Towards Sustainable Construction in China: A Systematic Review of Barriers to Offsite Methods

Abstract

1. Introduction

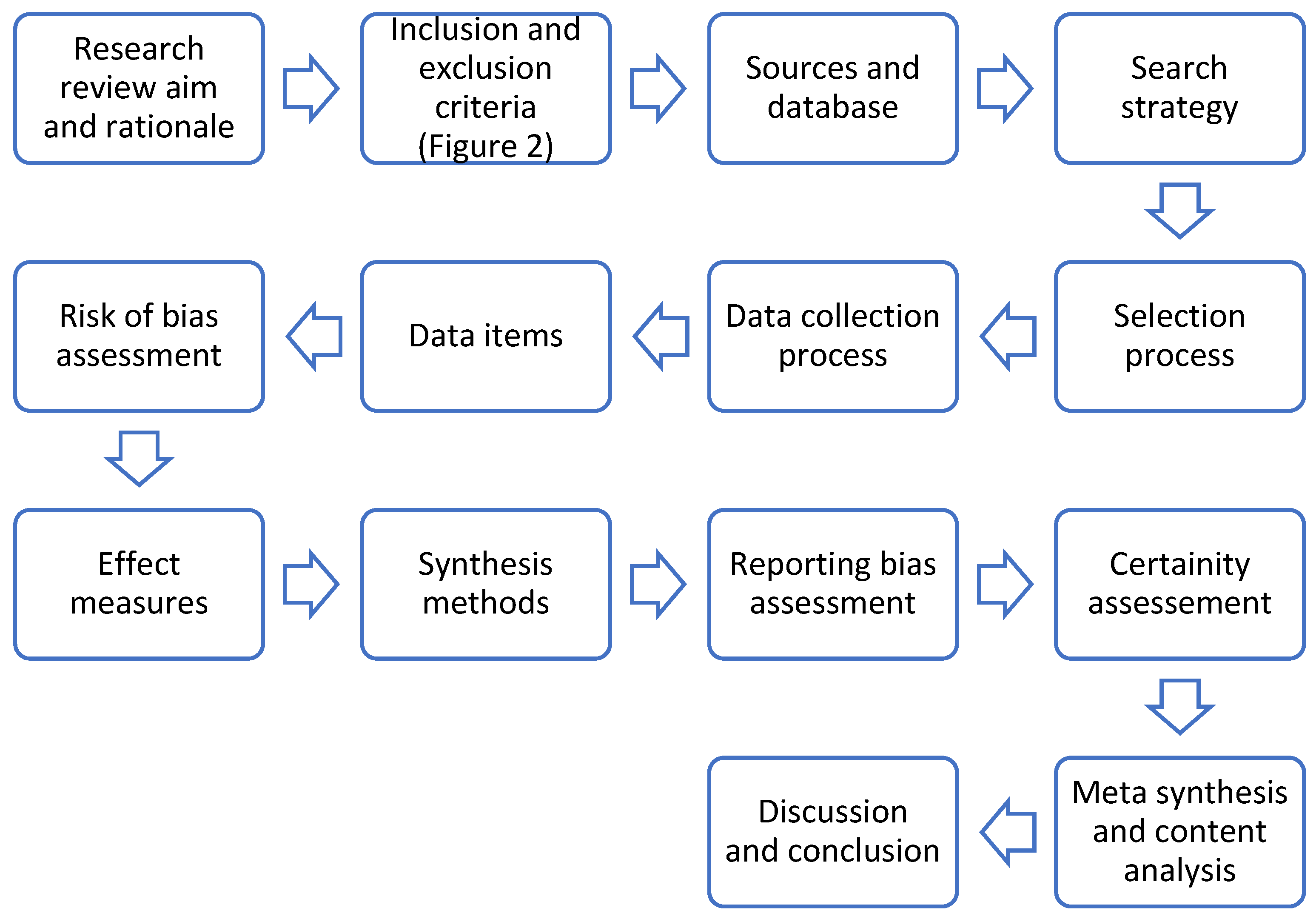

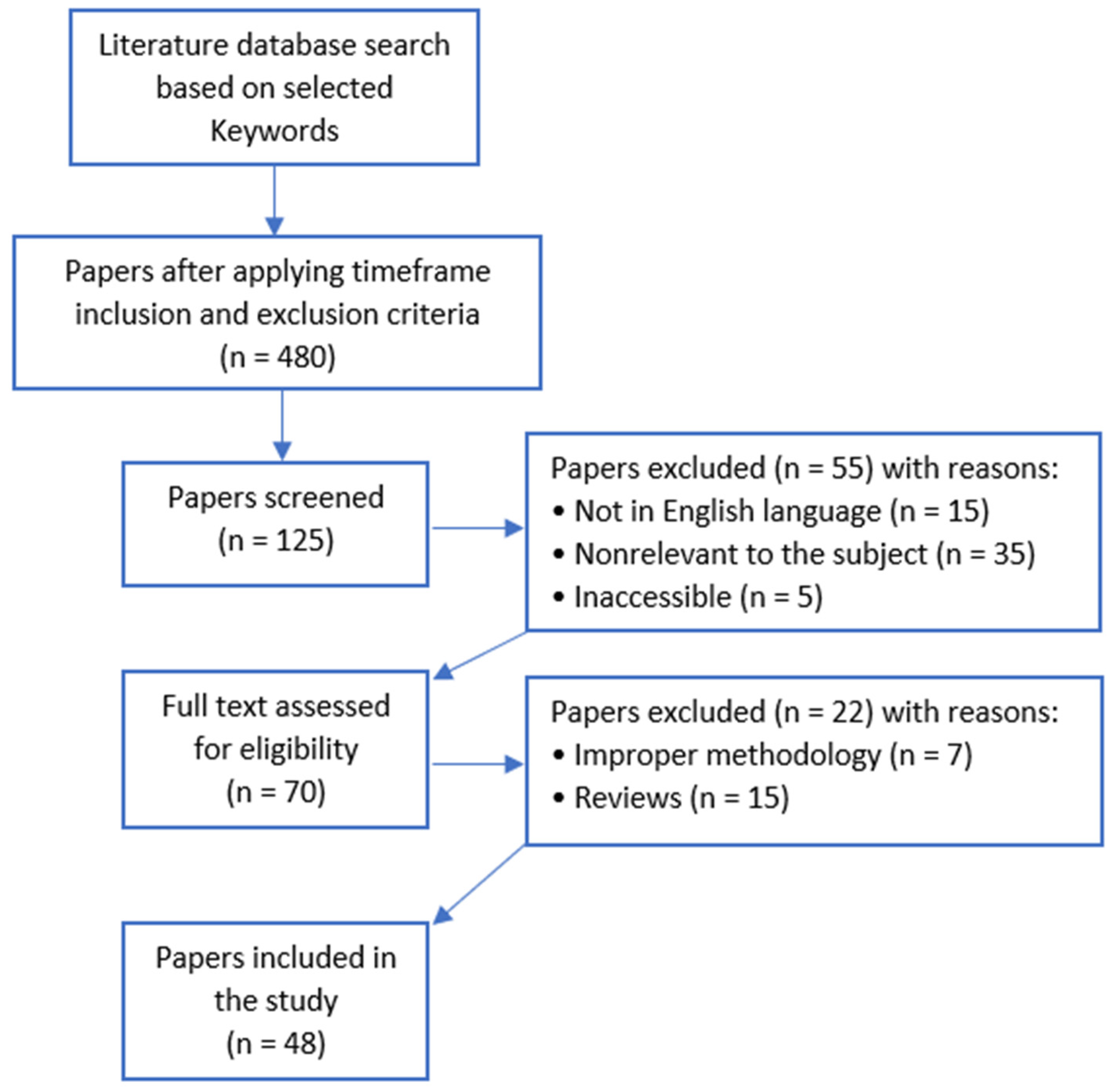

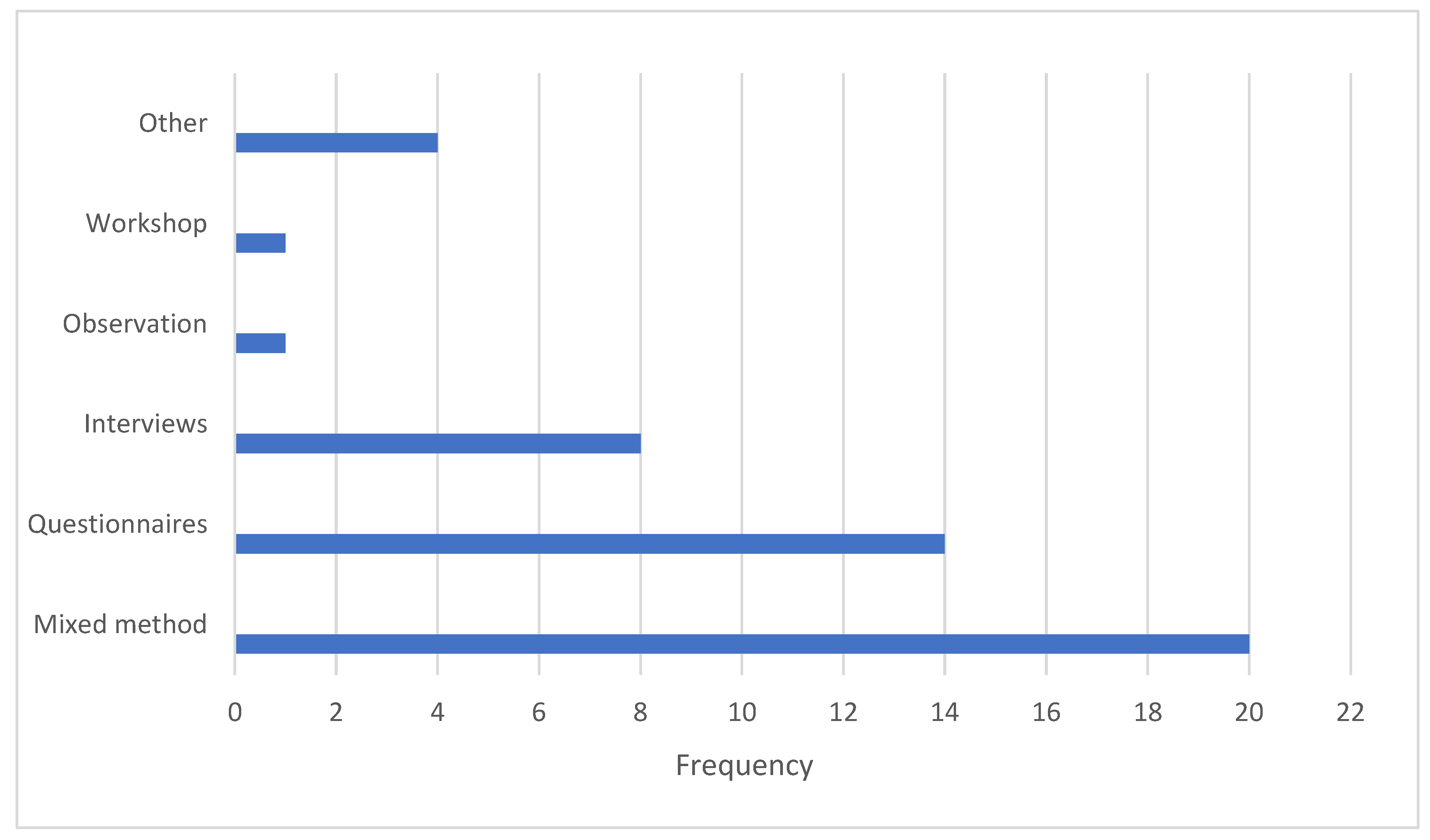

2. Methodology

3. Results and Discussion

3.1. Barriers

| No. | Barriers | Source | PESTLE Category | Freq. | Rank |

|---|---|---|---|---|---|

| B1 | Limited OSC expertise and capabilities within the organisation | [19,20,21,22,24,31,33,34,37,38,39,40,43,44,45,48,49,50,53,54,55,56,57,58,59,60,61,62,63,64,65] | Social | 31 | 1 |

| B2 | Absence of a design codes and national standards for prefabrications | [10,19,20,21,33,37,38,39,42,43,44,45,48,49,50,53,54,55,56,60,61,64,65,66,67,68] | Political/Legal Technical | 26 | 2 |

| B3 | Poor integration and cooperation between value chain stakeholders | [19,32,34,38,39,40,42,43,44,45,48,50,55,56,57,58,59,61,64,65,66,67] | Social Technical | 22 | 3 |

| B4 | Immature regulatory system/insufficient policy constraints | [10,19,20,21,22,33,37,39,40,45,46,47,48,54,56,57,59,61,68,69] | Political/Legal | 21 | 4 |

| B5 | Lack of standardised management practices for OSC in project delivery/complexity in management | [10,21,22,39,41,48,49,53,54,56,60,63,64,65,66,67,70] | Technical | 17 | 5 |

| B6 | Transportation limitations | [10,21,32,39,42,43,54,55,57,59,60,62,63,64,66,70] | Technical | 16 | 6 |

| B7 | Increased project costs | [10,21,22,24,39,43,44,45,48,53,55,56,57,65,70] | Economical | 15 | 7 |

| B8 | Limited government support and financial incentives | [10,20,37,38,44,48,55,56,57,66,68,71,72,73] | Economical Political/Legal | 14 | 8 |

| B9 | Increased capital cost | [10,19,20,24,37,38,39,40,45,48,54,55,56,65] | Economical | 14 | 8 |

