1. Introduction

Modern Methods of Construction (MMC) are increasingly regarded as a strategic response to global housing challenges. In the face of affordability crises, labor shortages, climate imperatives, and rising demands for build quality and delivery speed, MMC offers promising alternatives to traditional construction through techniques such as prefabrication, modularization, and Design for Manufacture and Assembly (DfMA). These approaches shift significant portions of construction off-site, enabling greater quality control, faster project timelines, and improved environmental performance [

1,

2].

Early adopters—including Japan, Germany, and Sweden—have demonstrated the potential of MMC to deliver systemic productivity and sustainability gains [

3]. However, these outcomes were not the result of isolated technological interventions. Instead, they stemmed from the long-term development of industrial capabilities, supportive policy frameworks, and cultural alignment [

4,

5].

In contrast, emerging adopters often pursue MMC through reductionist strategies—treating it as a fixed set of methods rather than a systemic transformation. This leads to poor implementation outcomes as critical enablers such as integrated planning, skilled labor development, and institutional readiness are overlooked [

6,

7]. Even in academic discourse, MMC is frequently positioned as a product or process innovation, rather than a socio-technical system.

Given the institutional and cultural variability across contexts, there is no universal path to successful MMC adoption. While some countries (e.g., the UK, Singapore) have pursued top-down strategies, others (e.g., Sweden, Japan) have succeeded through gradual, embedded innovation. Transplanting models without accounting for local conditions risks inefficiencies or failure [

4].

Despite the growing interest in MMC, few studies systematically compare how adoption unfolds across diverse institutional, cultural, and industrial settings. Existing literature often focuses on single-country cases or technical innovations, offering limited guidance on the broader conditions that shape success or failure. This study addresses that gap by providing a context-sensitive, cross-national analysis of MMC implementation. It identifies structural prerequisites, distinguishes between transferable and context-dependent elements, and distills actionable lessons for governments and industry actors navigating MMC adoption in emerging markets.

This study examines MMC adoption at a national level without distinguishing between applications in new construction versus building renovation. While both areas are important, the analysis focuses on systemic factors that influence adoption broadly, rather than on specific implementation contexts.

The remainder of this paper is organized as follows:

Section 2 provides an overview of MMC definition and historical evolution.

Section 3 outlines the methodology and country selection rationale.

Section 4 presents the cross-case findings.

Section 5 synthesizes transferable insights and distinguishes context-specific practices.

Section 6 and

Section 7 conclude with implications of the research, limitations, and future research.

2. Research Background

2.1. Overview of Modern Methods of Construction

The field of off-site construction is characterized by overlapping and sometimes inconsistent terminology. Terms such as “Industrialized Building” (IB), “Off-Site Production” (OSP), “Prefabrication,” “Modular Construction,” and “Modern Methods of Construction” (MMC) are frequently used interchangeably across different countries and contexts. While this reflects the global and evolving nature of the field, it also risks obscuring important distinctions. For the purposes of this paper, the term MMC is used as a broad, internationally recognized label that encompasses a range of off-site approaches, while drawing conceptually from the foundational literature on Industrialized Building (IB).

MMC refers to a spectrum of innovative construction techniques designed to improve efficiency, quality, and sustainability by shifting significant portions of construction away from traditional on-site practices toward off-site manufacturing and assembly. These methods include prefabrication, modular construction, and Design for Manufacture and Assembly (DfMA). Prefabrication involves producing components in a controlled factory setting, enhancing quality and consistency. Modular construction assembles entire volumetric units off-site, while DfMA streamlines design to facilitate easier manufacturing and faster on-site assembly.

The core advantages of MMC include reduced construction timelines, improved safety, enhanced quality control, and diminished environmental impact. However, the adoption of MMC continues to face challenges such as fragmented regulatory environments, supply chain limitations, and market inertia.

From a theoretical perspective, MMC shares considerable overlap with the concept of IB, as developed by Lessing [

8]. IB provides a more comprehensive socio-technical framework that extends beyond construction methods to include organizational innovation, supply chain integration, and process coordination. Lessing’s framework identifies nine organizational enablers for successful industrialized construction: planning and process control, developed technical systems, prefabrication, long-term relationships, logistics, customer focus, digitalization, re-use of experience, and continuous improvement [

9,

10]. IB is further defined by three fundamental characteristics: (1) components are manufactured in controlled production environments, (2) production and assembly follow standardized processes with documented quality control, and (3) design, production, and on-site assembly are systematically integrated through coordinated procedures.

While various theoretical lenses such as diffusion of innovation and institutional theory have been applied [

11], these are not the focus of this study. Instead, this research adopts an empirical approach to examine how MMC has been implemented across different policies and industry environments. By building on the theoretical foundations of IB and focusing on practical outcomes from international case studies, the paper aims to offer actionable insights into the conditions under which MMC can be successfully adopted.

To understand how different countries have approached MMC, it is important to trace the historical trajectories that shaped industrialized building practices across contexts. The following section provides this cross-national perspective.

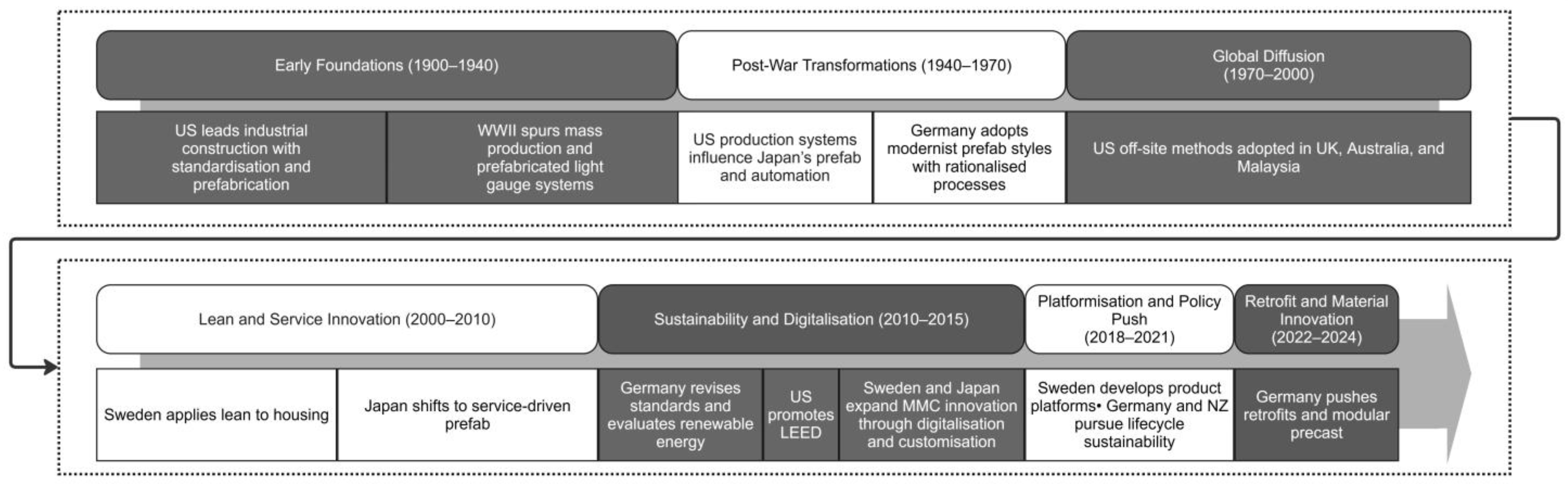

2.2. Historical Evolution and Cross-Country Experiences

The evolution of MMC practices reveals distinct phases of innovation across countries. In the early 20th century, the United States played a pioneering role in industrial architecture, introducing standardized construction methods and early prefabrication in factory design [

12]. During and after World War II, Germany and the United States embraced prefabricated systems for military and worker housing. This shift laid the groundwork for modern rapid construction techniques. These wartime innovations were later adapted by Japan, where American production logic influenced the emergence of mass customization and automation in the building sector [

13,

14].

