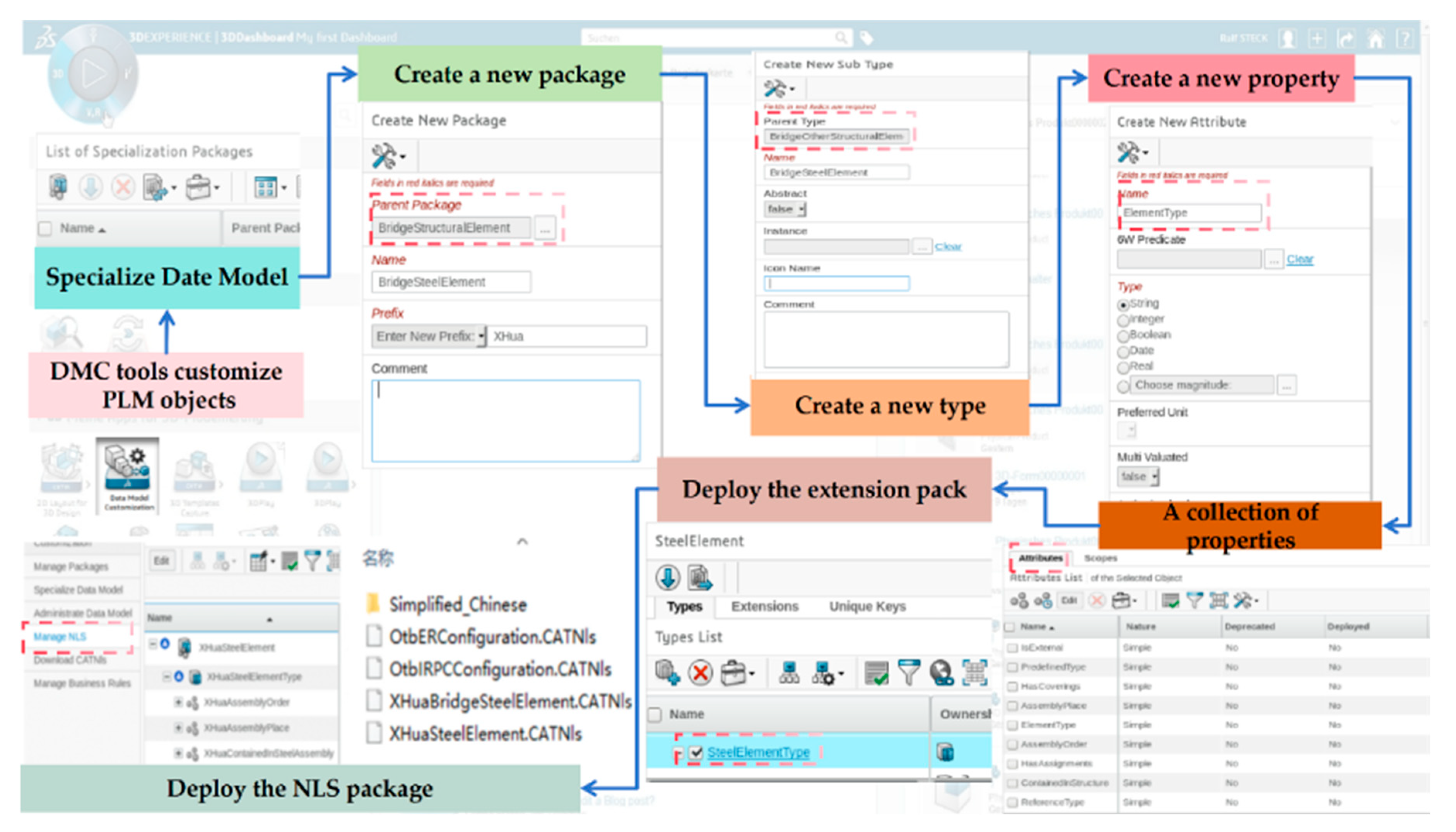

5. Steel Bridge Information Model Extension and Modeling Based on the 3DEXPERIENCE Platform

5.1. IFC Data Extension Workflow Based on the 3DEXPERIENCE Platform

- DMC Tools Customize PLM Objects: Using the DMC (Data Model Customization) module, domain-specific extended entities such as bridge components are created by inheriting and customizing base PLM types, enabling tailored expansion of the model structure.

- Specialize Data Model: The customized objects are further structured into a hierarchical semantic data model tailored for steel bridges. For example, specialized component classes such as IfcSteelBoxGirder and IfcStiffener are defined, along with their assembly logic and geometric semantics.

- Create a New Package: A dedicated extension package is created via the platform configuration tools. The package includes versioning, namespace assignment, and inheritance paths to encapsulate all definitions of extended objects, properties, and associated resources.

- Create a New Type: Within the extension package, specific IFC extension types—such as IfcSteelBoxGirder (inheriting from IfcBeam)—are registered. Each type is configured with an icon, description, export status, and multilingual support.

- Add New Property: Identification, design, fabrication, and maintenance-related property fields are defined for each extended object. These fields support a variety of data types, including enumerations, Boolean, and string types, thereby enhancing semantic expressiveness.

- A Collection of Properties: Multiple property fields are grouped into standardized property sets (IfcPropertySet), each with clearly defined application scopes and export control rules to ensure consistent semantic interpretation across platforms.

- Deploy the Extension Pack: The extension package is deployed to the TXO (Technical XML Output) module and registered, enabling integrated access and utilization of the extended model by platform tools such as CATIA and ENOVIA.

- Deploy the NLS Package: A multilingual National Language Support (NLS) package is released to guarantee accurate understanding and application of the extended model in diverse linguistic environments.