| B10 | Limited knowledge and understanding of OSC’s potential advantages | [10,21,22,32,44,45,46,54,56,57,58,65,71,73] | Social | 14 | 8 |

| B11 | Insufficient facilities and supply chain alternatives/restricted manufacturing capacity | [10,19,20,21,33,37,38,43,50,54,56,70,74] | Technical | 13 | 11 |

| B12 | Low-quality/performance of prefabricated components | [10,20,21,31,33,37,38,54,55,56,61,62] | Technical | 12 | 12 |

| B13 | Reluctance to change/conservative and risk-averse mindset | [10,19,21,22,38,39,45,46,54,55,57,63] | Social | 12 | 12 |

| B14 | Site layout limitations | [10,21,24,38,39,54,55,57,59,63,74] | Technical | 11 | 14 |

| B15 | Insufficient equipment and technologies for effective project delivery | [19,31,39,45,48,49,59,61,64,65] | Technical | 10 | 15 |

| B16 | Inadequate promotion in the marketplace | [22,24,45,46,48,53,65,69,71] | Social | 9 | 16 |

| B17 | Limited/uncertainty of market demand | [10,19,21,45,54,56,57,66,74] | Social | 9 | 16 |

| B18 | Limited investment in research and development (R&D) across the sector | [19,45,46,48,53,56,57,71] | Economical | 8 | 18 |

| B19 | Unfavourable building regulations | [10,21,22,43,44,48,54,66] | Political/Legal | 8 | 19 |

| B20 | Limiting for aesthetic and creative or complex design | [10,21,38,43,54,55,56,63] | Technical | 8 | 20 |

| B21 | Lack of design flexibility and adaptability to late-stage changes | [19,38,39,44,55,57,66] | Technical | 7 | 21 |

| B22 | Insufficient information and guidance about OSC | [20,22,37,49,55,57,61] | Technical | 7 | 21 |

| B23 | Lacking the ability to attain economies of scale | [19,33,39,44,48,56,60] | Economical | 7 | 21 |