By the mid- to late 20th century, off-site construction methods developed in the United States gained international popularity. Countries such as the United Kingdom, Australia, and Malaysia began to explore these innovative techniques [

15]. In the early 2000s, Sweden emerged as a leader in integrating lean principles into industrialized housing, focusing on standardization and error-proofing [

16]. Concurrently, Japan began shifting its industry towards service-oriented prefabrication, enhancing building delivery with post-occupancy services and customization options [

4].

More recently, the emphasis has shifted toward environmental sustainability and digital innovation. Germany has revised its energy efficiency and insulation standards, expanded modular construction using precast concrete kits, and aligned with European sustainability frameworks [

1,

17]. Sweden has promoted digitalization and platform-based product systems [

18,

19], while Canada has embraced off-site industrialized construction as a strategic response to post-pandemic inflation and material shortages [

7]. In parallel, New Zealand has advanced the use of mass timber and undertaken extensive efforts to reduce residential construction waste through prefabrication and life cycle assessment [

20,

21].

Figure 1 illustrates the diversity of development trajectories across mature MMC markets.

3. Methodology

This research is grounded in an interpretivist epistemology, recognizing that MMC adoption patterns are socially constructed and context-dependent rather than following universal laws [

22]. Such an orientation is particularly appropriate in construction industry research, where historical trajectories, regulatory structures, and market dynamics profoundly influence technological change [

23,

24]. It aligns with comparative policy traditions that prioritize contextual meaning and institutional analysis over statistical generalization [

25,

26], especially relevant in MMC research where adoption success depends on systemic interactions between policy frameworks, production capabilities, and cultural acceptance [

10,

27].

The study adopts a structured cross-case comparative design, grounded in

socio-

technical transition theory [

28] and informed by Eisenhardt [

29] inductive case method and George and Bennett [

30] structured, focused comparison framework. Viewing MMC adoption as a systemic transition rather than a discrete technological substitution, the analysis explicitly considers the interaction between technological capabilities, institutional arrangements, market structures, cultural norms, and workforce capacity. This perspective shaped both the structure of the cross-country narratives and the coding of thematic categories.

3.1. Comparative Analysis Framework

3.1.1. Theoretical Approach

This study employs a cross-national comparative design based on pattern-matching logic [

30,

31]. Rather than seeking to control differences between countries, this approach systematically examines how different combinations of institutional, cultural, and policy factors relate to MMC adoption outcomes across diverse national contexts. An approach widely used in housing and construction policy research where institutional and cultural factors significantly shape technological adoption [

27,

32].

Pattern-matching logic is particularly suited to this research because it allows for the identification of universal patterns that appear consistently across different national contexts, suggesting transferable principles for MMC adoption. Context-specific configurations are identified where particular combinations of local factors enable successful implementation, highlighting the importance of adaptation to local conditions.

This approach acknowledges the principle of equifinality—that multiple pathways may lead to successful MMC adoption. For instance, Sweden’s incremental, industry-led evolution may achieve similar outcomes to Singapore’s top-down, government-mandated approach, but through entirely different mechanisms.

The analytical framework builds on established comparative methodology while adapting to the specific requirements of cross-national MMC analysis. It draws from diffusion of innovation theory [

11], institutional theory perspectives on construction innovation [

4], and industrialized building frameworks [

8], but applies pattern-matching logic to identify which factors consistently associate with successful MMC adoption across different contexts.

3.1.2. Country Selection Strategy

Seven countries were selected using purposive sampling to maximize analytical leverage for pattern-matching across diverse contexts:

Geographic representation: Countries from different continents (North America, Europe, Asia-Pacific) to identify universal versus regionally specific patterns and avoid Western-centric bias in MMC analysis.

MMC maturity variation: Countries at different stages of MMC development—from early pioneers (Japan, Sweden) to recent policy-driven adopters (UK, Singapore) to emerging markets (Australia, US)—enabling analysis of different implementation pathways and their outcomes over time.

Institutional diversity: Variation in governance systems (federal vs. unitary), economic models (market-led vs. state-directed), and regulatory approaches to capture how different institutional configurations influence MMC adoption success.

Cultural and economic context variation: Different cultural orientations toward innovation, risk tolerance, and standardization, combined with varying demographic and housing pressures that drive MMC adoption.

Data accessibility: Countries with sufficient English-language documentation of policies, industry practices, and academic analysis to enable systematic comparison while maintaining analytical rigor.

Economic baseline: Focus on developed economies to analyze institutional and cultural factors rather than basic economic capacity differences, ensuring MMC adoption patterns reflect strategic choices rather than resource constraints.

This selection strategy enables pattern-matching analysis by providing sufficient variation across key dimensions while maintaining analytical feasibility. The diversity is treated as analytical leverage rather than a limitation, allowing for the identification of both universal success factors and context-dependent implementation approaches.

A summary of selected indicators is provided in

Table 1, with the full dataset available in the

Supplementary Materials (Table S1). These indicators are not intended to imply strict equivalence but to demonstrate controlled variation across key contextual factors while maintaining sufficient economic development for systematic analysis of institutional and cultural influences.

3.2. Data Collection and Expert Validation

This study employs a two-phase approach combining systematic documentary analysis with expert validation to ensure robustness and practical relevance of findings.

Phase 1: Documentary Analysis

The primary data collection involved systematic compilation and analysis of:

66 MMC company cases across the seven countries, identified through industry databases, trade publications, and government reports

26 major government initiatives and policy frameworks

Academic literature on MMC adoption (2000–2024)

Industry reports from construction research organizations and policy documents and regulatory frameworks

Company selection criteria included: (1) documented involvement in MMC/prefabrication projects, (2) publicly available information on business models and implementation approaches, (3) operational history sufficient to assess outcomes, and (4) representation across different MMC typologies (volumetric, panelized, hybrid systems). These cases include a mix of successful and less successful MMC implementations, selected to reflect diversity in adoption approaches and outcomes.

The final selection of 66 companies and 26 government initiatives was guided by representativeness and data availability. These cases span different MMC typologies (volumetric, panelized, hybrid), encompass both successful and unsuccessful implementations, and reflect a balance across the seven national contexts (Summarized in

Table 2). Alternative candidates were excluded where insufficient public documentation prevented systematic comparison.

Phase 2: Expert Validation

To enhance the validity and practical relevance of the analysis, findings were subjected to structured expert review. Four leading international MMC practitioners were selected based on:

More than 20 years of senior experience in MMC implementation

Cross-national project exposure

Recognition as thought leaders in the field (publications, speaking engagements, industry awards)

Representation across different stakeholder perspectives (contractors, manufacturers, consultants)

The expert consultation process involved:

Presentation of preliminary findings and analytical framework

Structured feedback on country characterizations and success/failure factors

Validation of transferability assessments

Identification of missing elements or misinterpretations

Expert input led to several refinements, including recalibration of market adoption percentages, clarification of regulatory complexity in federal systems, and enhanced understanding of cultural factors influencing adoption. This validation process strengthens the credibility of findings beyond what documentary analysis alone could achieve.

3.3. Analytical Process

The analytical process unfolded through four sequential stages:

Country Narrative Construction—Structured narratives were developed for each country, synthesizing historical adoption trajectories, key policy and regulatory milestones, implementation models, supply chain structures, and cultural–institutional contexts.

Cultural receptivity was assessed using data from the Schwartz Value Survey and World Values Survey, which capture national-level orientations toward innovation, hierarchy, and collectivism.