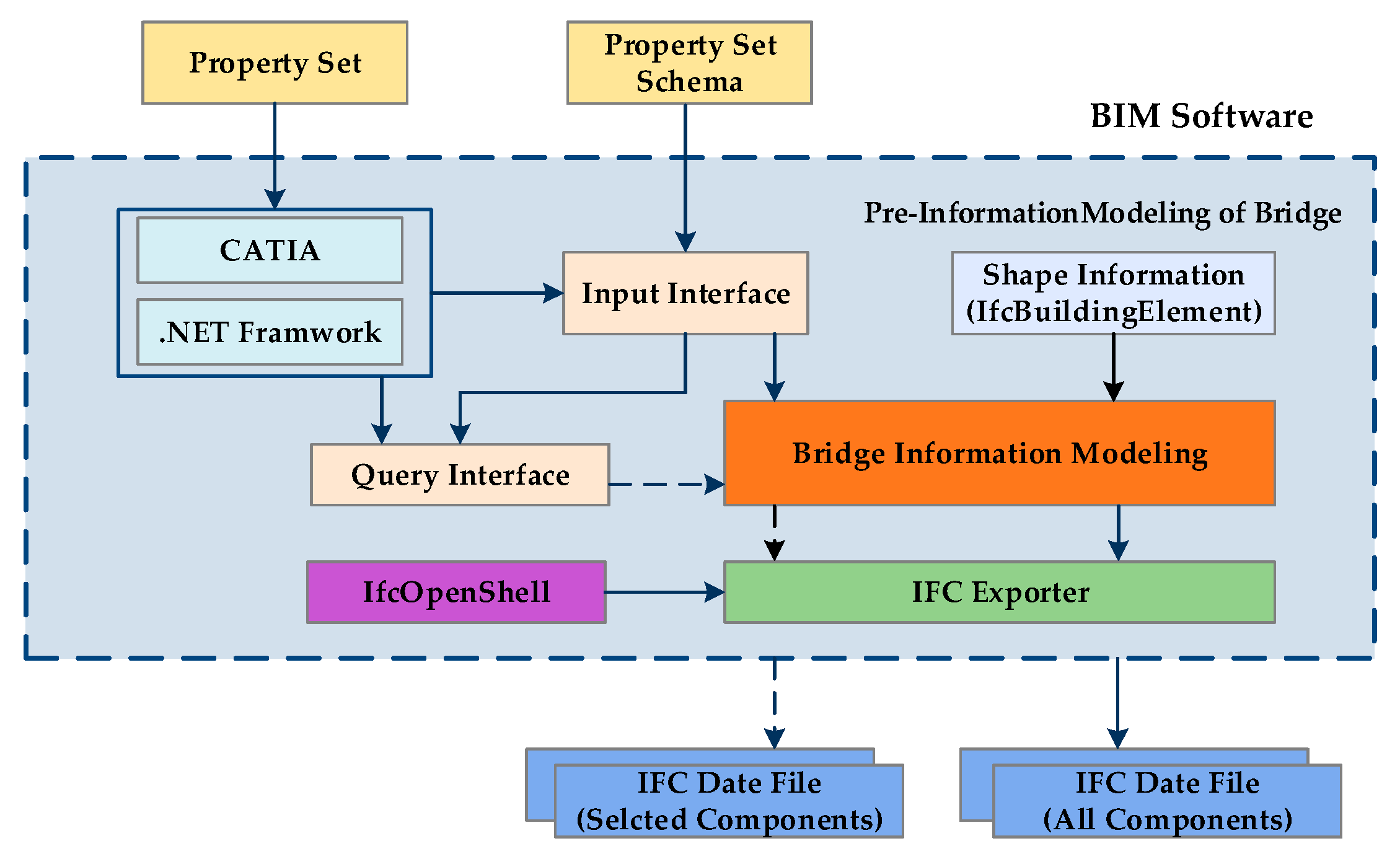

5.2. Information Modeling Workflow for Steel Bridges

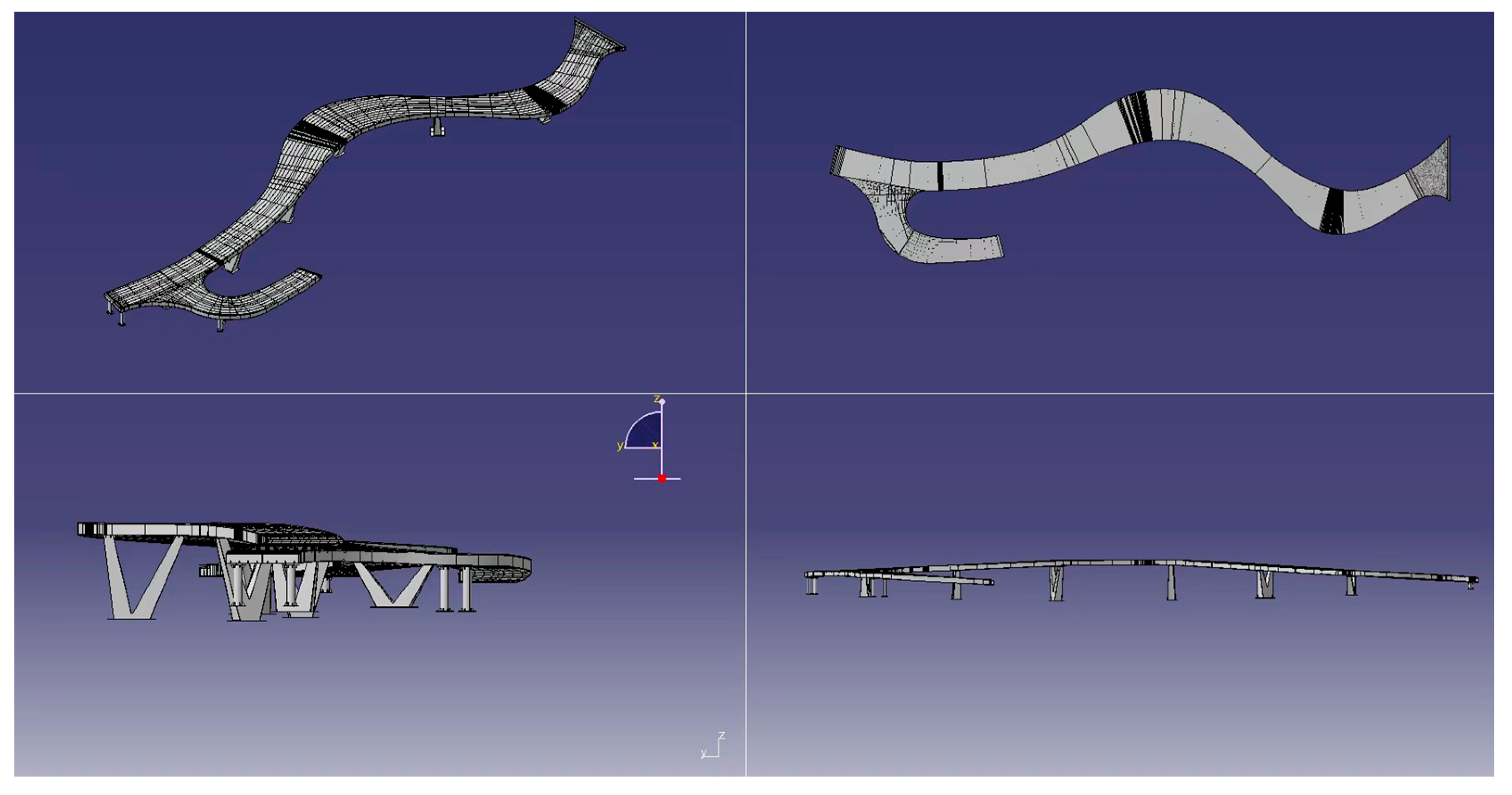

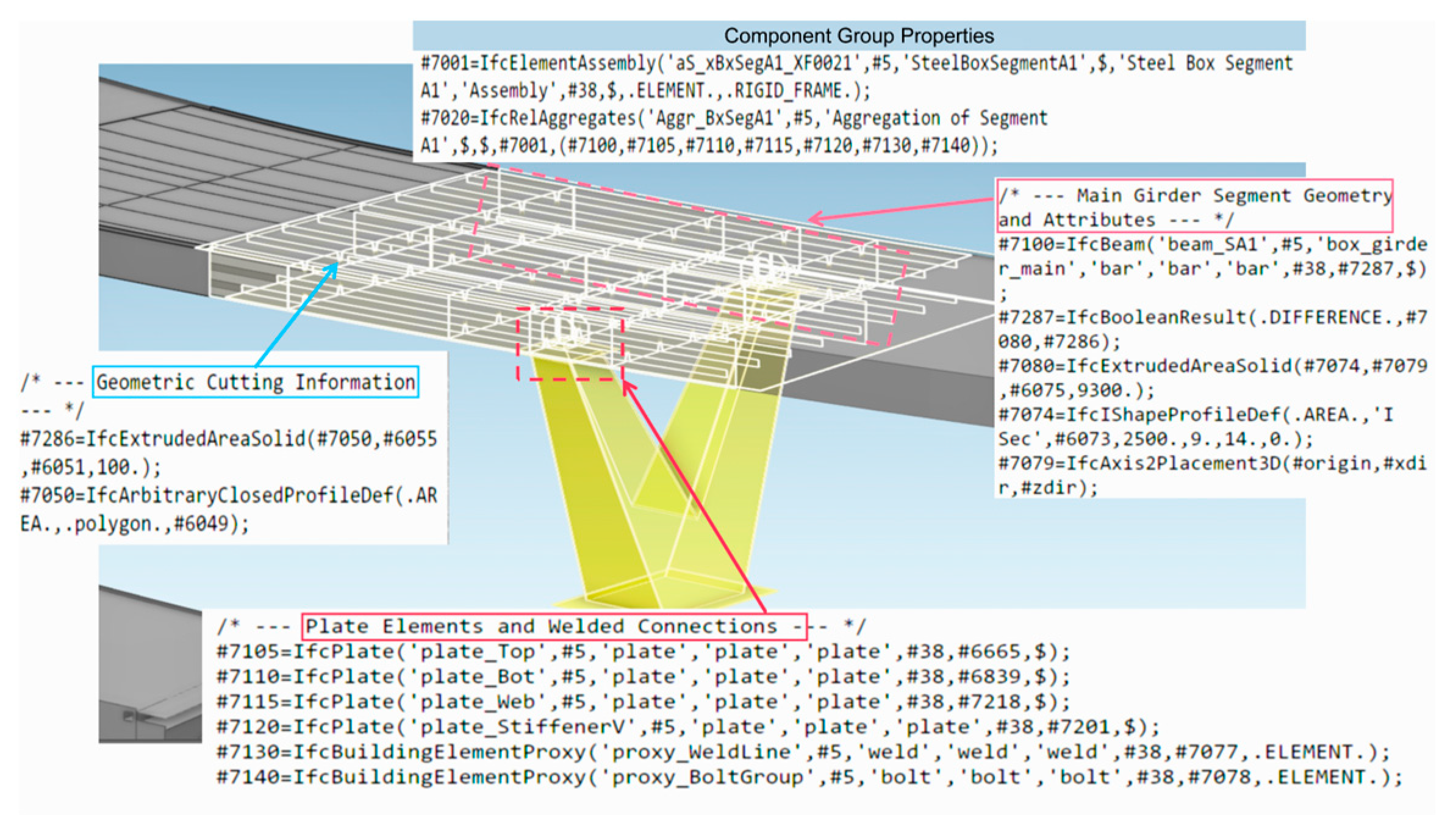

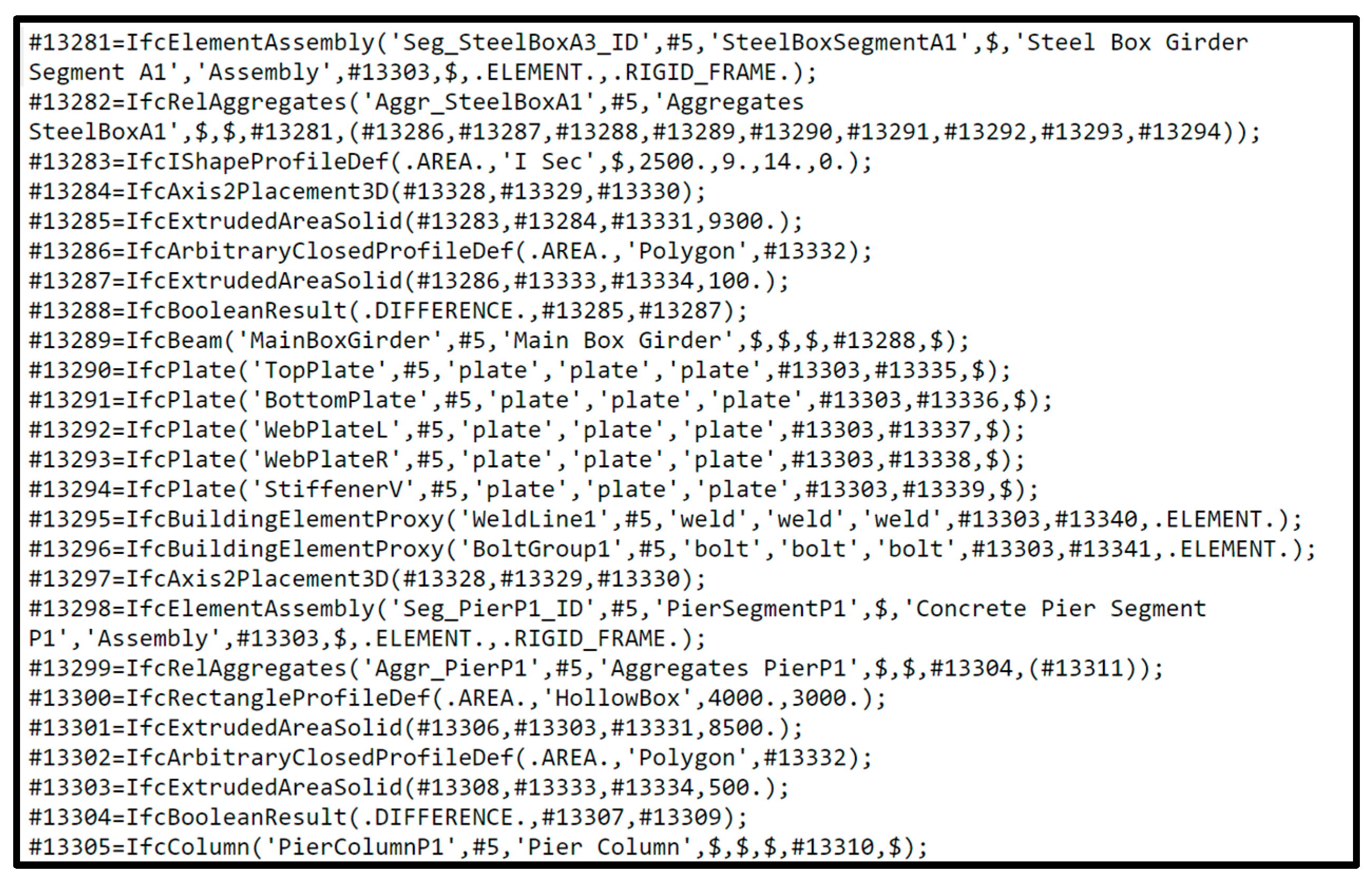

- Geometry Modeling: Parametric geometric modeling of steel bridge components—such as main girders, webs, diaphragms, and stiffeners—is carried out using the CATIA platform. This step enhances the modularity and reusability of the model components.