| B24 | Demand significant coordination and scheduling throughout the construction process | [21,43,54,63,65,67,70] | Technical | 7 | 21 |

| B25 | Absence of certification and accreditation for manufacturing products/methods | [39,42,44,49,57,64] | Political/Legal | 6 | 25 |

| B26 | Narrow range of standard prefabricated components/monotony of structure type | [19,38,39,57,64,75] | Technical Social | 6 | 25 |

| B27 | Uncertainty over quality and performance | [22,38,39,47,57] | Social | 5 | 27 |

| B28 | Prolonged lead times for finalised project planning and design stages | [38,39,55,57,65] | Technical Economical | 5 | 27 |

| B29 | Inadequate/poorly defined business model | [10,21,43,54,56] | Economical | 5 | 27 |

| B30 | Sceptical attitudes and unfavourable perceptions of OSC | [10,38,39,44] | Social | 4 | 30 |

| B31 | High transportation costs | [22,24,44,57] | Economical | 4 | 30 |

| B32 | Restrictive construction tolerances | [38,57,65,66] | Technical | 4 | 30 |

| B33 | Complex interfaces that clash with traditional project process | [10,41,57,65] | Technical | 4 | 30 |

| B34 | Project necessitates bespoke design/Modular design complexity | [41,43,55,63] | Technical | 4 | 30 |

| B35 | Environmental constraints | [31,57,74] | Environmental | 3 | 35 |

| B36 | Demand increased clarity, accuracy, and thorough decision-making during the initial planning phase | [38,43,59] | Technical | 3 | 35 |

| B37 | Unsuitable standard contractual terms | [49,61] | Political/Legal | 2 | 37 |

| B38 | Project condition | [43,70] | Technical Economical | 2 | 37 |

| B39 | Difficulty in securing funding | [66] | Economical | 1 | 39 |

| B40 | Lack or complicated quality assurance and control during project delivery | [64] | Technical | 1 | 39 |

