Experimental and Finite Element Investigation of Bond Strength of Earthen Mortar–Brick Interfaces in Historic Masonry Structures

Abstract

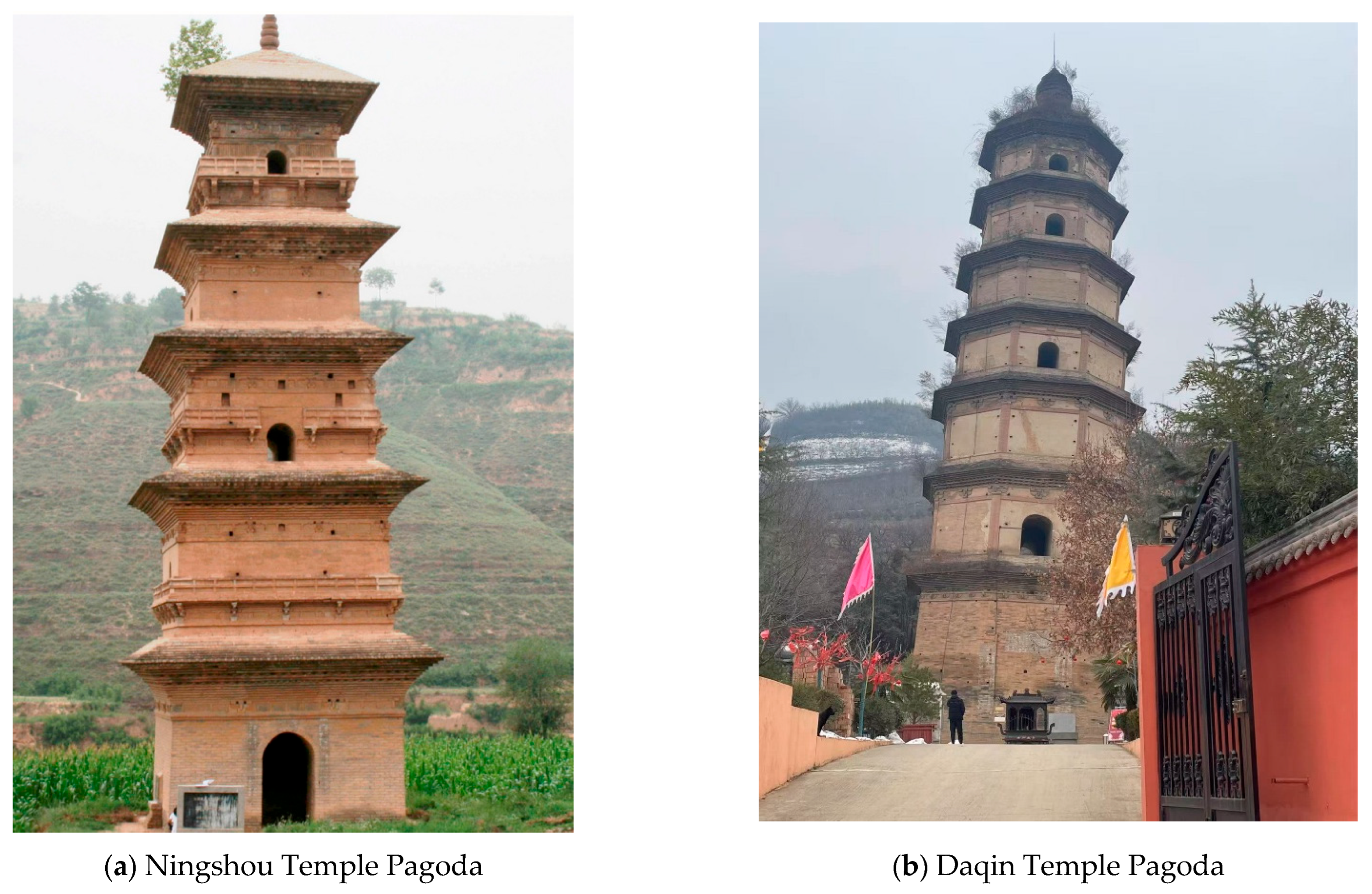

1. Introduction

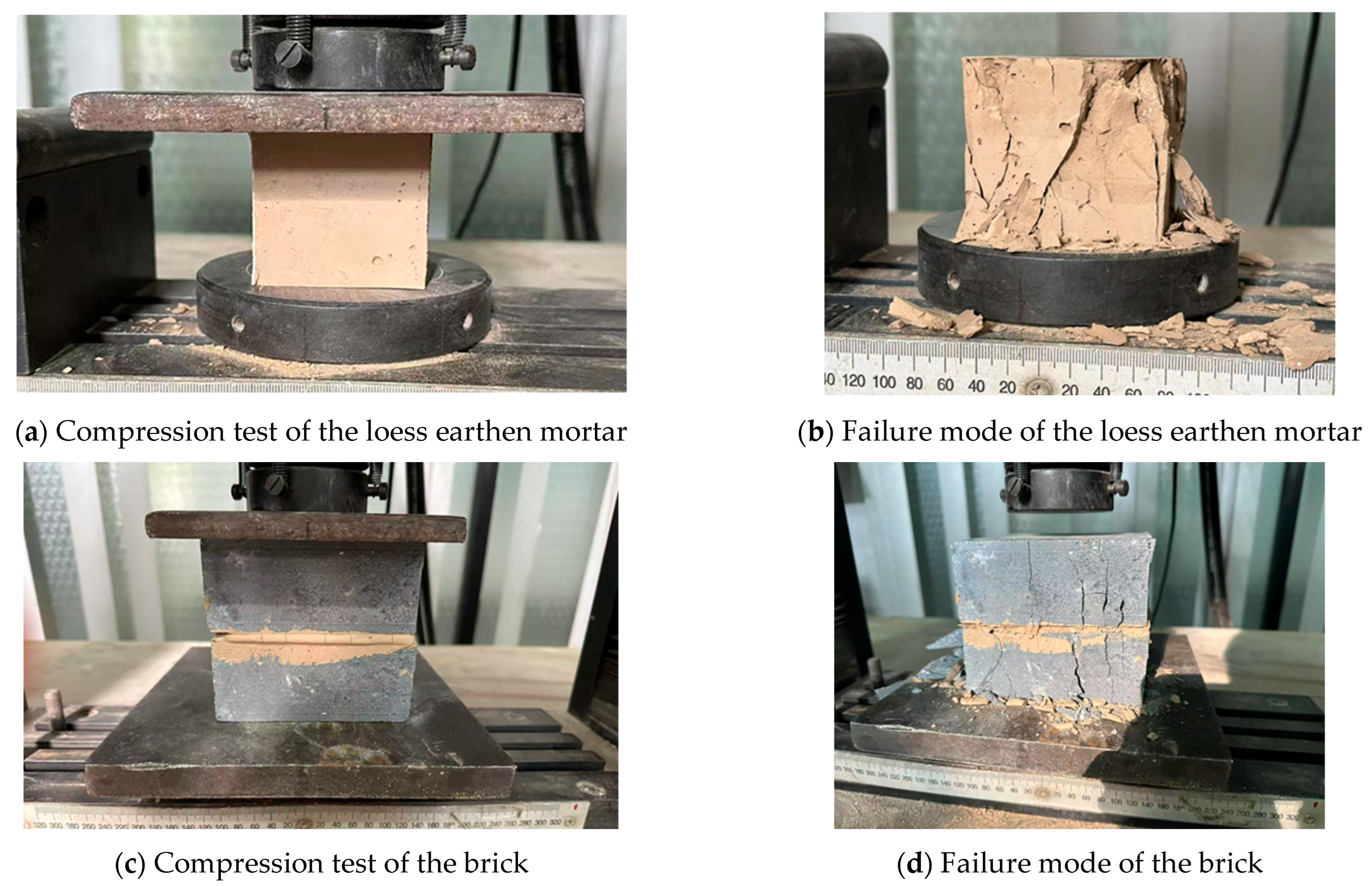

2. Material Test

2.1. Test of Loess Earthen Mortar

2.2. Test of Traditional Blue-Gray Fired Brick

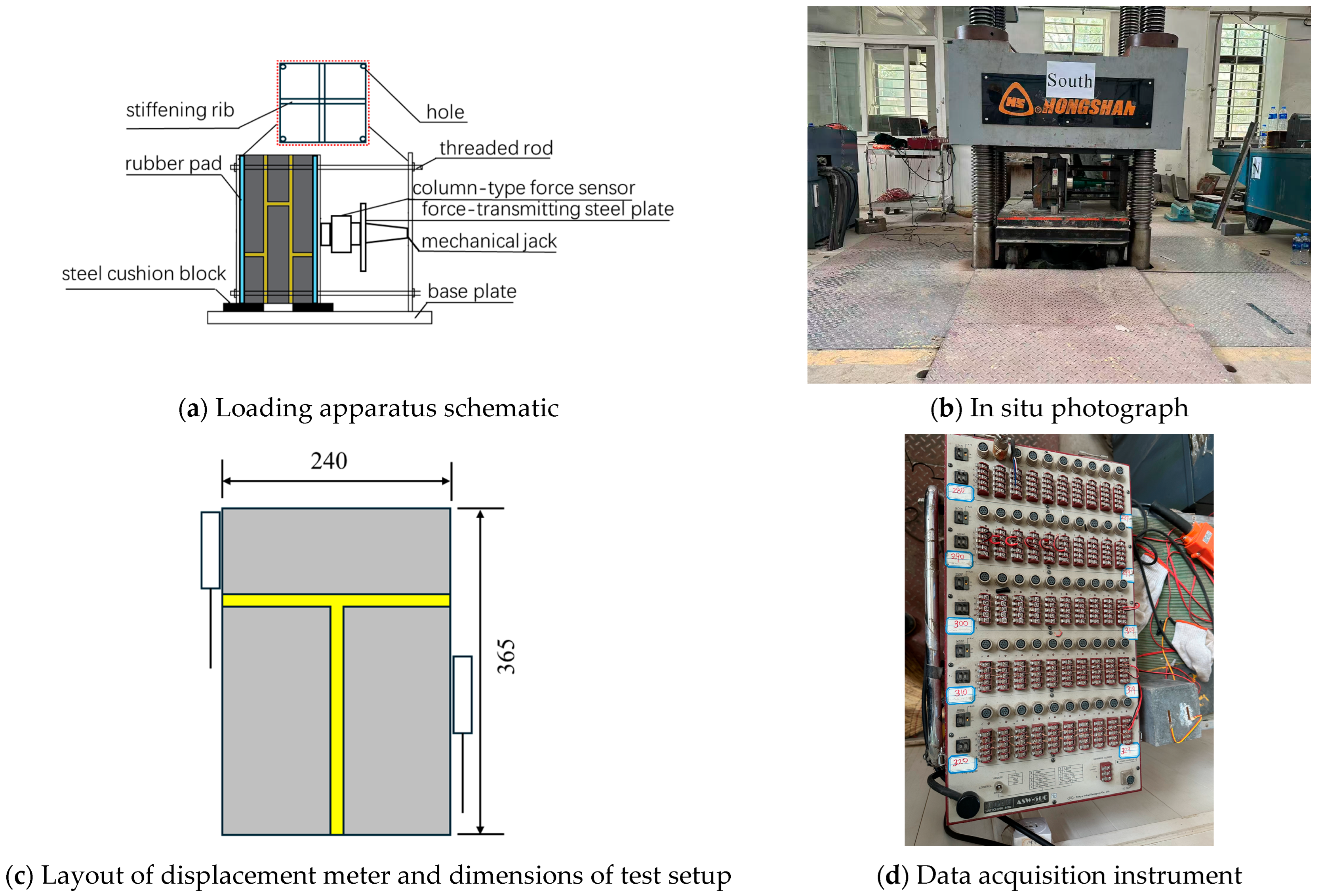

3. Experimental Test

3.1. Specimen Configuration and Fabrication

3.2. Loading Protocol and Instrumentation

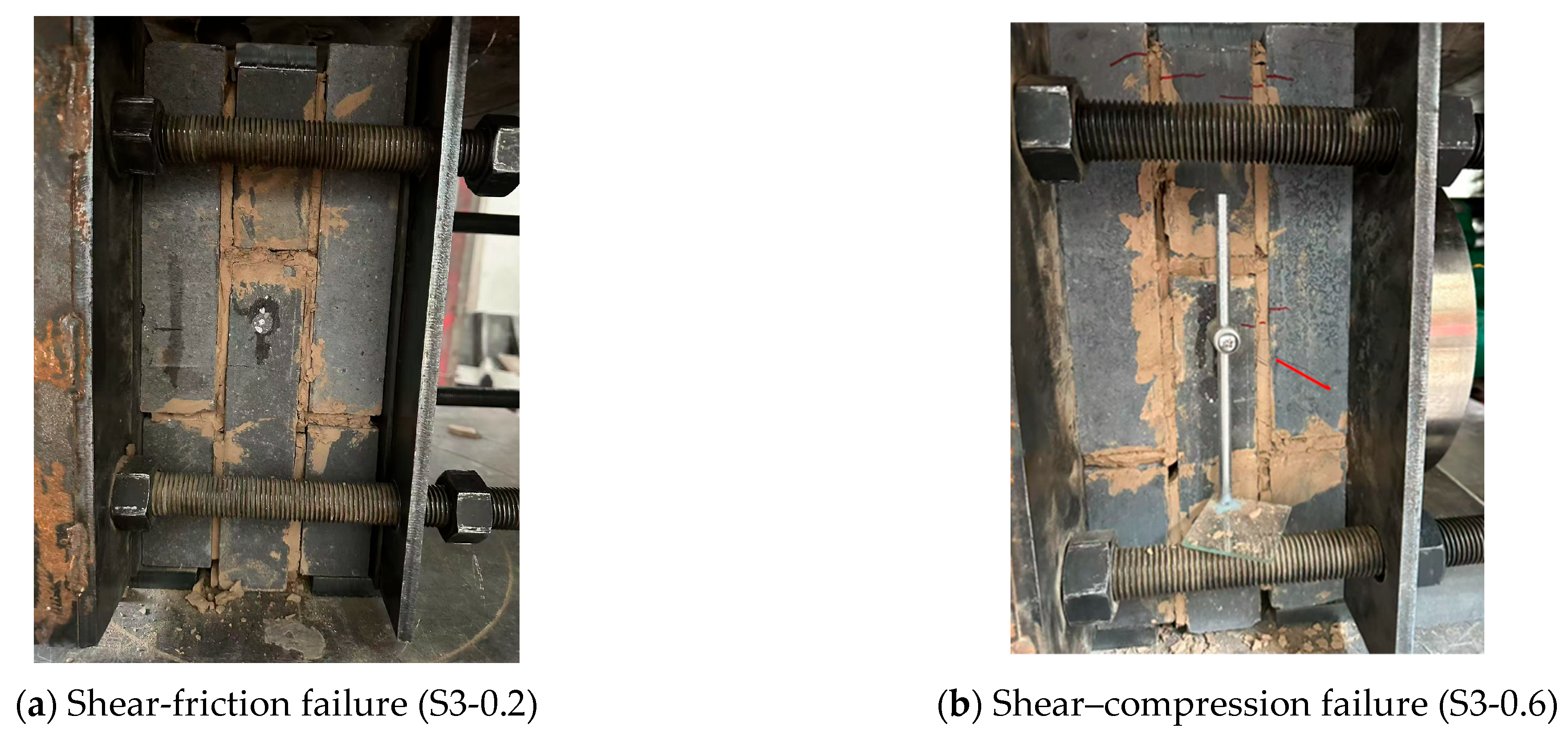

