1. Introduction

According to Brozovisky, Labonnote, and Vigren [

1], additive manufacturing (AM) has gained significant attention within architecture, engineering, and construction (AEC), experiencing exponential growth since the second half of the 2010s. This growing interest is driven mainly by the numerous advantages AM brings—the possibility of creating complex and customizable geometries, utilizing materials more efficiently, and enhancing both safety and productivity.

However, one of the main challenges for applying AM in AEC is the size of buildings and construction components. Addressing this requires large-scale AM equipment, such as gantry-mounted systems, to cover larger construction areas. Nevertheless, the scalability of these systems presents significant challenges, including transportation, access, and assembly. These systems require the machinery to cover an area larger than the building’s footprint, which is not always feasible. Furthermore, these machines operate on only three axes, which limit material deposition capacity, and the shape of the objects produced [

2].

Conversely, robotic arms offer a promising alternative for AM in the AEC industry, generally referred to as robotic additive manufacturing (RAM). The growing interest in this technology is due to its flexibility, enhanced motion control from multiple rotational axes, compact size, and ease of transportation and installation [

2]. These qualities introduce new manufacturing parameters that enhance the ability to produce complex and optimized geometries, as well as the ability to build in hard-to-reach locations.

However, the increased range of motion and potential for generating complex forms with robotic arms also introduce greater complexity into the design process. It becomes necessary to account for and precisely control new variables, which in turn must be optimized throughout the process. This significant potential, combined with the challenges of this technology, has led to a notable increase in research interest in RAM for construction in recent years, resulting in a substantial body of information on the topic from various perspectives, technologies, and issues.

Although the configuration of RAM systems depends on a variety of factors—such as the material, project goals, and available resources— most of the current research in AEC centers on extrusion-based systems using multi-axis robotic arms, particularly for production with concrete and thermoplastics [

3]. In addition to these materials, according to Puzatova et al. [

4], clay has emerged as a promising and increasingly utilized material for RAM applications. Given this scenario, this review focuses specifically on extrusion-based RAM systems that employ multiaxial robotic arms for fabricating elements using thermoplastic and paste-like materials, including cementitious and earth-based compositions, and both natural and synthetic mineral foams.

With this delimitation, this literature review aims to explore the evolution of extrusion-based RAM systems, their primary geographic distributions, and research collaboration networks through co-authorship analysis. The main goal is to identify and categorize key research areas—identified here as process, design, material, and equipment (including relevant hardware and software configurations). In conclusion, this study examines the advantages and limitations of current RAM applications, identifies research gaps, and highlights emerging opportunities for future exploration.

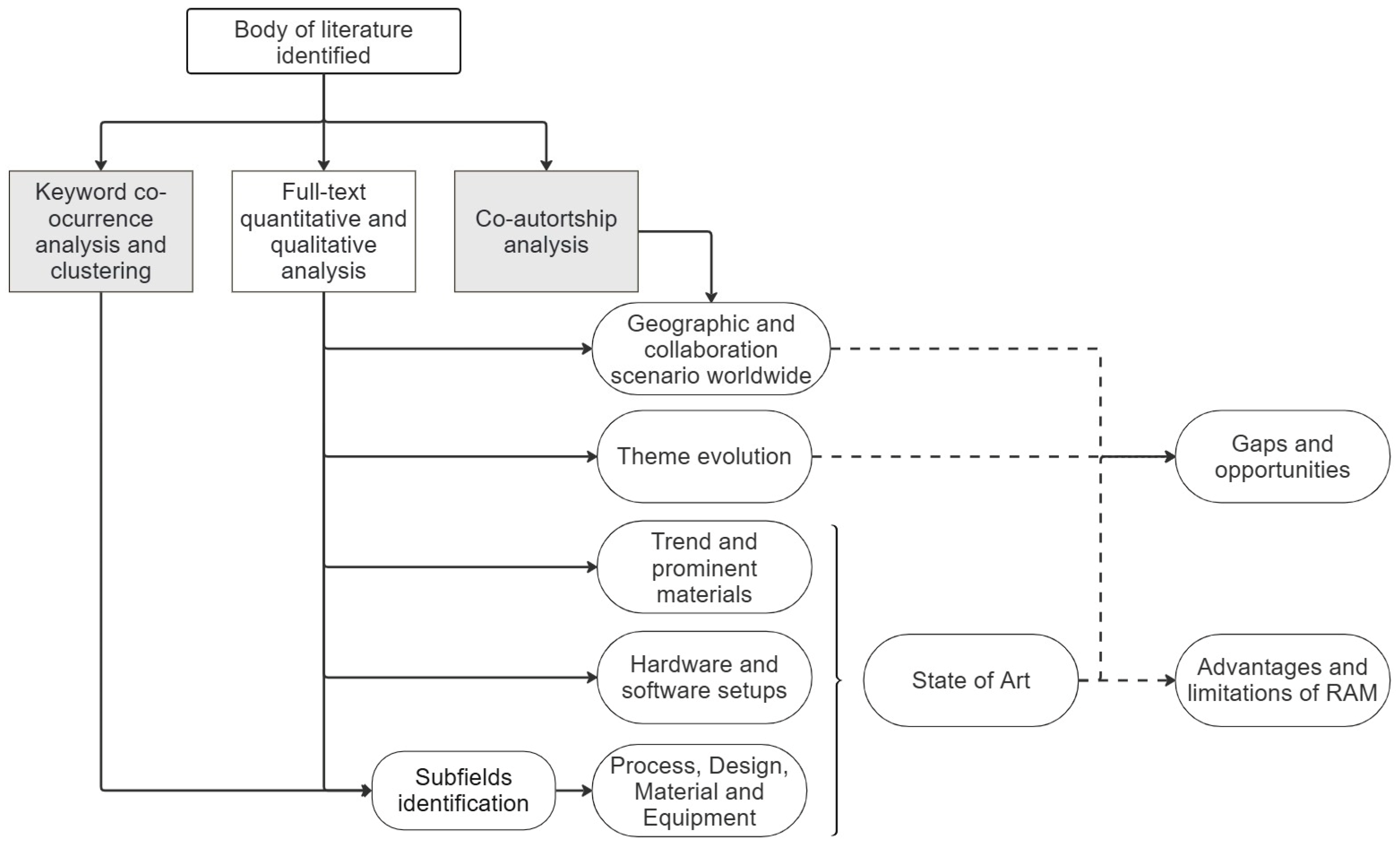

Figure 1 synthesizes the systematic review workflow.

2. Theoretical Framework

Industry 4.0 (I4.0) consists of concepts of decentralization and self-regulating production through the integration of technologies that guarantee that information is present in all phases of the production process [

1,

5,

6]. Parvanda and Kala [

5] describe nine technologies that define I4.0, highlighting AM and automated robotics among them. Applied to the AEC industry, these concepts give rise to Construction 4.0 (C4.0), a transformation framework based on three pillars: (1) industrialization of production through prefabrication, AM, modularization, and robotics; (2) cyber–physical systems through IoT, sensors, actuators, and robots; and (3) digital technologies such as Building Information Modeling (BIM), artificial intelligence (AI), cloud computing, Big Data, Blockchain, virtual reality, and simulation [

1]. The adoption of C4.0 in construction has the potential to increase productivity and efficiency and reduce environmental impacts [

1]. However, its adoption depends on a workforce with high technical expertise, which is a challenge for an industry that is often slow to adopt innovations [

1,

5,

7].

A review by Brozovisky, Labonnote, and Vigren [

1] analyzing 3950 papers on digital technologies in AEC found that AM and robotics rank fourth and fifth in publication volume, respectively. While robotics research peaked in the 1980s and then declined, AM has grown steadily since the mid-2010s, with significant acceleration after 2020. This growth is partly related to renewed interest in robotic arms for large-scale AM in construction, as their flexibility and cooperative capabilities can help meet the speed and scale requirements typical of the AEC industry. Given this growing relevance, it is essential to define what AM and robotics encompass and how it is applied in the construction context.

ISO/ASTM 52900 [

8] defines AM as a process that builds components by joining materials, usually layer by layer, based on three-dimensional model data. Techniques vary according to the state of the material—liquids, suspensions, powders, sheets, pastes, or filaments—and the way the object is formed, such as sintering, fusion, polymerization, lamination, extrusion, or injection [

9]. In the AEC industry, extrusion-based AM is the most studied technique [

3,

10]. Paste deposition modeling uses pastes that solidify through the evaporation of water or solvents [

9]. Materials investigated in AM for AEC include cementitious composites, polymers, metals, ceramics, biological composites, and wood [

11]. For large-scale applications, two main system types are used: gantry-controlled systems and robotic arm-based systems [

2,

4].

One of the main challenges of AM is the close relationship between materials, production, and design. It is necessary to calibrate several variables, including those defined during the design stage, as they can directly affect the fabrication process and the quality of the component [

12]. For example, when extruding cement or clay, the material must be fluid enough to pass through the extruder and rigid enough to support its weight and the weight of the layers above while maintaining adhesion [

13]. This requires careful control of rheological properties, process parameters such as the toolpath, movement speed, and extrusion rate, as well as AM system settings such as the nozzle shape and deposition surface.

Robotic arms bring new possibilities to AM in construction by automating fabrication through programmed movements, which increases precision and scalability [

3]. In contrast to the individually operated machinery of the third industrial revolution, robotics enables production processes to function as an integrated system [

6]. Multi-axis robotic arms—usually with six axes—enable complex motion. In parallel, mobile platforms enable work at various heights and positions, and coordinated systems of multiple robots can construct large structures together [

4]. Their advantages include producing complex geometries, operating in restricted or hazardous environments, and adapting to different site conditions [

3,

7]. Also, in architecture and construction, robotics offers an exploratory opportunity to rethink fabrication chains through empirical and interdisciplinary approaches [

6].

Limitations include lower load capacity compared to gantry systems, reduced rigidity, and difficulties in handling coarse aggregates in concrete. In addition, construction sites present changing conditions, environmental factors, and the large size and weight of building components, all of which can make implementation more difficult.

The combination of Construction 4.0 concepts, the flexibility of AM, and the capabilities of robotic arms define an essential field of research in AEC. This integration expands design possibilities but also introduces challenges such as adapting AM to large-scale elements and managing complex manufacturing variables—factors that have motivated much of the current research and are at the core of this review. However, despite its growing relevance, the literature still contains relatively few review studies focusing specifically on extrusion-based RAM in the AEC context, as discussed in the following section.