| Total | 377 |

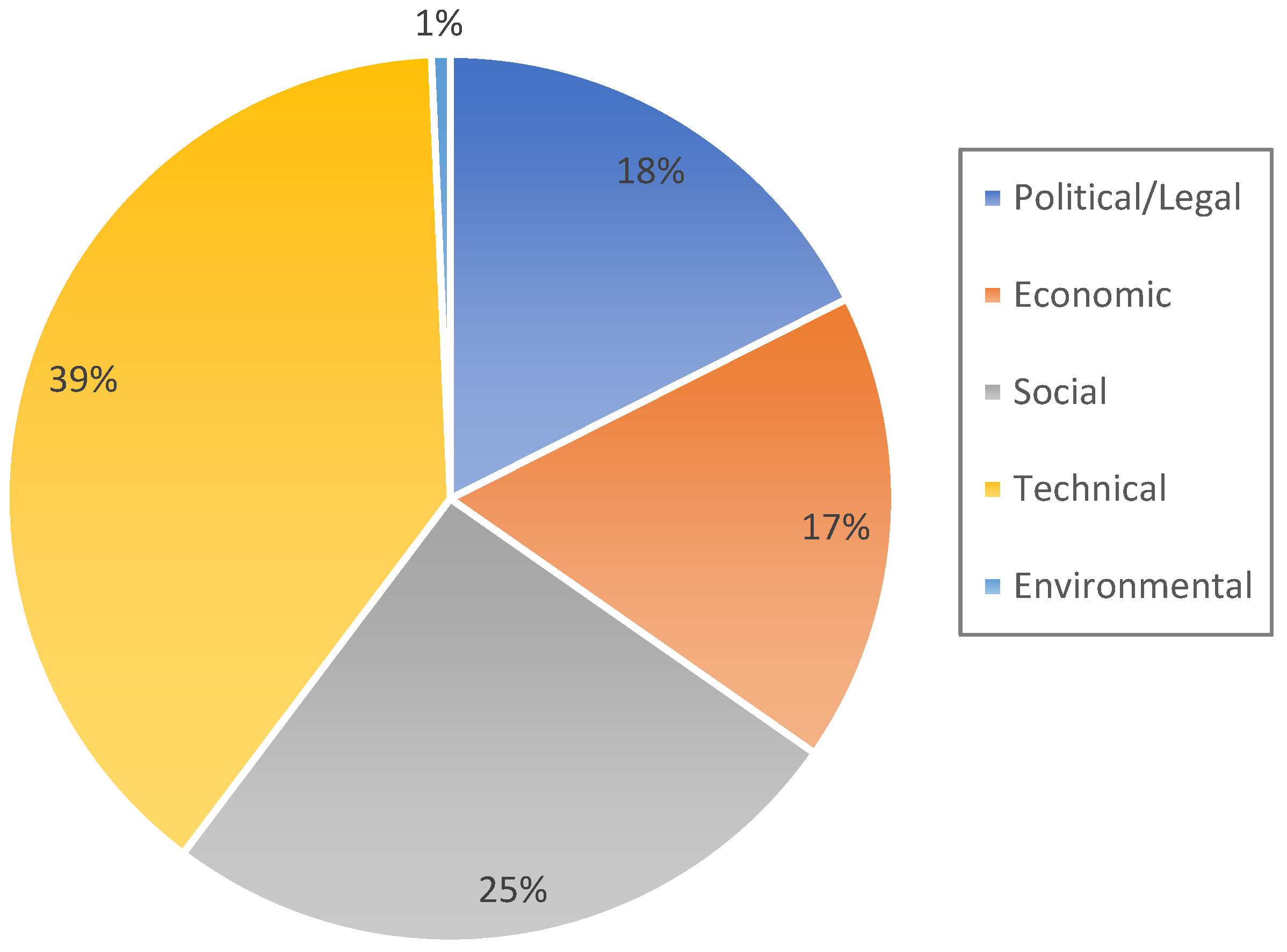

3.2. PESTLE Analysis

3.2.1. Political/Legal Barriers

3.2.2. Economic Barriers

3.2.3. Social Barriers

3.2.4. Technical Barriers

3.2.5. Environmental Barriers

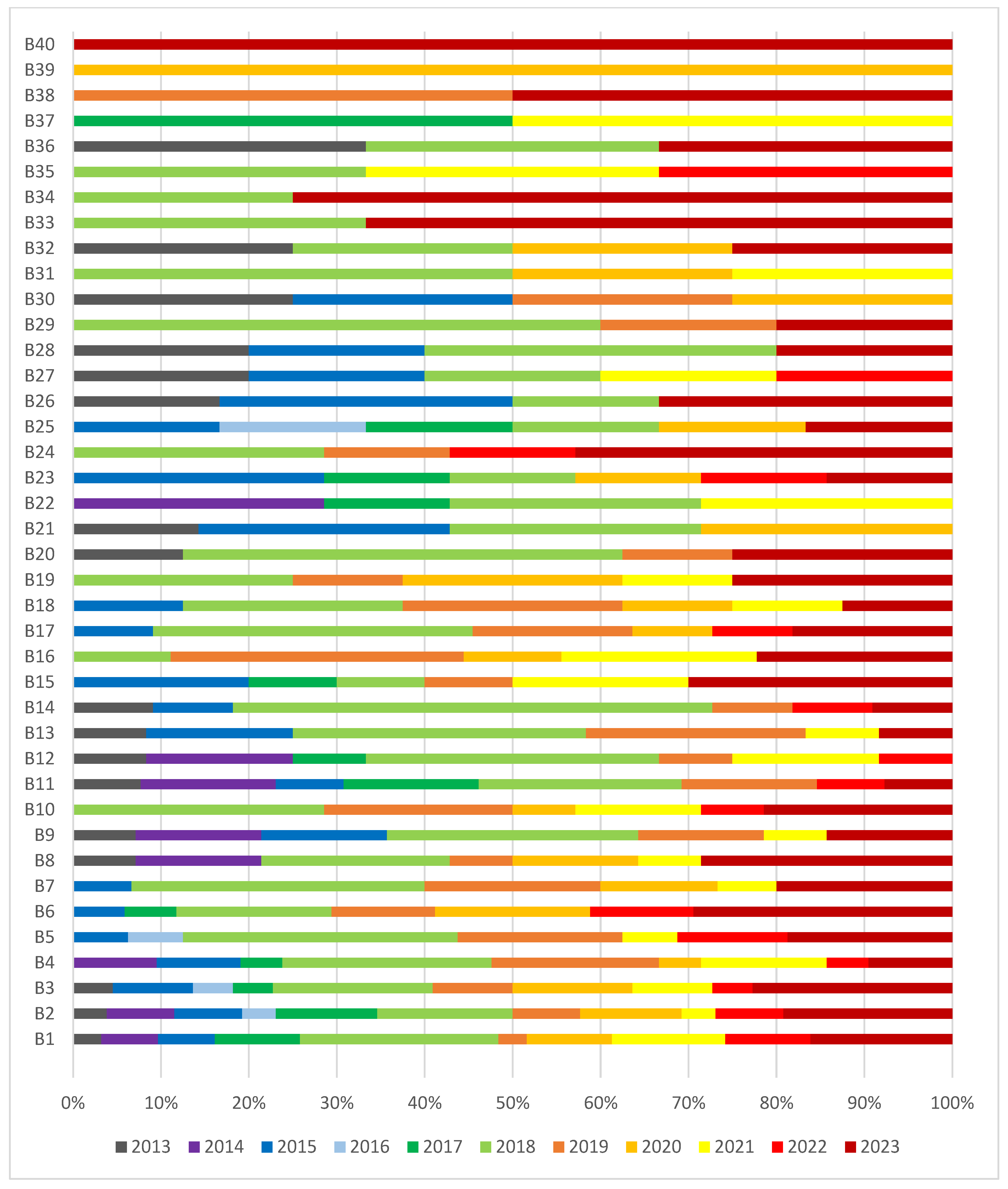

3.3. Analysis of Barriers by Timeframe

4. Conclusions

- Absence of a design code and national standards for prefabrications (political/legal).

- Increased project costs (economic).

- Limited OSC expertise and capabilities within the organisation (social).

- Poor integration and cooperation between value chain stakeholders (technical).

- Environmental constraints (environmental).

5. Policy and Regulatory Recommendations

- Professional training programmes should be made available for construction industry practitioners to strengthen their knowledge and expertise in prefabrication and OSC. Such programmes enable construction enterprises to build the capability needed to successfully transition to OSC. Designers can then deliver smarter and more integrated designs, while consultants gain the confidence to communicate its benefits to clients and recommend OSC, helping to reduce hesitation toward adoption. For contractors, training ensures they are better equipped to apply OSC and manage its logistics effectively. Ultimately, clients and developers can gain a full understanding of the value of OSC, increasing their confidence and making them more likely to demand OSC solutions. Additionally, since OSC technologies have not yet been prioritised in Chinese higher education, it is important to introduce new subjects and update existing curricula in construction-related programmes to incorporate necessary knowledge.

- The establishment of a standardisation system as a foundation element of OSC development. One of the key means of achieving standardisation is to establish comprehensive and mature procedural standards and robust legal frameworks that guide the decisions of construction stakeholders including developers, clients, consultants, designers, contractors, and regulatory bodies throughout the construction process. This supports higher quality, reduces engineering errors, modifications, and maintenance costs, and ultimately optimises material usage while minimising construction waste. Additionally, establishing a modulus-based standard system for OSC enables harmonised fittings and components, ensuring standardised production and interchangeability, efficient installation, economies of scale, and reduced costs.

- Providing financial incentives can largely encourage stakeholders to adopt OSC. Offering tax breaks such as reductions, exemptions, or lower provincial rates, would help ease developers’ tax burden and make OSC more attractive. At the same time, governments can introduce mandatory measures to discourage heavy reliance on traditional construction, such as by imposing higher taxes on enterprises that continue using such methods. Gradually, tax instruments such as energy taxes and carbon taxes could be applied in the OSC market, with rates adjusted according to their environmental impact. Additionally, offering expedited permits and granting pre-sale permits in advance would further support construction enterprises by reducing approval delays, accelerating project timelines, and improving cash flow.

- The establishment of a cost management system and efficient business model for OSC is key to reduce production and project cost. Such a system can improve cost control, enhance efficiency, and ultimately increase the revenue of enterprises, improving the maturity of the market. Additionally, by formulating and monitoring appropriate market prices for prefabricated components, demand can be aligned with the purchasing capacity of different stakeholders. This approach not only stimulates market demand but also fosters healthy competition, encouraging wider adoption of OSC.

- The establishment of an information exchange platform for OSC can greatly enhance communication and collaboration among different stakeholders. Such a platform would allow stakeholders to share experiences and best practices, reduce information asymmetry, and facilitate the development of standardised prefabricated designs. Additionally, it could support the dissemination of cutting-edge knowledge on OSC, helping to accelerate adoption and improve overall industry performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| First Athor, Year, Citation Number | All Studies | Qualitative Studies | Quantitative Non-Randomised | Quantitative Descriptive | Mixed Methods | Score | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | S2 | 1.1 | 1.2 | 1.3 | 1.4 | 1.5 | 3.1 | 3.2 | 3.3 | 3.4 | 3.5 | 4.1 | 4.2 | 4.3 | 4.4 | 4.5 | 5.1 | 5.2 | 5.3 | 5.4 | 5.5 | ||

| Zhai, 2013 [38] | Y | Y | Y | Y | Y | C | Y | 80% | |||||||||||||||

| Rahman, 2014 [20] | Y | Y | Y | Y | Y | Y | Y | 100% | |||||||||||||||

| Zhang, 2014 [37] | Y | Y | Y | Y | Y | Y | Y | 100% | |||||||||||||||

| Luo, 2015 [39] | Y | Y | Y | Y | C | Y | Y | Y | Y | Y | C | Y | Y | Y | Y | N | C | 70% | |||||

| Mao, 2015 [19] | Y | Y | Y | Y | C | Y | Y | Y | N | Y | C | Y | Y | Y | Y | C | Y | 70% | |||||

| Li, 2016 [42] | Y | Y | Y | Y | Y | Y | Y | 100% | |||||||||||||||

| Li, 2017 [33] | Y | Y | Y | Y | Y | Y | Y | Y | C | Y | Y | Y | Y | Y | Y | Y | Y | 90% | |||||

| Gan, 2017 [49] | Y | Y | Y | Y | Y | Y | N | Y | Y | Y | Y | Y | Y | Y | Y | N | Y | 85% | |||||

| Xue, 2017 [50] | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | 100% | |||||

| Hong, 2018 [24] | Y | Y | Y | Y | Y | Y | N | C | Y | Y | Y | Y | Y | Y | Y | Y | Y | 85% | |||||

| Ji, 2018 [59] | Y | Y | Y | Y | Y | Y | C | N | Y | Y | Y | Y | Y | Y | Y | Y | C | 80% | |||||

| Gan, 2018 [54] | Y | Y | Y | Y | Y | Y | Y | 100% | |||||||||||||||

| Gan, 2018 [21] | Y | Y | N | Y | Y | Y | Y | 80% | |||||||||||||||

| Zhang, 2018 [55] | Y | Y | Y | Y | Y | Y | N | Y | Y | Y | Y | Y | Y | Y | Y | N | Y | 85% | |||||

| Jiang, 2018 [56] | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | 100% | |||||

| Han, 2018 [57] | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | 100% | |||||