4. Test Results and Analysis

4.1. Observed Failure Modes and Mechanisms

4.2. Interfacial Shear Strength

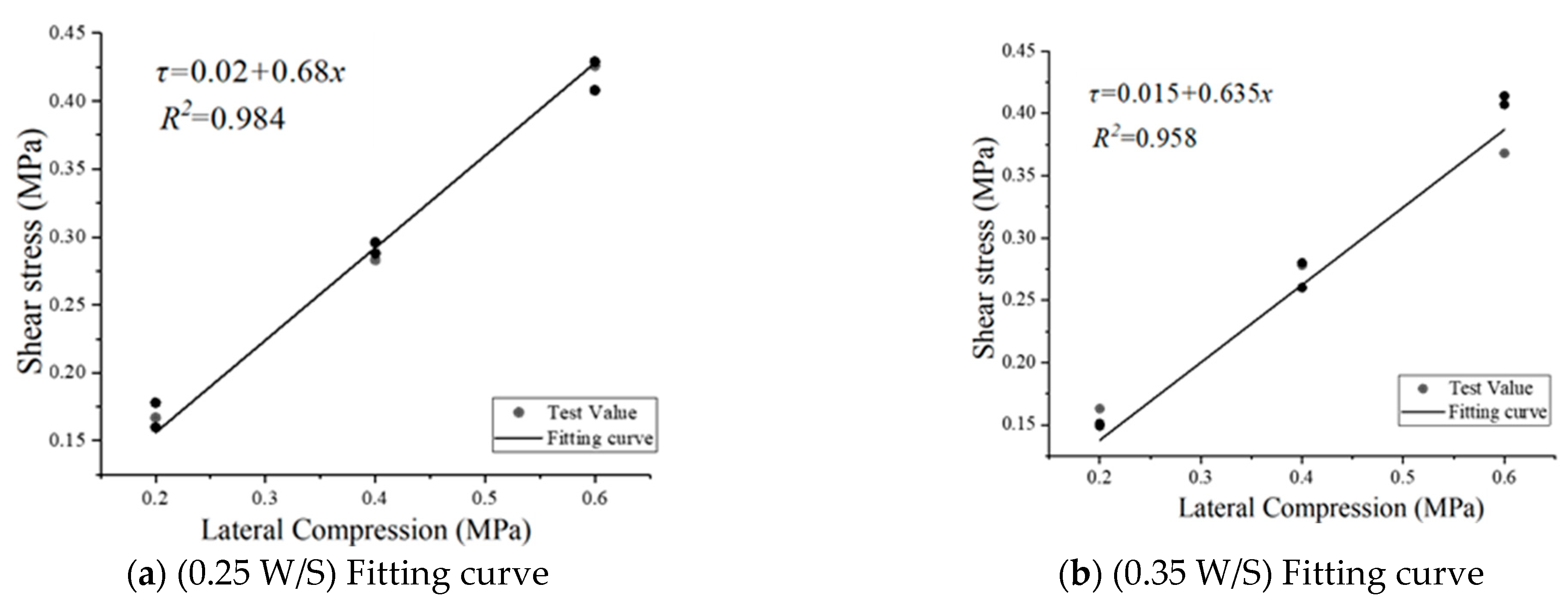

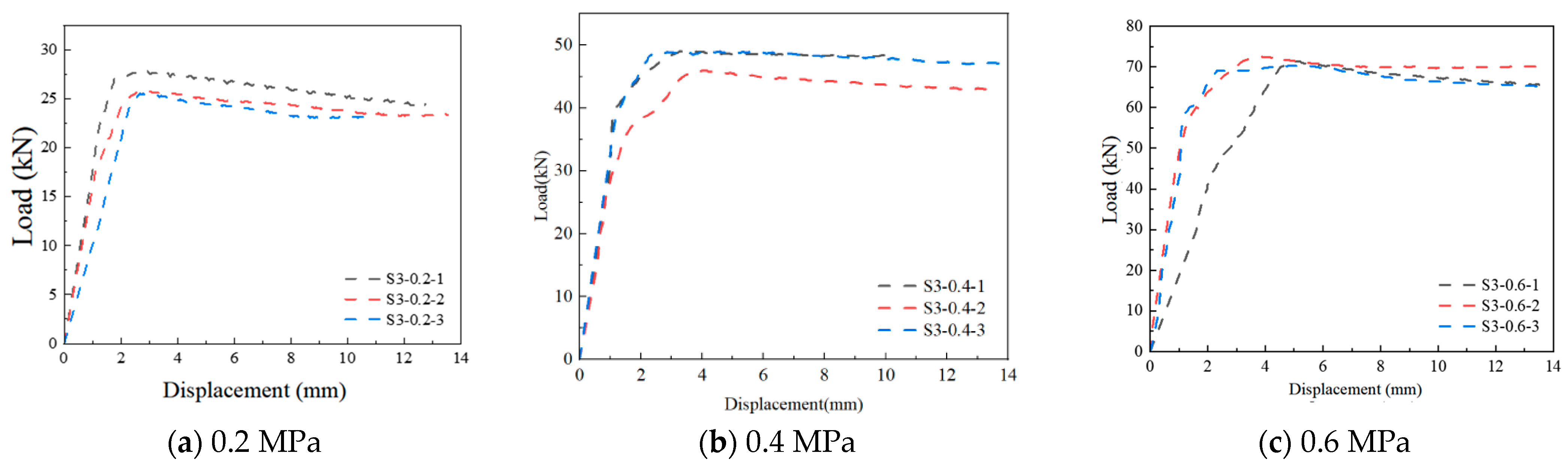

4.3. Analysis of Test Data

5. FE Numerical Simulation

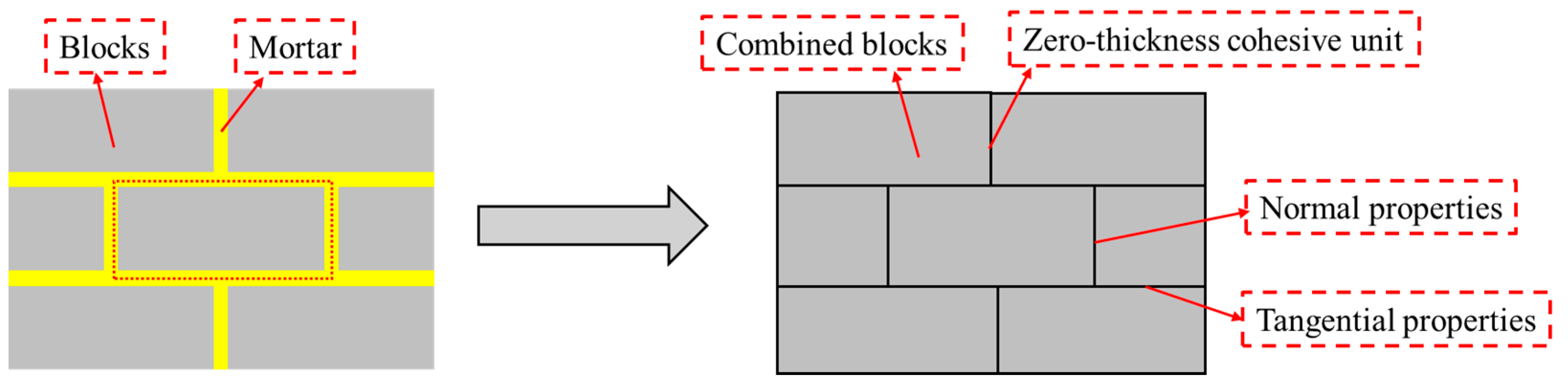

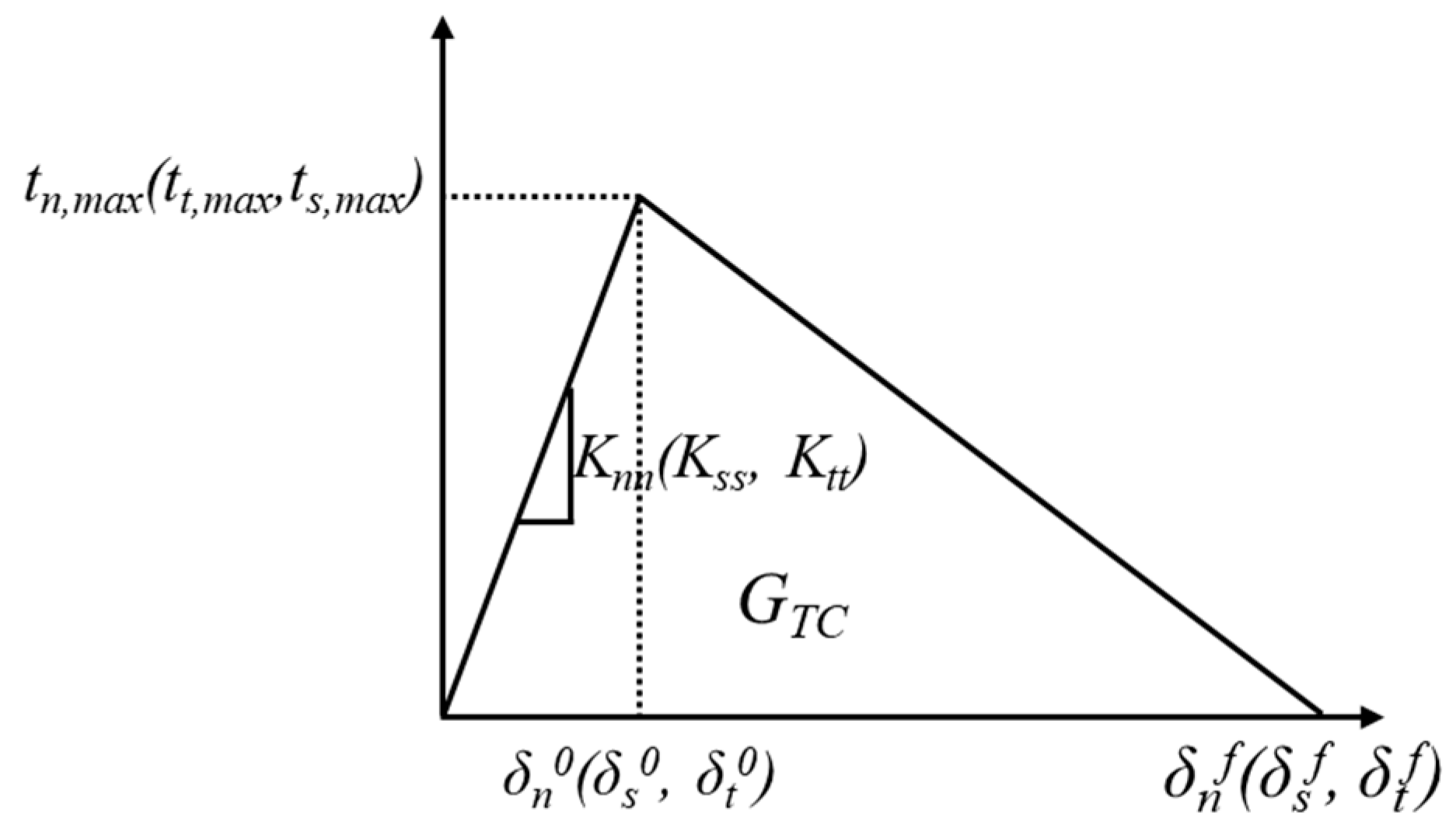

5.1. Model Overview

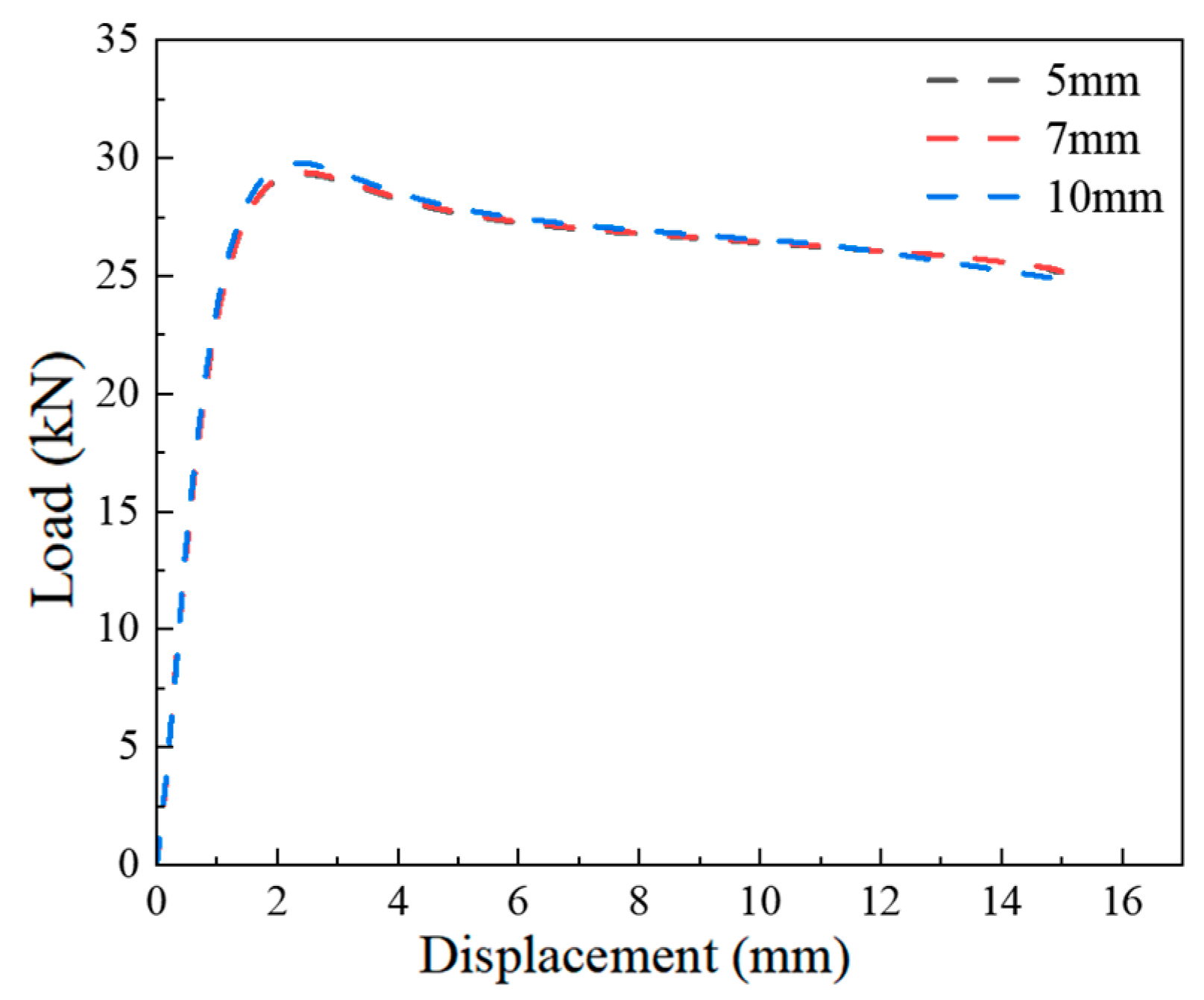

5.2. Mesh Sensitivity Analysis

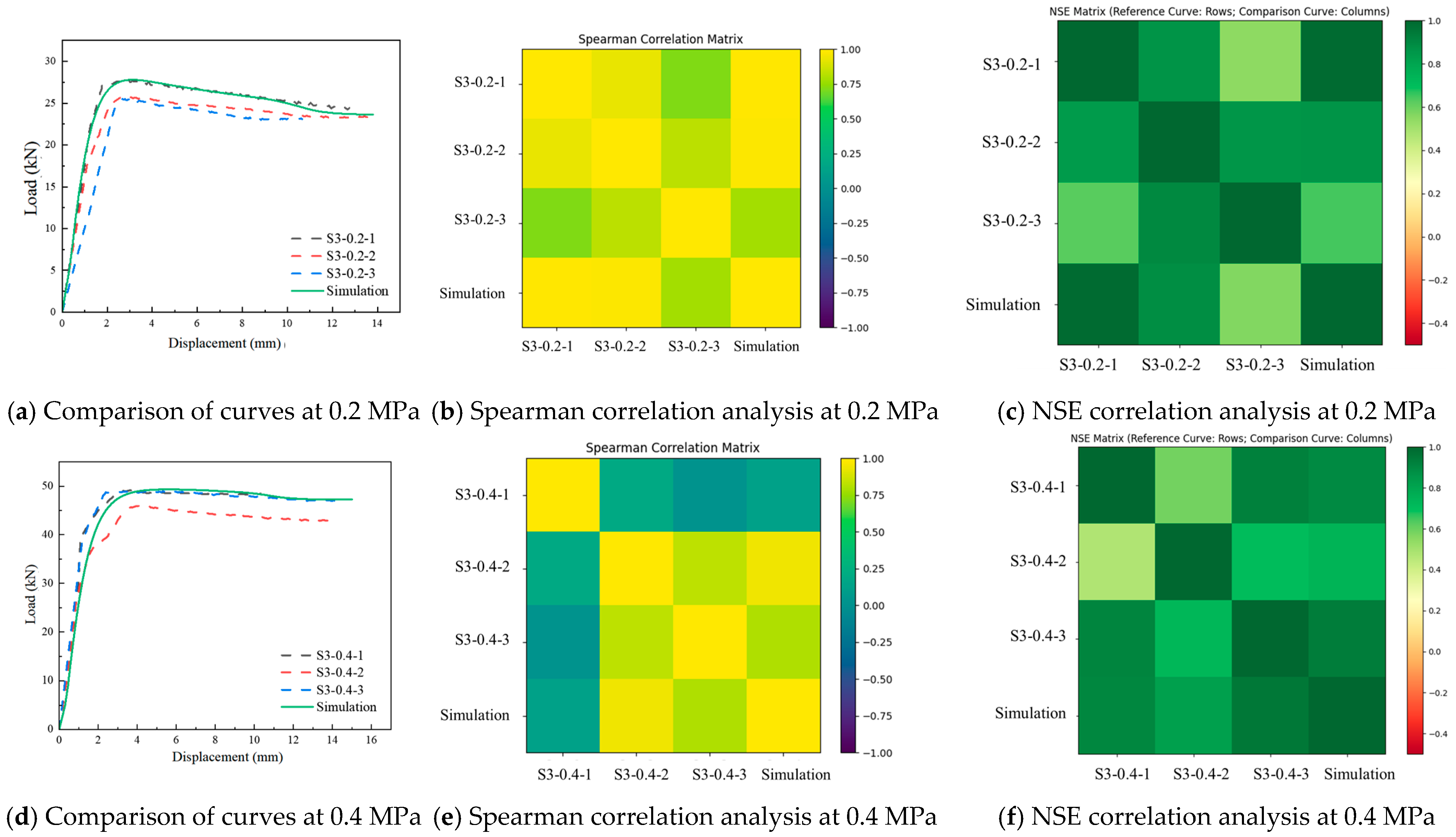

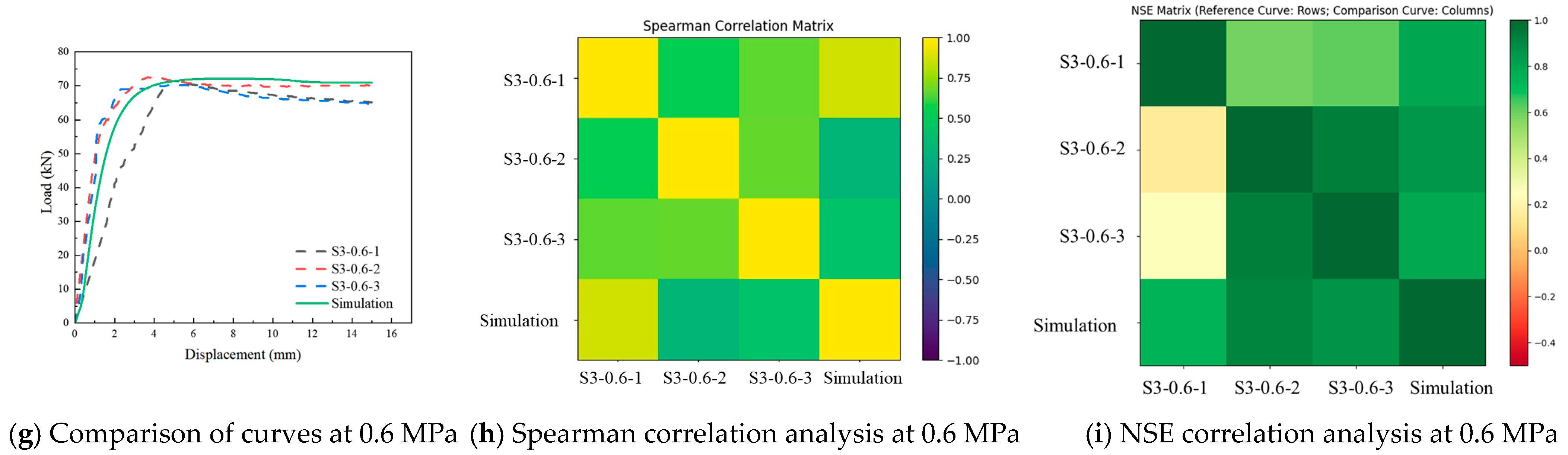

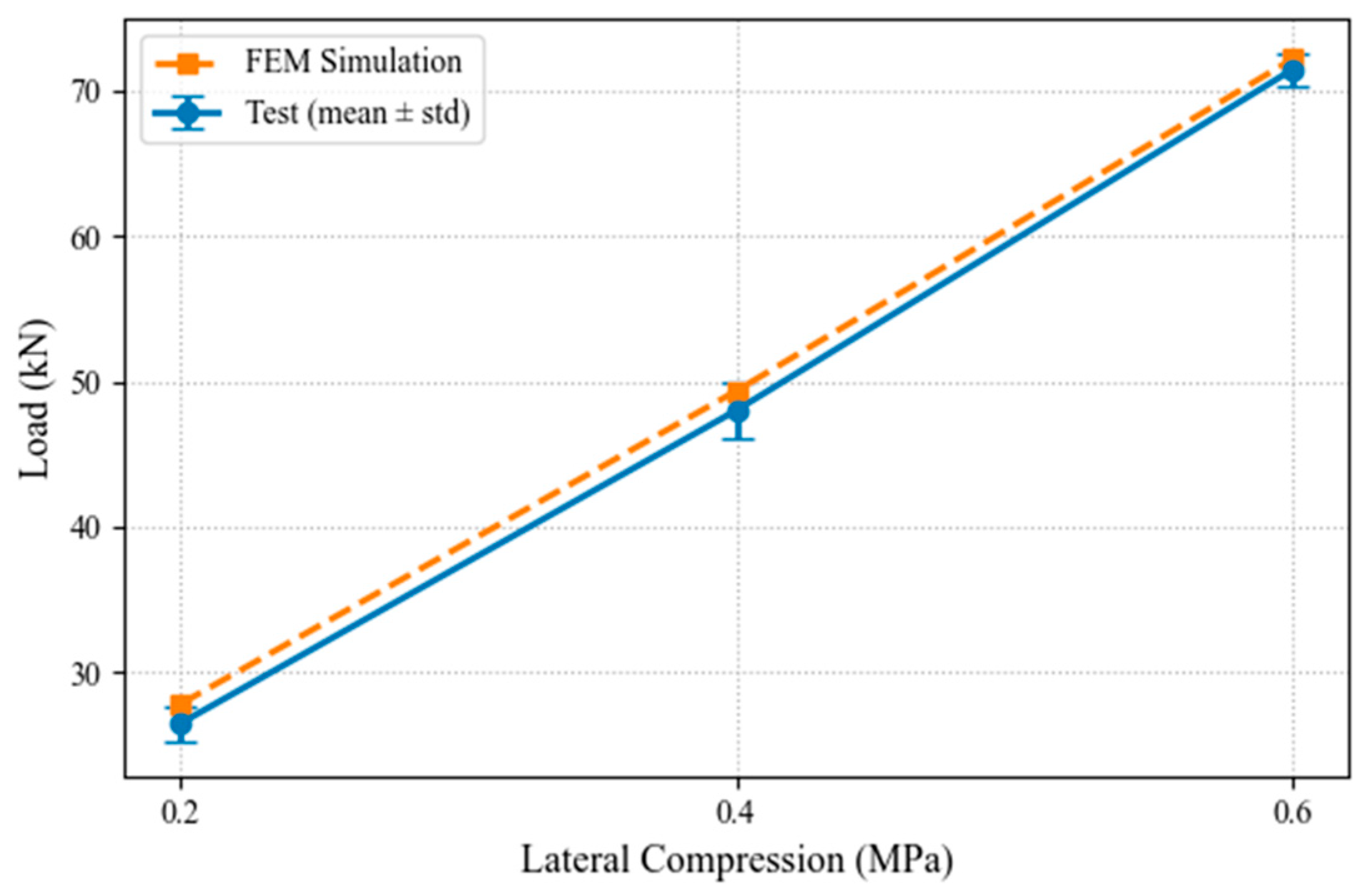