- Attribute Injection: Design and fabrication stage attributes are embedded into the components via PartProperties and User Defined Feature (UDF) templates. The Engineering Knowledge Language (EKL) scripting mechanism is employed to enable automated value assignment, conditional logic, and inter-property linkage.

- IFC-Based Semantic Extension: Using TXO and DMC tools, native IFC entities (e.g., IfcBeam, IfcPlate) are extended to define bridge-specific subclasses (e.g., IfcSteelGirder, IfcStiffener), which are then linked to corresponding customized property sets (IfcPropertySet).

- Model Assembly: In accordance with the semantic decomposition structure defined by the IFC 4 × 3 standard for bridges, the extended components are systematically assembled into a complete IFC project structure, ensuring consistent multi-level representation.

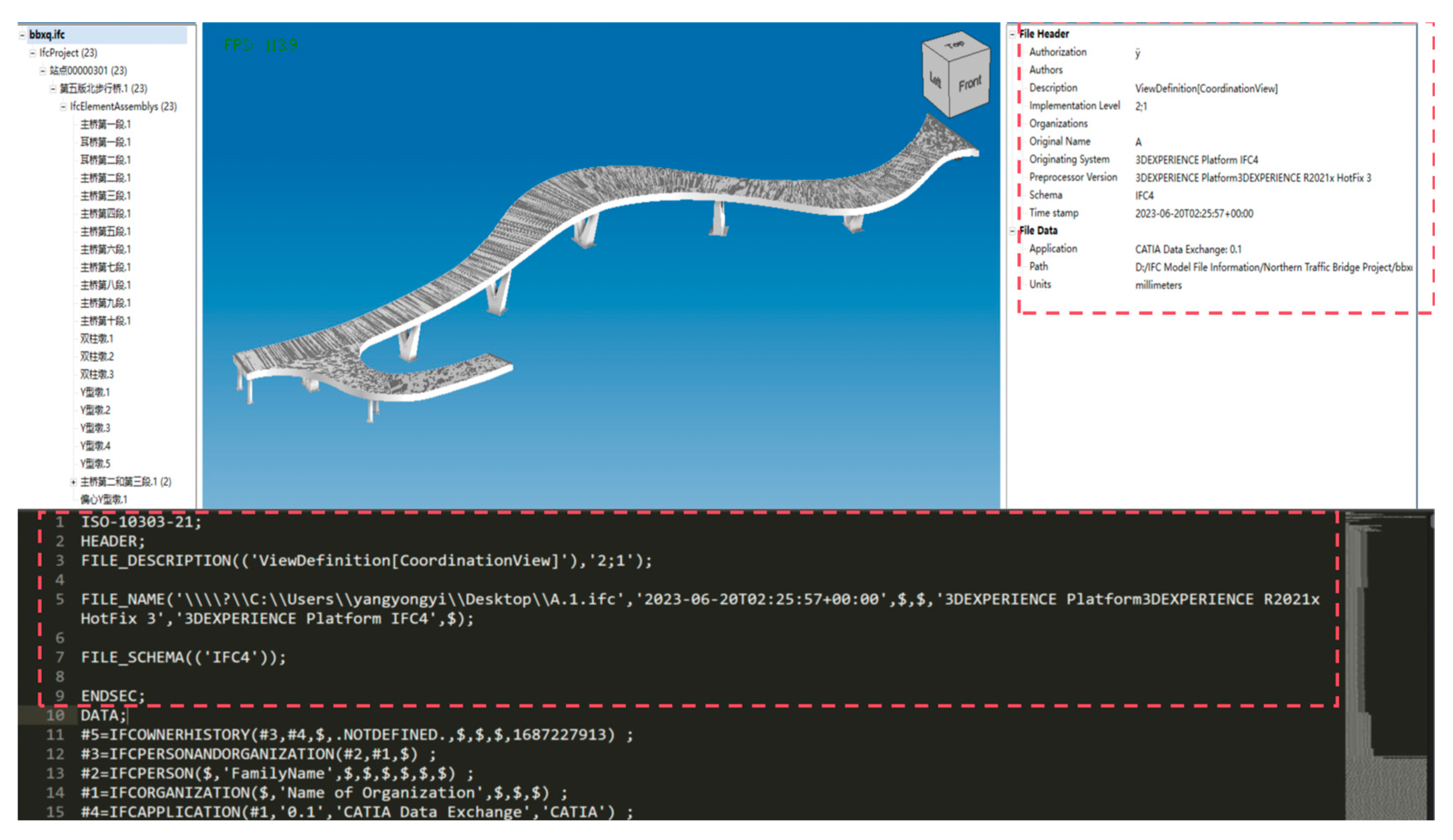

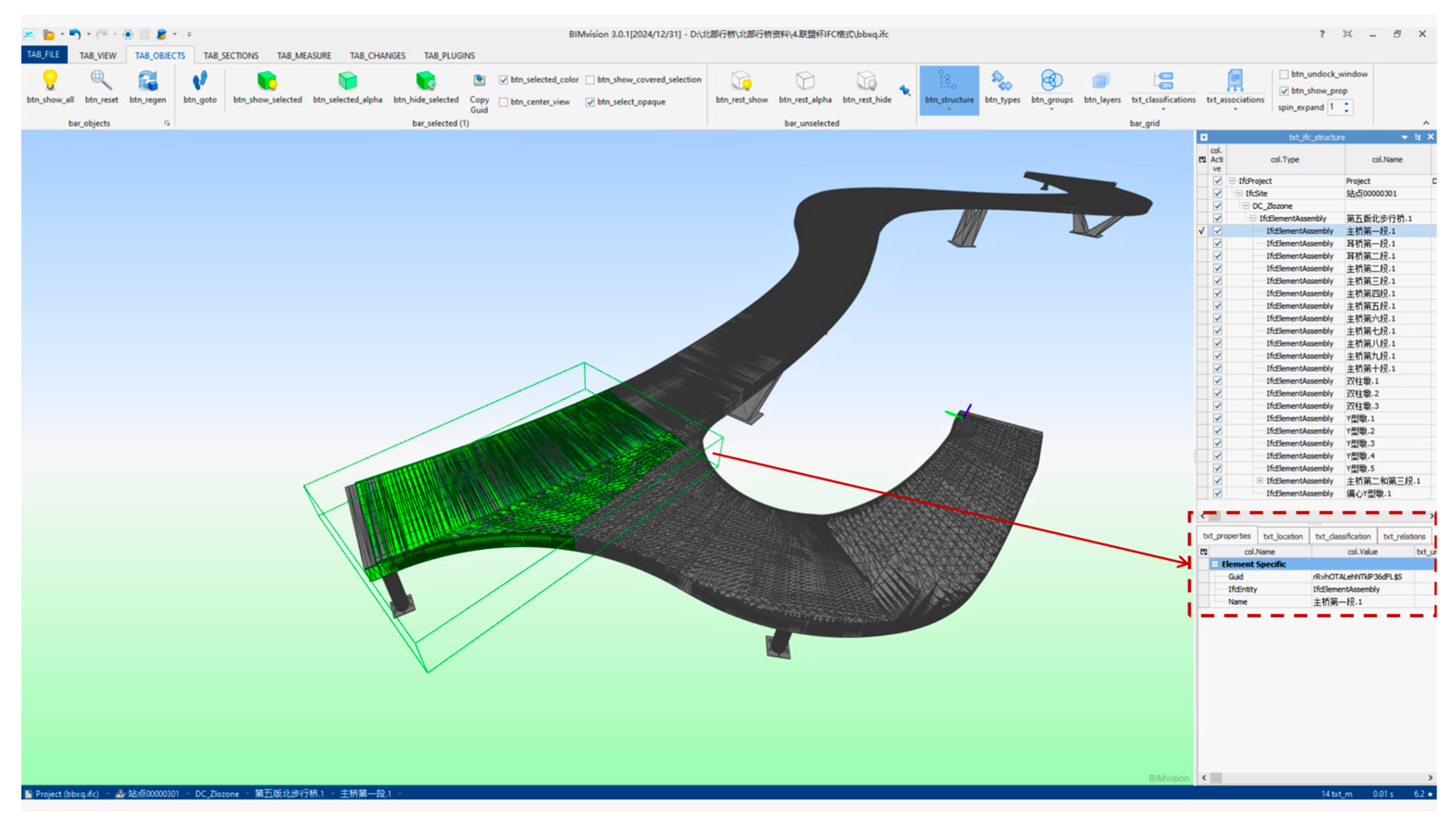

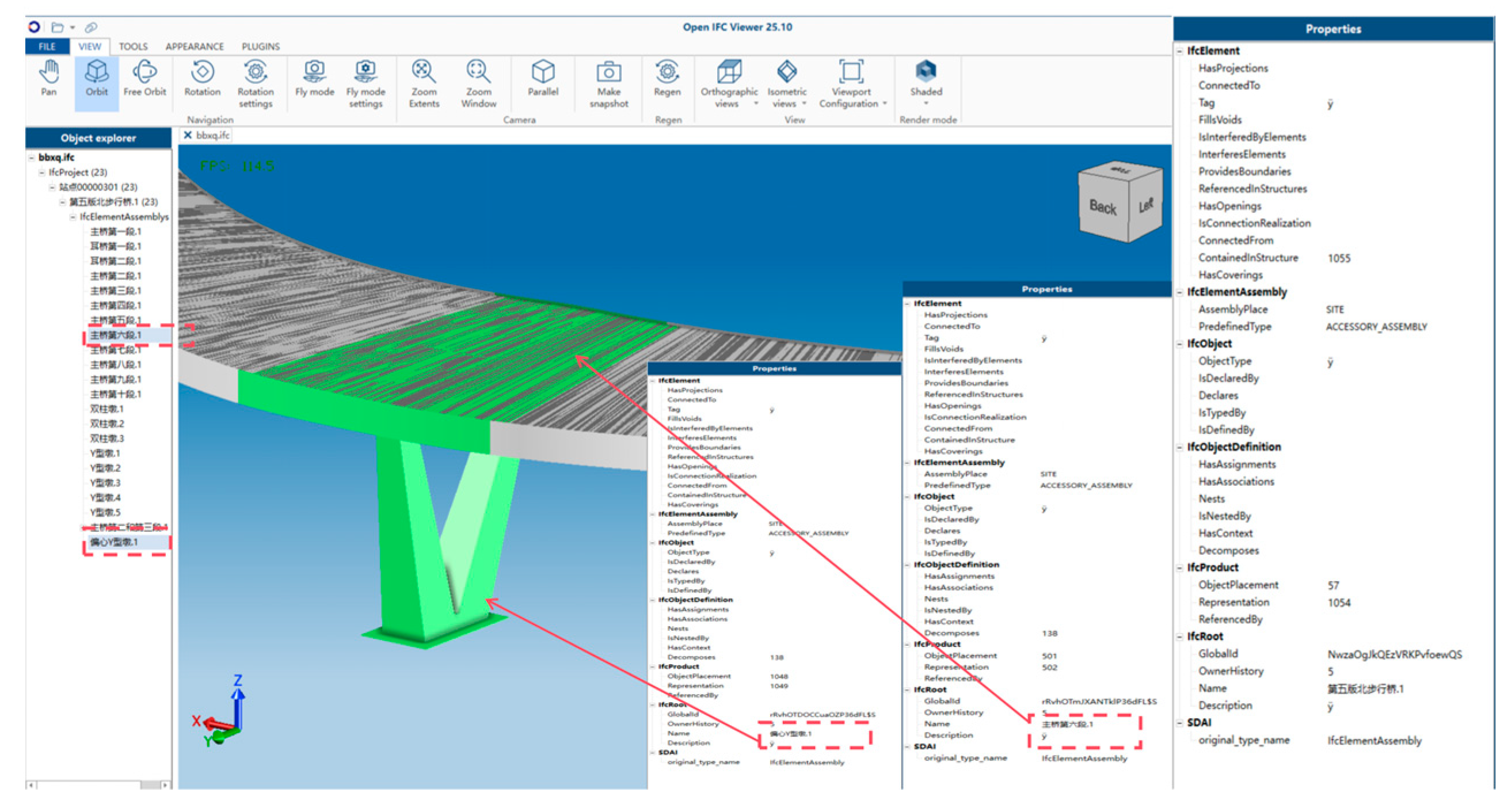

- IFC Export & Verification: The extended bridge model is exported to the .ifc format using IfcOpenShell. Its semantic expressiveness and cross-platform compatibility are subsequently validated through testing on BIM platforms such as BIMvision, usBIM, and OpenIFCViewer.