| Wu, 2019 [45] | Y | Y | Y | Y | Y | Y | Y | 100% | |||||||||||||||

| Gan, 2019 [10] | Y | Y | Y | Y | N | Y | Y | 80% | |||||||||||||||

| Dou, 2019 [46] | Y | Y | Y | Y | Y | Y | Y | 100% | |||||||||||||||

| Dou, 2019 [70] | Y | Y | Y | Y | Y | Y | C | Y | Y | Y | Y | Y | Y | Y | Y | C | Y | 85% | |||||

| Li, 2019 [71] | Y | Y | Y | Y | N | Y | Y | 80% | |||||||||||||||

| Gong, 2019 [32] | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | 100% | |||||

| Li, 2020 [66] | Y | Y | Y | Y | Y | Y | Y | 100% | |||||||||||||||

| Yuan, 2020 [34] | Y | Y | Y | Y | Y | Y | Y | 100% | |||||||||||||||

| Jiang, 2020 [44] | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | 100% | |||||

| Dang, 2020 [53] | Y | Y | Y | Y | Y | C | C | Y | Y | Y | C | Y | Y | Y | Y | Y | C | 70% | |||||

| Wu, 2021 [40] | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | 100% | |||||

| Ji, 2021 [31] | Y | Y | Y | Y | Y | Y | Y | 100% | |||||||||||||||

| Zhang, 2021 [61] | Y | Y | Y | Y | Y | Y | Y | 100% | |||||||||||||||

| Li, 2021 [22] | Y | Y | Y | Y | Y | NA | Y | 80% | |||||||||||||||

| Wang, 2021 [72] | Y | Y | Y | Y | Y | Y | Y | 100% | |||||||||||||||

| Li, 2022 [58] | Y | Y | N | Y | Y | Y | Y | 80% | |||||||||||||||

| Zhang, 2022 [67] | Y | Y | Y | Y | Y | C | C | Y | N | Y | Y | Y | Y | Y | Y | N | C | 65% | |||||

| Luo, 2022 [60] | Y | Y | Y | Y | Y | Y | Y | 100% | |||||||||||||||

| Shang, 2022 [47] | Y | Y | Y | Y | Y | NA | Y | 80% | |||||||||||||||

| Yang, 2022 [62] | Y | Y | Y | Y | Y | NA | Y | 80% | |||||||||||||||

| Lu, 2022 [75] | Y | Y | Y | Y | Y | Y | C | Y | Y | Y | C | Y | Y | Y | Y | N | C | 70% | |||||

| Pan, 2023 [43] | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | 100% | |||||

| Cao, 2023 [69] | Y | Y | Y | Y | Y | Y | Y | 100% | |||||||||||||||

| Sun, 2023 [68] | Y | Y | Y | Y | Y | Y | Y | 100% | |||||||||||||||

| Wang, 2023 [48] | Y | Y | Y | Y | Y | Y | C | C | Y | Y | Y | Y | Y | Y | Y | Y | Y | 85% | |||||

| Zhai, 2023 [76] | Y | Y | Y | Y | Y | Y | Y | 100% | |||||||||||||||

| Dou, 2023 [73] | Y | Y | Y | Y | N | Y | Y | 80% | |||||||||||||||

| Liu, 2023 [74] | Y | Y | C | Y | Y | NA | Y | 60% | |||||||||||||||

| Sing, 2023 [63] | Y | Y | N | Y | Y | Y | Y | 80% | |||||||||||||||

| Zhang, 2023 [64] | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | 100% | |||||

| Chen, 2023 [41] | Y | Y | Y | Y | Y | Y | Y | 100% | |||||||||||||||

| Wuni, 2023 [65] | Y | Y | Y | Y | Y | C | Y | 80% | |||||||||||||||

Appendix B

| Paper Title | Citation Number | Journal | Year | Methodology | Project Type | OSC Term |

|---|---|---|---|---|---|---|

| Factors impeding the offsite production of housing construction in China: an investigation of current practice | [38] | Construction Management and Economics | 2013 | Questionnaire | Housing | Offsite production |

| Barriers of Implementing Modern Methods of Construction | [20] | Journal of management in engineering | 2014 | Questionnaire | General Buildings | MMC |

| Exploring the challenges to industrialised residential building in China | [37] | Habitat International | 2014 | Questionnaire | Housing | IBS |

| Risk factors affecting practitioners’ attitudes toward the implementation of an industrialized building system A case study from China | [39] | Engineering, Construction & Architectural Management | 2015 | Mixed Method | Housing | IBS |

| Major Barriers to Off-Site Construction: The Developer’s Perspective in China | [19] | Journal of Management in Engineering | 2015 | Mixed Method | General Buildings | OSC |

| Schedule risks in prefabrication housing production in Hong Kong: a social network analysis | [42] | Journal of cleaner production | 2016 | Interviews | Housing | Prefabrication |

| Modular and Offsite Construction of Piping: Current Barriers and Route | [33] | Applied Sciences | 2017 | Mixed Method | MEP construction | Prefabrication |

| Critical Factors Affecting the Quality of Industrialized Building System Projects in China | [49] | Sustainability | 2017 | Mixed Method | General Buildings | IBS |

| Factors Affecting the Capital Cost of Prefabrication—A Case Study of China | [50] | Sustainability | 2017 | Mixed Method | General Buildings | Prefabrication |

| Barriers to promoting prefabricated construction in China: A cost benefit analysis | [24] | Journal of Cleaner Production | 2018 | Mixed Method | General Buildings | PC |

| Assessing and Prioritising Delay Factors of Prefabricated Concrete Building Projects in China | [59] | Applied sciences | 2018 | Mixed Method | General Buildings | PC |

| Barriers to the transition towards off-site construction in China: An Interpretive structural modeling approach | [54] | Journal of Cleaner Production | 2018 | Interviews | General Buildings | OSC |

| Overcoming barriers to off-site construction through engaging stakeholders: A two-mode social network analysis | [21] | Journal of Cleaner Production | 2018 | Questionnaire | General Buildings | OSC |

| The hindrance to using prefabrication in Hong Kong’s building industry | [55] | Journal of Cleaner Production | 2018 | Mixed Method | General Buildings | PC/PBs |

| Constraints on the Promotion of Prefabricated Construction in China | [56] | Sustainability | 2018 | Mixed Method | General Buildings | PC |

| Identifying barriers to off-site construction using grey DEMATEL approach: case of China | [57] | Journal of Civil Engineering & Management | 2018 | Mixed Method | General Buildings | OSC |

| Factors influencing the application of prefabricated construction in China: From perspectives of technology promotion and cleaner production | [45] | Journal of Cleaner Production | 2019 | Questionnaire | General Buildings | PC/PBs |

| Exploring the interaction among factors impeding the diffusion of prefabricated building technologies: Fuzzy cognitive maps | [10] | Engineering Construction & Architectural Management | 2019 | Interviews | General Buildings | PC |

| Measuring the Factors that Influence the Diffusion of Prefabricated Construction Technology Innovation | [46] | KSCE Journal of Civil Engineering | 2019 | Questionnaire | General Buildings | PC |

| Factors Influence China’s Off-Site Construction Technology Innovation Diffusion | [70] | Sustainability | 2019 | Mixed Method | General Buildings | OSC |

| ISM-based relationship among critical factors that affect the choice of prefabricated concrete buildings in China | [71] | International Journal of Construction Management | 2019 | Interviews | General Buildings | PBs |

| Modeling Constraints for the On-Site Assembly Process of Prefabrication Housing Production: A Social Network Analysis | [32] | Sustainability | 2019 | Mixed Method | Housing | PHP |

| Research on investment risk influence factors of prefabricated building projects | [66] | Journal of Civil Engineering & Management | 2020 | Questionnaire | General Buildings | PC |

| Research on the Barrier Analysis and Strength Measurement of a Prefabricated Building Design | [34] | Sustainability | 2020 | Observation | Housing | PBs |

| Factors affecting prefabricated construction promotion in China: A structural equation modeling approach | [44] | PLoS ONE | 2020 | Mixed Method | General Buildings | PC |