5.3. Comparison and Verification of Test and Simulation Results

6. Conclusions

- (1)

- Increasing lateral compression from 0.2 MPa to 0.6 MPa markedly enhances the bond strength at the loess earthen mortar–brick interface, with peak shear strength from 0.155 MPa to 0.396 MPa and the initial damage displacement postponed from 2.303 mm to 3.881 mm, showing that confinement has a beneficial effect on shear resistance. Conversely, higher water–soil ratios reduce the peak shear capacity of the masonry.

- (2)

- As lateral compression increases, internal micro-defects exert a greater influence, reducing the consistency among experimental load–displacement curves. This effect accounts for the observed 18% drop in inter-specimen correlation under high confinement.

- (3)

- Spearman rank correlation analysis reveals a very high agreement (r = 0.98) between experimental and numerical results under low confinement. Additionally, in the Nash–Sutcliffe efficiency (NSE) analysis, the correlation degree between experimental and numerical curves reaches 0.987 under low confinement, further confirming the good consistency between the two. Although under higher confinement, the Spearman correlation decreases to r = 0.86 due to increased scatter, the NSE analysis still shows a favorable correlation degree of 0.95 between the experimental and simulated curves. Moreover, the simulated and experimental peak shear loads remain essentially identical, with a maximum deviation of less than 5%. This collectively confirms the validity and predictive accuracy of the proposed FE modeling approach for investigating bond strength of loess earthen mortar–brick interfaces.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fan, Y.; Song, S.; Huang, J.; Lu, Y.; Liu, J.; Zhen, Q.; Bashir, S. Study on weathering mechanism of masonry bricks of ancient temples in Shanxi province using Dingxiang Hongfu temple masonry brick. Constr. Build. Mater. 2019, 222, 500–510. [Google Scholar] [CrossRef]

- Qian, K.; Song, Y.; Lai, J. Characterization of historical mortar from ancient city walls of Xindeng in Fuyang, China. Constr. Build. Mater. 2022, 315, 125780. [Google Scholar] [CrossRef]