Previous Literature Reviews

Previous literature reviews have compared robotic manipulators to other systems [

3,

4,

14]. Puzatova et al. [

4] have evaluated and compared the main AM technologies for large-scale construction, emphasizing the differences between robotic arms and gantry-based 3D printers. Huang, Xu, and Li [

14] investigated the impact of different AM systems on the forms of concrete construction components, also focusing on comparing in situ and prefabrication with printers on gantries and robotic arms.

Collectively, these three studies agree that the primary advantage of robotic arms is their flexibility of movement, which supports the production of complex geometries and innovative manufacturing approaches [

3,

4,

14], as well as anti-collision capabilities in the work area and scalability [

3]. In addition, the initial reviews highlight concrete as the most widely studied material for robotic arm-based AM in construction [

3,

4], followed by PLA and ABS, and most research has focused on extrusion-based methods [

3]. There is also an increasing interest in earth-based alternatives for RAM [

4].

However, there is some disagreement about the scalability of robotic arm-based AM processes. Gantry systems are robust and have a greater production capacity for large-scale structures. Concurrently, robotic arms use their workspace more efficiently, are more mobile, and support coordinated operations [

4]. Another disadvantage is a low load capacity, as well as reduced accuracy, strength, and rigidity, along with the lack of robotic arms specifically designed for construction, particularly those with features that facilitate on-site production [

3].

Although their contributions, these reviews do not provide detailed explanations of the criteria for including studies, which makes their scope harder to replicate. Additionally, RAM in AEC is considered a subset within broader discussions on additive manufacturing, comparing it to other systems, rather than examining in depth the challenges and opportunities posed by multi-axis robotic systems.

In contrast, this review concentrates exclusively on extrusion-based AM with paste-like and thermoplastic materials using robotic arms. By classifying subfields, synthesizing representative studies, and identifying emerging themes, this article not only consolidates fragmented knowledge but also establishes a clearer picture of the state of the art in paste-like and thermoplastic materials in RAM.

3. Materials and Methods

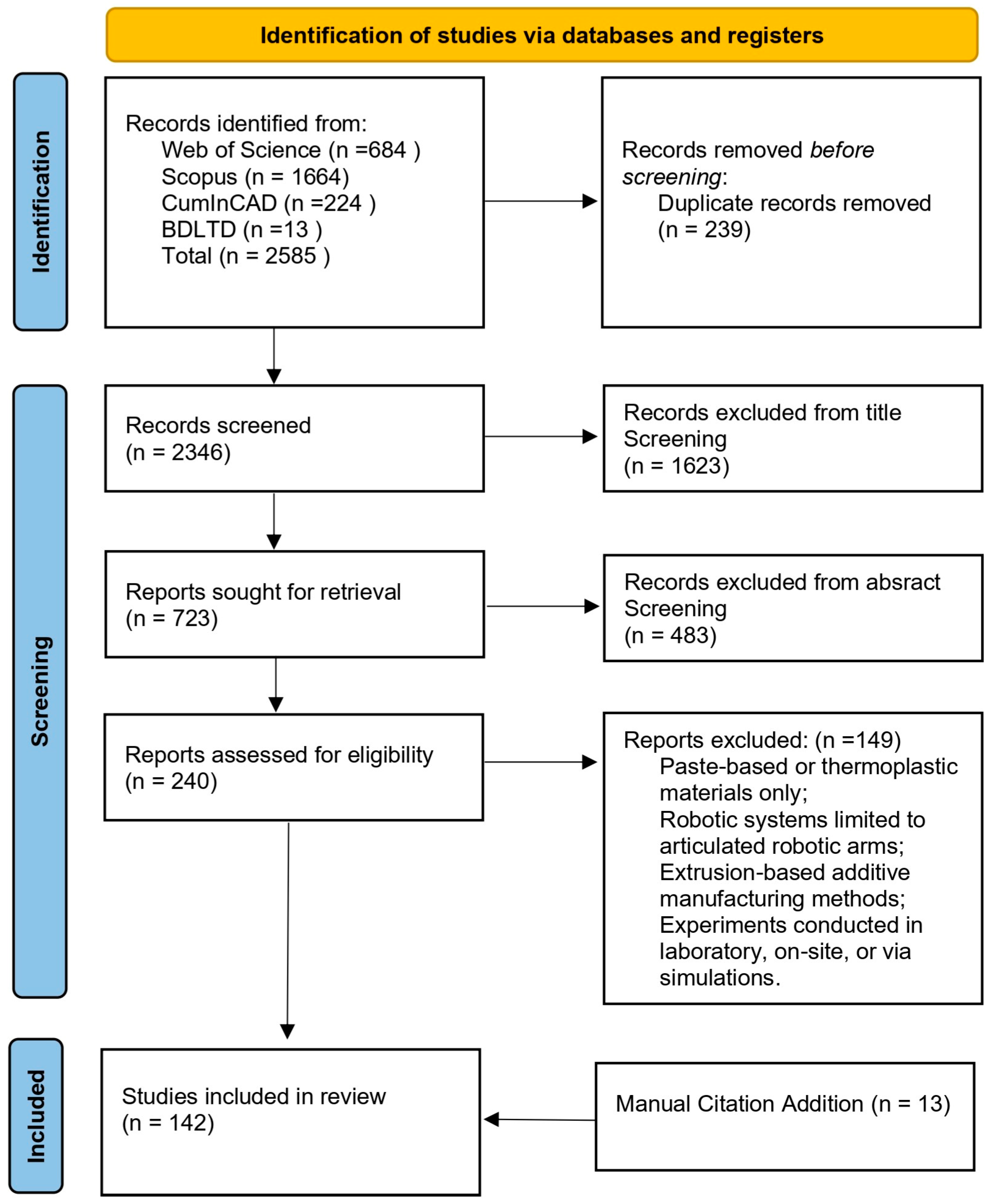

This review follows the steps outlined by Kitchenham [

15]: (1) identification, (2) selection of primary studies, (3) quality assessment, (4) data extraction, and (5) data synthesis. In the filtering and selection process, the PRISMA protocol was also used as a supporting tool to enhance the transparency and organization of this review. This review considers studies within a specific scope based on the following criteria: experiments using paste-based and thermoplastic materials; robotic systems limited to articulated robotic arms; extrusion-based AM methods; and experiments carried out in laboratory settings, on-site, or through simulations.

It considers journal and conference articles published in English, Spanish, or Portuguese, covering the period from 2014 to 2025. This study considers these languages because one of the databases, Cumulative Index in Computer-Aided Architectural Design (CumInCAD), brings together publications from several sibling associations in computational design. Among them, SIGraDi has a long tradition of publishing not only in English but also in Portuguese and Spanish. Including all three languages allows this review to capture relevant works that might otherwise be overlooked. The databases accessed included Web of Science, Scopus, CumInCAD, and the Brazilian Digital Library of Theses and Dissertations.

After testing the inclusion of several more specific terms, which yielded very few results, this study considers broader search terms, adapting query strings as needed for each database. The search targeted article titles, abstracts, and keywords. Additionally, this review considers other publications manually selected, not retrieved by the database searches, but cited in other relevant works. Only those that are closely aligned with this study’s topic and meet the established selection criteria were added (

Table 1).

Inclusion and exclusion criteria: (a) removal of duplicate articles; (b) evaluation of titles for thematic alignment; (c) review of abstracts for thematic consistency; (d) assessment of complete texts for subject relevance. These stages followed the PRISMA protocol (Preferred Reporting Items for Systematic Reviews and Meta-Analyses), particularly in the application of well-defined inclusion/exclusion criteria and in the transparent reporting of each filtering stage;

Final screening and classification: At this stage, this review examined each article’s goals, methodologies, and findings to evaluate the extent to which they directly addressed the research questions. Studies offering well-documented empirical evidence, mainly when based on experimental or other comprehensive approaches, are particularly important, as these tend to produce more dependable results. The evaluation considered the complete set of questions guiding this review—from trends in publication and geographic scope to process control, hardware and software configurations, materials, comparative advantages of robotic arms, and gaps or opportunities for future work. Studies that met these standards were included in the final synthesis. The study’s quality assessment process was also guided by PRISMA principles, ensuring that the final set of included studies met consistent and transparent quality standards.

Data extraction: Compilation of both quantitative and qualitative data in spreadsheets with support from Mendeley Desktop software.

Synthesis of results: (a) Quantitative synthesis—bibliometric analysis of co-authorship networks, co-occurrence, and keyword clustering performed using VOSviewer; (b) Descriptive synthesis—qualitative evaluation of extracted data, considering limitations in experimental consistency, generalizability, and scalability of reported results.

To conduct the assessment of the papers included in this review, this study followed these research questions:

How has the number of publications evolved in the past decade?

In which geographical context has the topic been studied?

What are the subfields and research trends in RAM within the AEC industry?

How has research been addressing issues of design and process control in RAM?

What are the hardware and software configurations used in RAM for construction?

What are the most used materials?

What are the advantages and limitations of using robotic arms for AM in construction compared to other equipment?

What are the main research gaps and opportunities in this field?

By applying the search strategy and selection criteria described above, this study identified a total of 142 experimental articles on RAM published in peer-reviewed journals and conference proceedings.

Figure 2 synthesizes the screening process.

3.1. Bibliometric Analysis

For the bibliometric analysis, this review used VOSviewer 1.6.20 software, which generates bibliometric data networks based on an imported bibliographic database. In the graphical maps output by VOSviewer, nodes represent categories of information such as documents, sources, authors, organizations, countries, and keywords. Node size is proportional to the number of occurrences, while links represent relationships between nodes. The thickness of each link corresponds to the strength and proximity between connected nodes. Nodes with greater proximity and stronger links are clustered via machine learning algorithms to define categories within the analyzed topic [

16].

3.1.1. Co-Authorship Networks

Co-authorship network analysis identifies collaborative relationships among authors working on the same topic. By mapping these connections, it is possible to determine which researchers operate independently and which are part of collaborative efforts. Such mapping reveals opportunities for future partnerships that could accelerate scientific progress in this field. The analysis included only authors who had co-published at least two articles. This approach yields a range of insights, including the relationship between co-authorship, citation counts, and publication volume. It enables the identification of whether advances in the field are concentrated within a few collaborative groups, distributed among several groups, or isolated among individual researchers [

17]. The network also enables tracking of collaborations across countries and institutions. Accordingly, we compiled the countries and institutional affiliations for all authors of each article within the identified collaboration groups.

3.1.2. Co-Occurrence Networks and Keyword Clustering

Co-occurrence networks and keyword clustering reveal how research topics are connected, helping to identify key areas of focus, emerging trends, and gaps in the field. This type of literature analysis relies exclusively on reported bibliometric data, reducing the risk of bias from the reviewers [

17].