| Critical Factors Influencing the Sustainable Construction Capability in Prefabrication of Chinese Construction Enterprises | [53] | Sustainability | 2020 | Mixed Method | General Buildings | PC |

| Factors influencing transaction costs of prefabricated housing projects in China: developers’ perspective | [40] | Engineering, Construction & Architectural Management | 2021 | Mixed Method | Housing | PHP |

| Factors Influencing Sleeve Grouting Quality for Prefabricated Building: An Interpretive Structural Modeling Approach | [31] | Advances in Civil Engineering | 2021 | Interviews | General Buildings | PBs |

| Identification of Critical Factors Influencing Prefabricated Construction Quality and Their Mutual Relationship | [61] | Sustainability | 2021 | Workshop | General Buildings | PC |

| Barriers to the development of prefabricated buildings in China: a news coverage analysis | [22] | Engineering, Construction & Architectural Management | 2021 | Other | General Buildings | PBs |

| Analysing factors affecting developers’ behaviour towards the adoption of prefabricated buildings in China | [72] | Environment, Development & Sustainability | 2021 | Questionnaire | General Buildings | PBs |

| Diffusion prediction of prefabricated construction technology under multi-factor coupling | [58] | Building Research & Information | 2022 | Questionnaire | General Buildings | PC |

| Critical Factors Influencing Interface Management of Prefabricated Building Projects: Evidence from China | [67] | Sustainability | 2022 | Mixed Method | General Buildings | PBs |

| Fuzzy Cognitive Map-Enabled Approach for Investigating the Relationship between Influencing Factors and Prefabricated Building Cost Considering Dynamic Interactions | [60] | Journal of Construction Engineering & Management | 2022 | Questionnaire | General Buildings | PBs |

| The Efficiency of the Chinese Prefabricated Building Industry and Its Influencing Factors: An Empirical Study | [47] | Sustainability | 2022 | Other | General Buildings | PBs |

| Network Model Analysis of Quality Control Factors of Prefabricated Buildings Based on the Complex Network Theory | [62] | Buildings | 2022 | Other | General Buildings | PBs |

| Influencing Factors Analysis of Supply Chain Resilience of Prefabricated Buildings Based on PF-DEMATEL-ISM | [75] | Buildings | 2022 | Mixed Method | General Buildings | PBs |

| Implementing modular integrated construction in high-rise high-density cities: perspectives in Hong Kong | [43] | Building Research & Information | 2023 | Mixed Method | General Buildings | MIC |

| Evaluating risk in prefabricated building construction under EPC contracting using structural equation modeling: a case study of Shaanxi Province, China | [69] | Buildings | 2023 | Questionnaire | General Buildings | PBs |

| Research on the Restrictive Factors of Vigorous Promotion of Prefabricated Buildings in Yancheng under the Background of “Double Carbon” | [68] | Sustainability | 2023 | Questionnaire | General Buildings | PBs |

| Research on the Barriers and Strategies to Promote Prefabricated Buildings in China | [48] | Buildings | 2023 | Mixed Method | General Buildings | PBs |

| Design for Assembly (DFA) Evaluation Method for Prefabricated Buildings | [76] | Buildings | 2023 | Interviews | General Buildings | PBs |

| Development strategy for prefabricated construction projects: a tripartite evolutionary game based on prospect theory | [73] | Engineering, Construction & Architectural Management | 2023 | Interviews | General Buildings | PC |

| Research on the tripartite evolution strategy of prefabricated building promotion based on the deepening of demand-side interests | [74] | PLoS ONE | 2023 | Other | General Buildings | PBs |

| Developing an analytic hierarchy process-based decision model for modular construction in urban areas | [63] | Journal of Engineering, Design & Technology | 2023 | Questionnaire | General Buildings | MIC |

| Analysis of Factors Affecting Prefabricated Building Quality Based on ISM-BN | [64] | Sustainability | 2023 | Mixed Method | General Buildings | PBs |

| Factors influencing construction time performance of prefabricated house building: A multi-case study | [41] | Habitat International | 2023 | Interviews | Housing | PBs |

| Exploring the challenges of implementing design for excellence in industrialized construction projects in China | [65] | Building Research & Information | 2023 | Questionnaire | General Buildings | Industrialised construction |

References

- United Nations Environment Programme. 2022 Global Status Report for Buildings and Construction: Towards a Zero Emission, Efficient and Resilient Buildings and Construction Sector; United Nations Environment Programme: Nairobi, Kenya, 2022. [Google Scholar]

- Chang, R.D.; Zuo, J.; Zhao, Z.Y.; Soebarto, V.; Lu, Y.; Zillante, G.; Gan, X.L. Sustainability attitude and performance of construction enterprises: A China study. J. Clean. Prod. 2018, 172, 1440–1451. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhao, D.; Wang, D.; Xing, Y. Sustainable performance of buildings through modular prefabrication in the construction phase: A comparative study. Sustainability 2019, 11, 5658. [Google Scholar] [CrossRef]

- Nadim, W. Modern Methods of Construction. In Construction Innovation and Process Improvement; Akintoye, A., Goulding, J.S., Zawdie, G., Eds.; Wiley-Blackwell: Hoboken, NJ, USA, 2012; pp. 209–233. [Google Scholar]

- Goodier, C.; Gibb, A. Future opportunities for offsite in the UK. Constr. Manag. Econ. 2007, 25, 585–595. [Google Scholar] [CrossRef]

- Zhou, J.; Li, Y.; Ren, D. Quantitative study on external benefits of prefabricated buildings: From perspectives of economy, environment, and society. Sustain. Cities Soc. 2022, 86, 104132. [Google Scholar] [CrossRef]

- Tsz Wai, C.; Wai Yi, P.; Ibrahim Olanrewaju, O.; Abdelmageed, S.; Hussein, M.; Tariq, S.; Zayed, T. A critical analysis of benefits and challenges of implementing modular integrated construction. Int. J. Constr. Manag. 2023, 23, 656–668. [Google Scholar] [CrossRef]

- Autodesk. Three Examples of Modular and Prefab Hospitals Constructed to Fight COVID-19. Autodesk. Available online: https://www.autodesk.com/design-make/articles/modular-hospitals (accessed on 15 October 2024).

- Jiang, R.; Mao, C.; Hou, L.; Wu, C.; Tan, J. A SWOT analysis for promoting off-site construction under the backdrop of China’s new urbanisation. J. Clean. Prod. 2018, 173, 225–234. [Google Scholar] [CrossRef]

- Gan, X.L.; Chang, R.D.; Langston, C.; Wen, T. Exploring the interactions among factors impeding the diffusion of prefabricated building technologies: Fuzzy cognitive maps. Eng. Constr. Archit. Manag. 2019, 26, 535–553. [Google Scholar] [CrossRef]

- Du, H.; Han, Q.; Sun, J.; Wang, C.C. Adoptions of prefabrication in residential sector in China: Agent-based policy option exploration. Eng. Constr. Archit. Manag. 2023, 30, 1697–1725. [Google Scholar] [CrossRef]

- Su, Y.; Xue, H.; Han, R.; Zhang, S.; Sun, Z.; Song, Y. Policies of improving developers’ willingness to implement prefabricated building: A case study from China. J. Civ. Eng. Manag. 2023, 29, 289–302. [Google Scholar] [CrossRef]

- Shanghai Municipal Housing Administration, Municipal Development and Reform Commission, Municipal Administration of Planning, Land and Resources, and Municipal Finance Bureau. Opinions on the Implementation of the Prefabricated Building 2014901. 2014. Available online: http://www.shjx.org.cn/article-6597.aspx (accessed on 15 October 2024).