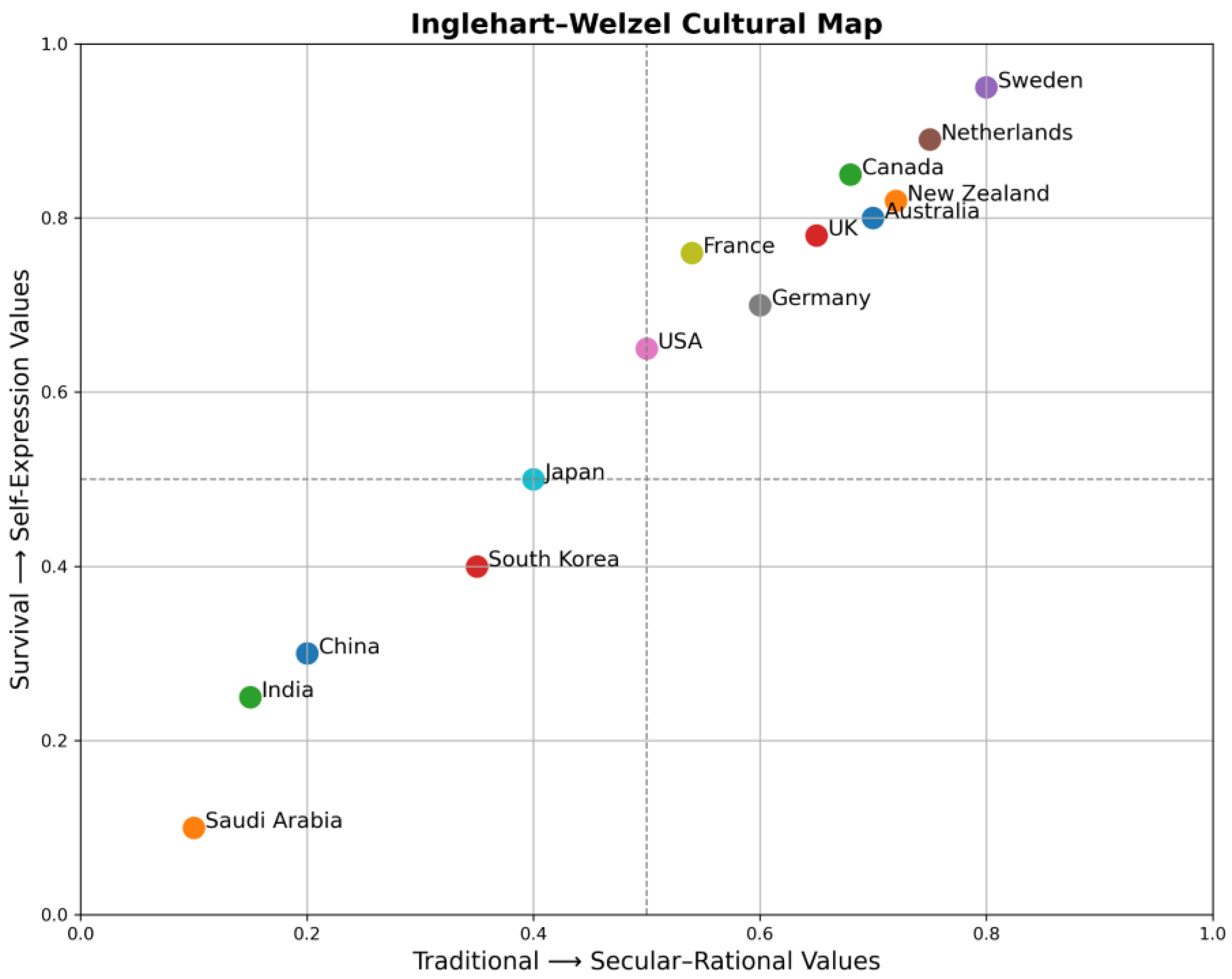

Figure 2 plots the seven countries within the Schwartz Cultural Value Quadrant, visually illustrating their relative positions across these dimensions. This helped contextualize differences in MMC adoption by linking cultural factors to the systemic conditions assessed in the framework.

These cultural positions were used as a contextual layer for interpreting patterns in the scoring rubric (

Table 3) and the comparative synthesis (

Table 4), ensuring that institutional and industrial factors were considered alongside societal dynamics.

Thematic Coding—Each case was coded against the eight-category framework (

Section 3.4), combining deductive categories from MMC literature with inductive refinement from case evidence, and recognizing interdependencies between themes.

Scoring and Comparative Mapping—A three-point scoring rubric (Strong = 3, Moderate = 2, Weak = 1) was applied to each thematic category using clearly defined criteria (see

Supplementary Materials). Countries were then mapped against the thematic matrix, allowing identification of recurring factor configurations. Comparative tables were used to test whether certain combinations—such as strong regulatory support, mature supply chain integration, and positive cultural receptivity—were consistently associated with higher MMC adoption maturity.

Cross-Case Synthesis and Rival Explanation Testing—Thematic scores and narratives were integrated to identify patterns, outliers, and disconfirming cases. Rival explanations were explicitly tested—for example, examining whether high MMC uptake could occur without strong cultural receptivity, or whether market-led models performed better than public-led approaches under certain institutional conditions. Findings were cross-validated against existing socio-technical transition literature to ensure theoretical coherence and robustness.

The eight analytical dimensions were applied as equally weighted categories for comparative purposes. This approach was chosen to maintain methodological consistency across diverse contexts rather than privileging any single dimension. However, we recognize that in practice some factors (e.g., regulatory support, cultural receptivity) exert greater influence. The seven countries were selected because they combine structural comparability—high-income economies with mature construction industries—with divergent MMC trajectories, providing a controlled yet varied basis for comparison.

Although the framework captures market adoption and business model variation, it does not treat financial viability as a standalone dimension. Our analysis revealed that direct costs, return on investment, and financing mechanisms are often decisive in shaping adoption trajectories. Future iterations of the framework could include a dedicated financial viability category to capture these critical factors more explicitly.

By embedding the socio-technical transition framework at the heart of the analytical process, this study moves beyond surface-level macroeconomic comparisons to interrogate the systemic configurations that underpin successful or stalled MMC adoption.

3.3.1. Thematic Framework Development

The analytical framework for this study was designed to capture the systemic nature of MMC adoption, drawing explicitly from

socio-

technical transition theory [

28] alongside established innovation and construction management literature. This lens frames MMC not as an isolated technological substitution but as a transformation embedded in, and shaped by, the interaction of technological capabilities, institutional arrangements, market logics, cultural norms, and skills systems.

Framework development followed a hybrid deductive–inductive process. Deductively, it was informed by convergent findings in:

Innovation diffusion theory [

11], providing baseline adoption categories;

Institutional theory [

4], emphasizing the role of regulatory and governance structures; and

Industrialized building enablers [

8], highlighting integrated processes and supply chain coordination.

Inductively, it was refined through pattern recognition in the case study data, ensuring the categories could capture the interplay of cultural, economic, and organizational factors that emerged as critical in cross-country variation. For example, Cultural Receptivity emerged from repeated observation that societal attitudes toward standardization, automation, and factory work strongly conditioned adoption trajectories—an element underrepresented in prior MMC frameworks. Similarly, Business Model Type emerged from observations that successful MMC adoption required fundamentally different organizational approaches than traditional construction, necessitating analysis of public–private configurations not captured in standard innovation frameworks.

The final framework consists of eight interrelated thematic categories:

Regulatory Support—presence and coherence of MMC-specific policies and their integration into building codes;

Market Adoption—quantitative penetration of MMC across sectors and project types;

R&D/Tech Integration—level of investment in MMC innovation, automation, and digitalization;

Supply Chain Integration—degree of coordination between design, manufacturing, and construction processes;

Business Model Type—dominant organizational configurations (public-led, private-led, vertically integrated, hybrid);

Skills Development—scope and institutionalization of MMC-relevant training and qualifications;

Cultural Receptivity—societal alignment with industrialization and innovation in construction;

MMC Implementation Logic—coherence and clarity of strategic adoption pathways.

Rather than treating these categories as isolated variables, the framework conceptualizes them as interacting elements within a socio-technical system. This enables the analysis to move beyond linear cause–effect assumptions, recognizing that MMC adoption is path-dependent and context-contingent. It also provides a structured basis for cross-case comparison, allowing the study to test how different configurations of these elements align with more or less successful adoption outcomes.