This work filtered the keywords that appeared at least three times. VOSviewer can identify synonyms and related terms (such as “technologies” and “technological”). To ensure accurate results, a two-step process helped to refine the data after an initial analysis: (a) removing technical terms that carry the same meaning—for instance, “path” and “toolpath”; and (b) eliminating generic terms that are irrelevant for segmentation, such as “construction,” among others.

Next, this work considers the clustering of keywords based on the co-occurrence matrix. A bibliometric network grouped nodes based on their link strength and proximity. The stronger the association between two nodes—as measured by the “Total Link Strength” parameter—the closer the relationship between the topics within a given cluster. This clustering analysis and the interpretation of keywords were essential for defining the research subfields.

3.2. Mapping the State of the Art

This review presents the state of the art as a structured overview of the most advanced knowledge, methods, and practices in RAM for AEC to date, with a focus on paste-like and thermoplastic materials. This approach involves not only synthesizing the most relevant studies and technical advances but also mapping how research efforts are organized into subfields of study, highlighting trends, and identifying areas where knowledge remains limited.

Therefore, based on the analysis of 142 studies and supported by the keyword co-occurrence analysis, this review identified four main subfields of RAM: Process, Design, Materials, and Equipment. Although many studies overlap across these domains, classification was guided by each study’s primary research objective. For example, investigations focused on the geometric exploration of clay were placed under Design, while studies testing clay mixtures to improve material performance were placed under Materials.

Given both the number of studies and their alignment with the broader research agenda of this review, Process and Design emerge as the most prominent subfields. Thus, these two were further segmented into emerging themes, and representative studies were selected to illustrate the state of the art, considering their relevance, citation frequency, ability to exemplify specific advances, or recency within the field. By contrast, the subfields of Materials and Equipment are addressed more briefly, with emphasis on their definition.

Although specific studies on Materials and Equipment were not further segmented and analyzed,

Section 5.4.1 and

Section 5.4.2 synthesize contributions across the entire body of the literature, highlighting the materials and technologies most frequently adopted in RAM research. Collectively, these insights provide the foundation for identifying the research gaps and opportunities discussed in the following sections.

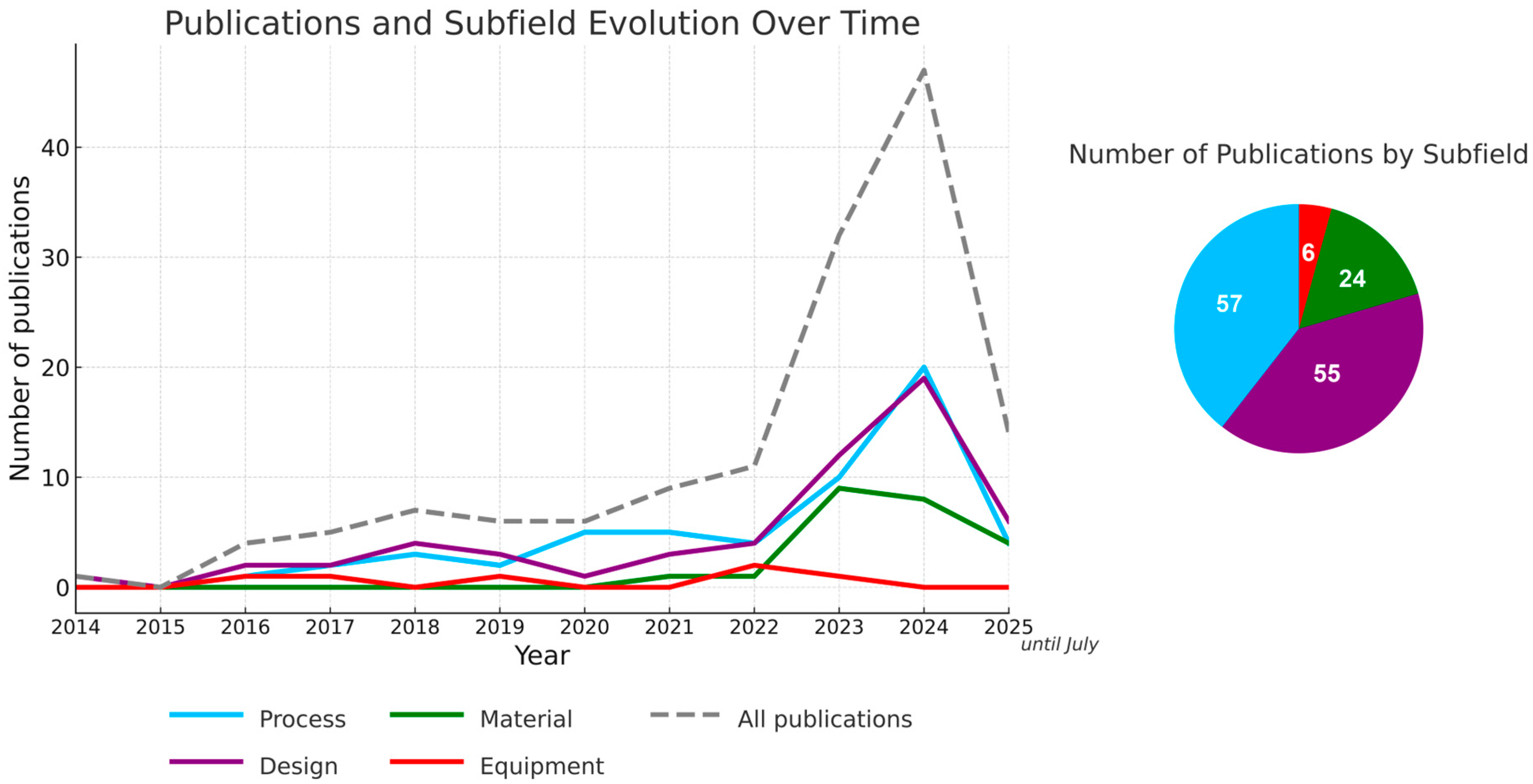

4. Results

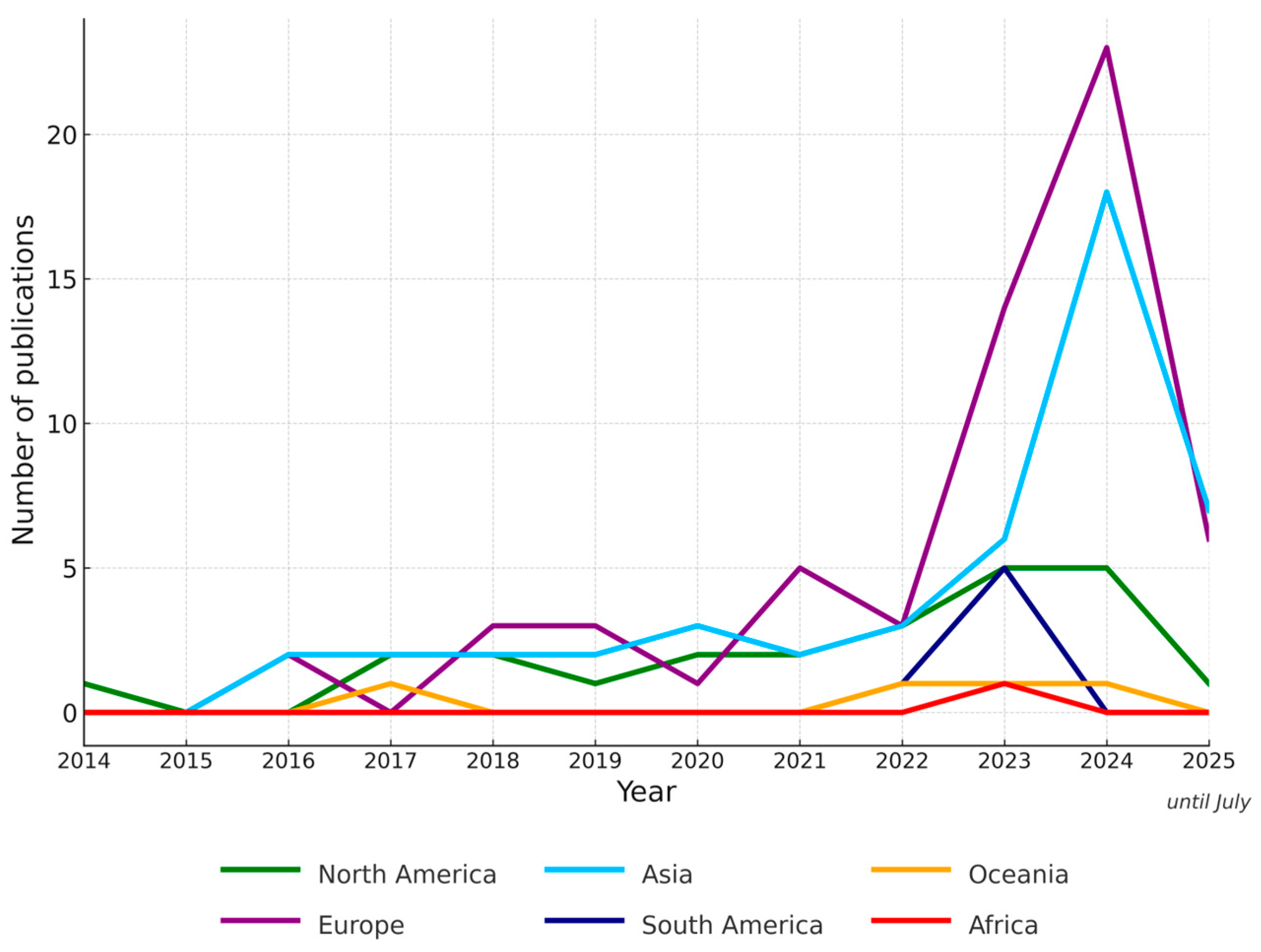

This review considers 142 scientific articles, of which 88 were published in conference proceedings and 54 in journals. As shown in

Figure 3, publications on the topic began to grow exponentially from 2022 onward. This rise aligns with the increasing interest in additive manufacturing (AM) in the context of Industry 4.0 [

5] and, more specifically, Construction 4.0 [

1], which has experienced exponential growth since 2020. Additionally, the aftermath of the COVID-19 pandemic may have contributed to the number of publications between 2022 and 2024. During this period, many projects faced interruptions in their experimental phases, which may have delayed the completion of studies requiring laboratory validation.

With the return to in-person work, some of these studies may have been completed and published within a short period, contributing to the peak observed in 2024. There is a lower number of publications recorded in 2025—14 so far, as the year is still in progress. In this context, tracking the numbers in the following years will be essential to understand what drives this scenario.