- Jin, P.; Zhang, Y.; Wang, S. Characterization of the superficial weathering of bricks on the City Wall of Xi’an, China. Constr. Build. Mater. 2017, 149, 139–148. [Google Scholar] [CrossRef]

- Orlando, M.; Becattini, G.; Betti, M. Multilevel structural evaluation and rehabilitation design of an historic masonry fortress. J. Build. Eng. 2023, 63, 105379. [Google Scholar] [CrossRef]

- Tsiavos, A.; Sextos, A.; Stavridis, A. Low-cost hybrid design of masonry structures for developing countries: Shaking table tests. Soil Dyn. Earthq. Eng. 2021, 146, 106675. [Google Scholar] [CrossRef]

- Uranjek, M.; Bokan-Bosiljkov, V. Influence of freeze–thaw cycles on mechanical properties of historical brick masonry. Constr. Build. Mater. 2015, 84, 416–428. [Google Scholar] [CrossRef]

- Cavalagli, N.; Kita, A.; Castaldo, V.L.; Ubertini, F. Hierarchical environmental risk mapping of material degradation in historic masonry buildings: An integrated approach considering climate change and structural damage. Constr. Build. Mater. 2019, 215, 998–1014. [Google Scholar] [CrossRef]

- Erkal, A.; D’Ayala, D.; Sequeira, L. Assessment of wind-driven rain impact, related surface erosion and surface strength reduction of historic building materials. Build. Environ. 2012, 57, 336–348. [Google Scholar] [CrossRef]

- Pineda, P. Collapse and upgrading mechanisms associated to the structural materials of a deteriorated masonry tower. Nonlinear assessment under different damage and loading levels. Eng. Fail. Anal. 2016, 63, 72–93. [Google Scholar] [CrossRef]

- Christy, C.F.; Shanthi, R.M.; Tensing, D. Bond strength of the brick masonry. Int. J. Civ. Eng. Technol. 2012, 3, 380–386. [Google Scholar]

- Groot, C. Effects of Water on Mortar-Brick Bond; Technische Universiteit Delft: Delft, The Netherlands, 1993. [Google Scholar]

- Dehghan, S.M.; Najafgholipour, M.A.; Baneshi, V. Mechanical and bond properties of solid clay brick masonry with different sand grading. Constr. Build. Mater. 2018, 174, 1–10. [Google Scholar] [CrossRef]

- Kumble, P.; Prashant, S.; Achar, N. Bond strength of alkali-activated flyash based masonry system for sustainable construction. SN Appl. Sci. 2023, 5, 360. [Google Scholar] [CrossRef]

- Lourenço, P.B.; Barros, J.O.; Oliveira, J.T. Shear testing of stack bonded masonry. Constr. Build. Mater. 2004, 18, 125–132. [Google Scholar] [CrossRef]

- Zhou, Z.; Walker, P.; D’Ayala, D. Strength characteristics of hydraulic lime mortared brickwork. Proc. Inst. Civ. Eng.-Constr. Mater. 2008, 161, 139–146. [Google Scholar] [CrossRef]

- Singh, S.B.; Munjal, P. Bond strength and compressive stress-strain characteristics of brick masonry. J. Build. Eng. 2017, 9, 10–16. [Google Scholar] [CrossRef]

- Briceño, C.; Azenha, M.; Vasconcelos, G. Influence of conditioning of clay bricks over shear strength of brick masonry. J. Build. Eng. 2024, 82, 108138. [Google Scholar] [CrossRef]

- Segura, J.; Bernat, E.; Mendizabal, V. Experimental comparison of two testing setups for characterizing the shear mechanical properties of masonry. J. Build. Eng. 2021, 44, 103277. [Google Scholar] [CrossRef]

- Costigan, A.; Pavía, S. Influence of the Mechanical Properties of Lime Mortar on the Strength of Brick Masonry. In Historic Mortars: Characterisation, Assessment and Repair; Springer: Dordrecht, The Netherlands, 2012; pp. 359–372. [Google Scholar]

- Behera, B.; Nanda, R.P. In-plane shear strengthening of brick masonry panel with geogrid reinforcement embedded in bed and bed-head joints mortar. Eng. Struct. 2021, 227, 111411. [Google Scholar] [CrossRef]

- Briceño, C.; Azenha, M.; Vasconcelos, G. Influence of Type of Mortar and Unit Conditioning in the Shear Bond Strength of Brick-Mortar Assemblages. In International Brick and Block Masonry Conference; Springer Nature: Cham, Switzerland, 2024; pp. 451–462. [Google Scholar]

- Fonseca, F.S.; Fortes, E.S.; Parsekian, G.A. Compressive strength of high-strength concrete masonry grouted prisms. Constr. Build. Mater. 2019, 202, 861–876. [Google Scholar] [CrossRef]

- Barr, S.; McCarter, W.J.; Suryanto, B. Bond-strength performance of hydraulic lime and natural cement mortared sandstone masonry. Constr. Build. Mater. 2015, 84, 128–135. [Google Scholar] [CrossRef]

- Sarhosis, V.; Garrity, S.W.; Sheng, Y. Influence of brick–mortar interface on the mechanical behaviour of low bond strength masonry brickwork lintels. Eng. Struct. 2015, 88, 1–11. [Google Scholar] [CrossRef]

- Lourenço, P.B.; Ciocci, M.P.; Greco, F. Traditional techniques for the rehabilitation and protection of historic earthen structures: The seismic retrofitting project. Int. J. Archit. Herit. 2019, 13, 15–32. [Google Scholar] [CrossRef]

- Chen, T.S.; Chen, H. An Analysis of the Reasons for the Slow Development of Brick and Stone Structures in Ancient Chinese Architecture. Jiangsu Archit. 2010, 6, 47–50. (In Chinese) [Google Scholar] [CrossRef]

- Zizi, M.; Corlito, V.; Lourenço, P.B. Seismic vulnerability of masonry churches in Abruzzi region, Italy. Structures 2021, 32, 662–680. [Google Scholar] [CrossRef]

- Valente, M.; Milani, G. Damage survey, simplified assessment, and advanced seismic analyses of two masonry churches after the 2012 Emilia earthquake. Int. J. Archit. Herit. 2019, 13, 901–924. [Google Scholar] [CrossRef]

- Scamardo, M.; Zucca, M.; Crespi, P. Seismic vulnerability evaluation of a historical masonry tower: Comparison between different approaches. Appl. Sci. 2022, 12, 11254. [Google Scholar] [CrossRef]

- Malcata, M.; Ponte, M.; Tiberti, S. Failure analysis of a Portuguese cultural heritage masterpiece: Bonet building in Sintra. Eng. Fail. Anal. 2020, 115, 104636. [Google Scholar] [CrossRef]

- Kumar, N.; Amirtham, R.; Pandey, M. Plasticity based approach for failure modelling of unreinforced masonry. Eng. Struct. 2014, 80, 40–52. [Google Scholar] [CrossRef]

- Kumar, N.; Barbato, M. New constitutive model for interface elements in finite-element modeling of masonry. J. Eng. Mech. 2019, 145, 04019022. [Google Scholar] [CrossRef]