3.3.2. Scoring and Assessment Protocol

Each thematic category was assessed using a standardized 3-point scale (Strong = 3, Moderate = 2, Weak = 1) with detailed criteria for each rating level, following established practices in comparative qualitative research for enabling systematic cross-case comparison while avoiding false precision [

36].

Table 3 outlines the criteria for each dimension, with scores ranging from weak (1) to strong (3). These thresholds were developed by synthesizing international literature, industry reports, and expert consultation, ensuring they are both theoretically grounded and practically applicable.

Consistency was maintained through several key practices. Each theme was evaluated using clearly defined assessment criteria, as outlined in the detailed rubric provided in the

Supplementary Materials. The same evidence standards were systematically applied across all countries to ensure uniformity. Where quantitative indicators were available, they were cross-referenced with qualitative assessments to strengthen the validity of findings. Additionally, scoring decisions were regularly reviewed to confirm alignment with the established criteria.

Country assessments were conducted independently for each theme before integration, and scoring decisions were documented with supporting evidence from multiple sources to ensure transparency and reproducibility [

37]. This systematic approach to scoring and documentation follows protocols established in framework analysis methodology [

38,

39]. Our approach mirrors recent comparative MMC studies [

40,

41], which use structured thematic matrices to compare policy and performance outcomes across multiple national cases.

3.4. Reliability and Validity Considerations

Several measures were implemented to enhance the reliability and validity of the comparative analysis. A structured coding protocol was applied consistently across all cases, with pre-defined assessment criteria limiting subjective interpretation and enhancing inter-rater reliability [

42]. Construct validity was strengthened through multiple data source triangulation and explicit documentation of scoring decisions [

29].

Where conflicting information emerged across sources, priority was given to: (1) official government data and policy documents, (2) peer-reviewed academic sources, (3) industry reports from established organizations, and (4) company-specific information. This hierarchical approach follows established practices for managing conflicting evidence in comparative research. Conflicting assessments were noted and, where possible, resolved through additional source consultation or acknowledgment of uncertainty.

Internal validity was enhanced through pattern matching across cases and systematic search for disconfirming evidence [

43]. The thematic framework was validated against existing MMC adoption literature and refined through preliminary analysis of high-profile cases (Japan, Sweden) to ensure categories captured relevant adoption factors, strengthening content validity [

44].

Four experts were consulted, each with more than two decades of senior-level MMC experience. Their backgrounds covered contracting, manufacturing, consulting, and policy advisory roles, ensuring broad stakeholder representation. Consultation took place through structured feedback sessions in which preliminary findings and country narratives were presented, followed by written comments. Expert input clarified regulatory complexity in federal systems, refined market adoption estimates, and confirmed the plausibility of cross-country cultural interpretations.

The study’s reliance on secondary sources introduces potential reporting bias, and publication lags may affect currency. The scoring approach involves interpretive judgment, particularly for qualitative themes like cultural receptivity. These limitations are mitigated through transparent methodology and detailed documentation.

Regarding external validity, the findings offer analytical rather than statistical generalization [

31], providing theoretical insights that may transfer to similar contexts while acknowledging case study limitations. The results of this systematic comparison are synthesized into thematic comparison tables (

Tables S2–S7 in Supplementary Materials), which display each country’s assessment across the eight analytical dimensions and form the empirical foundation for identifying success factors, failure patterns, and transferable insights.

The full list of cases is available upon request to the journal editor for verification purposes, though not publicly shared due to intellectual property constraints.

4. Findings

4.1. Cross-Country Analysis

A systematic comparison of MMC adoption factors across the seven countries is presented in the

Supplementary Materials (Tables S2–S7), providing the empirical foundation for the analyses below.

4.1.1. United Kingdom: Public–Private Collaboration

The United Kingdom presents a distinctive case of top-down, policy-driven MMC adoption with significant government intervention. Since the publication of the “Fixing our Broken Housing Market” report in 2017, the UK government has positioned MMC as a central solution to housing shortages and construction industry inefficiencies. This approach is exemplified by the establishment of a dedicated MMC taskforce in 2021 and the implementation of strategic partnership programs requiring at least 25% of homes to be delivered via MMC [

45,

46].

While this policy-led approach has successfully elevated MMC’s profile in the UK construction sector, our analysis reveals limitations in implementation flexibility. The UK’s MMC definition framework, while comprehensive in categorizing different approaches, has inadvertently narrowed industry focus to specific production methods, particularly volumetric modulation and panelized systems [

40]. This over-reliance on select production methods has created challenges for broader innovation in the sector, similar to standardization constraints observed in other MMC markets [

5].

The UK’s approach is characterized by strong public sector involvement combined with a focus on technical innovation rather than business model transformation [

41]. This positioning aligns with the UK’s moderate scores on cultural openness to change, suggesting a preference for structured innovation within established frameworks rather than disruptive change [

47]. The emphasis on technical solutions over process transformation contrasts with more integrated approaches seen in other markets [

26].

Despite considerable government backing, market response has been slower than anticipated, highlighting a disconnect between policy ambitions and industry readiness [

6]. This tension is particularly evident in the contrast between substantial public investment and the relatively modest increase in MMC market share, which remains below targets set in government strategic plans.

The collapse of Ilke Homes in 2023 highlights the fragility of government-supported MMC ventures that scaled rapidly without secure demand pipelines. Despite favorable policy rhetoric and procurement frameworks, Ilke’s business model struggled to balance high capital expenditure with inconsistent market absorption. This case underscores the limits of relying on central government contracts without broader cultural acceptance and diversified financing.

The UK case demonstrates how policy-driven approaches can rapidly elevate MMC’s priority but may struggle to overcome deeply embedded traditional construction practices without corresponding attention to cultural acceptance and market transformation. The emphasis on production methods rather than systemic change represents both a strength in providing clear direction and a limitation in adapting to diverse project requirements and regional variations.

4.1.2. Sweden: Operational Excellence

Sweden represents a distinctive approach to MMC adoption characterized by gradual, incremental changes over decades rather than sudden policy shifts. This evolutionary approach has fostered strong cultural acceptance of industrialized construction methods throughout the supply chain and among end users [

18]. Swedish housing manufacturer Boklok (a joint venture between Ikea and Skanska) exemplifies this approach, having refined its modular housing concept since the early 1990s through continuous iteration rather than revolutionary change.

The Swedish model is distinguished by its integration of lean principles into industrialized housing construction, emphasizing error-proofing and standardized maintenance while preserving flexibility and team responsibility from traditional practices [

16]. This balance between industrialization and craft values has created a more sustainable transition than approaches focused solely on technological change, reflecting broader patterns in Scandinavian construction innovation [

9].

Sweden’s position on our MMC implementation framework shows a balanced approach between private sector leadership and strategic innovation, with moderate government support. This aligns with Sweden’s high scores on cultural openness to change and self-expression values, creating a cultural environment receptive to innovation while maintaining quality expectations.

Despite these successes, our analysis identified persistent challenges in production scalability and cost management. Swedish industrialized housebuilders report difficulties in achieving economies of scale due to local planning authorities’ varying requirements, which limit standardization opportunities [

5]. This tension between standardization and local adaptation reflects broader challenges in industrialized construction systems [

10]. Furthermore, the focus on quality and sustainability in Swedish MMC methods, while advantageous for long-term efficiency, generates short-term cost premiums that may hinder market competitiveness [

19].

The example from Sweden demonstrates that cultural acceptance and a sustained dedication to gradual enhancements can lead to sustainable MMC adoption, even in the absence of the dramatic policy interventions observed in other nations [

16]. However, it also highlights the complexity of balancing standardization with local adaptation and managing the cost implications of quality-focused approaches, challenges that extend beyond the Swedish context.

4.1.3. Singapore: Direct Government Intervention

Singapore presents a case of highly coordinated government-led MMC adoption with exceptional alignment between national strategic objectives and construction industry transformation. The city-state’s approach to industrialized construction is characterized by strong government mandates integrated into its broader economic and urban development strategy, exemplified by the Construction Industry Transformation Map (ITM) launched in 2017 which emphasizes Design for Manufacturing and Assembly (DfMA) technologies [

48].