In this context, the upward trend in RAM research demonstrates an increasing interest in robotic fabrication methods. Although it develops at a slower pace compared to other industries, this scenario is consistent with the AEC’s history of gradually adopting new technologies and processes.

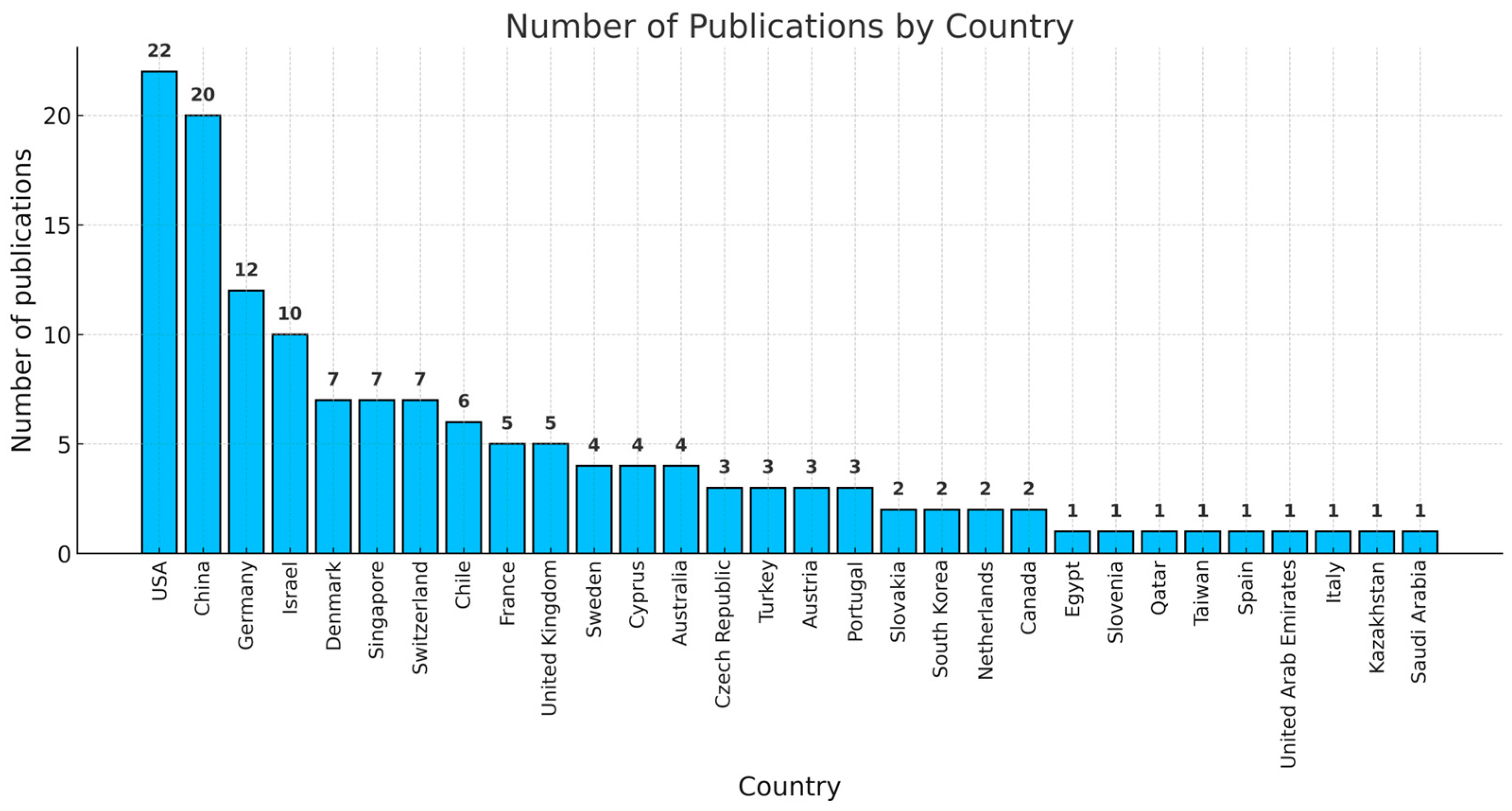

Geographically, most publications are specific to North America, with the United States leading with 23 publications (

Figure 4). In Asia, China stands out with 20 publications, followed by Israel (10) and Singapore (7), highlighting the region’s growing relevance in RAM research. Europe, as a continent, has the most significant number of works, although more fragmented, with highlights from Germany (12), Denmark (7), France (5), the United Kingdom (5), Switzerland (4), Sweden (4), Cyprus (4), Austria (3), and the Czech Republic (3). In South America, as

Figure 5 shows, works on the topic began to be published in 2022, with Chile being the only country on the continent to have recorded experimental contributions on RAM (six publications). In Oceania and Africa, there is a limited presence, with four publications originating from Australia and one from Egypt.

These results are consistent with those found by Xu et al. [

3], which indicate that agreements on a broader scope of research focus on RAM in the US and some Asian and European countries (

Figure 4). However, the results also suggest a growing interest in the topic in South America, with a concentration still in Chile. Despite this, other initiatives in the Global South, notably laboratories with robotic arms and an interest in developing RAM experiments, are signaling a movement toward advancing the topic in the region. There is also a sporadic presence of research in Oceania, such as Australia, and Africa, such as Egypt, although with limited participation. This scenario, which shows signs of progress in expanding the topic beyond the US, China, and Europe, is still very embryonic. It highlights that there is ample space for exploration, with great potential for the development of the topic at a global level in the years to come.

4.1. Bibliometric Analysis

4.1.1. Co-Authorship Networks

The co-authorship analysis considered authors who published at least two papers on RAM, comprising a total of 67 researchers.

Table 2 characterizes these groups.

Overall, the cooperation landscape reveals a still-fragmented scenario. While some research groups have established international partnerships, most networks consist of nationally based clusters. This low level of integration among groups may be due to the developmental stage of the topic, which remains relatively new and heavily experimental. Moreover, the high costs of infrastructure and the need for specialized equipment for large-scale additive manufacturing tend to concentrate research in a few centers capable of housing such facilities, making broader partnerships difficult.

Henriques et al. [

6] advocated for collaborative research networks in robotics within the context of AEC in South America—an argument that also extends to the need for a global network. The authors argue that exchange between researchers with diverse expertise can accelerate critical training and develop solutions adapted to local contexts. Furthermore, networked collaboration fosters research complementarity and helps avoid redundant efforts on parallel projects addressing the same problem. However, overcoming this fragmentation will require stronger coordination among universities, technology centers, and companies, along with support for internationally scaled cooperative projects.

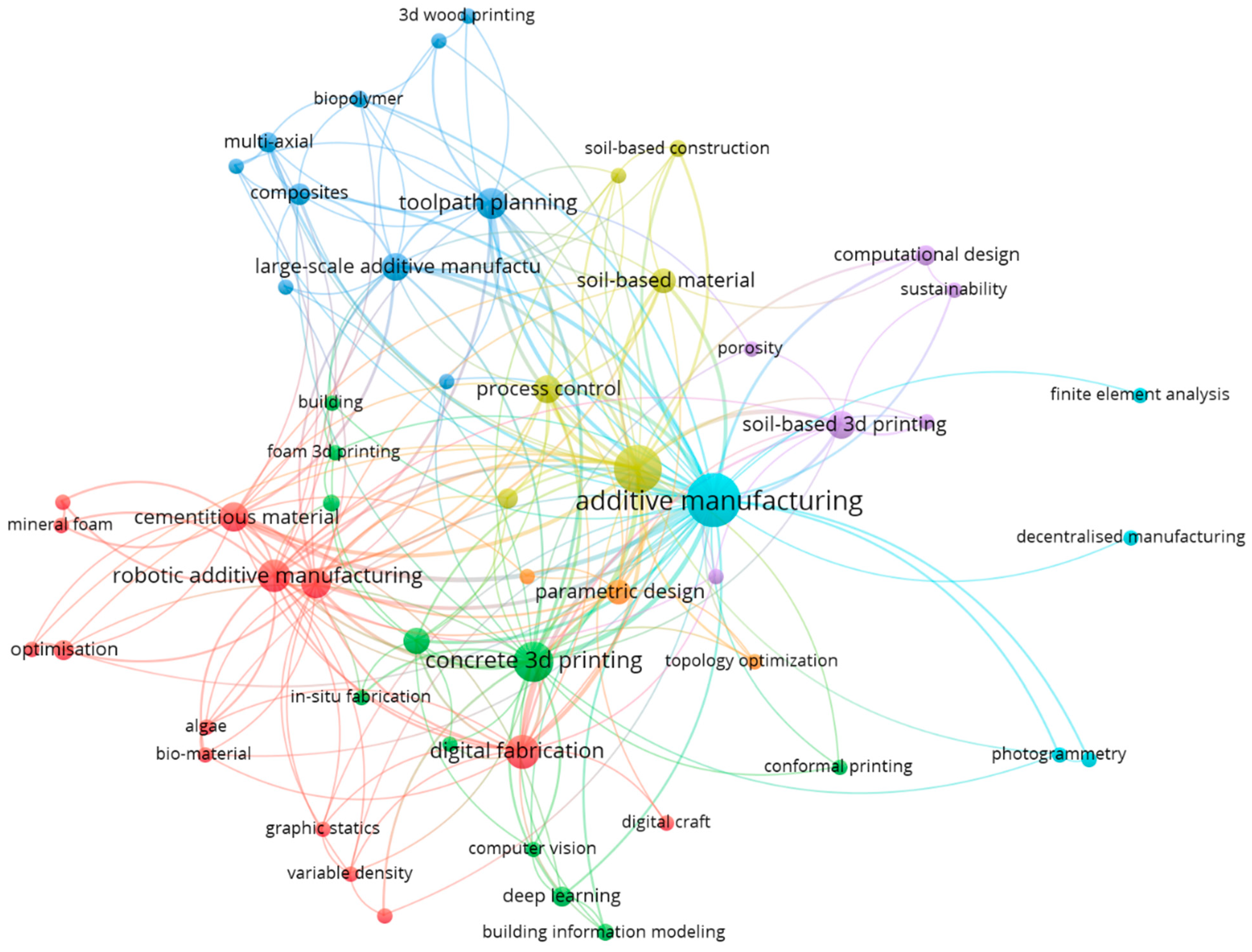

4.1.2. Keyword Co-Occurrence Network

Figure 6 illustrates the results of the keyword co-occurrence network analysis for the examined articles. It is worth noting that the clusters do not always reflect clear conceptual relationships, which emphasizes the importance of this study as a tool to support subfield classification, helping to reduce interpretative biases. Therefore, the groups are not rigid, closed structures. Some keywords may appear out of context and be disregarded, while others, grouped coherently, help reveal the thematic focus of each set—although this identification may vary in degree of clarity. Finally, this study identified some groups with strong connections and thematic similarities, which were therefore analyzed together (

Table 3).