6. Case Study

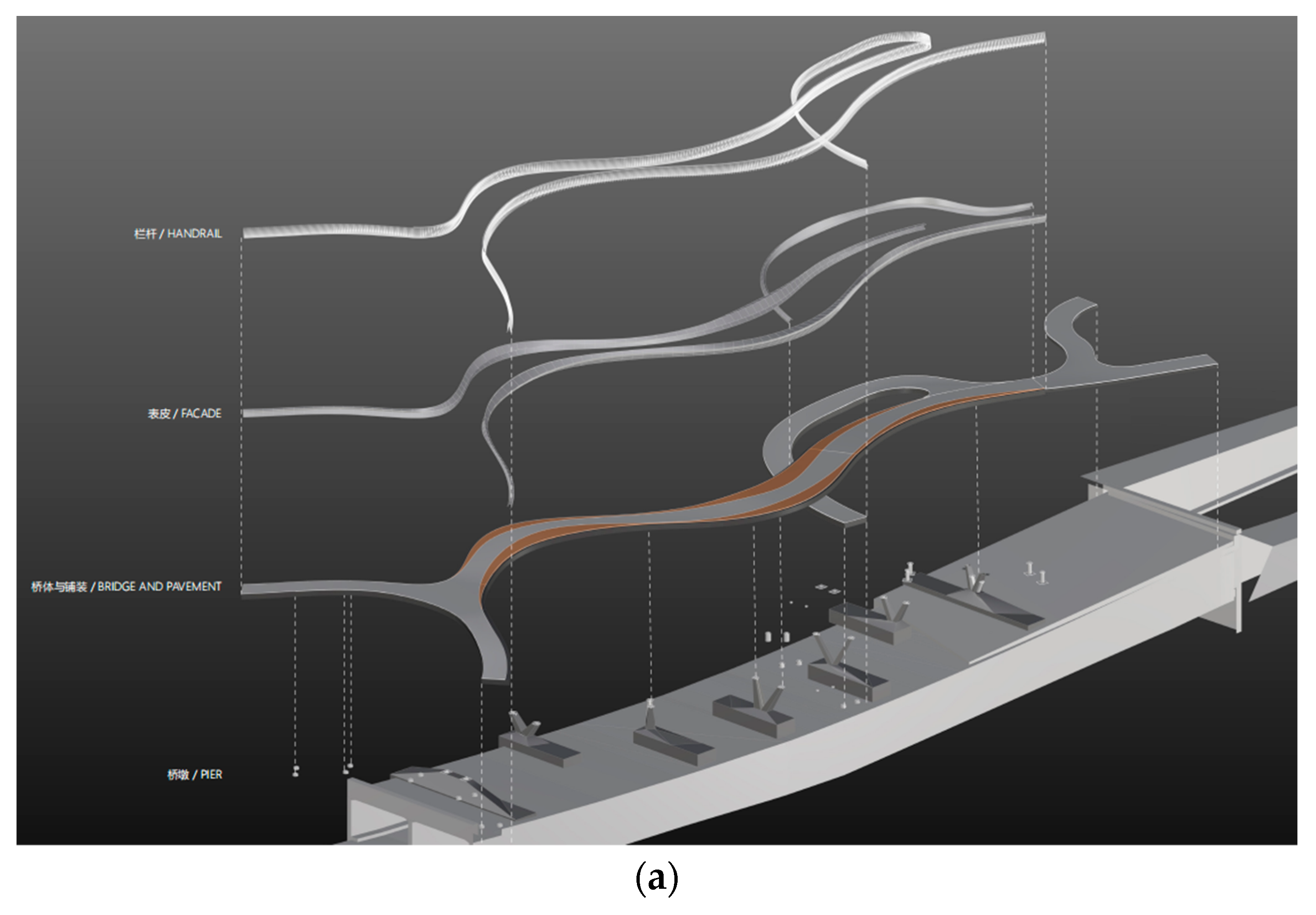

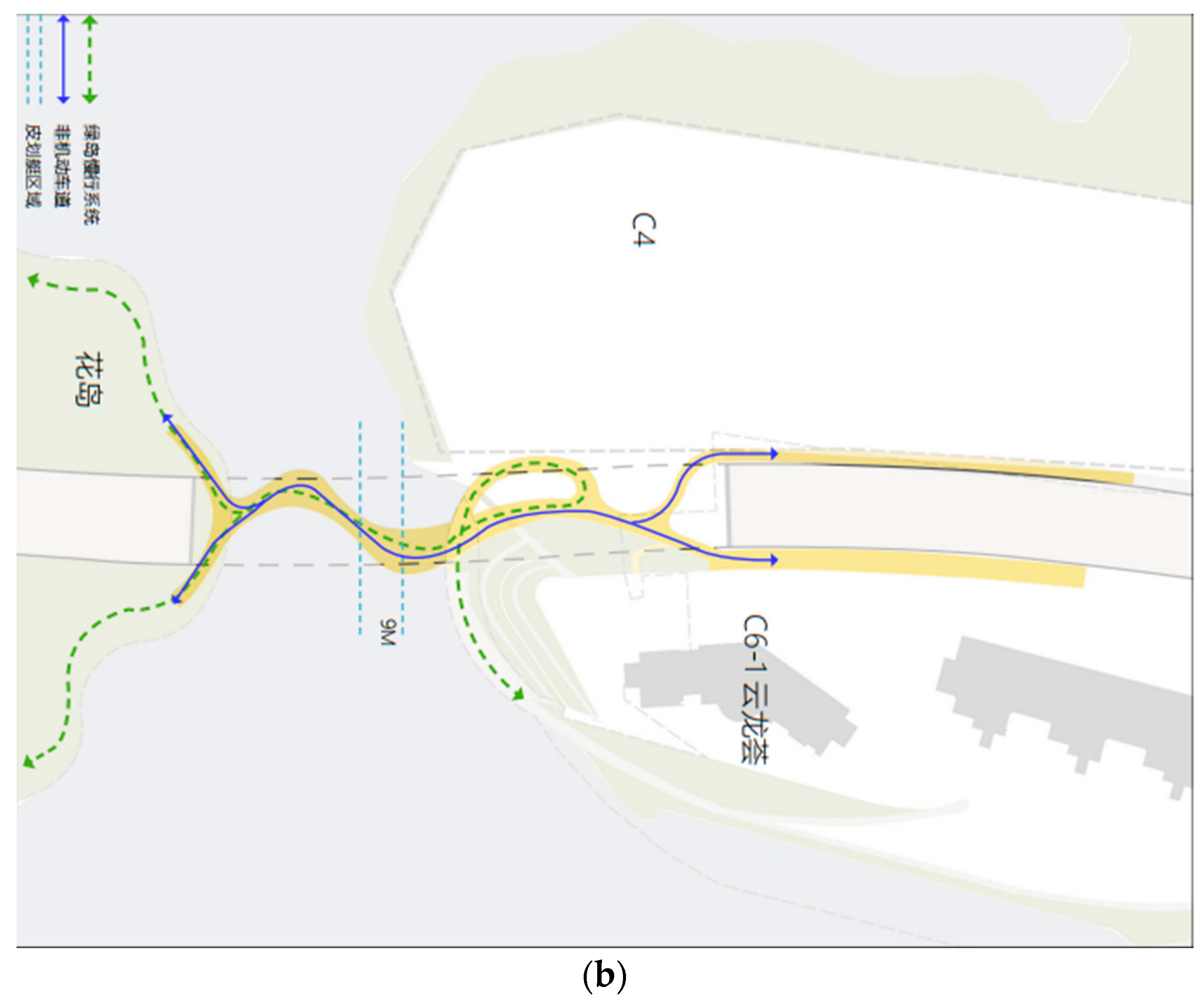

6.1. Case Overview and Modeling Results

6.2. Display of Component-to-IFC Matching Results

7. Conclusions

- (1)

- Leveraging the EXPRESS language of the IFC standard and its EXPRESS-G diagrammatic representation, a multi-level semantic model covering spatial structure units, components, assemblies, and parts was developed. This significantly strengthens the consistency and semantic completeness of BIM data representation across design, manufacturing, and assembly stages.

- (2)

- On the 3DEXPERIENCE platform, the integration of the TXO module and DMC tools enabled the implementation of extended IFC entity definitions and their system-level deployment. Standardized export of geometric and attribute information was achieved via IfcOpenShell. Cross-platform validation in CATIA, BIMvision, and usBIM environments demonstrated efficient sharing, accurate parsing, and robust interoperability, thereby confirming the strong engineering applicability and practical value of the proposed method.