Singapore’s Building and Construction Authority (BCA) has implemented comprehensive policies requiring prefabricated construction technologies in both public and commercial sectors [

49]. This directive approach is exemplified by the mandatory adoption of Prefabricated Prefinished Volumetric Construction (PPVC) for selected land parcels since 2014 and the introduction of the Buildability Framework, which incentivizes higher degrees of prefabrication and standardization through mandated minimum buildability scores. Additionally, the government has made Building Information Modelling (BIM) mandatory for new building projects with gross floor areas over 5000 m

2, demonstrating its commitment to technological integration [

50].

What distinguishes Singapore’s approach is the substantial investment in developing the necessary ecosystem to support MMC adoption. The government has established extensive training programs to address skills gaps, creating specialized courses and certification pathways for construction professionals transitioning to industrialized methods [

51]. This comprehensive skills development strategy has been critical in overcoming workforce resistance to new technologies and practices, addressing the organizational change management challenges that accompany technological adoption.

Our analysis positions Singapore in the upper-left quadrant of our MMC implementation framework, indicating strong public sector involvement with a focus on technical innovation. This positioning aligns with Singapore’s moderate scores on individualism and higher uncertainty avoidance in cultural dimensions [

47,

52,

53], reflecting a society comfortable with top-down governance approaches.

Despite its successes, Singapore’s MMC model reveals notable challenges, including resistance from the private sector due to high upfront costs and logistical challenges [

51,

54]. While this pragmatic approach accelerated adoption, it created challenges in developing indigenous innovation capabilities. The BCA has played a crucial role in addressing these constraints through regulatory standards, promotional activities, and facilitating coordination among stakeholders to ensure smooth implementation [

55]. More recently, Singapore has shifted toward building local expertise through university-industry collaborations and dedicated research centers focused on construction industrialization.

The Singapore case demonstrates how decisive government action, when coupled with comprehensive ecosystem development and skills training, can rapidly transform construction practices. However, it also highlights that successful top-down implementation relies on broader governance structures that may not be easily replicated in countries with different political systems and cultural contexts, consistent with broader findings on policy transfer in construction innovation.

4.1.4. United States: Experimentation and Venture Capital

The United States exhibits a distinctly market-driven approach to MMC adoption characterized by venture capital-supported innovation and entrepreneurial dynamism [

56,

57]. Unlike countries with centralized national strategies, the US model has evolved through private sector leadership with limited federal coordination, resulting in diverse regional ecosystems and specialized market niches for industrialized construction [

52].

Leading the way in the adoption of US MMC are venture-backed companies that are developing innovative business models and technical solutions [

57]. This strategy highlights the US’s role in our framework as primarily driven by the private sector, emphasizing a balance between technical advancements and strategic innovation. Companies like Katerra (despite its eventual bankruptcy) and Factory_OS exemplify this approach, attracting significant venture capital investment to develop integrated design-build-manufacture solutions rather than simply replicating prefabrication systems established in Europe (e.g., Sweden, Germany) and Asia (e.g., Japan, Singapore).

However, our analysis reveals significant challenges stemming from the fragmented regulatory environment across states and municipalities. The lack of standardized building codes and approval processes for industrialized construction creates substantial barriers to scaling MMC solutions nationally [

56]. Companies must navigate differing requirements across jurisdictions, limiting economies of scale and increasing compliance costs. This regulatory fragmentation reflects the decentralized governance structure in the US construction sector and represents a persistent barrier that cannot be overcome through private investment alone [

58].

The US approach lacks the coordinated skills development initiatives seen in countries like Singapore or Japan. Training for MMC remains largely company-specific rather than industry-wide, creating potential bottlenecks in workforce development as adoption increases.

In the United States, the bankruptcy of Katerra in 2021 provides another cautionary example. While heavily backed by venture capital and technologically ambitious, Katerra was unable to navigate fragmented state-level regulations or disrupt entrenched supply chains. Its collapse illustrates the challenges of pursuing a highly centralized, vertically integrated model in a decentralized regulatory environment.

The US example shows how market-driven innovation can produce a variety of creative MMC solutions [

57,

59]. However, it also underscores the difficulties of expanding these solutions without consistent regulations or coordinated industry standards. The eventual failure of highly capitalized ventures like Katerra demonstrates that even substantial private investment struggles to overcome systemic barriers without complementary policy support and industry coordination.

4.1.5. Germany: Engineering Excellence

Germany represents a balanced and methodical approach to MMC adoption, characterized by an emphasis on quality, precision engineering, and systematic implementation. Rather than pursuing rapid transformation through policy mandates or venture capital, Germany has developed industrialized construction capabilities through consistent technical refinement and strong integration with its broader manufacturing excellence tradition [

60].

Central to Germany’s approach is the systematic standardization of building components and processes, particularly evident in its prefabricated concrete element systems. Research indicates that German manufacturers have developed modular construction kits using precast concrete elements that balance standardization with flexibility. This approach reflects Germany’s engineering culture, which prioritizes robust technical solutions and durability over rapid innovation cycles, with studies identifying technical standardization as a key success factor across industrial and housing sectors [

60,

61].

Germany’s position in our MMC implementation framework shows a balance between public and private sector involvement, with a stronger emphasis on technical excellence than business model innovation. German MMC implementation demonstrates systematic integration of digital planning tools, with four-dimensional Building Information Modelling (4D BIM) and precast methods improving productivity and sustainability in large-scale industrial projects [

62].

Post-World War II reconstruction significantly influenced Germany’s MMC development, as prefabricated building systems were adopted to address housing shortages efficiently. Unlike some countries where prefabrication gained negative associations with lower quality, Germany maintained high standards throughout this period, enabling industrialized construction to retain public acceptance and credibility [

60].

Our analysis reveals that Germany’s commitment to energy efficiency and sustainability has further strengthened its MMC approach. German funding programs for retrofitting older buildings have opened new markets for industrialized renovation solutions. This shows how environmental policies can support the adoption of industrialized construction methods [

17]. The integration of prefabrication with sustainability goals demonstrates reduced waste, improved energy efficiency, and support for environmental objectives [

61,

62].

The German model’s strength lies in its integration of MMC into broader construction quality and performance standards rather than treating it as a separate construction category. This integration has facilitated steady adoption without the boom-and-bust cycles seen in more policy-dependent or venture-backed approaches. However, the emphasis on quality and compliance also introduces challenges in cost-competitiveness and flexibility for novel applications, particularly when compared to more agile, market-driven approaches. Studies identify industry resistance, high initial investment, and fragmented supply chains as key barriers, while recommending value chain integration and standardization as mitigation strategies.

Germany demonstrates how cultural acceptance of technical excellence, combined with balanced regulatory frameworks and industry collaboration, can create sustainable MMC adoption paths that emphasize quality and performance alongside efficiency.

4.1.6. Japan: Cultural Integration

Japan exemplifies a uniquely comprehensive approach to MMC adoption characterized by deep cultural integration of modular principles and remarkable technological advancement in prefabrication. Unlike many Western countries, where industrialized construction is still considered innovative, Japan has normalized factory-produced housing through decades of continuous refinement and cultural alignment [

4].

The Japanese housing industry has evolved through both incremental and disruptive innovations, driven by a distinctive socio-economic and cultural environment including frequent earthquakes, reduced human resources, and a strong service attitude [

4]. Companies like Sekisui House, one of Japan’s largest housebuilders, have consistently invested in advanced manufacturing technologies, creating highly automated production systems capable of delivering customized homes at scale. This approach has enabled Japan to build approximately twice as many new homes via MMC annually compared to countries with similar economic development.

What distinguishes Japan’s approach is the concept of mass customization, allowing for highly individualized homes produced through industrial processes. This balance between standardization and personalization has been critical to consumer acceptance, addressing potential concerns about homogeneity in prefabricated housing [

6]. The Japanese model demonstrates that industrialization need not compromise design variety or personal expression, with manufacturers successfully implementing mass customization processes to produce high-quality, zero-energy houses at marketable prices [

63].