Cluster 1 brings together studies that experiment with new materials in RAM, aiming to improve both performance and sustainability in buildings and components. Cluster 2 points to research on process management, where BIM, computer vision, and machine learning are combined to connect digital modeling with on-site execution. Clusters 3 and 4 both concentrate on process control and optimization, with a strong focus on robotic path planning strategies such as toolpath planning and non-planar slicing, while also showing continued interest in earth-based materials.

Clusters 5 and 7 emphasize the design dimension, highlighting the use of computational and parametric tools to create complex geometries, enable mass customization, and promote sustainable applications. Together, they underline the importance of digital workflows that carry ideas from design through to fabrication. Cluster 6, however, exhibits lower coherence, as it is based on infrequently used keywords and therefore does not constitute a distinct or well-defined subfield of RAM within the AEC industry.

5. State of the Art in RAM for AEC

This section outlines the state of the art in RAM for AEC by mapping how research efforts are structured into distinct subfields and segments (

Figure 7). The identification and description of these subfields represent a contribution in themselves, as they clarify the main directions in which knowledge has advanced. Alongside the detailed analysis of Process and Design, this review also synthesizes trends in Materials and in hardware and software setups, offering a comprehensive picture of how the field has evolved and where challenges and opportunities remain.

5.1. Process

This subfield covers studies focused on identifying, understanding, and controlling operational variables such as extrusion speed, toolpath, and curing time. Rather than addressing a specific geometry, the emphasis is on the manufacturing process itself, from parameter testing and calibration to material deposition. The definition of this subfield was primarily shaped by Clusters 2, 3, and 4 from the keyword co-occurrence analysis, and the reviewed articles point to three main segments (

Table 4).

5.1.1. Assessment and Prediction of Manufacturing Variables

The first segment focuses on assessing and predicting manufacturing variables, examining how parameters such as deposition angle, cost, time, and surface quality impact both the process and the product, with some studies developing predictive models.

Several studies have investigated the impact of equipment configurations and extrusion parameters on print stability, accuracy, and interlayer bonding in RAM. Together, they demonstrate that nozzle geometry, extrusion rate, filament dimensions, and deposition strategies, such as angled deposition, strongly influence both performance and material behavior. Large-scale experiments with UHPC highlight the role of robotic systems, extruder type, and pumping method in determining layer stability, showing that auger extrusion and rectangular nozzles provide better shape fidelity, while cavity pumps reduce stability [

18].

Clay-based studies emphasize flexibility in parameter manipulation, such as variations in filament dimensions, flow rate, and toolpath density, and show how this can improve stability but often creates trade-offs between speed, resolution, and material consumption [

28]; changes in flow rate, nozzle size, and nozzle–filament distance affect filament thickness, interlayer adhesion, and surface texture, allowing both structural and aesthetic variation [

27]; and adjustments to nozzle height in relation to the clay filament can significantly strengthen interlayer bonds, though other tested variables showed less consistent impact [

25].

Building on efforts to understand the influence of parameters, several studies have developed predictive and simulation models to anticipate RAM outcomes and support process optimization. AI-based approaches automate toolpath planning and evaluate fabrication scenarios in advance, thereby improving precision and adaptability; however, they still face scalability limits with complex geometries [

40]. Parametric simulations by Breseghello, Sanin, and Naboni [

31], later refined by Breseghello and Naboni [

30], aligned virtual toolpaths with physical results, incorporating material displacement and gravity effects. This approach shows that deformation can be anticipated and even exploited as a design strategy, as demonstrated in full-scale and prototype applications. Complementing these approaches, modeling has been used to capture the interactions of flow rate, air pressure, and curing additives, achieving strong predictive accuracy for filament geometry [

2].

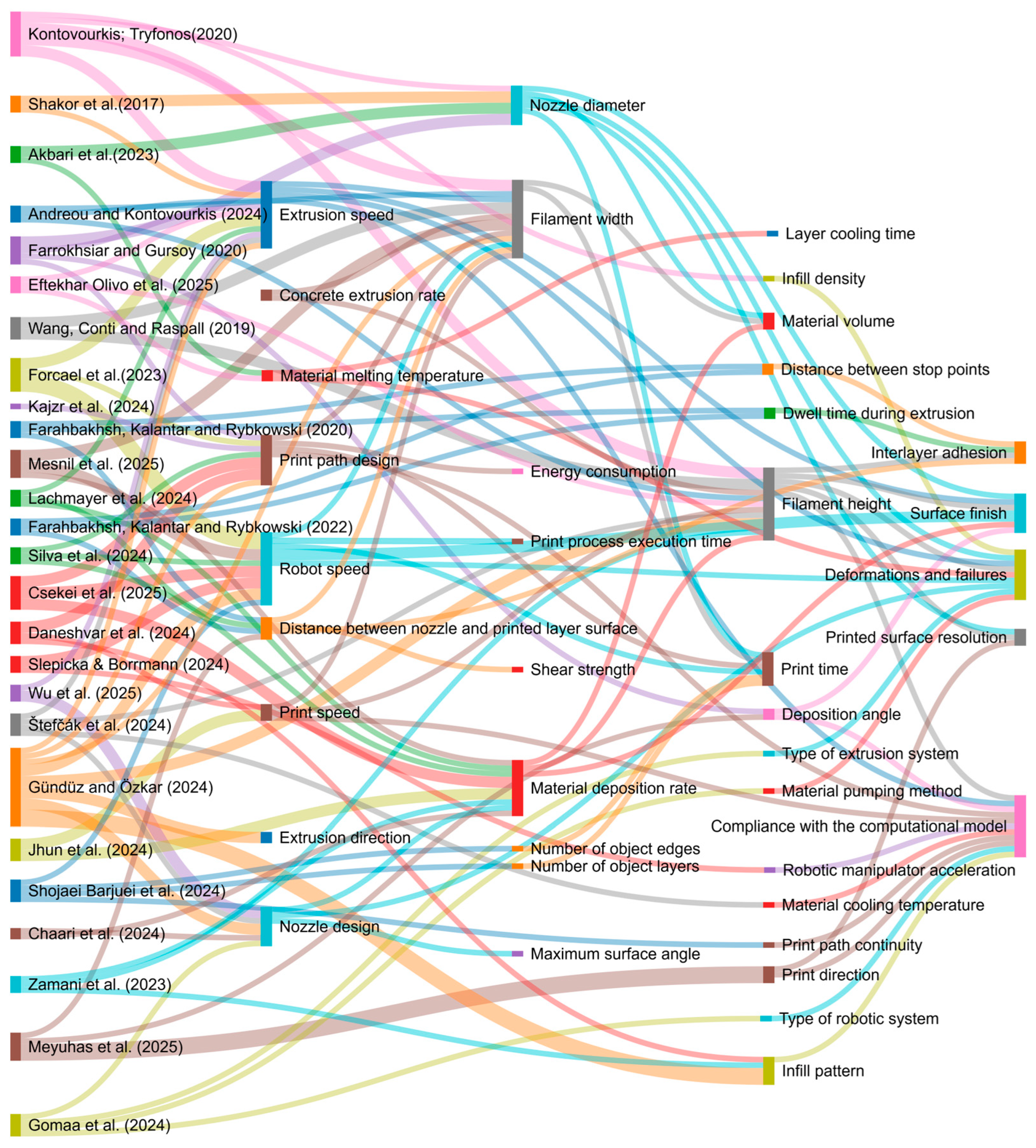

These case studies demonstrate advances in understanding and predicting the influence of fabrication parameters on printed objects, clarifying the trade-offs involved and how variable manipulation can improve specific outcomes. In this context,

Figure 8 presents a Sankey diagram illustrating the flow of relationships between independent fabrication parameters, the dependent parameters, and physical characteristics of the 3D printed objects. This flow, based on the set of variables identified across all studies within this segment, indicates that the complexity of process parameters remains one of the key challenges to the broader adoption of RAM technology in the AEC industry.

5.1.2. Process Control and Optimization Models

The second segment focuses on process control and optimization, utilizing computational models and algorithms to calibrate variables such as speed, toolpath, and layer sequencing, thereby enhancing accuracy, efficiency, and reliability.

Energy efficiency has been studied through both modeling and algorithmic approaches. Kajzr et al. [

43] developed an energy consumption model for a specific robot and compared its performance with other robots and RAM systems. The model showed that articulated robots demand more energy than gantry-based systems, framing efficiency as a key process parameter. Beyond hardware considerations, algorithms that optimize multi-robot movements have shown that energy use can be significantly reduced in large-scale construction [

53]. One approach highlights the impact of hardware configuration, while the other focuses on coordination strategies. Taken together, they demonstrate that improving energy efficiency requires interventions at both the Equipment and Process levels. These studies highlight energy modeling as a crucial element in advancing process optimization in RAM.

Fabrication efficiency and quality have been addressed through workflow integration and toolpath calibration. Linking BIM and RAM reduces fabrication time and enhances product quality [

52], while non-equidistant toolpaths mitigate filling defects, reduce geometric errors, and shorten production time [

50]. Both approaches demonstrate how computational integration and geometric refinement can drive efficiency through different digital-to-physical pipelines.

Structural strength has been addressed through innovative deposition strategies. For example, Bhooshan et al. [

46] demonstrated an optimization method for precisely calibrating inclined deposition angles with a block interface to enhance the compressive strength performance of large concrete components. Additionally, motion precision has been targeted as a performance objective through algorithmic control by applying a Fourier Series-based approach to robotic arm movements, resulting in higher precision in axis control during simulations of large-scale fabrication.

Collectively, these examples demonstrate an orientation toward transforming RAM into an integrated and intelligent system. This trajectory aligns with the broader Construction 4.0 framework, where cyber–physical integration, AI, and simulation are central to productivity and sustainability gains [

1,

3,

5].

5.1.3. Real-Time Feedback Systems for Fabrication Variable Control

The third segment focuses on real-time feedback systems, which monitor and adjust fabrication parameters during printing to compensate for external factors that can compromise quality and stability.

Research on RAM has increasingly focused on feedback systems capable of monitoring and adjusting the process during fabrication. Early work concentrated on integrating digital models with robotic control, combining BIM data, computer vision, and sensor feedback to enable automated placement tasks and bidirectional coordination between design and fabrication [

60,

62]. These approaches demonstrated the potential of information models to support dynamic interaction between digital workflows and physical production.