- Han, Y.; Wang, L.; Kang, R. Influence of consumer preference and government subsidy on prefabricated building developer’s decision-making: A three-stage game model. J. Civ. Eng. Manag. 2023, 29, 35–49. [Google Scholar] [CrossRef]

- The People’s Republic of China. The 14th Five-Year Plan (2021–2025) for National Economic and Social Development and Vision 2035 of the People’s Republic of China; Xinhua News Agency: Beijing, China, 2021.

- Han, Y.; Fang, X.; Zhao, X.; Wang, L. Exploring the impact of incentive policy on the development of prefabricated buildings: A scenario-based system dynamics model. Eng. Constr. Archit. Manag. 2023, 31, 4697–4725. [Google Scholar] [CrossRef]

- Dou, Y.; Xue, X.; Wang, Y.; Luo, X.; Shang, S. New media data-driven measurement for the development level of prefabricated construction in China. J. Clean. Prod. 2019, 241, 118353. [Google Scholar] [CrossRef]

- Alhawamdeh, M.; Lee, A. A systematic review and meta-synthesis of the barriers of offsite construction projects. Int. J. Constr. Manag. 2024, 25, 1087–1099. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.; Pan, W.; Ye, K. Major barriers to off-site construction: The developer’s perspective in China. J. Manag. Eng. 2015, 31, 04014043. [Google Scholar] [CrossRef]

- Rahman, M.M. Barriers of implementing modern methods of construction. J. Manag. Eng. 2014, 30, 69–77. [Google Scholar] [CrossRef]

- Gan, X.; Chang, R.; Wen, T. Overcoming barriers to off-site construction through engaging stakeholders: A two-mode social network analysis. J. Clean. Prod. 2018, 201, 735–747. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, S.; Meng, Q.; Hu, X. Barriers to the development of prefabricated buildings in China: A news coverage analysis. Eng. Constr. Archit. Manag. 2021, 28, 2884–2903. [Google Scholar] [CrossRef]

- U.S. Department of Housing and Urban Development. Offsite Construction for Housing: Research Roadmap; U.S. Department of Housing and Urban Development: Washington, DC, USA, 2023; p. 83.

- Hong, J.; Shen, G.Q.; Li, Z.; Zhang, B.; Zhang, W. Barriers to promoting prefabricated construction in China: A cost–benefit analysis. J. Clean. Prod. 2018, 172, 649–660. [Google Scholar] [CrossRef]

- Xie, F.; Fu, X.; Huang, R. Promoting the application of off-site construction in China’s residential building industry from the angle of ecosystem. Systems 2023, 11, 140. [Google Scholar] [CrossRef]

- Chang, W.; Hong-Jun, G.; Lyu-Shui, Z.; Hai-Lin, Y. China’s urban minerals policies: Evolution, problems and countermeasures—A quantitative research. J. Clean. Prod. 2018, 197, 114–123. [Google Scholar] [CrossRef]

- Chang, Y.; Li, X.; Masanet, E.; Zhang, L.; Huang, Z.; Ries, R. Unlocking the green opportunity for prefabricated buildings and construction in China. Resour. Conserv. Recycl. 2018, 139, 259–261. [Google Scholar] [CrossRef]

- Levy, Y.; Ellis, T.J. A systems approach to conduct an effective literature review in support of information systems research. Informing Sci. 2006, 9, 181–212. [Google Scholar] [CrossRef] [PubMed]

- Peters, M.D.J.; Godfrey, C.M.; Khalil, H.; McInerney, P.; Parker, D.; Soares, C.B. Guidance for conducting systematic scoping reviews. JBI Evid. Implement. 2015, 13, 141–146. [Google Scholar] [CrossRef] [PubMed]

- Singh, V.K.; Singh, P.; Karmakar, M.; Leta, J.; Mayr, P. The journal coverage of Web of Science, Scopus and Dimensions: A comparative analysis. Scientometrics 2021, 126, 5113–5142. [Google Scholar] [CrossRef]

- Ji, Y.; Zhao, Z.; Yao, F.; Li, H.X.; Li, Y.; Du, X. Factors influencing sleeve grouting quality for prefabricated building: An interpretive structural modeling approach. Adv. Civ. Eng. 2021, 2021, 5598424. [Google Scholar] [CrossRef]

- Gong, P.; Teng, Y.; Li, X.; Luo, L. Modeling constraints for the on-site assembly process of prefabrication housing production: A social network analysis. Sustainability 2019, 11, 1387. [Google Scholar] [CrossRef]

- Li, X.; Li, Z.; Wu, G. Modular and offsite construction of piping: Current barriers and route. Appl. Sci. 2017, 7, 547. [Google Scholar] [CrossRef]

- Yuan, Z.; Ni, G.; Wang, L.; Qiao, Y.; Sun, C.; Xu, N.; Wang, W. Research on the barrier analysis and strength measurement of a prefabricated building design. Sustainability 2020, 12, 2994. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Critical success factors for modular integrated construction projects: A review. Build. Res. Inf. 2020, 48, 763–784. [Google Scholar] [CrossRef]

- Hansen, S. Characterizing interview-based studies in construction management research: Analysis of empirical literature evidences. In Proceedings of the International Conference on Innovations in Social Sciences Education and Engineering (ICOISSEE), Bandung, Indonesia, 7 August 2021; pp. 1–12. [Google Scholar]

- Zhang, X.; Skitmore, M.; Peng, Y. Exploring the challenges to industrialized residential building in China. Habitat Int. 2014, 41, 176–184. [Google Scholar] [CrossRef]

- Zhai, X.; Reed, R.; Mills, A. Factors impeding the offsite production of housing construction in China: An investigation of current practice. Constr. Manag. Econ. 2014, 32, 40–52. [Google Scholar] [CrossRef]

- Luo, L.Z.; Mao, C.; Shen, L.Y.; Li, Z.D. Risk factors affecting practitioners’ attitudes toward the implementation of an industrialized building system: A case study from China. Eng. Constr. Archit. Manag. 2015, 22, 622–643. [Google Scholar] [CrossRef]

- Wu, H.; Qian, Q.K.; Straub, A.; Visscher, H.J. Factors influencing transaction costs of prefabricated housing projects in China: Developers’ perspective. Eng. Constr. Archit. Manag. 2022, 29, 476–501. [Google Scholar] [CrossRef]

- Chen, Y.; Zhu, D.; Tian, Z.; Guo, Q. Factors influencing construction time performance of prefabricated house building: A multi-case study. Habitat Int. 2023, 131, 102731. [Google Scholar] [CrossRef]

- Li, C.Z.; Hong, J.; Xue, F.; Shen, G.Q.; Xu, X.; Mok, M.K. Schedule risks in prefabrication housing production in Hong Kong: A social network analysis. J. Clean. Prod. 2016, 134, 482–494. [Google Scholar] [CrossRef]

- Pan, W.; Yang, Y.; Pan, M. Implementing modular integrated construction in high-rise high-density cities: Perspectives in Hong Kong. Build. Res. Inf. 2023, 51, 354–368. [Google Scholar] [CrossRef]

- Jiang, W.; Huang, Z.; Peng, Y.; Fang, Y.; Cao, Y. Factors affecting prefabricated construction promotion in China: A structural equation modeling approach. PLoS ONE 2020, 15, e0227787. [Google Scholar] [CrossRef]

- Wu, G.; Yang, R.; Li, L.; Bi, X.; Liu, B.; Li, S.; Zhou, S. Factors influencing the application of prefabricated construction in China: From perspectives of technology promotion and cleaner production. J. Clean. Prod. 2019, 219, 753–762. [Google Scholar] [CrossRef]

- Dou, Y.; Xue, X.; Zhao, Z.; Jiang, Y. Measuring the factors that influence the diffusion of prefabricated construction technology innovation. KSCE J. Civ. Eng. 2019, 23, 3737–3752. [Google Scholar] [CrossRef]

- Shang, Z.; Wang, F.; Yang, X. The efficiency of the Chinese prefabricated building industry and its influencing factors: An empirical study. Sustainability 2022, 14, 10695. [Google Scholar] [CrossRef]

- Wang, Q.; Shen, C.; Guo, Z.; Zhu, K.; Zhang, J.; Huang, M. Research on the barriers and strategies to promote prefabricated buildings in China. Buildings 2023, 13, 1200. [Google Scholar] [CrossRef]

- Gan, Y.; Shen, L.; Chen, J.; Tam, V.W.Y.; Tan, Y.; Illankoon, I.M.C.S. Critical factors affecting the quality of industrialized building system projects in China. Sustainability 2017, 9, 216. [Google Scholar] [CrossRef]

- Xue, H.; Zhang, S.; Su, Y.; Wu, Z. Factors affecting the capital cost of prefabrication—A case study of China. Sustainability 2017, 9, 1512. [Google Scholar] [CrossRef]

- Aguilar, F.J. Scanning the Business Environment. Available online: https://lccn.loc.gov/67011688 (accessed on 7 December 2024).