Japan’s position on our implementation framework reveals a balanced approach with private sector leadership but substantial public support for research and development. This positioning reflects Japan’s distinctive cultural values that combine respect for tradition with openness to technological advancement, creating a society receptive to innovation within established social structures [

47].

The historical context of post-World War II reconstruction and Japan’s vulnerability to earthquakes have been significant drivers of MMC adoption [

64]. The integration of prefabricated housing can be traced back to early 20th-century efforts to modernize everyday life, with the introduction of western prefabricated construction playing a significant role in shaping cultural acceptance [

65]. Unlike many countries that abandoned prefabrication after addressing immediate post-war housing needs, Japan committed to continuously improving construction quality through industrialization, establishing prefabrication as a premium rather than a temporary solution.

Our analysis reveals minimal resistance to MMC adoption in Japan compared to other countries. This cultural acceptance stems from several factors, including traditional Japanese architecture’s modular principles, a cultural emphasis on precision and efficiency, and successful positioning of prefabricated housing as high-quality and technologically advanced rather than as merely cost-effective alternatives. The service-oriented approach, focusing on services related to the building’s utilization phase and involving customers in the process, has been crucial in gaining consumer acceptance and creating competitive advantages [

4].

Japan’s case demonstrates how cultural alignment, consistent investment in research and development, and successful positioning of industrialized construction as a premium offering can create sustainable MMC adoption. The Japanese approach highlights the importance of adapting industrialization to cultural contexts rather than simply transferring manufacturing models from other industries or countries.

4.1.7. Australia: Crisis-Driven Innovation

Australia presents a case of early-stage MMC adoption shaped by federal governance complexity and growing housing pressures [

52]. While market penetration remains modest (estimated at 3–7%), momentum has accelerated since 2023, driven by acute affordability challenges and a projected construction workforce shortfall of over 80,000 by 2029 [

66].

The National Construction Code provides the regulatory framework, yet planning and approval processes remain devolved to eight state governments. This fragmentation constrains standardization and discourages nationally scalable manufacturing investment, mirroring US challenges. Early research identified high costs, regulatory hurdles, and industry resistance as primary obstacles, issues that persist alongside limited industry maturity [

67].

Policy interest has grown recently. While earlier strategies like the National Housing and Homelessness Agreement (2018) lacked MMC provisions, 2024 marked a shift with

$54 million in federal MMC development commitments and new regulatory guidance [

68]. However, Australia’s vast geography and dispersed population centers make transportation of prefabricated components costly, hindering the development of efficient supply chain networks [

69].

Our analysis positions Australia as having moderate regulatory support with fragmented standardization efforts. State-level regulatory variations create challenges similar to the United States, though smaller in scale, posing difficulties for systematic MMC implementation requiring standardized processes and supply chain integration.

Despite these challenges, Australia has demonstrated particular strength in specific market segments. Student accommodation has emerged as a key area where MMC approaches have gained traction, with several major projects successfully utilizing modular construction techniques. Research indicates that operational benefits have shifted to strategic advantages, with recent studies emphasizing government support, digital technologies, and industry collaboration as key enablers [

70,

71].

The Australian approach reflects moderate R&D investment through university-industry collaboration on sustainability initiatives. However, digital technology integration remains slower than advanced markets like Sweden and Japan, with studies highlighting needs for BIM frameworks to address implementation challenges [

67,

69].

Cultural acceptance of MMC in Australia appears mixed, with some segments of the market expressing concerns about quality and durability, while others embrace the innovation and sustainability benefits. Wong, Whelan and Holdsworth [

71] identified that contractor readiness for greater use of prefabrication requires addressing unlearning and counter-knowledge barriers. This divided reception reflects Australia’s position as an emerging adopter, where market education and demonstration projects remain crucial for broader acceptance.

Australia demonstrates challenges faced by countries developing MMC capabilities without sustained policy commitment (like Singapore) or long-term industry evolution (like Sweden and Japan). However, Australia’s later adopter status offers advantages through learning from international best practices, combined with strong institutions and environmental imperatives, potentially enabling accelerated adoption through targeted strategies [

72].

4.2. Common Factors

Our cross-country analysis revealed several recurring factors that appear to influence successful MMC adoption regardless of specific national context. These common elements suggest potential transferable lessons for countries seeking to advance industrialized construction methods.

4.2.1. Policy Alignment and Long-Term Commitment

Across successful cases, we observed that MMC adoption thrives when aligned with broader policy objectives beyond just construction efficiency. Countries like Singapore and Japan demonstrate how embedding MMC within larger national priorities (such as addressing housing shortages, improving environmental sustainability, or enhancing disaster resilience) builds stronger support ecosystems. This alignment ensures policy continuity beyond political cycles, with Germany and Sweden exemplifying how long-term commitment to industrialized construction (spanning decades rather than years) enables systematic improvement and industry adaptation.

4.2.2. Cultural Considerations and Market Positioning

The cultural positioning of MMC significantly impacts acceptance and adoption rates. Successful implementation strategies acknowledge and adapt to cultural values rather than attempting to overcome them. Market-driven strategies focused on innovation and customization tend to be more successful in countries that embrace change, such as Sweden and the United States. Conversely, in contexts with stronger traditional values or higher uncertainty avoidance, regulatory frameworks and quality certifications provide necessary assurance. The Japanese approach of positioning prefabrication as a premium, high-quality option rather than merely a cost-saving measure demonstrates how effective market positioning can overcome potential cultural resistance.

4.2.3. Skills Development and Knowledge Transfer

Comprehensive skills development emerges as a critical factor across all successful MMC implementations. Singapore’s specific training programs, Japan’s industry-academia cooperation, and Germany’s incorporation of MMC methods into vocational education highlight the need for workforce development alongside technology growth. Our analysis indicates that skills gaps frequently bottleneck MMC scaling more than technological or regulatory barriers. Successful approaches treat workforce development as an integral component of the MMC ecosystem rather than an afterthought.

4.2.4. Integration of Digital Technologies

While not equally advanced across all countries studied, the integration of digital technologies, particularly Building Information Modeling (BIM) and parametric design tools, consistently appears as an enabler of successful MMC implementation. These technologies facilitate the precision required for off-site manufacturing while enabling the customization necessary for market acceptance. Countries with more advanced digital integration in their construction sectors (e.g., Sweden and Japan) demonstrate greater flexibility in balancing standardization with design variety.

4.2.5. Balanced Stakeholder Involvement

Our analysis reveals that the most sustainable MMC adoption occurs when both public and private sectors play complementary roles. Purely market-driven approaches (as sometimes seen in the US) struggle with fragmentation and scaling challenges, while exclusively top-down implementations (as in certain UK initiatives) may face industry resistance or implementation gaps. The balanced approaches seen in Germany and Sweden, with appropriate roles for government, industry, academia, and end-users, appear more resilient to market fluctuations and political changes.

4.2.6. Financial Viability and Policy Incentives

Financing structures and policy incentives played a critical role in shaping MMC adoption across the seven countries studied. In Singapore, strong state-led support—through the Construction Productivity Roadmap, subsidies for Integrated Construction and Prefabrication Hubs (ICPHs), and grants for workforce upskilling—reduced entry costs and accelerated adoption. Sweden provides grants and low-interest loans that offset the otherwise high capital expenditure required for automated timber factories, thereby sustaining competitiveness. In contrast, the UK introduced procurement frameworks and strategic partnerships, but these proved insufficient to prevent the collapse of major firms such as Ilke Homes and L&G Modular. Germany has leveraged renovation subsidies linked to energy efficiency goals, complemented by significant public R&D investment through initiatives such as the Fraunhofer Institutes. In the United States, the absence of federal incentives left adoption to fragmented state-led programs, producing inconsistent returns on investment. Japan demonstrates how long-term stability can be achieved when costs are amortized across decades of sustained demand, while in Australia moderate state and federal support has yet to fully overcome cost barriers. These findings show that sustainable MMC adoption is not only a matter of technology and culture but also of financing arrangements that align with long-term policy commitments.