- Zhang, S.; Mousavi, S.M.T.; Richart, N. Micro-mechanical finite element modeling of diagonal compression test for historical stone masonry structure. Int. J. Solids Struct. 2017, 112, 122–132. [Google Scholar] [CrossRef]

- Zhang, S.; Richart, N.; Beyer, K. Numerical evaluation of test setups for determining the shear strength of masonry. Mater. Struct. 2018, 51, 110. [Google Scholar] [CrossRef]

- Zhang, S.; Hofmann, M.; Beyer, K. A 2D typology generator for historical masonry elements. Constr. Build. Mater. 2018, 184, 440–453. [Google Scholar] [CrossRef]

- GB/T50129-2011; Standard Test Method for Basic Mechanical Properties of Masonry. China Construction Industry Press: Beijing, China, 2011. (In Chinese)

- JGJ/T 70-2009; Standard of Test Method for Basic Performance of Construction Mortar. China Construction Industry Press: Beijing, China, 2009. (In Chinese)

- GB/T 2542-2012; Wall Brick Test Method. China Construction Industry Press: Beijing, China, 2012. (In Chinese)

- Shi, S.; Wang, D.; Li, Z. Shear Performance of New-to-Old Concrete Under Different Interface Treatments. Coatings 2025, 15, 805. [Google Scholar] [CrossRef]

- Yang, N.; TENG, D. Shear performance of Tibetan stone masonry under shear-compression loading. Eng. Mech. 2020, 37, 221–229. [Google Scholar]

- Alfano, G.; Sacco, E. Combining interface damage and friction in a cohesive-zone model. Int. J. Numer. Methods Eng. 2006, 68, 542–582. [Google Scholar] [CrossRef]

- Mehmood, T.; Abid, M.A.; Chatveera, B. Sustainable Reinforcement Methods for Brick Masonry Walls: An Experimental and Finite Element Analysis Approach. Buildings 2025, 15, 2180. [Google Scholar] [CrossRef]

- Hashemi, S.M.; Ayoub, A. Improved Bond Stress-Slip Relationships for Carbon Fibre-Reinforced Polymer-Strengthened Masonry Triplets. Buildings 2024, 14, 257. [Google Scholar] [CrossRef]

- Yang, W.Z. Constitutive relationship model for masonry under compression. Build. Struct. 2008, 38, 80–82. [Google Scholar] [CrossRef]

- Zheng, N. Research on the Seismic Performance of Prefabricated Structural Columns Constrained Masonry Structures; Chongqing University: Chongqing, China, 2010. [Google Scholar]

- Yang, W.; Yuan, S.; Yang, C. Experimental study on the full stress-strain curve of mortar under uniaxial compression. Build. Struct. 2019, 49, 114–119. [Google Scholar] [CrossRef]

- Guo, Z.H.; Shi, X.D. Principles and Analysis of Reinforced Concrete; Tsinghua University Press: Beijing, China, 2003. [Google Scholar]

- Page, A.W. The biaxial compressive strength of brick masonry. Proc. Inst. Civ. Eng. 1981, 71, 893–906. [Google Scholar] [CrossRef]

- Benzeggagh, M.L.; Kenane, M. Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus. Compos. Sci. Technol. 1996, 56, 439–449. [Google Scholar] [CrossRef]

| Materials | Quantity | Density (g/cm3) | Compressive Strength (MPa) | Modulus of Elasticity (MPa) |

|---|---|---|---|---|

| Traditional blue-gray fired brick | 6 | 1.496 | 13.944 | 1504.743 |

| Loess earthen mortar (0.25 W/S) | 6 | 1.788 | 3.055 | 186.825 |

| Loess earthen mortar (0.30 W/S) | 6 | 1.743 | 2.802 | 166.548 |

| Loess earthen mortar (0.35 W/S) | 6 | 1.718 | 2.670 | 158.822 |

| Specimen Number | Water–Soil Ratio | Lateral Compression (MPa) | Quantity |

|---|---|---|---|

| S1-0.2 | 0.25 | 0.2 | 3 |

| S1-0.4 | 0.25 | 0.4 | 3 |

| S1-0.6 | 0.25 | 0.6 | 3 |

| S2-0.2 | 0.30 | 0.2 | 3 |

| S3-0.2 | 0.35 | 0.2 | 3 |

| S3-0.4 | 0.35 | 0.4 | 3 |

| S3-0.6 | 0.35 | 0.6 | 3 |

| Specimen Number | Interface Shear Stiffness (N/mm3) | Initial Damage Displacement (mm) | Maximum Load (kN) | Shear Strength (MPa) |

|---|---|---|---|---|

| S1-0.2 | 0.069 | 2.213 | 29.493 | 0.168 |

| S1-0.4 | 0.086 | 3.685 | 50.647 | 0.289 |

| S1-0.6 | 0.101 | 3.779 | 73.741 | 0.421 |

| S2-0.2 | 0.059 | 2.595 | 28.267 | 0.161 |

| S3-0.2 | 0.055 | 2.303 | 27.085 | 0.155 |

| S3-0.4 | 0.076 | 3.187 | 47.761 | 0.273 |

| S3-0.6 | 0.092 | 3.881 | 69.434 | 0.396 |

| Type | ψ | e | fb0/fc0 | K | µ |

|---|---|---|---|---|---|

| Bricks | 30 | 0.1 | 1.16 | 0.6667 | 0.001 |

| Mortar | 30 | 0.1 | 1.16 | 0.6667 | 0.001 |

| Specimen Number | Test Load (kN) | Simulated Load (kN) | Error% |

|---|---|---|---|

| S1-0.2 | 29.493 | 29.38 | 0.383 |

| S1-0.4 | 50.647 | 51.93 | 2.533 |

| S1-0.6 | 73.741 | 75.5 | 2.385 |

| S2-0.2 | 28.267 | 28.4 | 0.470 |

| S3-0.2 | 27.085 | 27.8 | 2.64 |

| S3-0.4 | 47.761 | 49.34 | 3.306 |

| S3-0.6 | 69.434 | 72.15 | 3.911 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, T.; Xue, J.; Wu, C.; Sui, Y.; Feng, Y. Experimental and Finite Element Investigation of Bond Strength of Earthen Mortar–Brick Interfaces in Historic Masonry Structures. Buildings 2025, 15, 3278. https://doi.org/10.3390/buildings15183278

Zhang T, Xue J, Wu C, Sui Y, Feng Y. Experimental and Finite Element Investigation of Bond Strength of Earthen Mortar–Brick Interfaces in Historic Masonry Structures. Buildings. 2025; 15(18):3278. https://doi.org/10.3390/buildings15183278

Chicago/Turabian StyleZhang, Tian, Jianyang Xue, Chenwei Wu, Yan Sui, and Yuanshen Feng. 2025. "Experimental and Finite Element Investigation of Bond Strength of Earthen Mortar–Brick Interfaces in Historic Masonry Structures" Buildings 15, no. 18: 3278. https://doi.org/10.3390/buildings15183278

APA StyleZhang, T., Xue, J., Wu, C., Sui, Y., & Feng, Y. (2025). Experimental and Finite Element Investigation of Bond Strength of Earthen Mortar–Brick Interfaces in Historic Masonry Structures. Buildings, 15(18), 3278. https://doi.org/10.3390/buildings15183278