- (3)

- The proposed BIM modeling approach provides a systematic solution for the digital design and delivery of complex steel bridge projects. It effectively alleviates inconsistencies and inefficiencies in multi-disciplinary collaboration and cross-stage data transfer. The research outcomes carry substantial theoretical significance and engineering value for promoting BIM standardization in steel bridge projects, supporting industry-wide digital transformation, and enhancing full lifecycle management.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alizadehsalehi, S.; Hadavi, A.; Huang, J.C. From BIM to Extended Reality in AEC Industry. Autom. Constr. 2020, 116, 103254. [Google Scholar] [CrossRef]

- Sacks, R.; Koskela, L.; Dave, B.A.; Owen, R. Interaction of Lean and Building Information Modeling in Construction. J. Constr. Eng. Manag. 2010, 136, 968–980. [Google Scholar] [CrossRef]

- Criminale, A.; Langar, S. Challenges with BIM Implementation: A Review of Literature. In Proceedings of the 53 rd ASC Annual International Conference Proceedings, Seattle, WA, USA, 5–8 April 2017. [Google Scholar]

- Zhang, Q.L.; Tang, Z.H.; Man, Y.L. BIM Full Data-exchange Technology of Steel Structure Based on Industry Foundation Class Standard. J. TONGJI Univ. Sci. 2024, 52, 331–339. [Google Scholar]

- Li, X.; Xu, J.; Zhang, Q. Research on Construction Schedule Management Based on BIM Technology. Procedia Eng. 2017, 174, 657–667. [Google Scholar] [CrossRef]

- Gao, G.; Liu, Y.-S.; Wang, M.; Gu, M.; Yong, J.-H. A Query Expansion Method for Retrieving Online BIM Resources Based on Industry Foundation Classes. Autom. Constr. 2015, 56, 14–25. [Google Scholar] [CrossRef]

- Lai, H.H.; Deng, X.Y.; Liu, X.L. IFC-based BIM data sharing and exchange. CHINA Civ. Eng. J. 2018, 51, 121–128. [Google Scholar] [CrossRef]

- Amor, R. Analysis of the Evolving IFC Schema. In Proceedings of the 32nd CIB W78 Information Technology for Construction Conference (CIB W78 2015), Eindhoven, The Netherlands, 27–29 October 2015. [Google Scholar]

- ISO 16739-1:2024; Industry Foundation Classes (IFC) for Data Sharing in the Construction and Facility Management Industries Part 1: Data Schema. International Organization for Standardization: Geneva, Switzerland, 2024. Available online: https://www.iso.org/standard/84123.html (accessed on 28 July 2025).

- Liu, L.; Li, B.; Zlatanova, S.; Van Oosterom, P. Indoor Navigation Supported by the Industry Foundation Classes (IFC): A Survey. Autom. Constr. 2021, 121, 103436. [Google Scholar] [CrossRef]

- Vanlande, R.; Nicolle, C.; Cruz, C. IFC and Building Lifecycle Management. Autom. Constr. 2008, 18, 70–78. [Google Scholar] [CrossRef]

- Söbke, H.; Peralta, P.; Smarsly, K.; Armbruster, M. An IFC Schema Extension for BIM-Based Description of Wastewater Treatment Plants. Autom. Constr. 2021, 129, 103777. [Google Scholar] [CrossRef]

- Hossain, M.A.; Yeoh, J.K.W. BIM for Existing Buildings: Potential Opportunities and Barriers. IOP Conf. Ser. Mater. Sci. Eng. 2018, 371, 012051. [Google Scholar] [CrossRef]

- Eadie, R.; Browne, M.; Odeyinka, H.; McKeown, C.; McNiff, S. BIM Implementation throughout the UK Construction Project Lifecycle: An Analysis. Autom. Constr. 2013, 36, 145–151. [Google Scholar] [CrossRef]

- Industry Foundation Classes (IFC)—Building SMART International. Available online: https://www.buildingsmart.org/standards/bsi-standards/industry-foundation-classes/ (accessed on 28 July 2025).

- ISO 10303-11:2004; Industrial Automation Systems and Integration—Product Data Representation and Exchange Part 11: Description Methods: The EXPRESS Language Reference Manual. International Organization for Standardization: Geneva, Switzerland, 2004. Available online: https://www.iso.org/standard/38047.html (accessed on 28 July 2025).

- W3C Extensible Markup Language (XML). Available online: https://www.w3.org/TR/xml11/ (accessed on 28 July 2025).

- Lee, Y.-C.; Eastman, C.M.; Solihin, W. An Ontology-Based Approach for Developing Data Exchange Requirements and Model Views of Building Information Modeling. Adv. Eng. Inform. 2016, 30, 354–367. [Google Scholar] [CrossRef]

- Lee, S.-H.; Jeong, Y.-S. A System Integration Framework through Development of ISO 10303-Based Product Model for Steel Bridges. Autom. Constr. 2006, 15, 212–228. [Google Scholar] [CrossRef]

- Lee, S.H.; Park, S.I.; Park, K.Y. IFC property set-based approach for generating semantic information of steel box girder bridge components. KSCE J. Civ. Environ. Eng. Res. 2014, 34, 687–697. [Google Scholar] [CrossRef]

- Park, S.I.; Lee, S.-H.; Almasi, A.; Song, J.-H. Extended IFC-Based Strong Form Meshfree Collocation Analysis of a Bridge Structure. Autom. Constr. 2020, 119, 103364. [Google Scholar] [CrossRef]

- Ji, Y.; Borrmann, A.; Obergrieβer, M. Toward the Exchange of Parametric Bridge Models Using a Neutral Data Format. In Proceedings of the Computing in Civil Engineering, Miami, FL, USA, 19–22 June 2011; American Society of Civil Engineers: Reston, VA, USA, 2011; pp. 528–535. [Google Scholar]

- Lee, S.-H.; Kim, B.-G. IFC Extension for Road Structures and Digital Modeling. Procedia Eng. 2011, 14, 1037–1042. [Google Scholar] [CrossRef]

- Wu, J.; Chen, J.; Chen, G.; Wu, Z.; Zhong, Y.; Chen, B.; Ke, W.; Huang, J. Development of Data Integration and Sharing for Geotechnical Engineering Information Modeling Based on IFC. Adv. Civ. Eng. 2021, 2021, 8884864. [Google Scholar] [CrossRef]

- Zhu, H.X.; Xu, Z. Research on information collaboration and model construction for top-down design of prefabricated buildings. J. Graph. 2021, 42, 289–298. [Google Scholar]

- He, Q.; Jin, C.X.; Gao, T.C.; Wang, P. Research on BIM Model of Railway Track Structure Based on IFC Standard Extension. J. Graph. 2023, 44, 357–367. [Google Scholar]

- Yang, Y.; Li, J.; Zhang, Z.; Liu, Y. Research on Information Extension of Mountainous Rack Railway Engineering Based on IFC Standard. Sci. Rep. 2024, 14, 21557. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, S.; Wang, C.; Zhu, G.; Liu, H.; Wang, X. Extended IFC-Based Information Exchange for Construction Management of Roller-Compacted Concrete Dam. Autom. Constr. 2024, 163, 105427. [Google Scholar] [CrossRef]