4.3. Unique Contextual Insights

Our cross-country comparison revealed several distinctive contextual factors that influence MMC adoption patterns, highlighting how local conditions shape implementation strategies and outcomes. These insights underscore the importance of adapting MMC approaches to specific national environments rather than applying universal solutions.

4.3.1. Geographic and Demographic Pressures

The intensity and nature of housing pressures create different imperatives for MMC adoption across countries. Singapore’s limited land and high population density demand efficient construction. This urgency has prompted more proactive policy measures than those typically seen in countries with fewer space constraints. Conversely, countries with declining rural populations, like Japan, have leveraged MMC to maintain construction quality in regions with diminishing local construction workforces. These contrasting demographic pressures illustrate how MMC can address different challenges depending on local context.

4.3.2. Disaster Resilience Requirements

Countries prone to natural disasters exhibit distinctive MMC implementation patterns focused on resilience. Japan’s earthquake vulnerability has driven precision engineering in prefabricated systems that might appear over-engineered in less seismically active regions. This emphasis on structural performance has positioned Japanese MMC as a premium product rather than primarily a cost-saving approach. Similar patterns appear in hurricane-prone regions of the United States, where resilience requirements create specific localized barriers and opportunities for industrialized construction methods.

4.3.3. Existing Construction Ecosystem Maturity

The pre-existing construction industry structure significantly influences optimal MMC implementation strategies. Germany’s strong tradition of skilled trades and technical education provided a foundation for quality-focused industrialization that differs markedly from approaches in countries with more fragmented labor markets. Similarly, Sweden’s collaborative industry structure facilitated the incremental approach that might struggle in more adversarial construction environments. These variations suggest that MMC strategies must be calibrated to existing industry capabilities rather than attempting to replace them entirely.

4.3.4. Financing and Insurance Mechanisms

Our analysis revealed notable differences in how financial systems support or obstruct the adoption of MMC. Countries like Japan and Germany, with mortgage and insurance systems that assess prefabricated buildings, show a smoother market acceptance. In contrast, areas in the US where financial institutions lack standardized methods for valuing and ensuring industrialized construction face greater challenges. These financial ecosystem differences create substantial yet often overlooked barriers to MMC scaling that operate independently of technical or regulatory considerations.

4.3.5. Local Material Availability and Supply Chains

Resource availability creates distinctive regional variations in MMC approaches. Countries rich in timber resources, such as Sweden and certain regions of the United States, have established wood-based industrial systems. In contrast, concrete-based methods are prevalent in Singapore and Japan. These material differences reflect not only resource availability but also cultural building traditions and local expertise, creating path dependencies that influence optimal MMC strategies. Successfully imported MMC approaches typically adapt to local material ecosystems rather than replicating original material specifications.

These contextual insights illuminate why seemingly similar MMC approaches yield different outcomes across countries and why successful strategies in one context may struggle when directly transferred to another. They suggest that effective MMC implementation requires careful adaptation to local conditions rather than wholesale adoption of models from other countries, regardless of their success in their original context.

To complement the country narratives and thematic analysis presented above,

Table 4 provides a comparative summary of the seven national cases across the eight analytical dimensions. This table highlights both the shared enablers of successful MMC adoption and the unique pathways each country has followed. It also illustrates the areas where systemic misalignments persist, setting the stage for the discussion of transferable lessons and policy implications in

Section 5.

5. Discussion

Our analysis of MMC adoption across various countries highlights a range of factors that influence success or failure in different settings. In this section, we summarize our findings into key success factors, failure factors, and valuable lessons that can guide more effective MMC implementation strategies.

5.1. Success Factors

5.1.1. Long-Term Commitment to MMC Innovation

Countries demonstrating sustained MMC success share a characteristic of long-term, consistent commitment to industrialized construction development. Sweden and Japan stand out as exemplars of this approach, having pursued incremental improvements over decades rather than seeking rapid transformation. This extended timeframe has allowed for the evolution of both technical systems and supporting ecosystems, including supply chains, regulatory frameworks, and workforce development. For instance, Japan’s post-war investment in production technology highlights how persistent innovation and mass customization principles create cumulative advantages that short-term initiatives cannot match. Similarly, Sweden’s slow but steady integration of lean principles into industrial housing, illustrates the benefits of gradual yet continuous enhancement. This finding suggests that MMC adoption benefits from strategic patience and sustained investment rather than expecting transformative results from isolated policy interventions.

5.1.2. Integration of Cultural and Contextual Considerations

Successful MMC implementation strategies demonstrate careful alignment with existing cultural values and contextual realities rather than attempting to overcome them. Japan’s approach of positioning industrialized housing as technologically advanced and customizable aligns with cultural values of precision and quality. Similarly, Germany’s integration of MMC into its tradition of engineering excellence leverages existing cultural strengths. This integration extends beyond cultural values to physical contexts, adapting MMC to local material availability, climate requirements, and existing building traditions. The most effective strategies treat MMC as a flexible methodology rather than a one-size-fits-all solution. This approach allows for adaptation to improve local construction practices.

5.1.3. Comprehensive Training Programs and Capacity Building

Our analysis reveals that countries achieving the most sustainable MMC adoption have invested significantly in developing human capital alongside technological systems. Singapore’s extensive training infrastructure, Japan’s industry-academia partnerships, and Germany’s integration of MMC techniques into vocational education demonstrate how workforce development enables implementation success. Singapore’s Buildability Scoring System, for instance, exemplifies how training, regulation, and incentives can be integrated into a coherent national strategy. These training ecosystems address not only technical skills but also the collaborative competencies required for the integrated supply chains that characterize industrialized construction. As MMC fundamentally changes workflows and responsibilities within the construction process, comprehensive capacity building emerges as essential for overcoming resistance and enabling effective implementation.

These typological clusters reflect the underlying logic identified across regulatory, market, and cultural dimensions (see

Supplementary Materials Tables S2–S7 for detailed comparative scoring).

5.2. Failure Factors

5.2.1. Over-Reliance on Top-Down Approaches

While government leadership can accelerate MMC adoption, our analysis indicates that purely top-down implementation approaches often struggle to achieve sustainable market transformation. The UK’s experience demonstrates how policy-driven initiatives, despite substantial investment and political support, can face implementation challenges when industry stakeholders are not adequately engaged as partners. Similarly, certain US ventures with significant venture capital backing but insufficient industry integration have struggled to overcome systemic barriers. Successful approaches balance policy leadership with industry ownership, creating space for market adaptation while maintaining strategic direction.

5.2.2. Lack of Flexibility in Production Models

MMC initiatives focused narrowly on specific production methods rather than broader construction system transformation show higher failure rates across countries studied. Rigid production models that cannot adapt to varying project requirements, regional differences, or market fluctuations prove vulnerable to changing conditions. This limitation appears particularly pronounced in approaches that attempt to directly transfer manufacturing models from other industries without sufficient adaptation to construction’s unique characteristics. The most resilient MMC systems demonstrate modularity not just in their products but in their production processes, allowing adaptation to different scales, typologies, and market segments.

5.2.3. Overemphasis on Product at the Expense of Process

Our analysis shows that MMC initiatives focusing predominantly on product innovation while neglecting process transformation often struggle to achieve sustainable impact. The UK case is particularly instructive—recent parliamentary reports indicate that excessive attention to novel product solutions and building types has sometimes diverted focus from the fundamental process changes required for successful industrialization. This product-centric approach has resulted in sophisticated technical solutions that struggle to integrate into existing construction workflows and supply chains.

The most successful MMC implementations demonstrate balanced attention to both product and process innovation, recognizing that industrialized construction requires not just new components but transformed workflows, integrated digital systems, and reconfigured supply chains. Countries like Sweden exemplify sustainable MMC adoption by treating it as a holistic system transformation rather than a simple replacement of materials or components.