More recent work has shifted toward direct monitoring of extruded material. Jhun et al. [

63] employed low-cost laser sensors to measure filament dimensions during printing, with validation through static and in situ tests showing millimeter-level accuracy and reduced fabrication errors. Naboni, Breseghello, and Sanin [

68] integrated a depth camera with generative design algorithms to continuously capture environmental data and adjust toolpaths in near real time. Their prototypes on irregular terrain confirmed the feasibility of adaptive fabrication under non-ideal site conditions.

These studies reflect a progression in real-time systems, moving from model-driven integration to sensor-based monitoring and, more recently, to adaptive, environment-aware fabrication. Across all cases, the evidence suggests that advancing this line of research is crucial to addressing the scalability of RAM in AEC. Yet, despite its importance, the literature includes only eleven studies on environment-aware and adaptive systems, revealing a significant gap that still limits the broader application of RAM.

5.2. Design

This subfield encompasses studies that utilize RAM in conjunction with computational design methods to develop workflows for complex and innovative geometries, addressing challenges related to design, customization, and object performance. The focus primarily lies on the geometry of the object, while process calibration, although necessary, remains secondary. The definition of this subfield was shaped mainly by Clusters 5 and 7 from the keyword co-occurrence analysis, and the reviewed articles revealed two main segments (

Table 5).

5.2.1. Design of Complex and Customized Geometries

The first segment centers on complex and customized geometries, exploring how RAM enables the production of components adapted to mass customization strategies, local contexts, and specific construction requirements. These studies highlight the potential of robotic fabrication to go beyond standardized forms, allowing for unique and context-specific solutions.

Studies have investigated the use of RAM to develop complex shapes that adapt design solutions to specific contexts and constraints, thereby turning fabrication strategies into an extension of the design process. Paquet et al. [

80] applied computational design, combined with RAM, to create urban cooling islands featuring earth-based walls that directly influenced thermal insulation. Ribeiro et al. [

82] focused on adapting to irregular terrain by fabricating customized slabs on rocky slopes, combining photogrammetry, parametric modeling, and custom toolpaths with sand-based supports. At the building scale, multiple robotic arms have been coordinated for on-site fabrication, with nozzle rotation allowing compliance with site-specific conditions [

90].

Other works have emphasized mass customization. Yuan et al. [

91] developed a parametric design-to-fabrication process using thermoplastics, enabling the production and assembly of unique panels for a full-scale pavilion. Salem, Abdelmohsen, and Mansour [

87] demonstrated the fabrication of doubly curved façade panels with local, low-cost materials through non-planar deposition and multipoint forming, highlighting both technical feasibility and economic potential.

While these studies demonstrate RAM’s potential to move beyond standardized forms toward complex, customized, and context-specific designs, the research still explores the integration of a narrow range of fabrication variables into the design process, with limited attention to design strategies that address challenges such as integrating structural reinforcement or scaling large-scale structures.

5.2.2. Performance-Based Geometry

The second focuses on performance-based geometry, examining how RAM can optimize material distribution within objects to improve operational performance while minimizing resource use. In this segment, complex forms may also emerge, but the primary aim is to achieve efficiency and functionality through design.

Jipa et al. [

108] applied inclined layer extrusion with modified nozzles and additives to fabricate vaulted concrete slabs, achieving lighter elements that reduced material use while maintaining structural integrity. Bao, Yan, and Xie [

114] pursued a similar principle through computational optimization, using bidirectional evolutionary structural optimization to design a tree-like prototype. RAM enabled the translation of digitally optimized forms into full-scale structures, leveraging robotic flexibility to create structurally efficient forms.

Other studies emphasize multifunctionality and environmental performance. Recyclable PETG formwork has been utilized for irregular concrete walls, resulting in a 70% reduction in concrete consumption while validating the approach in curved and vertical prototypes. However, material durability declined after repeated cycles [

116]. Clay-based façade walls integrating ventilation channels optimized for displacement ventilation further illustrate how robotic extrusion can embed airflow functions within geometry, linking structural fabrication with environmental design [

115].

Taken together, these studies demonstrate how RAM supports performance-driven design by integrating efficiency, structural logic, and multifunctionality into the geometry itself. While computational optimization and robotic flexibility provide powerful tools for material savings and enhanced functionality, applications remain limited to small sets of prototypes.

5.3. Materials

The Materials subfield comprises studies that investigate RAM using various materials and examine their effects on manufacturing quality and performance, as well as the operational behavior of a given object. These investigations may assess the impact of specific additives or ingredients, compare different materials and composites, or explore quantitative variations within the same formulation. This subfield was strongly influenced by Cluster 1 and, to some extent, Cluster 2, as indicated by the keyword co-occurrence analysis (

Table 6).

Figure 8.

The Sankey diagram represents the flow of relationships between fabrication parameters, and the 3D-printed objects including studies [

18,

20,

21,

22,

24,

25,

26,

27,

28,

33,

34,

35,

36,

38,

39,

40,

42,

43,

44,

61,

62,

63,

67,

72,

76,

133]. Source: the authors (2025).

Figure 8.

The Sankey diagram represents the flow of relationships between fabrication parameters, and the 3D-printed objects including studies [

18,

20,

21,

22,

24,

25,

26,

27,

28,

33,

34,

35,

36,

38,

39,

40,

42,

43,

44,

61,

62,

63,

67,

72,

76,

133]. Source: the authors (2025).

Trend and Prominent Materials

Most of the reviewed studies (54) investigate concrete as the primary material for RAM. This finding aligns with the results by Xu et al. [

3], confirming that concrete is the most used construction material globally, whose mechanical behavior is well understood. Nonetheless, its use in additive manufacturing still poses numerous challenges, notably the precise tuning of additives to control curing time, allowing for continuous extrusion, while ensuring structural support to the deposition of successive layers. Of these studies, half fall under the Process subfield, indicating a trend of using a well-known material, focusing on process control.

Following concrete, earth-based materials, such as clay (including ceramics derived from it), are the second most investigated category in RAM. Among these, a significant portion (41%) belongs to the Design subfield, suggesting that such materials are particularly relevant to research groups focused on architectural and design-oriented processes. Furthermore, most of the thirteen articles categorized under the Process subfield, using clay as the primary material, concentrate on analyzing the effects of fabrication parameter settings to improve the quality of 3D-printed objects.

Many studies examining clay advocate for its sustainable attributes and highlight the potential for local sourcing of raw materials, enabled by RAM [

27,

28,

33,

87,

96,

124]. Clay also possesses rheological properties that make it particularly suitable for extrusion: under pressure, it maintains a homogeneous consistency, which enables continuous and uniform flow through the extruder nozzle [

101,

123]. Additionally, clay is considered a cost-effective material because of its low acquisition and maintenance costs [

87,

98]. It also exhibits good thermal performance, as noted by Salem, Abdelmohsen, and Mansour [

87], making it particularly suitable for certain climates, which explains its broader use in RAM applications.

A particular characteristic of building materials such as mortars, concrete, and clay is the importance of controlling all three dimensions of the extruded filaments. Manipulating these dimensions directly impacts the quality and performance of the final component. Thus, unlike traditional fused filament fabrication (FFF), in RAM, calibrating these dimensions is essential to control the geometric properties of the object, either to meet specific design strategies or to align the physical model with its computational counterpart.

Beyond concrete and clay, twenty-four studies explore the use of thermoplastics in RAM, while five investigate synthetic [

94,

148] or mineral foams [

112,

113,

138]. Other studies explore alternative and sustainable materials, including biocomposites and bioplastics. Recently, there has been a growing interest in using wood-based pastes, with four studies focusing on mixtures derived from sawdust reuse [

139,

141], recycled wood blends [

125], and cellulose microfibers [

136].

5.4. Equipment

A fourth subfield, defined by six studies, focuses on the development of RAM equipment for different purposes within the fabrication process. Although not directly reflected in the keyword co-occurrence clusters, these works reveal an emerging interest in designing devices—such as extruders and auxiliary tools—specifically for AEC applications. The studies emphasize the need for accessible, construction-oriented equipment that can address the challenges of on-site use and experimental applications. They explore strategies such as adapting robotic systems to construction environments, designing custom extruders, and creating support tools tailored to RAM workflows. While still limited in number, these contributions represent an important step toward expanding the technical capabilities of RAM and addressing a key technological gap in the AEC industry (

Table 7).

5.4.1. Hardware Setup for Robotic Additive Manufacturing

We analyzed the equipment configurations described in thirty studies that provided details on the RAM systems used in their experiments. Based on this analysis of the equipment and workflows, we highlight four component groups that define an RAM system.

The first group comprises the robotic arm and its controller. This equipment is responsible for moving the material along the toolpath. Robotic arms offer a higher degree of motion flexibility, which depends on the number of rotational axes and their capacity for horizontal and/or vertical displacement.

The second group includes the equipment for storing, preparing, and transporting the material to the robotic arm’s end-effector. Variations in this group determine whether the RAM process operates with a continuous or intermittent flow and whether the material flow rate is constant or variable.

The third group consists of the extruder, which is attached to the end-effector of the robotic arm. This component can range from a simple nozzle to more complex extruders with mechanisms for controlling the material flow.

Finally, the fourth component is the deposition surface. This surface can vary in shape and texture, which in turn influences the adhesion and stability of the deposited material.

Robotic Arm and Controller

The variation among robotic arms lies primarily in the number of rotational axes and the axes of displacement. In terms of rotation, the literature reports robotic arms with 3 to 9 degrees of freedom; however, six-axis robotic arms are by far the most used in experiments. Robotic arms with six or more axes of motion offer greater control and movement flexibility. Typically, they permit the adjustment of extrusion orientation during the process, allowing for the fabrication of complex and optimized geometries, including curved surfaces, inclined forms, and cantilevered elements.

Additionally, installing robotic arms on mobile platforms enables horizontal and, in some cases, vertical displacement, in addition to rotational movement. These platforms extend the robots’ operational reach beyond their fixed working envelope, directly impacting the scalability of component production, particularly for large-scale structures.

For example, Xu et al. [

90] presented a study involving robotic arms on mobile platforms to facilitate movement on construction sites. The platform allows an additional reach of 14 m on the X-axis, 1.3 m on the Y-axis, and 1.4 m on the Z-axis. Zhang et al. [

58] used 6-axis robotic arms on holonomic mobile platforms equipped with location sensors and odometers. Alabbasi, Agkathidis, and Chen [

117] mounted the robotic arm on a rail platform with a horizontal reach of 60 cm. Finally, Keating et al. [

148] developed a complex robotic system by installing a 6-axis robotic arm suspended by another 4-axis articulated robotic arm on a tracked platform. This arrangement enables the platform to move during the fabrication process.