- Alhawamdeh, M.; Lee, A. A behavioral framework for construction waste minimization: The case of Jordan. Int. J. Environ. Sustain. 2021, 17, 9. [Google Scholar] [CrossRef]

- Dang, P.; Niu, Z.; Gao, S.; Hou, L.; Zhang, G. Critical factors influencing the sustainable construction capability in prefabrication of Chinese construction enterprises. Sustainability 2020, 12, 8996. [Google Scholar] [CrossRef]

- Gan, X.; Chang, R.; Zuo, J.; Wen, T.; Zillante, G. Barriers to the transition towards off-site construction in China: An Interpretive structural modeling approach. J. Clean. Prod. 2018, 197, 8–18. [Google Scholar] [CrossRef]

- Zhang, W.; Lee, M.W.; Jaillon, L.; Poon, C.S. The hindrance to using prefabrication in Hong Kong’s building industry. J. Clean. Prod. 2018, 204, 70–81. [Google Scholar] [CrossRef]

- Jiang, L.; Li, Z.; Li, L.; Gao, Y. Constraints on the promotion of prefabricated construction in China. Sustainability 2018, 10, 2516. [Google Scholar] [CrossRef]

- Han, Y.; Wang, L. Identifying barriers to off-site construction using grey DEMATEL approach: Case of China. J. Civ. Eng. Manag. 2018, 24, 364–377. [Google Scholar] [CrossRef]

- Li, T.; Li, Z.; Dou, Y. Diffusion prediction of prefabricated construction technology under multi-factor coupling. Build. Res. Inf. 2023, 51, 333–353. [Google Scholar] [CrossRef]

- Ji, Y.; Qi, L.; Liu, Y.; Liu, X.; Li, H.X.; Li, Y. Assessing and prioritising delay factors of prefabricated concrete building projects in China. Appl. Sci. 2018, 8, 2324. [Google Scholar] [CrossRef]

- Luo, L.; Wu, X.; Hong, J.; Wu, G. Fuzzy cognitive map-enabled approach for investigating the relationship between influencing factors and prefabricated building cost considering dynamic interactions. J. Constr. Eng. Manag. 2022, 148, 04022081. [Google Scholar] [CrossRef]

- Zhang, K.; Tsai, J.S. Identification of critical factors influencing prefabricated construction quality and their mutual relationship. Sustainability 2021, 13, 11081. [Google Scholar] [CrossRef]

- Yang, S.; Hou, Z.; Chen, H. Network model analysis of quality control factors of prefabricated buildings based on the complex network theory. Buildings 2022, 12, 1874. [Google Scholar] [CrossRef]

- Sing, M.; Chan, J.; Liu, H.; Ngai, N.N. Developing an analytic hierarchy process-based decision model for modular construction in urban areas. J. Eng. Des. Technol. 2023, 21, 1212–1229. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, M.; Zhao, L.; Chen, M. Analysis of factors affecting prefabricated building quality based on ISM-BN. Sustainability 2023, 15, 9682. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Wu, Z.; Shen, G.Q. Exploring the challenges of implementing design for excellence in industrialized construction projects in China. Build. Res. Inf. 2023, 51, 301–315. [Google Scholar] [CrossRef]

- Li, X.J. Research on investment risk influence factors of prefabricated building projects. J. Civ. Eng. Manag. 2020, 26, 599–613. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Z.; Ma, S.; Li, L.; Yuan, M. Critical factors influencing interface management of prefabricated building projects: Evidence from China. Sustainability 2022, 14, 5418. [Google Scholar] [CrossRef]

- Sun, H.; Fang, Y.; Yin, M.; Shi, F. Research on the restrictive factors of vigorous promotion of prefabricated buildings in Yancheng under the background of “Double Carbon”. Sustainability 2023, 15, 1737. [Google Scholar] [CrossRef]

- Cao, P.; Lei, X. Evaluating risk in prefabricated building construction under EPC contracting using structural equation modeling: A case study of Shaanxi Province, China. Buildings 2023, 13, 1465. [Google Scholar] [CrossRef]

- Dou, Y.; Xue, X.; Zhao, Z.; Luo, X. Factors influence China’s off-site construction technology innovation diffusion. Sustainability 2019, 11, 1849. [Google Scholar] [CrossRef]

- Li, D.; Li, X.; Feng, H.; Wang, Y.; Fan, S. ISM-based relationship among critical factors that affect the choice of prefabricated concrete buildings in China. Int. J. Constr. Manag. 2022, 22, 977–992. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, F.; Sang, P.; Song, H. Analysing factors affecting developers’ behaviour towards the adoption of prefabricated buildings in China. Environ. Dev. Sustain. 2021, 23, 14245–14263. [Google Scholar] [CrossRef]

- Dou, Y.; Sun, X.; Ji, A.; Wang, Y.; Xue, X. Development strategy for prefabricated construction projects: A tripartite evolutionary game based on prospect theory. Eng. Constr. Archit. Manag. 2023, 30, 105–124. [Google Scholar] [CrossRef]

- Liu, M.; Chen, Y. Research on the tripartite evolution strategy of prefabricated building promotion based on the deepening of demand-side interests. PLoS ONE 2023, 18, e0290299. [Google Scholar] [CrossRef] [PubMed]

- Lu, J.; Wang, J.; Song, Y.; Yuan, C.; He, J.; Chen, Z. Influencing factors analysis of supply chain resilience of prefabricated buildings based on PF-DEMATEL-ISM. Buildings 2022, 12, 1595. [Google Scholar] [CrossRef]

- Zhai, Y.; Sun, Y.; Li, Y.; Tang, S. Design for Assembly (DFA) Evaluation Method for Prefabricated Buildings. Buildings 2023, 13, 2692. [Google Scholar] [CrossRef]

- Mao, C.; Xie, F.; Hou, L.; Wu, P.; Wang, J.; Wang, X. Cost analysis for sustainable off-site construction based on a multiple-case study in China. Habitat Int. 2016, 57, 215–222. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alhawamdeh, M.; Lee, A. Towards Sustainable Construction in China: A Systematic Review of Barriers to Offsite Methods. Buildings 2025, 15, 3299. https://doi.org/10.3390/buildings15183299

Alhawamdeh M, Lee A. Towards Sustainable Construction in China: A Systematic Review of Barriers to Offsite Methods. Buildings. 2025; 15(18):3299. https://doi.org/10.3390/buildings15183299

Chicago/Turabian StyleAlhawamdeh, Mahmoud, and Angela Lee. 2025. "Towards Sustainable Construction in China: A Systematic Review of Barriers to Offsite Methods" Buildings 15, no. 18: 3299. https://doi.org/10.3390/buildings15183299

APA StyleAlhawamdeh, M., & Lee, A. (2025). Towards Sustainable Construction in China: A Systematic Review of Barriers to Offsite Methods. Buildings, 15(18), 3299. https://doi.org/10.3390/buildings15183299