5.2.4. Regulatory and Standardization Challenges

Fragmented or inappropriate regulatory frameworks emerge as persistent barriers to MMC scaling. The US case illustrates how jurisdictional variations in building codes and approval processes create significant inefficiencies for industrialized approaches designed for scale and standardization. Even in countries with more centralized governance, regulatory systems originally designed for traditional construction can create unnecessary obstacles for MMC adoption.

These challenges extend beyond technical standards to include procurement frameworks, insurance requirements, and financing models that inadvertently disadvantage MMC relative to conventional construction. For instance, regulatory ambiguity or lack of standardized accreditation for prefabricated systems in some countries delays project approval, undermining the efficiency gains MMC promises. The contrast between the fragmented US environment and more integrated models in countries like Singapore highlights how alignment in policy and regulatory settings influences implementation outcomes.

5.3. Transferable Lessons

5.3.1. Scalable Policies and Frameworks

While complete policy transfer between different national contexts is rarely effective, our analysis identified scalable policy approaches that can be adapted across different environments. Performance-based rather than prescriptive regulations appear more transferable across contexts, as they establish desired outcomes without dictating specific technical solutions. Similarly, demonstration projects that create learning laboratories for MMC implementation offer adaptable models for different contexts. These approaches provide policy scaffolding that can be calibrated to different cultural and economic environments while maintaining consistent principles.

5.3.2. Role of Public–Private Partnerships

The most transferable implementation models leverage strategic partnerships between public and private sectors, assigning roles that align with their respective strengths. Government leadership plays a crucial role in setting standards, funding research, and ensuring market stability through procurement policies. This support enhances private sector innovation, facilitates commercial growth, and drives technical development. Such partnerships distribute risk appropriately and create sustainable implementation ecosystems. This collaborative approach appears adaptable across different political and economic systems, though the specific balance of responsibilities may vary according to local governance traditions.

5.3.3. Addressing Local Resistance and Skills Gaps

Successful approaches across diverse contexts share strategies for overcoming resistance and developing necessary capabilities. Effective stakeholder engagement that addresses legitimate concerns about job transformation rather than dismissing them has proven critical in multiple countries. Proactive skills development strategies that provide clear pathways for current construction workers to transition into new roles can effectively address workforce challenges. These human-centered approaches to change management represent highly transferable elements that can be adapted to different cultural contexts while maintaining their core principles.

Our findings indicate that while specific MMC technologies and policies may not be directly transferable between countries, the principles underlying successful implementation, long-term commitment, cultural integration, balanced governance, flexible production approaches, and comprehensive capacity building can be adapted to diverse contexts. Effective MMC adoption requires calibration to local conditions rather than imposition of standardized approaches, regardless of their success elsewhere.

5.4. Reflexive Consideration of Alternative Explanations

To test the robustness of our findings, we considered several alternative explanations commonly proposed in the literature. While each offers partial insights into MMC adoption patterns, our cross-country analysis suggests that these factors alone are insufficient to explain observed outcomes. The following reflections clarify the role of these variables and how they interact with the institutional, cultural, and strategic dimensions discussed earlier.

5.4.1. Economic Cycles and Market Conditions

MMC adoption is often linked to macroeconomic trends—construction booms potentially reducing the need for innovation, or downturns limiting investment. Yet our analysis includes high-growth economies (e.g., Singapore) and stable markets (e.g., Sweden) where MMC has flourished. Moreover, the failure of capitalized ventures like Katerra during favorable conditions supports the argument that systemic alignment matters more than economic cycles alone.

5.4.2. Labor Market Structure

Labor shortages and high wage environments are thought to incentivize offsite methods. While this holds for Singapore, Japan’s MMC adoption persists despite a stable skilled workforce, and the US—despite shortages—has not seen widespread uptake. Labor dynamics appear to shape urgency but do not guarantee successful adoption in the absence of enabling institutional settings.

5.4.3. Geographic and Demographic Constraints

Spatial conditions such as land scarcity or density are often cited as drivers of MMC. Singapore fits this model, but countries with diverse geographies (e.g., Sweden and Australia) have also progressed, while dense US regions lag. This indicates that geography frames possibilities but does not dictate outcomes.

5.4.4. Technological Path Dependency

Historical industrial patterns and early investments may create MMC trajectories, as seen in Japan or Sweden. However, countries like Singapore have successfully redirected their construction industries through deliberate policy. While path dependency matters, it can be actively reoriented.

5.4.5. Regulatory Harmonization

Regulatory fragmentation is frequently identified as a barrier. Yet the UK’s relatively unified system has not ensured implementation success, while Germany has succeeded under a federal system. Harmonization is beneficial, but not decisive without accompanying capability and cultural alignment.

5.4.6. Global Supply Chain Integration

Some argue that MMC adoption hinges on access to globalized supply chains. While this can enhance scalability, early adopters like Sweden and Japan developed strong domestic supply bases first. Overreliance on imported technologies, without contextual adaptation, often undermines implementation.

These considerations underscore the multidimensional nature of MMC adoption. While economic, geographic, and historical factors shape the context, successful implementation consistently hinges on policy coherence, institutional readiness, and cultural compatibility.

A longitudinal perspective underscores that sustainable MMC adoption is rarely achieved through short-term interventions. Japan’s post-war trajectory, Sweden’s incremental lean integration, and Singapore’s phased government mandates illustrate how decades of iterative adjustment underpin systemic transformation. By contrast, short-lived initiatives without continuity often fail to yield enduring change. Future research should systematically track MMC trajectories over time to better assess long-term sustainability.

For EU member states such as Germany and Sweden, national MMC strategies are shaped not only by domestic policies but also by EU-level frameworks. Initiatives such as the European Green Deal and the Renovation Wave have created incentives for energy-efficient construction and retrofitting, indirectly supporting the uptake of industrialized and prefabricated methods. While our analysis primarily focused on national policies, these supranational drivers provide an important backdrop that influences regulatory direction and funding mechanisms.

6. Implications

Our comparative analysis yields important implications for advancing effective MMC implementation across policy, industry, and research domains.

6.1. Policy Design: Aligning MMC with Broader System Goals

Effective MMC policies require integration with broader national agendas rather than standalone interventions. Singapore’s success demonstrates how embedding MMC within housing, industrial, and environmental priorities ensures policy continuity and coordination beyond political cycles.

Performance-based regulations appear more transferable across contexts than prescriptive approaches. By emphasizing outcomes like energy efficiency or quality rather than dictating specific technical solutions, such frameworks allow MMC to compete fairly with traditional methods while accommodating local innovation.

Policy design must balance certainty with adaptability. While clear, stable signals are essential for attracting long-term investment, overly rigid prescriptions can inhibit innovation. Sweden’s incremental, consultative approach demonstrates how phased implementation can foster both market confidence and strategic flexibility.

Skills development must be embedded within MMC policy frameworks rather than treated as an afterthought. Our analysis consistently shows workforce capacity presenting greater barriers than technical or regulatory hurdles. Evaluation frameworks should extend beyond short-term outputs like unit completions to capture lifecycle performance, quality improvements, and sector-wide capacity building.

6.2. Industry Strategy: Whole-of-System Coordination

Successful MMC implementation depends on whole-of-system coordination rather than isolated technological advances. Companies must achieve alignment across design, manufacturing, logistics, assembly, and post-completion services. The failure of high-profile US ventures underscores the risks of overinvesting in manufacturing while neglecting integration with broader delivery ecosystems.

MMC strategies require careful calibration to local contexts—material availability, workforce characteristics, regulatory constraints, and consumer expectations. Standardized approaches rarely succeed when applied wholesale across different geographies with distinct opportunities and constraints.

Digital infrastructure connecting design, production, and on-site assembly has emerged as foundational to MMC success. Companies that develop robust digital capabilities demonstrate greater adaptability and resilience, suggesting digital maturity should be prioritized as a core capability rather than secondary consideration.

Collaborative business models are increasingly necessary to distribute risks appropriately across stakeholders. Traditional contracting structures often misalign with MMC’s interdependent processes, requiring new approaches that better align incentives and responsibilities across project ecosystems.