Material Storage, Preparation, and Feeding

The setup of this equipment depends on the type of material and whether continuous feed is required. Typically, the material moves via mechanical pumping, which is common for pasty materials, or suction, in the case of thermoplastic granules, through a hose connected to the end-effector of the robotic arm [

30,

137,

151]. In RAM with clay, the material is typically prepared in advance and stored before being pumped to the extruder.

For cementitious materials, when mixing occurs beforehand, the storage system must keep the material agitated to prevent premature curing. For example, Breseghello and Naboni [

30] used a separate tank for storing and mixing concrete, then transported it to a pump that feeds the material directly to the extruder nozzle attached to the robotic arm’s end-effector. Alternatively, some systems prepare materials separately and mix them just before extrusion. Meisel et al. [

151] prepared the concrete using an m-Tec Duo Mix 2000 mixer-pump, which blends dry concrete with water while extruding, enabling continuous mixing throughout the fabrication process. In this case, the material flow is constant and controlled by the pumping system. Similarly, in Bedarf et al. [

112], both the foam base paste and its additive are regulated by a progressive cavity pump that delivers the mixture to the extruder nozzle.

In the second setup, the material storage unit is mounted directly on the robotic arm. This system is standard in experiments with thermoplastics and clay. In clay-based systems [

85,

86,

124], the researchers manually fill the tank, and the material is pushed toward the extruder nozzle. For bioplastics, Alarcón and Svilans [

142] stored the material in granule tanks or filament rolls. However, these systems operate discontinuously, requiring periodic interruptions to reload material, which affects their scalability and fabrication time [

137].

Extruder

Extruders are generally composed of two components: the nozzle and a drive mechanism that regulates material flow. The primary mechanisms identified in the literature operate through compressed air, piston-driven systems (pneumatic, hydraulic, or electric), or rotary systems—typically augers or screws—controlled by stepper motors.

Pneumatic systems require an air compressor, a sealed tank with a connected compressed air hose and an extruder nozzle. This system forces air into the tank through the hose, which pushes the material through the extruder nozzle. The main advantage is the ease of assembly and operation. However, these mechanisms have less control over material flow, especially at stopping points, where delays in stopping the flow lead to material accumulation or component failures [

69,

70,

124]. Furthermore, according to Farahbakhsh, Kalantar, and Rybkowski [

25], due to the inconsistent material flow, the size of the tank must comply with the load capacity of the robotic arm, especially when it is attached to the robot.

According to Asaf et al. [

137], the piston system consists of a material tank with a piston installed on top. The piston applies pressure to the material for extrusion, pneumatically or electromechanically. This system has a linear relationship between the piston and the output flow speed. The movement mechanism and piston diameter vary according to the load capacity of the arm terminal operator and the material’s characteristics. This system is suitable for laboratory-scale experiments due to its simplicity and ease of operation [

137]. However, it also requires the tank to be mounted on the robotic arm and entails manual refilling [

85,

86].

Rotary systems consist of a stepper motor driver to rotate a screw or auger within a cylindrical chamber, which in turn moves the clay through the extruder nozzle. The stepper motor is responsible for applying mechanical pressure to the material being discharged from the tank, thereby ensuring a consistent and precise material flow [

26].

Furthermore, an Arduino board with an on–off button connected to the stepper motor can control the extruder flow according to the robotic arm trajectory programming [

86,

123]. In the case of thermoplastic extruders [

142], Arduino boards integrated with the extruders can regulate the temperature of the heating system.

Asaf et al. [

137] stated that rotary systems operate continuously, increasing manufacturing efficiency. Rosenwasser, Mantell, and Sabin [

124] highlighted precise control and the possibility of automating material flow as the main advantages of this system. On the other hand, they noted that the assembly is restricted to a vertical position, which limits the operation of the robotic arm. Furthermore, it is a more complex system to produce and operate compared to the previous two. The choice between mechanisms depends on the project’s specific needs, considering both scalability and efficiency [

137].

Regarding the extruder nozzle, variations depend on its shape and dimensions, which impact layer resolution and filament shape. The most common shapes are circular, elliptical, and rectangular. Circular nozzles do not produce filament shape variation depending on the deposition angle [

88]. In contrast, rectangular extruder nozzles show more potential for filament variation via deposition angle. Felbrich et al. [

95] designed an extruder nozzle featuring steel blades for extruding wide, curved thermoplastic strips, mimicking the spiral structure of snail shells in architectural forms.

The size of the extruder nozzle will depend on the characteristics and volume of the material. Experiments with thermoplastics usually require extruder nozzles with diameters of 2, 4, and 6 mm. Clay presents a greater variety of layer resolutions, with dimensions ranging from 0.5 mm to 40 mm. The experiments with cementitious materials, due to the presence of aggregates, require extruder nozzles with larger dimensions, starting at 15 mm.

Deposition Surface

Most of the analyzed studies deposit the material on horizontal surfaces. However, in some cases, experiments are performed with curved deposition surfaces, on a mobile platform controlled by a robotic arm [

123,

145]. During the process, the curved platform helps maintain the object’s shape, preventing warping and breakage. The 3D-printed object is dried and cured directly over the mold, on the curved surface, guaranteeing that the final curvature meets the designed tolerances [

123]. Prado and Son [

145] also used a curved surface as a base for thermoplastic on textile membranes in a proposal that integrates these two materials to produce lightweight structures with complex geometries.

Naboni, Breseghello, and Sanin [

68] built a deposition platform with a gravel bed to shape an irregular terrain. This surface enabled them to test AM with an environmental change detection system, allowing the toolpath to adapt according to site characteristics. Subsequently, Breseghello et al. [

66] developed a robotic process that combines terrain modeling with RAM in concrete, using the excavated soil as an adaptive deposition surface that directly impacts the shape of complex geometries.

Salem, Abdelmohsen, and Mansour [

87] developed a multipoint platform consisting of vertical actuators for double-curved façade panels. These actuators, arranged in a 4 × 4 grid, created an adaptable surface for depositing clay in complex shapes.

Finally, Taher, Asut, and van der Spoel [

115] recommended that the choice of deposition surface ensure strong adhesion throughout the fabrication process, suggesting considering the use of materials and coatings to prevent water absorption, dry shocks, excessive shrinkage, and warping. Additionally, a protective covering, such as a plastic sheet, can be used on the deposition platform to prevent moisture absorption.

5.4.2. Software Setup for Robotic Additive Manufacturing

According to Lettori et al. [

153], a typical AM process involves the following steps: (1) geometry modeling; (2) geometry processing for AM, which involves object decomposition, deposition orientation, slicing, and toolpath definition; (3) AM simulation; (4) manufacturing; and (5) post-processing. Although other possibilities exist, this is a commonly adopted process. These procedures typically require the integration of software to facilitate the seamless coordination process between digital model design and robotic fabrication.

In the modeling stage, Rhinoceros 3D is by far the most widely adopted software, with sixty studies using it as a primary digital modeling tool, followed by the BIM platform Autodesk Revit, with eight occurrences. This preference is primarily due to the widespread adoption of these programs in the industry and their integration with programming environments that enable algorithmic-parametric modeling, through platforms such as Python or Grasshopper plugins for Rhinoceros 3D and Dynamo for Revit. In addition to parametric modeling, these platforms support customized geometry processing for fabrication, a step often necessary for generating feasible toolpaths according to the geometry.

Specifically, in the Grasshopper programming environment, several extensions (plugins) enable the entire workflow on a single platform, from digital modeling to robotics programming. These include the HAL, Taco ABB, KUKA|PRC, Robot, and other extensions. This flexibility creates a closed and integrated process, eliminating the need for multiple platforms, which further explains why Rhinoceros is the most popular choice for the modeling stage.

Nonetheless, recent studies have explored integrated workflows using BIM platforms, particularly Autodesk Revit [

62], which has developed a BIM-based communication method called Fabrication Information Modeling (FIM). Although the workflow involves multiple platforms, the data management capabilities of BIM enable a central model to integrate all stages, resulting in a closed-loop and bidirectional data flow between digital modeling and additive manufacturing. This process includes processing, simulation, fabrication configurations, and the generation of robotic control code.

Finally, standalone software can also execute the processing, simulation, and robotic programming stages, many of which cover two or more phases or even the whole workflow. In this case, the digital model is imported into these platforms to complete the subsequent phases in an integrated environment. In this sense, the choice of this software defines the approach to data transfer between digital tools. These platforms will determine the level of integration between data [

47], which is crucial to avoid information loss and prevent it from affecting quality during the fabrication process (

Table 8).

6. Advantages and Limitations of Using Robotic Arms for AM in Construction

The use of RAM offers several advantages but also presents significant challenges that limit broader adoption in the AEC industry. Therefore, mapping and understanding both the strengths and limitations of this technology are essential to leverage its potential and address its constraints. In this sense, this section presents the key advantages and challenges based on the evaluations and insights of the studies reviewed.

The most frequently mentioned advantage—highlighted in 66 studies—is the flexibility of motion enabled by the degrees of rotational freedom in robotic arms. This aligns with previous studies by Puzatova et al. [

4], Xu et al. [

3], and Huang, Xu, and Li [

14]. The kinematic capabilities of these arms provide enhanced path programming and movement control, enabling greater flexibility in deposition. According to the literature review, this translates into benefits such as improved precision and surface finish [

153], enhanced performance and reduced interlayer stress [

58], the ability to create complex geometries [

27,

87,

122,

139], material savings [

48,

118], variation in layer geometry [

89,

145], generation of multi-axial layers [

48,

85,

99,

100,

139], and greater tolerance for producing overhanging structures and adapting to site-specific conditions—such as tight corners or sloped deposition surfaces—allowing material to be deposited perpendicular to the angle of the substrate [

129].

The second key advantage is the multifunctionality and collaborative capacity of robotic arms [

2,

59,

66,

87,

142,

147,

151]. These systems can perform complementary tasks—such as additive, subtractive, and formative operations—using the same platform. Moreover, robotic arms accommodate various materials and process configurations. Multiple robotic arms can also work collaboratively to carry out complex operations with high performance and precision.

Time and cost savings are also significant, cited benefits [

2,

47,

94,

151]. Robotic systems are faster to set up and require less infrastructure compared to gantry-based systems, reducing the setup time and streamlining execution. This efficiency makes RAM a more cost-effective solution, particularly in projects with tight schedules and budgets.