- Wang, Q.; Li, J.; Yao, H.; Li, Z.; Jia, X. Research on IFC-Based Tunnel Monitoring Information Integration and Visual Warning Scheme. Buildings 2025, 15, 2221. [Google Scholar] [CrossRef]

- Zhang, Z.; Meng, X. IFC-based information exchange framework research and implementation between architectural and structural design. Build. Struct. 2024, 54, 149–154. [Google Scholar]

- Lai, H.; Deng, X. Interoperability Analysis of Ifc-Based Data Exchange between Heterogeneous Bim Software. J. Civ. Eng. Manag. 2018, 24, 537–555. [Google Scholar] [CrossRef]

- Bao, L.S.; An, P.L.; Wang, P.; Liang, W.; Yu, L. Research on Visualization of Bridge Safety Information Based on IFC. J. Shenyang Jianzhu Univ. Nat. Sci. 2022, 38, 682–689. [Google Scholar]

- Sheik, N.A.; Veelaert, P.; Deruyter, G. Exchanging Progress Information Using IFC-Based BIM for Automated Progress Monitoring. Buildings 2023, 13, 2390. [Google Scholar] [CrossRef]

- Seo, J.; Kim, I. Industry Foundation Classes-Based Approach for Managing and Using the Design Model and Planning Information in the Architectural Design. J. Asian Archit. Build. Eng. 2009, 8, 431–438. [Google Scholar] [CrossRef][Green Version]

- Zhiliang, M.; Zhenhua, W.; Wu, S.; Zhe, L. Application and Extension of the IFC Standard in Construction Cost Estimating for Tendering in China. Autom. Constr. 2011, 20, 196–204. [Google Scholar] [CrossRef]

- Liu, Y.; Li, M.; Wong, B.C.L.; Chan, C.M.; Cheng, J.C.P.; Gan, V.J.L. BIM-BVBS Integration with openBIM Standards for Automatic Prefabrication of Steel Reinforcement. Autom. Constr. 2021, 125, 103654. [Google Scholar] [CrossRef]

- China Railway BIM Alliance (CRBIM). Railway BIM Data Standard Version 1.0. China Railw. BIM Alliance 2016, 177. [Google Scholar] [CrossRef]

| Attribute Name | Data Type | Description | Example |

|---|---|---|---|

| UniqueCoding | IfcLable | Unique identifier of the component | BXG001-A-001 |

| Name | IfcLable | Official name of the component | Steel Box Girder |

| TypeDesignator | IfcLable | Steel component type identifier | BoxGirder_Type_A |

| ProductionLotId | IfcLable | Production Batch Number | LOT20240715 |

| ProductionDate | IfcLable | Manufacturing Date | 20220801 |

| SerialNumber | IfcLable | Serial Number | SN000321 |

| PieceMark | IfcLable | Part Identification Number | BM-GZ-001-A |

| LocationNumbe | IfcLable | Installation Location Code | Span2-Girder3 |

| Installer | IfcLable | Installed By | CDZX |

| InstallationData | IfcLable | Installation Date | 20220801 |

| Material | IfcLable | Material Type | Q370qE |

| Intensity | IfcPressureMeasure | Strength Properties | 48 MPa |

| Density | IfcMassDensityMeasure | Density Information | 2420 kg/m3 |

| ElasticModulus | IfcPressureMeasure | Modulus of Elasticity | 35,300 MPa |

| PoissonRatio | IfcLable | Poisson’s Ratio | 0.16 |

| Description | IfcLable | Description of the Component | Steel Box Girder |

| Name | Data Type | Explain | Example |

|---|---|---|---|

| Type | IfcLable | Component Type | Main beam |

| SectionForm | IfcLable | Cross-Section Type | Cabinet type |

| Length | IfcLengthMeasure | Design Length of Component | 12,500 mm |

| Width | IfcLengthMeasure | Component Width | 2500 mm |

| Height | IfcLengthMeasure | Component Height | 1800 mm |

| Thickness | IfcLengthMeasure | Main Plate Thickness | 16 mm |

| DesignDeflection | IfcLengthMeasure | Deflection Control Standard | L/600 |

| Camber | IfcLengthMeasure | Designed Camber | 80 mm |

| FatigueClass | IfcLable | Fatigue Classification | 90 MPa |

| Name | Data Type | Explain | Example |

|---|---|---|---|

| FabricationCode | IfcIdentifier | Fabrication Component ID | GX-L1-001 |

| WorkshopID | IfcLable | Workshop ID | WKS-03 |

| ProcessingDate | IfcDate | Fabrication Date | 2024-07-16 |

| NCProgram | IfcURIReference | NC Fabrication File | nc://gx-l1-001.nc |

| WeldingMethod | IfcLable | Welding Procedure | Submerged Arc Welding |

| HoleConfiguration | IfcLable | Hole Position Parameters | Φ22@100 mm |

| CuttingMethod | IfcLable | Cutting Method | CNC Plasma Cutting |

| SurfaceTreatment | IfcLable | Surface Treatment Method | Sa2.5 Sandblasting |

| CoatingType | IfcLable | Coating Method | Epoxy Intermediate Coating |

| QRCode | IfcURIReference | QR Code Identifier for Component | qr://gx-l1001.png |

| Evaluation Metric | Information Retention Rate of IFC Models Exported by Different Software/% | |||

|---|---|---|---|---|

| 3DEXPERIENCE | Tekla | Revit | ArchiCAD | |

| Geometric Appearance | 100.00 | 100.00 | 100.00 | 100.00 |

| Spatial Positioning | 93.25 | 78.5 | 41.08 | 30.19 |

| Component Sections | 93.25 | 78.5 | 41.08 | 30.19 |

| Fabrication Cuts & Notches | 88.03 | 71.23 | 0 | 0 |

| Attributes (Design/Fabrication) | 100.00 | 70.1 | 56.42 | 100 |

| Parametric Group Information | 100.00 | 100.00 | 100.00 (Non-parametric) | 0 |

| Overall Retention Rate | 93.85 | 83.1 | 71.23 | 69.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Xiang, J.; Zhang, Z. Research on BIM Modeling of Steel Bridges Based on IFC Extensions. Buildings 2025, 15, 3376. https://doi.org/10.3390/buildings15183376

Yang Y, Xiang J, Zhang Z. Research on BIM Modeling of Steel Bridges Based on IFC Extensions. Buildings. 2025; 15(18):3376. https://doi.org/10.3390/buildings15183376

Chicago/Turabian StyleYang, Yongyi, Jianguo Xiang, and Zizhen Zhang. 2025. "Research on BIM Modeling of Steel Bridges Based on IFC Extensions" Buildings 15, no. 18: 3376. https://doi.org/10.3390/buildings15183376

APA StyleYang, Y., Xiang, J., & Zhang, Z. (2025). Research on BIM Modeling of Steel Bridges Based on IFC Extensions. Buildings, 15(18), 3376. https://doi.org/10.3390/buildings15183376