Some researchers highlighted the compact size and reach of robotic arms as advantages [

3,

53,

59,

91,

145,

148,

151]. Compared to gantry systems, robotic arms promote more efficient use of workspace, facilitating their transport to remote and difficult-to-access locations, and their use in a variety of construction contexts. As highlighted by Huang, Xu, and Li [

14], their compact size is particularly advantageous due to the increased physical reach relative to the equipment’s footprint, enabling the 3D printing of complex and detailed shapes in confined spaces. Specifically in AM with thermoplastics, robotic systems offer considerably greater reach than conventional desktop 3D printers, which enables large-scale projects.

Although some authors have highlighted the reach and size of robotic arms as an advantage of this equipment, others attribute disadvantages to this characteristic, as noted by Puzatova et al. [

4]. For example, according to Keating et al. [

148], robotic arms have a limited load capacity compared to larger systems. Allah, Anane, and Iordanova [

47] highlighted that stationary robotic arms have a maximum reach of approximately 3.9 to 4.7 m, limiting their ability to fabricate larger objects. Additionally, rotational movement can restrict mobility in certain deposition zones, particularly at greater heights [

34].

This divergence in perceptions of the reach of robotic arms is related to the divergence between previous reviews on the scalability of AM with robotic manipulators. When evaluating the individual size and reach of a 3D printer with a gantry system and an AM system, the arm’s reach is more limited. From this perspective, gantry systems indeed have an advantage in terms of fabrication scale. However, these same systems are challenging to assemble and require a larger footprint than the building itself.

Robotic systems are flexible, easy to assemble and move, and can work in collaboration with other robotic arms or other types of equipment. Also, when installed on mobile platforms, they have an advantageous reach ratio proportional to their size. Therefore, these characteristics enable robotic arms to produce AM components that are much larger than their size. However, this requires designing the object with scalability in mind, considering the use of this technology in all design phases.

A significant challenge associated with RAM is its technical complexity and the need for advanced programming skills [

34,

85,

91,

96,

97,

100,

121,

139,

145,

148]. The flexible movement of robotic arms requires highly customized programming to prevent collisions and maintain consistent deposition. Fine-tuning of deposition speed and toolpath is often necessary to prevent errors such as material gaps [

34]. These demands increase the need for specialized knowledge in both software and hardware, requiring significant training for designers and operators alike [

96,

148].

Finally, the current use of RAM still depends mainly on industrial robotic arms originally developed for controlled environments, which makes it challenging to apply them directly on construction sites [

3,

33,

47,

152]. Therefore, fabricating directly on the construction site poses a challenge due to a lack of control over external conditions, such as temperature, humidity, relief, and terrain obstacles [

92]. These factors limit the integration of RAM into everyday construction workflows and its widespread adoption.

7. Research Gaps and Opportunities

An analysis of the literature on RAM in construction reveals research gaps that present opportunities for advancing the technology and its application in the AEC sector. The following section presents the main research gaps and opportunities based on the literature review.

7.1. Gaps

One of the main gaps is improving fabrication efficiency, especially by mitigating the challenges of manufacturing large structures and synchronizing multiple robots. Furthermore, it is necessary to overcome constraints such as a lack of control over external conditions, including temperature and humidity, which can disrupt the manufacturing process. In this respect, Im, Al-Othman, and del Castillo [

70] pointed out that one way to achieve this is through real-time quality control using feedback systems. Another important gap reported is the lack of robotic systems designed explicitly for the AEC industry. Therefore, systems capable of adapting to different terrains and environments are needed, as well as solutions to expand the reach of robotic arms to make them suitable for large-scale AEC tasks, aligning with the gap identified by Xu et al. [

3].

Regarding the Design, few studies have explored the unique features of RAM and its potential applications in building design and component development. Overall, research tends to investigate only a limited set of fabrication variables, many of which are explored more extensively in other AM systems [

14]. Additionally, a few studies have addressed strategies for segmenting large-scale structures based on fabrication process constraints. Furthermore, the integration of structural reinforcements remains a significant challenge, despite recent advances in this area [

29,

60,

61,

108].

Broad investigations into the control and interdependence of geometric and fabrication parameters, as well as their impact on the manufactured object, are also lacking. Farahbakhsh et al. [

26] emphasized the importance of research into layer geometry control to improve performance criteria, such as thermal performance. Similarly, Kipping and Schüppstuhl [

48] advocated for studies validating structural optimization strategies linked to RAM fabrication parameters.

Finally, limited research has investigated the generation, management, and use of RAM-related data. This review identified only five studies investigating interoperability between BIM platforms and RAM systems [

29,

42,

47,

52,

63]. There is a need to develop automation strategies for seamless integration without data loss [

52]. Additionally, studies integrating AI technologies and machine learning models into RAM for Design, control, and process auditing are still in early stages, despite recent advances in applying such technologies to optimize fabrication processes and enable real-time parameter monitoring [

61,

65,

67].

7.2. Research Opportunities

A promising research topic involves process control and fabrication efficiency, particularly the optimization of fabrication parameters to enhance quality and reduce time. Notable opportunities include minimizing the interruptions during the manufacturing process [

151], ensuring precise control of the distance between the extrusion nozzle and the deposition layer to maintain quality and compensate for deformation [

71], and achieving accurate control of concrete flow interruption during printing [

23]. Optimization models for these parameters—especially those incorporating predictive models and real-time feedback systems—are essential for managing both material properties and environmental variables [

34]. Additionally, automating fabrication settings based on object design and improving coordination among multiple robots in large-scale projects present further opportunities [

57].

The development of RAM-specific technologies and robotic cells for construction represents another key opportunity, particularly in adapting equipment to on-site conditions. These opportunities include designing auxiliary tools for RAM with materials such as clay and mortar, as well as extending the reach and functionality of robotic arms to suit large-scale projects. Developing affordable equipment tailored to specific geographic contexts—such as Latin America and Africa—also presents an opportunity to make the technology more accessible and inclusive.

Regarding design strategies, there is potential to expand the diversity and complexity of shapes, particularly in terms of size and scale. Opportunities exist in manipulating toolpaths through multi-axis rotation to enable non-planar layer deposition and the fabrication of cantilevered structures. There is also an opportunity for the development of RAM parameter optimization algorithms, focused on performance objectives and strategies for inserting structural reinforcements. Furthermore, design strategies can focus on scaling complex shapes and large structures, with approaches such as segmenting them into smaller parts, adapted to the reach of robots [

58], as well as the automation of form generation processes based on RAM constraints.

Finally, the use of BIM with RAM represents an opportunity for coordination between construction information and the manufacturing process. Digital twins can also help adapt the construction site in response to environmental data, creating a bridge between the physical and digital environments for more adaptive and efficient processes (

Table 9).

8. Conclusions

This study presents the state of the art in RAM for the AEC industry through a systematic review of 142 articles published from 2015 to 2025. Our contribution includes a classification of four research subfields (Process, Design, Materials, and Equipment) based on both bibliometric analysis and a detailed review of the selected studies. Additionally, we mapped the main extrusion-based RAM systems that employ flexible robotic arms, outlined their advantages and limitations as reported by several authors through various types of experiments, and identified key research gaps and opportunities. Given the topic’s relevance, the method employed a search strategy using broad terms, which yielded a large number of results.

Over the past decade, there has been a notable increase in publications on RAM in the AEC industry, although its adoption remains limited in this sector. Since 2020, there has been a significant increase in publications, driven by growing interest in AM and Industry 4.0 within construction. Geographically, most publications originate from North America, with the United States leading the way. In Asia, China and Singapore host key research centers, while in Europe, Germany, Denmark, the United Kingdom, and Switzerland stand out. Chile is the only South American country with documented RAM-related publications, with studies appearing since 2022.

Concerning research subfields, this review identified four main domains: Process, Design, Materials, and Equipment. Research is predominantly concentrated in the first two areas; Materials and Equipment, although less developed in the literature, remain essential foundations for advancing RAM and enabling its integration into construction practice.

Process-oriented studies focus on controlling and optimizing manufacturing parameters—such as extrusion rates, deposition speeds, and toolpath strategies—to improve efficiency, quality, and predictability. Design studies, in turn, emphasize how robotic freedom of movement can support the creation of high-performance, complex, and customized geometries that are otherwise unfeasible with conventional methods. The predominance of these two areas reflects a clear priority: streamlining workflows and bridging the gap between digital models and physical outcomes. Process control and optimization research focus on understanding how production variables affect the performance and functionality of buildings during the fabrication process. This knowledge enables the predefinition and optimization of process parameters, as well as their dynamic adjustment through real-time feedback systems. Some studies are also addressing the coordination of multiple robotic arms to scale up production.

In terms of hardware and software, RAM hardware configurations typically consist of four components: the robotic system, storage system, extrusion system, and deposition platform. In terms of software, Rhinoceros and Grasshopper are widely adopted, with special emphasis on adding plugins for processing, simulation, and robotic programming, aiming to integrate all process data within a single platform.

Although few studies have investigated the multifunctionality and adaptability of robotic arms for developing optimized and complex geometries, this topic is gaining growing attention. Recent research has explored how robotic arms can enable complex forms and customized design strategies that are unfeasible with conventional fabrication methods, as well as material-efficient solutions that maintain performance.

Material research shows a notable and growing interest in clay. Its low cost, availability, and sustainability make it a preferred choice, especially in experimental studies that seek to align RAM with ecological and cultural contexts. While studies also test other materials, clay’s traditional role in construction and its adaptability to extrusion systems make it central to current investigations.

When considering the advantages and limitations of robotic arms in comparison to other equipment, the primary benefit of RAM over other systems lies in the robotic arms’ freedom of movement and multifunctionality. The main disadvantages are the size of the robotic arms and the complexity of programming. However, some authors also point to the size of the robotic arm as a positive feature, as it facilitates positioning and assembly of the equipment on the construction site.

Ultimately, this review identified several gaps and opportunities for future research. Several research gaps and opportunities exist regarding fabrication efficiency, the adaptation of robotic systems for construction, design strategies, control, and responsiveness to environmental conditions, as well as the integration of AI and machine learning models for process simulation and optimization.

This review employed a comprehensive search strategy to identify as many relevant studies as possible. While this ensured comprehensive coverage, it also reduced precision, since many results were only loosely related to the topic. Future reviews could refine the search strings to make the results more targeted. Another limitation is that the scope was restricted to extrusion-based RAM with flexible robotic arms, leaving other techniques and materials less explored. In addition, this study did not include a meta-analysis that could have quantified the relationship between fabrication parameters and performance outcomes. Incorporating such an approach would strengthen the statistical basis of the findings and complement the qualitative insights. Ultimately, a more systematic comparison of design strategies and process flows would be beneficial for understanding how different approaches intersect or diverge across various research contexts.